This study used the substitution ratio of BOF slag at 0%, 12%, 27% and 42% as coarse aggregate to substitute different aggregate gradation asphalt mixtures, with the time of dry mixing set at 15 s and 60 s for the wet mixing. The optimum asphalt content is determined from the average value of the corresponding asphalt contents to the maximum stability, the maximum unit weight, and 4% void rate, after calculating their optimum asphalt content, and creating the stability, with the test results being shown in

Table 6.

3.1. Optimum Asphalt Content

The optimum asphalt content of the asphalt mixtures should provide a mix with sufficient asphalt film thickness to provide good durability and avoid excessive asphalt drainage. The optimum asphalt content is determined from the average value of the corresponding asphalt contents to the maximum stability, the maximum unit weight and 4% void rate. Higher asphalt content might lead to a poor bonding behavior for aggregate. However, a lower asphalt content of mixtures will potentially be susceptible to rutting and cracking.

Optimum asphalt contents of dense, SMA, and PA-graded mixtures will be decreased when the BOF slag substituted proportion is increased. In BOF slag, the proportion of SiO

2 is less than in natural gravel. However, CaO occupies a higher proportion [

33,

34]. Since CaO is lipophilic, and BOF slag structure has higher surface area and porosity, which facilitates absorption by the asphalt cement to allow for the aggregate to bond with the asphalt more tightly [

13], and has proven BOF slag to be lipophilic, it can be easily absorbed and bond with asphalt cement. Chen et al. 2014 [

35] undertook similar research, which used the boiling water test to demonstrate, after BOF slag contacted with asphalt cement, it will form hydration products and the bonding behavior of BOF slag and asphalt cement; therefore, it can decrease the asphalt content demand on asphalt mixtures.

SMA and PA-graded were designed as the jumping gradation with less proportion of fine aggregate and need to fill a large number of asphalt cement in voids among aggregates; but with the substitution of BOF slag for natural aggregate, it could lower the quantity demanded for asphalt cement, as well as reduce the cost of asphalt binder.

3.2. Marshall Test Value

The Marshall Test variable values for the three asphalt mixture gradients containing different BOF slag contents are shown in

Table 6. In

Table 6, the stability of dense, SMA, and PA-graded asphalt mixtures will be increased with the increasing BOF slag substitution ratio. The apparent specific gravity of the BOF slag is greater than the traditional aggregate and has a better load-bearing capacity; the asphalt film attached to the aggregate surface is also thicker.

The stability of SMA and PA-graded asphalt mixtures is greater than that of the dense-graded ones. The stability of dense, SMA, and PA-graded mixtures were between 16.4 to 20 kN; 16.5 to 20.2 kN; and, 16.4 to 20.4 kN, respectively. The stability of all the asphalt mixtures complies with the minimum requirement value of 80 kN.

The flow value of asphalt mixture decreases with the increase in the BOF slag substitution ratio; furthermore, if the flow value is too high, it means that permanent deformation may easily result for the pavement, possibly causing the phenomenon of plastic flow. However, the flow value of SMA and PA mixtures is much higher than that of the dense-graded mixture, which might indicate that the porosity of SMA and PA gradation lack the fine aggregate filled void among the aggregate. As well, the optimum amount of asphalt cement is high; thus, relative skidding may easily occur among aggregates, increasing the flow value.

The unit weight of the asphalt mixture will increase with the increased BOF slag substitution ratio. BOF aggregate contains CaO, and its apparent specific gravity is greater than that of natural aggregate. Design coarse aggregate ratios of SMA and PA mixtures are more than that of the dense-graded mixture, and BOF slag was used to substitute for coarse aggregate; therefore, the unit weight of the asphalt mixture is obviously higher than that of the dense-graded one.

The void ratio is the ratio that is occupied by the void after mixing aggregate with an asphalt binder, and the specification is set at 3~5%. The results showed that the void ratio of asphalt mixture decreased with the increased BOF slag substitution ratio. Since SMA and PA mixtures lack fine aggregate to fill the voids among aggregate particles, mixtures need more asphalt binder to achieve void replacement so as to comply with the specification set at 3–5% for the asphalt mixture void ratio. Nevertheless, since the apparent specific gravity between BOF slag and natural aggregate differs from each other, the compaction energy would cause aggregate fracture in the rolling process, making the gap-aggregate for gradation. As a result, the aggregate particles of dense-graded asphalt mixture might be rearranged, leading to the plastic flow or causing an increased void ratio for the asphalt mixture.

