Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film

Abstract

:Featured Application

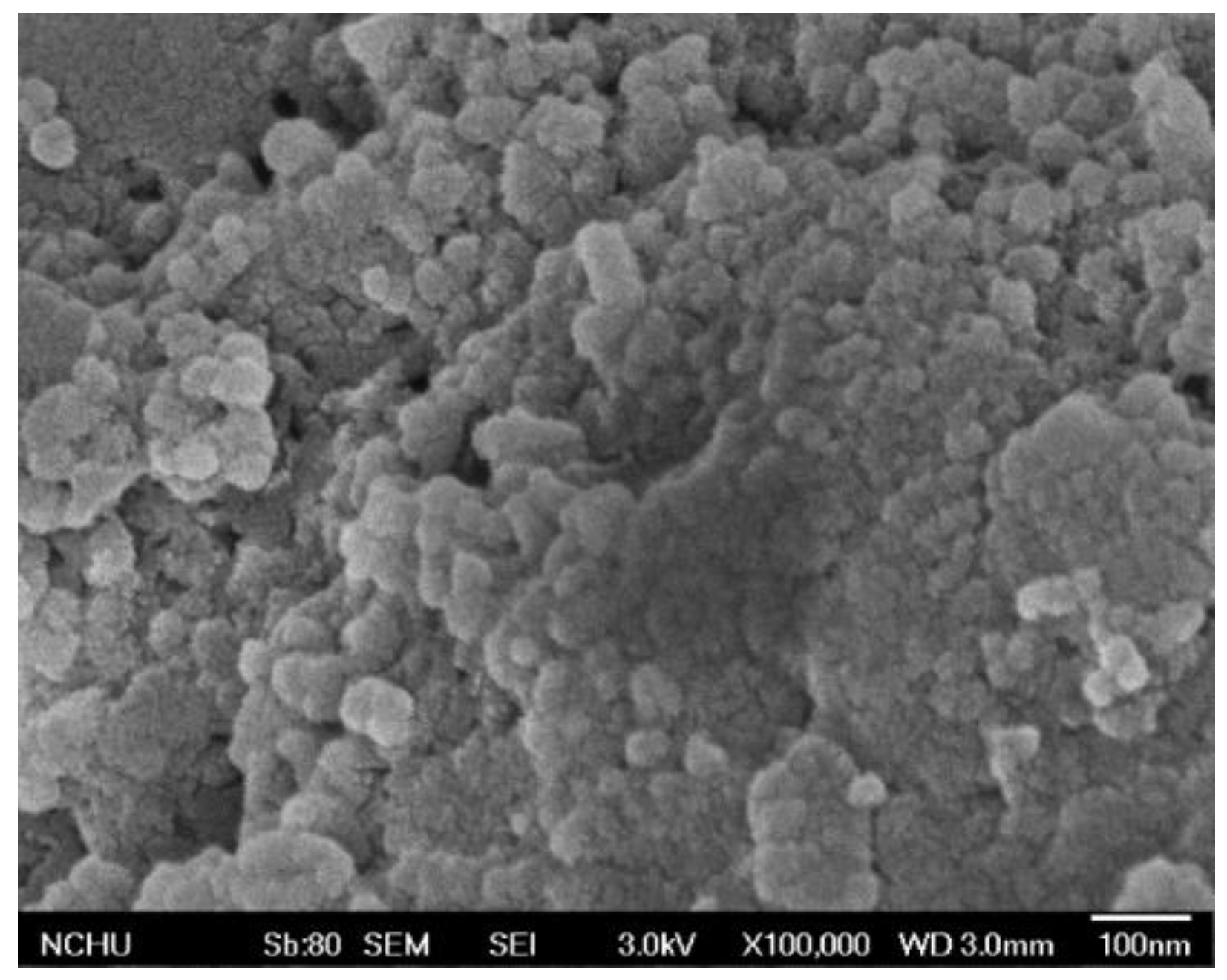

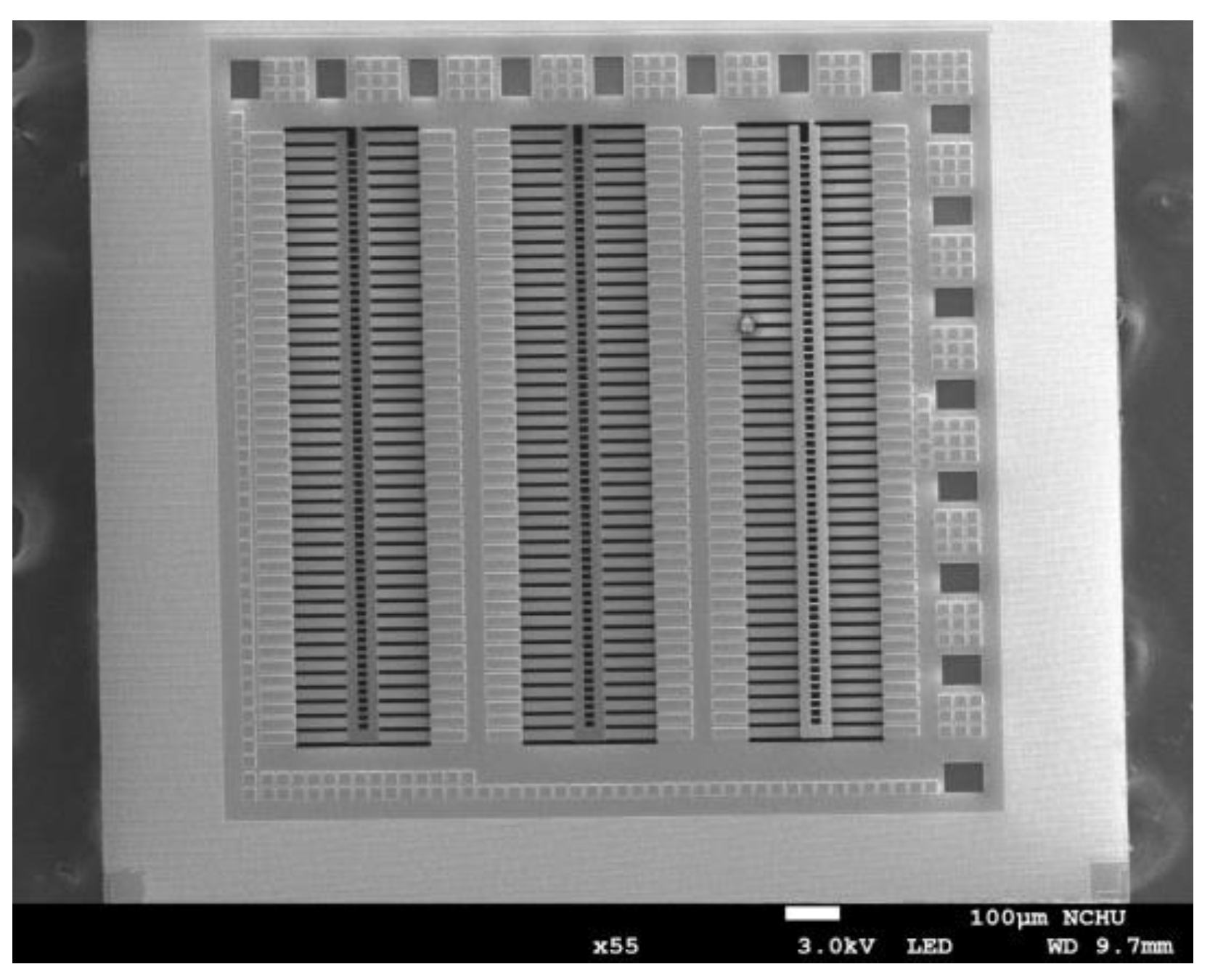

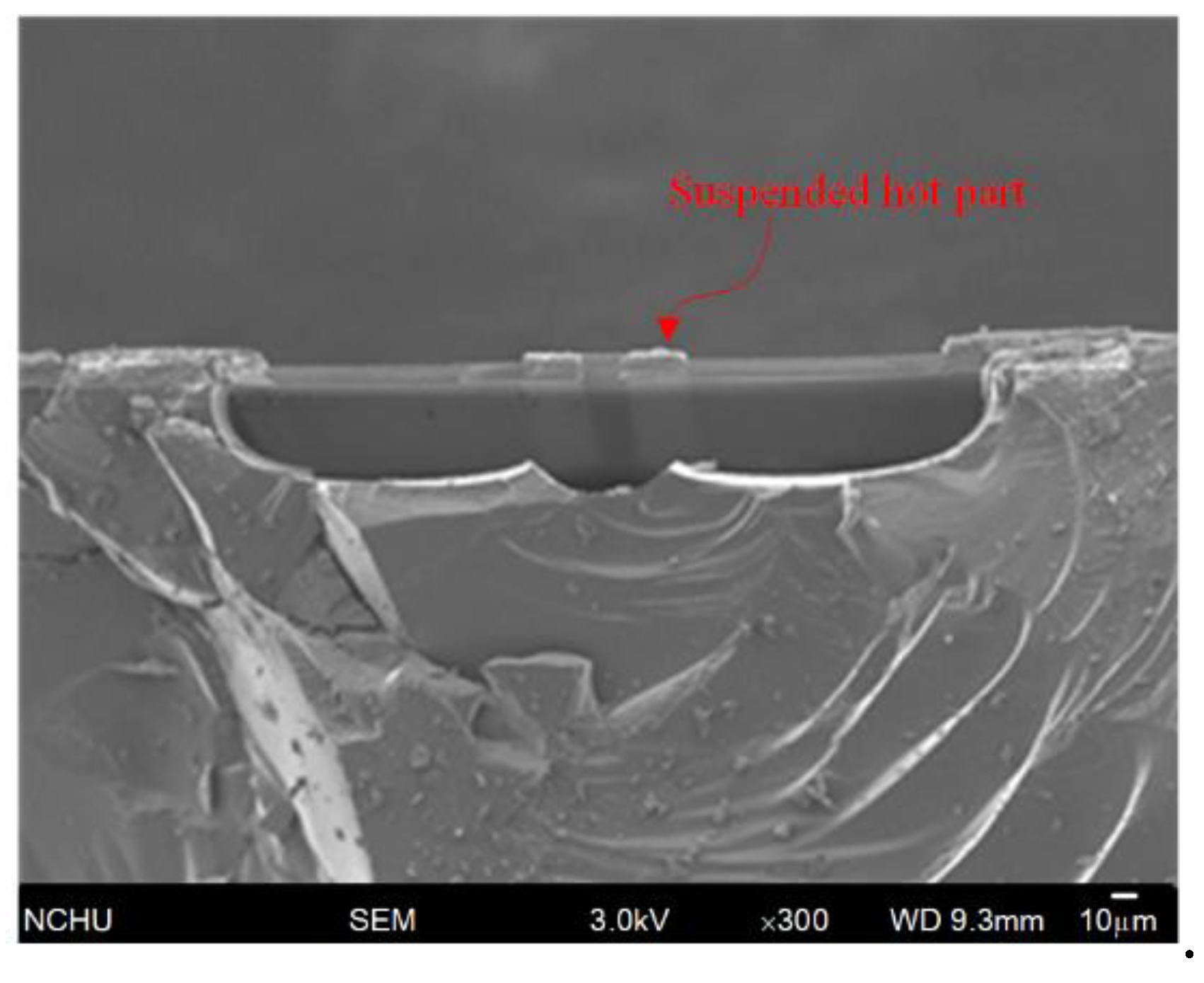

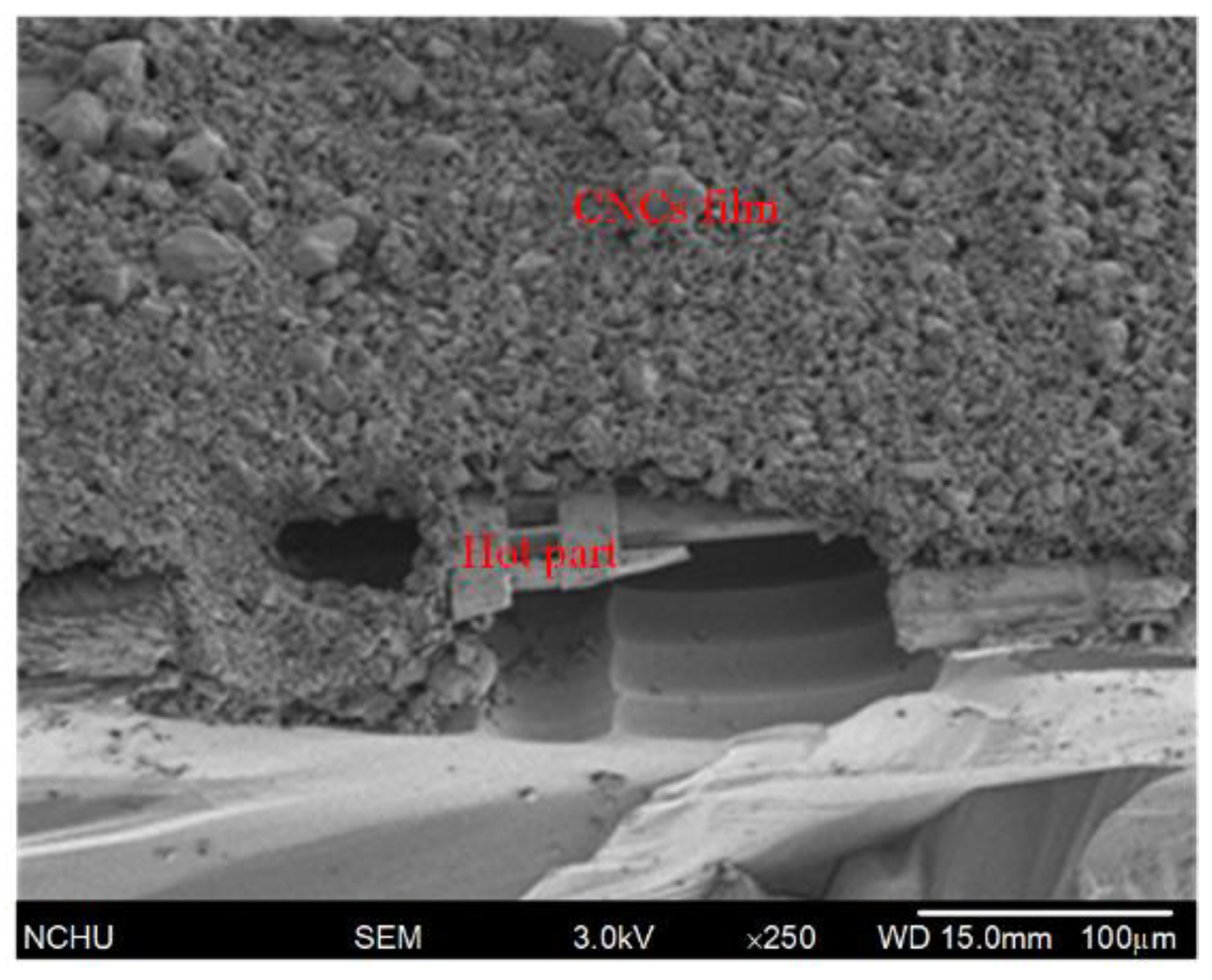

Abstract

1. Introduction

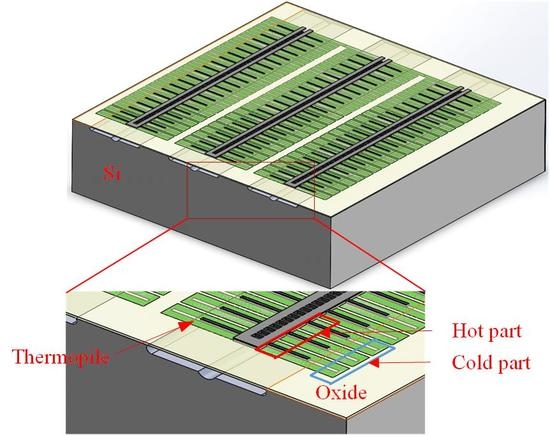

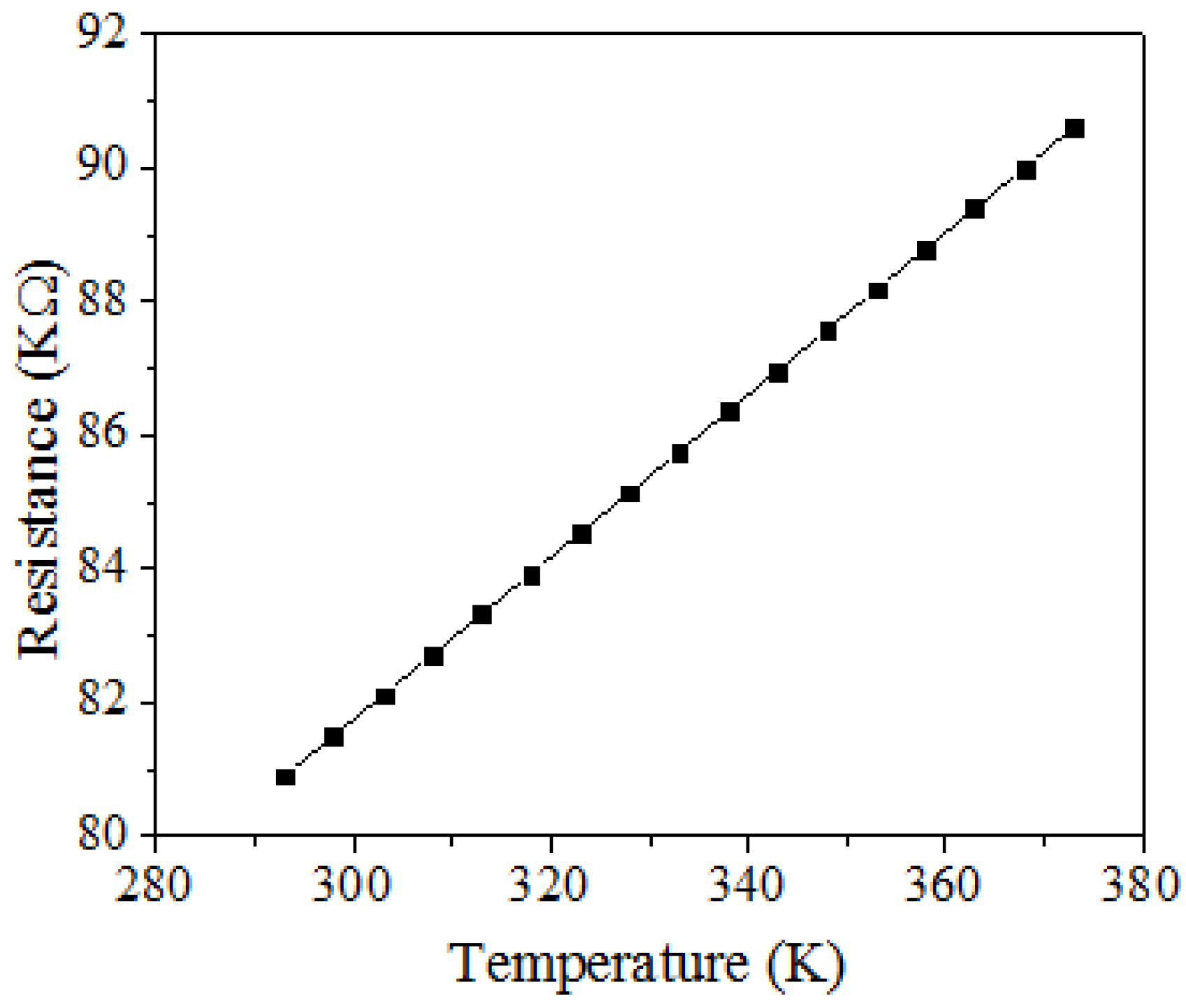

2. Design of Microgenerator

3. Fabrication of Microgenerator

