Evaluation of Interlaminar Stresses in Composite Laminates with a Bolt-Filled Hole Using a Linear Elastic Traction-Separation Description

Abstract

:1. Introduction

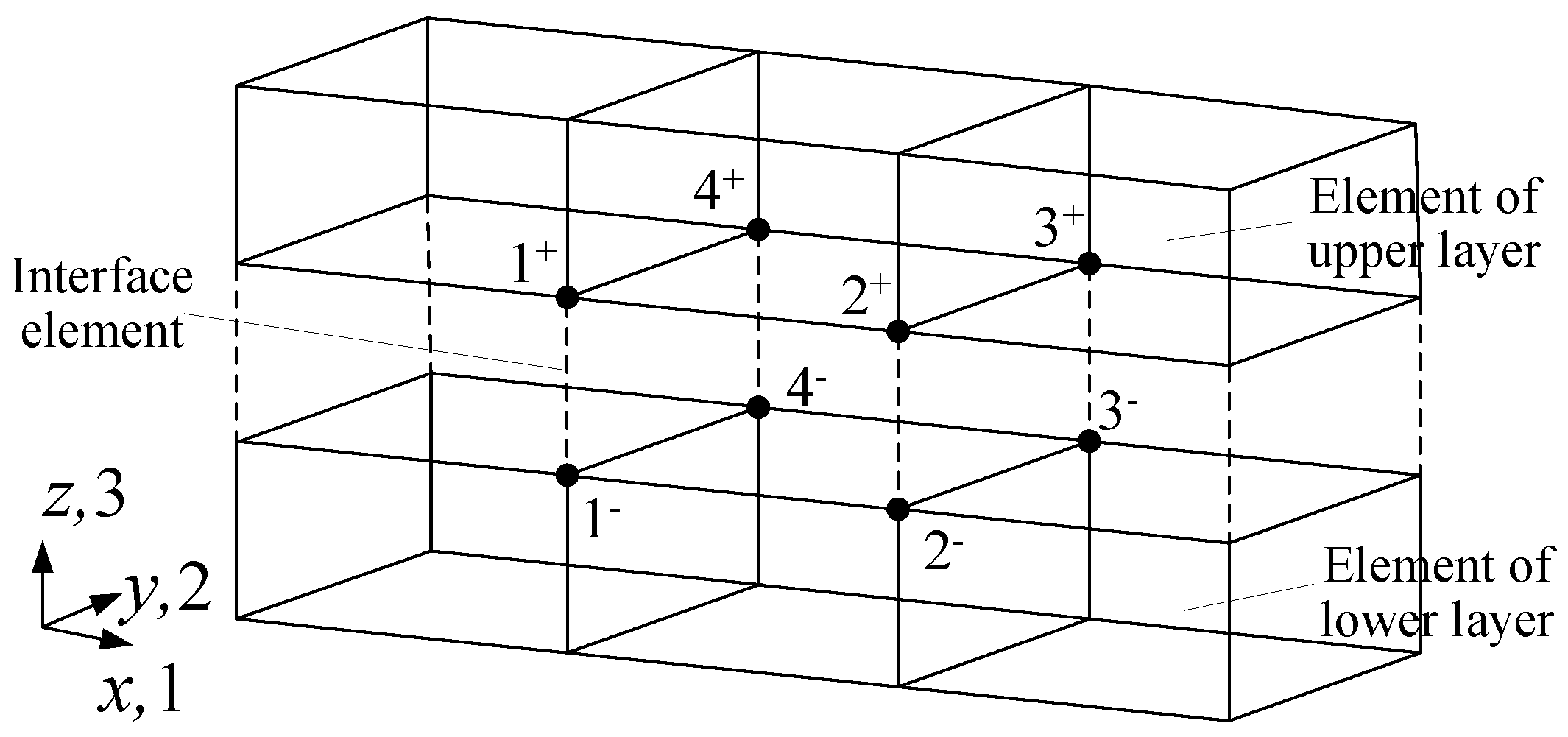

2. Linear Elastic Traction-Separation Constitutive Behavior of the Interface Model

3. Verification of the Interface Model with a Benchmark Problem

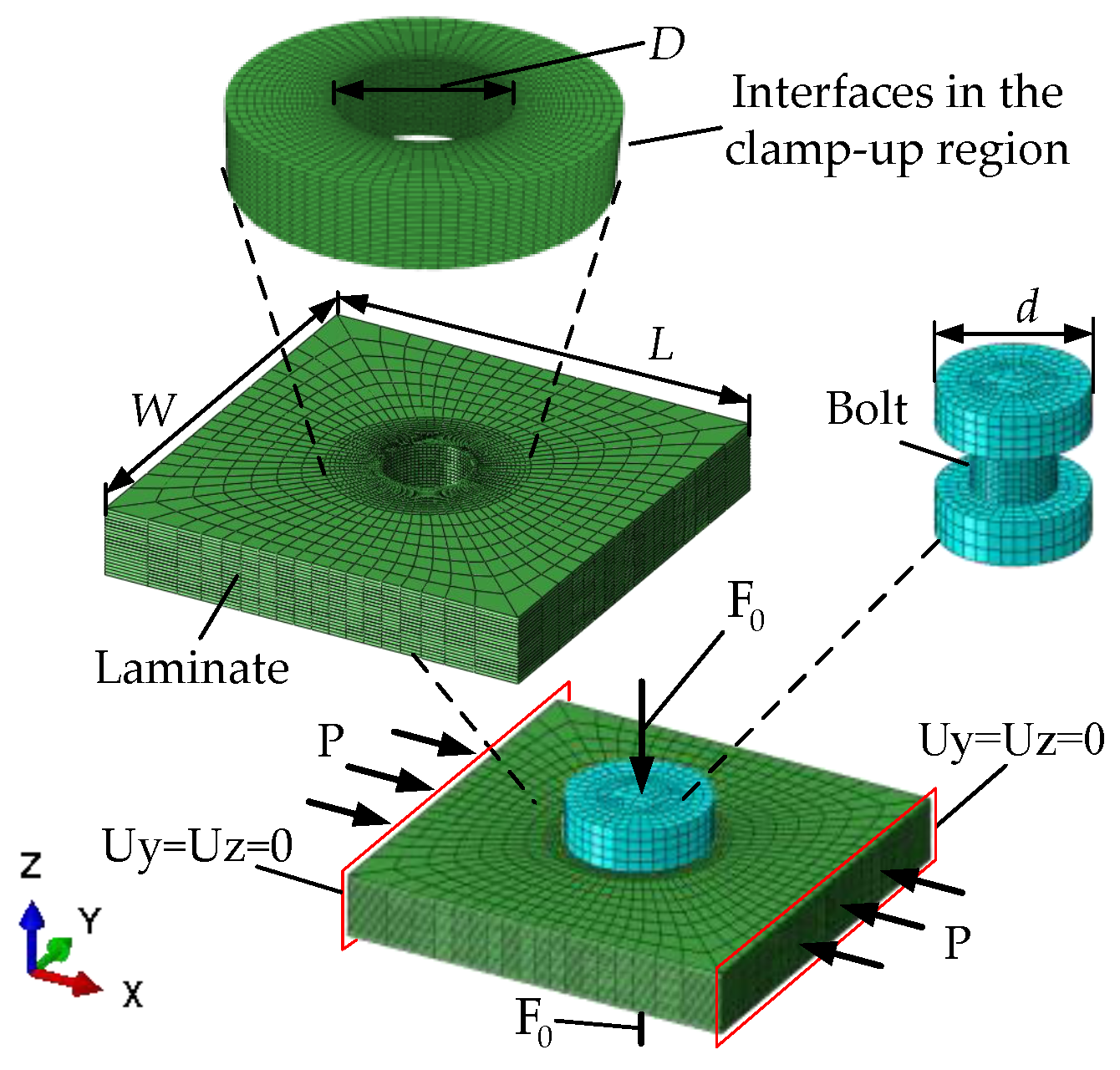

4. FEM of Composite Laminates with a Bolt-Filled Hole

5. Results

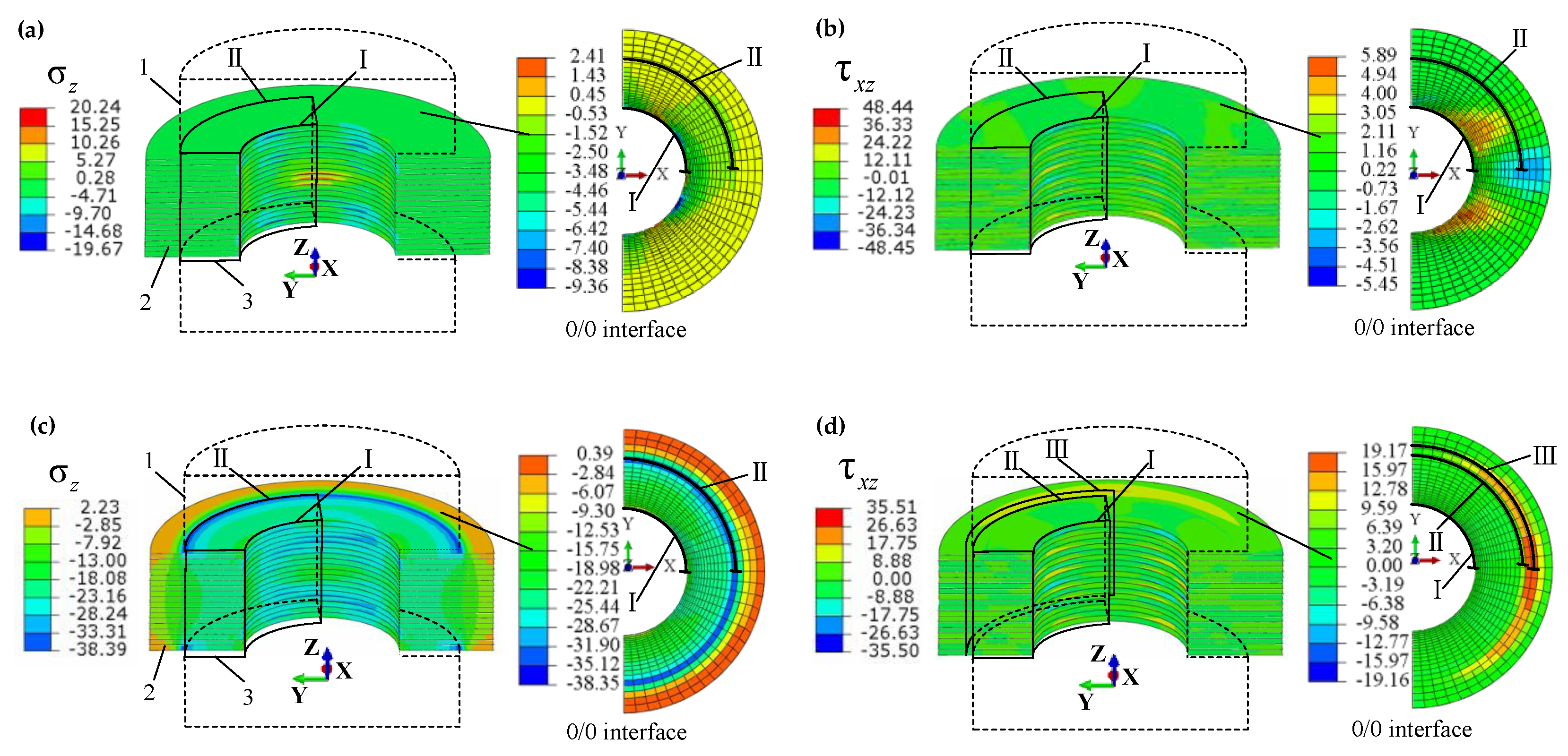

5.1. Interlaminar Stress Distributions in the Filled-Hole Laminate near the Hole

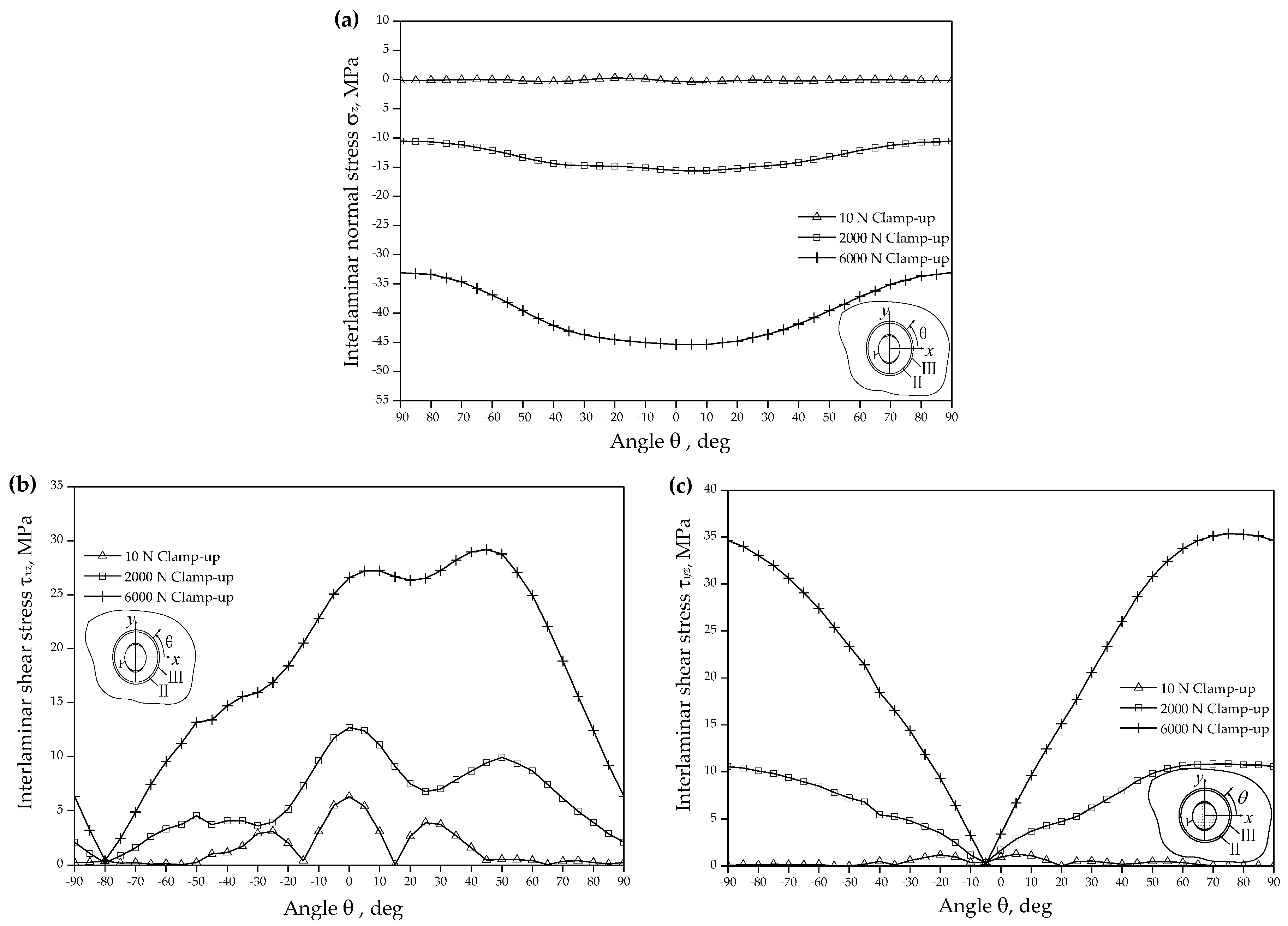

- For the non-tightened bolt case (clamping force F0 = 10 N), interlaminar stress concentrations mainly occur around the hole edge (Figure 6a,b, Position I), and tapers out at the interior of the laminate. This prediction is consistent with the previous phenomenon that laminated composites often exhibit transverse stress concentrations near material and geometric discontinuities (the so-called free-edge effect) [1]. In spite of the bolt, Position I can still be considered as geometric discontinuities, and the free-edge effects are observed here.

- For the tightened bolt case (clamping force F0 = 2000 N), the results show that the interlaminar stress concentrations in the filled-hole laminate occur at Position I, as well as the interior of the laminate near the periphery of the bolt head (Figure 6c,d, Position II). Note that Position II of the laminate is not a free edge. However, traditionally, the free edge effect is only a concern near the free edge of the laminate, and decay to zero as the distance from the free edge increases. is a negative value in the clamp-up region, in other words, is interlaminar compressive stress. According to Reference [41], the compression interlaminar stress is able to delay the delamination initiation.

- It should also be noted that the stress concentrations of and near Position II are not in the same circumference locations. The former at Position II is shown in Figure 6c,d. The latter is located near Position II, which is away from the hole in the in-plane direction, this position in the laminate is defined as Position III, as presented in Figure 6d.

