On the Impact of Particulate Matter Distribution on Pressure Drop of Wall-Flow Particulate Filters

Abstract

:1. Introduction

2. Wall-Flow DPF Model

- Mass conservation:

- Momentum conservation:

- Energy conservation:

- Chemical species conservation:

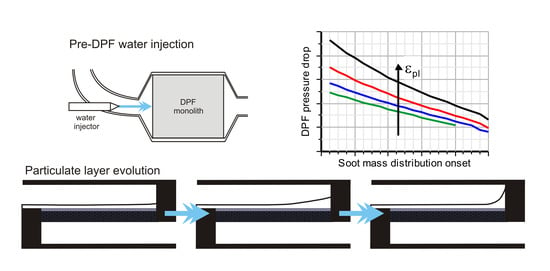

3. Experimental Setup

3.1. Tests

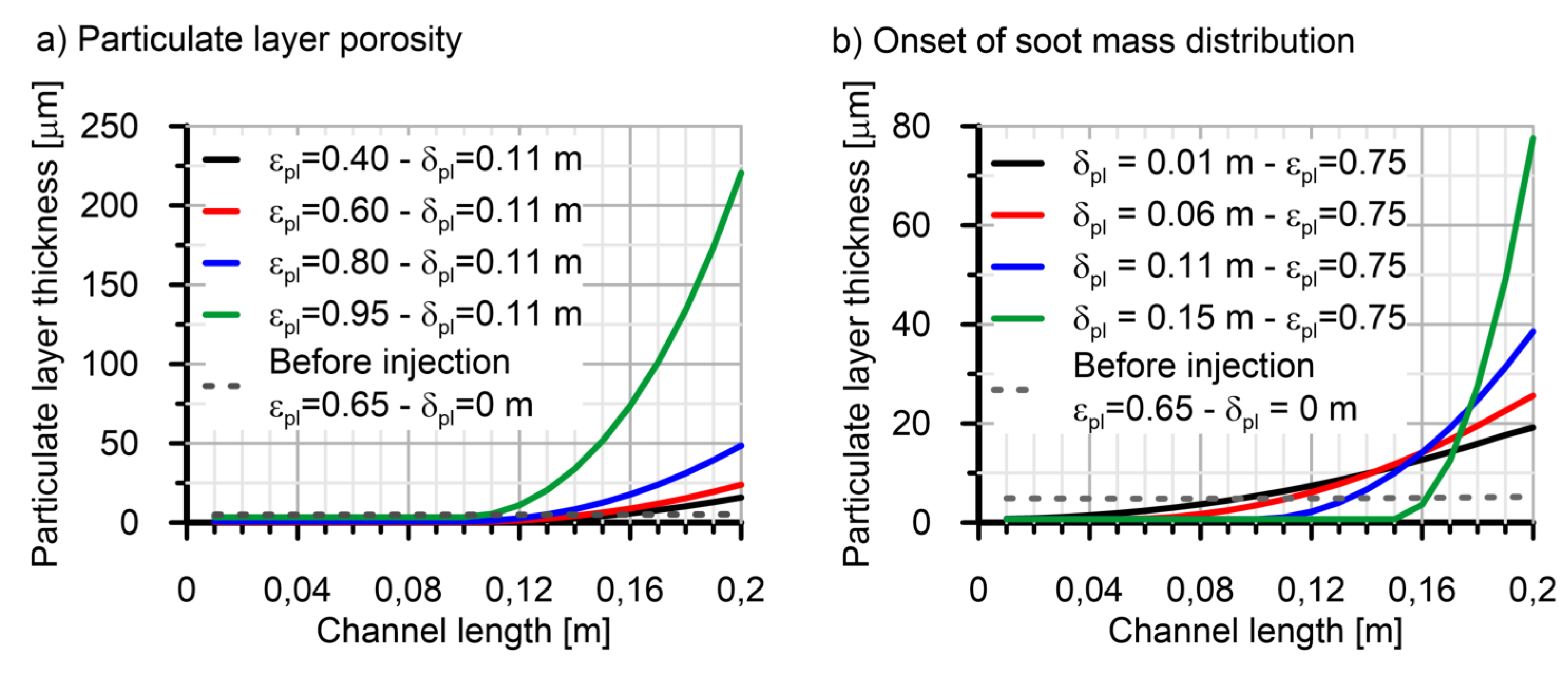

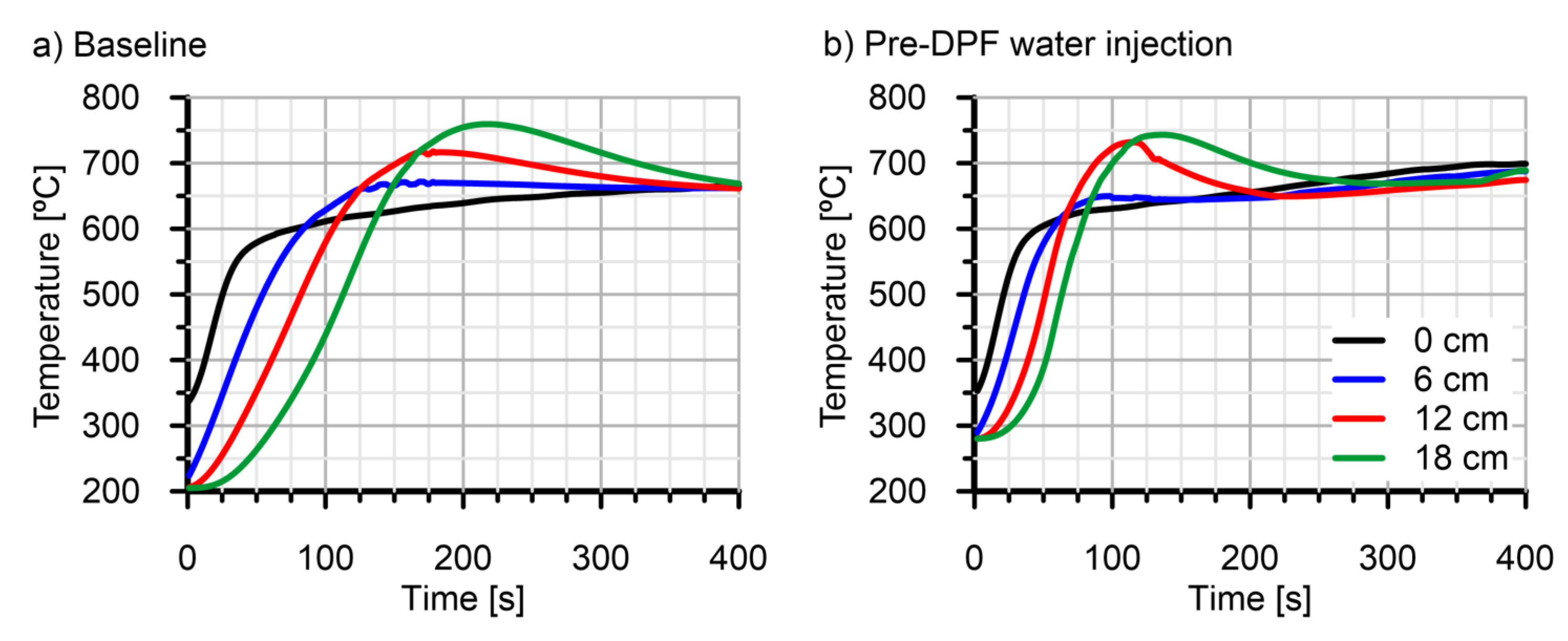

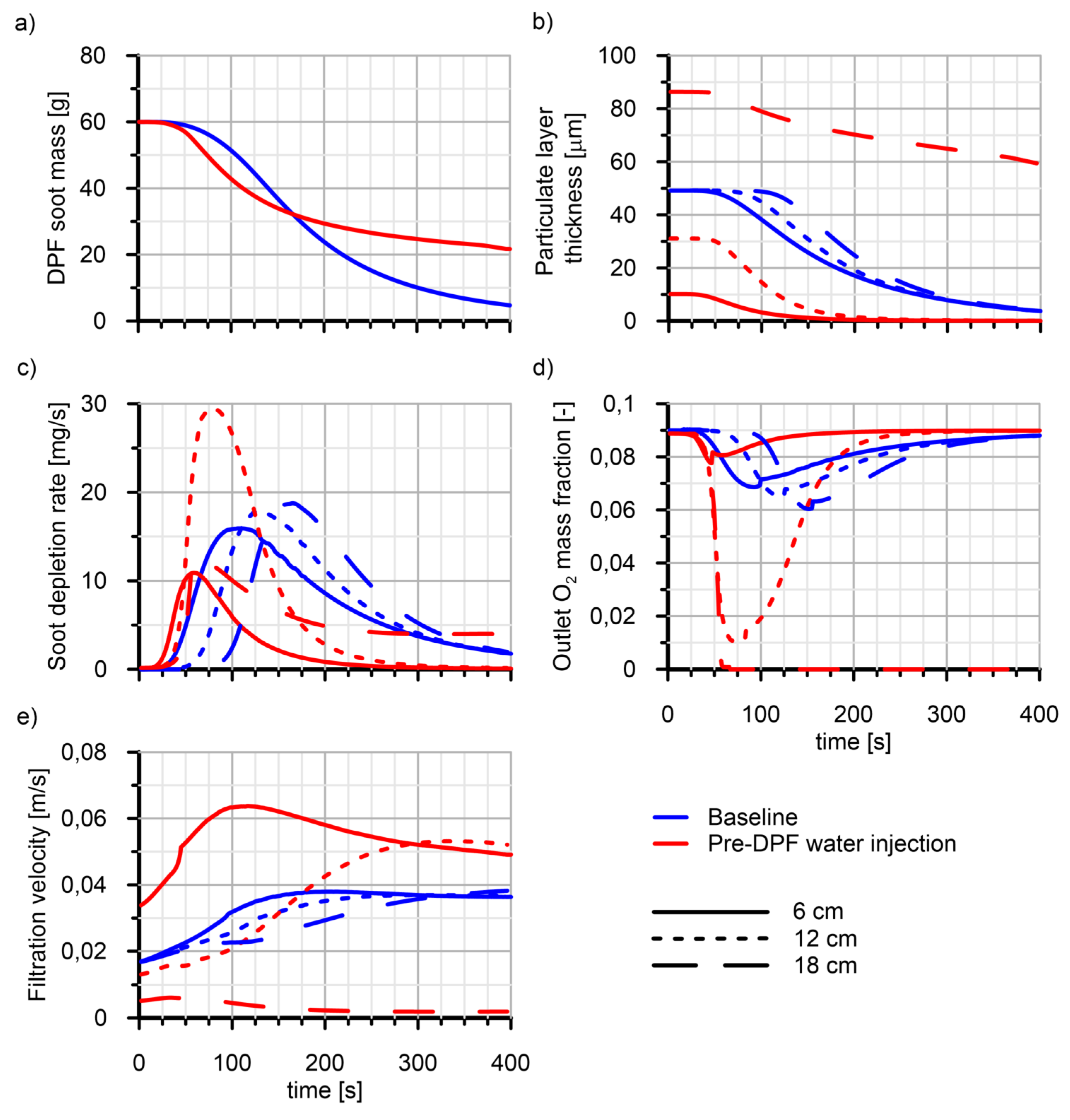

4. Discussion of the Results

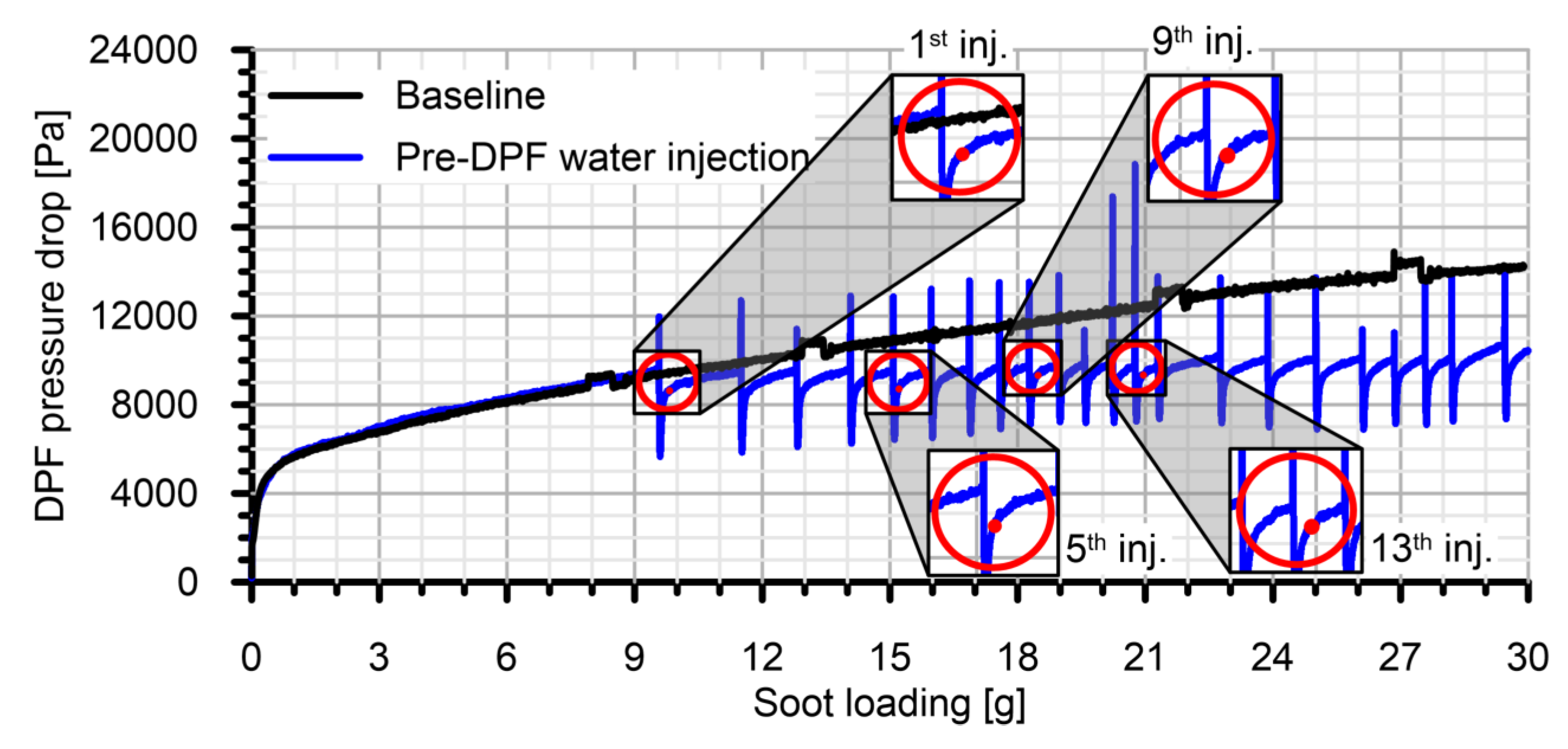

