An Integrated Open Approach to Capturing Systematic Knowledge for Manufacturing Process Innovation Based on Collective Intelligence

Abstract

:1. Introduction

2. Literature Review

2.1. Innovation-Oriented Knowledge Capture and Management

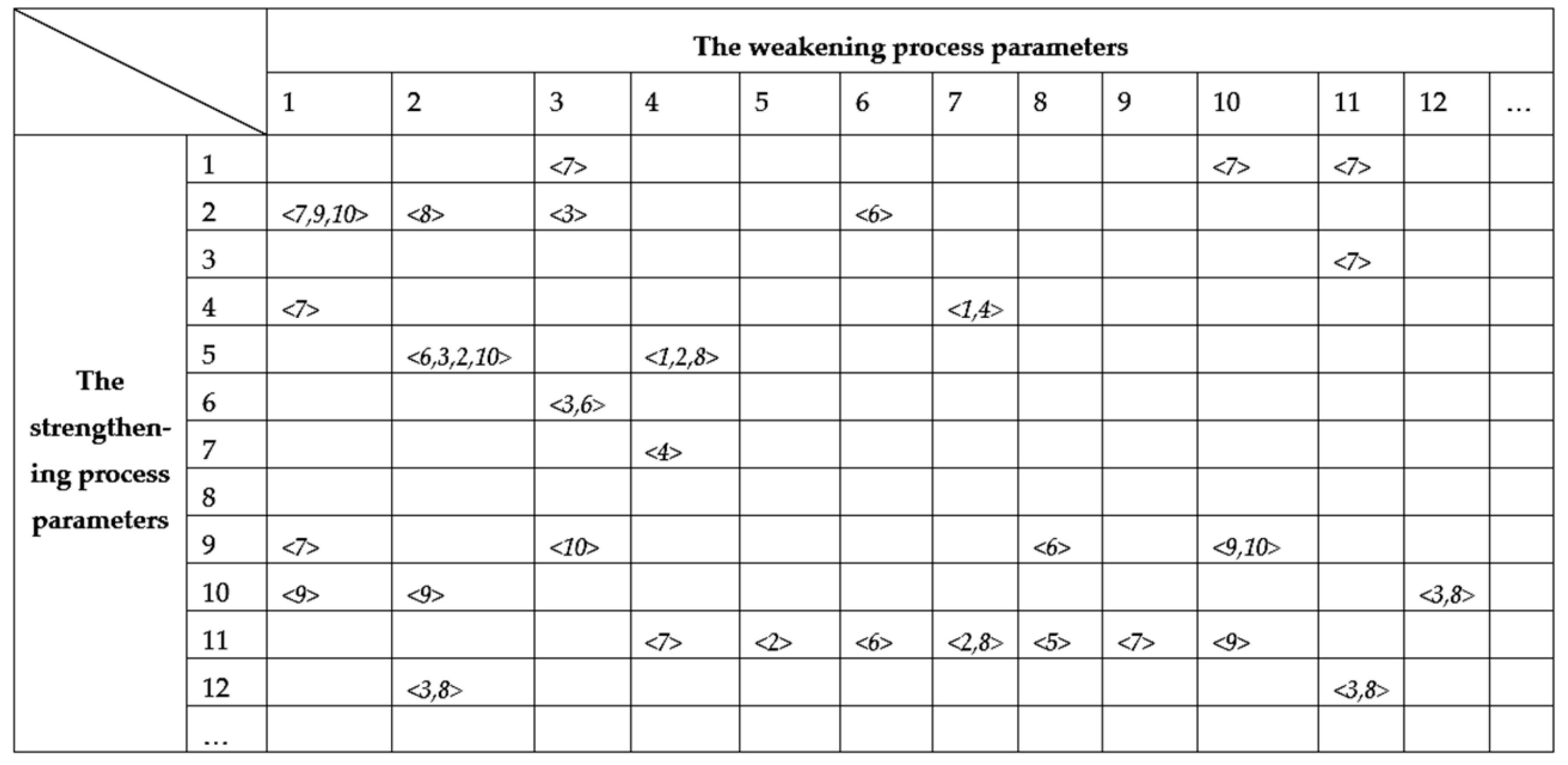

2.2. Computer-Aided Process Innovation

2.3. Summary

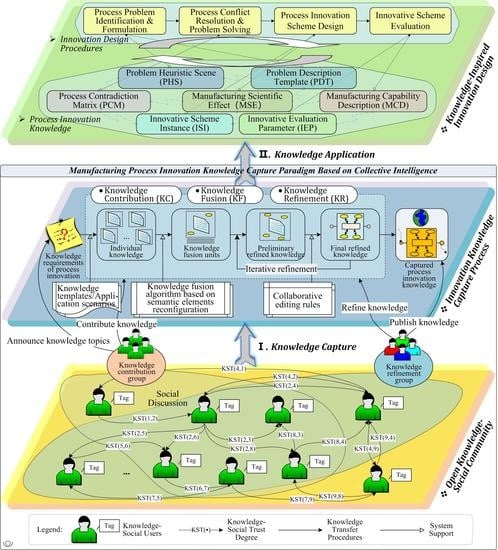

3. An Overall Paradigm for Innovation Knowledge Capture Based on Collective Intelligence

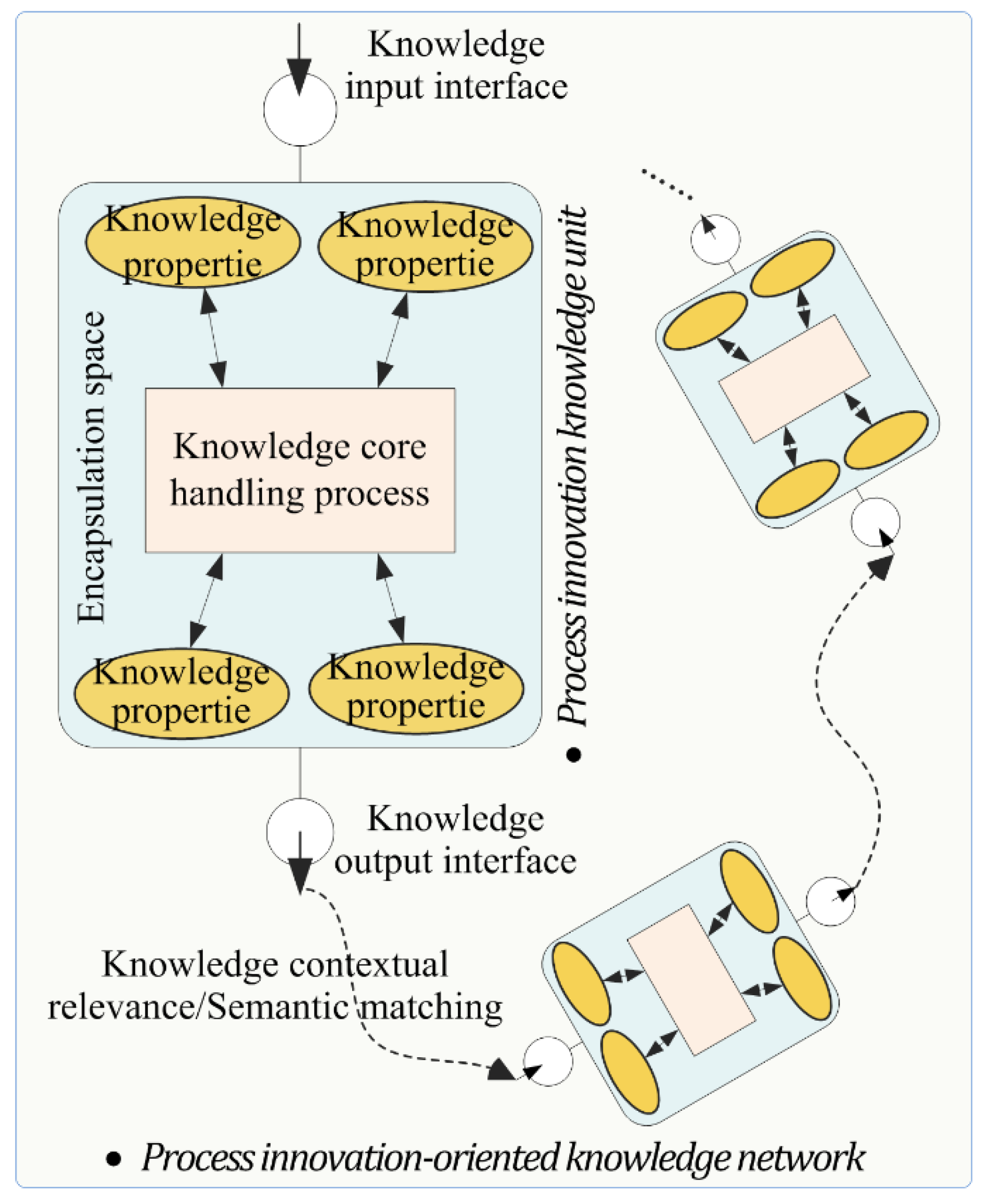

4. The Proposed PIKC-CI Method

4.1. Multi-Source Innovation Knowledge Fusion Based on Semantic Elements Reconfiguration

- (1)

- When the terminologies have similar meanings but different expressions, we can map terminology items into the terminology set logic tree of domain ontology, and the result can be denoted by . If , then ; if , then ; if , then .

- (2)

- When the terminology items have contrary logic, conflict resolution will depend on collective intelligence.

- (1)

- When concrete manifestation of semantic conflict is terminology conflict, those conflicts can be resolved according to Step 3.

- (2)

- When predicate items have similar meanings but different expressions, we denote the usage frequency of predicate terms by and , respectively. Similarly, the fusion result is denoted by . If , then ; if , then ; if , then .

- (3)

- When predicate items have contrary logic, conflicts resolution will depend on collective intelligence.

