Greenhouse Gas Emissions from Calf- and Yearling-Fed Beef Production Systems, With and Without the Use of Growth Promotants

Abstract

:Simple Summary

Abstract

1. Introduction

2. Experimental Section

2.1. System Boundary and Scope

2.2. Description of the Beef Production Systems

2.3. Description of Climate and Location

2.4. Description of Crop and Pasture Complex

2.5. Scaling

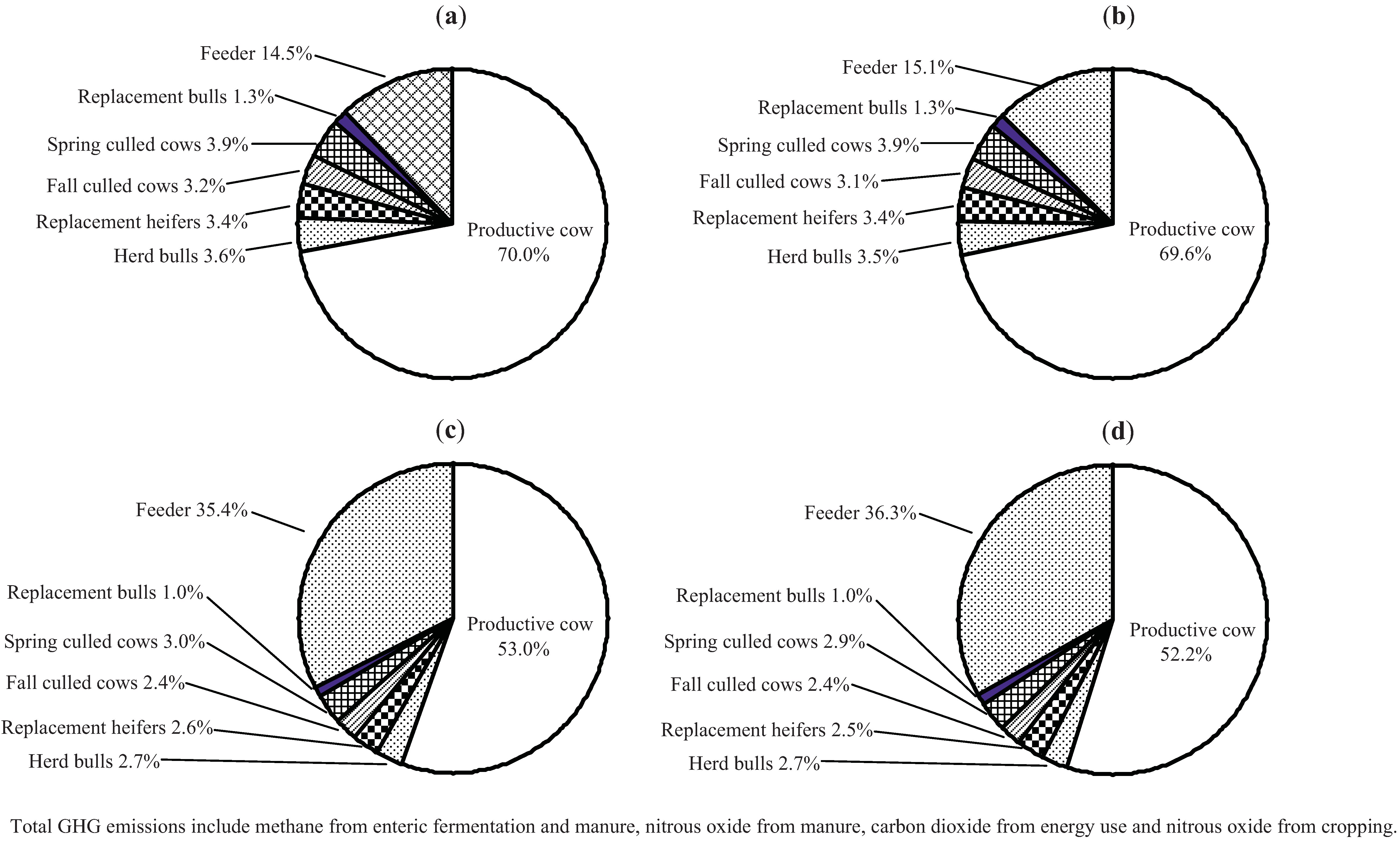

3. Results and Discussion

3.1. Land Use Efficiency

3.2. Soil Organic C-Sequestration

4. Conclusions

Acknowledgments

References and Notes

- How to Feed the World in 2050; FAO: Rome, Italy, 2009.

- Capper, J.L. Comparing the environmental impact of the US beef industry in 1977 to 2007. J. Anim. Sci. 2010, 2, 826. [Google Scholar]

- Capper, J.L. Replacing rose-tinted spectacles with a high-powered microscope: The historical versus modern carbon footprint of animal agriculture. Anim. Front. 2011, 1, 26–32. [Google Scholar]

- Hume, D.A.; Whitelaw, C.B.A.; Archibald, A.L. The future of animal production: Improving productivity and sustainability. J. Agr. Sci. 2011. [Google Scholar] [CrossRef]

- Ferrell, C.L.; Jenkins, T.G. Cow type and nutritional environment: Nutritional aspects. J. Anim. Sci. 1985, 61, 725–741. [Google Scholar]

- Alberta Agriculture and Rural Development. Economic, productive and financial benchmarks for Alberta cow/calf operations. 2005. Available online: http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/econ8479 (accessed on 1 October 2011). [Google Scholar]

- Pelletier, N.; Pirog, R.; Rasmussen, R. Comparative life cycle environmental impacts of three beef production strategies in the Upper Midwestern United States. Agr. Syst. 2010, 103, 380–389. [Google Scholar]