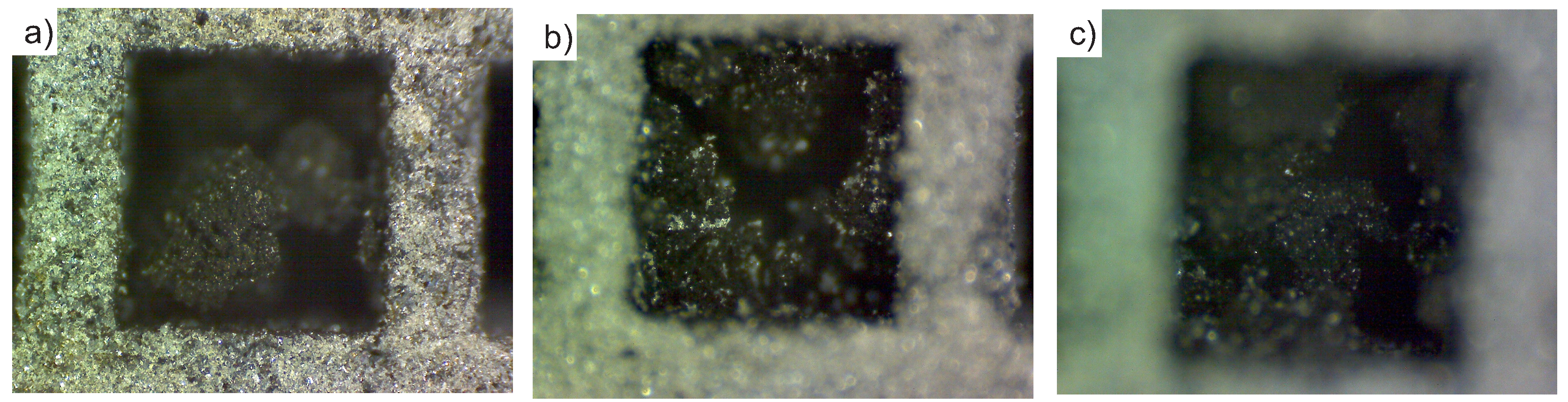

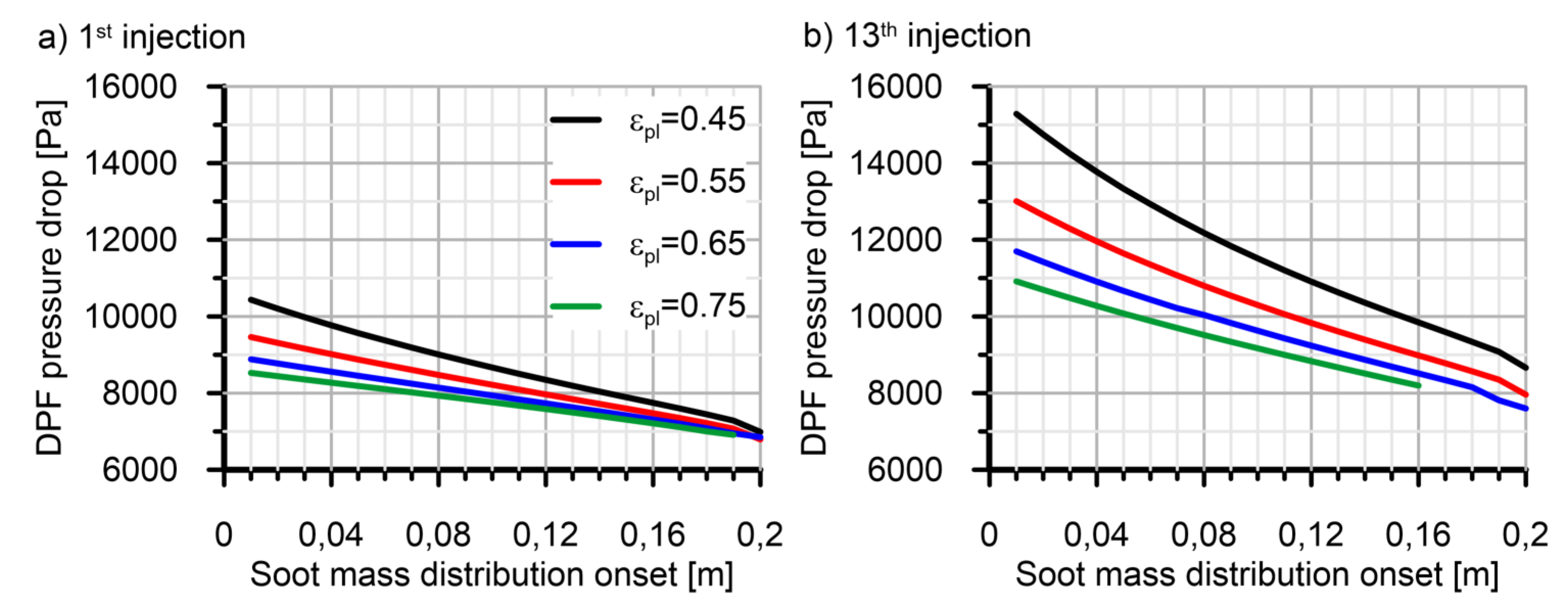

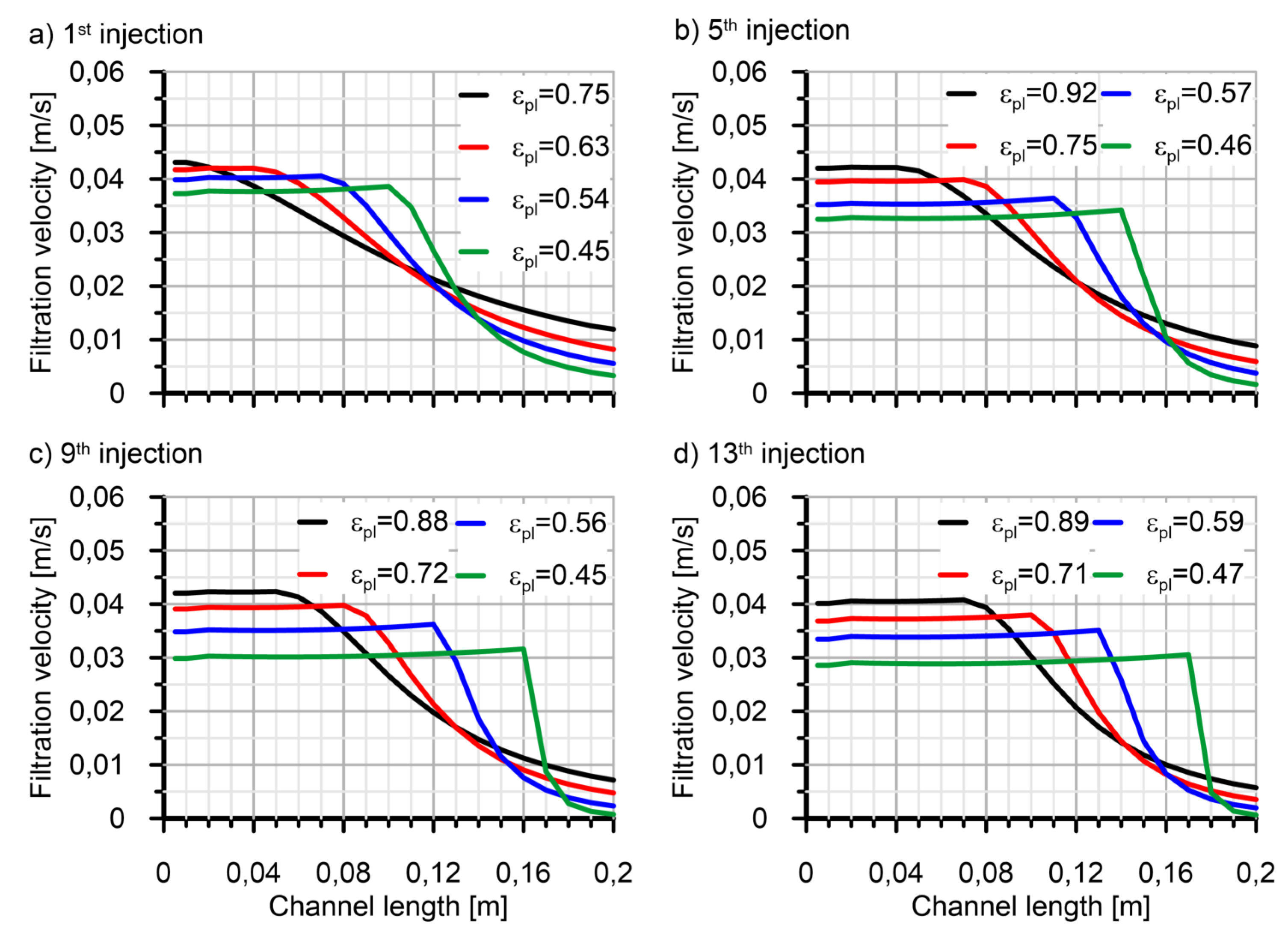

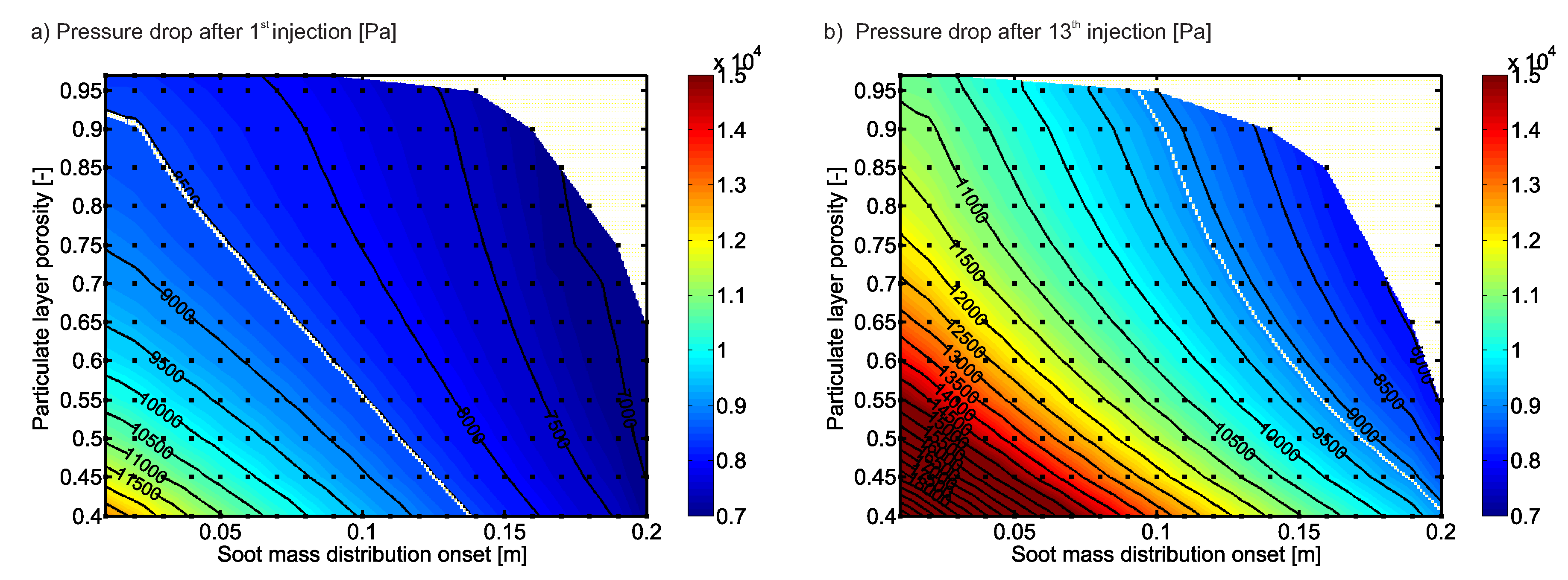

4.1. Pressure Drop

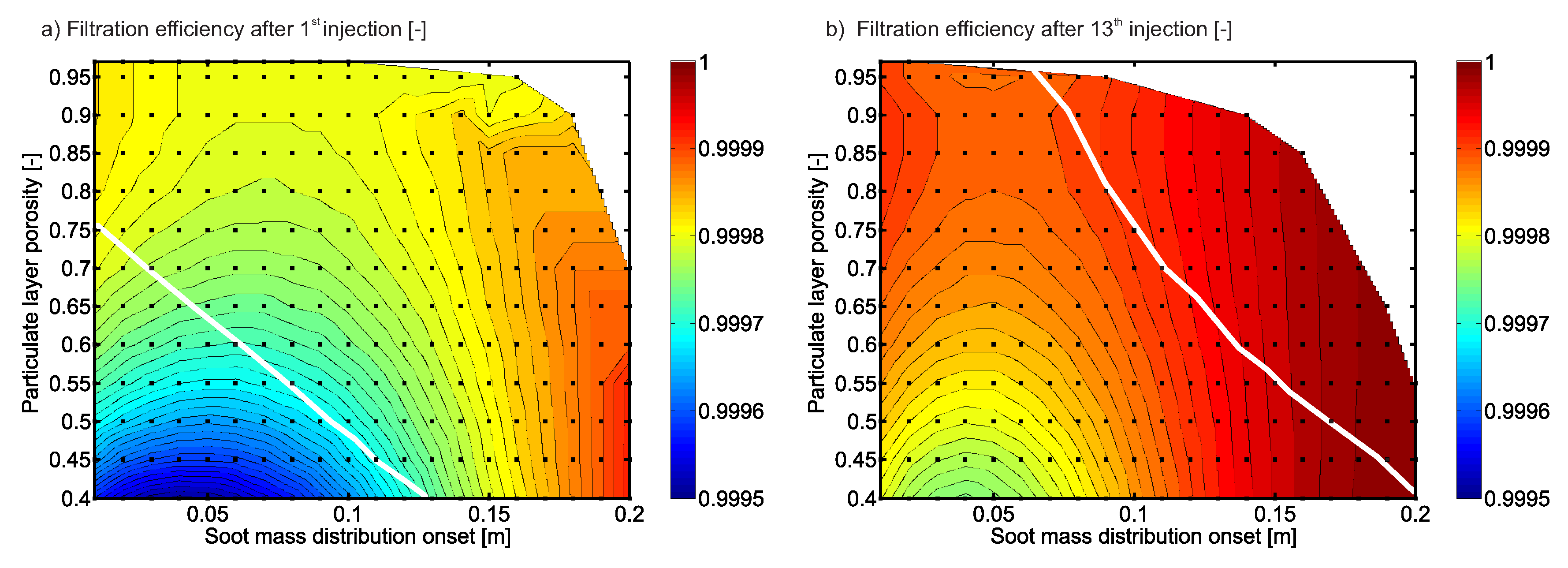

4.2. Filtration Efficiency and Regeneration

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| filtration area | |

| gas concentration | |

| collector unit diameter | |

| cell unit diameter | |

| mean pore diameter | |

| D | diameter |

