An Innovative and Efficient Method for Reverse Design of Wheel-Rail Profiles

Abstract

:1. Introduction

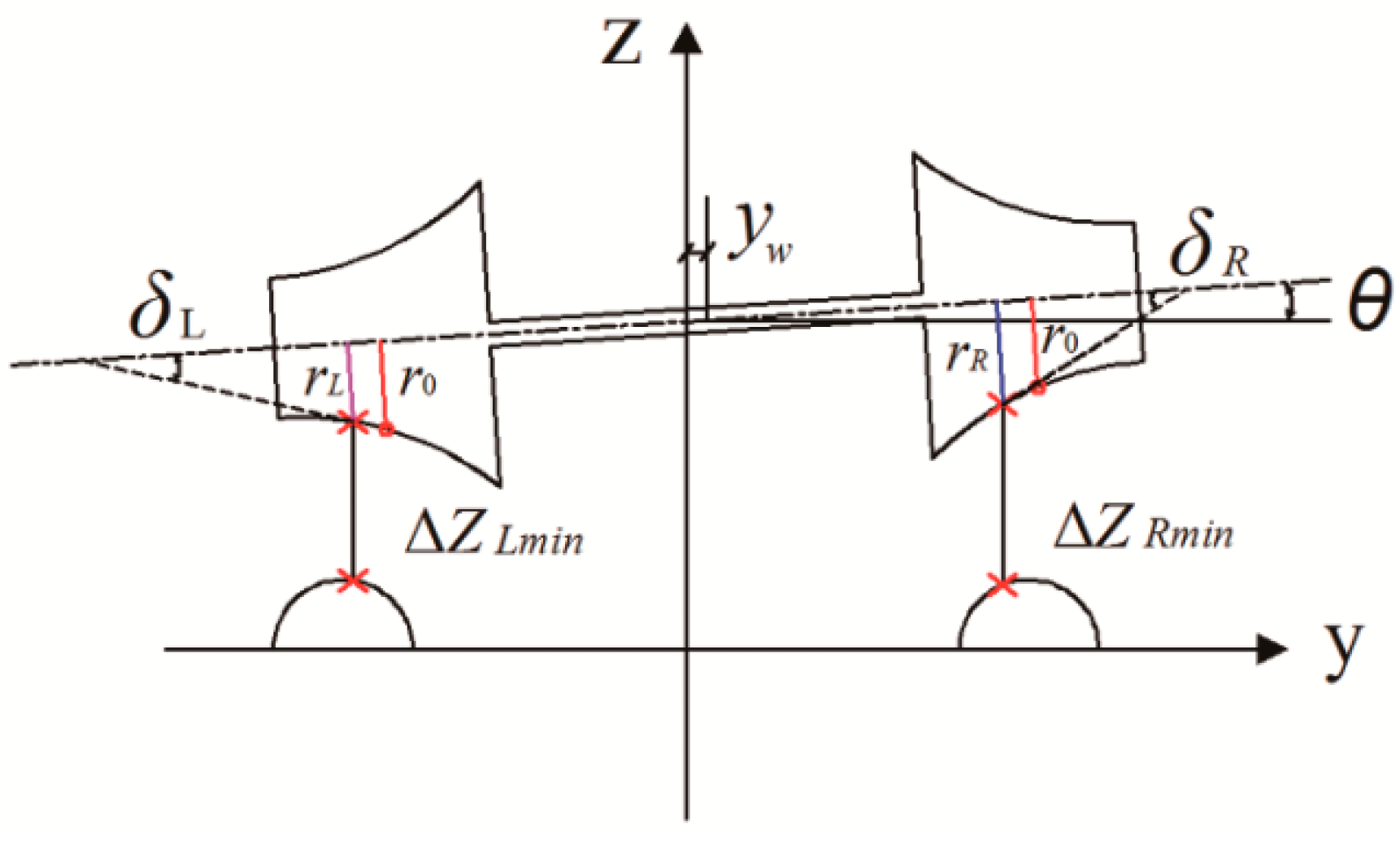

2. Geometric Analysis of Wheel-Rail Contact

2.1. Rolling Radius Difference

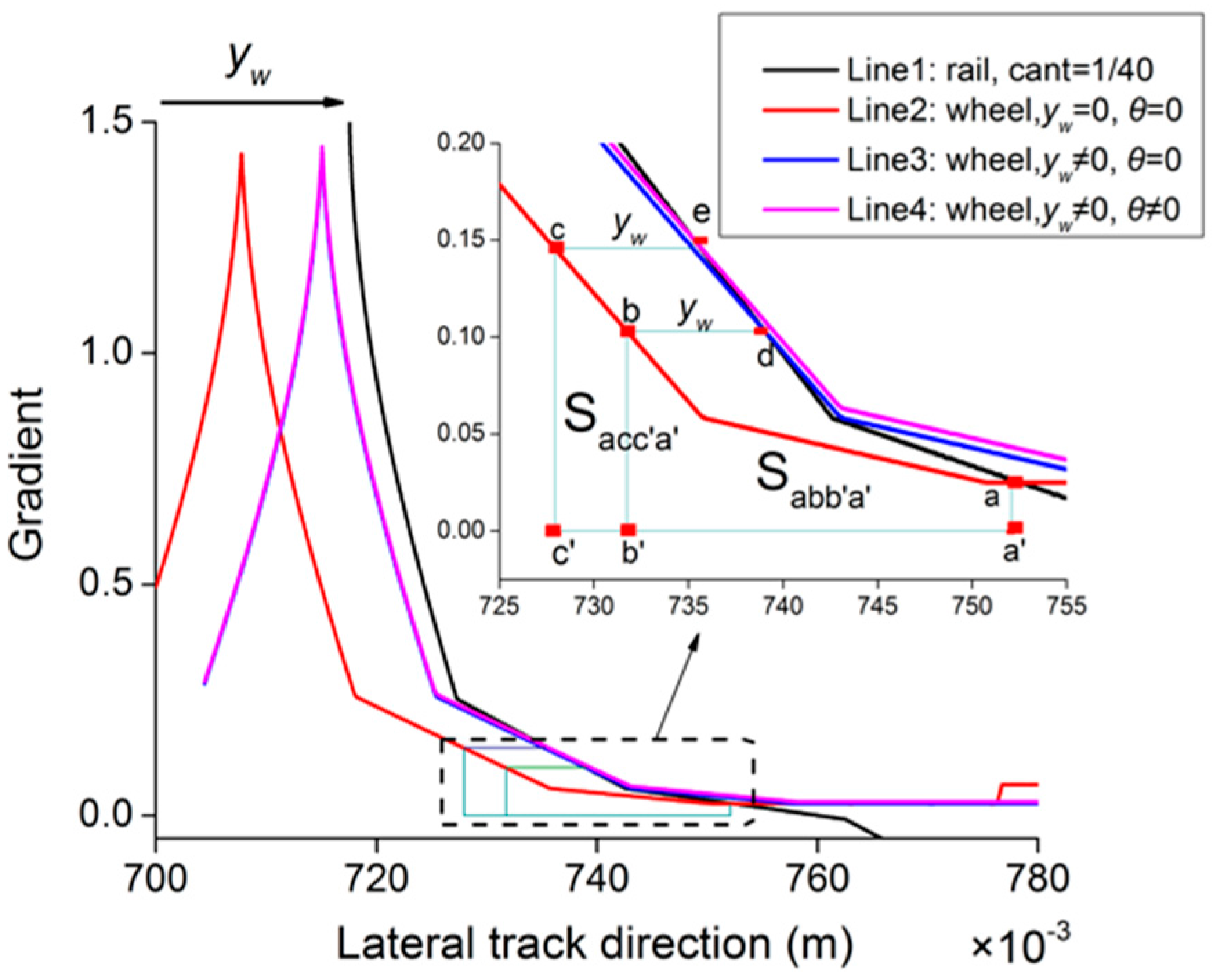

