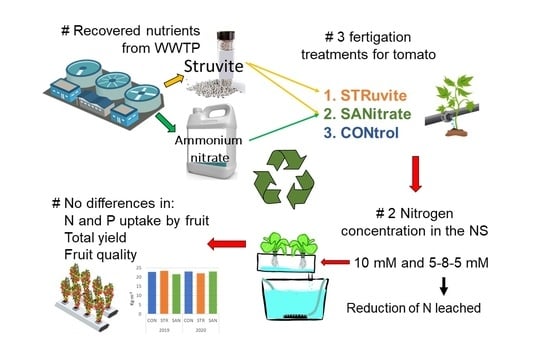

3.2. Struvite and Ammonium Nitrate Fertigation Treatments

Struvite solubilization results lead to prepare a concentrated nutrient solution (cNS) using nitric acid as acidifying agent [

33], boosted by the low pH of the ammonium nitrate in SAN treatment [

34], at pH range 1–2 to obtain an appropriate pH in the final dripper NS, considering the irrigation water properties. The cNS were kept constant during the assays, with pH values 1.2 ± 0.4 and 1.6 ± 0.5 for STR and SAN treatments, respectively.

Regarding the dripper NS, nutrients from recovered products (P, N, and Mg

2+) were detected and supplied to the plants, manifesting a good performance of struvite dissolution under field conditions. However, as the dissolution of struvite is not total and the percentage of P-struvite can vary, is important to be aware of the P-obtained from the dripper. The N-NO

3-/N-NH

4+ concentrations in the NS were kept constant (

Table S4), which exhibits a non-transformation of the ammonium while it is stored in the cNS.

Table 5 shows the mean measured nutrient concentration provided to the crop for each treatment and year. In the 2019 campaign, CON treatment had some problems with the dosing dispenser over the experiment, suppling a 9–12% less total N and P than the other treatments, showing significant differences. Mg

2+ supplied was significant for both years, due to the struvite composition. In order to keep the same K

+ concentration among the different NS of the treatments, the use of potassium sulphate was needed; this is the reason why the different concentration of sulphate was obtained. Results from the 2020 campaign show a better adjustment for the NS composition among the three applied treatments; only three out of 10 parameters differ significantly.

3.3. Leachates: Volume, Composition, and Nutrient Losses (N and P)

Considering that the fertigation management (irrigation time, water applied (834 ± 79 and 816 ± 77 L·m−2, in 2019 and 2020, respectively) and climatic conditions) were similar for all treatments within a year, the leaching of water, P, and N concentrations were compared. Moreover, considering the two different N concentrations (10 mM and a dynamic 5-8-5 mM) supplied with the NS and the non-statistically significant total yield for both crop seasons, even being different tomato varieties, the N and P dynamics were compared between years. However, all the comparison results for the years of the study can be the result of the genetic characteristics of the tomato varieties and other studies should be performed to confirm the issue.

Firstly, the leached volume was 186 ± 41 and 168 ± 24 L·m

−2 for 2019 and 2020, respectively, with mean leached volumes percentage in the range of 19–31% of the water supplied for all treatments and years. Regarding the P concentration leached within a year, no significant differences were found, except for April 2019, with higher values in STR treatment than SAN and CON (11 ± 4, 8 ± 3 and 4 ± 1 mg-P·L

−1, respectively) and April 2020, with higher values in SAN treatment than CON and STR (12 ± 2, 9 ± 2 and 6 ± 2 mg-P·L

−1, respectively). However, when considering the total amount leached, SAN and STR had higher values than CON in both years (3.9, 1.9, and 1.2 g-P·m

−2 in 2019 and 0.8, 0.9, and 0.5 g-P·m

−2, in 2020, representing 13.4, 6.7, 4.6, 3.4, 3.7, and 2.2% of the total P-supplied, respectively). Data reveals that the percentage of P-leached is lower when P concentration input is closer to 1 meq·L

−1 and that most of the P has been either taken up by the plants or remains in the substrate.

