Test Granular Materials Failure Using Bi-Directional Simple Shear Apparatus: A Review

Abstract

:1. Introduction

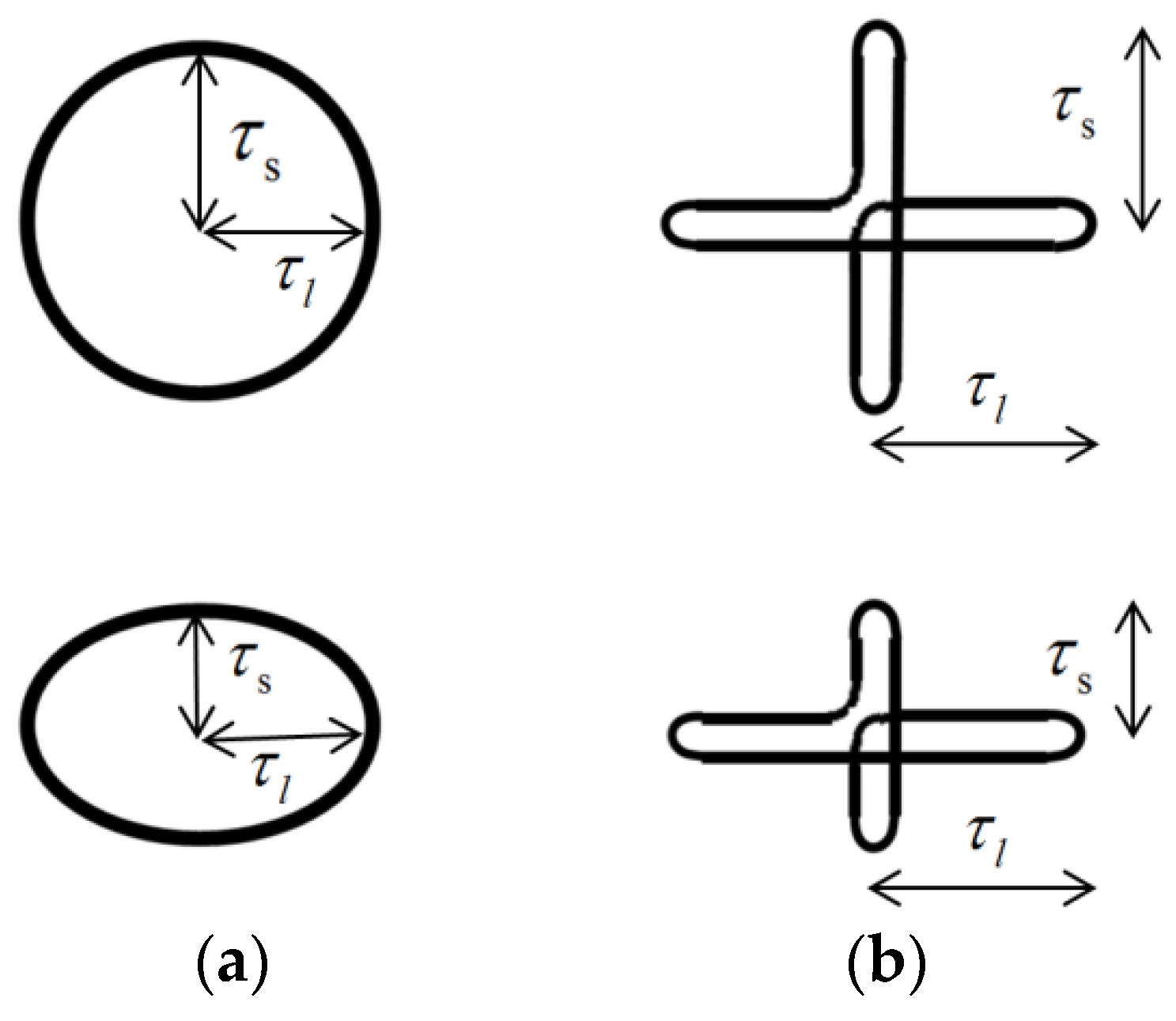

2. The Development of Bi-Directional Simple Shear Apparatuses

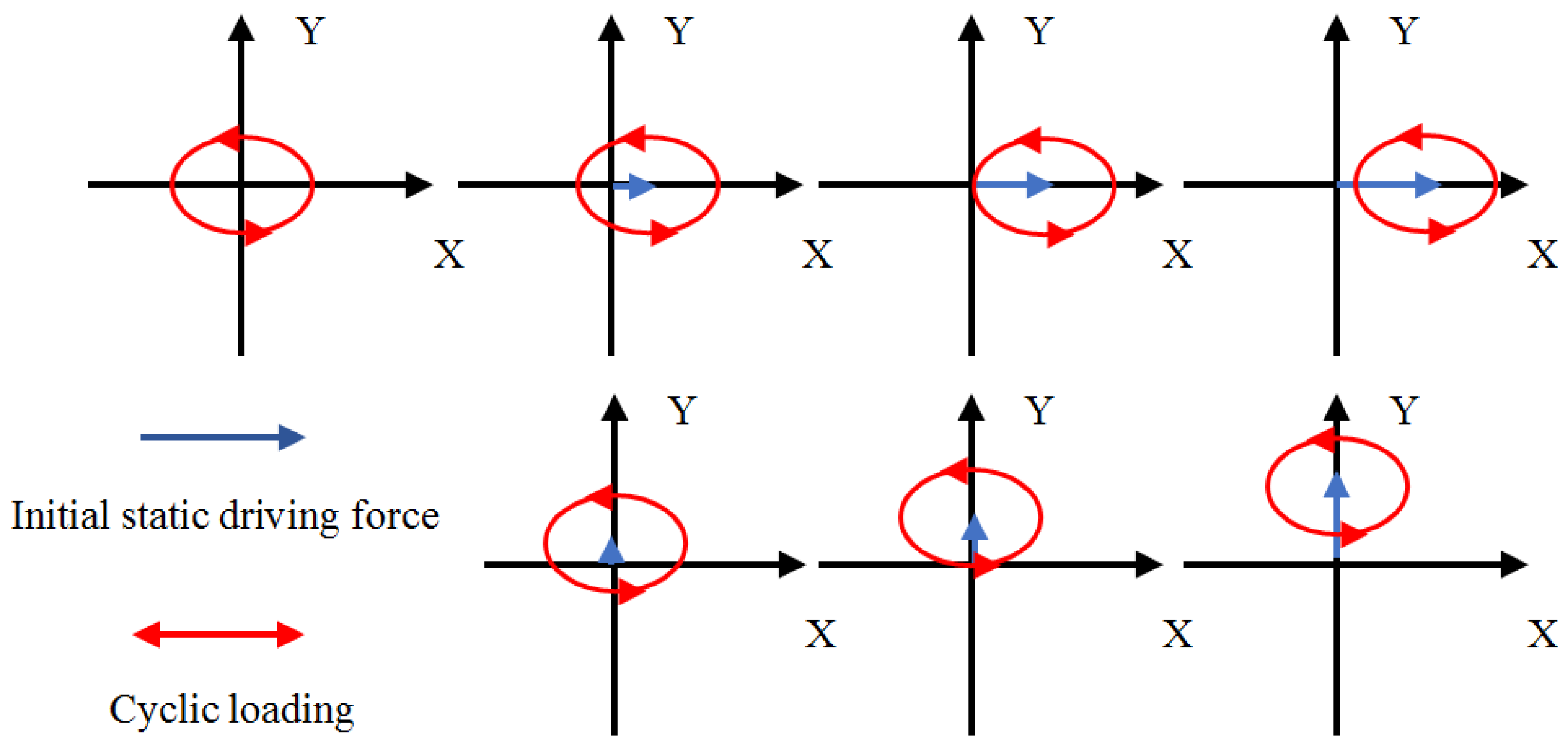

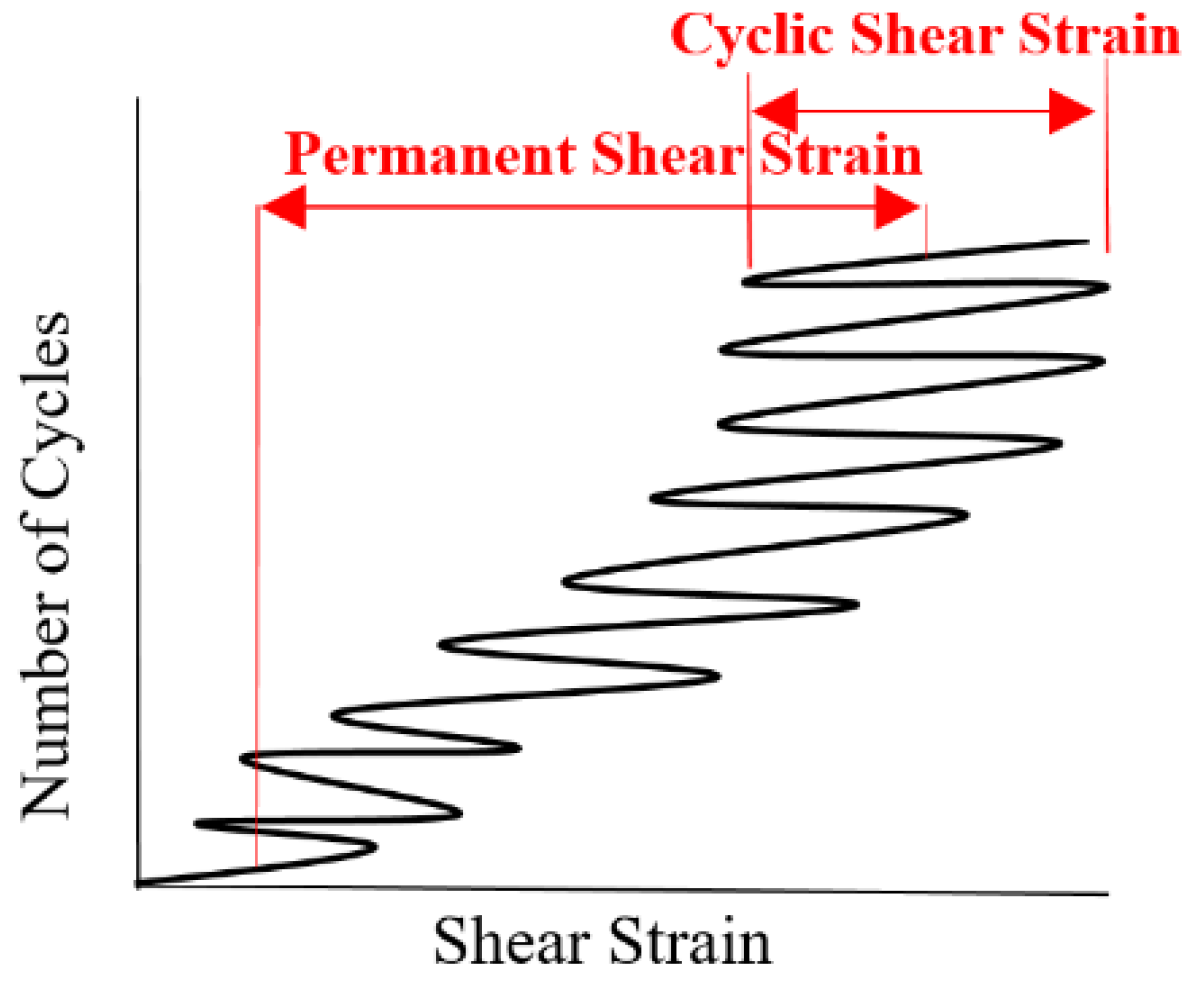

3. Bi-Directional Simple Shear Tests with Complex Loading Types

4. Bi-Directional Simple Shear Tests with Complex Loading Stages

5. Conclusions

Funding

Conflicts of Interest

References

- Jing, P.; Nowamooz, H.; Chazallon, C. Effect of Anisotropy on the Resilient Behaviour of a Granular Material in Low Traffic Pavement. Materials 2017, 10, 1382. [Google Scholar] [CrossRef] [PubMed]

- Roozbahani, M.M.; Borela, R.; Frost, J.D. Pore Size Distribution in Granular Material Microstructure. Materials 2017, 10, 1237. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.L.; Wang, X.L.; Lai, J.X.; Zhang, Q.; Wang, J.B. Response characteristics and preventions for seismic subsidence of loess in Northwest China. Nat. Hazards 2018, 92, 1909–1935. [Google Scholar] [CrossRef]