VMA is the occupation percentage of void in compacted aggregates without adding asphalt, and the standard specification is set at 13–14% as the minimum value. Rutting permanent may result if the value is less than the minimum value. The results showed that the asphalt mixture VMA value decreased with the increased BOF slag substitution ratio. The VMA value of the SMA-graded mixture is greater than that of the dense and PA-graded ones. BOF slag has porous properties, and asphalt cement can easily be permeated into the aggregate. Additionally, the traditional Marshall Mix Design method for the jumping gradation can easily increase the asphalt content; thus, the VMA values can be used to investigate whether or not the optimum amount of asphalt deviates from those of the others.

The VMA value of PA asphalt mixture without adding BOF slag is 17.8%, while the VMA values for BOF substitution ratios 40% and 60% are 16.8% and 15.8%, respectively. For the high-ratio mixture of BOF and aggregate, the VMA value decreased with the increased asphalt content. There might be relative skidding in SMA and PA-graded mixtures due to more asphalt binders.

Based on the Marshall testing results of BOF mixtures, it is indicated that the mechanism properties were increased with the increasing BOF slag substitution ratio for each asphalt mixture. An amount of 60% BOF slag substitution has the best engineering performance for each asphalt mixture. However, because the unit weight of BOF slag was greater than the natural aggregate, in order to avoid breakage and cause the degradation of aggregate during the mixing process, a BOF slag replacement of 60% was the optimum substitution for dense mixture. The replacement of 40% of BOF slag was the optimum substitution for SMA and PA mixtures.