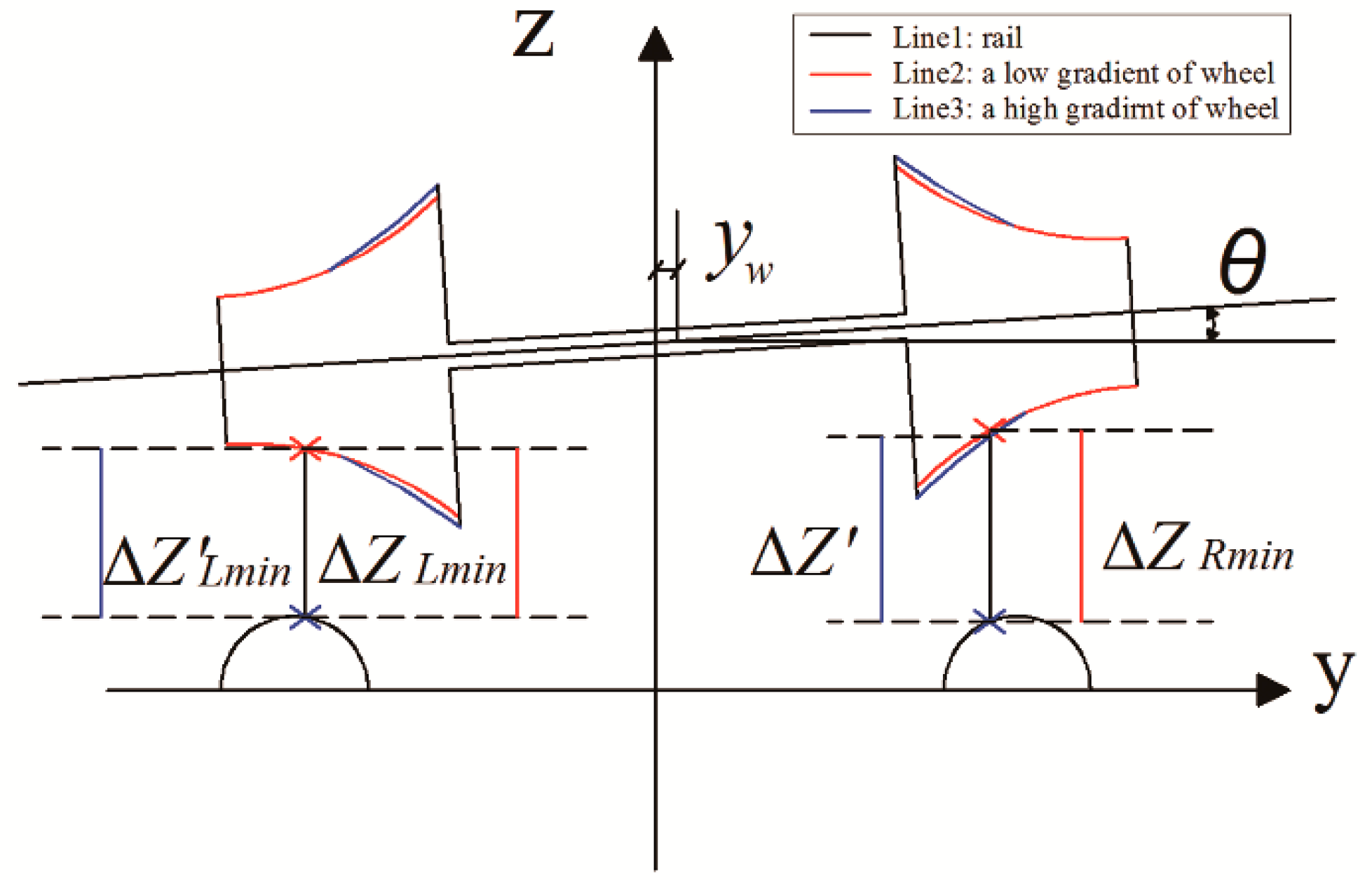

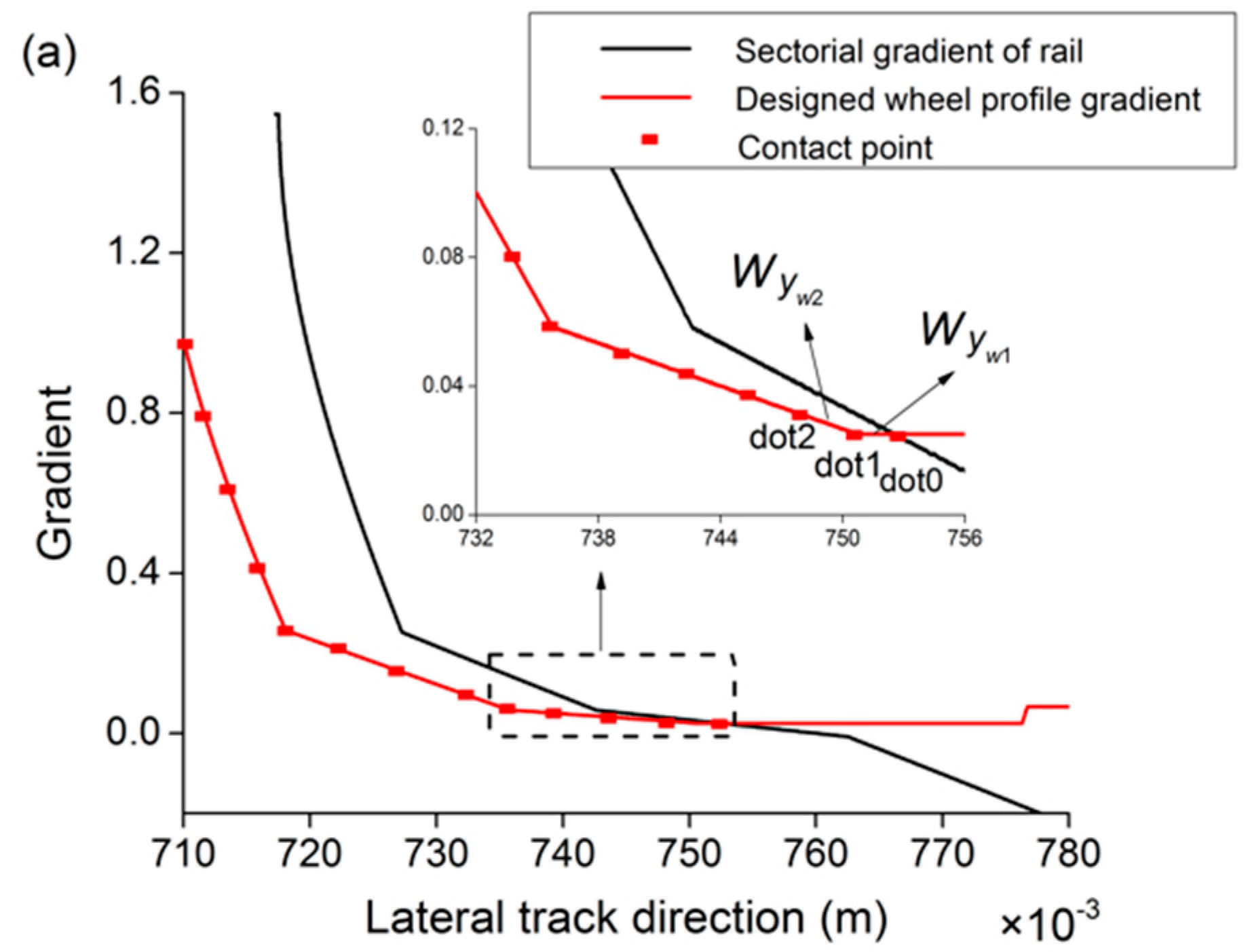

2.2. Gradient Control

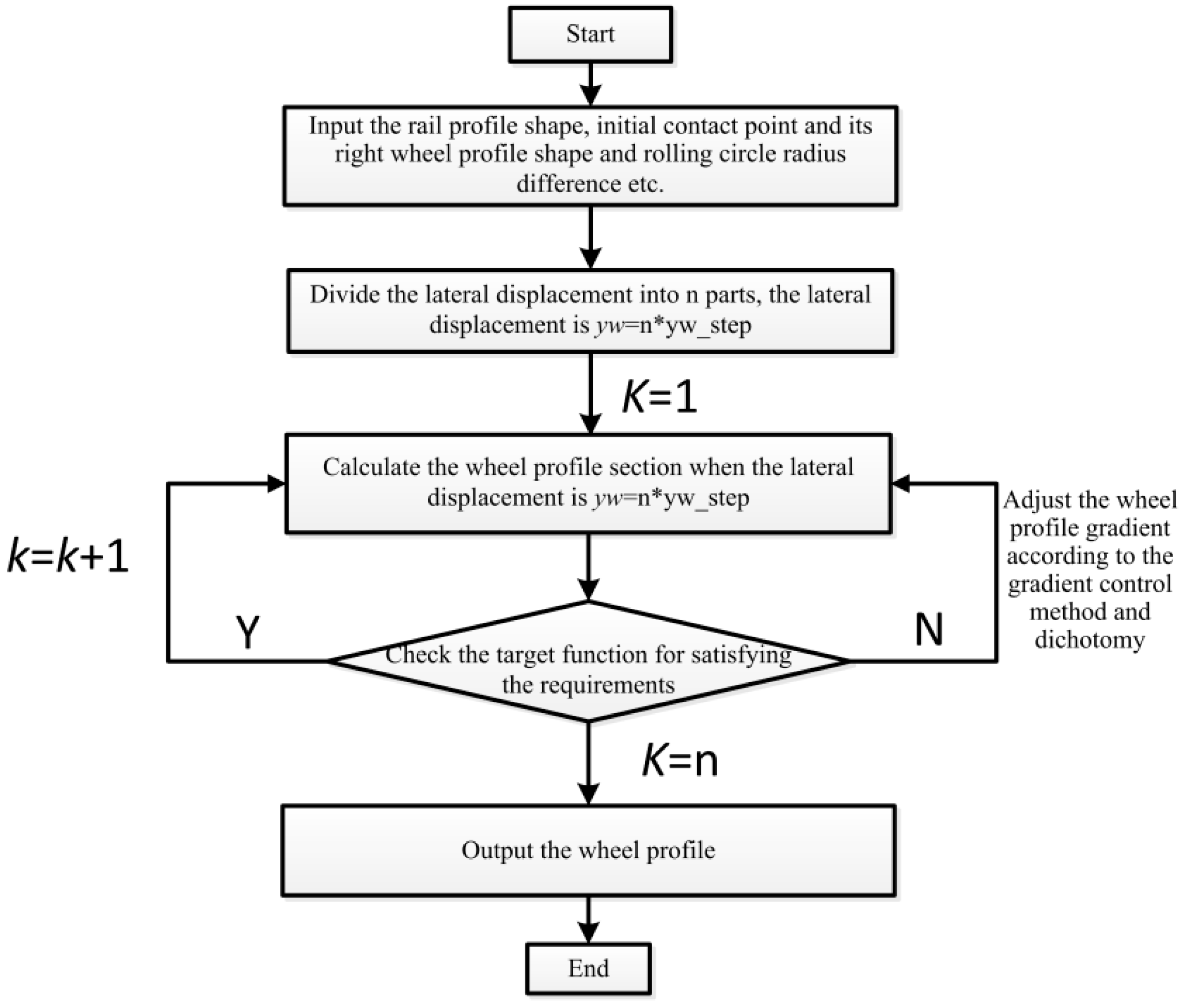

3. Reverse Profile Design Method

3.1. Postulated Conditions

- (1)

- The wheel and rail are both rigid bodies and the wheel-rail contact is single point contact;

- (2)

- Convex rail head, namely the tangent gradient of each point varies monotonously;

- (3)

- The given rolling radius difference increases monotonously with the wheelset lateral displacement.

