1. Introduction

Thermoelectric generation is a well-known way of converting waste heat into electrical energy by the Seebeck effect. Thermoelectric generation has many advantages, mainly because thermoelectric systems have no moving parts and also are compact in size and easy to apply anywhere. However, thermoelectric materials are relatively lower in efficiency than other waste heat recovery methods such as organic rankine cycle (ORC) or alkali-metal thermal to electric converter (AMTEC). Recently, thermoelectric materials have shown great advances in the figure of merit (ZT), especially for intermediate-temperature (600~1000 K) thermoelectric materials, through nano-structured material, band structure engineering, and grain boundary engineering. Skutterudite, a well-known intermediate-temperature thermoelectric material, shows a relatively high ZT of 1.6 at 800 K for n-type case, and 1.3 at 775 K for p-type case by nano-structuring [

1]. PbTe also shows peak ZT of 2.5 at 923 K, and average ZT 1.67 between 300 and 900 K which is due largely to its band structure engineering and nano-structuring [

2]. SnSe also stands out for the record-high ZT of 2.6 at 923 K which is attributed to the ultra-low lattice thermal conductivity caused by a layered structure [

3]. Many studies have been conducted to further investigate the thermoelectric properties of SnSe and also to develop the n-type SnSe, polycrystalline SnSe, and so on. Nonetheless, few studies have been reported on the SnSe thermoelectric devices or modules and their fabrication processing.

The fabrication processes of thermoelectric devices or modules are typically composed of material sintering, metallization, slicing, cutting, and bonding to electrodes and substrates. The metallization of thermoelectric materials is regarded as one of the most important processes because the high electrical and thermal contact resistances at the interface can significantly degrade the power output. The formation of the metallization layer should be made to lower the contact resistance as well as prevent inter-diffusion of composed elements. The Wang group investigated SnSe and metal contacts using the first-principle calculation which discovered that Ag, Au, and Ta contacts would make stable contact with SnSe due to its small lattice mismatch [

4]. Our group reported that the metallization of SnSe with an Ag and Ni bi-layer could lead to the formation of the thick intermetallic compounds, which act as a diffusion barrier, but it could be a reason for increasing the electrical contact resistance [

5].

In this work, the implementation of the single-layer metallization on the p-type polycrystalline SnSe thermoelectric material resulted in some drawbacks such as undesirable interfacial cracks and elemental diffusion. To overcome its drawbacks, we proposed a new metallization technique to form the multi-layer structure composed of Ag/Co/Ti layers. This Ag/Co/Ti multi-layered structure was demonstrated a relatively lower specific contact resistance and also acted as a good diffusion barrier for the SnSe thermoelectric material.