- Peters, G.M.; Rowley, H.V.; Wiedemann, S.; Tucker, R.; Short, M.D.; Schulz, M. Red meat production in Australia: Life cycle assessment and comparison with overseas studies. Environ. Sci. Technol. 2010, 44, 1327–1332. [Google Scholar]

- Cederberg, C.; Persson, M.; Neovius, K.; Molander, S.; Clift, R. Including carbon emissions from deforestation in the carbon footprint of Brazilian beef. Environ. Sci. Technol. 2011, 45, 1773–1779. [Google Scholar]

- Verge, X.P.C.; Dyer, J.A.; Desjardins, R.L.; Worth, D. Greenhouse gas emissions from the Canadian beef industry. Agr. Syst. 2008, 98, 126–134. [Google Scholar]

- Beauchemin, K.A.; Janzen, H.; Little, S.M.; McAllister, T.A.; McGinn, S.M. Life cycle assessment of greenhouse gas emissions from beef production in western Canada: A case study. Agr. Syst. 2010, 103, 371–379. [Google Scholar]

- Archer, J.A.; Richardson, E.C.; Herd, R.M.; Arthur, P.F. Potential for selection to improve efficiency of feed use in beef cattle: A review. Australian J. Agr. Res. 1999, 50, 147–161. [Google Scholar]

- Johnson, D.E.; Ferrell, C.L.; Jenkins, T.G. The history of energetic efficiency research: Where have we been and where are we going? J. Anim. Sci. 2003, 81, E27–E38. [Google Scholar]

- Crews, D.H., Jr. Genetics of efficient feed utilization and national cattle evaluation: A review. Genet. Mol. Res. 2005, 4, 152–165. [Google Scholar]

- Fairfull, R.W.; McMillan, L.; Muir, W.M. Poultry breeding: Progress and prospects for genetic improvement of egg and meat production. Available online: http://cgil.uoguelph.ca/pub/6wcgalp/6wcFairfull.pdf (accessed on 1 October 2011).