Figure 2a shows the monthly mean P-percentage leached per treatment and year, appreciating no differences among treatments.

Regarding the N concentration leached within the same year, no significant differences were found between treatments, except for April 2019 with higher N concentration in STR than SAN and CON, with 93 ± 36, 76 ± 35, and 54 ± 28 mg·L

−1, respectively. However, when considering the total amount of N leached in 2019, STR had the lower value with 38 g-N·m

−2, followed by CON and SAN with 43 and 60 g-N·m

−2, respectively, representing 28, 36, and 45 % of the N-leached. The dispersion among months is quite high, yet all the treatments showed a higher concentration of N leached in July and June (

Figure 2b;

Table S5), on fruit development stage. Nevertheless, considering the N-leached percentage, the initial development stage (March and April) had also high values (19–37%) due to the small size of the plant. Thus, in the 2020 campaign, the N supplied was lower and dynamic, 5-8-5 meq·L

−1. In the 2020 assay, the total amount of N leached was much lower, with values of 13, 11, and 8 g-N·m

−2 for CON, STR, and SAN, respectively, representing 16, 14, and 9% of the total N-applied. Both years followed a similar dynamic, July and April of 2020 having higher N-leached percentages. Nevertheless, in the 2020 campaign, the periods of high N-leached were reduced in nutrient concentration and time.

Figure 2a illustrates the mean N-percentage leached per treatment and year and

Figure 2b the N concentration leached evolution along both campaigns. Vegetable crops are particularly susceptible to having low N uptake efficiencies caused by several characteristics of vegetable cropping (i.e., excess N input, shallow rooting, wide row spacing, short growing cycle, climate conditions) [

17,

35], being associated with N losses to the environment and subsequent negative environmental impacts. However, this study highlights the fact that N leached may be reduced by lowering the standard N concentration in NS to approximately 8 mM for a greenhouse soilless tomato crop under Mediterranean climatic conditions [

17,

24,

36] and using a dynamic nutrient solution, due to its reduction in nutrient runoff, as other authors demonstrated [

24,

37]. Besides, some authors observed that a nutrient depletion at the end of the crop drives a fruit loading at the cost of N leaves reserves, suggesting an alternative strategy to limit N-waste [

38].

However, when recommending a N concentration, it is important to consider the irrigation amount supplied, since it seems pointless to determine a critical N concentration in solution since high or low rates of nutrient combined with low or high N concentrations in solution may lead to similar plant growth rates and environmental pollution. Thus, in our study, the mean amount of N leached was 47 ± 11 and 11 ± 3 g-N·m

−2 in 2019 and 2020, respectively. Even the N leached by 10 mM-N treatment is lower than that estimated by the regional N balance for the main greenhouse growing area in SE Spain, which suggested that N supplied annually by all sources, in soil and soilless trials, exceeds crop N uptake by 517–1058 kg-N·ha

−1 [

39,

40]. In soil crops, is it suggested the use of technology to schedule irrigation to reduce drainage amount, which substantially restricts the N losses. However, in a soilless trial, is it important to maintain a certain percentage of drainage to avoid salt accumulation in the “wet bulb”.

In the 2020 campaign, the N-NH

4+ was analyzed. Regarding the effects of the different N-NO

3-/N-NH

4+ ratio applied by the different treatments in the leachates, even no significant differences were detected except for August-20, the mean percentage of N-NH

4+ from the total N leached in 2020 was higher in SAN, followed by STR and CON, with 15, 8, and 3.5%, respectively. These results suggest that there was a partial nitrification process of the ammonium in the soilless cropping system, probably due to the low retention of the perlite. However, the growing season effect is remarkable, thus, N-NH

4+ does not usually have an adverse effect in summer weather due to rapid transformation and vigorous plant growth [

41].