2. Experiments

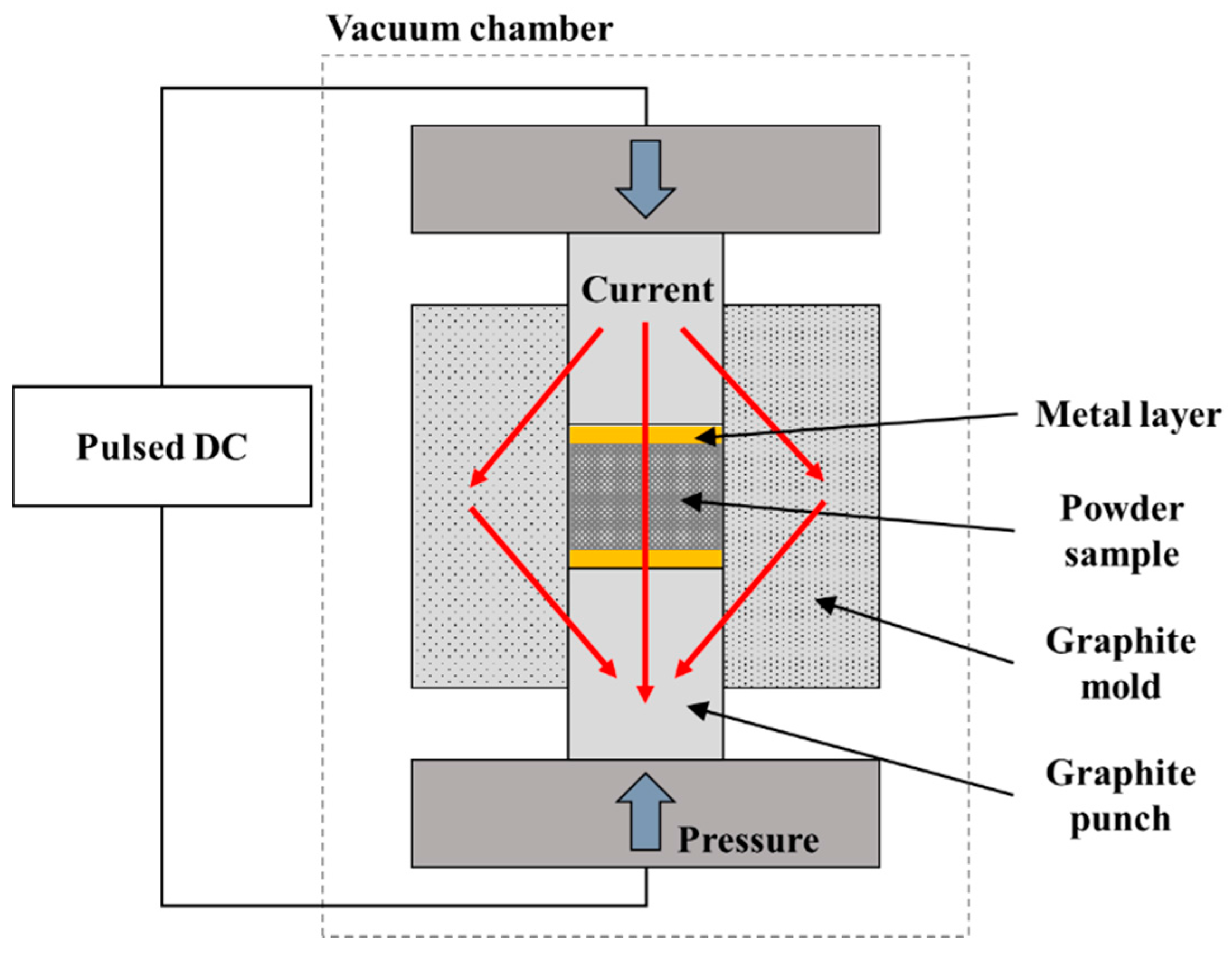

For the synthesis of pure SnSe ingots, a stoichiometric amount of the Sn (99.5%, Alfa Aesar, Haverhill, MA, USA) and Se (99.5%, Alfa Aesar) mixture powder was loaded into a fused silica tube and then it was heated up to 1220 K and held at the same temperature for 24 h under a vacuum condition. The pure SnSe ingots were pulverized manually with a mortar and pestle and then the pulverized powder was passed through a sieve to obtain a mixture powder of less than 45 μm. For the single-layer metallization on SnSe, a set of Ag powder (325 mesh, 99.99%, Sigma-Aldrich, St. Louis, MO, USA), Ni powder (325 mesh, 99.8%, Alfa Aesar), Ti powder (325 mesh, 99.99%, Alfa Aesar) was prepared. The spark plasma sintering (SPS, Fuji Electronic Industrial Co., Ltd., Kyoto, Japan) system was used to perform the SnSe sintering and metallization at the same time as shown in

Figure 1.

A previous study [

5] reported that both the metal powder and foil metallization methods showed no big differences on their interface bonding and electrical properties. Thus, for the multi-layer metallization, we prepared different metal foils such as Ag foil (25 μm, 99.99%, Alfa Aesar), Co foil (50 μm, 99.99%, Alfa Aesar), and Ti foil (50 μm, 99.99%, Alfa Aesar) with the intention of making regular interfaces over the entire region which are easily distinguishable from one another. The SnSe powder was sintered together with metallic layers at 550 °C for 10 min with 40 MPa pressure. This sintering step completed the formation of metallized SnSe ingots. In order to investigate their interfaces, SnSe ingots were cut into several small thermoelectric legs using a diamond wire saw. The microstructures of the interfaces were analyzed using a scanning electron microscope (SEM, Hitachi, Tokyo, Japan). The composition distributions of SnSe and metal elements were investigated using an energy dispersive spectroscopy (EDS) line-scan (Hitachi, Tokyo, Japan). The EDS line scan was conducted several times to verify that interface characteristics are almost the same over the entire region. Heat treatments were conducted at 723 K in an Ar atmosphere to verify the thermal stability of metallization interfaces [

6,

7]. To understand the effects of heat treatments, the electrical contact resistances were measured before and after heat treatments by home-made resistance scanning measurement equipment [

8].

