Analysis of the Energy Efficiency of a Pneumatic Booster Regulator with Energy Recovery

Abstract

:1. Introduction

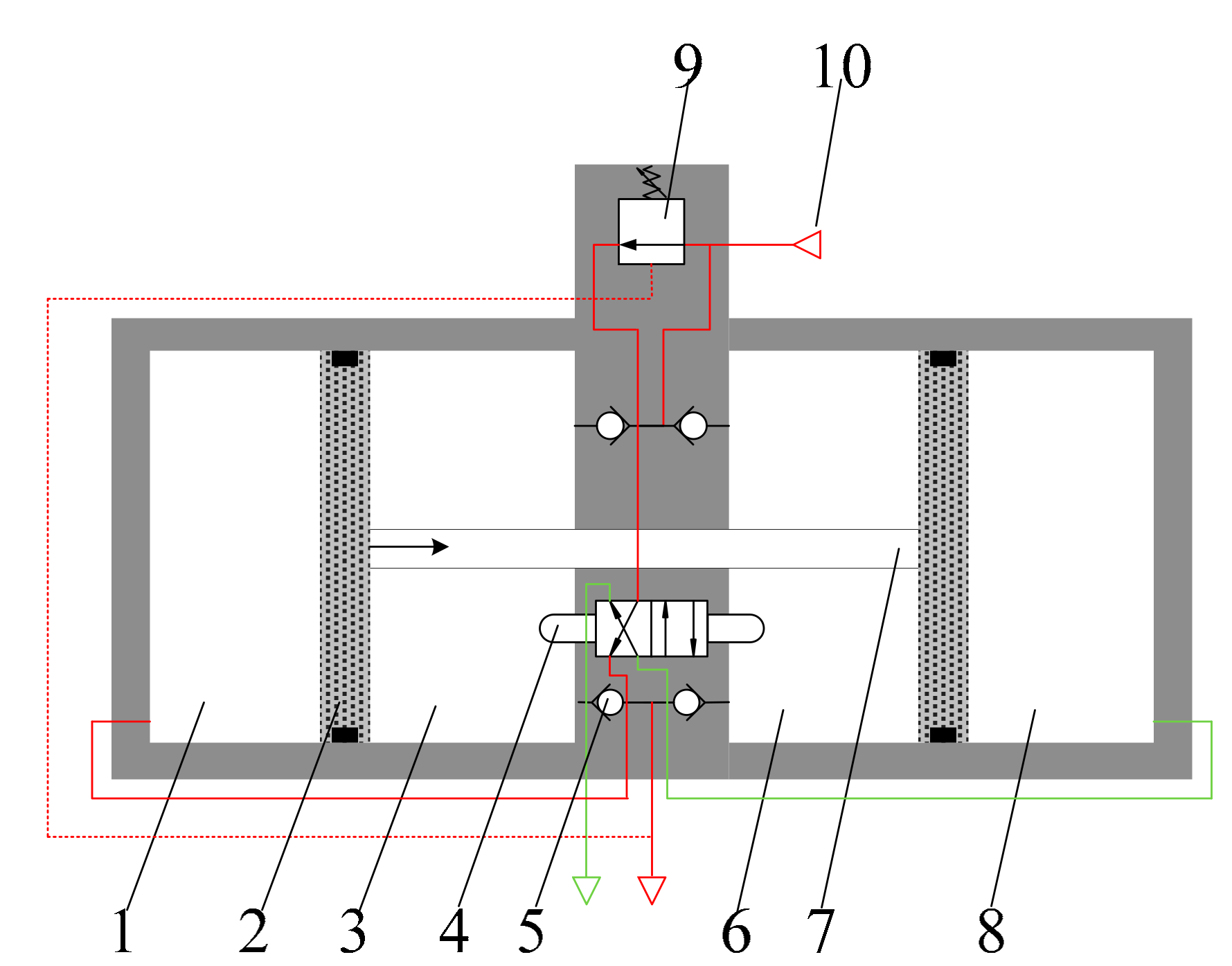

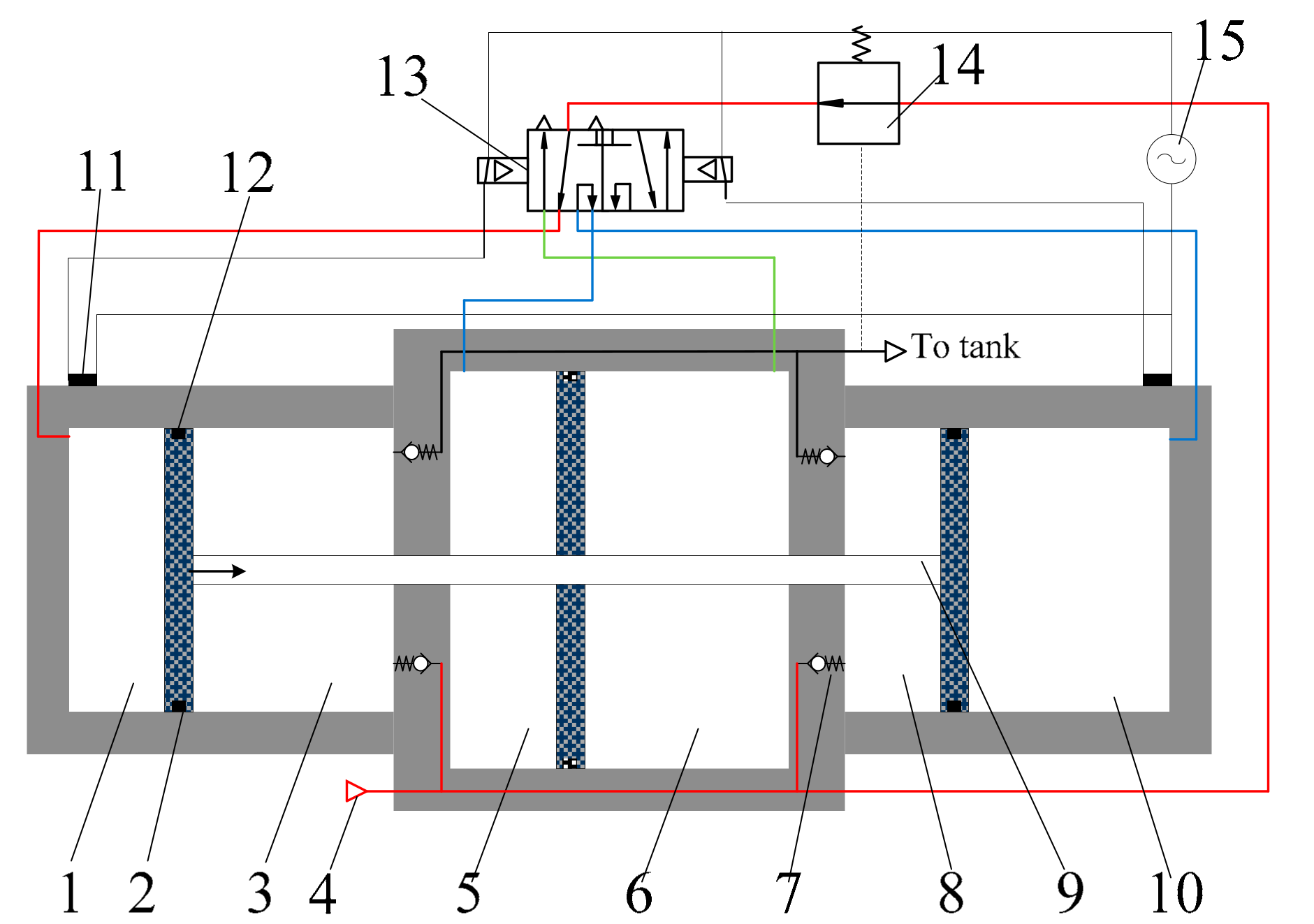

2. Working Principle of the Booster Regulator

3. Energy Efficiency Evaluation Method for Booster Regulator with Energy Recovery (VBA-R)

3.1. Concept of Air Power

3.2. Energy Efficiency of Booster Regulator

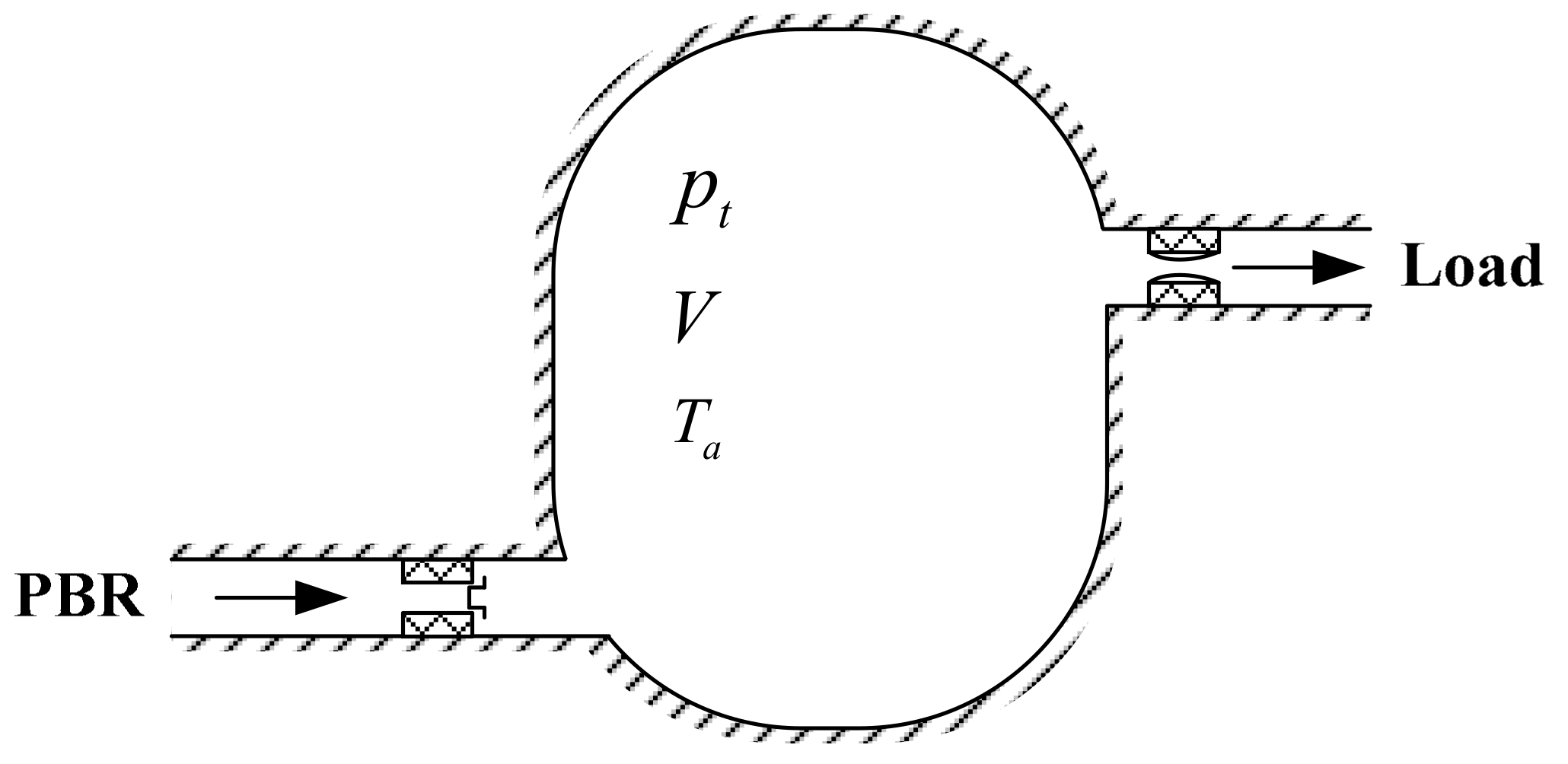

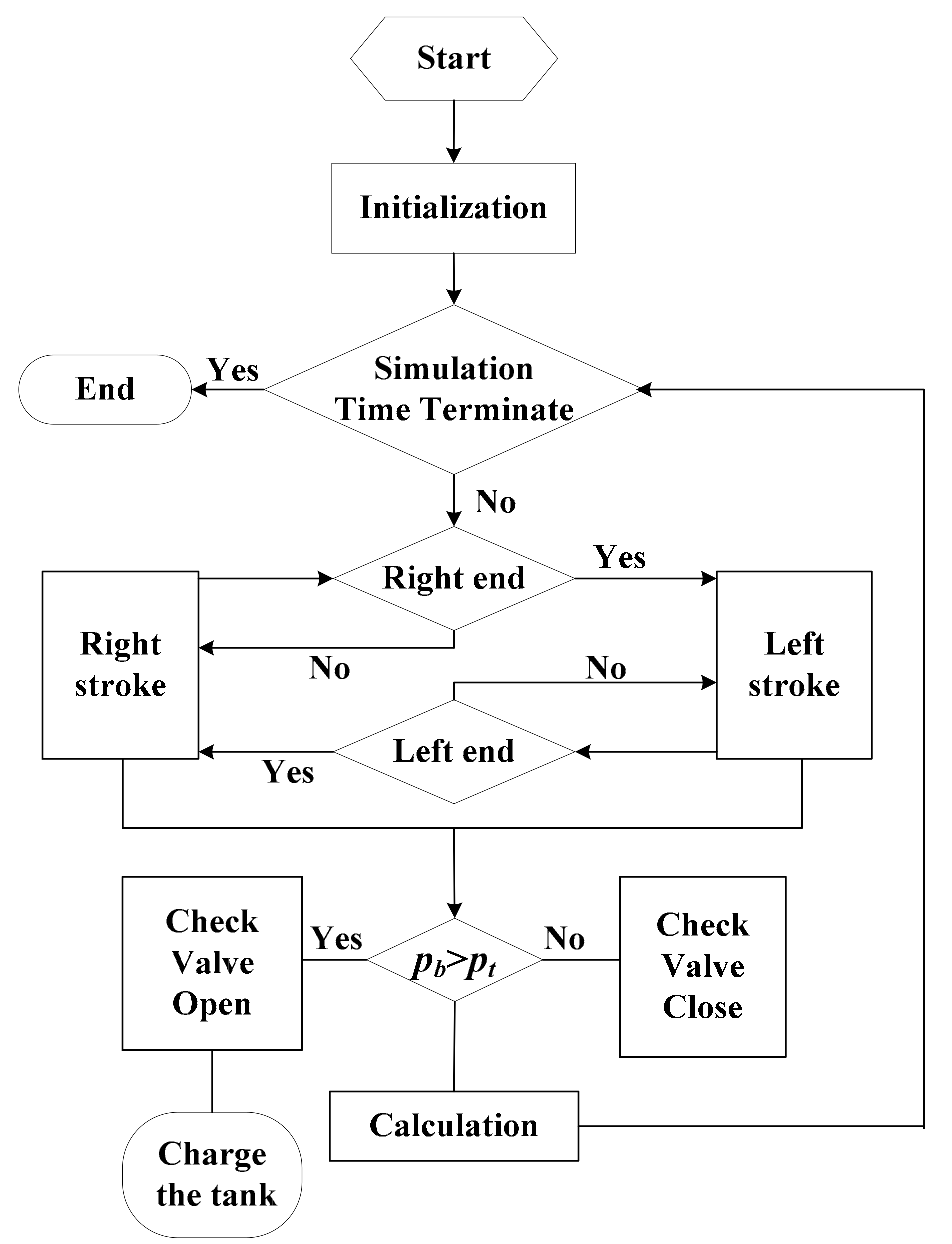