3.2. Method Description

4. Method Verification

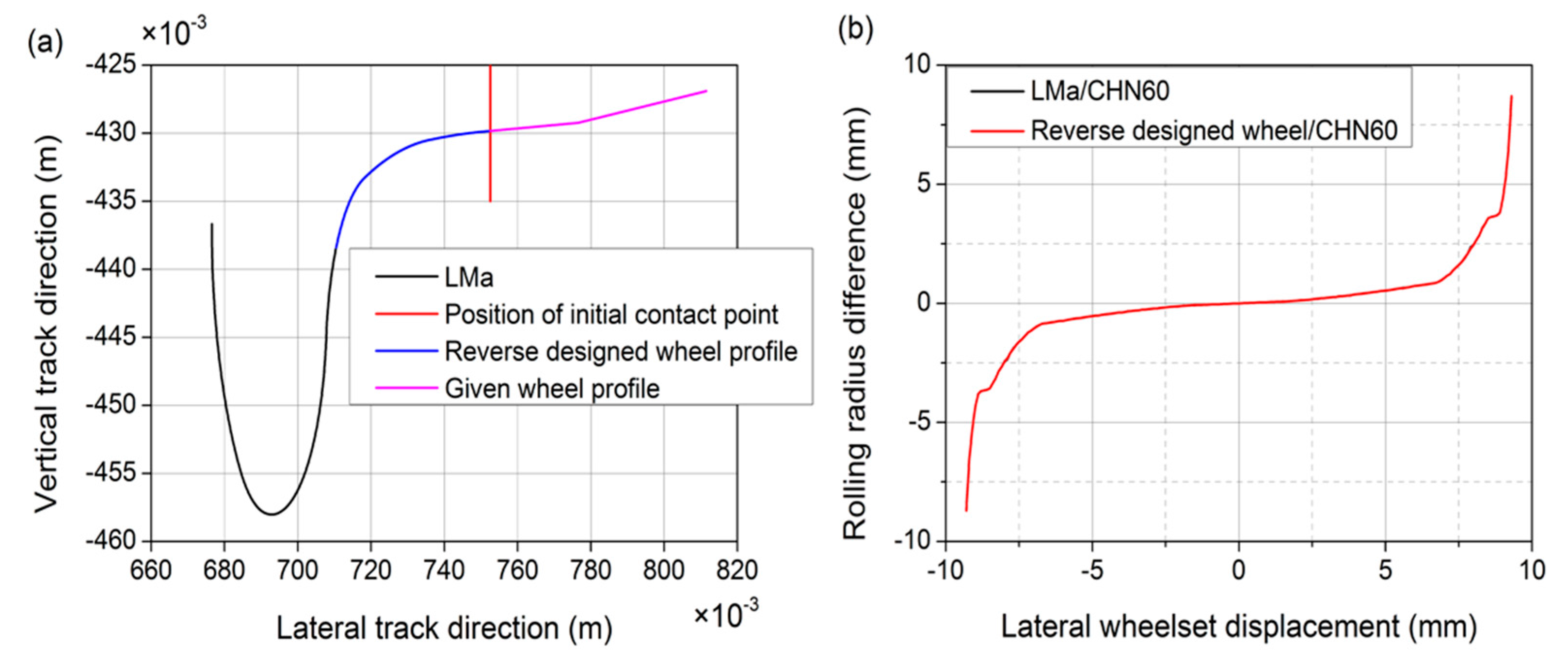

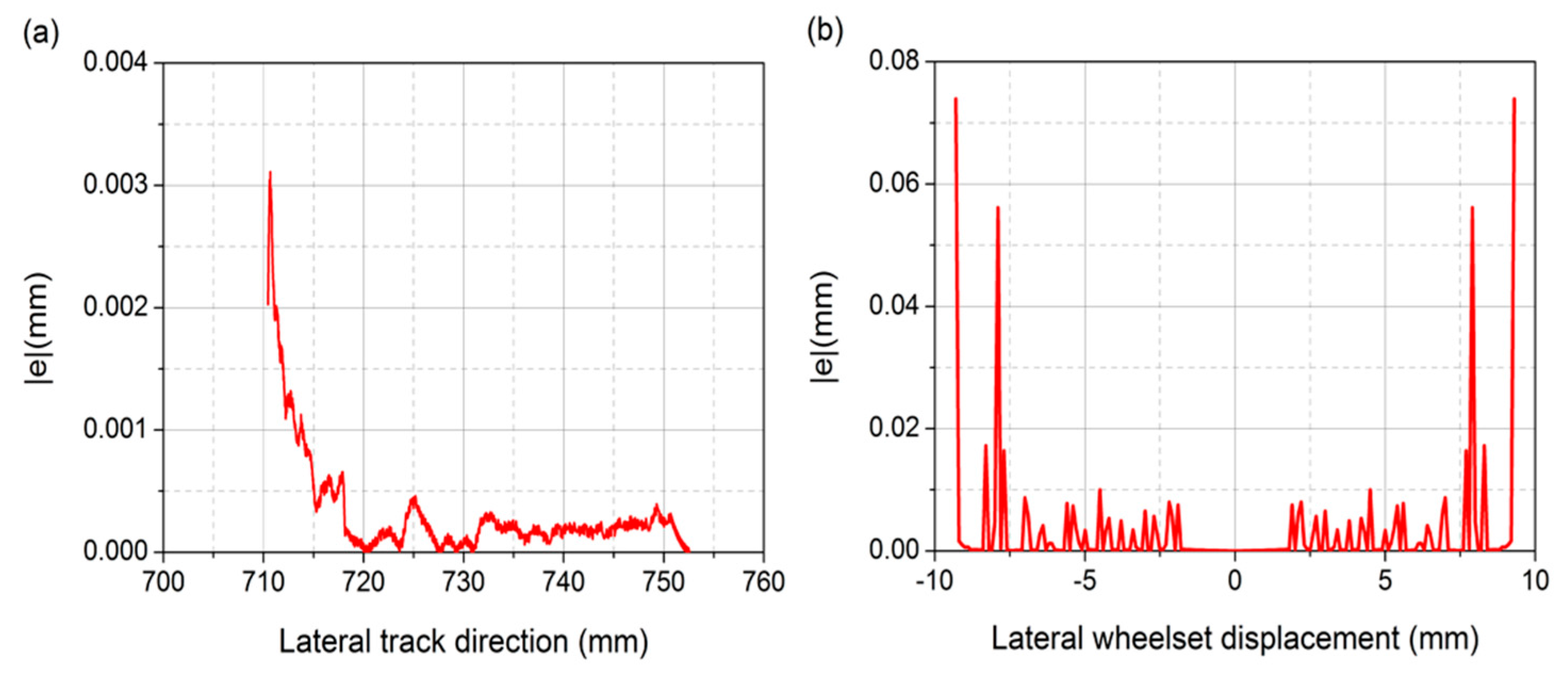

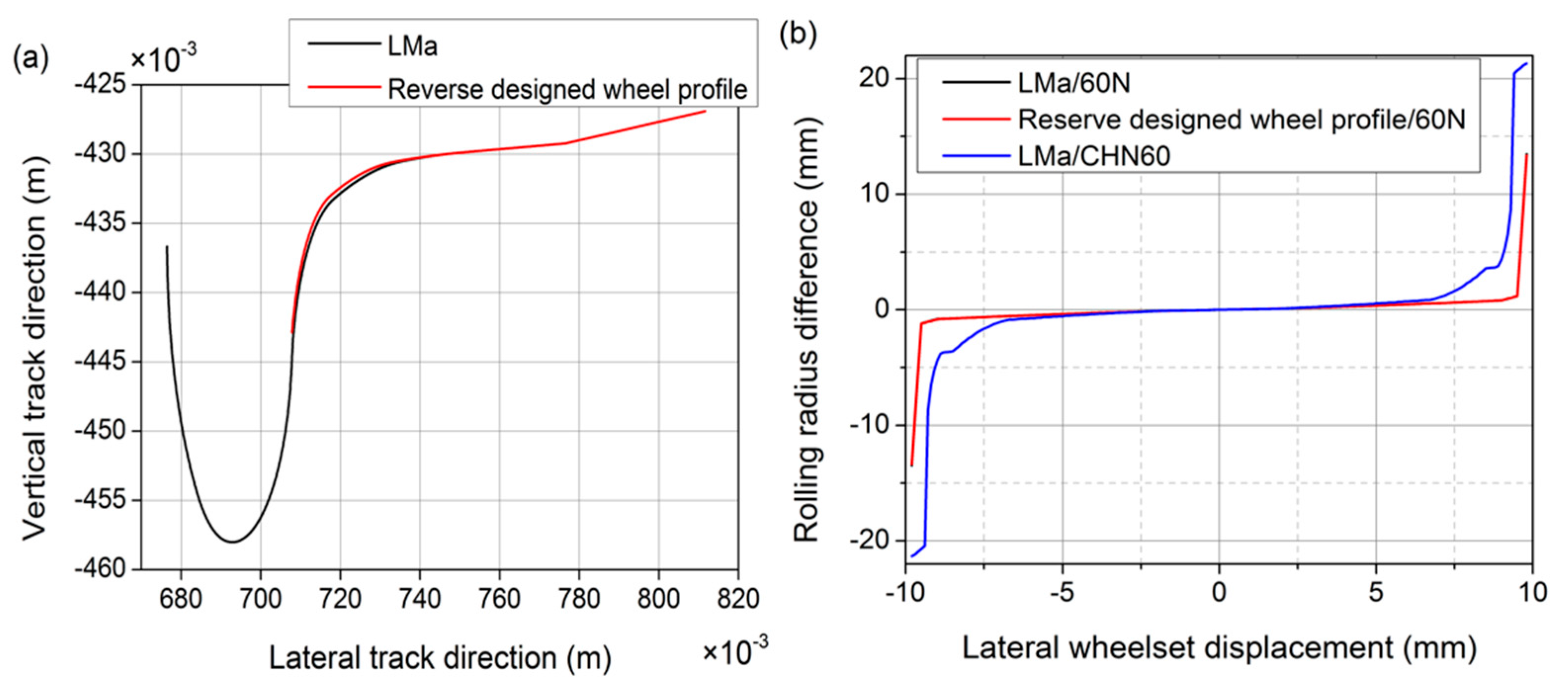

4.1. Design of Wheel Profile

- (1)

- The profile shape of the CHN60 rail is given;

- (2)

- The initial given contact point is the same as that of LMa and CHN60 rail;

- (3)

- The LMa wheel profile shape on the right of the initial contact point is given.