4.2. Collaborative Innovation Knowledge Refinement Based on Knowledge–Social Trust Degree

4.2.1. Credible Groups Construction

4.2.2. Procedure of Collaborative Knowledge Refinement

5. Case Study

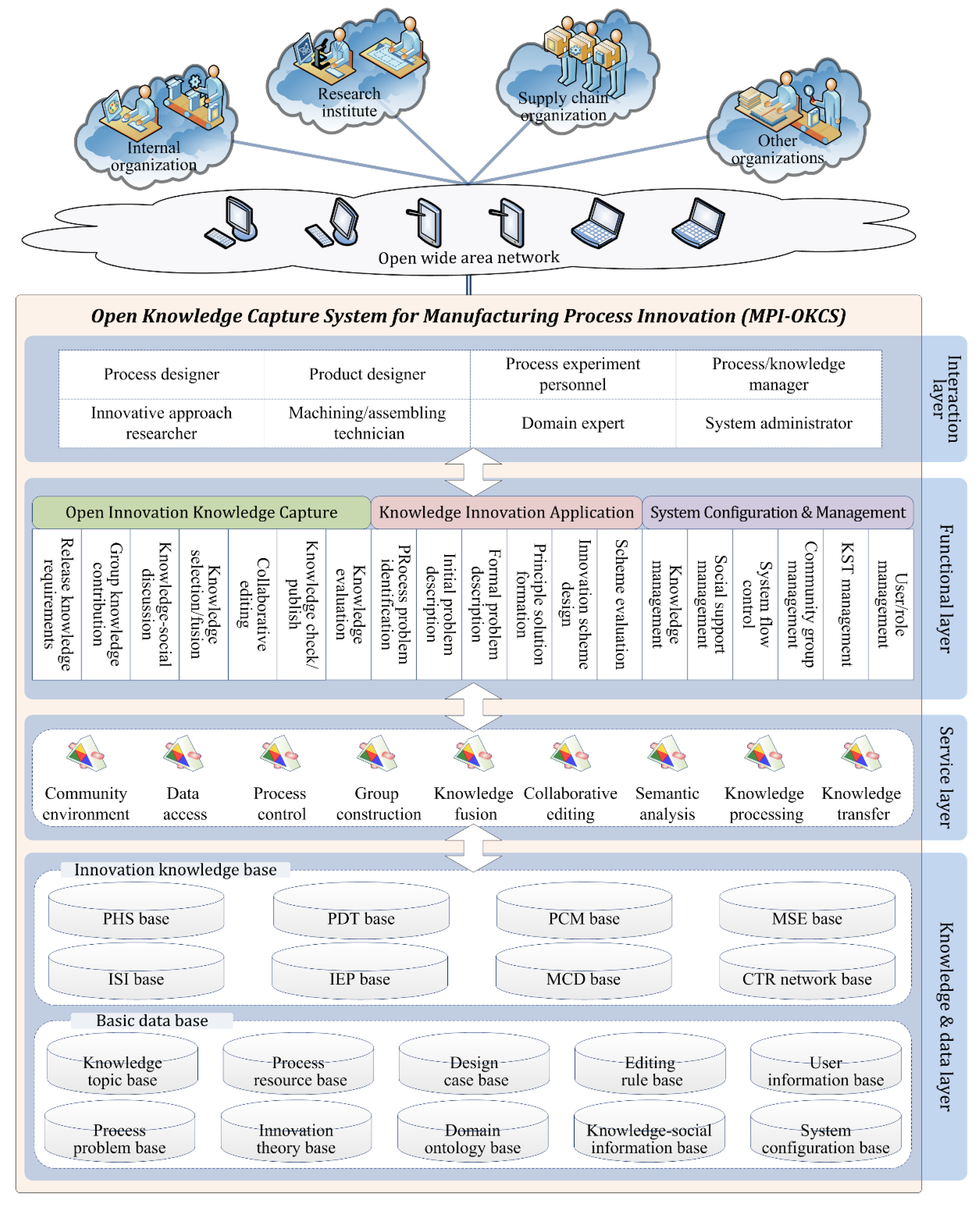

5.1. The Implementation of MPI-OKCS

5.2. An Illustrative Example of Welding Process Innovation Knowledge Capture and Application

6. Conclusions and Implications

- By considering the multi-type knowledge organization in innovation design and building a knowledge–social community, a novel holistic knowledge capture paradigm of PIKC-CI is proposed, which can realize the transformation from individual empirical knowledge to public refined knowledge in an open environment.

- Based on the domain ontology constraints, a multi-source process innovation knowledge fusion algorithm based on semantic elements reconfiguration is raised, with the corresponding semantic conflict resolution rules. This algorithm can effectively support preliminary automatic fusion for the contributed knowledge.

- A collaborative editing strategy based on knowledge lock and KST is applied to the iterative refinement of process innovation knowledge, which ensures that refined knowledge embraces the collective intelligence of knowledge–social users.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CAPI | computer-aided process innovation |

| CAM | computer-aided manufacturing |

| CAPP | computer-aided process planning |

| CAD | computer-aided design |

| CAE | computer-aided engineering |

| CAI | computer-aided innovation |