3. Results and Discussion

A metallization process is performed to form a metallic layer on the SnSe thermoelectric material and the formed metallic layer should act as a high electrical and thermal conductive layer as well as an inter-diffusion barrier layer. The Ag, Ni, or Ti metal layers were selected to make a single metallic layer each on SnSe because Ag has high electrical conductivity, and both Ni and Ti are well-known diffusion barrier materials [

9,

10,

11,

12,

13]. Because the sintering temperature of SnSe was already determined according to the optimized material properties, the metallization in this work was also conducted using SPS at the similar sintering condition. The bonding interfaces and element distributions were analyzed, as shown in

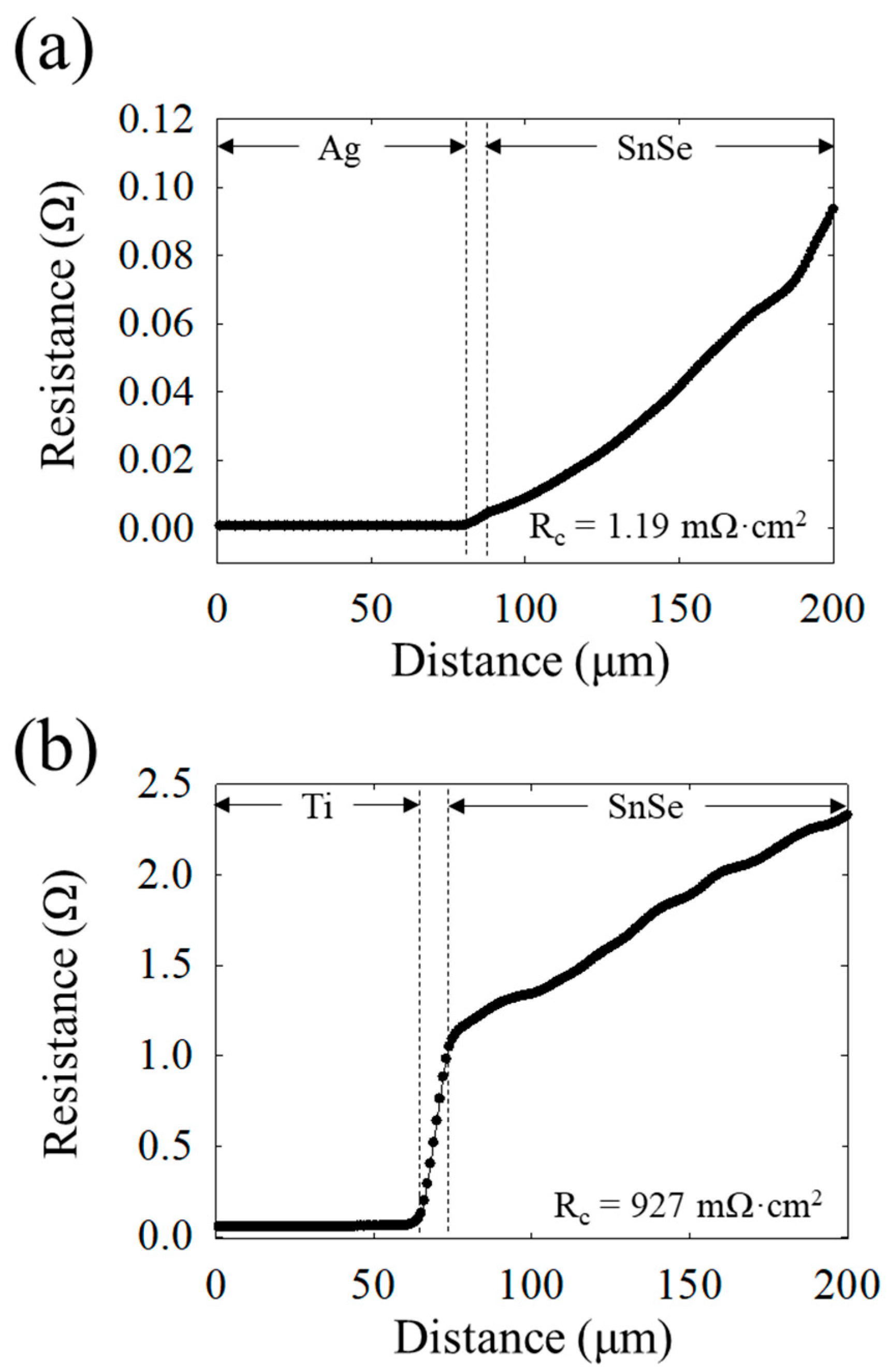

Figure 2.