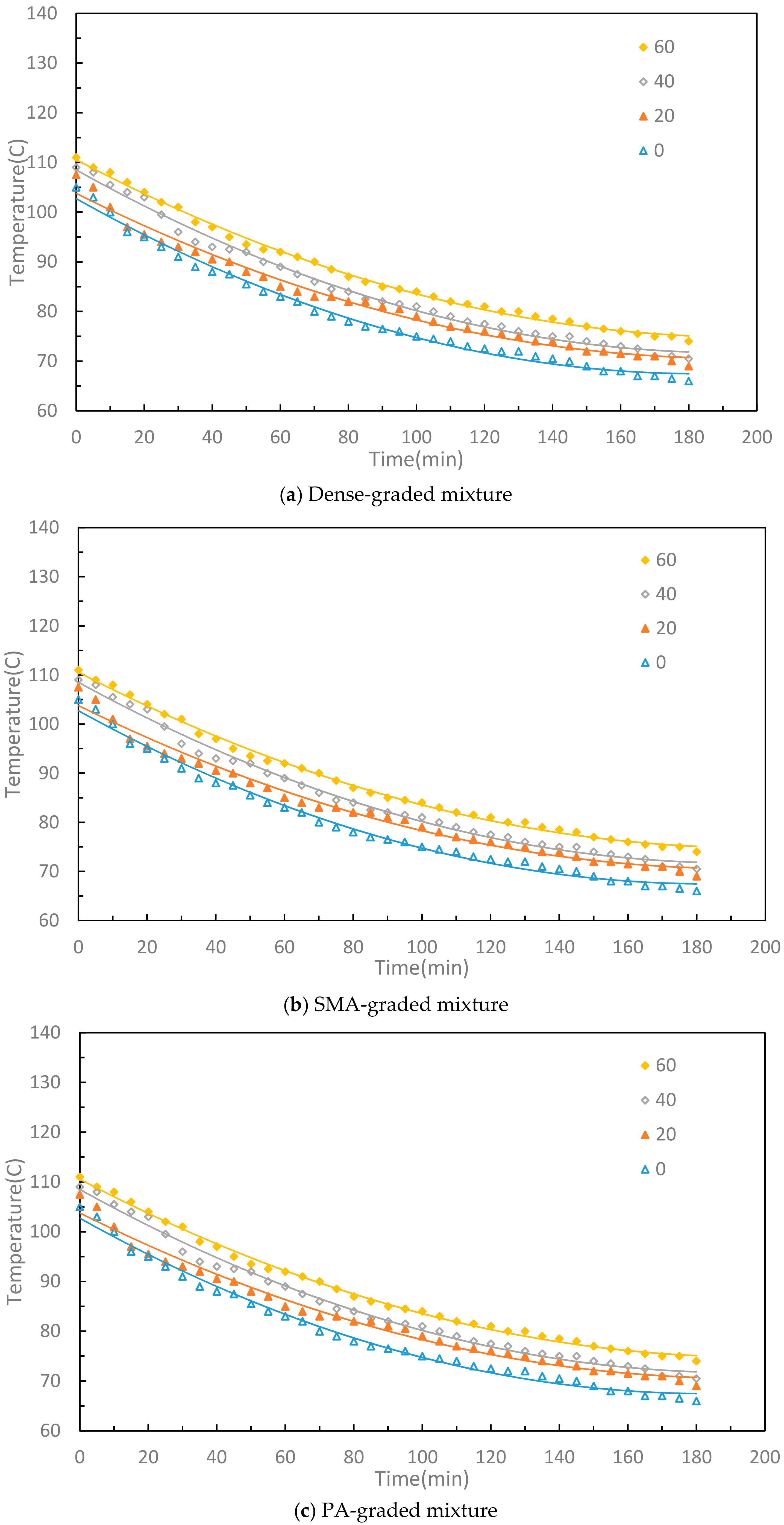

3.3. BOF Substitute Proportional Influence on Specimen Cooling

Figure 3 shows the temperature variations at different BOF slag substitution ratios in the specimens. Since the specimen surfaces were in contact with the air, the temperature dropped quickly. All of the specimens have a maximum cooling gradient in the initial high-temperature status. As seen in

Figure 3a, different amounts of BOF slag in dense-graded mixtures have a starting temperature of around 105–112 °C. The temperatures at the surface decreased quickly, but stabilized after 80–90 min. At the end of the measurements at 180 min, the mixtures contained 20% of BOF slag had reached a stable condition at a temperature of 67 °C. However, for BOF slag at 40% and 60%, the corresponding temperatures measured at 180 min were 69 °C and 74 °C, respectively.

Since the specimen is placed in a confined indoor space and the control room temperature is about 25 °C, the atmospheric temperature has only a slight effect on the cooling tendency among specimens. All of the specimens’ temperatures at 0 minutes are different.

As seen in of

Figure 3b,c, after SMA and PA-graded mixtures are cooled for 120 min, the temperature tended to moderate, indicating that the heat-releasing effect of SMA and PA-graded mixtures tended to moderate, with heat preservation effectiveness. Additionally, the cooling rate of SMA and PA-graded mixtures decreased with the increased substitute proportion of BOF slag, which is similar to the cooling effect of adding BOF slag in dense-graded mixtures, and the cooling rate decreased significantly. Similar replacement proportions of 0%, 20%, 40% and 60% had the temperature when compared at 180 min; where the temperatures of SMA gradation were 66 °C, 69 °C, 70 °C and 73 °C, respectively; the temperatures of the PA gradation were 68 °C, 69 °C, 70 °C and 74 °C, correspondingly.

After the compaction of asphalt specimens, the cooling temperature increased with the increased proportion of BOF slag, which means that besides having lipophilic qualities, BOF slag also has a heat preservation effect to maintain the temperature between aggregates, and facilitates the stable binding of asphalt with aggregate under sufficient temperature. The asphalt mixture used a high-proportion BOF aggregate; it needs to extend the heat to be released completely. The asphalt mixture can have highly stable properties. Furthermore, SMA and PA-graded mixtures are designed with a high proportion of coarse aggregate, and the aggregate skeleton is in direct contact between coarse aggregates to form the interlocking mechanism, as well as adding the high-proportion BOF as the coarse aggregate. Thus, the temperature can be preserved at the inter-contact status, and the cooling rate would be slow as well.

The purpose of this study was to estimate the cooling variable for each graded mixture and different BOF slag substitutions. Based on this, all of the specimens were placed in a confined space at room temperature and were maintained at 25 °C. The effects of different graded mixtures and slag substitutions on the cooling effect for each specimen are much higher than the atmospheric temperature.

