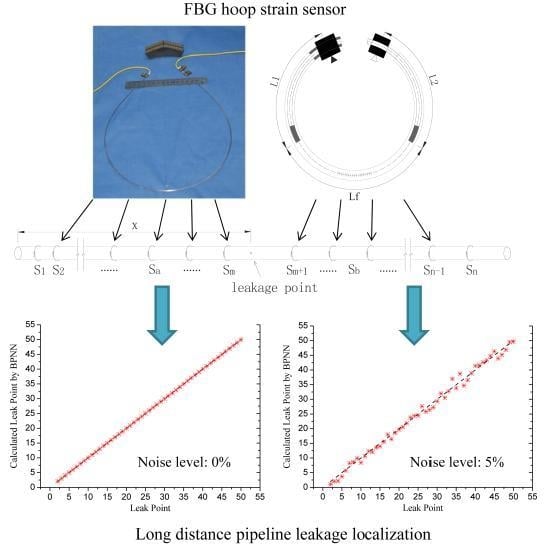

Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network

Abstract

:Featured Application

Abstract

1. Introduction

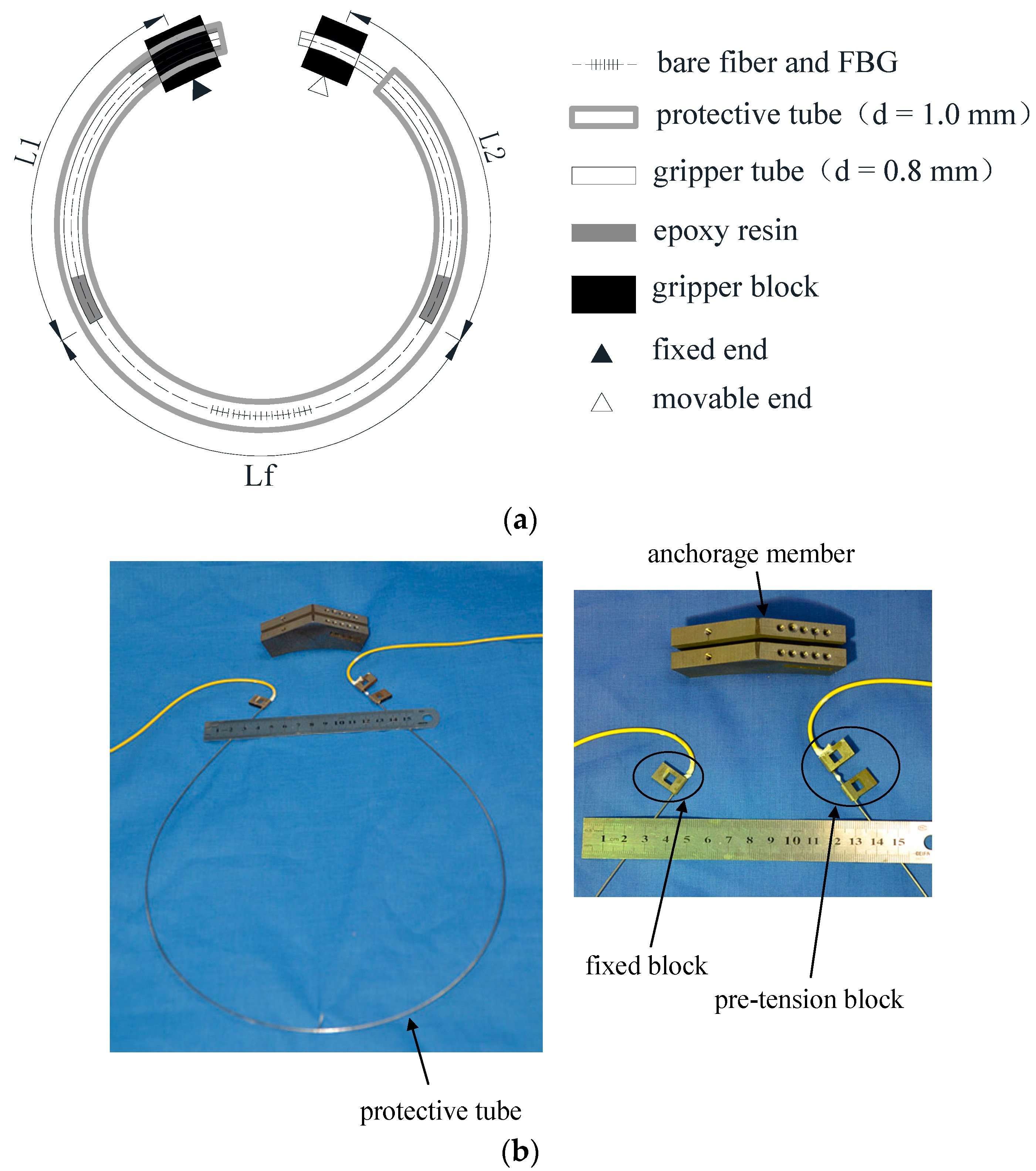

2. FBG Hoop Strain Sensor

2.1. FBG Hoop Strain Sensor Development

2.2. Leakage Detection by FBG Hoop Strain Sensor

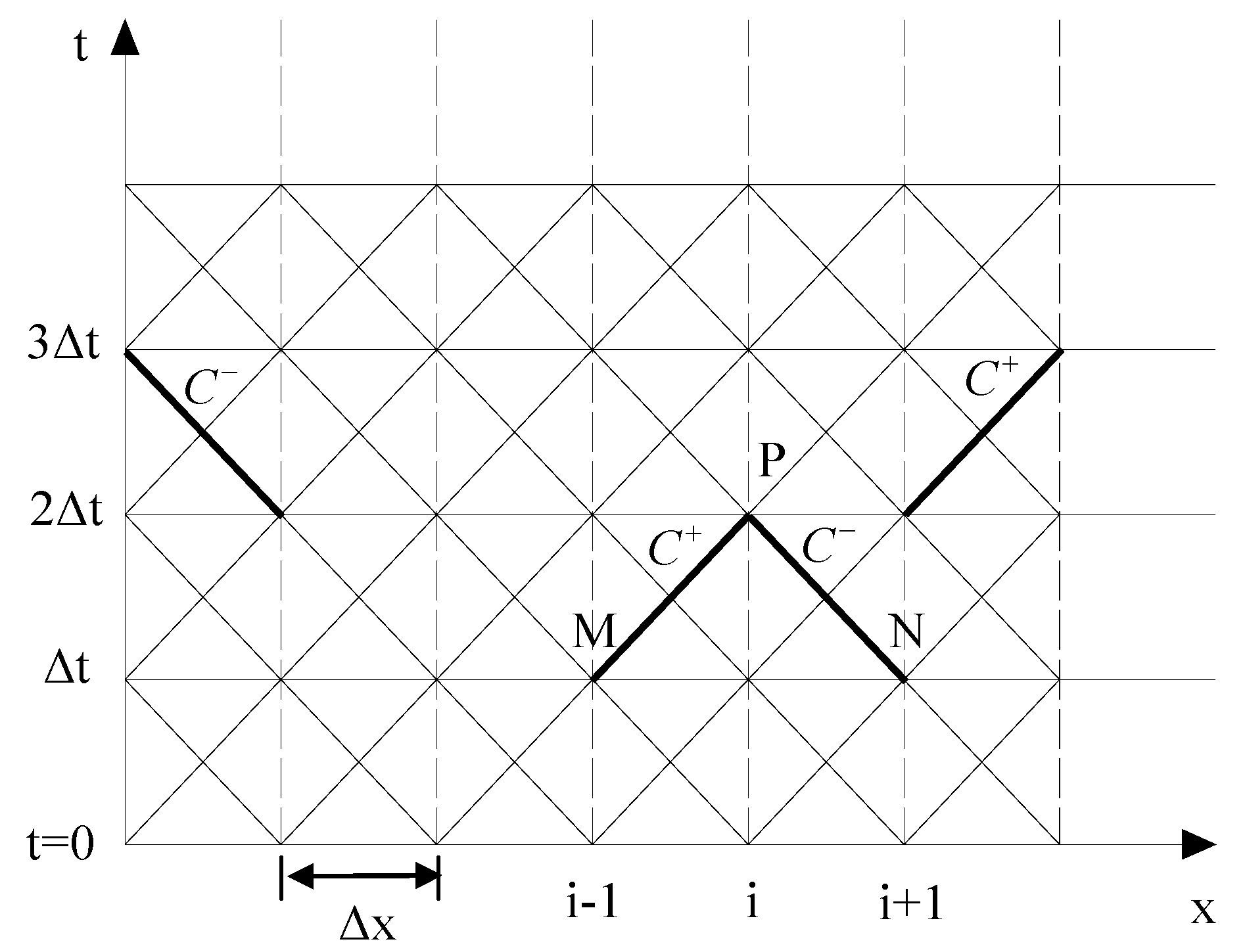