| specific stagnation internal energy | |

| porous wall filtration efficiency | |

| saturated fraction of porous wall thickness | |

| F | area |

| momentum transfer coefficient for square channels | |

| specific stagnation enthalpy | |

| k | permeability |

| kinetic constant of reagent n | |

| L | channel length |

| soot mass | |

| carbon molecular weight | |

| p | pressure |

| q | heat per unit of time and mass |

| specific surface | |

| t | time |

| u | velocity |

| filtration velocity | |

| particulate layer thickness | |

| porous wall thickness | |

| x | axial dimension |

| X | molar fraction |

| Y | mass fraction |

| z | tangential dimension |

| Greek letters | |

| α | honeycomb cell size |

| stoichiometric coefficient of reagent n | |

| soot mass distribution onset | |

| Δ | variation |

| ε | porosity |

| single sphere filtration efficiency | |

| μ | dynamic viscosity |

| ρ | gas density |

| carbon density | |

| soot packing density inside the porous wall | |

| σ | cell density |

| χ | shape factor |

| Subscripts | |

| cell | referred to the cell unit |

| e | effective |

| in | referred to the inlet channel |

| j | channel type |

| n | reagent (O2, NO2) |

| out | referred to the outlet channel |

| pl | referred to the particulate layer |

| reg | referred to the regeneration |

| w | referred to the porous wall |

| w0 | referred to the clean porous wall |

| Abbreviations | |

| 2LW | Two-step Lax and Wendroff method |

| DOC | Diesel Oxidation Catalyst |

| DPF | Diesel Particulate Filter |

| EEPS | Engine Exhaust Particle Sizer |

| FCT | Flux-Corrected Transport |

| HSDI | High-Speed Direct Injection |

| MoC | Method of Characteristics |

| NEDC | New European Driving Cycle |

| SCF | Stokes–Cunningham Factor |

| SCR | Selective Catalytic Reduction |

| SCRF | Selective Catalytic Reduction Filter |

| SEM | Scanning Electron Microscope |

References

- Johnson, T.V. Review of vehicular emissions trends. SAE Int. J. Engines 2015, 8, 1152–1167. [Google Scholar] [CrossRef]