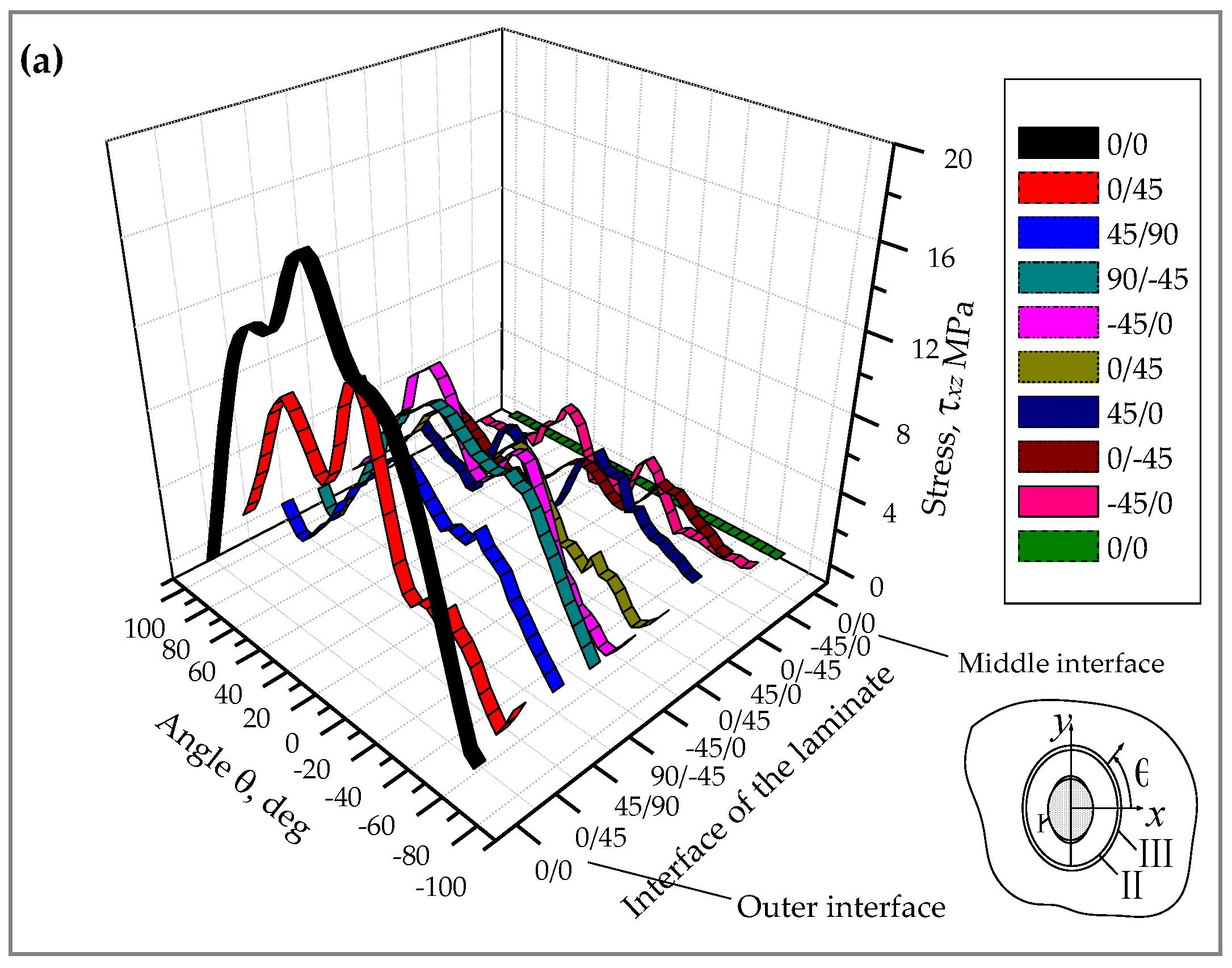

5.2. Stress Distributions at Each Interface around the Hole Edge and the Periphery of Bolt Head

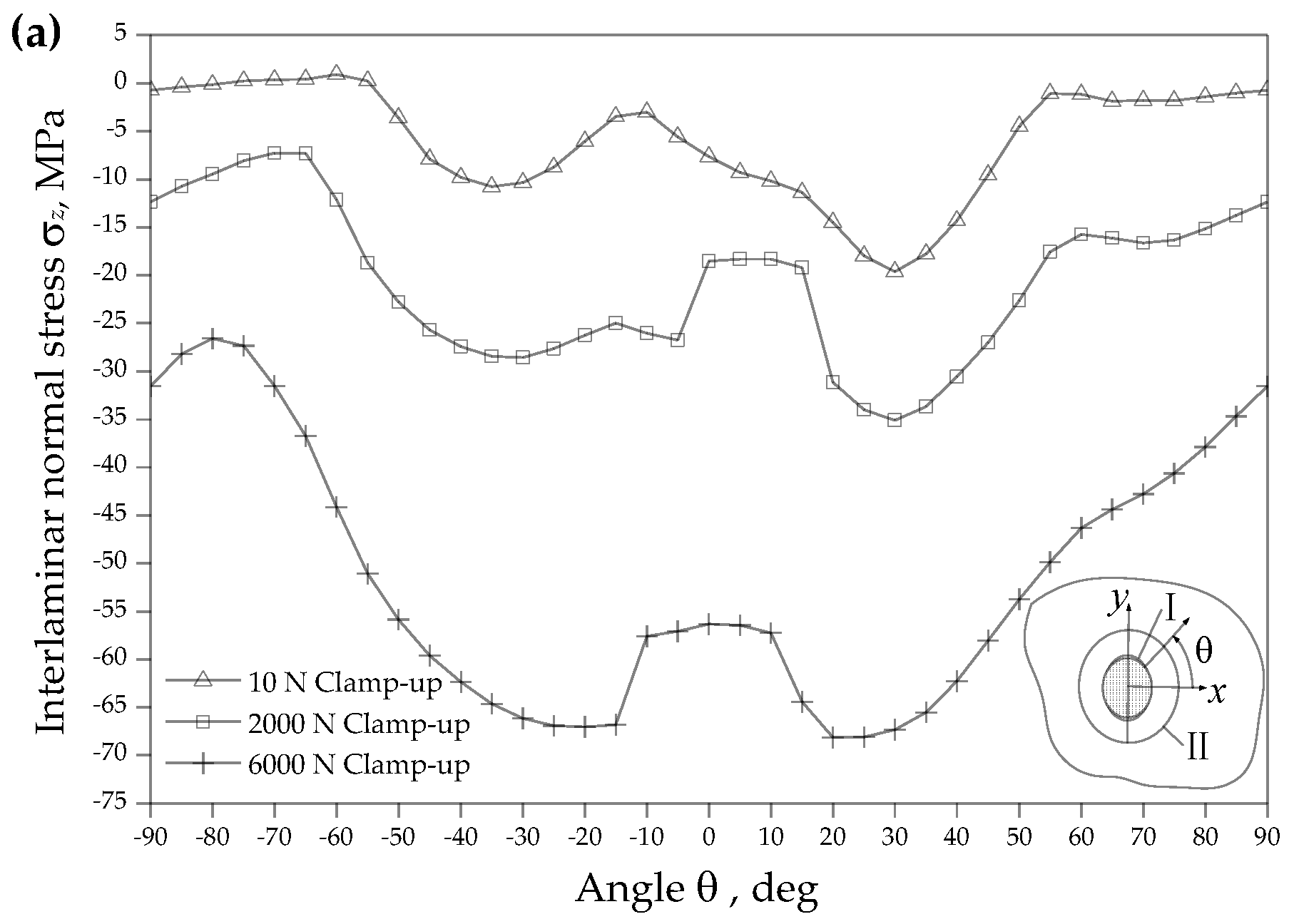

5.3. Stress Distributions at the 0/45 Interface near the Hole under Different Clamp-Up Load

- The interlaminar normal stress rises with increased clamp-up load in all regions of Position I at the 0/45 interface (Figure 9a). In addition, also shows interlaminar compressive stress at Position I for the case of F0 = 6000 N.

- A higher clamping force results in lower interlaminar shear stresses for most of the region around Position I (Figure 9b,c). This area is in the region around −80° < θ <−10° and 10° < θ < 55°. For the other areas around the hole, such as the region near θ = 0°, the interlaminar shear stresses almost become zero, regardless of the kind of bolt clamp-up load mentioned in this paper.