| ICT | information and communication technology |

| KC | knowledge contribution |

| KF | knowledge fusion |

| KR | knowledge refinement |

| TRIZ | the theory of inventive problem solving |

| PIKC-CI | process innovation knowledge capture based on collective intelligence |

| PHS | problem heuristic scene |

| PDT | problem description template |

| PCM | process contradiction matrix |

| MSE | manufacturing scientific effect |

| ISI | innovative scheme instance |

| IEP | innovative evaluation parameter |

| MCD | manufacturing capability description |

| KST | knowledge–social trust degree |

| MPI-OKCS | open knowledge capture system for manufacturing process innovation |

Appendix A

| No. | Parameters | Explanations |

|---|---|---|

| 1 | Material | Physical and chemical properties of materials |

| 2 | Mechanical properties | Stress, pressure, tensile strength etc. |

| 3 | Thickness | Thickness range of different materials can be welded |

| 4 | Strength | Mechanical strength after welding |

| 5 | Shape | Break/joint form, welding wire size, weld shape/aspect ratio, arc spacing etc. |

| 6 | Welding position | Butt contact, angular contact, lap joint, downward welding, vertical, horizontal and inverted welding, constraint degree |

| 7 | Temperature | Preheat temperature, heat treatment temperature, cooling temperature, temperature distribution etc. |

| 8 | Power | Welding current, arc voltage, power supply |

| 9 | Speed | Welding speed, wire feed speed, wire melting speed, cooling rate etc. |