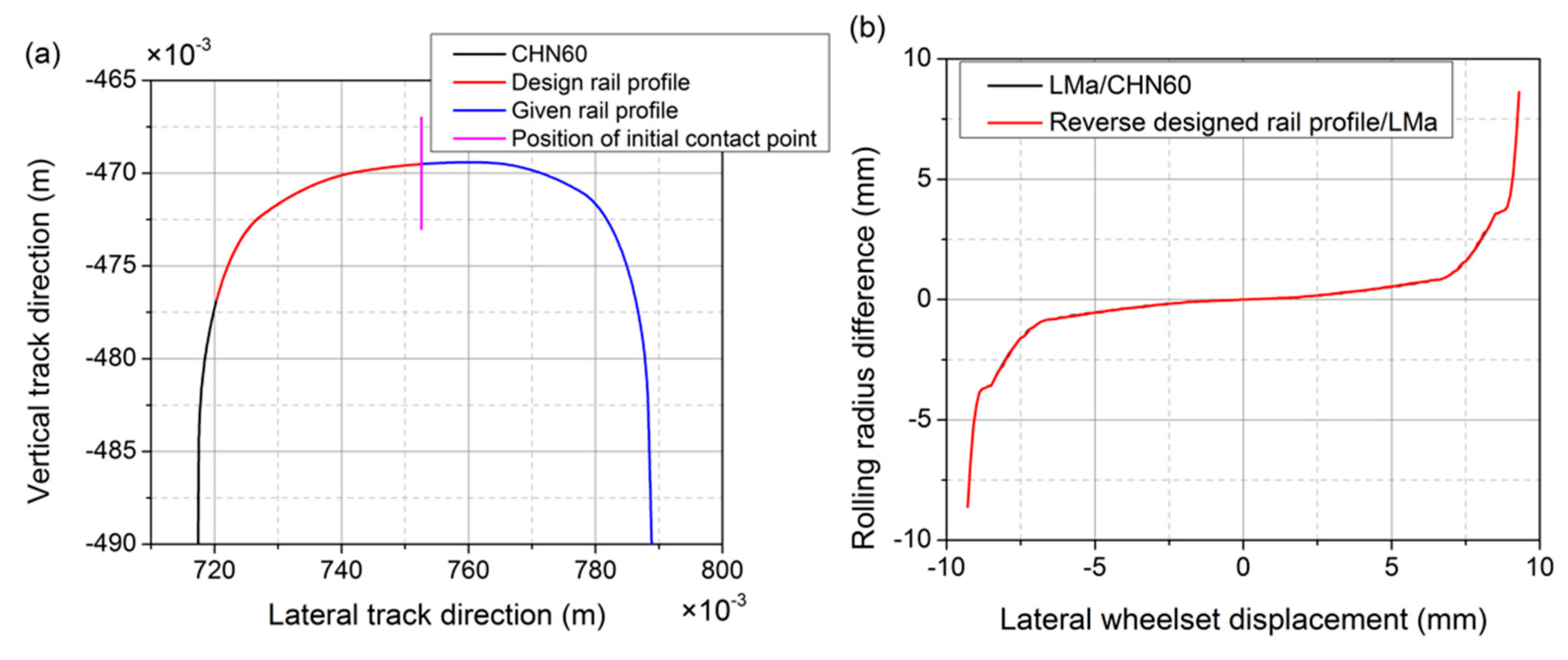

4.2. Design of Symmetric Rail Profiles

- (1)

- The LMa wheel profile is given;

- (2)

- The given initial contact point is the same as that of LMa and CHN60 rail;

- (3)

- The CHN60 rail profile shape on the right of the initial contact point is given.

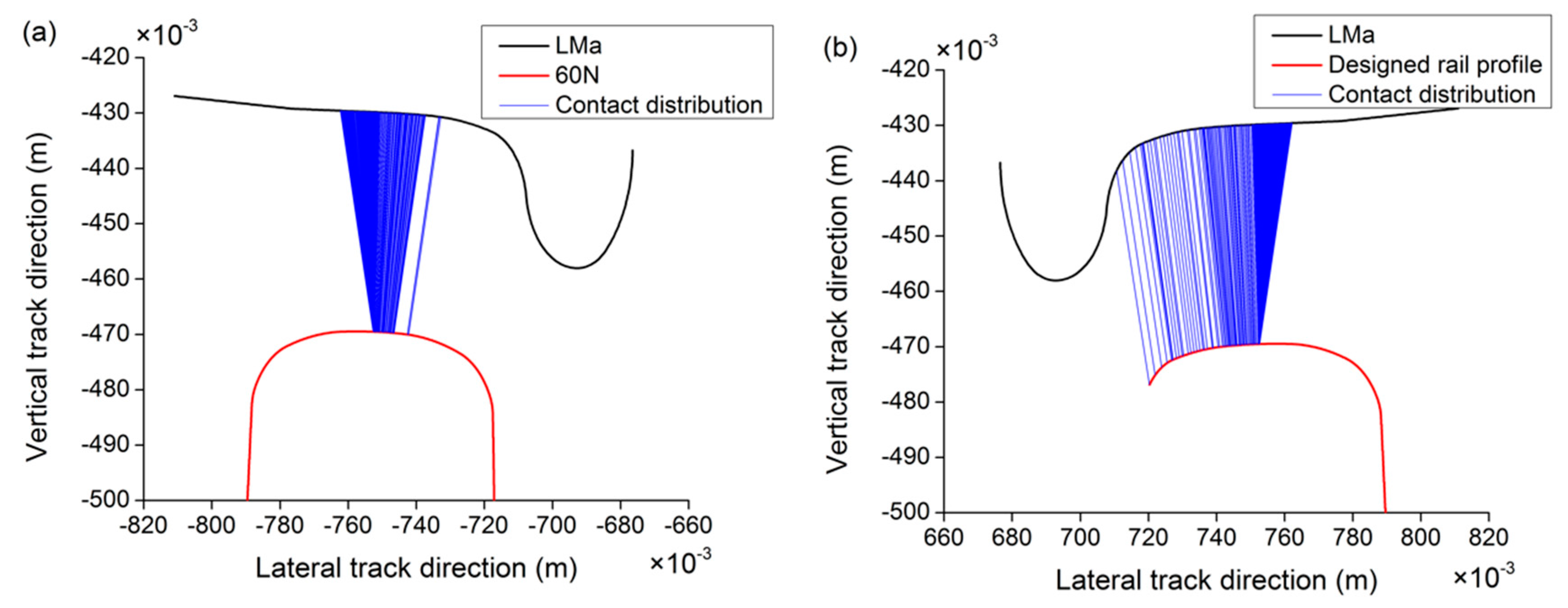

4.3. Designed of Non-Symmetric Rail Profiles

- (1)

- The LMa wheel profile is given;

- (2)

- The left rail profile is given (60 N rail profile);

- (3)

- The 60 N rail profile shape on the right of the initial contact point is given.

5. Application Example

- (1)

- The CHN60 rail profile shape is given;

- (2)

- The initial contact point is given;

- (3)

- The LMa wheel profile shape on the right of the initial contact point is given.