The Ni single-layer metallization formed a thick intermetallic compound (IMC) composed of Ni

5.63SnSe

2 and Ni

3Sn alloys, shown in

Figure 2a. These alloys are different in their crystal structures and cell sizes, causing severe cracks across the interfaces between the Ni and IMC layers. This indicates clearly that Ni is not suitable for SnSe metallization. On the other hand, both Ag and Ti layers were bonded robustly with SnSe without any cracks or delamination at the interfaces. However, the Sn element of SnSe was diffused into the Ag layer, as shown in

Figure 2b. This means that Sn could diffuse continuously into the Ag layer at the operating temperature, possibly degrading the thermoelectric property of SnSe. The Ti layer could prevent the Sn diffusion effectively, as shown in

Figure 2c.

The effect of the metallization on electrical contact property was also investigated by the specific contact resistance (SCR). In general, the SCR is defined by R

sc = R

c·A where A is an interfacial area and R

c is the resistance difference between thermoelectric materials and metallization layers. The metallized SnSe ingots were cut into rectangular-shaped segments to measure their interfacial areas easily.

Figure 3a,b present the resistance versus distance relations for the Ag and Ti metallization layers.

The SCR of the Ni metallization layer could not be measured mainly due to the severe cracks. The SCR measurement results for Ag and Ti were 1.19 and 927 mΩ∙cm2, respectively. The Ti metallization layer was bonded mechanically well with SnSe, but the electrical contact property was poor, causing a degradation of the thermoelectric power output.

In general, the SCRs of the intermediate-temperature thermoelectric legs need to be lower than 10

−5 Ω∙cm

2 in order to prevent any significant degradation of power output by any contact loss. However, this should be considered as the ratio of the resistance of thermoelectric materials to the contact resistance. The SnSe material shows a high ZT value due to its high Seebeck coefficient and low thermal conductivity, but its electrical conductivity is much lower than those of other intermediate-temperature materials, as shown in

Table 1.

The electrical conductivities of skutterudite and half-Heusler, both well-known intermediate-temperature thermoelectric materials, are above 1000 S/cm in overall temperature ranges [

1,

14]. The electrical conductivity of SnSe is only 18.1 S/cm, indicating that it is not necessary to have low SCR as in other materials [

15]. As a result, several 10

−3 Ω∙cm

2 SCR of SnSe thermoelectric material could be approximated to be the same as the 10

−4~10

−5 Ω∙cm

2 SCR of skutterudite and half-Heusler thermoelectric materials. The relation between the SCR and power output for the SnSe is calculated by the finite element method, as shown in

Figure 4.

The 8-couple SnSe thermoelectric module was designed to be 20 × 20 mm2 in size. The hot and cold side temperatures were 873 K and 293 K, respectively. When we define the SCR of 10−7 Ω∙cm2 as making no significant electrical contact loss, the power output is decreased about 1.9% for Ag and 86.6% for Ti metallization layer for the respective SCRs. Therefore, the Ag metallization, where the SCR is 1.15 mΩ∙cm2, is acceptable in contact resistance for SnSe legs and devices.