| 10 | Oxidability | Heat input, weld/base metal oxidation |

| 11 | Welding defects | Appearance defects, surface defects, cracks, incomplete penetration, not fusion etc. |

| 12 | Production efficiency | Welding utilization, product efficiency |

| … | … | … |

| No. | Principles | Explanations |

|---|---|---|

| 1 | Separation/detachment/compromise | a. Divide objects into separate parts; b. Make the object detachable; c. Increase the object segmentation. |

| 2 | Preparation before welding | a. The choice and treatment of the crevasses form; b. Pre-calculation processing. |

| 3 | Change one-dimension to multi-dimension (new dimension) | a. The material motion in the form of point, one-dimensional, two-dimensional, three-dimensional spatial distribution or conversion; b. Replacing single layer structure with multi-layer structure; c. Incline, side, or invert the object; d. To the opposite or adjacent surface of a specified surface. |

| 4 | Heat treatment | a. Normalizing; b. Quenching; c. Tempering; d. Annealing. |

| 5 | Turn the harm into benefit | a. Use harmful factors (especially the harmful effects of the medium) to gain beneficial effects; b. Harmful factors can be eliminated by a combination of harmful factors and one or more other harmful factors; c. Improve the extent of the operation of the harmful factors in order to achieve a state of harmless. |

| 6 | Substitution/replacement principle | a. Using two or more welding methods instead of a single welding method; b. The new welding consumables and solder are used to replace the old ones; c. The quantitative and faintness factors, fixed and variable parameters, irregular and regular state are converted into each other in welding; d. Using high energy density energy. |

| 7 | Welding material selection | a. Select stainless steel consumables according to ASME specifications; b. Select welding consumables by application or composition. |

| 8 | Dispersion principle (homogeneity) | a. The welding consumables should be of the same material (or of the similar mechanical properties) when welding a given object. B. Distract the stress of the stress concentration part. |

| 9 | Setting media protection | a. Replacing the normal environment with an inert environment; b. Introduction of a mixture or additive; c. Welding process in vacuum environment. |

| 10 | Composite/hybrid principle | a. Transfer from the same material to the mixture; b. Substitute a composition for a similar substance. |

| … | … | … |

References

- Neugebauer, R. Energy-Efficient Product and Process Innovations in Production Engineering. CIRP J. Manuf. Sci. Technol. 2011, 4, 127–128. [Google Scholar] [CrossRef]

- Wang, G.; Tian, X.; Geng, J.; Guo, B. A Process Innovation Knowledge Management Framework and Its Application. Adv. Mater. Res. 2013, 655–657, 2299–2306. [Google Scholar] [CrossRef]

- Geng, J.; Tian, X.; Jia, X.; Liu, S.; Zhang, Z. Review for computer aided methods of manufacturing process innovation. Comput. Integr. Manuf. Syst. 2016, 22, 2778–2790. [Google Scholar]

- Jafari, M.; Zarghami, H.R. Effect of TRIZ on enhancing employees’ creativity and innovation. Aircraft Eng. Aerosp. Technol. 2017, 89, 853–861. [Google Scholar] [CrossRef]

- Sun, X.; Shehab, E.; Mehnen, J. Knowledge modelling for laser beam welding in the aircraft industry. Int. J. Adv. Manuf. Technol. 2012, 66, 763–774. [Google Scholar] [CrossRef]

- Wang, C.N.; Huang, Y.F.; Le, T.N.; Ta, T.T. An innovative approach to enhancing the sustainable development of Japanese automobile suppliers. Sustainability 2016, 8, 420. [Google Scholar] [CrossRef]

- Yi, P.X.; Huang, M.; Guo, L.J.; Shi, T.L. Dual recycling channel decision in retailer oriented closed-loop supply chain for construction machinery remanufacturing. J. Clean. Prod. 2016, 137, 1393–1405. [Google Scholar] [CrossRef]

- Kang, D.; Lee, D.H. Energy and environment efficiency of industry and its productivity effect. J. Clean. Prod. 2016, 135, 184–193. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy management in manufacturing: From literature review to a conceptual framework. J. Clean. Prod. 2017, 167, 1464–1489. [Google Scholar] [CrossRef]

- Kobayashi, H. A systematic approach to eco-innovative product design based on life cycle planning. Adv. Eng. Inform. 2006, 20, 113–125. [Google Scholar] [CrossRef]

- U.S. President’s Council of Advisors on Science and Technology. Report to the President on Capturing Domestic Competitive Advantage in Advanced Manufacturing; U.S. President’s Council of Advisors on Science and Technology: Washington, DC, USA, 2012.