3. Calculation of Hoop Strain Time-History Curve

3.1. The Method of Characteristics

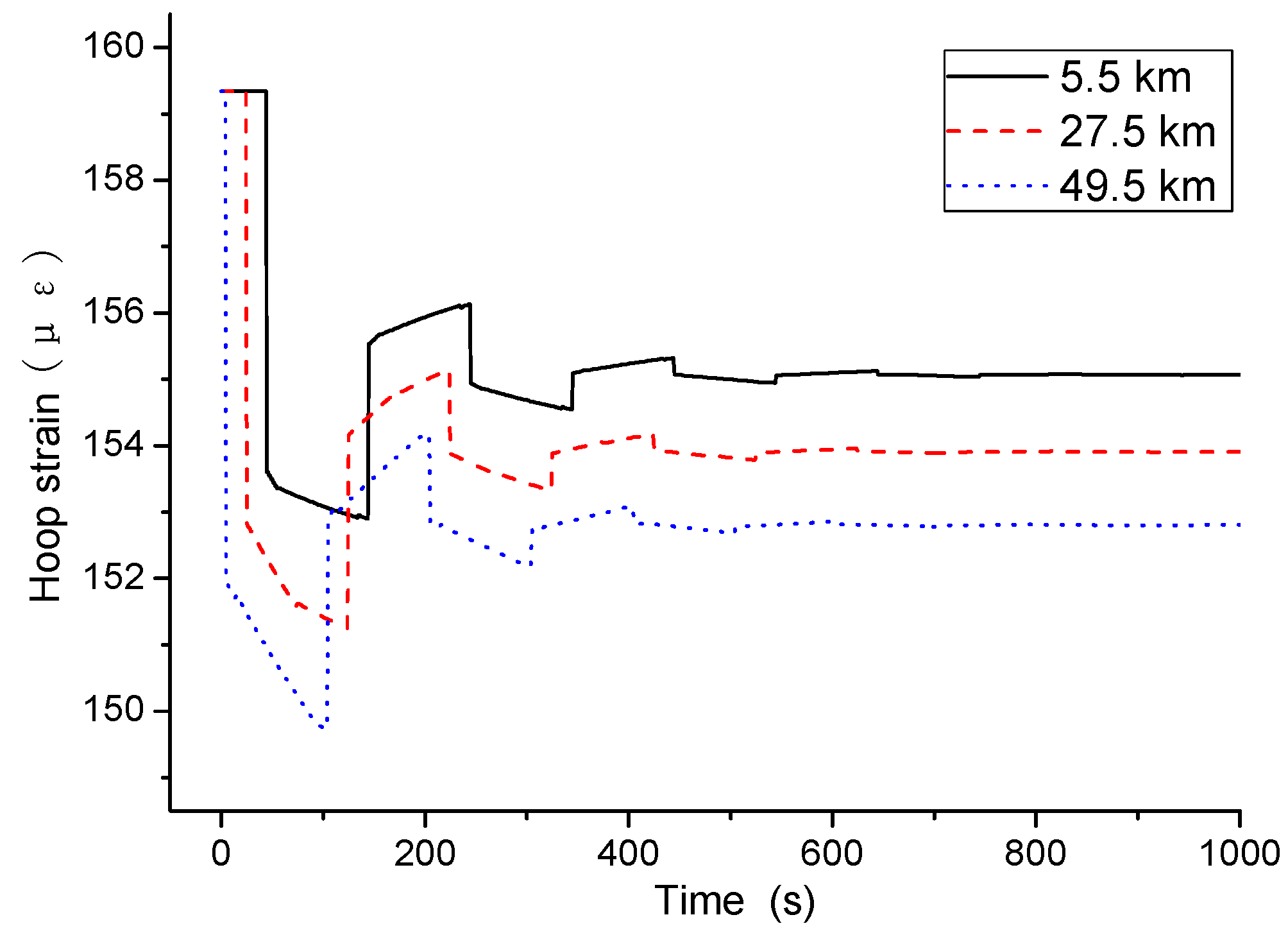

3.2. Simulation Study