- Bermúdez, V.; Serrano, J.R.; Piqueras, P.; García-Afonso, O. Assessment by means of gas dynamic modeling of a pre-turbo diesel particulate filter configuration in a turbocharged HSDI diesel engine under full-load transient operation. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2011, 225, 1134–1155. [Google Scholar] [CrossRef]

- Subramaniam, M.N.; Joergl, V.; Keller, P.; Weber, O.; Toyoshima, T.; Vogt, C.D. Feasibility Assessment of a pre-turbo after-treatment system with a 1D modeling approach. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Luján, J.M.; Bermúdez, V.; Piqueras, P.; García-Afonso, O. Experimental assessment of pre-turbo aftertreatment configurations in a single stage turbocharged Diesel engine. Part 1: Steady-state operation. Energy 2015, 80, 599–613. [Google Scholar] [CrossRef]

- Luján, J.M.; Serrano, J.R.; Piqueras, P.; García-Afonso, O. Experimental assessment of a pre-turbo aftertreatment configuration in a single stage turbocharged Diesel engine. Part 2: Transient operation. Energy 2015, 80, 614–627. [Google Scholar] [CrossRef]

- Lee, J.H.; Michael, J.; Brown, D.B. Evaluation of Cu-based SCR/DPF technology for diesel exhaust emission control. SAE Int. J. Fuels Lubr. 2009, 1, 96–101. [Google Scholar] [CrossRef]

- Watling, T.C.; Ravenscroft, M.R.; Avery, G. Development, validation and application of a model for an SCR catalyst coated diesel particulate filter. Catal. Today 2012, 188, 32–41. [Google Scholar] [CrossRef]

- Marchitti, F.; Nova, I.; Tronconi, E. Experimental study of the interaction between soot combustion and NH3–SCR exhaust reactivity over a Cu–Zeolite SDPF catalyst. Catal. Today 2016, 217, 110–118. [Google Scholar] [CrossRef]

- Konstandopoulos, A.G.; Kostoglou, M. Analysis of asymmetric and variable cell geometry wall-flow particulate filters. SAE Int. J. Fuels Lubr. 2014, 7, 489–495. [Google Scholar] [CrossRef]

- Bollerhoff, T.; Markomanolakis, I.; Koltsakis, G. Filtration and regeneration modeling for particulate filters with inhomogeneous wall structure. Catal. Today 2012, 188, 24–31. [Google Scholar] [CrossRef]

- Iwata, H.; Konstandopoulos, A.G.; Nakamura, K.; Ogiso, A.; Ogyu, K.; Shibata, T.; Ohno, K. Further experimental study of asymmetric plugging layout on DPFs: Effect of Wall thickness on pressure drop and soot oxidation. SAE Tech. Pap. 2015. [Google Scholar] [CrossRef]

- Serrano, J.R.; Bermúdez, V.; Piqueras, P.; García-Afonso, O. Pre-DPF water injection technique for loaded DPF pressure drop reduction and control. Appl. Energy 2015, 140, 234–245. [Google Scholar]

- Serrano, J.R.; Bermúdez, V.; Piqueras, P.; Angiolini, E. Application of pre-DPF water injection technique for pressure drop limitation. SAE Tech. Pap. 2015. [Google Scholar] [CrossRef]

- Wang, Y.; Wong, V.; Sappok, A.; Munnis, S. The sensitivity of DPF performance to the spatial distribution of ash inside DPF inlet channels. SAE Tech. Pap. 2013. [Google Scholar] [CrossRef]

- Sappok, A.; Govani, I.; Kamp, C.; Wang, Y.; Wong, V. In-situ optical analysis of ash formation and transport in diesel particulate filters during active and passive regeneration processes. SAE Int. J. Fuels Lubr. 2013, 6, 336–349. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Serrano, J.R.; Arnau, F.J.; Piqueras, P. A fluid dynamic model for unsteady compressible flow in wall-flow Diesel particulate filters. Energy 2011, 36, 671–684. [Google Scholar] [CrossRef]

- OpenWAM Website. CMT-Motores Tèrmicos (Universitat Politècnica de València). 2017. Available online: www.openwam.org (accessed on 15 January 2017).

- Galindo, J.; Serrano, J.R.; Arnau, F.J.; Piqueras, P. Description and analysis of a one-dimensional gas-dynamic model with Independent Time Discretization. In Proceedings of the ASME Internal Combustion Engine Division 2008 Spring Technical Conference ICES 2008, Chicago, IL, USA, 27–30 April 2008.

- Lax, P.; Wendroff, B. Systems of conservation laws. Commun. Pure Appl. Math. 1964, 17, 381–398. [Google Scholar] [CrossRef]

- Serrano, J.R.; Arnau, F.J.; Piqueras, P.; García-Afonso, O. Application of the two-step Lax&Wendroff-FCT and the CE-SE method to flow transport in wall-flow monoliths. Int. J. Comput. Math. 2014, 91, 71–84. [Google Scholar]

- Benson, R.S. The Thermodynamics and Gas Dynamics of Internal-Combustion Engines; Clarendon Press: New York, NY, USA, 1982; Volume 1. [Google Scholar]

- Desantes, J.M.; Serrano, J.R.; Arnau, F.J.; Piqueras, P. Derivation of the method of characteristics for the fluid dynamic solution of flow advection along porous wall channels. Appl. Math. Model. 2012, 36, 3144–3152. [Google Scholar] [CrossRef]