- Ramos, T.B.; Martins, I.P.; Martinho, A.P.; Douglas, C.H.; Painho, M.; Caeiro, S. An open participatory conceptual framework to support State of the Environment and Sustainability Reports. J. Clean. Prod. 2014, 64, 158–172. [Google Scholar] [CrossRef]

- Alvarado, A. Problems in the implementation process of advanced manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 64, 123–131. [Google Scholar]

- Hollen, R.M.A.; Van den Bosch, F.A.J.; Volberda, H.W. The Role of Management Innovation in Enabling Technological Process Innovation: An Inter-Organizational Perspective. Eur. Manag. Rev. 2013, 10, 35–50. [Google Scholar] [CrossRef]

- Mani, M.; Madan, J.; Lee, J.H.; Lyons, K.W.; Gupta, S.K. Sustainability characterisation for manufacturing processes. Int. J. Prod. Res. 2014, 52, 5895–5912. [Google Scholar] [CrossRef]

- Shin, S.J.; Kim, D.B.; Shao, G.; Brodsky, A.; Lechevalier, D. Developing a decision support system for improving sustainability performance of manufacturing processes. J. Intell. Manuf. 2017, 28, 1421–1440. [Google Scholar] [CrossRef]

- Främling, K.; Holmström, J.; Loukkola, J.; Nyman, J.; Kaustell, A. Sustainable PLM through Intelligent Products. Eng. Appl. Artif. Intell. 2013, 26, 789–799. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, Z.; Song, B. A novel two-stage method for acquiring engineering-oriented empirical tacit knowledge. Int. J. Prod. Res. 2014, 52, 5997–6018. [Google Scholar] [CrossRef]

- Stadler, C. Process Innovation and Integration in Process-Oriented Settings: The Case of the Oil Industry. J. Prod. Innov. Manag. 2011, 28, 44–62. [Google Scholar] [CrossRef]

- Wang, G.; Tian, X.; Hu, Y.; Evans, R.D.; Tian, M.; Wang, R. Manufacturing Process Innovation-Oriented Knowledge Evaluation Using MCDM and Fuzzy Linguistic Computing in an Open Innovation Environment. Sustainability 2017, 9, 1630. [Google Scholar] [CrossRef]

- Alexander, A.T.; Childe, S.J. Innovation: A knowledge transfer perspective. Prod. Plan. Control 2013, 24, 208–225. [Google Scholar] [CrossRef]

- Gao, J.; Bernard, A. An overview of knowledge sharing in new product development. Int. J. Adv. Manuf. Technol. 2017, 94, 1545–1550. [Google Scholar] [CrossRef]

- Leo Kumar, S.P. Knowledge-based expert system in manufacturing planning: State-of-the-art review. Int. J. Prod. Res. 2018, 1–25. [Google Scholar] [CrossRef]

- Waris, M.M.; Sanin, C.; Szczerbicki, E. Smart Innovation Engineering: Toward Intelligent Industries of the Future. Cybern. Syst. 2018, 1–16. [Google Scholar] [CrossRef]

- Wang, G.; Tian, X.; Geng, J.; Guo, B. A knowledge accumulation approach based on bilayer social wiki network for computer-aided process innovation. Int. J. Prod. Res. 2015, 53, 2365–2382. [Google Scholar] [CrossRef]

- Woolley, A.W.; Chabris, C.F.; Pentland, A.; Hashmi, N.; Malone, T.W. Evidence for a collective intelligence factor in the performance of human groups. Science 2010, 330, 686–688. [Google Scholar] [CrossRef] [PubMed]

- Denkena, B.; Shpitalni, M.; Kowalski, P.; Molcho, G.; Zipori, Y. Knowledge Management in Process Planning. CIRP Ann. Manuf. Technol. 2007, 56, 175–180. [Google Scholar] [CrossRef]