- Montanari, D.; Agostini, A.; Bonini, M.; Corti, G.; Ventisette, C.D. The Use of Empirical Methods for Testing Granular Materials in Analogue Modelling. Materials 2017, 10, 635. [Google Scholar] [CrossRef] [PubMed]

- Mohseni, E.; Tang, W.; Cui, H. Chloride Diffusion and Acid Resistance of Concrete Containing Zeolite and Tuff as Partial Replacements of Cement and Sand. Materials 2017, 10, 372. [Google Scholar] [CrossRef] [PubMed]

- Al Mahbub, A.; Haque, A. X-ray Computed Tomography Imaging of the Microstructure of Sand Particles Subjected to High Pressure One-Dimensional Compression. Materials 2016, 9, 890. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.X.; Mao, S.; Qiu, J.L.; Fan, H.B.; Zhang, Q.; Hu, Z.N.; Chen, J.X. Investigation progresses and applications of fractional derivative model in geotechnical engineering. Math. Probl. Eng. 2016, 3, 1–15. [Google Scholar] [CrossRef]

- Qiu, J.L.; Liu, H.Q.; Lai, J.X.; Lai, H.P.; Chen, J.X.; Wang, K. Investigating the long-term settlement of a tunnel built over improved loessial foundation soil using jet grouting technique. J. Perform. Constr. Facil. 2018. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Kumar, P. Waste foundry sand in concrete: A review. Constr. Build. Mater. 2017, 156, 661–674. [Google Scholar] [CrossRef]

- Bourguiba, A.; Ghorbel, E.; Cristofol, L.; Dhaoui, W. Effects of recycled sand on the properties and durability of polymer and cement based mortars. Constr. Build. Mater. 2017, 153, 44–54. [Google Scholar] [CrossRef]

- Seed, H.B.; Lee, K.L. Undrained strength characteristics of cohesionless soils. J. Soil Mech. Found. Div. 1967, 93, 333–360. [Google Scholar]

- Vaid, Y.P.; Chern, J.C.L. Effect of static shear on resistance to liquefaction. Soils Found. 1983, 23, 47–60. [Google Scholar] [CrossRef]

- Ishihara, K. Liquefaction and flow failure during earthquake. Géotechnique 1993, 43, 351–415. [Google Scholar] [CrossRef]

- Sze, H.Y.; Jun, Y. Initial static shear effect on cyclic liquefaction behaviour of sand. Trans. Hong Kong Inst. Eng. 2009, 16, 56–62. [Google Scholar]

- Vaid, Y.P.; Stedman, J.D.; Sivathayalan, S. Confining stress and static shear effects in cyclic liquefaction. Can. Geotech. J. 2001, 38, 580–591. [Google Scholar] [CrossRef]

- Sivathayalan, S.; Ha, D. Effect of static shear stress on the cyclic resistance of sands in simple shear loading. Can. Geotech. J. 2011, 48, 1471–1484. [Google Scholar] [CrossRef]

- Ishihara, K. Soil Behaviour in Earthquake Geotechnics; Claredon Press: Oxford, UK, 1996. [Google Scholar]

- Tatsuoka, F.; Iwasaki, T.; Fukushima, S.; Sudo, H. Stress conditions and stress histories affecting shear modulus and damping of sand under cyclic loading. Soils Found. 1979, 19, 29–43. [Google Scholar] [CrossRef]

- Dakoulas, P.; Sun, Y. Fine Ottawa sand: Experimental behavior and theoretical predictions. J. Geotech. Eng. 1992, 118, 1906–1923. [Google Scholar] [CrossRef]

- Yang, L.T. Experimental Study of Soil Anisotropy Using Hollow Cylinder Testing. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2013. [Google Scholar]

- Sivathayalan, S.; Logeswaran, P.; Manmatharajan, V. Cyclic resistance of a loose sand subjected to rotation of principal stresses. J. Geotech. Geoenvironmental Eng. 2015, 141, 1–13. [Google Scholar] [CrossRef]

- Towhata, I.; Ishihara, K. Undrained strength of sand undergoing cyclic rotation of principal stress axes. Soils Found. 1985, 25, 135–147. [Google Scholar] [CrossRef]

- Cai, Y.Y. An Experimental Study of Non-Coaxial Soil Behaviour Using Hollow Cylinder Testing. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2010. [Google Scholar]

- Cai, Y.Y.; Yu, H.S.; Wanatowski, D.; Li, X. Noncoaxial Behavior of Sand under Various Stress Paths. J. Geotech. Geoenviron. Eng. 2013, 139, 1381–1395. [Google Scholar] [CrossRef]

- Budhu, M. The mechanics of failure under cyclic simple shear strain. Soils Found. 1988, 28, 119–129. [Google Scholar] [CrossRef]

- Roscoe, K. An apparatus for the application of simple shear to soil samples. In Proceedings of the 3rd International Conference in Soil Mechanics and Foundation Engineering, Zurich, Switzerland, 16–27 August 1953; Volume 1, pp. 186–191. [Google Scholar]

- Bjerrum, L.; Landva, A. Direct simple-shear tests on a Norwegian quick clay. Géotechnique 1966, 16, 1–20. [Google Scholar] [CrossRef]

- Franke, E.; Kiekbusch, M.; Schuppener, B. A new direct simple shear device. Geotech. Test. J. 1979, 2, 190–199. [Google Scholar]

- Ishihara, K.; Yamazaki, F. Cyclic simple shear tests on saturated sand in multi-directional loading. Soils Found. 1980, 20, 45–59. [Google Scholar] [CrossRef]

- Boulanger, R.W.; Chan, C.K.; Seed, H.B.; Seed, R.B. A Low-compliance bi-directional cyclic simple shear apparatus. Geotech. Test. J. 1993, 16, 36–45. [Google Scholar]

- Baxter, C.D.P.; Bradshaw, A.S.; Ochoa-Lavergne, M.; Hankour, R. DSS test results using wire-reinforced membranes and stacked rings. Geotech. Spec. Publ. 2010, 199, 600–607. [Google Scholar]

- Kwan, W.; EI Mohtar, C. Comparison between shear strength of dry sand measured in CSS device using wire-reinforced membranes and stacked rings. In Proceedings of the Geo-Congress (ASCE), Atlanta, GA, USA, 23–26 February 2014; pp. 1111–1119. [Google Scholar]