3.4. The Effects of BOF Slag Contents on the Specimen Cooling Interval

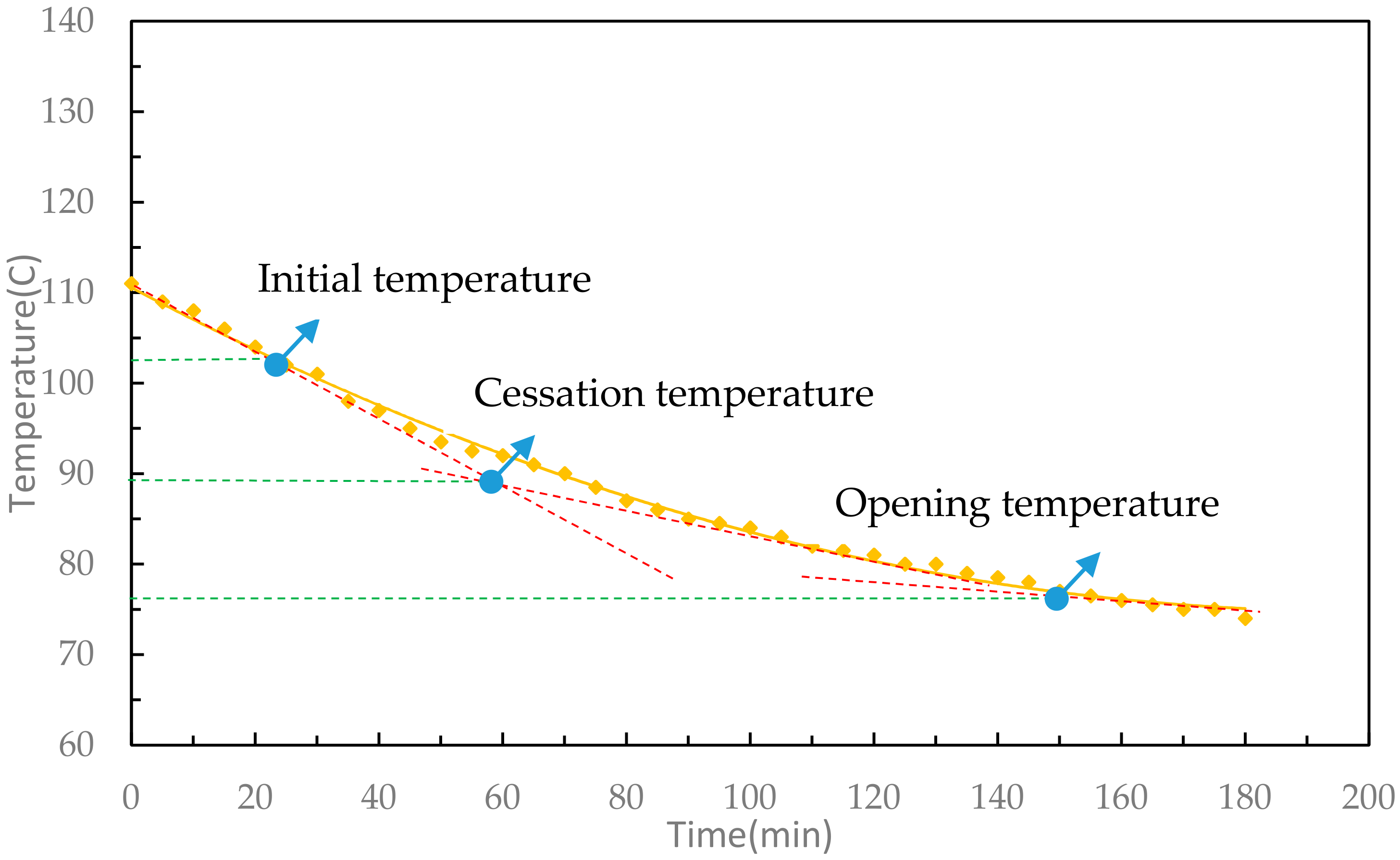

Huang and Lin (2011) established the three zones by the temperature-time curves: initial temperature, cessation temperature, and equilibrium temperature, respectively [

17], as can be seen in

Figure 4. The initial temperature zone represents the temperature changes from the time the asphalt mixtures leave the plant to the end of the compaction. The mixtures reach a more stable state at the cessation temperature. In addition, the equilibrium temperature indicated that the asphalt temperature could basically be the proper time to be ‘open to traffic’.