4. Leakage Localization Based on BP Neural Network

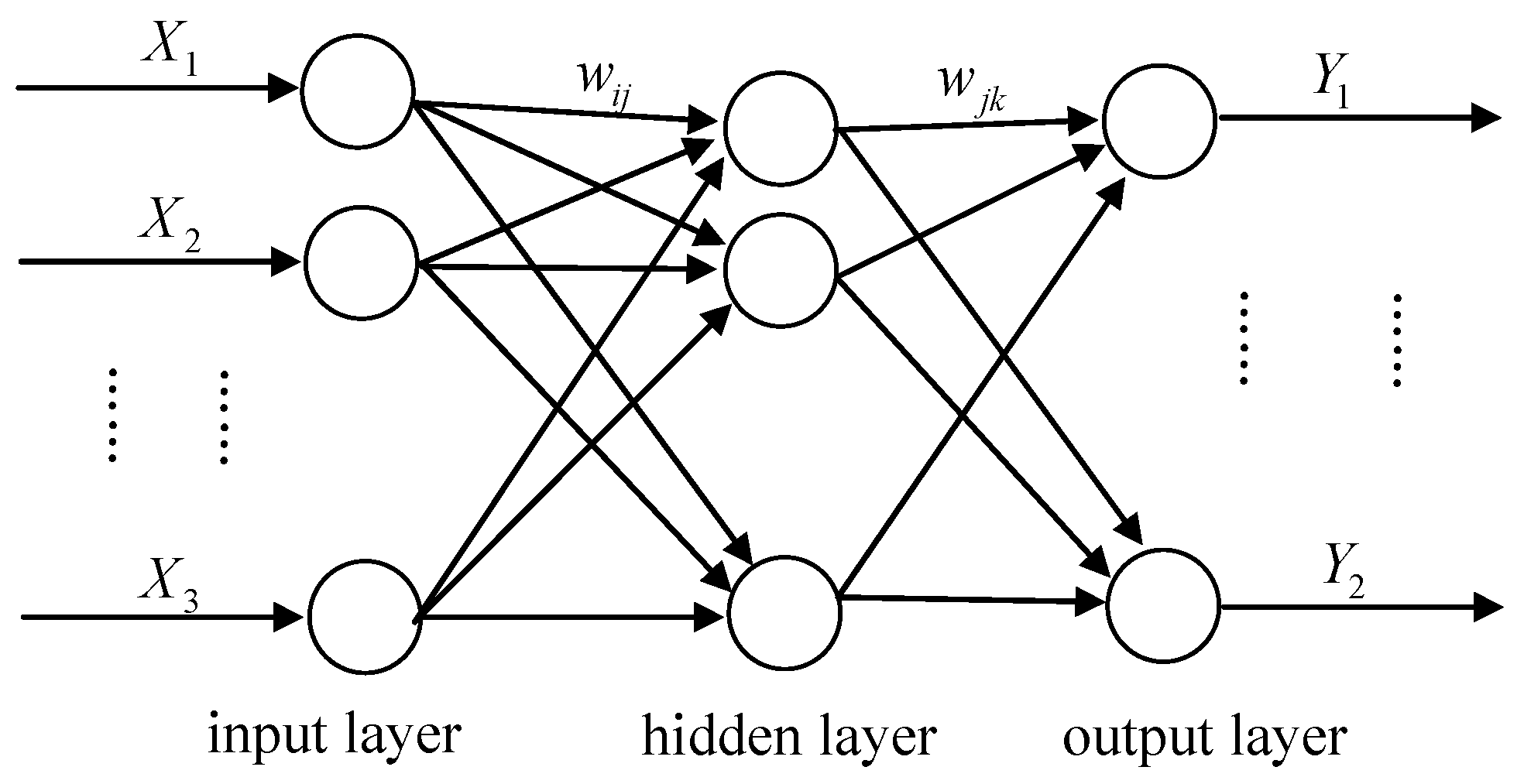

4.1. Back-Propagation Neural Network

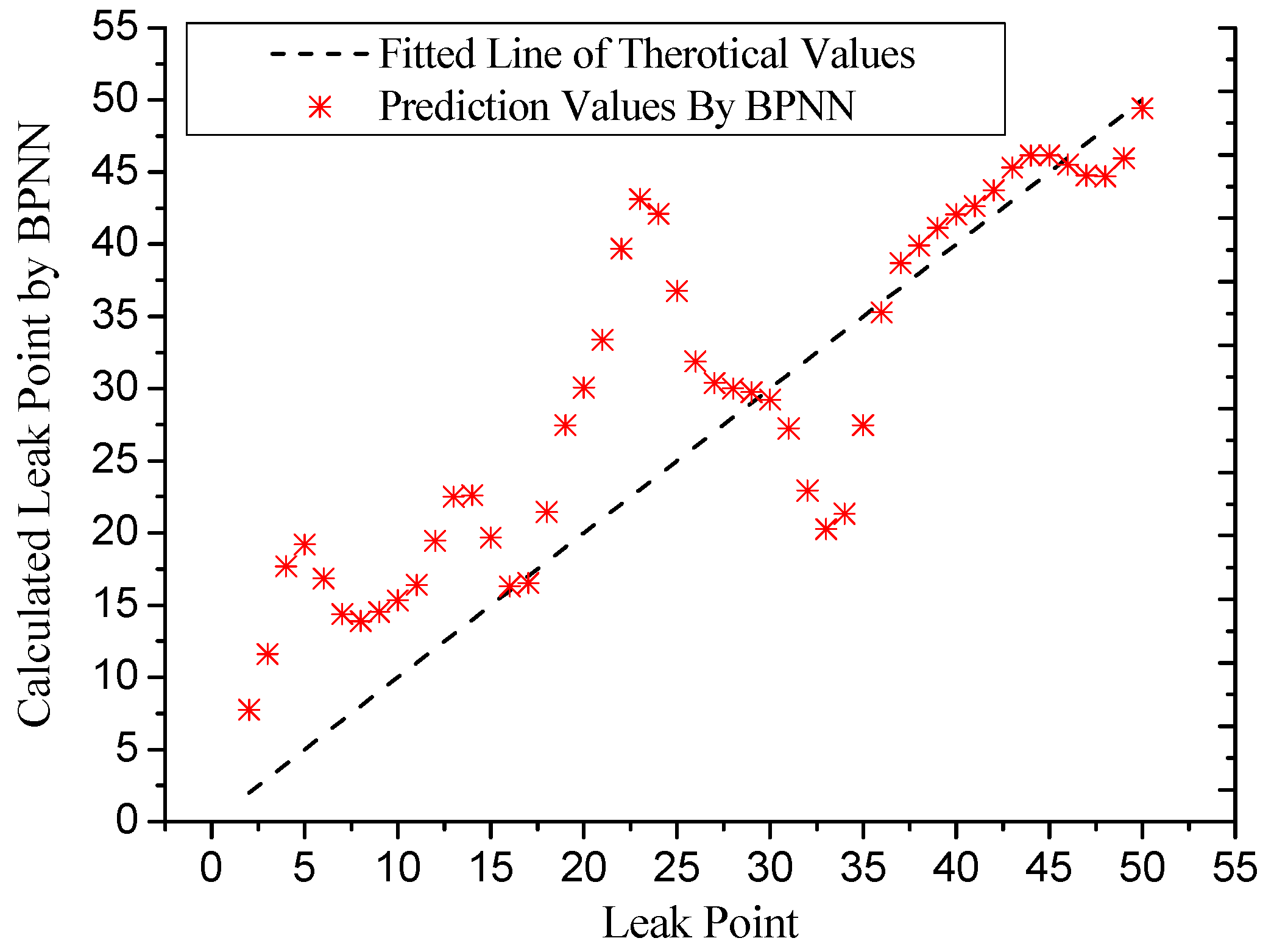