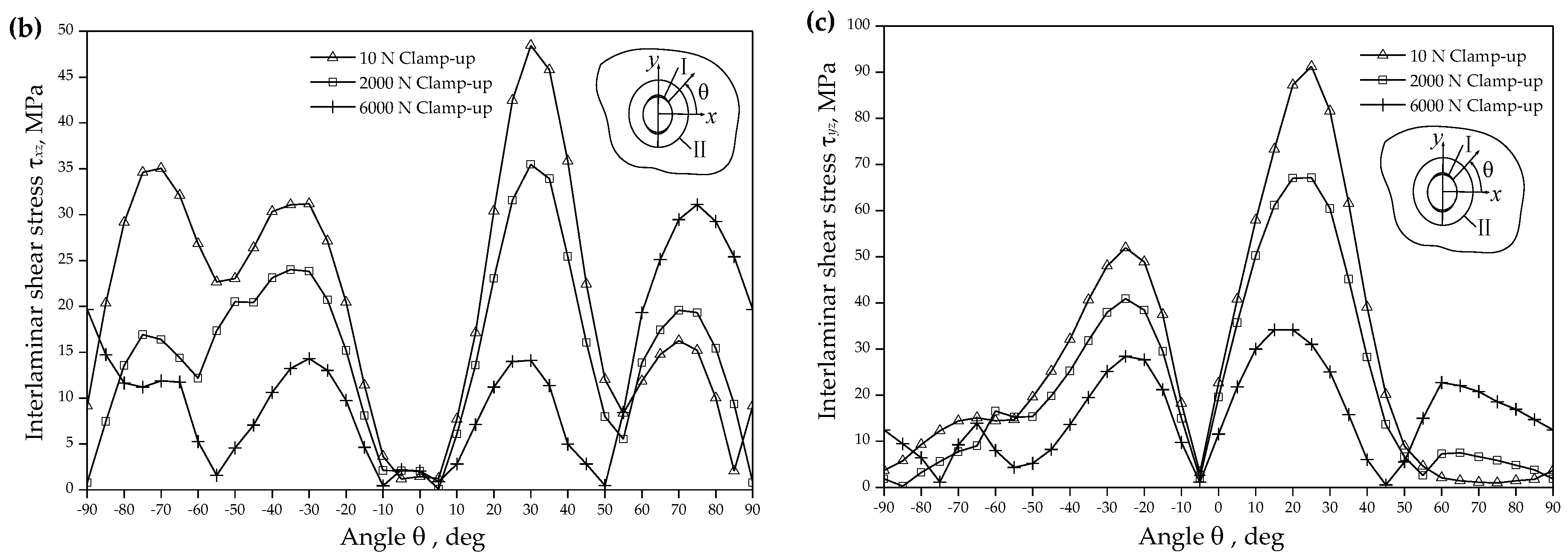

- For the clamping force F0 = 10 N, both the interlaminar normal and shear stresses are almost zero in most areas at Position III, except in region −50° < θ < 45°. This is consistent with the results obtained in Section 5.1.

- With the increase in clamp-up load, both interlaminar normal stress (Figure 10a) and interlaminar shear stresses (Figure 10b,c) increase in most of the circular region. This is different from the interlaminar stress distributions in the laminate at Position I. At Position III, the phenomenon of the interlaminar shear stress reduction does not appear with the increase in clamp-up load. In contrast, shear stress increases with the increase of the clamping force.

6. Discussion

7. Conclusions

- For the filled-hole laminate with tightened clamp-up load, the tightened bolt will change the interlaminar stress distribution state in the filled-hole laminate. The interlaminar stress concentration occurs both at the hole edge and the laminate interior near the outer edge of the bolt head. This phenomenon is different from the traditional free edge effect of an open-hole laminate. Correspondingly, for the case of non-tightened bolts, the interlaminar stress concentration only occurs near the hole edge.

- The interlaminar normal and shear stress concentrations in the laminate near the periphery of the bolt head are not distributed in the same circumference location. The former is located under the periphery of the bolt head, whereas the latter occurs near the bolt-head edge away from the hole in the in-plane direction, which is at the outer interface of the filled-hole laminate in the thickness direction.

- The clamp-up load plays a more important role in the interlaminar stress distribution in the laminate near the periphery of the bolt head. With an increase in the clamp-up load, both the interlaminar normal stress and interlaminar shear stresses rise around the bolt head in a large region. However, the magnitude of interlaminar shear stresses is reduced for most of the region around the hole.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reddy, J.N. Mechanics of Laminated Composite Plates and Shells: Theory and Analysis, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004; p. 613. [Google Scholar]

- Zhang, C.; Binienda, W.K.; Goldberg, R.K. Free-edge effect on the effective stiffness of single-layer triaxially braided composite. Compos. Sci. Technol. 2015, 107, 145–153. [Google Scholar] [CrossRef]

- Whitney, T.J.; Iarve, E.V.; Brockman, R.A. Singular stress fields near contact boundaries in a composite bolted joint. Int. J. Solids Struct. 2004, 41, 1893–1909. [Google Scholar] [CrossRef]