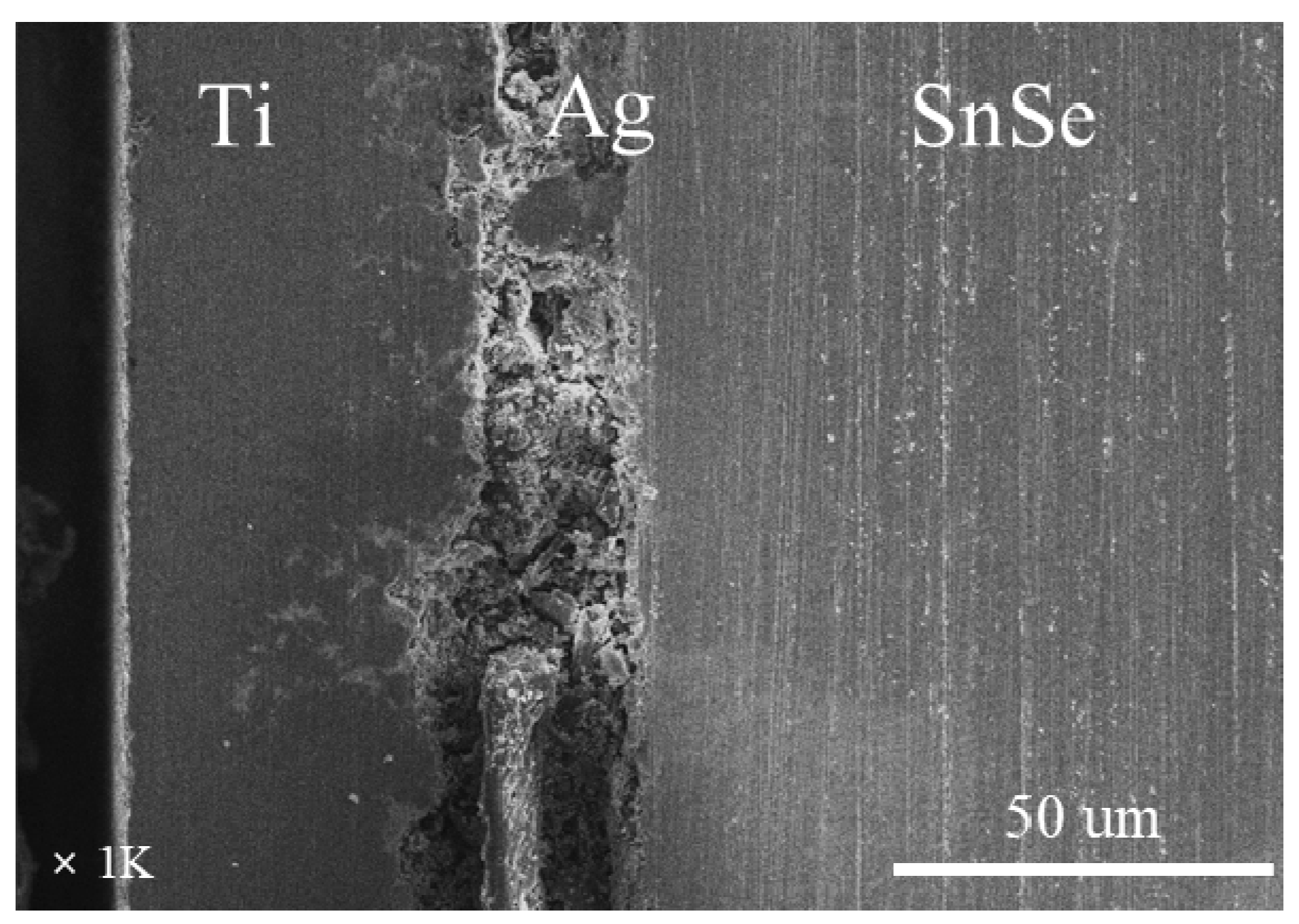

The analysis results show that it is difficult to apply a single metallization layer on the SnSe thermoelectric material due to its interface cracks, element diffusion, or high electrical contact resistivity. In order to complement these drawbacks, a multi-layer metallization technique was used in this work. Based on the single-layer metallization experiments, it is found that Ag can be used as a metallic contact layer and Ti can be used as a diffusion barrier. The Ag/Ti bi-layer was formed on SnSe and the interfacial cracks were found to exist at the interface between Ag and Ti layers, as shown in

Figure 5.

The bi-layer metallization seems unsuitable mainly because the difference in the coefficient of thermal expansion (CTE) between Ag (18.9 × 10

−6 K

−1) and Ti (8.6 × 10

−6 K

−1) is so large that an interfacial thermal stress is induced. To resolve this issue, as a buffer layer, we used the Co layer where CTE is 13 × 10

−6 K

−1. Finally, the interface characteristics of the Ag/Co/Ti multi-layer metallization were analyzed by EDS line scanning and SCR, as shown in