- Moussa, A. Radial Stresses in Sand in Constant Volume Static and Cyclic Simple Shear Tests; Internal Report No. 51505-10; Norwegian Geotechnical Institute: Oslo, Norway, 1974. [Google Scholar]

- Dyvik, R.; Zimmie, T.F.; Floess, C.H.L. Lateral stress measurements in direct simple shear device. Lab. Shear Strength Soils 1981, 740, 191–206. [Google Scholar]

- Dyvik, R.; Zimmie, T.F. Lateral stress measurements during static and cyclic direct simple shear testing. In Proceedings of the 3rd International Conference on the Behavior of Off–Shore Structures, Cambridge, UK; 1982; Volume 2, pp. 363–372. [Google Scholar]

- Matsuda, H.; Nhan, T.T.; Ishikura, R. Prediction of excess pore water pressure and post-cyclic settlement on soft clay induced by uni-directional and multi-directional cyclic shears as a function of strain path parameters. Soil Dyn. Earthq. Eng. 2013, 49, 75–88. [Google Scholar] [CrossRef]

- Kammerer, A. Undrained Response of Monterey 0/30 Sand under Multidirectional Cyclic Simple Shear Loading Conditions. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2002. [Google Scholar]

- Boulanger, R.W.; Seed, R.B. Liquefaction of sand under bidirectional monotonic and cyclic loading. J. Geotech. Eng. 1995, 121, 870–878. [Google Scholar] [CrossRef]

- Finn, W.D.L. Aspects of constant volume cyclic simple shear. In Advances in the Art of Testing Soils under Cyclic Conditions; ASCE Convention: Detroit, MI, USA, 1985; pp. 74–98. [Google Scholar]

- Dyvik, R.; Berre, T.; Lacasse, S.; Raadim, B. Comparison of truly undrained and constant volume direct simple shear tests. Géotechnique 1987, 37, 3–10. [Google Scholar] [CrossRef]

- Budhu, M. Lateral stresses observed in two simple shear apparatus. J. Geotech. Eng. 1985, 111, 698–711. [Google Scholar] [CrossRef]

- Boulanger, R.; Chan, C.; Seed, H.; Seed, R.; Sousa, J.A. Low-Compliance BiDirectional Cyclic Simple Shear Apparatus. Geotech. Test. J. 1993, 16, 36–45. [Google Scholar]

- Jaime, A. A two-direction cyclic shear apparatus. In Proceedings of the 5th Pan American Conference on Soil Mechanics and Foundation Engineering, Buenos Aires, Argentine, 17–22 November 1975; Volume 2, pp. 395–402. [Google Scholar]

- Casagrande, A.; Rendon, F. Gyratory Shear Apparatus, Design, Testing Procedures; Technical Report No. S-78-i5; Corps of Engineers Waterways Experiment Station: Vicksburg, MS, USA, 1978. [Google Scholar]

- DeGroot, D.J.; Germaine, J.T.; Ladd, C.C. The multidirectional direct simple shear apparatus. Geotech. Test. J. 1993, 16, 283–295. [Google Scholar]

- Rutherford, C.J. Development of a Multi-Directional Direct Simple Shear Testing Device for Characterization of the Cyclic Shear Response of Marine Clays. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2012. [Google Scholar]

- Biscontin, G. Modeling the Dynamic Behavior of Lightly Overconsolidated Soil Deposits on Submerged Slopes. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2001. [Google Scholar]

- Harder, L.F.; Boulanger, R.W. Application of Kσ and Kα correction factors. In Proceedings of the NCEER Workshop on Evaluation of Liquefaction Resistance of Soils; Technical Report NCEER-97-0022; Youd, T.L., Idriss, I.M., Eds.; National Center for Earthquake Engineering Research, SUNY: Buffalo, NY, USA, 1997; pp. 167–190. [Google Scholar]

- Idriss, I.M.; Boulanger, R.W. Estimating Kα for use in evaluating cyclic resistance of sloping ground. In Proceedings, 8th US-Japan Workshop on Earthquake Resistant Design of Lifeline Facilities and Countermeasures against Liquefaction; Report MCEER-03-0003; Hamada, O., Bardet, Eds.; MCEER, SUNY: Buffalo, NY, USA, 2003; pp. 449–468. [Google Scholar]

- Boulanger, R.W.; Seed, R.B.; Chan, C.K. Effects of Initial Static Driving Shear Stresses on the Liquefaction Behavior of Saturated Cohesionless Soils; Technical Report No. UCB/GT/91-01; University of California: Berkeley, CA, USA, 1991. [Google Scholar]

- Boulanger, R.W.; Seed, R.B.; Chan, C.K.; Seed, H.B.; Sousa, J.B. Liquefaction Behavior of Saturated Sands under Uni-Directional and Bi-Directional Monotonic and Cyclic Simple Shear Loading; Technical Report No. UCB/GT-91/08; University of California: Berkeley, CA, USA, 1991. [Google Scholar]

- Seed, H.B.; Idriss, I.M.; Makdisi, F.I.; Banerjee, N.G. Representation of Irregular Stress Time Histories by Equivalent Uniform Stress Series in Liquefaction Analysis; Technical Report No. EERC75-29; University of California Berkeley: Berkeley, CA, USA, 1975. [Google Scholar]

- Ishihara, K.; Nagase, H. Multi-directional irregular loading tests on sand. Soil Dyn. Earthq. Eng. 1988, 7, 201–212. [Google Scholar] [CrossRef]

- Matsuda, H.; Hendrawan, A.P.; Ishikura, R.; Kawahara, S. Effective stress change and post-earthquake settlement properties of granular materials subjected to multi-directional cyclic simple shear. Soils Found. 2011, 51, 873–884. [Google Scholar] [CrossRef]

- Matsuda, H.; Shinozaki, H.; Okada, N.; Takamiya, K.; Shinyama, K. Effects of multi-directional cyclic shear on the post-earthquake settlement of ground. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. Paper No. 2890. [Google Scholar]