- Zhou, Y.; Nezhad, H.Y.; McCarthy, M.A.; Wan, X.; McCarthy, C. A Study of Intra-laminar Damage in Double-lap, Multi-bolt, Composite Joints with Variable Clearance using Continuum Damage Mechanics. Compos. Struct. 2014, 116, 441–452. [Google Scholar] [CrossRef]

- Zhou, Y.; Nezhad, H.Y.; Hou, C.; Wan, X.; McCarthy, C.T.; McCarthy, M.A. A three dimensional implicit finite element damage model and its application to single-lap multi-bolt composite joints with variable clearance. Compos. Struct. 2015, 131, 1060–1072. [Google Scholar]

- Chowdhury, N.M.; Chiu, W.K.; Wang, J.; Chan, P. Experimental and finite element studies of bolted, bonded and hybrid step lap joints of thick carbon fibre/epoxy panels used in aircraft structures. Compos. B Eng. 2016, 100, 68–77. [Google Scholar] [CrossRef]

- Polymer Matrix Composites: Guidelines for Characterization of Structural Materials. Available online: http://www.sae.org/images/books/toc_pdfs/R422.pdf (accessed on 17 January 2017).

- Camanho, P.P.; Matthews, F.L. Stress analysis and strength prediction of mechanically fastened joints in FRP: A review. Compos. A Appl. Sci. Manuf. 1997, 28, 529–547. [Google Scholar] [CrossRef]

- Ireman, T. Three-dimensional stress analysis of bolted single-lap composite joints. Compos. Struct. 1998, 43, 195–216. [Google Scholar] [CrossRef]

- McCarthy, M.A.; McCarthy, C.T.; Lawlor, V.P.; Stanley, W.F. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints part I—Model development and validation. Compos. Struct. 2005, 71, 140–158. [Google Scholar] [CrossRef]

- Caccese, V.; Berube, K.A.; Fernandez, M.; Melo, J.D.; Kabche, J.P. Influence of stress relaxation on clamp-up force in hybrid composite-to-metal bolted joints. Compos. Struct. 2009, 89, 285–293. [Google Scholar] [CrossRef]

- Egan, B.; McCarthy, C.T.; McCarthy, M.A.; Frizzell, R.M. Stress analysis of single-bolt, single-lap, countersunk composite joints with variable bolt-hole clearance. Compos. Struct. 2012, 94, 1038–1051. [Google Scholar] [CrossRef]

- Feo, L.; Marra, G.; Mosallam, A. Stress analysis of multi-bolted joints for FRP pultruded composite structures. Compos. Struct. 2012, 94, 3769–3780. [Google Scholar] [CrossRef]

- Zhao, L.; Qin, T.; Zhang, J.; Shan, M.; Fei, B. Determination method of stress concentration relief factors for failure prediction of composite multi-bolt joints. J. Compos. Mater. 2015, 49, 1667–1680. [Google Scholar] [CrossRef]

- Yan, Y.; Wen, W.D.; Chang, F.K.; Shyprykevich, P. Experimental study on clamping effects on the tensile strength of composite plates with a bolt-filled hole. Compos. A Appl. Sci. Manuf. 1999, 30, 1215–1229. [Google Scholar] [CrossRef]

- Castanie, B.; Creze, S.; Barrau, J.J.; Lachaud, F.; Risse, L. Experimental analysis of failures in filled hole compression tests of carbon/epoxy laminate. Compos. Struct. 2010, 92, 1192–1199. [Google Scholar] [CrossRef]

- Pagano, N.J. Exact Solutions for Rectangular Bidirectional Composites and Sandwich Plates. J. Compos. Mater. 1969, 4, 20–34. [Google Scholar]

- Bhara, A.; Satsangi, S.K. Accurate transverse stress evaluation in composite/sandwich thick laminates using a C0 HSDT and a novel post-processing technique. Eur. J. Mech. A Solids 2011, 30, 46–53. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, W. A global higher-order zig-zag model in terms of the HW variational theorem for multilayered composite beams. Compos. Struct. 2016, 158, 128–136. [Google Scholar]

- Fagiano, C.; Abdalla, M.M.; Kassapoglou, C.; Gurdal, Z. Interlaminar stress recovery for three-dimensional finite elements. Compos. Sci. Technol. 2010, 70, 530–538. [Google Scholar] [CrossRef]

- Vidal, P.; Gallimard, L.; Polit, O. Assessment of variable separation for finite element modeling of free edge effect for composite plates. Compos. Struct. 2015, 123, 19–29. [Google Scholar] [CrossRef]

- Sahoo, R.; Singh, B.N. A new trigonometric zigzag theory for static analysis of laminated composite and sandwich plates. Aerosp. Sci. Technol. 2014, 35, 15–28. [Google Scholar] [CrossRef]

- Chen, W.; Jia, P. Interlaminar stresses analysis and the limit state function approximating methods for composite structure reliability assessment: A selected review and some perspectives. J. Compos. Mater. 2012, 47, 1535–1547. [Google Scholar] [CrossRef]

- Hartman, T.B.; Hyer, M.W.; Case, S.W. Stress recovery in composite laminates including geometrically nonlinear and dynamic effects. AIAA J. 2016, 54, 2521–2529. [Google Scholar] [CrossRef]