- Quintane, E.; Mitch Casselman, R.; Sebastian Reiche, B.; Nylund, P.A. Innovation as a knowledge-based outcome. J. Knowl. Manag. 2011, 15, 928–947. [Google Scholar] [CrossRef]

- Esterhuizen, D.; Schutte, C.S.L.; du Toit, A.S.A. Knowledge creation processes as critical enablers for innovation. Int. J. Inf. Manag. 2012, 32, 354–364. [Google Scholar] [CrossRef]

- Xu, J.; Houssin, R.; Caillaud, E.; Gardoni, M. Fostering continuous innovation in design with an integrated knowledge management approach. Comput. Ind. 2011, 62, 423–436. [Google Scholar] [CrossRef]

- Bosch-Mauchand, M.; Belkadi, F.; Bricogne, M.; Eynard, B. Knowledge-based assessment of manufacturing process performance: Integration of product lifecycle management and value-chain simulation approaches. Int. J. Comput. Integr. Manuf. 2013, 26, 453–473. [Google Scholar] [CrossRef]

- Wang, G.; Tian, X.; Geng, J.; Evans, R.; Che, S. Extraction of Principle Knowledge from Process Patents for Manufacturing Process Innovation. Proc. CIRP 2016, 56, 193–198. [Google Scholar] [CrossRef]

- Van de Vrande, V.; de Jong, J.P.J.; Vanhaverbeke, W.; de Rochemont, M. Open innovation in SMEs: Trends, motives and management challenges. Technovation 2009, 29, 423–437. [Google Scholar] [CrossRef]

- Huizingh, E.K.R.E. Open innovation: State of the art and future perspectives. Technovation 2011, 31, 2–9. [Google Scholar] [CrossRef]

- Carbone, F.; Contreras, J.; Hernández, J.Z.; Gomez-Perez, J.M. Open Innovation in an Enterprise 3.0 Framework: Three Case Studies. Expert Syst. Appl. 2012, 39, 8929–8939. [Google Scholar] [CrossRef]

- Cappa, F.; Del Sette, F.; Hayes, D.; Rosso, F. How to deliver open sustainable innovation: An integrated approach for a sustainable marketable product. Sustainability 2016, 8, 1341. [Google Scholar] [CrossRef]

- Hüsig, S.; Kohn, S. “Open CAI 2.0”—Computer Aided Innovation in the era of open innovation and Web 2.0. Comput. Ind. 2011, 62, 407–413. [Google Scholar] [CrossRef]

- Schumpeter, J.A. The Theory of Economic Development; Harvard University Press: Cambridge, MA, USA, 1934. [Google Scholar]

- Ayhan, M.B.; Öztemel, E.; Aydin, M.E.; Yue, Y. A quantitative approach for measuring process innovation: A case study in a manufacturing company. Int. J. Prod. Res. 2013, 51, 3463–3475. [Google Scholar] [CrossRef]

- Leon, N.; Cho, S.K. Computer aided innovation. Comput. Ind. 2009, 60, 537–538. [Google Scholar] [CrossRef]

- Kiritsis, D.; Koukias, A.; Nadoveza, D. ICT supported lifecycle thinking and information integration for sustainable manufacturing. Int. J. Sustain. Manuf. 2014, 3, 229–249. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Xu, X.; Wang, L.; Newman, S.T. Computer-aided process planning—A critical review of recent developments and future trends. Int. J. Comput. Integr. Manuf. 2011, 24, 1–31. [Google Scholar] [CrossRef]

- Lukic, D.; Milosevic, M.; Antic, A.; Borojevic, S.; Ficko, M. Multi-criteria selection of manufacturing processes in the conceptual process planning. Adv. Prod. Eng. Manag. 2017, 12, 151–162. [Google Scholar] [CrossRef]

- Raymond, L.; Bergeron, F.; Croteau, A.-M. Innovation capability and performance of manufacturing SMEs: The paradoxical effect of IT integration. J. Organ. Comput. Electron. Commer. 2013, 23, 249–272. [Google Scholar] [CrossRef] [Green Version]