- DeGroot, D.J.; Ladd, C.C.; Germaine, J.T. Undrained multidirectional direct simple shear behavior of cohesive soil. J. Geotech. Eng. 1996, 122, 91–98. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Yu, H.; Roberts, G. Monotonic Direct Simple Shear Tests on Sand under Multidirectional Loading. Int. J. Geomech. 2017, 17, 1–10. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Yu, H.; Roberts, G. Effect of Sample Reconstitution Methods on the Behaviors of Sand under Shearing. J. Test. Eval. 2018, 46, 1–8. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Yu, H.; Roberts, G. Correlations between the stress paths of a monotonic test and a cyclic test under the same initial conditions. Soil Dyn. Earthq. Eng. 2017, 101, 153–156. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Yu, H.; Roberts, G. Principal Stress Rotation under Bidirectional Simple Shear Loadings. KSCE J. Civ. Eng. 2018, 22, 1651–1660. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y. Non-coaxiality of sand under bi-directional shear loading. R. Soc. Open Sci. 2018, 5, 172076. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Authors (Year) | Tested Materials | Tested Stress Paths | Findings |

|---|---|---|---|

| Ishihara and Yamazaki (1980) | Fuji River Sand | 1. Circular cyclic loading. 2. Elliptic cyclic loading. 3. Alternating cyclic loading. * Truly undrained test | 1. Increasing secondary shear stress decreases liquefaction resistance. 2. Rocking motions exists. |

| Ishihara and Nagase (1988) | Fuji River Sand | Irregular shear stress: time histories of horizontal accelerations of recorded ground surface during few earthquakes. * Truly undrained test | 1. Increasing secondary shear stress decreases liquefaction resistance, and irregular loading increased the liquefaction resistance. 2. Rocking motions still exists. |

| Boulanger and Seed (1995) | Modified Sacramento River Sand | Drained monotonic shear (in X and Y direction) and secondary undrained cyclic shear (in X direction). * Constant volume test | 1. When the two stresses are in the same direction, liquefaction resistance usually increases with increasing the consolidation shear stress. 2. When cyclic shear stress is applied perpendicular to the consolidation shear stress, liquefaction resistance decreases with increasing consolidation shear stress. |