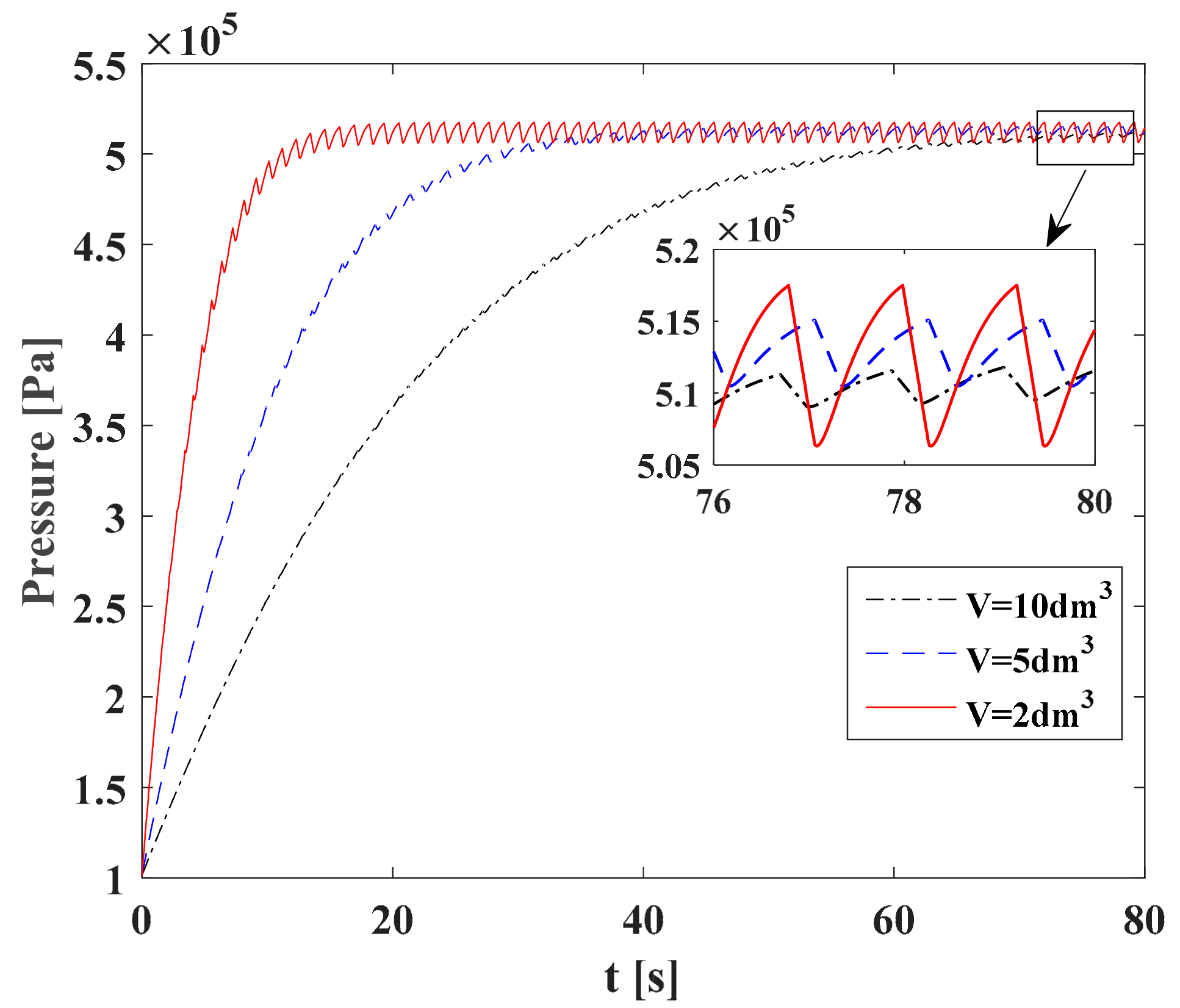

3.3. Pressure Response of VBA-R

- (1)

- Air is an ideal gas and it satisfies the ideal gas state equation;

- (2)

- The initial temperature of air in each chamber is the same as the atmosphere, and so is the air source;

- (3)

- The dead volume of each chamber is very small and can be set as the same;

- (4)

- The air tank can exchange heat sufficiently with the surroundings, and it can be considered as an isothermal tank.

