Nozzle Printed-PEDOT:PSS for Organic Light Emitting Diodes with Various Dilution Rates of Ethanol

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Cleaning Substrate

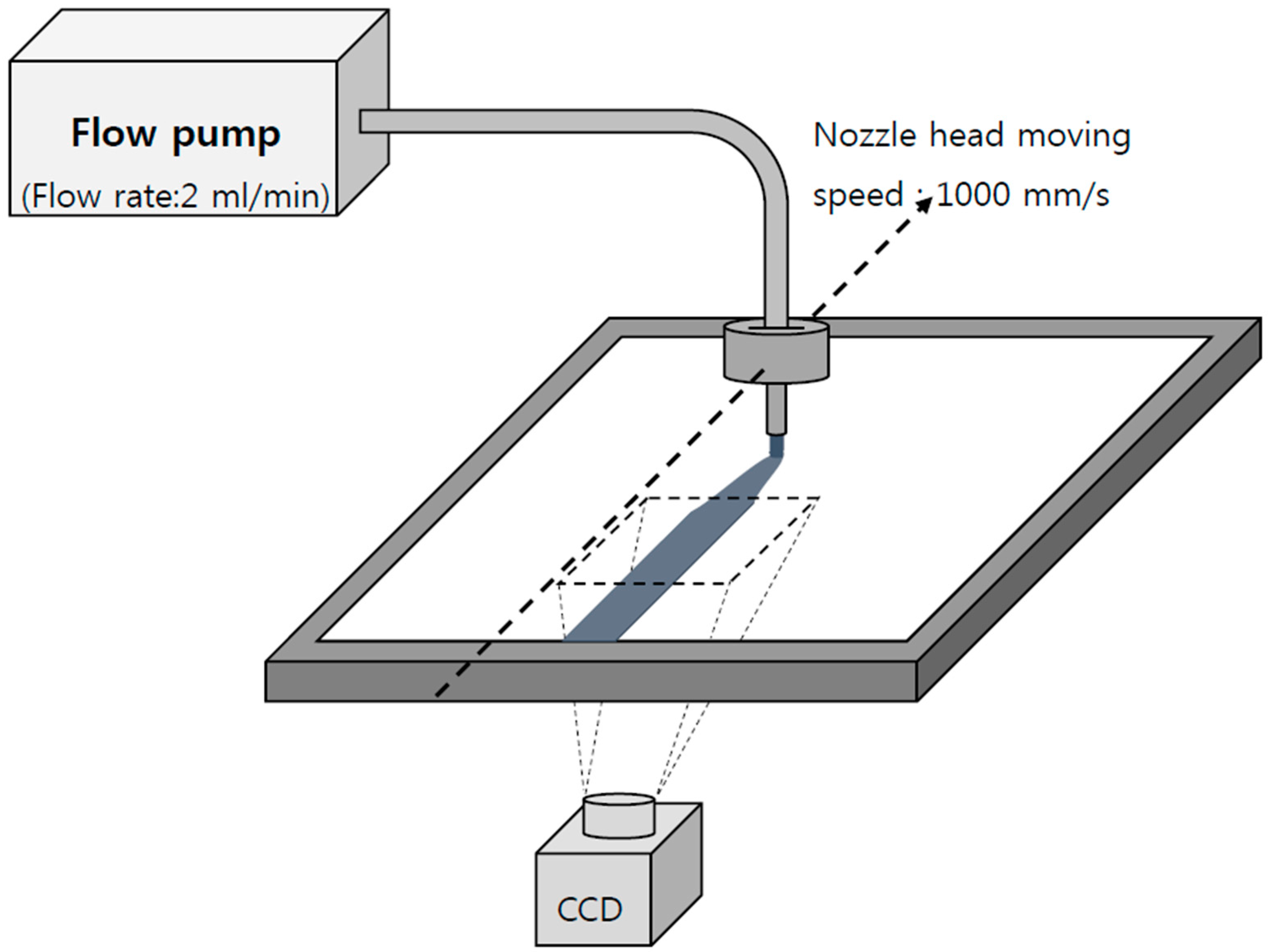

2.3. Fabrication of PEDOT:PSS Line Pattern

- ●

- Printing speed of 1000 mm/s

- ●

- Ink injection rate of 2 mL/min

- ●

- Stage temperature of 24 °C (±0.5 °C)