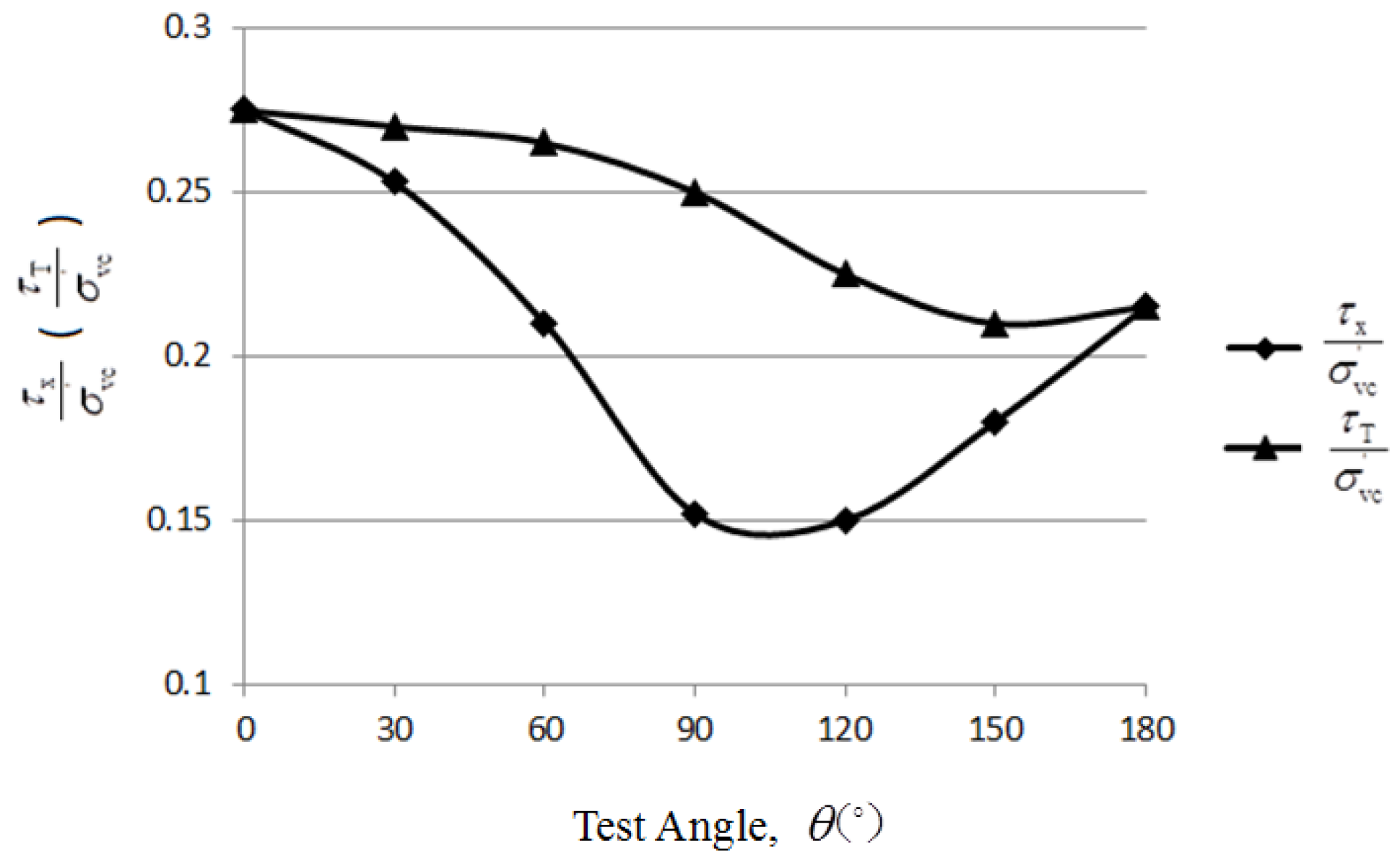

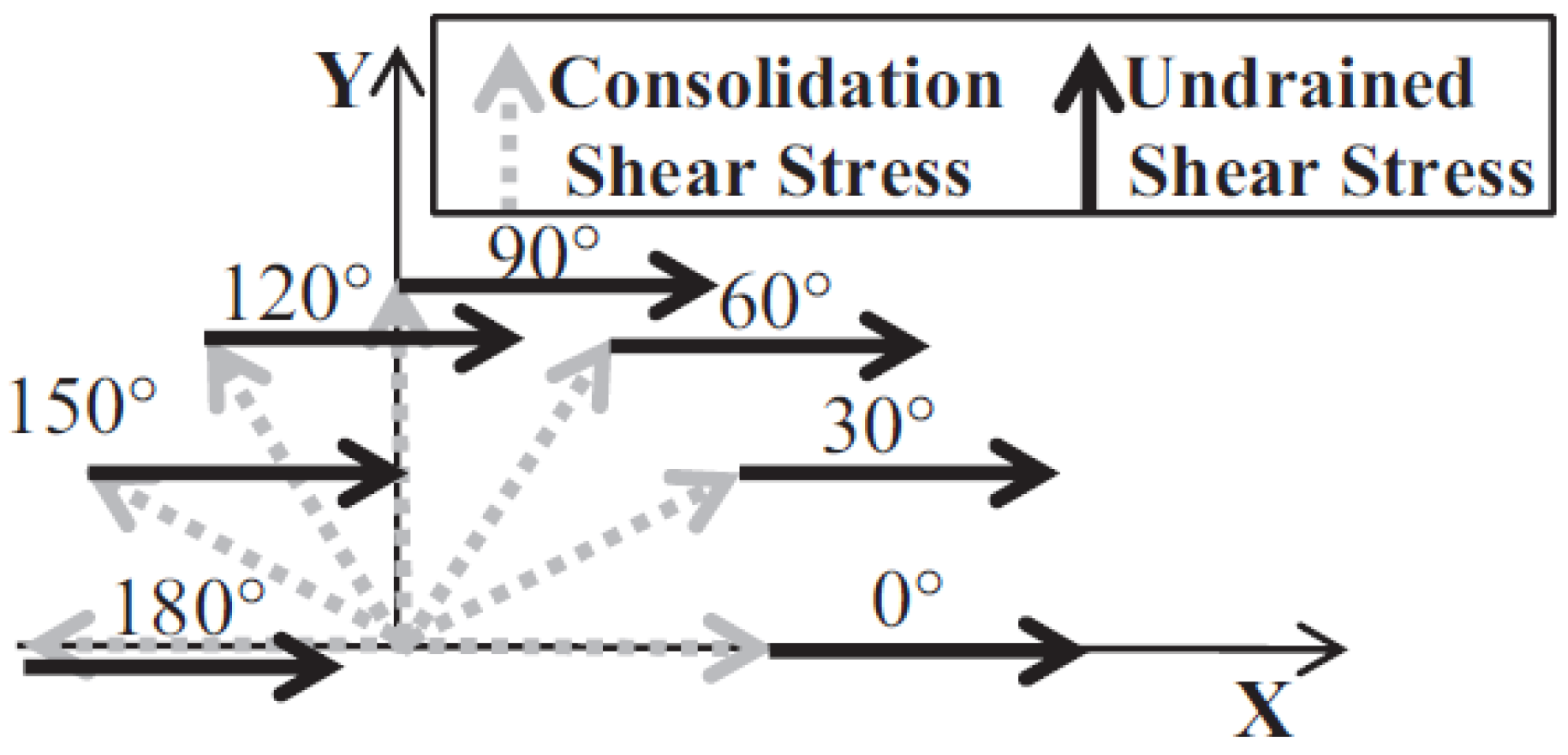

| DeGroot et al. (1996) | Boston Blue Clay | Drained monotonic shear (in 0°-180°to X direction) directions + secondary undrained monotonic shear(in X direction). * Constant volume test | Peak shear strength (in X direction) decreases dramatically in tests with an angle from 0° to 120°, and then increases in tests with an angle from 120° to 180°. |

| Biscontin (2001) | Young Bay Mud | 1. Drained monotonic shear (in 0°–180°to X direction) directions + secondary undrained monotonic shear (in X direction). 2. Drained monotonic shear (in 0°and 90°to X direction) directions + secondary undrained cyclic shear (in X direction). * Truly undrained test | 1. Consolidation shear stress and its loading angle to secondary undrained monotonic shear stress have effect on shear behavior. 2. Undrained monotonic shear strength increases with increasing consolidation shear stress. 3. Shear strain development (magnitude and direction) is different in cyclic tests with different stress histories. |

| Kammerer (2002) | Monterey #30 Sand | 1. One-directional cyclic loading. 2. Circular/elliptic cyclic loading. 3. Figure 8 cyclic loading. With 0° and 90° consolidation shear stress. * Truly undrained test | 1. Cyclic shear strength in a bi-directional simple shear is more complex than a one-directional simple shear test. 2. Reduction factors, developed by Seed et al. [57], and Ishihara and Yamazaki [29], may not reflect the differences in liquefaction triggering between a one-directional simple test and a corresponding uni-directional simple shear test under the same testing conditions. |

| Matsuda et al. (2011) | Toyoura Sand and GBFS | 1. One-directional cyclic loading. 2. Circular cyclic loading. * Constant volume test | 1. Generally, the amplitude of shear displacement has a significant effect on the changes of the effective stress of Toyoura sand and GBFS. 2. At a higher amplitude of shear displacement, cyclic shear direction has little effect on effective stress. |

| Rutherford (2012) | Mexico Gulf Clay | 1. Monotonic test. 2. One-directional cyclic loading. 3. Circular cyclic loading. 4. Figure 8 cyclic loading. * Truly undrained test | 1. Stress reversal affects excess pore water pressure generation. 2. Figure 8 tests accumulate permanent strain faster than other stress paths. |

| Matsuda et al. (2013) | Kaolinite Clay | 1. One-directional cyclic loading. 2. Circular cyclic loading. 3. Elliptic cyclic loading with different phase differences. * Constant volume test | 1. At the same amplitude of the shear displacement and number of cycles, excess pore water pressure and post-liquefaction settlement caused during multi-directional loading is greater than that under one-directional loading. 2. Excess pore water pressure and post-liquefaction settlement caused during multi-directional loading is increased by phase difference. |

| Li et al. (2017) | Leighton Buzzard Sand Fraction B | Drained monotonic shear (in 0°–180°to X direction) directions and secondary undrained monotonic shear (in X direction). * Constant volume test | 1. Magnitude of consolidation shear stress ratio affects the shear behavior. 2. Consolidation shear stress densifies the soil samples, and the role of densification is predominant over the role of angles under a small consolidation shear stress ratio. |