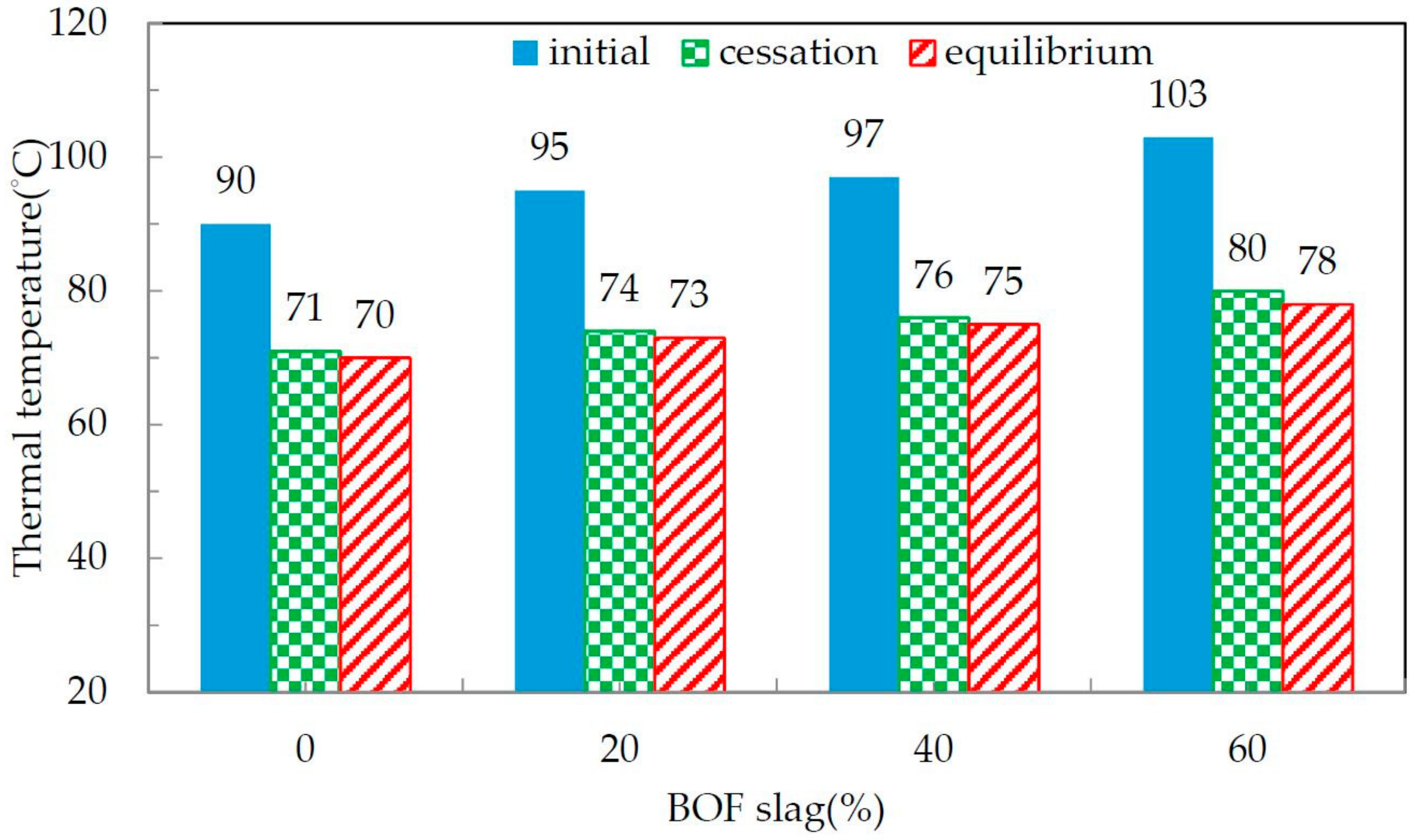

In this study, the temperature-time curves for mixtures containing various BOF slag content are shown in

Figure 5,

Figure 6 and

Figure 7. Temperatures corresponding to the three inflection points of the curve were defined as the points. From

Figure 5, it can be seen that the initial temperature on dense mixtures decreases as the BOF slag content increases. For a dense specimen without BOF slag, the initial temperature was 95°C; for a specimen with 60% BOF slag, the initial temperatures drops to 90 °C. This means that the BOF slag in the dense mixtures can store the thermal energy longer.

The cessation and equilibrium temperature increases as the BOF slag content increases. Willoughby et al. 2000 [

37] defined the cessation temperature as the asphalt mixture temperature at which the density of asphalt pavement cannot be improved with additional compaction effort. Based on this concept, for mixtures without and with 100% BOF slag, the cessation temperatures drop to 76 °C and 86 °C, respectively. The BOF slag in the dense mixtures could reach stability earlier at a higher temperature than those without BOF slag specimen. For mixtures without and with 60% BOF slag, the equilibrium temperature drops to 70 °C and 79 °C, respectively. This phenomenon indicates that the use of BOF slag has a stable nature, even if the equilibrium temperature is higher than the pure, dense specimen, about 9 °C, and it can be ‘open to traffic’ on asphalt pavement.