3.3.1. Flow Rate Characteristics Equation

3.3.2. Gas State Equation

3.3.3. Energy Conservation Equation

3.3.4. Kinematic Equation of Piston

3.3.5. Pressure Response in Tank

4. Simulation and Experiment on VBA-R

4.1. Simulation Model

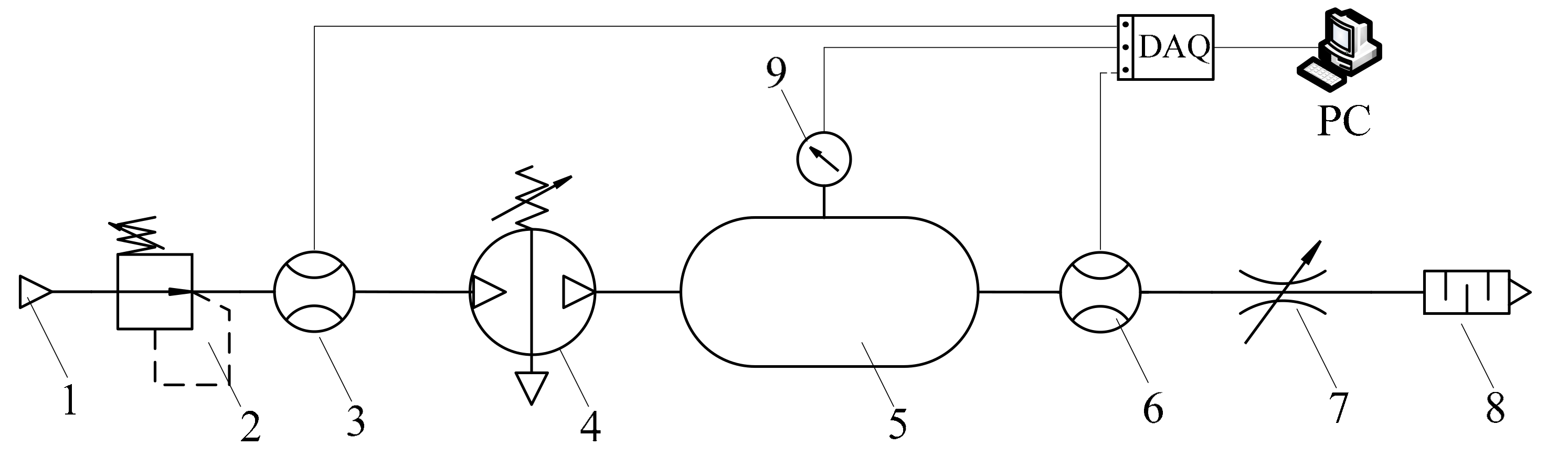

4.2. Energy Efficiency Test

5. Results and Discussion

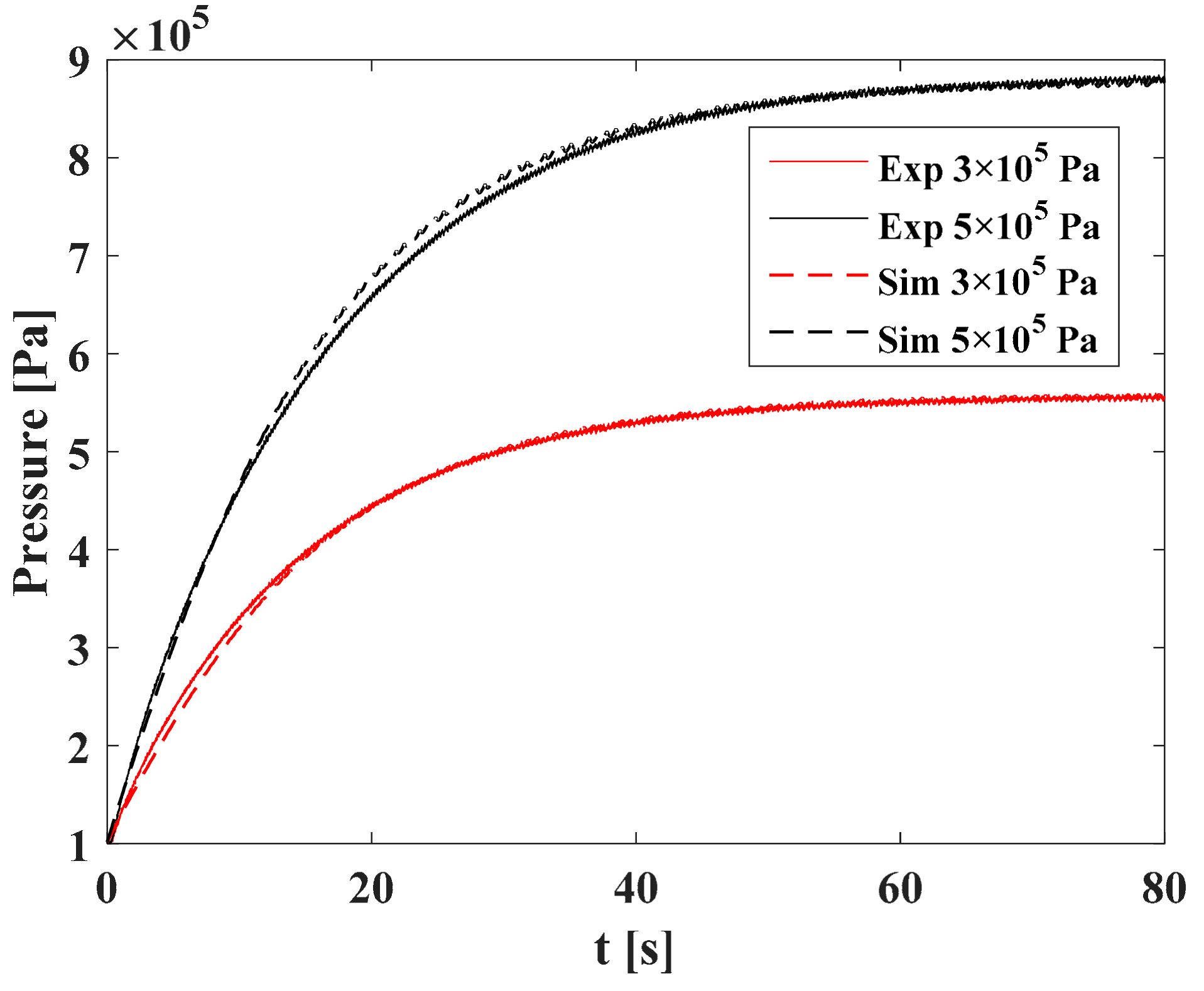

5.1. Experiment Results

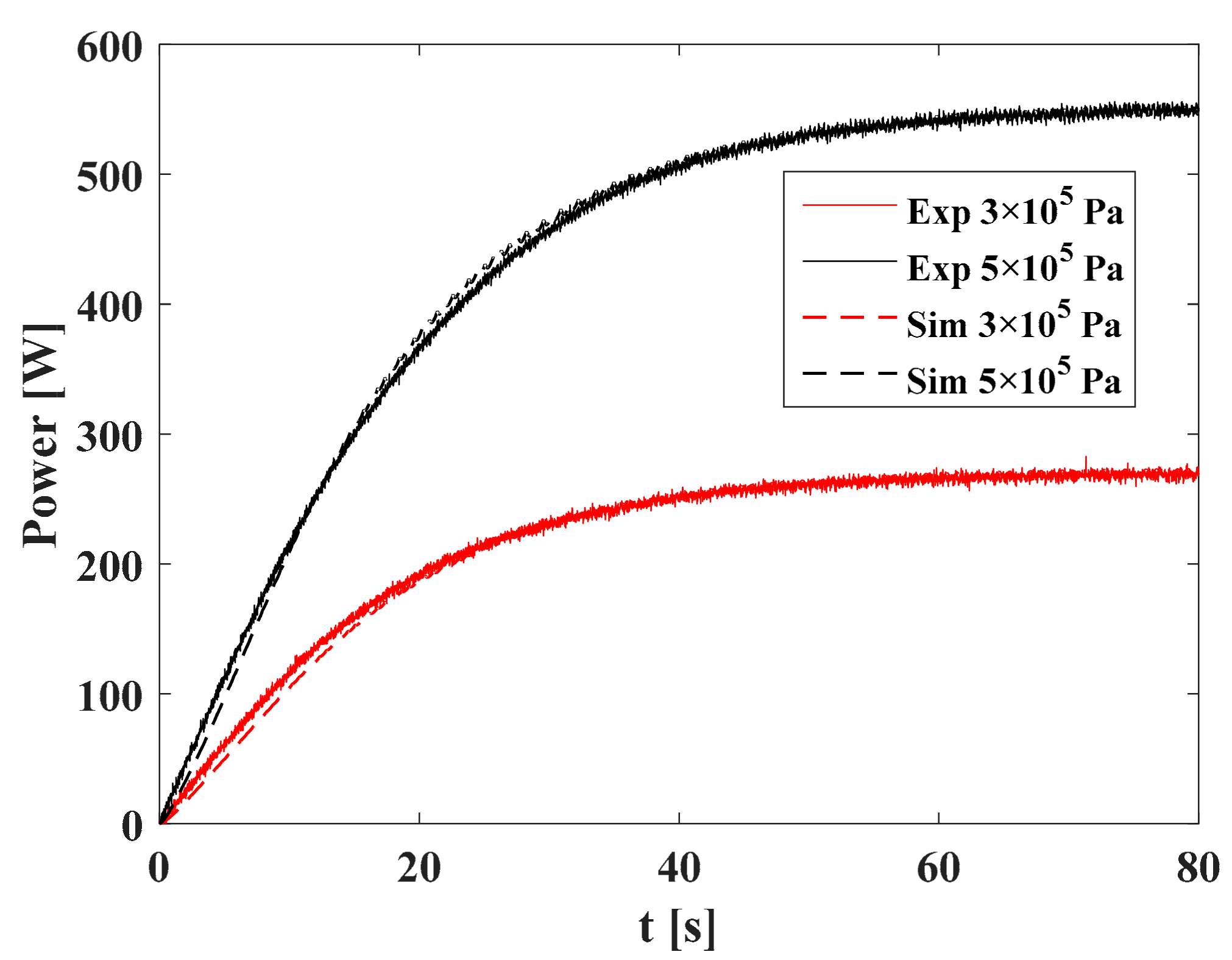

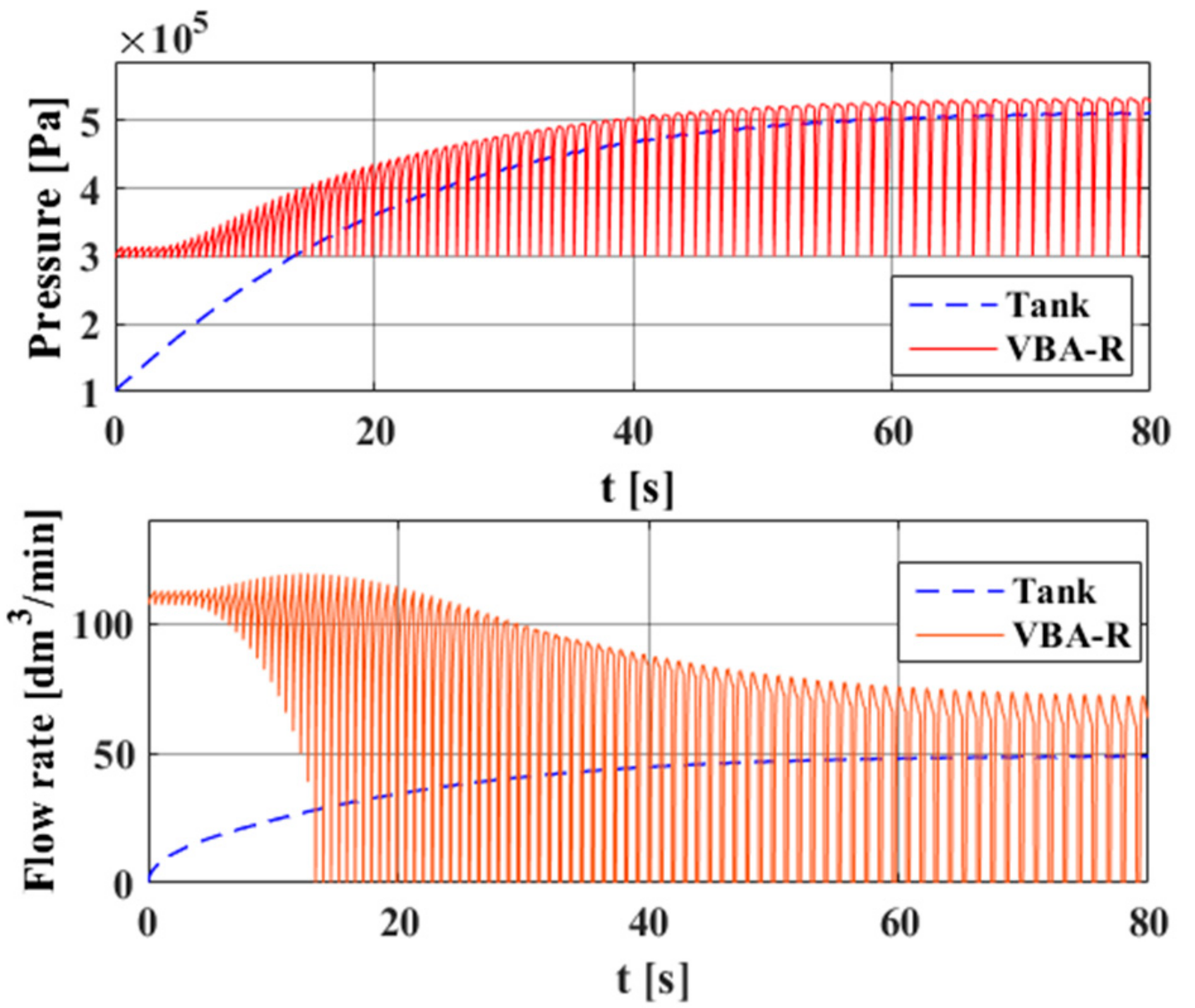

5.2. Characteristics of VBA-R

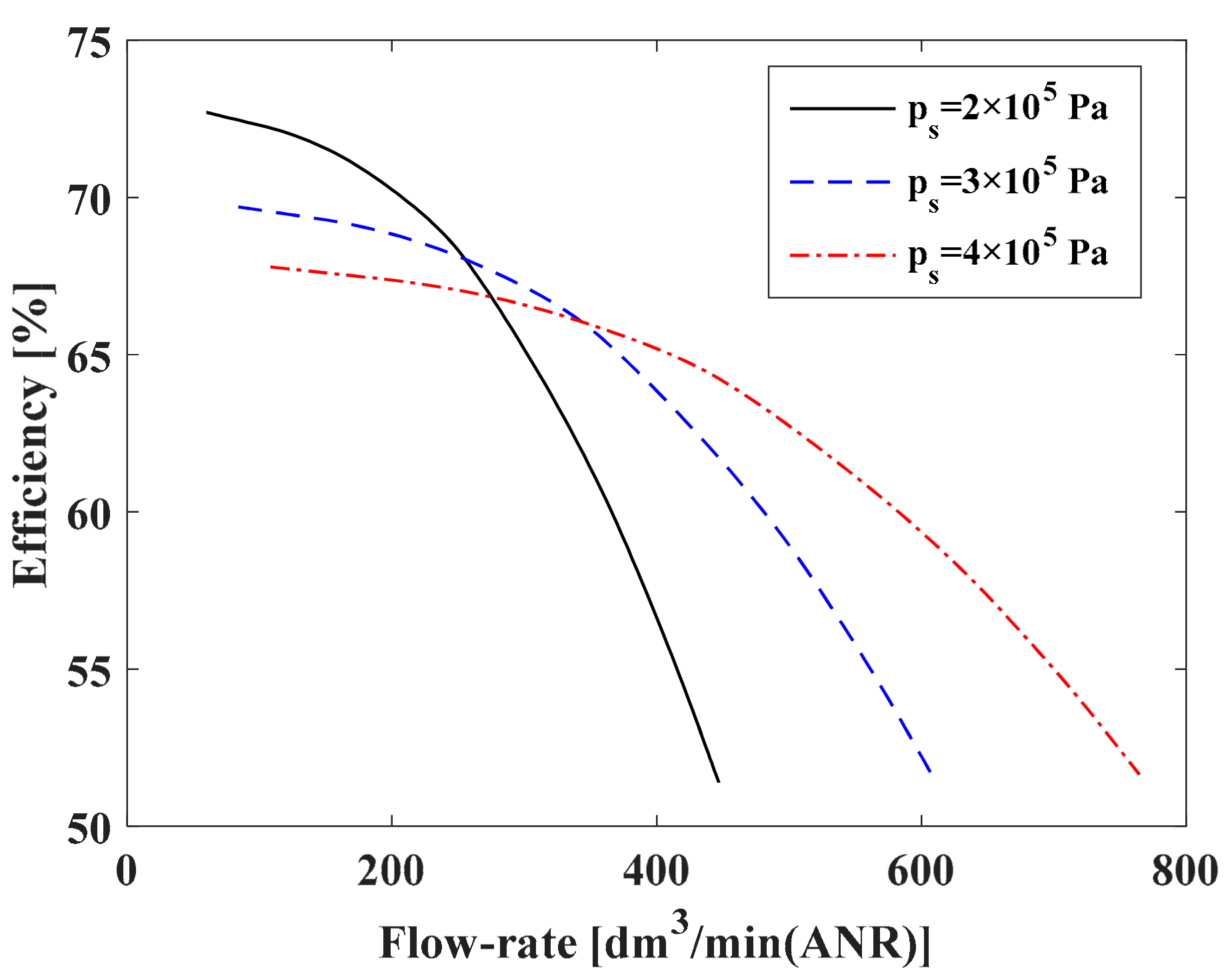

5.3. Energy Efficiency of VBA-R

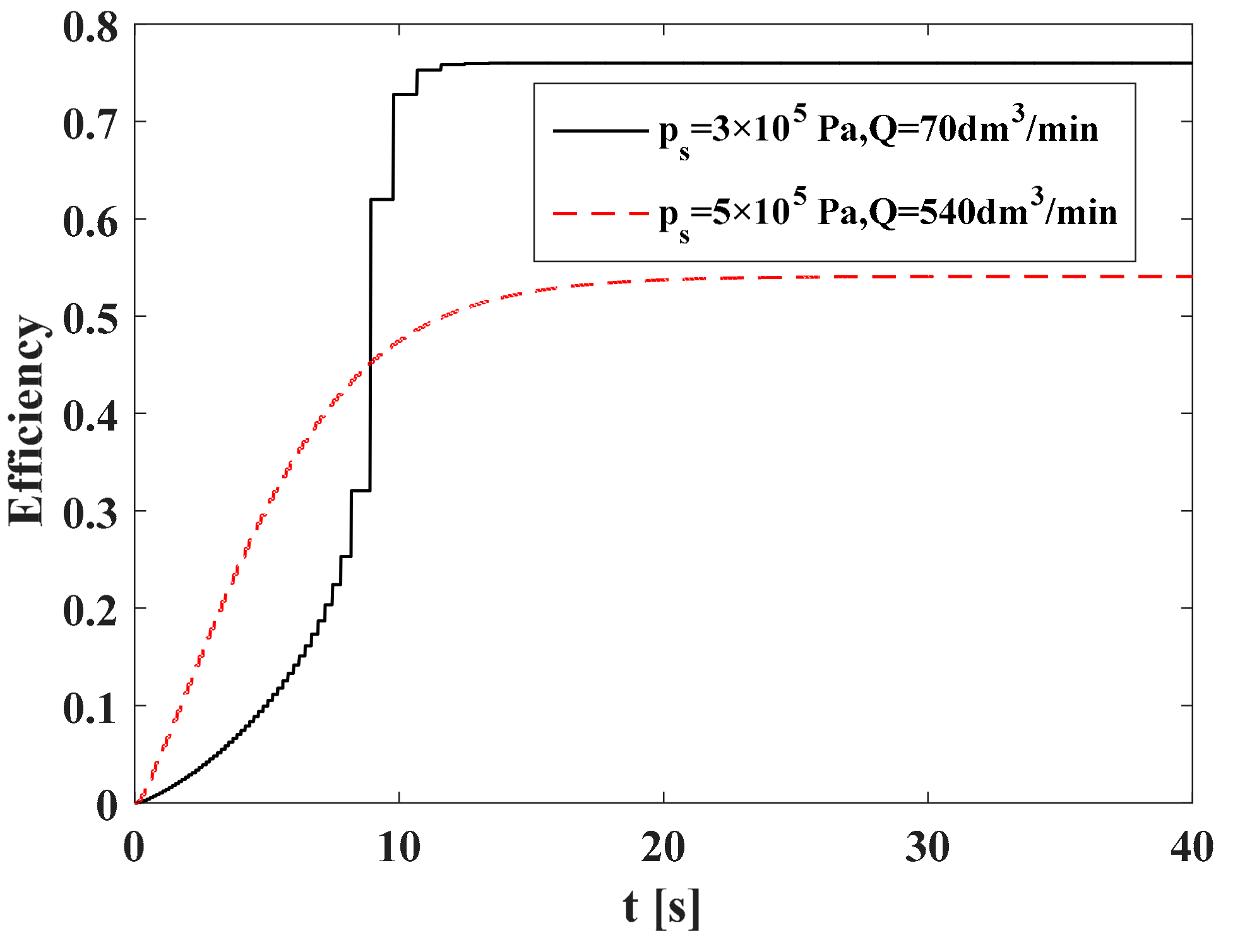

5.3.1. Effect of Supply Pressure and Flow Rate