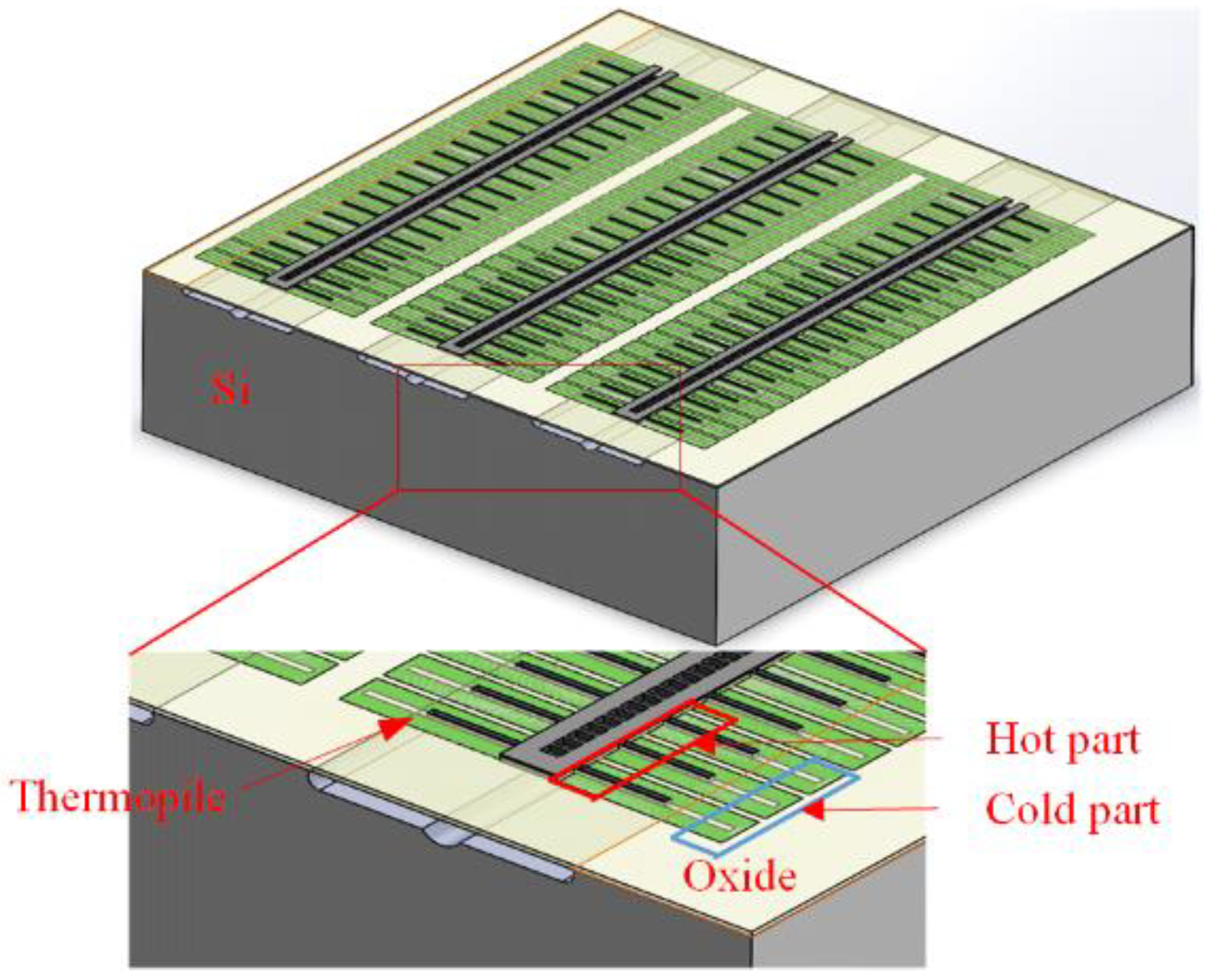

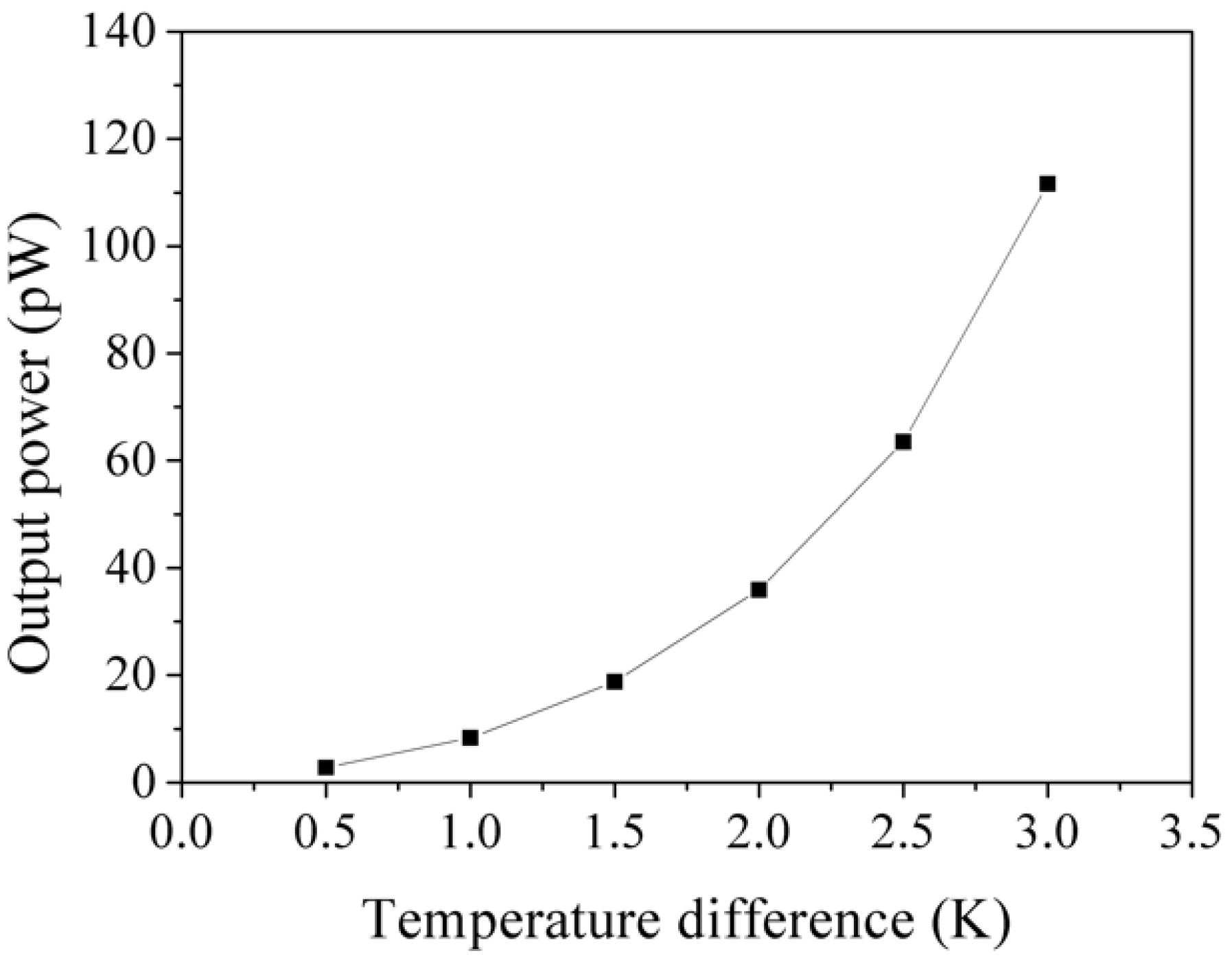

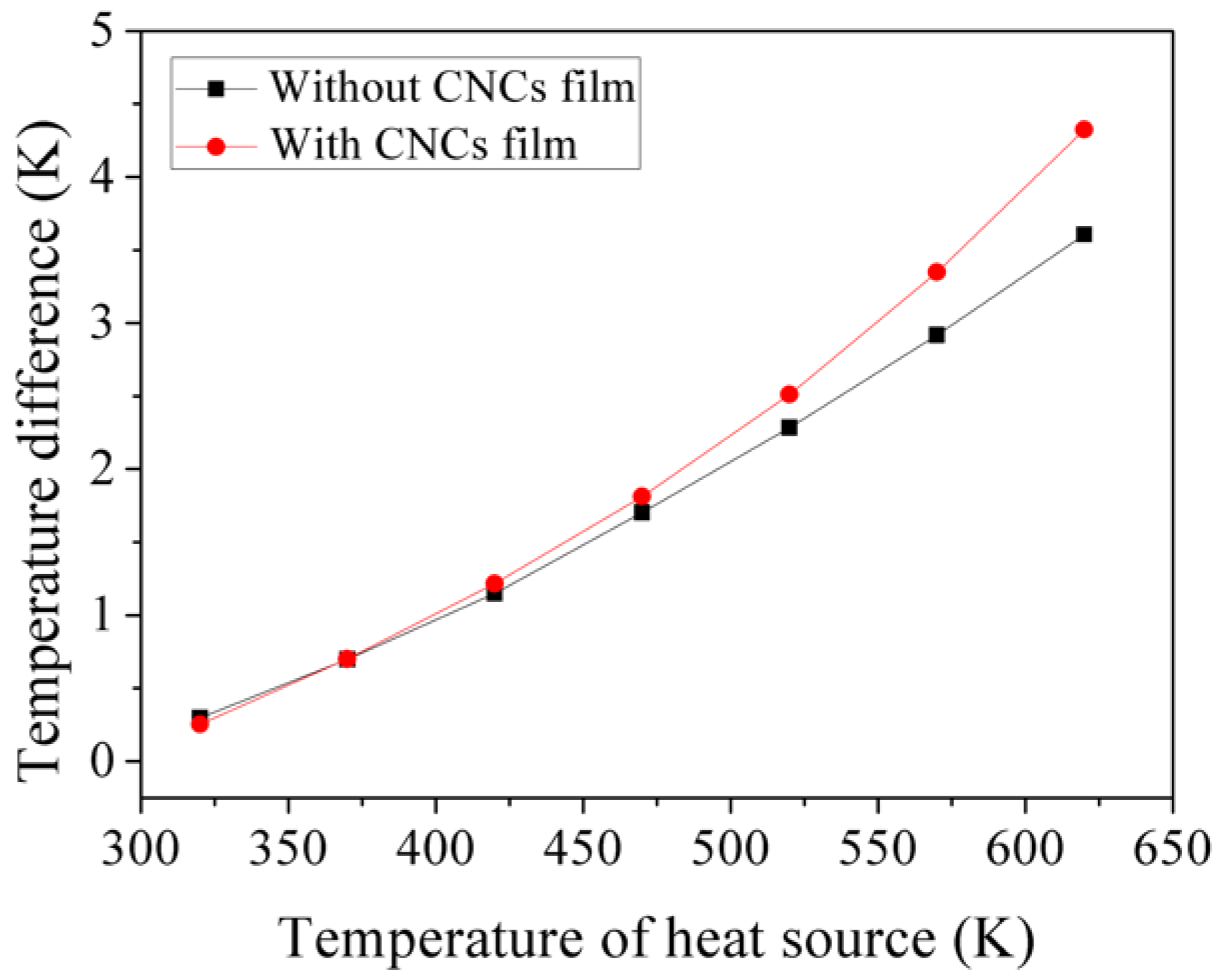

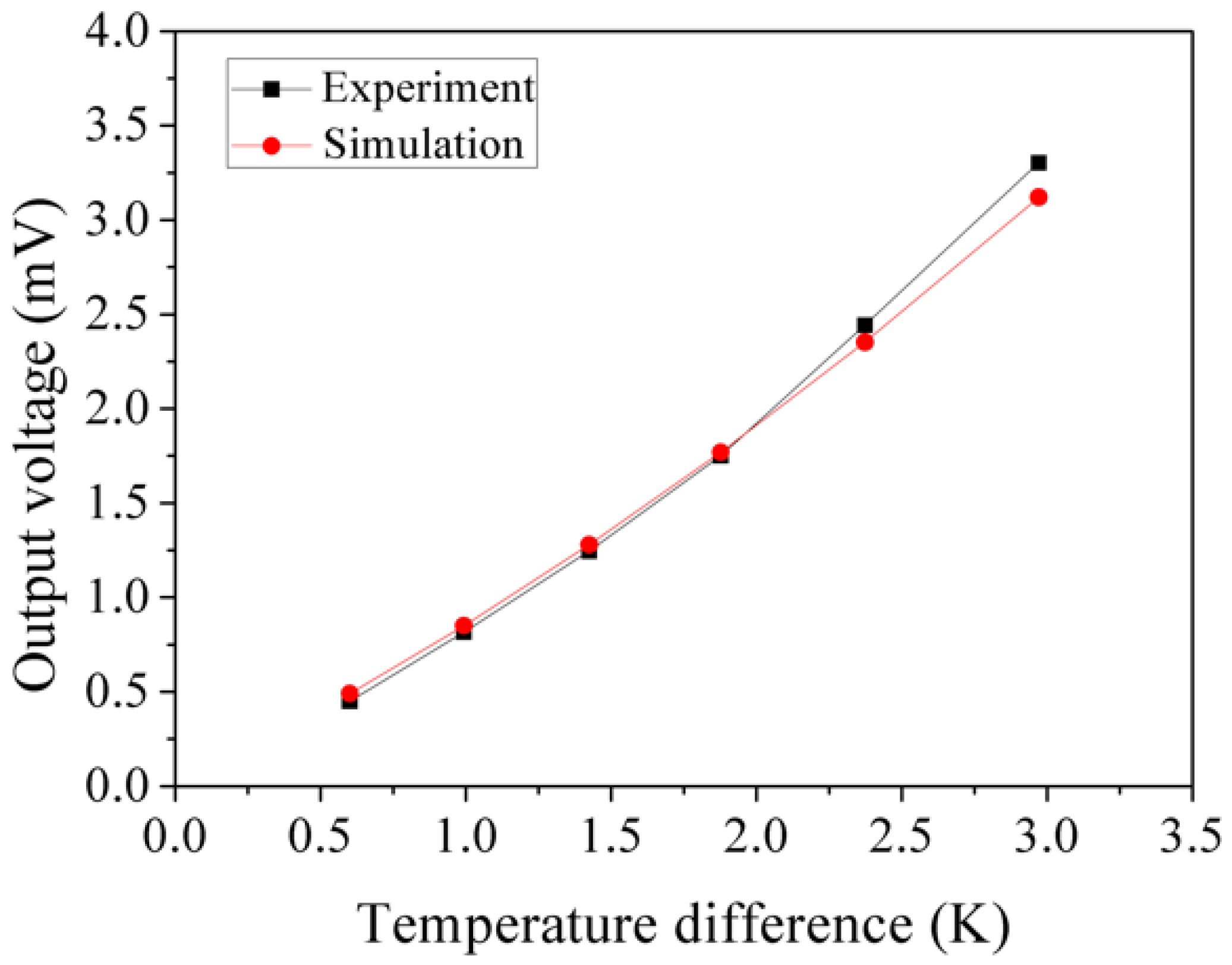

4. Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, W.; Ling, Z.; Yu, W.; Shi, J. A review of MEMS scale piezoelectric energy harvester. Appl. Sci. 2018, 8, 645. [Google Scholar] [CrossRef]

- Lin, C.Y.; Hsu, C.C.; Dai, C.L. Fabrication of a micromachined