From

Figure 6, the initial, cessation, and equilibrium temperature on SMA mixtures increase as the BOF slag content increases. The mixture, which is made with a high amount of the coarse particles, forms a coarse aggregate skeleton. This increases the interlocking of the aggregates and provides better stone-to-stone contact, which serves as a load carrying mechanism, and, hence, provides better loading resistance. SMA specimen coarse aggregate particles form a stone-to-stone contact skeleton that can transfer thermal energy and increase all of the temperature zones. Moreover, cessation and equilibrium temperatures of the SMA mixtures were not significantly different. This indicates that asphalt mixtures with BOF slag can be compacted and opening at higher temperatures as compared with those without BOF slag.

From

Figure 7, the initial, cessation and equilibrium temperature on PA mixtures increase as the BOF slag content increases. A similar trend is also observed for the cooling interval within the SMA mixture. However, the PA mixture had a lower initial temperature interval than the SMA mixture. As mentioned earlier, for the mixtures with 40% and 60% of BOF slag, the VMA values of all the PA mixtures were higher than those of the SMA mixture, and, therefore, contain higher amounts of coarse aggregate ((19, 12.5 and 4.75 mm aggregate size). Asphalt mixtures increase the porosity and contain a higher amount of coarse aggregate, which decreases the thermal conductivity, resulting in a higher temperature. A similar trend is also observed in the study results of Mohajerani et al. 2017 [

38].

3.5. Void Distribution of the Asphalt Mixture

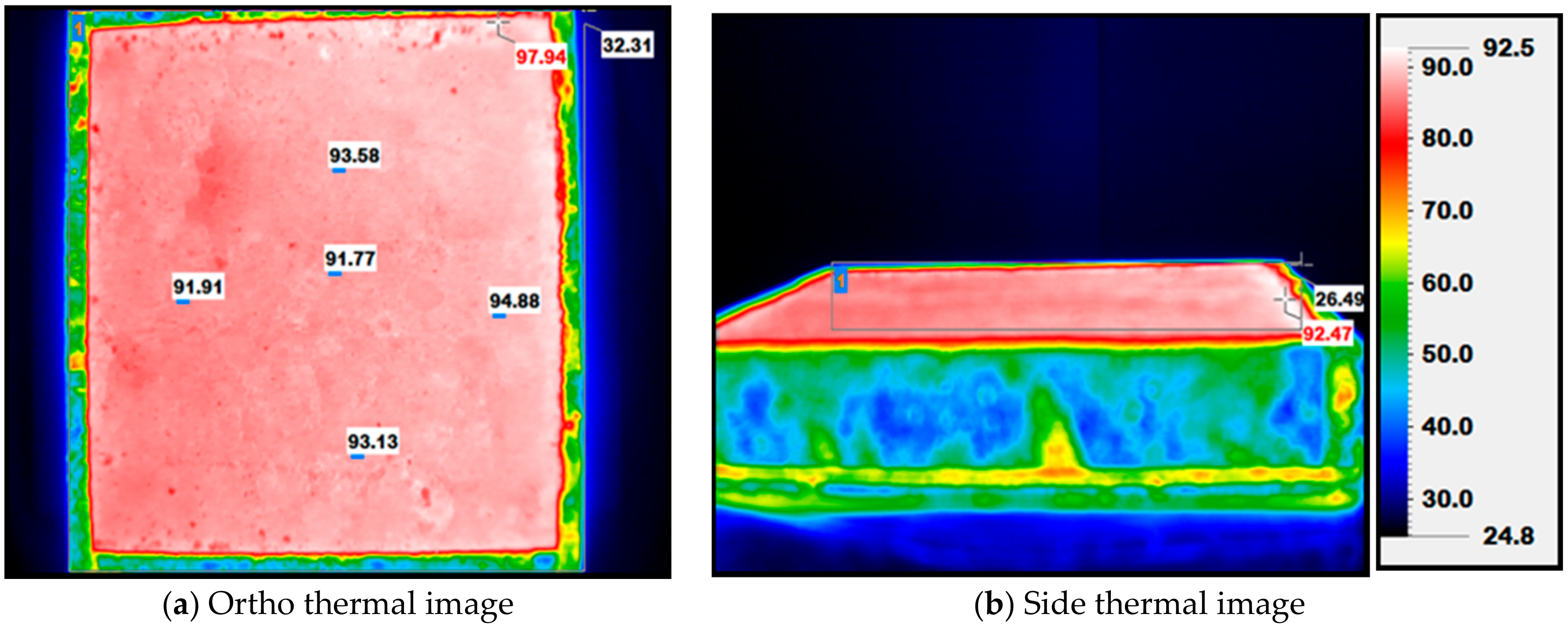

This study used infrared thermal imaging photos to prove the void distribution of the specimen by adding 40% BOF aggregate into three asphalt mixture gradations, for example, when comparing the cooling time at the 60th minute. As shown in