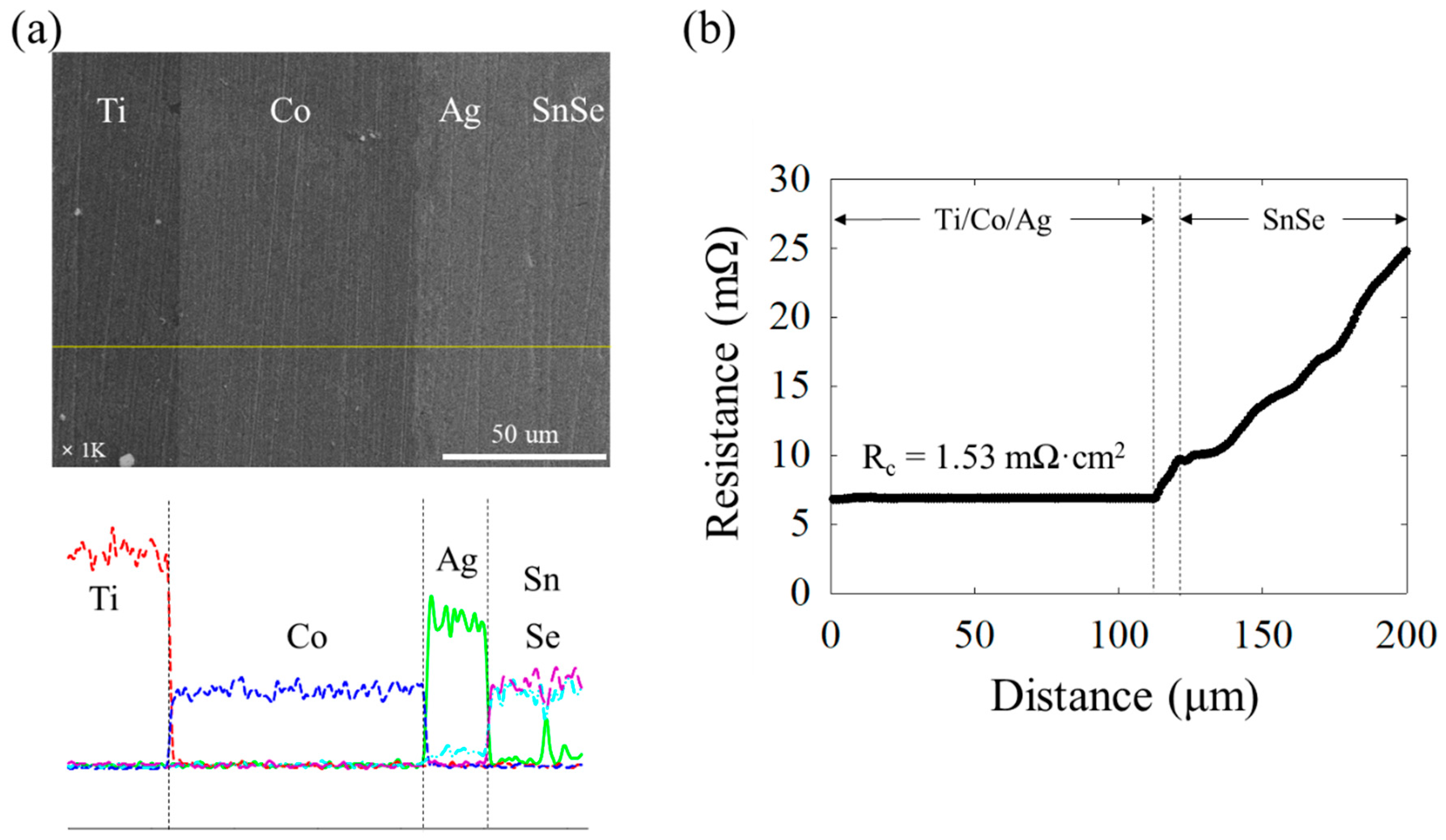

Figure 6a,b.

The metallization layers and SnSe are bonded robustly and their interfaces are clearly distinguished by EDS line scanning. The Sn and Se elements are not diffused into the Co and Ti layers. The SCR of the Ag/Co/Ti multi-layer is 1.53 mΩ∙cm2 which is similar to that of the Ag single-layer. The multi-layer metallization can simultaneously achieve both high electrical contact and good diffusion barrier properties.

In order to verify the thermal stability of the multi-layer metallization, heat treatments were conducted at 723 K for 20 h under an Ar atmosphere. The Ag/Co/Ti multi-layer structure was maintained robustly and the IMC of each interface did not increase even after heat treatment, as shown in

Figure 7a.

However, the EDS line scanning analysis revealed that the Sn and Se elements were diffused into the Ag layer which could lead to a slight increase in SCR of 2.27 mΩ∙cm

2 in

Figure 7b. As shown in

Figure 4, the 20 h heat treatments may cause a negligible reduction in power output of about 0.5%.