- Merks, J.W.M. One Century of Genetic Changes in Pigs and Future Needs. The Challenge of Genetic Change in Animal Production; Hill, W.G., Bishop, S.C., McGuirk, B., McKay, J.C., Simm, G., Webb, A.J., Eds.; BSAS: Edinburgh, UK, 2000; pp. 8–19. Available online: http://bsas.org.uk/downloads/genchan/paper2.pdf (accessed on 1 October 2011).

- Chen, P.; Baas, T.J.; Mabry, J.W.; Dekkers, J.C.M.; Koehler, K.J. Genetic parameters and trends for lean growth rate and its components in U.S. Yorkshire, Duroc, Hampshire, and Landrace pigs. J. Anim. Sci. 2002, 80, 2062–2070. [Google Scholar]

- Hermesch, S. Genetic improvement of lean meat growth and feed efficiency in pigs. Australian J. Exper. Agr. 2004, 44, 383–391. [Google Scholar]

- Basarab, J.A.; Baron, V.S.; Okine, E.K. Discovering Nutrition Related Opportunities in the Carbon Credit System for Beef cattle. In Proceedings of 30th Western Nutrition Conference, Winnipeg, MB, Canada, 23–24 September 2009; pp. 241–260.

- NRC. Nutrient Requirements of Beef Cattle, 7th ed.; National Academy Press: Washington, DC, USA, 2000. [Google Scholar]

- IPCC. Third Assessment Report, Climate Change 2001: The Scientific Basis Contribution of Working Group 1 to the Third Assessment Report of the IPCC. Available online: http://www.grida.no/publications/other/ipcc_tar/?src=/climate/ipcc_tar/wg1/248.htm (accessed on 1 October 2011).

- IPCC. Revised Guidelines for National Greenhouse Gas Inventories. IPCC/OECD/IEA/IGES. Volume 4. Agriculture, Forestry and Other Land Use. Chapter 11. N2O emissions from managed soils and CO2 emissions from lime and urea application. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4-Volume_4/V4._11-Ch11_N2O&CO2pdfhtm (accessed on 1 October 2011).

- Basarab, J.A.; McCartney, D.; Okine, E.K.; Baron, V.S. Relationships between progeny residual feed intake and dam productivity traits. Can. J. Anim. Sci. 2007, 87, 489–502. [Google Scholar]

- Basarab, J.A.; Colazo, M.G.; Ambrose, D.J.; Novak, S.; McCartney, D.; Baron, V.S. Residual feed intake adjusted for backfat thickness and feeding frequency is independent of fertility in beef heifers. Can. J. Anim. Sci. 2011, 91, 573–584. [Google Scholar]

- Basarab, J.A.; Okine, E.K.; Baron, V.S.; Marx, T.; Ramsey, P.; Ziegler, K.; Lyle, K. Methane emissions from enteric fermentation in Alberta’s beef cattle population. Can. J. Anim. Sci. 2005, 85, 501–512. [Google Scholar]

- CCAC Canadian Council on Animal Care. Guide to the Care and Use of Experimental Animals. In Canadian Council on Animal Care; Olfert, E.D., Cross, B.M., McWilliams, A.A., Eds.; CCAC: Ottawa ON, Canada, 1993; Volume 1. [Google Scholar]

- López-Campos, Ó.; Aalhus, J.L.; Okine, E.K.; Baron, V.S.; Basarab, J.A. Effects of Calf Production Systems and Growth Promotants on Production and Profitability; Final Report; Alberta Livestock and Meat Agency Ltd.: Edmonton, AB, Canada, 2012. [Google Scholar]

- Newman, J.A.; Rahnefeld, G.W.; Tong, A.K.W.; Jones, S.D.M.; Fredeen, H.T.; Weiss, G.M.; Bailey, D.R.C. Slaughter and carcass traits of calves from first-cross and reciprocal back-cross beef cows. Can. J.Anim. Sci. 1994, 74, 621–632. [Google Scholar]

- Ecological Stratification Working Group. A National Ecological Framework for Canada; Agriculture and Agri-Food Canada: Ottawa, ON, Canada, 1995. [Google Scholar]