Figure 8a, the dense mixture surface temperature image shows the center temperature of the specimen to be 91.7 °C; the temperature at the right side of the specimen is 94.8 °C. Since the heat exchange process would be transferred to the area with more voids, it is determined that the right side of the specimen may have more voids.

Based on measuring of the surface and internal temperatures from the sides of the dense mixture, as shown in

Figure 8b, it is found that the surface temperature of the specimen is about 92.4°C, and its internal temperature cooling rate is fast. The yellow area is about 60–70 °C, which shows that after compacting the pavement in the cooling phase, the internal heat energy of asphalt mixture is continuously transferred upward; therefore, the surface temperature of pavement was higher than the internal one. In measuring the test results, as expected, for dense mixture, there was a significant difference between the internal and surface temperatures. Furthermore, from the thermal image, it can be determined that the distribution of voids of dense mixture is not uniform and the thermal energy temperature is inconsistent. This indicates that the non-uniform distribution of the voids on dense mixture caused the cooling process to decrease the loading resistance.

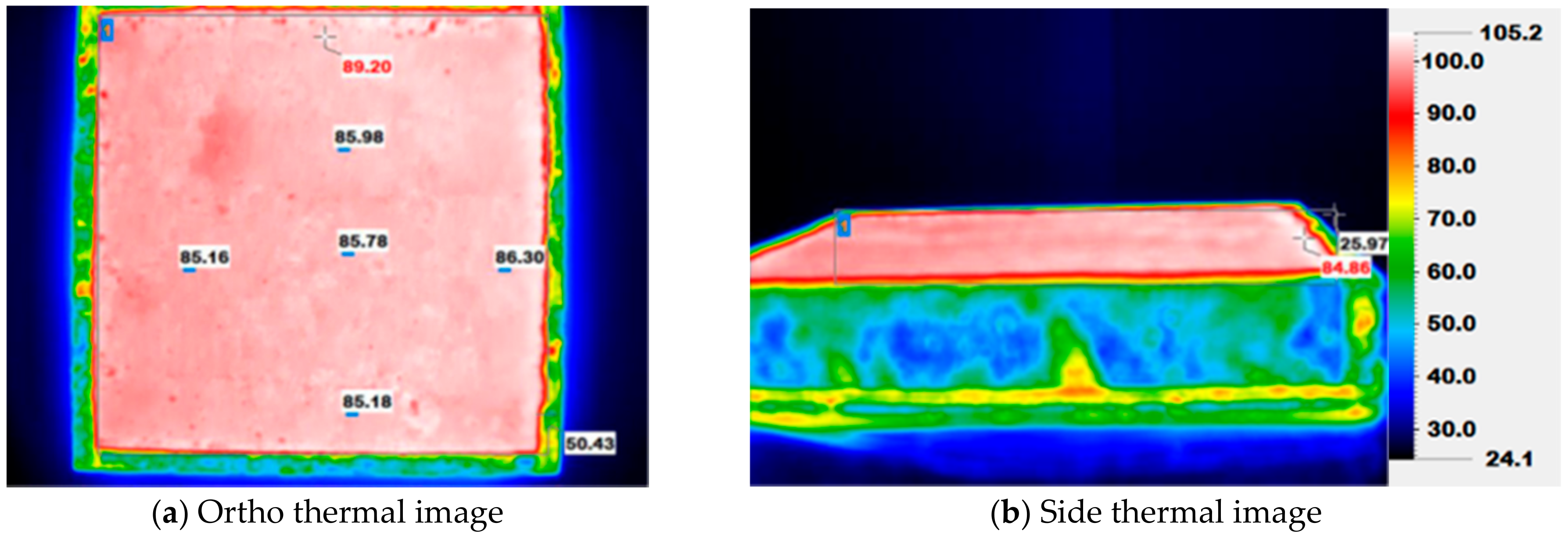

From

Figure 9a, it can be found that the center temperature of the SMA specimen was 85.78 °C; those temperatures around the sides without any significant difference were about 85.16–85.98 °C, meaning that the internal void of the SMA mixture was more uniform than that of the dense mixture. The characteristic of the asphalt binder exhibits viscous-plastic behavior at a higher temperature. Thus, the film of the asphalt binder can be filled with voids during the high-temperature mixing process, and it would have smaller voids and heat energy that might not be easily dissipated. Observed from the side thermal image, as shown in