capacitive switch using the CMOS-MEMS technology. Micromachines 2015, 6, 1645–1654. [Google Scholar] [CrossRef]

- Blanche, P.A.; LaComb, L.; Wang, Y.; Wu, M.C. Diffraction-based optical switching with MEMS. Appl. Sci. 2017, 7, 411. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chen, J.H. Development of dual-axis MEMS accelerometers for machine tools vibration monitoring. Appl. Sci. 2016, 6, 201. [Google Scholar] [CrossRef]

- Fong, C.F.; Dai, C.L.; Wu, C.C. Fabrication and characterization of a micro methanol sensor using the CMOS-MEMS technique. Sensors 2015, 15, 27047–27059. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yang, J.; Xu, D. A high power density micro-thermoelectric generator fabricated by an integrated bottom-up approach. J. Microelectromech. Syst. 2016, 25, 744–749. [Google Scholar] [CrossRef]

- Yuan, Z.; Ziouche, K.; Bougrioua, Z.; Lejeune, P.; Lasri, T.; Leclercq, D. A planar micro thermoelectric generator with high thermal resistance. Sens. Actuators A Phys. 2015, 221, 67–76. [Google Scholar] [CrossRef]

- Perez-Marin, A.P.; Lopeandia, A.F.; Abad, L.; Ferrando-Villaba, P.; Garcia, G.; Lopez, A.M.; Munoz-Pascual, F.X.; Rodriguez-Viejo, J. Micropower thermoelectric generator from thin Si membranes. Nano Energy 2014, 4, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Kouma, N.; Nishino, T.; Tsuboi, O. A high-output-voltage micro-thermoelectric generator having high-aspect-ratio structure. J. Micromech. Microeng. 2013, 23, 114005. [Google Scholar] [CrossRef]

- Feng, Q.; Shi, X.; Xing, Y.; Li, T.; Li, F.; Pan, D.; Liang, H. Thermoelectric microgenerators using a single large-scale Sb doped ZnO microwires. J. Alloys Compd. 2018, 739, 298–304. [Google Scholar] [CrossRef]

- Yamamuro, H.; Hatsuta, N.; Wachi, M.; Takei, Y.; Takashiri, M. Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators. Coatings 2018, 8, 22. [Google Scholar] [CrossRef]

- Hashimoto, S.; Asada, S.; Xu, T.; Oba, S.; Himeda, Y.; Yamato, R.; Matsukawa, T.; Matsuki, T.; Watanabe, T. Anomalous Seebeck coefficient observed in silicon nanowire micro thermoelectric generator. Appl. Phys. Lett. 2017, 111, 023105. [Google Scholar] [CrossRef]