- ●

- Atmosphere of 50% (±5%) relative humidity

- ●

- PEDOT:PSS baking condition of 100 °C/30 min after solvent evaporation

2.4. Fabrication of OLED Device

2.5. Measurement

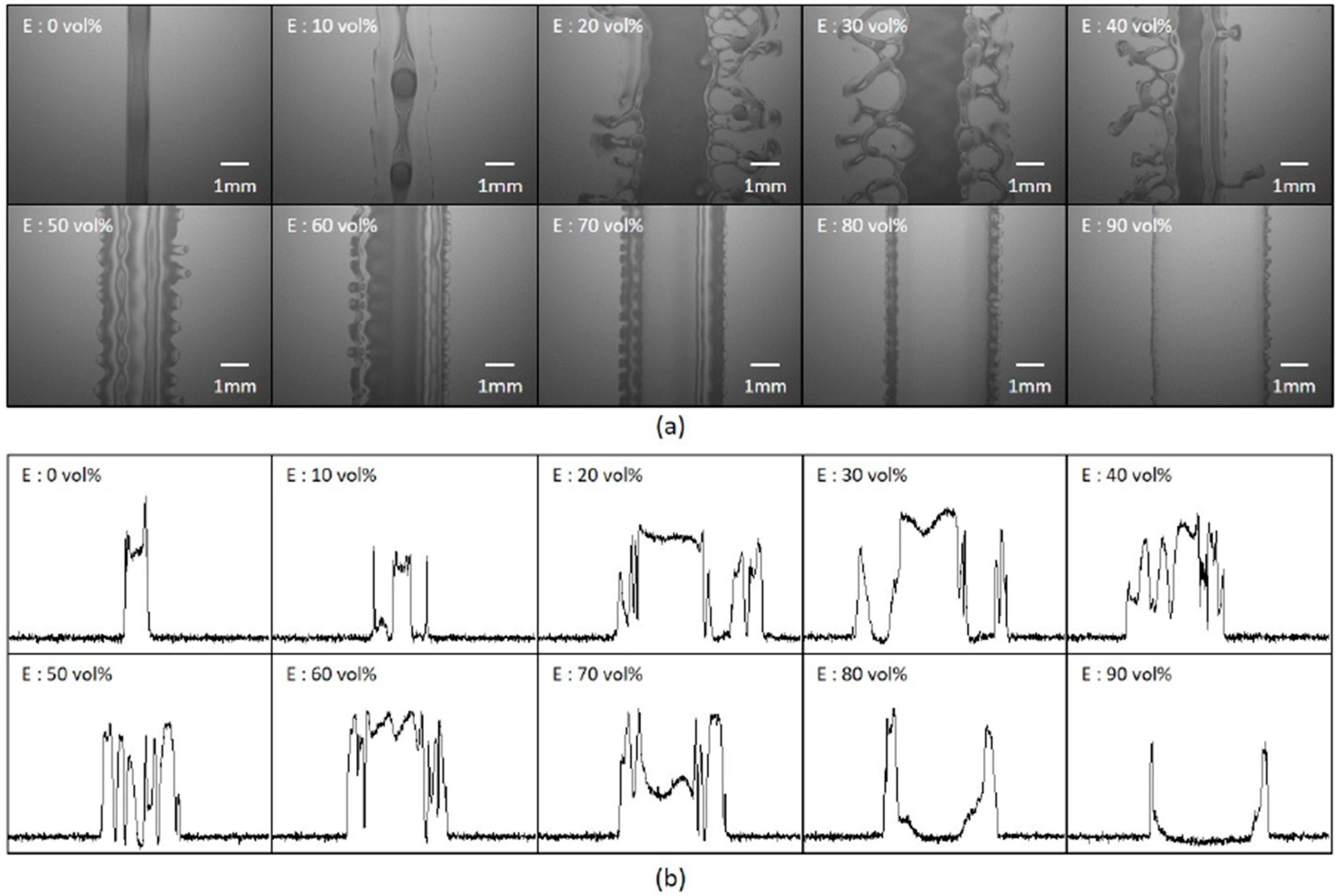

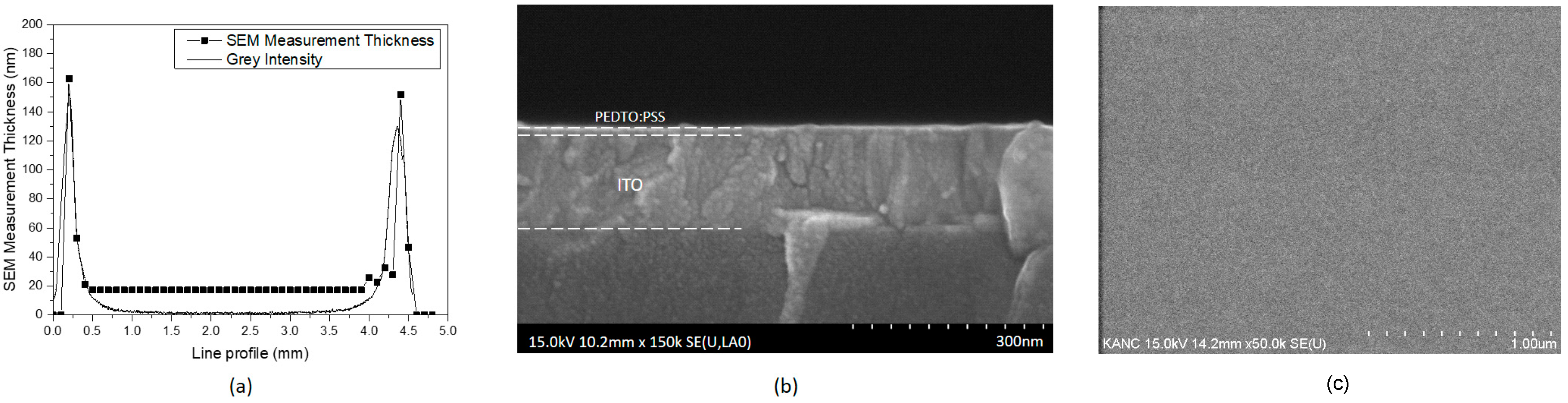

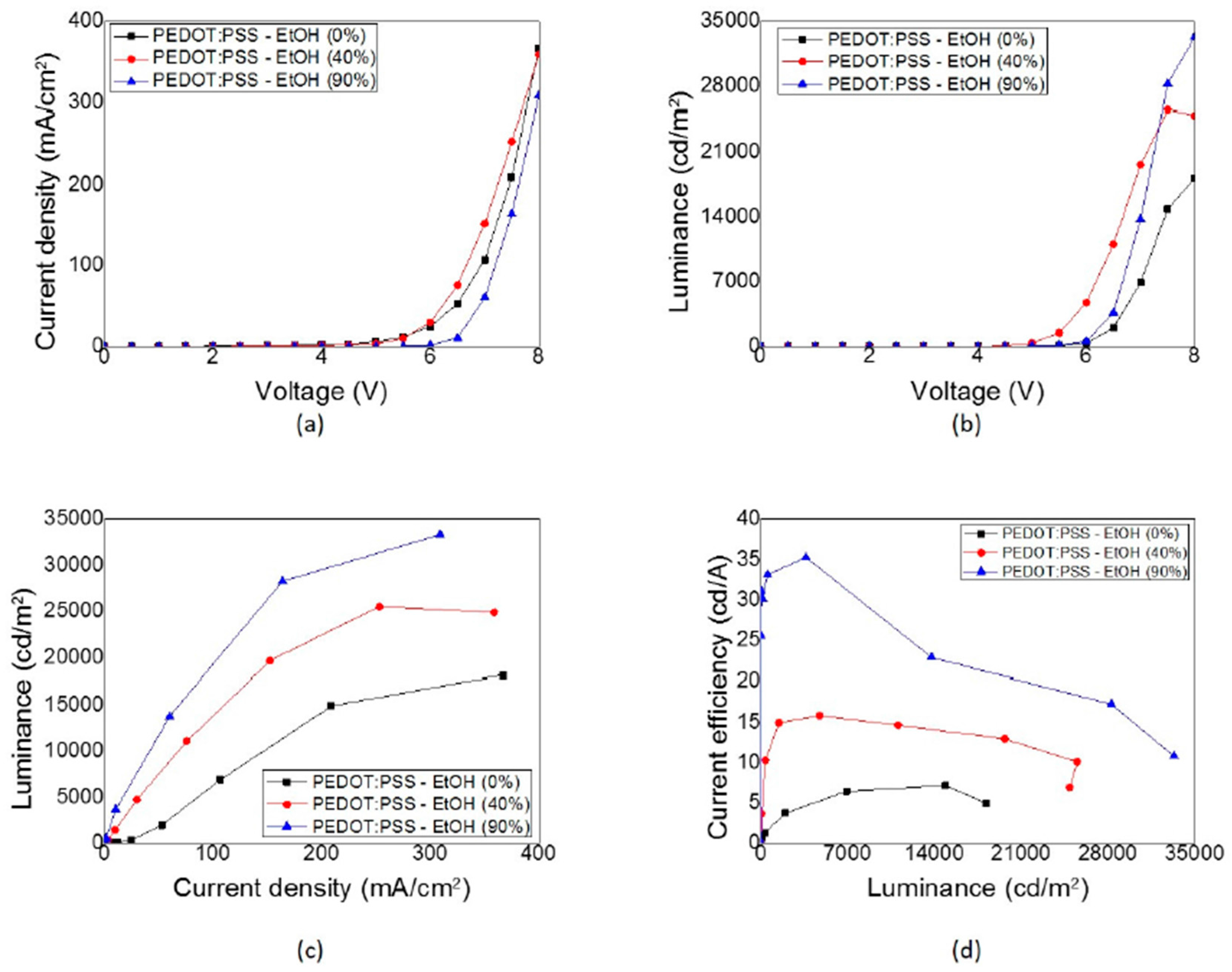

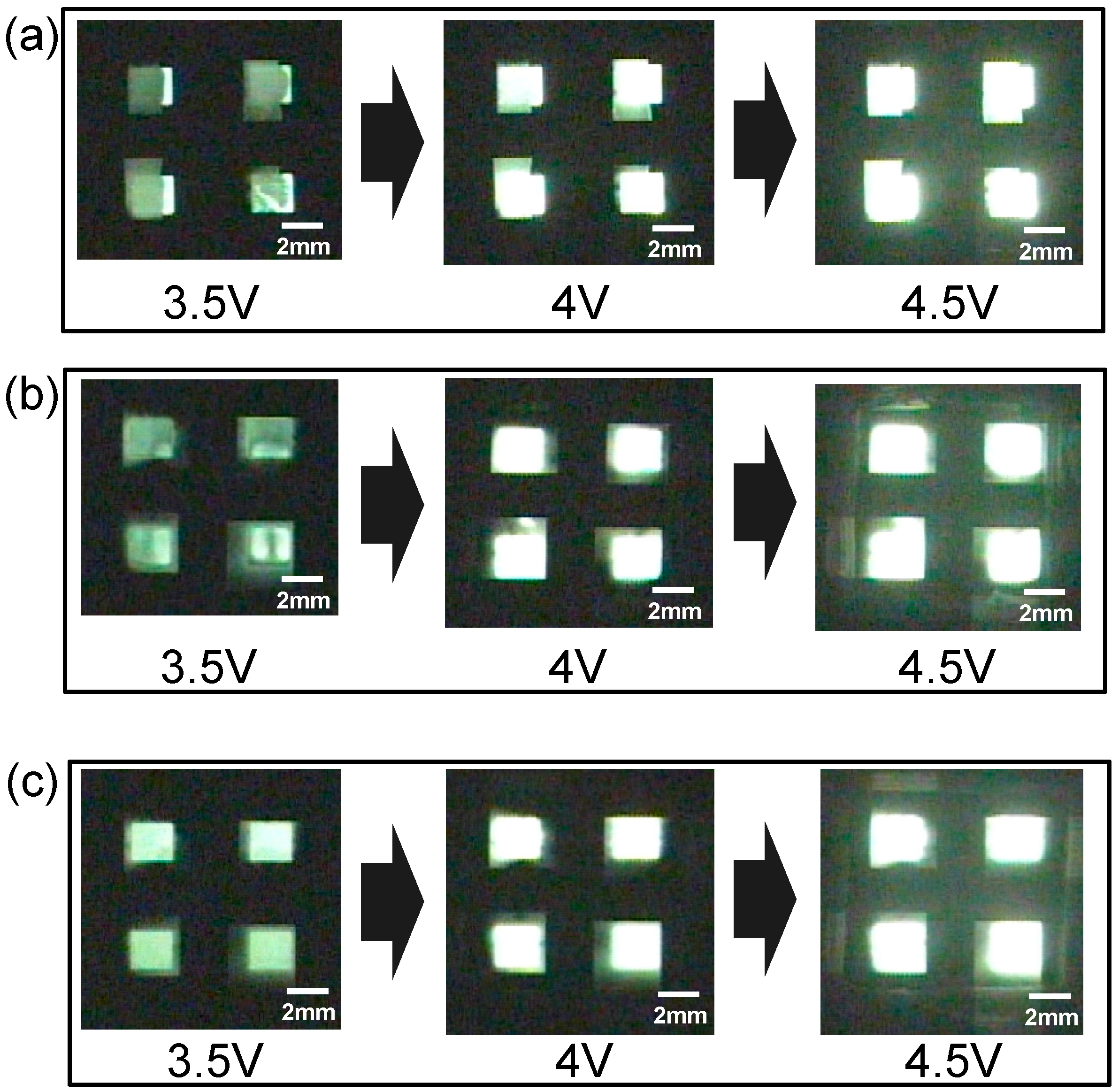

3. Result and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gelinck, G.H.; Huitema, H.E.A.; van