Figure 9b, the SMA mixture heat can be transferred from the internal space up to the surface of the specimen. Since its internal voids are more uniform, its internal heat energy (yellow area) area occupied a larger range (60–80 °C); this showed that, in the cooling phase, the uniform void distribution can maintain the temperature with a slower heat dissipation rate than that of the dense mixture.

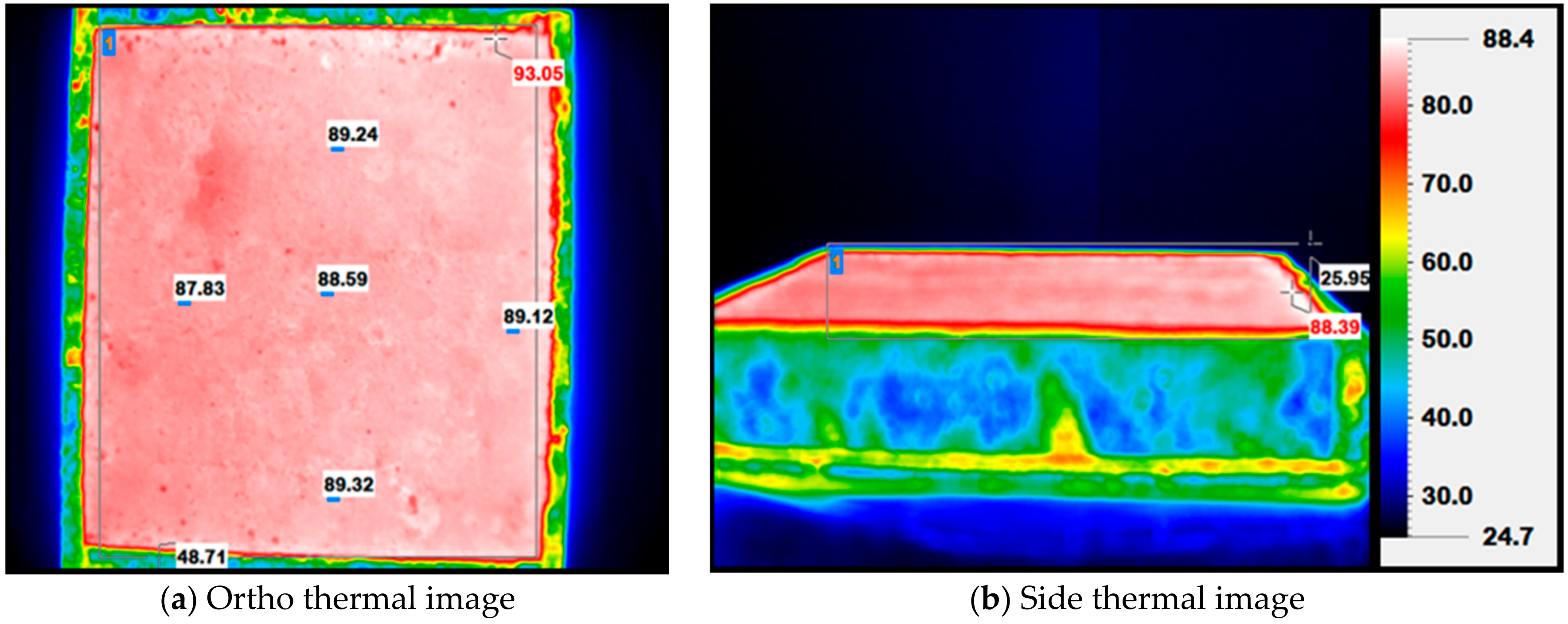

As shown in

Figure 10a, when the center temperature of the PA mixture is 88.59 °C, temperatures at the sides without any significant difference are about 89.12–87.83 °C. A similar trend is also observed for the SMA mixture. In

Figure 10b, the internal heat energy (yellow area) area on the PA specimen is more significant (60–80 °C), which means that after adding BOF slag into the PA mixture, it increased the heat preservation effect of BOF slag with a slower cooling rate, promoting the bonding capacity for the PA mixture.