4.2. BPNN for Leakage Localization

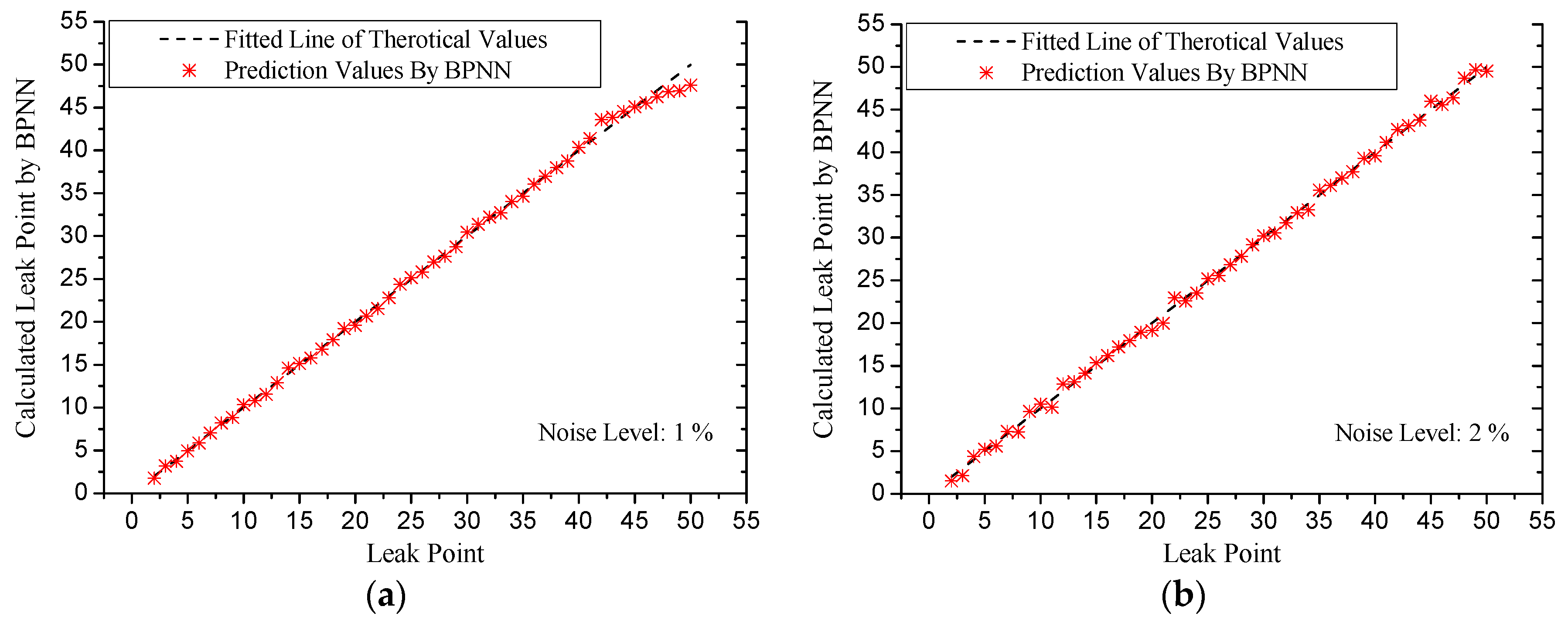

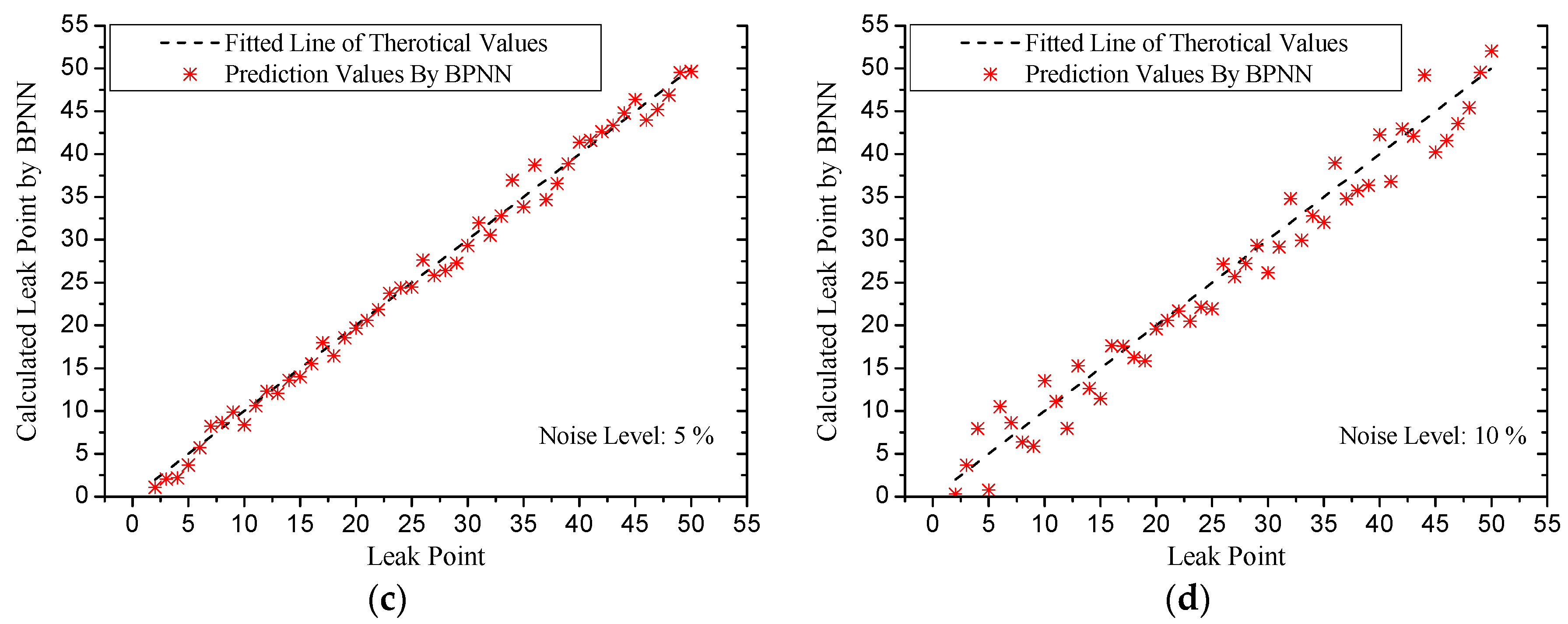

4.3. Method Validation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Inaudi, D.; Glisic, B. Long-Range Pipeline Monitoring by Distributed Fiber Optic Sensing. J. Press. Vessel Technol. 2010, 132, 763–772. [Google Scholar] [CrossRef]