Veenendaal, E.; Cantatore, E.; Schrijnemakers, L.; van der Putten, J.B.; Geuns, T.C.; Beenhakkers, M.; Giesbers, J.B.; Huisman, B.-H. Flexible active-matrix displays and shift registers based on solution-processed organic transistors. Nat. Mater. 2004, 3, 106–110. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wan, X.; Liu, Y.; Zuo, Y.; Li, Z.; He, G.; Long, G.; Ni, W.; Li, C.; Su, X. Small molecules based on benzo [1,2-b:4,5-b′] dithiophene unit for high-performance solution-processed organic solar cells. J. Am. Chem. Soc. 2012, 134, 16345–16351. [Google Scholar] [CrossRef] [PubMed]

- Gans, B.J.D.; Duineveld, P.C.; Schubert, U.S. Inkjet printing of polymers: State of the art and future developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar] [CrossRef]

- Lavery, L.L.; Whiting, G.L.; Arias, A.C. All ink-jet printed polyfluorene photosensor for high illuminance detection. Org. Electron. 2011, 12, 682–685. [Google Scholar] [CrossRef]

- Cai, M.; Xiao, T.; Hellerich, E.; Chen, Y.; Shinar, R.; Shinar, J. High-efficiency solution-processed small molecule electrophosphorescent organic light-emitting diodes. Adv. Mater. 2011, 23, 3590–3596. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.-H.; Kim, J.-J.; Kim, H.-J. High performance inkjet printed phosphorescent organic light emitting diodes based on small molecules commonly used in vacuum process. Thin Solid Films 2012, 520, 6954–6958. [Google Scholar] [CrossRef]