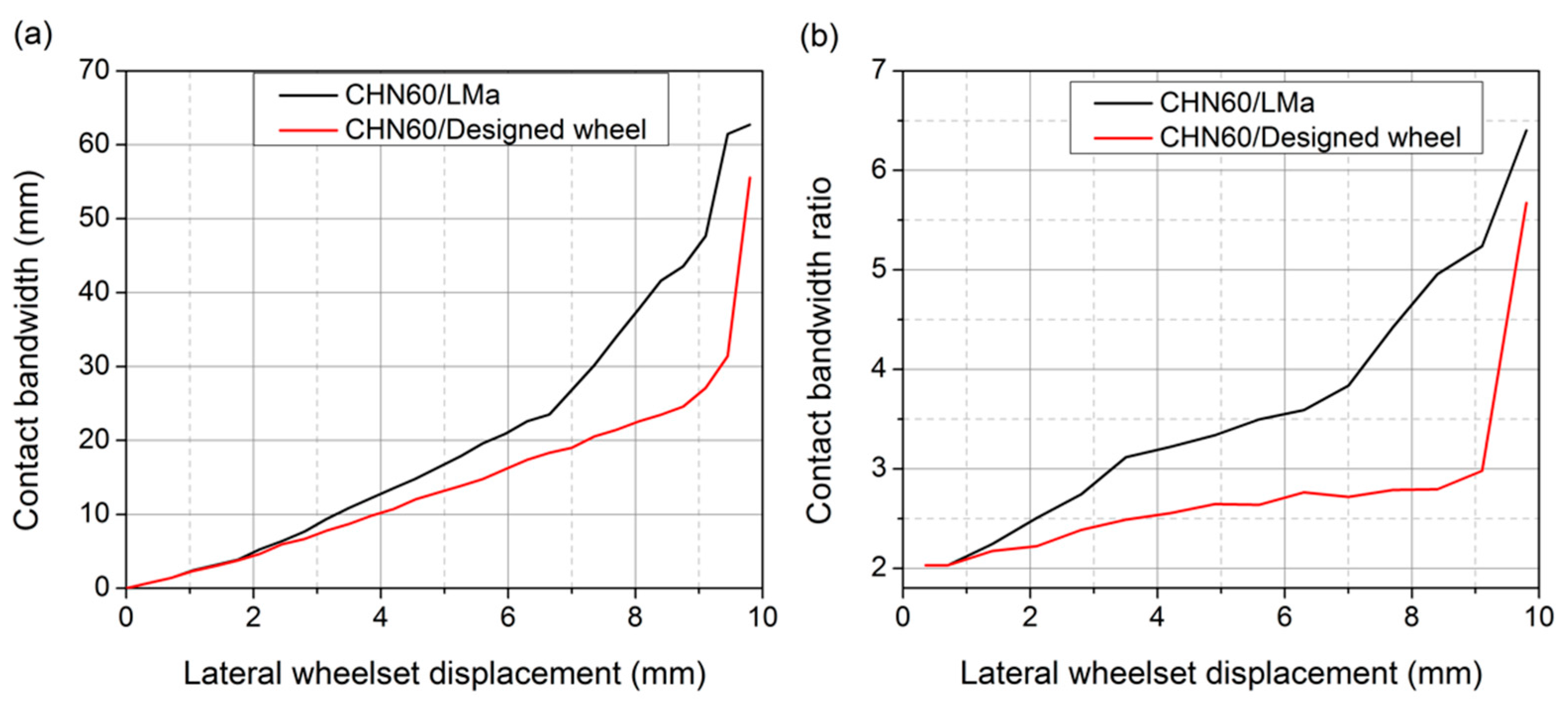

5.1. Contact Bandwidth

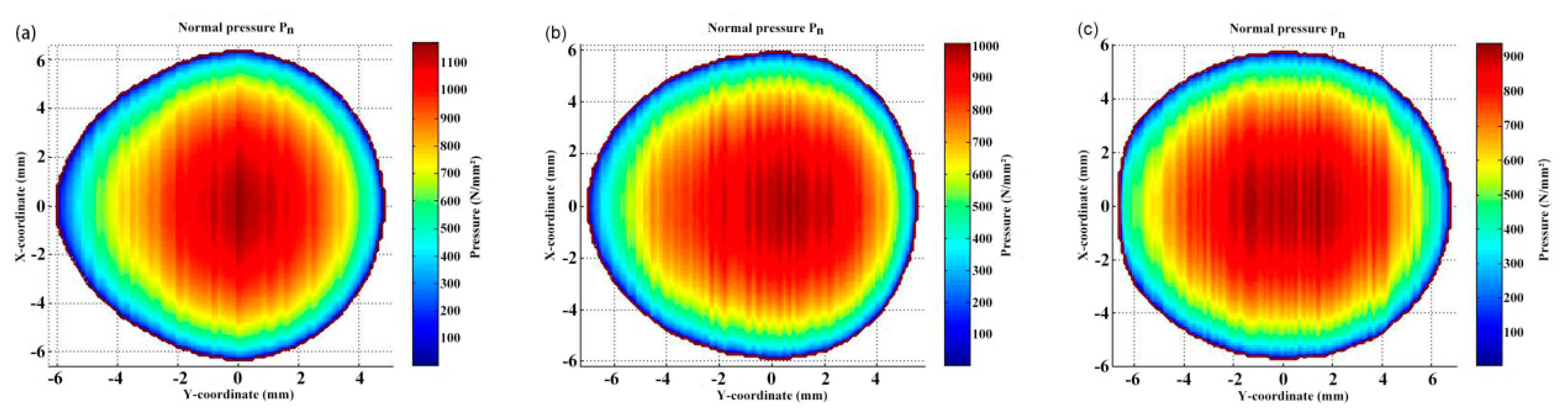

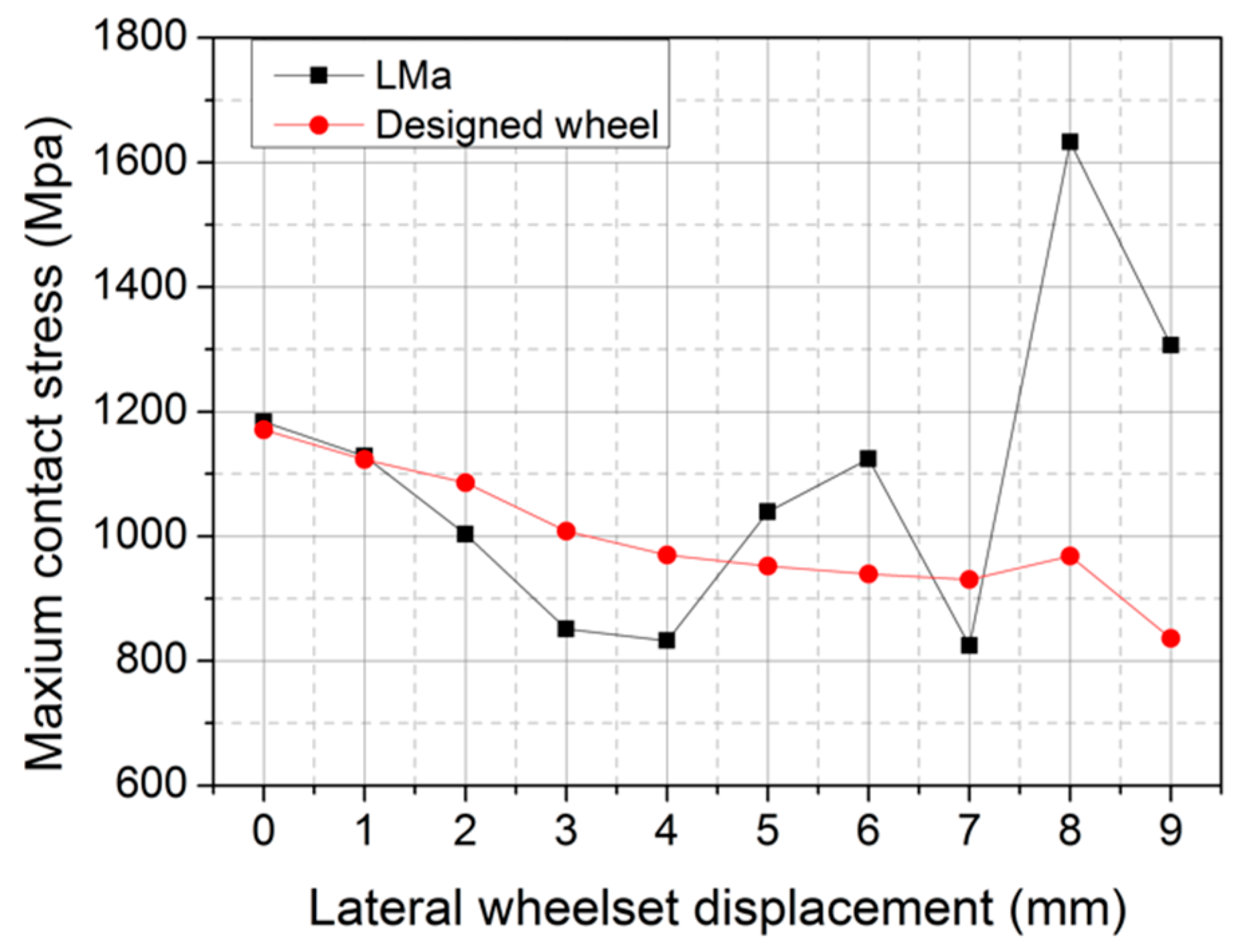

5.2. Wheel-Rail Contact Stress and Contact Patch Distribution

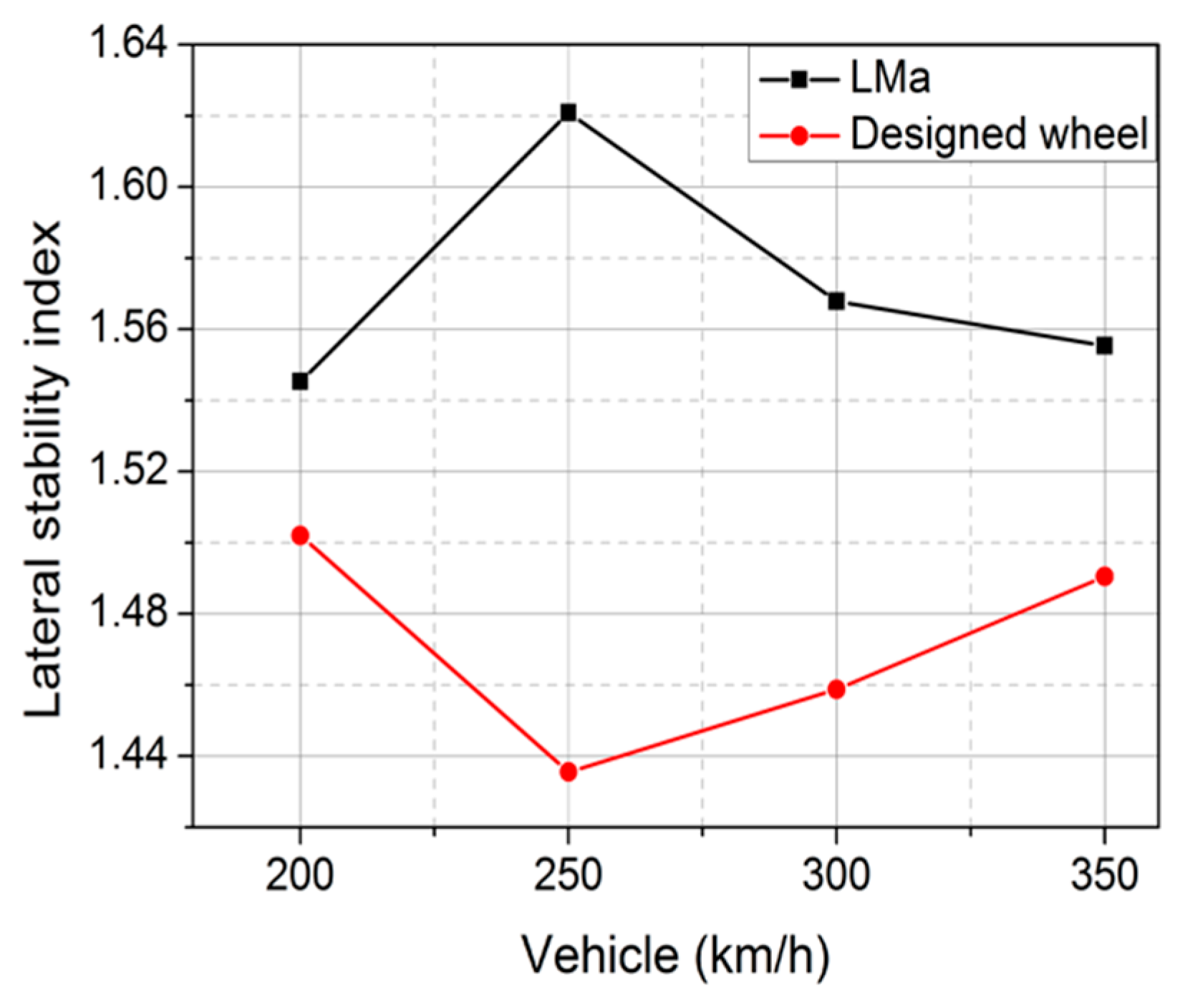

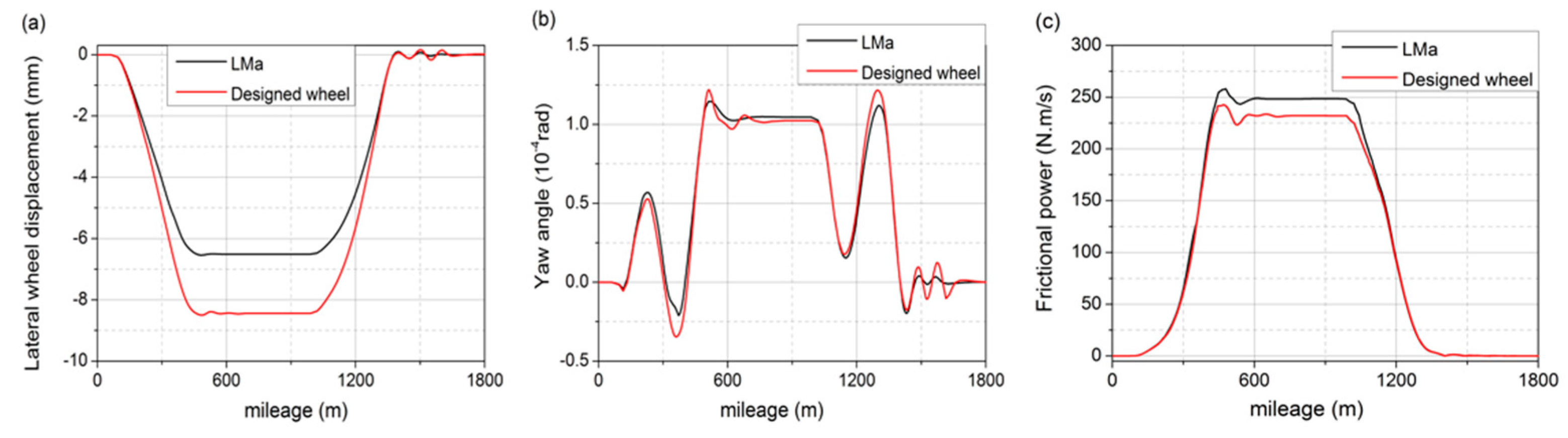

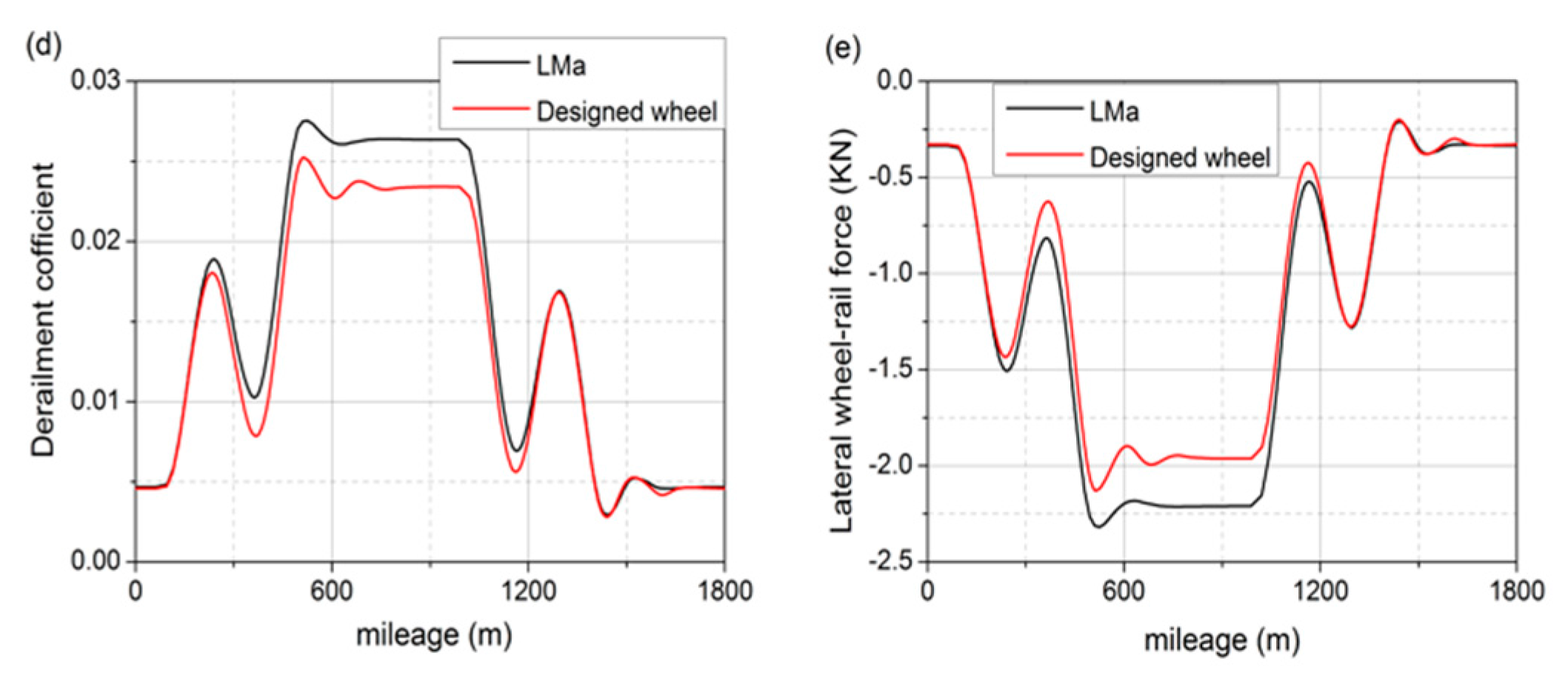

5.3. Dynamic Performance Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Souza, A.F.D. Influence of the wheel and rail treads profile on the hunting of the vehicles. Trans. ASME 1985, 107, 167–174. [Google Scholar]

- Enblom, R. Deterioration mechanisms in the wheel-rail interface with focus on wear prediction: A literature review. Veh. Syst. Dyn. 2009, 47, 661–700. [Google Scholar] [CrossRef]

- Magel, E.E.; Kalousek, J. The application of contact mechanics to rail profile design and rail grinding. Wear 2002, 253, 308–316. [Google Scholar] [CrossRef]

- An, B.; Wang, P.; Xu, J.; Chen, R.; Cui, D. Observation and Simulation of Axle Box Acceleration in the Presence of Rail Weld in High-Speed Railway. Appl. Sci. 2017, 7, 1259. [Google Scholar] [CrossRef]

- Heller, R.; Law, H.E. Optimizing the wheel profile to improve rail vehicle dynamic performance. Veh. Syst. Dyn. 1979, 8, 116–122. [Google Scholar] [CrossRef]

- Smith, R.; Kalouse, K.J. A design methodology for wheel and rail profiles for use on steered railway vehicles. Wear 1991, 144, 329–342. [Google Scholar] [CrossRef]

- Leary, J.F.; Handal, S.N. Development of freight car wheel profiles-a case study. Wear 1991, 144, 353–362. [Google Scholar] [CrossRef]

- Wu, H.M. Investigation of Wheel/Rail Interaction on Wheel Flange Climb Derailment and Wheel/Rail Profile Compatibility. Ph.D. Thesis, Illinois Institute of Technology, Chicago, IL, USA, 2000. [Google Scholar]

- Persson, I.; Iwnicki, S.D. Optimization of railway wheel profiles using a genetic algorithm. Veh. Syst. Dyn. 2004, 41, 517–527. [Google Scholar]