- Yusof, Y.; Latif, K. Survey on computer-aided process planning. Int. J. Adv. Manuf. Technol. 2014, 75, 77–89. [Google Scholar] [CrossRef] [Green Version]

- Cakir, M.C.; Cilsal, O.O. Implementation of a contradiction-based approach to DFM. Int. J. Comput. Integr. Manuf. 2008, 21, 839–847. [Google Scholar] [CrossRef]

- Duflou, J.R.; D’hondt, J. Applying TRIZ for systematic manufacturing process innovation: The single point incremental forming case. Proc. Eng. 2011, 9, 528–537. [Google Scholar] [CrossRef]

- Sheu, D.D.; Chen, C.-H.; Yu, P.-Y. Invention principles and contradiction matrix for semiconductor manufacturing industry: Chemical mechanical polishing. J. Intell. Manuf. 2012, 23, 1637–1648. [Google Scholar] [CrossRef]

- Geng, J.; Tian, X. Knowledge-Based Computer Aided Process Innovation Method. Adv. Mater. Res. 2010, 97–101, 3299–3302. [Google Scholar] [CrossRef]

- Guo, B.; Geng, J.; Wang, G. Knowledge Fusion Method of Process Contradiction Units for Process Innovation. Proc. Eng. 2015, 131, 816–822. [Google Scholar] [CrossRef]

- Duran-Novoa, R.; Leon-Rovira, N.; Aguayo-Tellez, H.; Said, D. Inventive problem solving based on dialectical negation, using evolutionary algorithms and TRIZ heuristics. Comput. Ind. 2011, 62, 437–445. [Google Scholar] [CrossRef]

- Lykourentzou, I.; Papadaki, K.; Vergados, D.J.; Polemi, D.; Loumos, V. CorpWiki: A self-regulating wiki to promote corporate collective intelligence through expert peer matching. Inf. Sci. 2010, 180, 18–38. [Google Scholar] [CrossRef]

- Heidorn, G. Intelligent Writing Assistance. In Handbook of Natural Language Processing; CRC Press: Boca Raton, FL, USA, 2000; pp. 181–207. [Google Scholar]

| Rules | Descriptions |

|---|---|

| Rule 1 | The read locks are compatible with each other. More than one read locks can be placed on one knowledge object at the same time. Group members of knowledge refinement are allowed to hold read lock of the corresponding knowledge objects. |

| Rule 2 | The write locks are mutually exclusive with each other for a locked region. This means that only one write lock can be placed on the same knowledge object at a certain moment, and for a knowledge element only one editor may hold the write lock. |

| Rule 3 | After participants publish their comments and exchange views on the knowledge object to be refined, members who obtained a positive evaluation of more than a certain level can apply to be the refinement editor. |

| Rule 4 | If a knowledge element has been locked, the write lock requests will be put forward. Meanwhile, notifications are sent to the owners of write locks whenever the latter form queues in front of certain knowledge objects. Specifically, a system timer process, which sends time-stamped notifications to the owners of write locks, can be employed to prevent the starvation of other editing operations whenever there are editing operations waiting for more than a certain time to access certain objects. |

| Rule 5 | Group managers have the permission to grant write locks to a suitable group member at all times. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Hu, Y.; Tian, X.; Geng, J.; Hu, G.; Zhang, M. An Integrated Open Approach to Capturing Systematic Knowledge for Manufacturing Process Innovation Based on Collective Intelligence. Appl. Sci. 2018, 8, 340. https://doi.org/10.3390/app8030340

Wang G, Hu Y, Tian X, Geng J, Hu G, Zhang M. An Integrated Open Approach to Capturing Systematic Knowledge for Manufacturing Process Innovation Based on Collective Intelligence. Applied Sciences. 2018; 8(3):340. https://doi.org/10.3390/app8030340

Chicago/Turabian StyleWang, Gangfeng, Yongbiao Hu, Xitian Tian, Junhao Geng, Gailing Hu, and Min Zhang. 2018. "An Integrated Open Approach to Capturing Systematic Knowledge for Manufacturing Process Innovation Based on Collective Intelligence" Applied Sciences 8, no. 3: 340. https://doi.org/10.3390/app8030340