- Gorter, H.; Coenen, M.J.J.; Slaats, M.W.L.; Ren, M.; Lu, W.; Kuijpers, C.J.; Groen, W.A. Toward inkjet printing of small molecule organic light emitting diodes. Thin Solid Films 2013, 532, 11–15. [Google Scholar] [CrossRef]

- Kim, K.; Kim, G.; Lee, B.R.; Ji, S.; Kim, S.-Y.; An, B.W.; Song, M.H.; Park, J.-U. High-resolution electrohydrodynamic jet printing of small-molecule organic light-emitting didoes. Nanoscale 2015, 7, 13410–13415. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Shtein, M.; Forrest, S.R. Direct patterning of organic light-emitting devices by organic-vapor jet printing. Appl. Phys. Lett. 2005, 86, 113504. [Google Scholar] [CrossRef]

- Ding, Z.; Xing, R.; Fu, Q.; Ma, D.; Han, Y. Patterning of pinhole free small molecular organic light-emitting films by ink-jet printing. Org. Electron. 2011, 12, 703–709. [Google Scholar] [CrossRef]

- Groenendaal, L.B.; Jonas, F.; Freitag, D.; Pielartzik, H.; Reynolds, J.R. Poly(3,4-ethylenedioxythiophene) and Its Derivatives: Past, Present, and Future. Adv. Mater. 2000, 12, 481–494. [Google Scholar] [CrossRef]

- Xing, K.Z.; Fahlman, M.; Chen, X.W.; Inganas, O.; Salaneck, W.R. The electronic structure of poly(3,4-ethylene-dioxythiophene): Studied by XPS and UPS. Synth. Met. 1997, 89, 161–165. [Google Scholar] [CrossRef]

- Chiba, T.; Pu, Y.J.; Kido, J. Solution-processed white phosphorescent tandem organic light-emitting devices. Adv. Mater. 2015, 27, 4681–4687. [Google Scholar] [CrossRef] [PubMed]

- Marica, S.; Tadeja, M.; Maja, S.; Marta, K.G. Development of image analysis procedures for evaluation of printed electronics quality. Inf. MIDEM 2011, 41, 12–17. [Google Scholar]

- Gonzalez, B.; Calvar, N.; Gomez, E.; Dominguez, A. Density, dynamic viscosity, and derived properties of binary mixtures of methanol or ethanol with water, ethyl acetate, and methyl acetate at T = (293.15, 298.15, and 303.15) K. J. Chem. Thermodyn. 2007, 39, 1578–1588. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, J.; Katz, H.E.; Fang, F.; Opila, R.L. Promising thermoelectric properties of commercial PEDOT:PSS materials and their Bi2Te3 powder composites. Appl. Mater. Interfaces 2010, 2, 3170–3178. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Jung, J.H.; Lee, D.E.; Joo, J. Enhancement of electrical conductivity of PEDOT:PSS by a change of solvents. Synth. Met. 2002, 126, 311–316. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, D.G.; Kang, M.; Kim, J.B.; Kang, K.-T. Nozzle Printed-PEDOT:PSS for Organic Light Emitting Diodes with Various Dilution Rates of Ethanol. Appl. Sci. 2018, 8, 203. https://doi.org/10.3390/app8020203

Yoon DG, Kang M, Kim JB, Kang K-T. Nozzle Printed-PEDOT:PSS for Organic Light Emitting Diodes with Various Dilution Rates of Ethanol. Applied Sciences. 2018; 8(2):203. https://doi.org/10.3390/app8020203

Chicago/Turabian StyleYoon, Dai Geon, MinGyu Kang, Jong Beom Kim, and Kyung-Tae Kang. 2018. "Nozzle Printed-PEDOT:PSS for Organic Light Emitting Diodes with Various Dilution Rates of Ethanol" Applied Sciences 8, no. 2: 203. https://doi.org/10.3390/app8020203