- Novales, M.; Orro, A.; Bugarin, M.R. Use of a genetic algorithm to optimize wheel profile geometry. Proc. Inst. Mech. Eng. Part F 2007, 221, 467–476. [Google Scholar] [CrossRef]

- Shevtsov, I.Y.; Markine, V.L.; Esveld, C. Optimal design of wheel profile for railway vehicles. Wear 2005, 258, 1022–1030. [Google Scholar] [CrossRef]

- Shevtsov, I.Y.; Markine, V.L.; Esveld, C. An inverse shape design method for railway wheel profiles. Struct. Multidiscip. Optim. 2007, 33, 243–253. [Google Scholar] [CrossRef]

- Shevtsov, I.Y.; Markine, V.L.; Esveld, C. Design of railway wheel profile taking into account of rolling contact fatigue and wear. Wear 2005, 265, 1273–1282. [Google Scholar] [CrossRef]

- Jahed, H.; Farshi, B.; Eshraghi, M.A.; Nasr, A. A numerical optimization technique for design of wheel profiles. Wear 2008, 264, 1–10. [Google Scholar] [CrossRef]

- Polach, O. Wheel profile design for target conicity and wide tread wear spreading. Wear 2011, 271, 195–202. [Google Scholar] [CrossRef]

- Gerlici, J.; Lack, T. Railway wheel and rail head profiles development based on the geometric characteristics shapes. Wear 2011, 271, 246–258. [Google Scholar] [CrossRef]

- Igensti, M.; Innocenti, A.; Marini, L.; Meli, E.; Rindi, A.; Toni, P. Wheel profile optimization on railway vehicles from the wear viewpoint. Int. J. Non-Linear Mech. 2103, 53, 41–54. [Google Scholar] [CrossRef]

- Igensti, M.; Marini, L.; Meli, E.; Rindi, A. Development of a Model for the Prediction of Wheel and Rail Wear in the Railway Field. J. Comput. Nonlinear Dyn. 2012, 7, 041004-1–041004-14. [Google Scholar] [CrossRef]

- Shen, G.; Ayasse, J.B.; Choller, H.; Pratt, I. A unique design method for wheel profiles by considering the contact angle function. Proc. Inst. Mech. Eng. Part F 2003, 217, 25–30. [Google Scholar] [CrossRef]

- Shen, G.; Zhong, X.B. A design method for wheel profiles according to the rolling radius difference function. Proc. Inst. Mech. Eng. Part F 2011, 225, 457–462. [Google Scholar] [CrossRef]