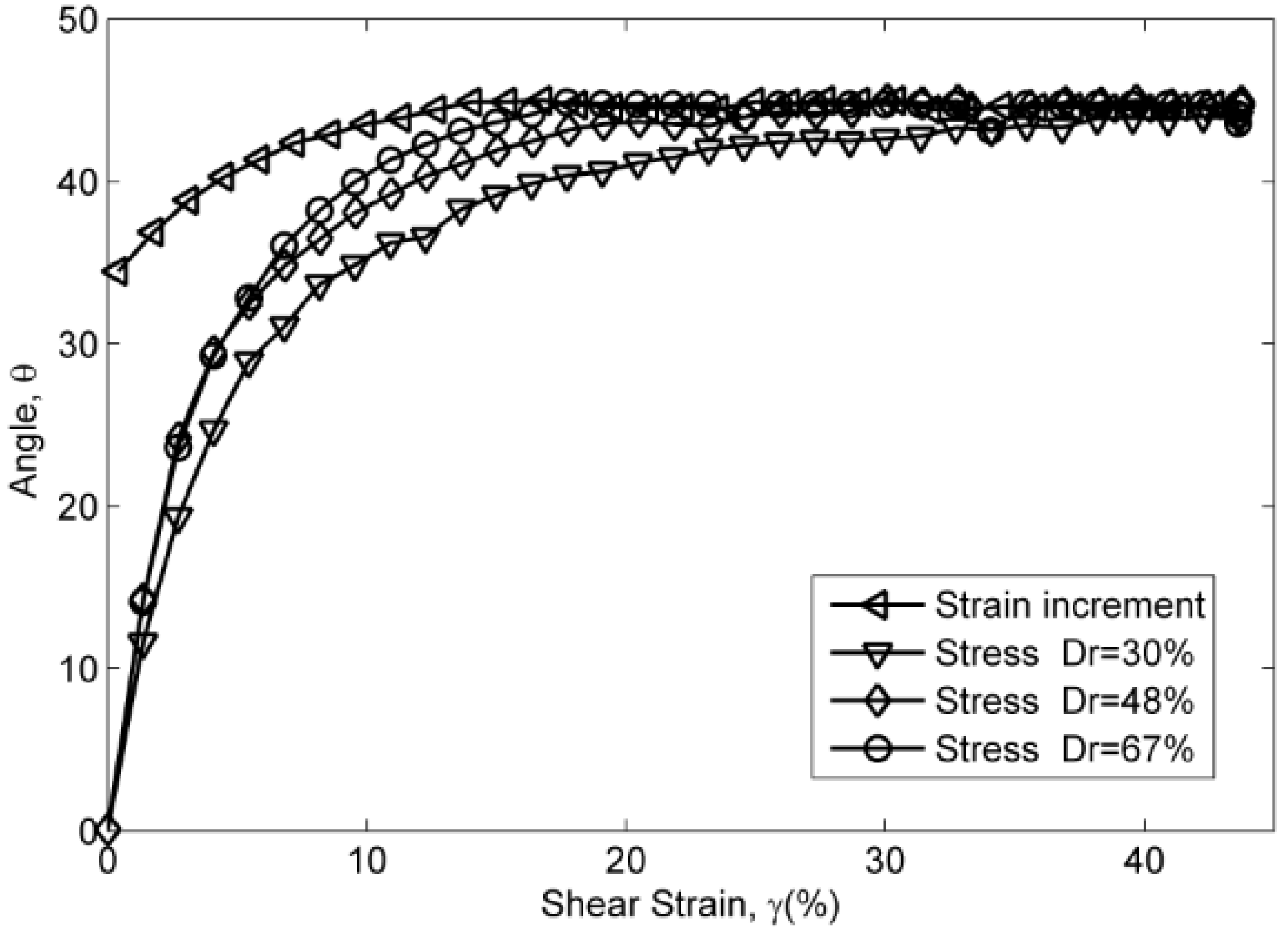

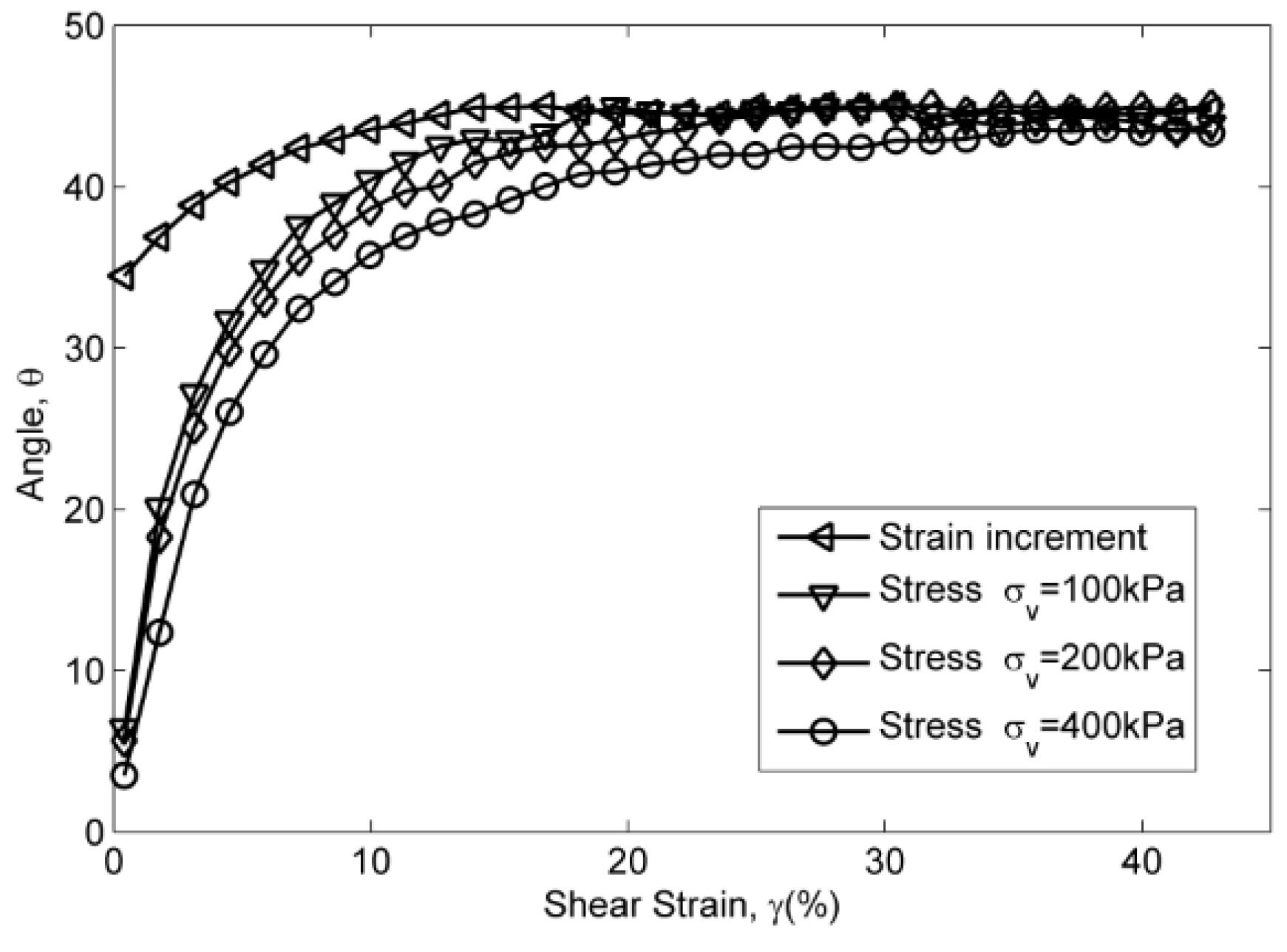

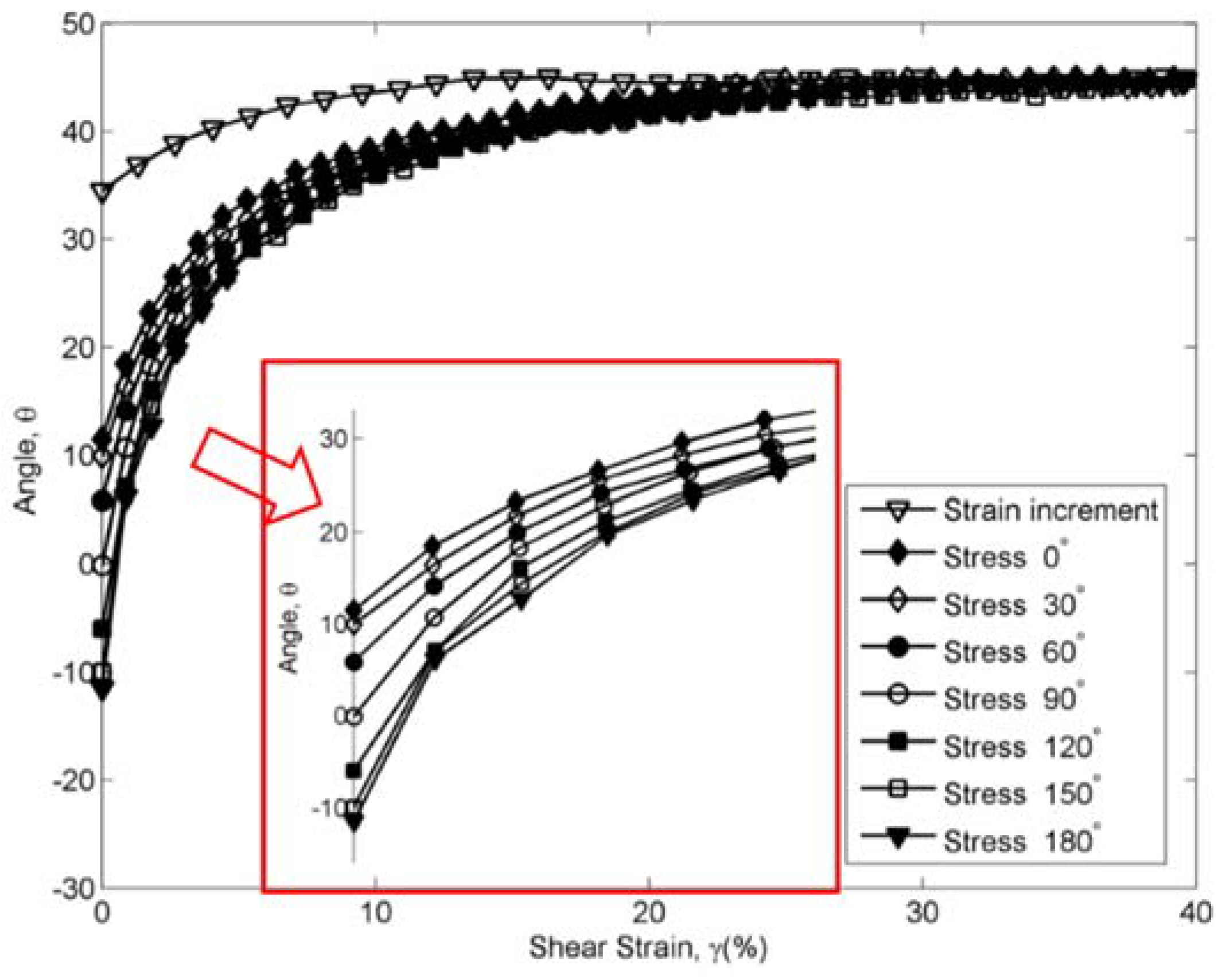

| Li et al. (2018) | Leighton Buzzard Sand Fraction B | Drained monotonic shear (in 0°–180°to X direction) directions and secondary undrained monotonic shear (in X direction). * Constant volume test | 1. Increasing the relative density decreases the level of non-coaxiality, and increasing the effective vertical stress increases the non-coaxiality. 2. The greatest non-coaxiality is found in the test with the angle of 180°, and the smallest difference of these axes is in the test with the angle of 0°. |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y. Test Granular Materials Failure Using Bi-Directional Simple Shear Apparatus: A Review. Appl. Sci. 2018, 8, 1140. https://doi.org/10.3390/app8071140

Li Y. Test Granular Materials Failure Using Bi-Directional Simple Shear Apparatus: A Review. Applied Sciences. 2018; 8(7):1140. https://doi.org/10.3390/app8071140

Chicago/Turabian StyleLi, Yao. 2018. "Test Granular Materials Failure Using Bi-Directional Simple Shear Apparatus: A Review" Applied Sciences 8, no. 7: 1140. https://doi.org/10.3390/app8071140