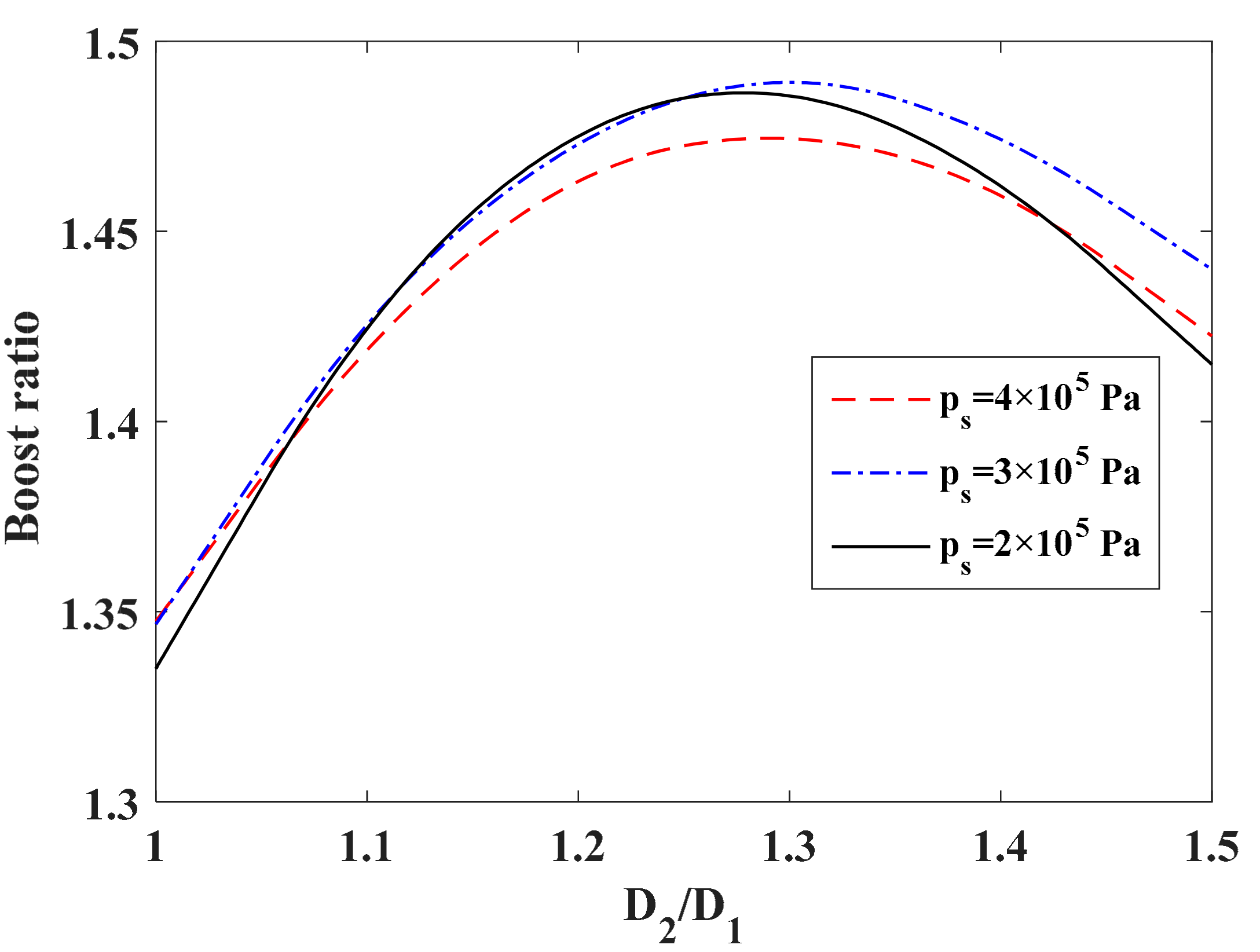

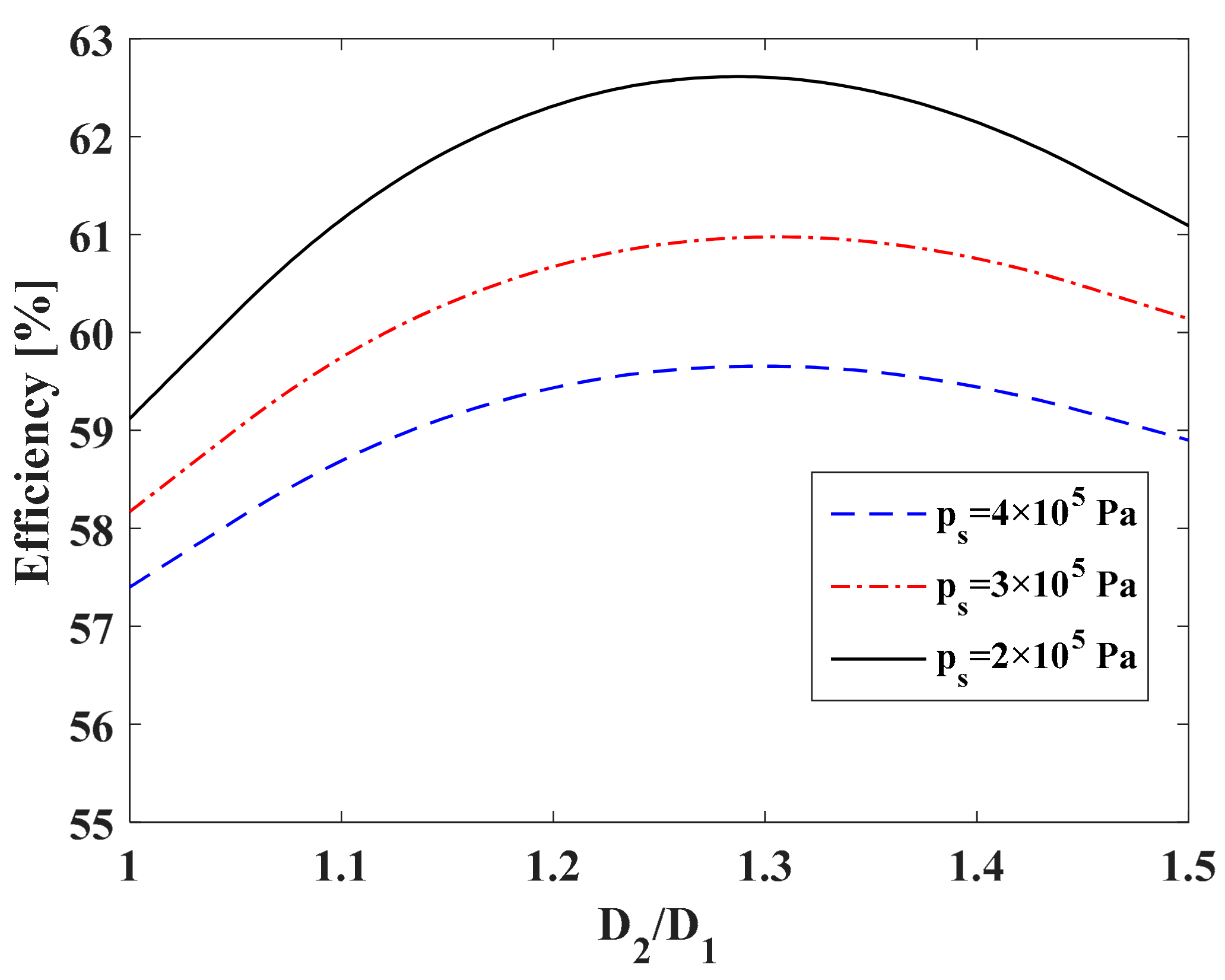

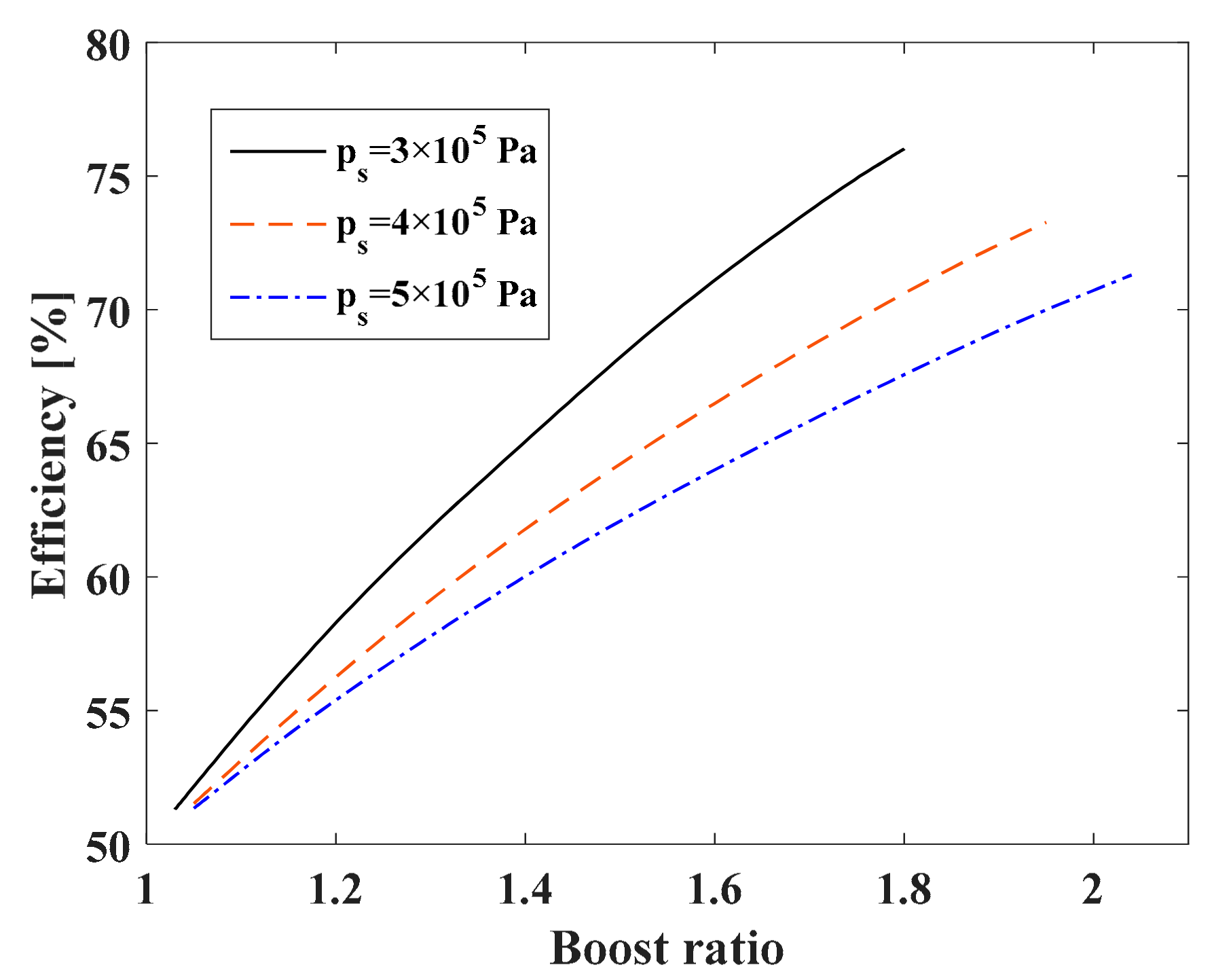

5.3.2. Effect of Diameter Ratio

5.3.3. Effect of Operate Conditions

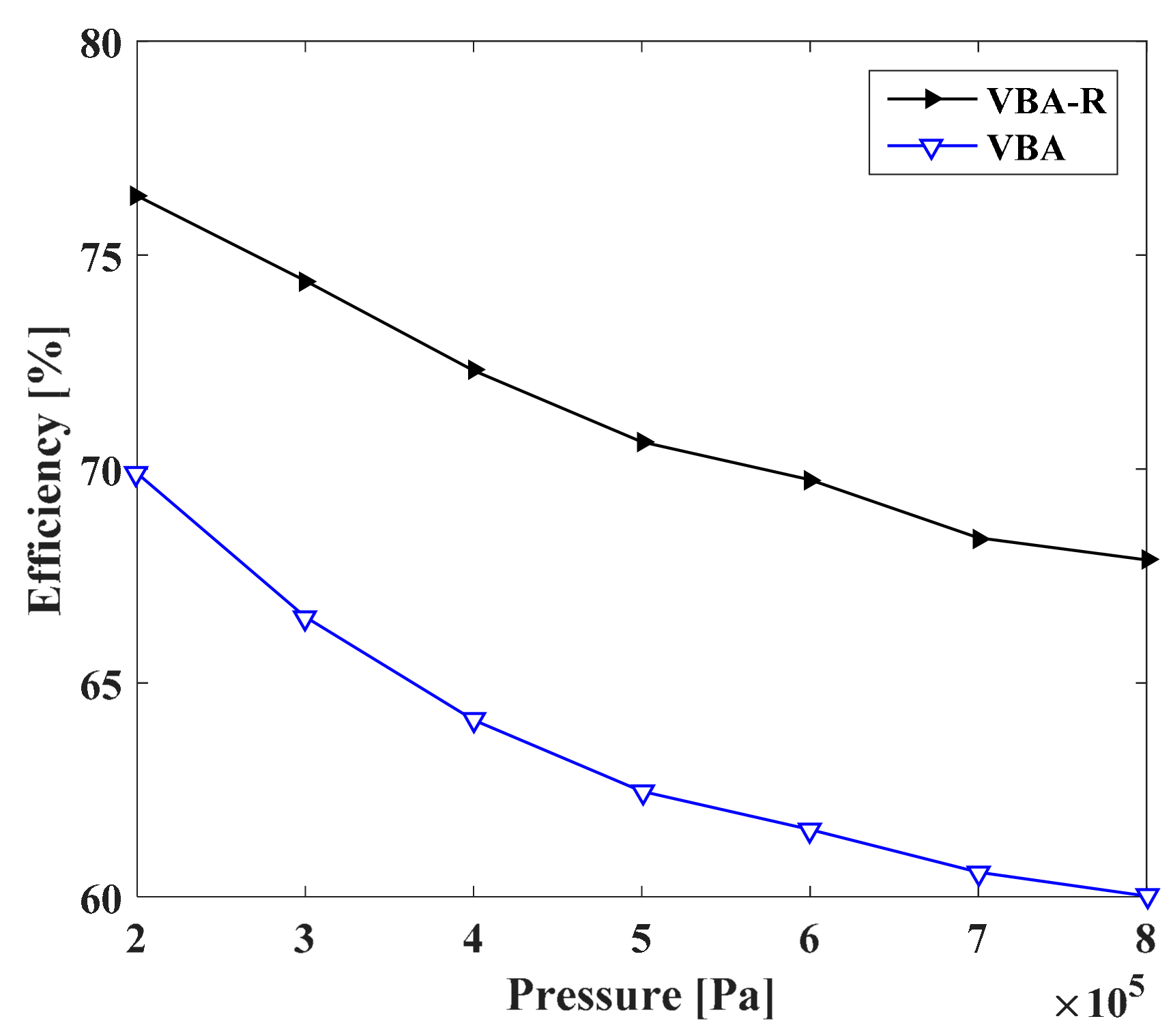

5.4. Comparison of VBA and VBA-R

5.4.1. Comparison of Flow-Rate Characteristics

5.4.2. Comparison of Energy Efficiency

6. Conclusions

- (1)

- The system outputs, especially the pressure, were less than those of the booster regulator. When the air consumption increased, the boost ability decreased, and the tank output became much smaller;

- (2)

- The energy efficiency was directly affected by the supply pressure, and it decreased with increasing supply pressure or decreasing boost ratio;