- Yan, S.Z.; Chyan, L.S. Performance enhancement of BOTDR fiber optic sensor for oil and gas pipeline monitoring. Opt. Fiber Technol. 2010, 16, 100–109. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, P.; Vuran, M.C.; Al-Rodhaan, M.A.; Al-Dhelaan, A.M.; Akyildiz, I.F. MISE-PIPE: Magnetic induction-based wireless sensor networks for underground pipeline monitoring. Ad Hoc Netw. 2011, 9, 218–227. [Google Scholar] [CrossRef]

- Yoon, S.; Ye, W.; Heidemann, J.; Littlefield, B.; Shahabi, C. SWATS: Wireless Sensor Networks for Steamflood and Waterflood Pipeline Monitoring. IEEE Netw. 2011, 25, 50–56. [Google Scholar] [CrossRef]

- Meng, L.; Li, Y.; Wang, W.; Fu, J. Experimental study on leak detection and location for gas pipeline based on acoustic method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Ozevin, D.; Harding, J. Novel leak localization in pressurized pipeline networks using acoustic emission and geometric connectivity. Int. J. Press. Vessel Pip. 2012, 92, 63–69. [Google Scholar] [CrossRef]

- Zadkarami, M.; Shahbazian, M.; Salahshoor, K. Pipeline leak diagnosis based on wavelet and statistical features using Dempster-Shafer classifier fusion technique. Process Saf. Environ. 2017, 105, 156–163. [Google Scholar] [CrossRef]

- Zadkarami, M.; Shahbazian, M.; Salahshoor, K. Pipeline leakage detection and isolation: An integrated approach of statistical and wavelet feature extraction with multi-layer perceptron neural network (MLPNN). J. Loss Prev. Process 2016, 43, 479–487. [Google Scholar] [CrossRef]

- Qu, Z.; Feng, H.; Zeng, Z.; Zhuge, J.; Jin, S. A SVM-based pipeline leakage detection and pre-warning system. Measurement 2010, 43, 513–519. [Google Scholar] [CrossRef]

- Ni, L.; Jiang, J.; Pan, Y. Leak location of pipelines based on transient model and PSO-SVM. J. Loss Prev. Process 2013, 26, 1085–1093. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, L.; Liang, W. Detection of small leakage from long transportation pipeline with complex noise. J. Loss Prev. Process 2011, 24, 449–457. [Google Scholar] [CrossRef]

- Li, H.; Li, D.; Song, G. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Li, H.N.; Yi, T.H.; Ren, L.; Li, D.S.; Huo, L.S. Reviews on innovations and applications in structural health monitoring for infrastructures. Struct. Monit. Maint. 2014, 1, 1–45. [Google Scholar] [CrossRef]

- Jia, Z.; Ren, L.; Li, H.; Ho, S.; Song, G. Experimental study of pipeline leak detection based on hoop strain measurement. Struct. Control Health Monit. 2015, 22, 799–812. [Google Scholar] [CrossRef]

- Ren, L.; Jia, Z.; Li, H.; Song, G. Design and experimental study on FBG hoop-strain sensor in pipeline monitoring. Opt. Fiber Technol. 2014, 20, 15–23. [Google Scholar] [CrossRef]

- Valizadeh, S.; Moshiri, B.; Salahshoor, K. Leak Detection in Transportation Pipelines Using Feature Extraction and KNN Classification. In Proceedings of the Pipelines Specialty Conference, San Diego, CA, USA, 15–19 August 2009; pp. 580–589. [Google Scholar]

| Leak Point | Hoop Strain Sensing Point | Leak Point | Hoop Strain Sensing Point | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | ||

| 2 | 23.04 | 22.63 | 22.22 | 21.81 | 21.40 | 27 | 23.51 | 23.01 | 22.02 | 21.61 | 21.20 |

| 3 | 23.03 | 22.62 | 22.21 | 21.80 | 21.39 | 28 | 23.51 | 23.01 | 22.01 | 21.60 | 21.19 |

| 4 | 23.02 | 22.61 | 22.20 | 21.79 | 21.38 | 29 | 23.51 | 23.01 | 22.00 | 21.59 | 21.18 |

| 5 | 23.02 | 22.61 | 22.20 | 21.79 | 21.38 | 30 | 23.51 | 23.01 | 22.00 | 21.59 | 21.18 |

| 6 | 23.01 | 22.60 | 22.19 | 21.78 | 21.37 | 31 | 23.51 | 23.01 | 21.99 | 21.58 | 21.17 |

| 7 | 23.00 | 22.59 | 22.18 | 21.77 | 21.36 | 32 | 23.51 | 23.01 | 22.52 | 21.57 | 21.16 |

| 8 | 22.99 | 22.58 | 22.17 | 21.76 | 21.35 | 33 | 23.51 | 23.02 | 22.52 | 21.56 | 21.15 |

