Effect of Meniscus Damping Ratio on Drop-on-Demand Electrohydrodynamic Jetting

Abstract

:1. Introduction

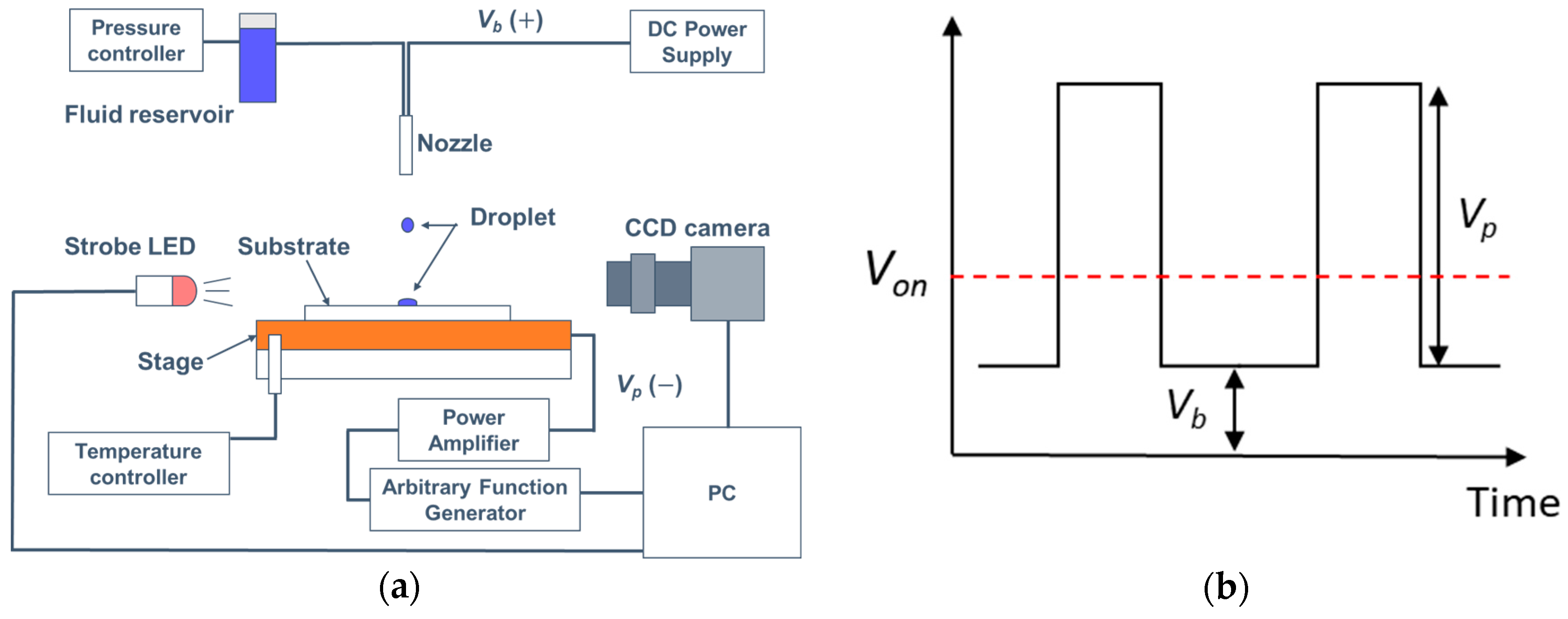

2. Experimental Setup

3. Linear Damping Approximation

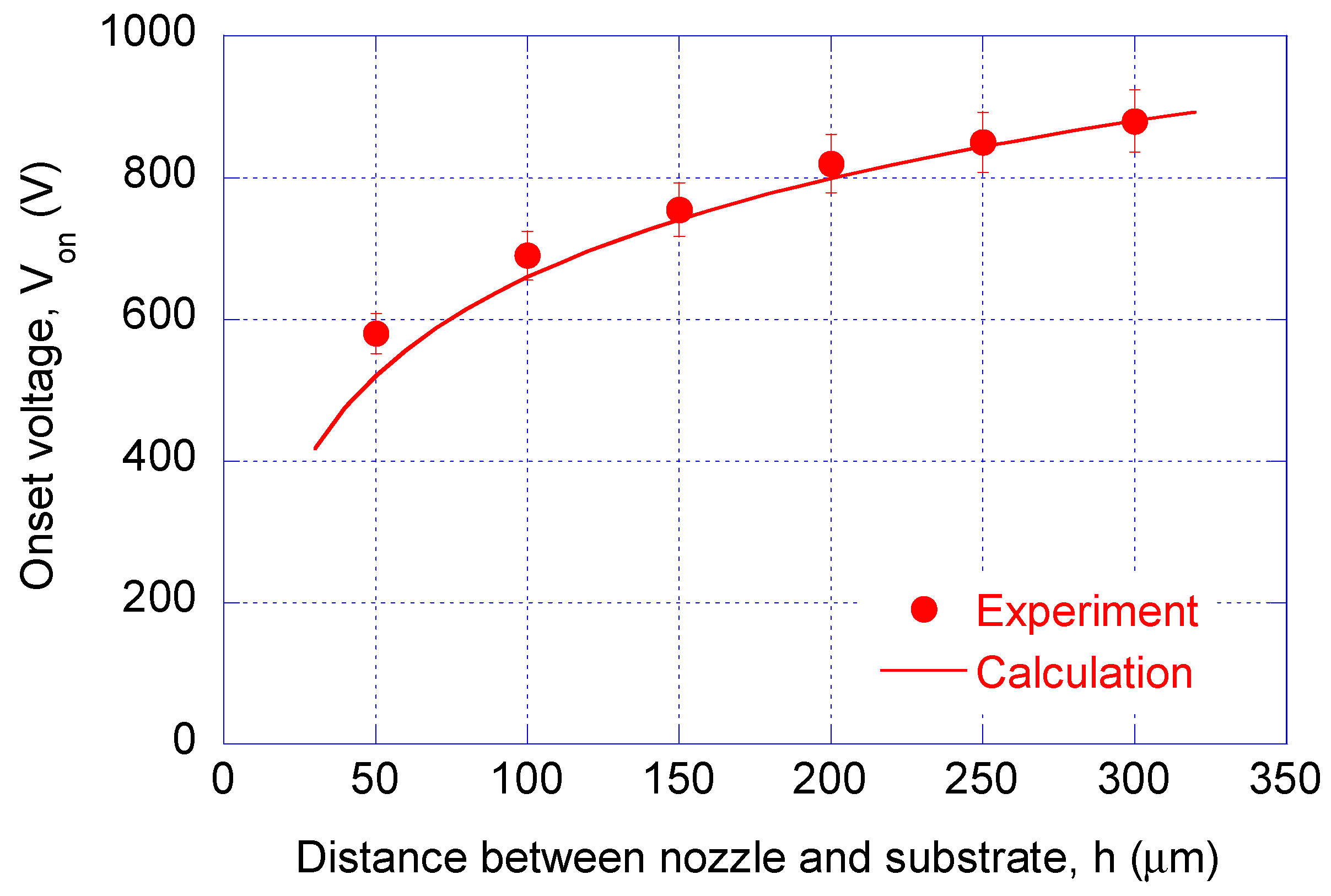

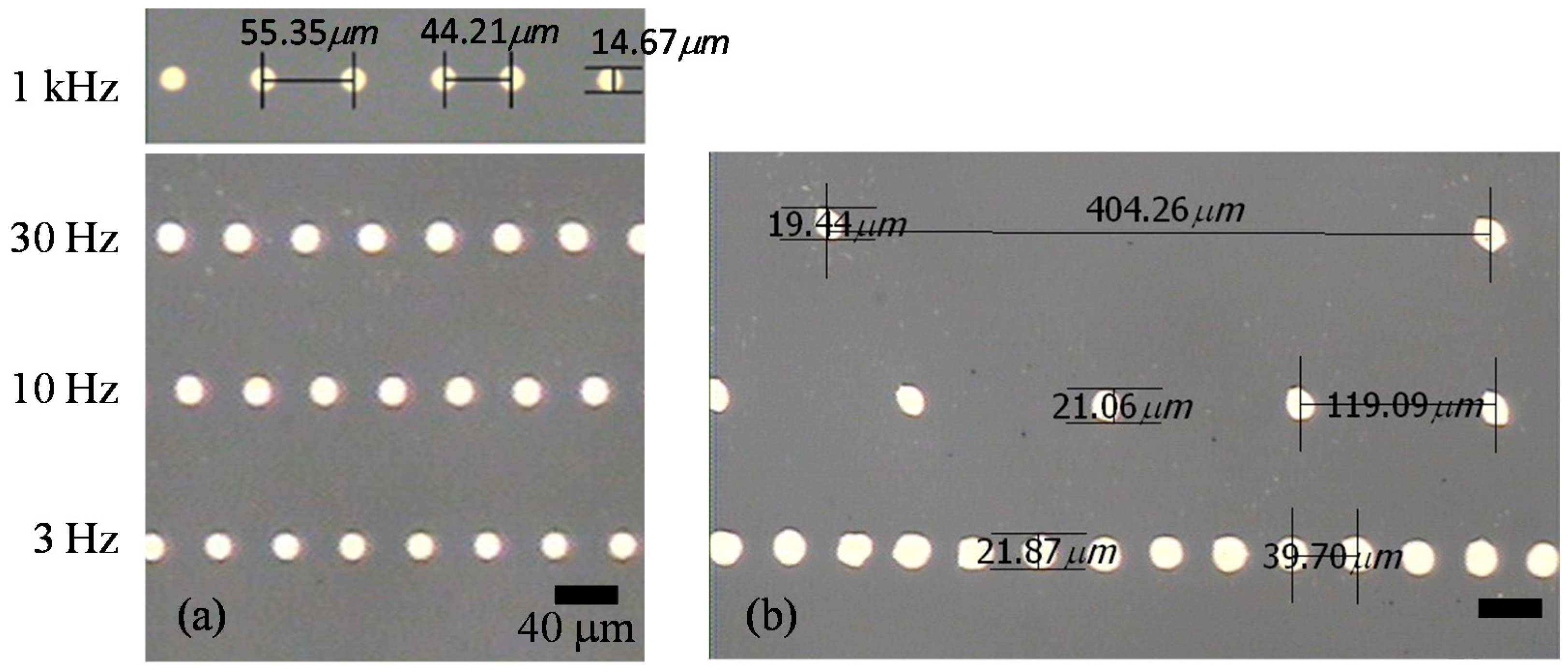

4. Results and Discussion

5. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ru, C.; Luo, J.; Xie, S.; Sun, Y. A review of non-contact micro- and nano-printing technologies. J. Micromech. Microeng. 2014, 24, 053001. [Google Scholar] [CrossRef]

- Park, J.U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, J.G.; et al. High-resolution electrohydrodynamic jet printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Li, J.L. On the meniscus deformation when the pulsed voltage is applied. J. Electrost. 2006, 64, 44–52. [Google Scholar] [CrossRef]

- Lee, S.; Song, J.; Kim, H.; Chung, J. Time resolved imaging of electrohydrodynamic jetting on demand induced by square pulse voltage. J. Aerosol Sci. 2012, 52, 89–97. [Google Scholar] [CrossRef]

- Li, J.; Zhang, P. Formation and droplet size of EHD drippings induced by superimposing an electric pulse to background voltage. J. Electrost. 2009, 67, 562–567. [Google Scholar] [CrossRef]

- Jayasinghe, S.; Edirisinghe, M. Electrostatic atomization of a ceramic suspension at pico-flow rates. Appl. Phys. A 2005, 80, 399–404. [Google Scholar] [CrossRef]

- Lee, A.; Jin, H.; Dang, H.W.; Choi, K.H.; Ahn, K.H. Optimization of experimental parameters to determine the jetting regimes in electrohydrodynamic printing. Langmuir 2013, 29, 13630–13639. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Barton, K.L.; Alleyne, A.G.; Ferreira, P.M.; Rogers, J.A. High-speed and drop-on-demand printing with a pulsed electrohydrodynamic jet. J. Micromech. Microeng. 2010, 20, 095026. [Google Scholar] [CrossRef]

- Kwon, K.-S.; Lee, D.-Y. Investigation of pulse voltage shape effects on electrohydrodynamic jets using a vision measurement technique. J. Micromech. Microeng. 2013, 23, 065018. [Google Scholar] [CrossRef]