- Marjanovic, M.; Vuksanovic, D. Layerwise solution of free vibrations and buckling of laminated composite and sandwich plates with embedded delaminations. Compos. Struct. 2014, 108, 9–20. [Google Scholar] [CrossRef]

- Naumenko, K.; Eremeyev, V.A. A layer-wise theory for laminated glass and photovoltaic panels. Compos. Struct. 2014, 12, 283–291. [Google Scholar] [CrossRef]

- Ahmadi, I. Interlaminar stress analysis in general thick composite cylinder subjected to nonuniform distributed radial pressure. Mech. Adv. Mater. Struct. 2016, 11, 1–71. [Google Scholar] [CrossRef]

- Esquej, R.; Castejon, L.; Lizaranzu, M.; Carrera, M.; Miravete, A.; Miralbes, R. A new finite element approach applied to the free edge effect on composite materials. Compos. Struct. 2013, 98, 121–129. [Google Scholar] [CrossRef]

- Dakshina Moorthy, C.M.; Reddy, J.N. Recovery of interlaminar stresses and strain energy release rates in composite laminates. Finite Elem. Anal. Des. 1999, 33, 1–27. [Google Scholar] [CrossRef]

- Sills, R.B.; Thouless, M.D. The effect of cohesive-law parameters on mixed-mode fracture-introduction. Eng. Fract. Mech. 2013, 109, 353–368. [Google Scholar] [CrossRef]

- Nezhad, H.Y.; Merwick, F.; Frizzell, R.M.; McCarthy, C.T. Numerical analysis of low velocity rigid body impact response of composite panels. Int. J. Crashworthines 2015, 20, 27–43. [Google Scholar] [CrossRef]

- Guillamet, G.; Turon, A.; Costa, J.; Linde, P. A quick procedure to predict free-edge delamination in thin-ply laminates under tension. Eng. Fract. Mech. 2016, 168, 28–39. [Google Scholar] [CrossRef]

- Krull, H.; Yuan, H. Suggestions to the cohesive traction-separation law from atomistic simulations. Eng. Fract. Mech. 2011, 78, 525–533. [Google Scholar] [CrossRef]

- Álvarez, D.; Blackman, B.R.K.; Guild, F.J.; Kinloch, A.J. Mode I fracture in adhesively-bonded joints: A mesh-size independent modelling approach using cohesive elements. Eng. Fract. Mech. 2014, 115, 73–95. [Google Scholar] [CrossRef]

- Kumar, D.; Roy, R.; Kweon, J.H.; Choi, J.H. Numerical modeling of combined matrix cracking and delamination in composite laminates using cohesive elements. Appl. Compos. Mater. 2016, 23, 397–419. [Google Scholar] [CrossRef]

- Camanho, P.P.; Davila, C.G. Mixed-Mode Decohesion Finite Elements for the Simulation of Delamination in Composite Materials. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20020053651.pdf (accessed on 17 January 2017).

- Barbero, E.J. Finite Element Analysis of Composite Materials Using Abaqus; CRC: Boca Raton, FL, USA, 2013; pp. 358–360. [Google Scholar]

- Turon, A.; Davila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

- Standard Practice for Filled-Hole Tension and Compression Testing of Polymer Matrix Composite Laminates; D6742/D6742M-12; ASTM International: West Conshohocken, PA, USA, 2012.

- McCarthy, C.T.; McCarthy, M.A.; Stanley, W.F.; Lawlor, V.P. Experiences with modeling friction in composite bolted joints. J. Compos. Mater. 2005, 39, 1881–1908. [Google Scholar] [CrossRef]

- Lagunegrand, L.; Lorriot, T.; Harry, R.; Wargnier, H.; Quenisset, J.M. Initiation of free-edge delamination in composite laminates. Compos. Sci. Technol. 2006, 66, 1315–1327. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis, Inc.: Philadelphia, PA, USA, 1999; p. 273. [Google Scholar]

- Thoppul, S.D.; Finegan, J.; Gibson, R.F. Mechanics of mechanically fastened joints in polymer-matrix composite structures—A review. Compos. Sci. Technol. 2009, 69, 301–329. [Google Scholar] [CrossRef]

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Feng, Y.; Xue, X.; Wang, W.; Bai, L. Evaluation of Interlaminar Stresses in Composite Laminates with a Bolt-Filled Hole Using a Linear Elastic Traction-Separation Description. Appl. Sci. 2017, 7, 93. https://doi.org/10.3390/app7010093

Cao Y, Feng Y, Xue X, Wang W, Bai L. Evaluation of Interlaminar Stresses in Composite Laminates with a Bolt-Filled Hole Using a Linear Elastic Traction-Separation Description. Applied Sciences. 2017; 7(1):93. https://doi.org/10.3390/app7010093

Chicago/Turabian StyleCao, Yong, Yunwen Feng, Xiaofeng Xue, Wenzhi Wang, and Liang Bai. 2017. "Evaluation of Interlaminar Stresses in Composite Laminates with a Bolt-Filled Hole Using a Linear Elastic Traction-Separation Description" Applied Sciences 7, no. 1: 93. https://doi.org/10.3390/app7010093