- Mao, X.; Shen, G. An inverse design method for rail grinding profiles. Veh. Syst. Dyn. 2017, 55, 1029–1044. [Google Scholar] [CrossRef]

- Mao, X.; Shen, G. A design method for rail profiles based on the geometric characteristics of wheel-rail contact. Proc. Inst. Mech. Eng. Part F 2017, 0, 1–11. [Google Scholar] [CrossRef]

- Xu, J.M.; Wang, P.; Wang, L.; Chen, R. Effects of profile wear on wheel-rail contact conditions and dynamic interaction of vehicle and turnout. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar] [CrossRef]

| Wheel Type | Max. Contact Stress (MPa) | ||

|---|---|---|---|

| Lateral Displacement 0 mm | Lateral Displacement 3 mm | Lateral Displacement 6 mm | |

| LMa | 1183.6 | 850.92 | 1123.6 |

| Optimized wheel | 1170.9 | 1008.4 | 939.2 |

| Dynamic Response | CHN60/LMa | CHN60/Optimized Wheel |

|---|---|---|

| Lateral wheel-rail force of the first wheelset at outer rail side (kN) | 2.3 | 2.1 |

| Friction power of the first wheelset at outer rail side (Nm/s) | 258 | 243 |

| Derailment coefficient of the first wheelset at outer rail side | 0.028 | 0.025 |

| Lateral displacement of the first wheelset (mm) | 6.5 | 8.5 |

| Attack angle of the first wheelset (rad) | 1.14 × 10−4 | 1.22 × 10−4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Hu, C.; Xu, J.; Wang, P.; Chen, J.; Gao, Y. An Innovative and Efficient Method for Reverse Design of Wheel-Rail Profiles. Appl. Sci. 2018, 8, 239. https://doi.org/10.3390/app8020239

Chen R, Hu C, Xu J, Wang P, Chen J, Gao Y. An Innovative and Efficient Method for Reverse Design of Wheel-Rail Profiles. Applied Sciences. 2018; 8(2):239. https://doi.org/10.3390/app8020239

Chicago/Turabian StyleChen, Rong, Chenyang Hu, Jingmang Xu, Ping Wang, Jiayin Chen, and Yuan Gao. 2018. "An Innovative and Efficient Method for Reverse Design of Wheel-Rail Profiles" Applied Sciences 8, no. 2: 239. https://doi.org/10.3390/app8020239