| 9 | 22.98 | 22.57 | 22.16 | 21.75 | 21.34 | 34 | 23.51 | 23.02 | 22.52 | 21.56 | 21.15 |

| 10 | 22.98 | 22.57 | 22.16 | 21.74 | 21.33 | 35 | 23.51 | 23.02 | 22.52 | 21.55 | 21.14 |

| 11 | 22.97 | 22.56 | 22.15 | 21.74 | 21.33 | 36 | 23.51 | 23.02 | 22.52 | 21.54 | 21.13 |

| 12 | 23.51 | 22.55 | 22.14 | 21.73 | 21.32 | 37 | 23.51 | 23.02 | 22.52 | 21.53 | 21.12 |

| 13 | 23.51 | 22.54 | 22.13 | 21.72 | 21.31 | 38 | 23.51 | 23.02 | 22.52 | 21.53 | 21.11 |

| 14 | 23.51 | 22.53 | 22.12 | 21.71 | 21.30 | 39 | 23.51 | 23.02 | 22.52 | 21.52 | 21.11 |

| 15 | 23.51 | 22.53 | 22.11 | 21.70 | 21.29 | 40 | 23.51 | 23.02 | 22.52 | 21.51 | 21.10 |

| 16 | 23.51 | 22.52 | 22.11 | 21.70 | 21.29 | 41 | 23.51 | 23.02 | 22.52 | 21.50 | 21.09 |

| 17 | 23.51 | 22.51 | 22.10 | 21.69 | 21.28 | 42 | 23.51 | 23.02 | 22.52 | 22.03 | 21.08 |

| 18 | 23.51 | 22.50 | 22.09 | 21.68 | 21.27 | 43 | 23.51 | 23.02 | 22.52 | 22.03 | 21.08 |

| 19 | 23.51 | 22.49 | 22.08 | 21.67 | 21.26 | 44 | 23.51 | 23.02 | 22.52 | 22.03 | 21.07 |

| 20 | 23.51 | 22.49 | 22.07 | 21.66 | 21.25 | 45 | 23.51 | 23.02 | 22.52 | 22.03 | 21.06 |

| 21 | 23.51 | 22.48 | 22.07 | 21.66 | 21.25 | 46 | 23.51 | 23.02 | 22.52 | 22.03 | 21.06 |

| 22 | 23.51 | 23.01 | 22.06 | 21.65 | 21.24 | 47 | 23.51 | 23.02 | 22.52 | 22.03 | 21.05 |

| 23 | 23.51 | 23.01 | 22.05 | 21.64 | 21.23 | 48 | 23.51 | 23.02 | 22.52 | 22.03 | 21.04 |

| 24 | 23.51 | 23.01 | 22.04 | 21.63 | 21.22 | 49 | 23.51 | 23.02 | 22.52 | 22.03 | 21.03 |

| 25 | 23.51 | 23.01 | 22.04 | 21.63 | 21.21 | 50 | 23.51 | 23.02 | 22.52 | 22.03 | 21.03 |

| 26 | 23.51 | 23.01 | 22.03 | 21.62 | 21.21 | ||||||

| Hidden Nodes | Standard Deviation | RMS Error | Regression Coefficient |

|---|---|---|---|

| 3 | 2.8616 | 2.8939 | 0.9798 |

| 5 | 1.8664 | 2.0083 | 0.9930 |

| 7 | 2.1291 | 2.3373 | 0.9927 |

| 10 | 0.6653 | 0.7381 | 0.9992 |

| 12 | 0.0266 | 0.0285 | 1.0000 |

| 15 | 0.0091 | 0.0101 | 1.0000 |

| 18 | 1.1984 | 1.2374 | 0.9973 |

| 20 | 0.3459 | 0.3639 | 0.9997 |

| Noise Level | Standard Deviation | RMS Error | Regression Coefficient |

|---|---|---|---|

| 1% | 0.2317 | 0.2441 | 0.9999 |

| 2% | 0.3948 | 0.4061 | 0.9996 |

| 3% | 0.6401 | 0.6355 | 0.999 |

| 5% | 0.9369 | 0.9275 | 0.9979 |

| 7% | 1.3422 | 1.3348 | 0.9956 |

| 10% | 1.7166 | 1.7473 | 0.9935 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Ren, L.; Li, H.; Sun, W. Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network. Appl. Sci. 2018, 8, 146. https://doi.org/10.3390/app8020146

Jia Z, Ren L, Li H, Sun W. Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network. Applied Sciences. 2018; 8(2):146. https://doi.org/10.3390/app8020146

Chicago/Turabian StyleJia, Ziguang, Liang Ren, Hongnan Li, and Wei Sun. 2018. "Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network" Applied Sciences 8, no. 2: 146. https://doi.org/10.3390/app8020146