- McCartney, D.H.; Block, H.C; Dubeski, D.L; Ohama, A.J. Review: The composition and availability of straw and chaff from small grain cereals for beef cattle in western Canada. Can. J. Anim. Sci. 2006, 86, 443–455. [Google Scholar]

- Etheridge, R.D.; Pesti, G.M.; Foster, E.H. A comparison of nitrogen values obtained utilizing the Kjeldahl nitrogen and Dumas combustion methodologies (Leco CNS 2000) on samples typical of animal nutrition analytical laboratory. Anim. Feed Sci. Technol. 1998, 73, 21–28. [Google Scholar]

- Nagy, C.N. Energy and Greenhouse Gas Emission Coefficients for Inputs Used in Agriculture. In Report to Prairie Adaptation Research Collaborative; Centre for Studies in Agriculture, Law and the Environment: Saskatoon, Canada, 2000; p. 11. [Google Scholar]

- Nagy, C.N. Energy Coefficients for Agriculture Inputs in Western Canada; CSALE Working Paper Series #2; Centre for Studies in Agriculture, Law and the Environment: Saskatoon, Canada, 1999; p. 44. [Google Scholar]

- Saskatchewan Agriculture Farm Machinery Custom Rental Guide 2008-09; Saskatchewan Agriculture: Regina, SK, Canada. Available online: www.agriculture.gov.sk.ca (accessed on 5 May 2008).

- Zentner, R.P.; Brandt, S.A.; Nagy, C.N.; Frick, B. Economics and Energy Use Efficiency of Alternative Cropping Strategies for the Dark Brown Soil Zone of Saskatchewan; Saskatchewan Agricultural Development Fund Final Report; Project # 20070029; Saskatchewan Agriculture Development Fund: Saskatoon, Canada, 2009. [Google Scholar]

- Snyder, C.S.; Bruulsema, T.W.; Jensen, T.L.; Fixen, P.E. Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agr. Ecosyst. Environ. 2009, 133, 247–266. [Google Scholar]

- Rochette, P.; Worth, D.E.; Lemke, R.L.; McConkey, B.G.; Pennock, D.J.; Wagner-Riddle, C.; Desjardins, R.L. Estimation of N2O emissions from agricultural soils in Canada. I. Development of a country-specific methodology. Can. J. Soil Sci. 2008, 88, 641–654. [Google Scholar]

- Worth, D.E.; Desjardins, R.L.; Agriculture and Agri-Food Canada, Ottawa, ON, Canada. Private Communication, 2011.

- Janzen, H.H.; Beauchemin, K.A.; Bruinsma, Y.; Campbell, C.A.; Desjardins, R.L.; Ellert, B.H.; Smith, E.G. The fate of nitrogen in agroecosystems: An illustration using Canadian estimates. Nutr. Cyc. Agroecosyst. 2003, 67, 85–102. [Google Scholar]

- Baron, V.; Agriculture and Agri-Food Canada, Lacombe, AB, Canada. Private Communication, 2011.

- Alberta Cow-Calf Audit; Alberta Agriculture, Food and Rural Development: Edmonton, AB, Canada, 2001.

- Little, S.; Linderman, J.; Maclean, K.; Janzen, H. HOLOS—A Tool to Estimate and Reduce Greenhouse Gases from Farms; Methodology and Algorithms for Versions 1.1x; Agriculture and Agri-Food Canada: Lethbridge, AB, Canada, 2008. [Google Scholar]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Environmental consequences of different beef production systems in the EU. J. Cleaner Prod. 2010, 18, 756–766. [Google Scholar]

- Cederberg, C.; Meyer, D.; Flysjo, A. Life Cycle Inventory of Greenhouse Gas Emissions and Use of Land and Energy in Brazilian Beef Production; The Swedish Institute for Food and Biotechnology: Gothenburg, Sweden, 2009. [Google Scholar]