- (3)

- When the supply pressure was constant, the energy efficiency decreased with the flow rate consumed by an increasing load;

- (4)

- Both the boost ratio and energy efficiency increased first and then decreased with the increasing recovery chamber diameter. When the diameter ratio was close to 1.3, the VBA-R has the largest boost ratio and energy efficiency;

- (5)

- The recovery chamber helped improve the boost ratio by 15–25% and energy efficiency by 5–10% under different operating conditions. Thus, it will save energy over long running times.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| b | critical pressure ratio |

| c | viscous friction coefficient |

| C | sonic conductance [m3/(s Pa)] |

| cv | volumetric specific heat [J/(kg K)] |

| cp | pressure specific heat [J/(kg K)] |

| D | piston diameter [m] |

| E | energy of air [J] |

| Ff | frictional force [N] |

| G | mass flow rate [kg/s] |

| h | heat transfer coefficient [W/(m2 K)] |

| H | enthalpy [J] |

| κ | specific heat index |

| M | mass of piston [kg] |

| η | energy efficiency |

| R | gas state constant, 287 [J/(kg K)] |

| ρ | density [kg/m3] |

| p | pressure [Pa] |

| P | air power [W] |

| q | heat exchange [J] |

| Q | volume flow rate [m3/s] |

| S | section area of piston [m2] |

| t | time [s] |

| T | cycle of booster regulator [s] |

| θ | temperature [K] |

| u | velocity of piston [m/s] |

| U | internal energy [J] |

| V | volume of chamber [m3] |

| Subscript | |

| 0 | standard state of atmosphere [20 °C,100 kPa] |

| 1 | upstream |

| 2 | downstream |

| ba/bb | boost chamber A/B |

| da/db | drive chamber A/B |

| ra/rb | recovery chamber A/B |

| bc/dc | boost/drive chamber |

| a | state of atmosphere |

| c | charge chamber |

| d | discharge chamber |

| t | air tank |

References

- Cai, M.L.; Kagawa, T. Energy consumption assessment and energy loss analysis in pneumatic system. Chin. J. Mech. Eng. 2007, 43, 69–74. [Google Scholar] [CrossRef]