- Park, J.; Kim, B.; Kim, S.-Y.; Hwang, J. Prediction of drop-on-demand (DOD) pattern size in pulse voltage-applied electrohydrodynamic (EHD) jet printing of Ag colloid ink. Appl. Phys. A 2014, 117, 2225–2234. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Byun, D. Mechanism of electrohydrodynamic printing based on ac voltage without a nozzle electrode. Appl. Phys. Lett. 2009, 94, 173509. [Google Scholar] [CrossRef]

- Xu, L.; Wang, X.; Lei, T.; Sun, D.; Lin, L. Electrohydrodynamic deposition of polymeric droplets under low-frequency pulsation. Langmuir 2011, 27, 6541–6548. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Oh, H.; Kim, S.S. Electrohydrodynamic drop-on-demand patterning in pulsed cone-jet mode at various frequencies. J. Aerosol Sci. 2008, 39, 819–825. [Google Scholar] [CrossRef]

- An, S.; Lee, M.W.; Kim, N.Y.; Lee, C.; Al-Deyab, S.S.; James, S.C.; Yoon, S.S. Effect of viscosity, electrical conductivity, and surface tension on direct-current-pulsed drop-on-demand electrohydrodynamic printing frequency. Appl. Phys. Lett. 2014, 105, 214102. [Google Scholar] [CrossRef]

- Stachewicz, U.; Yurteri, C.U.; Marijnissen, J.C.M.; Dijksman, J.F. Stability regime of pulse frequency for single event electrospraying. Appl. Phys. Lett. 2009, 95, 224105. [Google Scholar] [CrossRef]

- Marginean, I.; Nemes, P.; Vertes, A. Order-Chaos-Order Transitions in Electrosprays: The Electrified Dripping Faucet. Phys. Rev. Lett. 2006, 97, 064502. [Google Scholar] [CrossRef] [PubMed]

- Eyring, C.; Mackeown, S.; Millikan, R. Fields currents from points. Phys. Rev. 1928, 31, 900. [Google Scholar] [CrossRef]

- Relative Permittivity—The Dielectric Constant. Available online: http://www.engineeringtoolbox.com/relative-permittivity-d_1660.html (accessed on 8 May 2017.

- Stachewicz, U.; Dijksman, J.F.; Burdinski, D.; Yurteri, C.U.; Marijnissen, J.C. Relaxation times in single event electrospraying controlled by nozzle front surface modification. Langmuir 2009, 25, 2540–2549. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Nozzle # | ||

|---|---|---|---|

| A | B | C | |

| Approximate ink column height, H (m) | 0.2 | ||

| Distance between nozzle and substrate, h (µm) | 100 | ||

| Inner diameter of nozzle, dn (µm) | 30 | 15 | |

| Radius of the capillary far above the nozzle, b (µm) | 375 | 120 | 60 |

| Total length of the thinnest part, l (mm) | 3.0 | 1.2 | 1.2 |

| Bias voltage, Vb (V) | 650 | 620 | 450 |

| Parameter | Nozzle # | ||

|---|---|---|---|

| A | B | C | |

| Natural frequency inside the capillary, fc (Hz) | 224 | 224 | 448 |

| Damping ratio of the system, | 2.0 | 0.78 | 1.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.H.; Kang, H.; Kang, K.; Lee, S.H.; Cho, K.H.; Hwang, J.Y. Effect of Meniscus Damping Ratio on Drop-on-Demand Electrohydrodynamic Jetting. Appl. Sci. 2018, 8, 164. https://doi.org/10.3390/app8020164

Kim SH, Kang H, Kang K, Lee SH, Cho KH, Hwang JY. Effect of Meniscus Damping Ratio on Drop-on-Demand Electrohydrodynamic Jetting. Applied Sciences. 2018; 8(2):164. https://doi.org/10.3390/app8020164

Chicago/Turabian StyleKim, Samuel Haedong, Heuiseok Kang, Kyungtae Kang, Sang Ho Lee, Kwan Hyun Cho, and Jun Young Hwang. 2018. "Effect of Meniscus Damping Ratio on Drop-on-Demand Electrohydrodynamic Jetting" Applied Sciences 8, no. 2: 164. https://doi.org/10.3390/app8020164