- Maruyama, S.; Hizawa, T.; Takahashi, K.; Sawada, K. Optical-interferometry-based CMOS-MEMS sensor transduced by stress-induced nanomechanical deflection. Sensors 2018, 18, 138. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.Z.; Dai, C.L.; Yang, M.Z. Micro ethanol sensors with a heater fabricated using the commercial 0.18 μm CMOS process. Sensors 2013, 13, 12760–12770. [Google Scholar] [CrossRef] [PubMed]

- Mansoor, M.; Haneef, I.; Akhtar, S.; Rafiq, M.A.; De Luca, A.; Ali, S.Z.; Udrea, F. An SOI CMOS-based multi-sensor MEMS chip for fluidic applications. Sensors 2016, 16, 1608. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.Z.; Dai, C.L.; Lin, W.Y. Fabrication and characterization of polyaniline/PVA humidity microsensors. Sensors 2011, 11, 8143–8151. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.C.; Dai, C.L.; Hsu, C.C. Titanium dioxide nanoparticle humidity microsensors integrated with circuitry on-a-chip. Sensors 2014, 14, 4177–4188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Chodavarapu, V.P. Differential wide temperature range CMOS interface circuit for capacitive MEMS pressure sensors. Sensors 2015, 15, 4253–4263. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.Z.; Dai, C.L. Ethanol microsensors with a readout circuit manufactured using the CMOS-MEMS technique. Sensors 2015, 15, 1623–1634. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.L.; Peng, H.J.; Liu, M.C.; Wu, C.C.; Hsu, H.M.; Yang, L.J. A micromachined microwave switch fabricated by the complementary metal-oxide semiconductor post-process of etching silicon dioxide. Jpn. J. Appl. Phys. 2005, 44, 6804–6809. [Google Scholar] [CrossRef]

- Székely, V. New type of thermal-function IC: 4-quadrant multiplier. Electron. Lett. 1976, 12, 372–373. [Google Scholar] [CrossRef]

- Ankireddy, K.; Menon, A.K.; Iezzi, B.; Yee, S.K.; Losego, M.D.; Jur, J.S. Electrical conductivity, thermal behavior, and Seebeck coefficient of conductive films for printed thermoelectric energy harvesting systems. J. Electron. Mater. 2016, 45, 5561–5569. [Google Scholar] [CrossRef]

- Strasser, M.; Aigner, R.; Lauterbach, C.; Sturm, T.F.; Franosch, M.; Wachutka, G. Micro machined CMOS TEG as on-chip power supply. Sens. Actuators A 2004, 144, 362–370. [Google Scholar] [CrossRef]

- Toriyama, T.; Yajima, M.; Sugiyama, S. Thermoelectric micro power generator utilizing self-standing polysilicon-metal thermopile. In Proceedings of the IEEE Micro Electro Mechanical Systems, Interlaken, Switzerland, 25 January 2001; pp. 562–565. [Google Scholar]

- Glatz, W.; Muntwyler, S.; Hierold, C. Optimization and fabrication of thick flexible polymer based micro thermoelectric generator. Sens. Actuators A Phys. 2006, 132, 337–345. [Google Scholar] [CrossRef]

- Gardner, J.W.; Varadan, V.K.; Awadelkarim, O.O. Microsensors MEMS and Smart Devices; John Wiley & Sons Ltd.: Chichester, UK, 2001. [Google Scholar]

- Kao, P.H.; Shih, P.J.; Dai, C.L.; Kiu, M.C. Fabrication and Characterization of CMOS-MEMS Thermoelectric Micro Generator. Sensors 2010, 10, 1315–1325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, C.L.; Chiou, J.H.; Lu, M.S.C. A maskless post-CMOS bulk micromachining process and its application. J. Micromech. Microeng. 2005, 15, 2366–2371. [Google Scholar] [CrossRef]

- Dai, C.L.; Chen, H.L.; Chang, P.Z. Fabrication of a micromachined optical modulator using the CMOS process. J. Micromech. Microeng. 2001, 11, 612–615. [Google Scholar] [CrossRef]

- Jo, S.E.; Kim, M.K.; Kim, M.S.; Kim, Y.J. Flexible thermoelectric generator for human body heat energy harvesting. Electron. Lett. 2012, 48, 1015–1017. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Rabari, R.; Mahmud, S.; Heyst, B.V. Thermal energy harvesting from the human body using flexible thermoelectric generator (FTEG) fabricated by a dispenser printing technique. Energy 2016, 115, 1081–1091. [Google Scholar] [CrossRef]

- Peng, S.W.; Shih, P.J.; Dai, C.L. Manufacturing and characterization of a thermoelectric energy harvester using the CMOS-MEMS technology. Micromachines 2015, 6, 1560–1568. [Google Scholar] [CrossRef]

- Yeh, C.C.; Dai, C.L.; Shih, H.F. Fabrication and characterization of thermoelectric microgenerators with carbon nanotube. Sens. Mater. 2014, 26, 75–83. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-W.; Wu, C.-C.; Hsu, C.-C.; Dai, C.-L. Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film. Appl. Sci. 2018, 8, 1047. https://doi.org/10.3390/app8071047

Chen Y-W, Wu C-C, Hsu C-C, Dai C-L. Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film. Applied Sciences. 2018; 8(7):1047. https://doi.org/10.3390/app8071047

Chicago/Turabian StyleChen, Yu-Wei, Chyan-Chyi Wu, Cheng-Chih Hsu, and Ching-Liang Dai. 2018. "Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film" Applied Sciences 8, no. 7: 1047. https://doi.org/10.3390/app8071047