3.4. Fruit Yield, Quality, and Biomass

In both years’ assays, there were no significant differences in total yield between treatments. That means that the recovered products rich in N and P can substitute the conventional fertilizers without bad effects in tomato production. However, the marketable yield varies, being SAN treatment lower than CON in 2019, and STR treatment lower than SAN (but without differences with CON) in 2020 (

Table 6). Even so, no significant differences were observed in fruit quality (g·fruit

−1, caliber, and total soluble solids (SST)). The percentage of non-marketable fruits in 2019 was remarkable, but it was not influenced by treatment (results not showed). The tomato variety and high mean temperatures could explain that, mostly due to blossom-end rot [

24]. Moreover, a high NH

4+/NO

3- ratio could produce a reduction in marketable fruit for SAN treatment, in agreement with other authors [

42], being important to consider the ammonium tolerance of the plant species. As struvite use as raw material for a nutrient solution has not been investigated to our knowledge, no comparison to other studies can be done. Still, some authors [

12] found no significant differences in respect to fertilizer performance of AN as compared to the conventional use of synthetic N fertilizers in lettuce and maize crop, indicating that recovered AN are valuable N sources and therefore might be used as N fertilizers in crop cultivation.

Regarding total biomass (

Table 6), STR treatment shows more weight per unit of surface than the rest in 2019, being the treatment that received higher N input. Moreover, in 2020, when the N input was reduced, the total biomass did too. According to these results, several authors correlate positively the N availability with dry matter accumulation [

43] and the tendency to allocate biomass to vegetative tissue while there is no increase or decrease in fruit production, the well-known phenomena of excess N favoring vegetative growth [

44].

All the fruits’ nutrients concentrations obtained are in concordance with published data [

45,

46] without detecting any type of deficiency or stress, being the magnesium the only nutrient that showed significant differences within the same year, in the 2020 trial, with a higher amount in recovered treatments (STR and SAN) due to struvite composition (

Table 4). However, nutrient leaves’ content exhibited more dispersion in 2019, with a higher content of P and N in STR and SAN treatments (

Table 4), probably due to the higher amount supplied as other authors reported [

8]. These results confirm a good performance of the recovered products in the NS. Moreover, the analysis of heavy metals on fruit showed lower values than the ICP-AES detection threshold for Cd, Cr, Hg, Ni, and Pb. For Cu and Zn, CON had similar values than the other treatments (

Table S6), evidencing the security for health and environmental risk.

3.5. P and N Crop Uptake

P uptake by tomato plants increased significantly in STR and SAN, compared with CON in 2019, due to a higher P concentration in the NS (

Figure 3,

Table S7). However, what particularly increased was the P content in crop aerial biomass, but not in fruits, with no effects on total yield, as reported by other authors [

47]. Thus, in the 2020 campaign, when the P concentration between treatments was similar, no differences in the amount of P uptake were detected. Besides, the mean percentage for all treatments of P uptake from the total P supplied in 2020 was 54 ± 9% (30 ± 6% for biomass and 24 ± 7% for fruit), similar to other studies in hydroponics [

33].

N uptake showed significant differences only in N-aerial biomass, mainly in STR and SAN in 2019, indicating a similar tendency as P when the concentration in the NS is higher. However, when comparing the percentage of N uptake by the biomass from the total N applied, no differences are found within a year, meaning that the more nitrogen is applied, the more is absorbed by the biomass. These results agree with the conclusions obtained when comparing amongst both crop seasons, where the percentage of N uptake by the biomass is similar, being 24 ± 4% for both years, as other authors reported for tomato crops [

33]. However, there are significant differences among the fruits and the total N uptake, this last with values of 42 ± 3 and 59 ± 5% for 2019 and 2020, respectively (

Figure 4), considering a better N uptake efficiency with the 5-8-5 meq-N·L

−1 NS. Even so, some studies associate environmental pollution to the limited crop uptake of applied nutrients, often 30–40% of applied N, by fast-growing vegetable species [

48].