- Serrano, J.R.; Arnau, F.J.; Piqueras, P.; Garcia-Afonso, O. Packed bed of spherical particles approach for pressure drop prediction in wall-flow DPFs (diesel particulate filters) under soot loading conditions. Energy 2013, 58, 644–654. [Google Scholar] [CrossRef]

- Murtagh, M.; Sherwood, D.; Socha, L. Development of a diesel particulate filter composition and its effect on thermal durability and filtration performance. SAE Tech. Pap. 1994. [Google Scholar] [CrossRef]

- Fino, D.; Russo, N.; Millo, F.; Vezza, D.; Ferrero, F.; Chianale, A. New tool for experimental analysis of diesel particulate filter loading. Top Catal. 2009, 52, 13–20. [Google Scholar] [CrossRef]

- Konstandopoulos, A.G.; Johnson, J.H. Wall-flow diesel particulate filters—Their pressure drop and collection efficiency. SAE Tech. Pap. 1989. [Google Scholar] [CrossRef]

- Lapuerta, M.; Ballesteros, R.; Martos, F. A method to determine the fractal dimension of diesel soot agglomerates. J. Coll. Interface Sci. 2006, 303, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Serrano, J.R.; Climent, H.; Piqueras, P.; Angiolini, E. Filtration modeling in wall-flow particulate filters of low soot penetration thickness. Energy 2016, 112, 883–888. [Google Scholar] [CrossRef]

- Logan, B.E.; Jewett, D.G.; Arnold, R.G.; Bouwer, E.J.; O’Melia, C.R. Clarification of clean-bed filtration models. J. Environ. Eng. 1995, 121, 869–873. [Google Scholar] [CrossRef]

- Koltsakis, G.C.; Stamatelos, A.M. Modes of catalytic regeneration in Diesel particulate filters. Ind. Eng. Chem. 1997, 36, 4155–5165. [Google Scholar] [CrossRef]

- Bisset, E.J. Mathematical model of the thermal regeneration of a wall-flow monolith diesel particulate filter. Chem. Eng. Sci. 1984, 39, 1233–1244. [Google Scholar] [CrossRef]

- Galindo, J.; Serrano, J.R.; Piqueras, P.; García-Afonso, O. Heat transfer modeling in honeycomb wall-flow diesel particulate filters. Energy 2012, 43, 201–213. [Google Scholar] [CrossRef]

- Payri, F.; Broatch, A.; Serrano, J.R.; Piqueras, P. Experimental-theoretical methodology for determination of inertial pressure drop distribution and pore structure properties in wall-flow diesel particulate filters (DPFs). Energy 2011, 36, 6731–6744. [Google Scholar] [CrossRef]

- Angiolini, E. Contribution to the Understanding of Filtration and Pressure Drop Phenomena in Wall-Flow DPFs. Ph.D. Thesis, Universitat Politècnica de València, València, Spain, 2017. [Google Scholar]

- Konstandopoulos, A.G.; Skaperdas, E.; Masoudi, M. Microstuctural properties of soot deposits in diesel particulate traps. SAE Tech. Pap. 2002. [Google Scholar] [CrossRef]

- Bermúdez, V.; Serrano, J.R.; Piqueras, P.; Campos, D. Analysis of the influence of pre-DPF water injection technique on pollutants emission. Energy 2015, 89, 778–792. [Google Scholar] [CrossRef]

| #A [33] | #B [34] | ||

|---|---|---|---|

| Diameter (D) | (mm) | 132 | 140 |

| Channel length (L) | (mm) | 200 | 230 |

| Honeycomb cell size (α) | (mm) | 1.48 | 1.42 |

| Porous wall thickness () | (mm) | 0.31 | 0.46 |

| Cell density (σ) | (cpsi) | 200 | 180 |

| Porosity () | (-) | 0.41 | 0.41 |

| Mean pore diameter () | (μm) | 12.1 | 18.55 |

| Permeability () | (×10−13 m2) | 2.49 | 5.85 |

| Type | HSDI Diesel Passenger Car |

|---|---|

| Emission standards | Euro 4 |

| Displacement | 1997 cm3 |

| Bore | 85 mm |

| Stroke | 88 mm |

| Number of cylinders | 4 in line |

| Number of valves | 4 per cylinder |

| Compression ratio | 18:1 |

| Maximum power @ speed | 100 kW @4000 rpm |

| Maximum torque @ speed | 320 Nm @ 1750 rpm |

| Aftertreatment | Close-coupled DOC + Underfloor DOC-DPF |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bermúdez, V.; Serrano, J.R.; Piqueras, P.; Sanchis, E.J. On the Impact of Particulate Matter Distribution on Pressure Drop of Wall-Flow Particulate Filters. Appl. Sci. 2017, 7, 234. https://doi.org/10.3390/app7030234

Bermúdez V, Serrano JR, Piqueras P, Sanchis EJ. On the Impact of Particulate Matter Distribution on Pressure Drop of Wall-Flow Particulate Filters. Applied Sciences. 2017; 7(3):234. https://doi.org/10.3390/app7030234

Chicago/Turabian StyleBermúdez, Vicente, José Ramón Serrano, Pedro Piqueras, and Enrique José Sanchis. 2017. "On the Impact of Particulate Matter Distribution on Pressure Drop of Wall-Flow Particulate Filters" Applied Sciences 7, no. 3: 234. https://doi.org/10.3390/app7030234