- Li, T.C.; Wu, H.W.; Kuo, M.J. A study of gas economizing pneumatic cylinder. J. Phys. Conf. Ser. 2006, 48, 1227. [Google Scholar] [CrossRef]

- Cai, M.L.; Kagawa, T. Simulation for energy savings in pneumatic system. In Systems Modeling and Simulation; Springer: Tokyo, Japan, 2007; pp. 258–261. [Google Scholar]

- Wang, H.T.; Xiong, W.; Wang, X. Research on the static characteristics of air driven gas booster. Proc. JFPS Int. Symp. Fluid Power 2008, 2008, 715–718. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, M.L. Working characteristics of two kinds of air-driven boosters. Energy Convers. Manag. 2011, 52, 3399–3407. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhao, Y.Y.; Li, L.S.; Shu, P.C. Mathematical modeling of compression processes in air-driven boosters. Appl. Therm. Eng. 2007, 27, 1516–1521. [Google Scholar] [CrossRef]

- Shi, Y.; Jia, G.W.; Cai, M.L.; Xu, W.Q. Study on the dynamics of local pressure boosting pneumatic system. Math. Probl. Eng. 2015, 2015, 1–11. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, M.L. Dimensionless study on output flow characteristics of expansion energy used pneumatic pressure booster. J. Dyn. Syst. Meas. Control 2013, 135, 1–8. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, M.L. Dimensionless study on outlet flow characteristics of an air-driven booster. J. Zhejiang Univ. Sci. A 2012, 13, 481–490. [Google Scholar] [CrossRef]

- Merkelbach, S.; Murrenhoff, H. Exergy based analysis of pneumatic air saving measures. In ASME/BATH 2015 Symposium on Fluid Power and Motion Control; American Society of Mechanical Engineers: Chicago, IL, USA, 2015; p. V001T01A007. [Google Scholar]

- Harris, P.; Nolan, S.; O’Donnell, G.E. Energy optimisation of pneumatic actuator systems in manufacturing. J. Clean. Prod. 2014, 72, 35–45. [Google Scholar] [CrossRef]

- Cummins, J.J.; Barth, E.J.; Adams, D.E. Modeling of a pneumatic strain energy accumulator for variable system configurations with quantified projections of energy efficiency increases. In ASME/BATH 2015 Symposium on Fluid Power and Motion Control; American Society of Mechanical Engineers: Chicago, IL, USA, 2015; p. V001T01A055. [Google Scholar]

- Luo, X.; Wang, J.H.; Sun, H.; Derby, J.W.; Mangan, S.J. Study of a new strategy for pneumatic actuator system energy efficiency improvement via the scroll expander technology. IEEE/ASME Trans. Mechatron. 2013, 18, 1508–1518. [Google Scholar] [CrossRef]

- Luo, X.; Sun, H.; Wang, J.H. An energy efficient pneumatic-electrical system and control strategy development. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011. [Google Scholar]

- Shi, Y.; Wu, T.C.; Cai, M.L.; Wang, Y.X.; Xu, W.Q. Energy conversion characteristics of a hydropneumatic transformer in a sustainable-energy vehicle. Appl. Energy 2016, 171, 77–85. [Google Scholar] [CrossRef]

- Trujillo, J.A. Energy Efficiency of High Pressure Pneumatic Systems. Ph.D. Thesis, Polytechnic University of Catalonia, Barcelona, Spain, 2015. [Google Scholar]

- Cai, M.; Kawashima, K.; Kagawa, T. Power assessment of flowing compressed air. J. Fluids Eng. 2006, 128, 402–405. [Google Scholar] [CrossRef]

- ISO6358-1. Pneumatic Fluid Power—Determination of Flow-Rate Characteristics of Components Using Compressible Fluids—Part 1: General Rules and Test Methods for Steady-State Flow; International Organization for Standardization (ISO): Geneva, Switzerland, 2013. [Google Scholar]

- Kaasa, G.O.; Chapple, P.J.; Lie, B. Modeling of an electro-pneumatic cylinder actuator for nonlinear and adaptive control, with application to clutch actuation in heavy-duty trucks. In Proceedings of the 3rd International Ph.D. Symposium on Fluid Power, Terrassa, Spain, 30 June–2 July 2004. [Google Scholar]

- Okawa, Y.; Youn, C.; Kawashima, K.; Kagawa, T. Flow rate measurement via isothermal discharge method for hydrogen. Int. J. Hydrogen Energy 2012, 37, 18882–18887. [Google Scholar] [CrossRef]

- Harris, P.G.; O’Donnell, G.E.; Whelan, T. Modelling and identification of industrial pneumatic drive system. Int. J. Adv. Manuf. Technol. 2012, 58, 1075–1086. [Google Scholar] [CrossRef]

- Li, J.; Kawashima, K.; Fujita, T.; Kagawa, T. Control design of a pneumatic cylinder with distributed model of pipelines. Precis. Eng. 2013, 37, 880–887. [Google Scholar] [CrossRef]

- Baojun, H.; Fujita, T.; Kawashima, K.; Kagawa, T. Influence of pressure condition change on the flow rate characteristics of pneumatic valve. J. Jpn. Fluid Power Syst. Soc. 2001, 32, 143–149. [Google Scholar]

- Cai, M.L.; Kagawa, T. Design and application of air power meter in compressed air systems. In Proceedings of the Eco Design 2001: Second International Symposium; Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 11–15 December 2001. [Google Scholar]

| Components | Model | Parameters |

|---|---|---|

| Cylinder | CDG1YL63 CG1WLN80 | L:100 mm; D:63 mm L:100 mm; D:80 mm |

| Solenoid valve | SV3200R | C:4.5 × 10−8 m3/(s·Pa); b:0.3 |

| Check valve | AKH10-00 | C:4.8 × 10−8 m3/(s·Pa); b:0.3 |

| Throttle valve | AS300 | C:2.7 × 10−8 m3/(s·Pa); b:0.2 |

| PLC | FX1s-20MR | - |

| F.R.L Units | AC40D | 800 dm3/min 0.05–0.7 MPa |

| Air power meter | APM-L-800s | 8–800 dm3/min 0–1.2 kW |

| Pressure sensor | ISE80H | 0–1.0 MPa |

| Booster regulator | VBA20A-03 | 1 m3/min 0.2–1.0 MPa |

| Tank | VBAT10A1-15 | 10 dm3 |

| DAQ card | TNS6810 | - |

| Parameters | Piston Diameter (mm) | Piston Rod Diameter (mm) | Stroke (mm) | Supply Pressure (kPa(abs)) | Atmosphere Temperature (K) | Sonic Conductance of Throttle Valve (m3/(s·Pa)) | Tank Volume (L) |

|---|---|---|---|---|---|---|---|

| VBA-R | Dba = 63, Dra = 80 | 10 | 100 | 300 | 293 | 2.79 × 10−9 | 5.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Tadano, K.; Li, G.; Kagawa, T. Analysis of the Energy Efficiency of a Pneumatic Booster Regulator with Energy Recovery. Appl. Sci. 2017, 7, 816. https://doi.org/10.3390/app7080816

Yang F, Tadano K, Li G, Kagawa T. Analysis of the Energy Efficiency of a Pneumatic Booster Regulator with Energy Recovery. Applied Sciences. 2017; 7(8):816. https://doi.org/10.3390/app7080816

Chicago/Turabian StyleYang, Fan, Kotaro Tadano, Gangyan Li, and Toshiharu Kagawa. 2017. "Analysis of the Energy Efficiency of a Pneumatic Booster Regulator with Energy Recovery" Applied Sciences 7, no. 8: 816. https://doi.org/10.3390/app7080816