- Casey, J.W.; Holden, N.M. Quantification of GHG emissions from suckler-beef production in Ireland. Agr. Syst. 2006, 90, 79–98. [Google Scholar]

- Johnson, D.E.; Phetteplace, H.W.; Seidl, A.F.; Schneider, U.A.; McCarl, B.A. Management Variations of U.S. Beef Production Systems; Effects on Greenhouse Gas Emission and Profitability. Proceedings of 3rd International Methane and Nitrous Oxide Mitigation Conference, Beijing, China, 17–21 November 2003; Available online: http://www.coalinfo.net.cn/coalbed/meeting/2203/papers/agriculture/index.html#day1 (accessed on 1 October 2011).

- Malhi, S.S.; Lemke, R.L.; Liebig, M.A.; McConkey, B.; Schoenau, J.J.; Cihacek, L.J.; Campbell, C. Management strategies and practices for increasing storage of organic C and N in soil in cropping systems in the Northern Great Plains of North America. In Recent Trends in Soil Science and Agronomy Research in the Northern Great Plains of North America; Malhi, S.S., Gan, Y., Schoenau, J.J., Lemke, R.L., Liebig, M.A., Eds.; Research Signpost: Trivandrum, Kerala, India, 2010; pp. 325–384. [Google Scholar]

- Annex 3-Additional Methodologies; National Inventory Report (NIR) Part 2; Canada’s 2011 UNFCCC Submission 1990–2009; Environment Canada: Ottawa, ON, Canada, 2011; pp. 50–163.

- Bremer, E.; Janzen, H.H.; Ellert, B.H.; Mckenzie, R.H. Soil organic carbon after twelve years of various crop rotations in an Aridic Boroll. Soil Sci. Soc. Am. J. 2008, 72, 970–974. [Google Scholar]

- Bremer, E.; Janzen, H.H.; Johnston, A.M. Sensitivity of total, light-fraction and mineralizable organic matter to management practices in a Lethbridge soil. Can. J. Soil Sci. 1994, 74, 131–138. [Google Scholar]

- Mensah, F.; Schoenau, J.J.; Malhi, S.S. Soil carbon changes in cultivated and excavated land converted to grasses in east-central Saskatchewan. Biogeochemistry 2003, 63, 85–92. [Google Scholar]

- Nelson, J.D.J.; Schoeneau, J.J.; Malhi, S.S. Soil organic carbon changes and distribution in cultivated and restored grassland soils in Saskatchewan. Nutr. Cycl. Agroecosyst. 2008, 82, 137–148. [Google Scholar]

- Vleeshouwers, L.M.; Verhagen, A. Carbon emissions and sequestration by agricultural land use: A model study for Europe. Glogal Change Biol. 2002, 8, 519–530. [Google Scholar]

- Chan, K.Y.; Conyers, M.K.; Li, G.D.; Helyar, K.R.; Poile, G.; Oates, A.; Barchia, I.H. Soil carbon dynamics under different cropping and pasture management in temperate Australia: Results of three long-term experiments. Soil Res. 2011, 49, 320–328. [Google Scholar]

- Baron, V.S.; Young, D.G.; Dugas, W.A.; Mielnick, P.C.; La Bine, C.; Skinner, H.G.; Casson, J. Net Ecosystem Carbon Dioxide Exchange over a Temperate Short Season Grassland: Transition from Cereal to Perennial Forage. In Climate Change and Managed Ecosystems; Bhatti, J.S., Lal, R., Apps, M.J., Price, M.A., Eds.; CRC. Taylor and Francis: Boca Raton, FL, USA, 2006; pp. 163–174. [Google Scholar]

- Conant, R.T.; Paustian, K.; Elliot, E.T. Grassland management and conversion into grassland effects on soil carbon. Ecol. Appl. 2001, 11, 343–355. [Google Scholar]

- Franzluebbers, A.J. Achieving soil organic carbon sequestration with conservation agricultural systems in the Southeastern United States. Soil Sci. Soc. Am. J. 2010, 74, 347–357. [Google Scholar]

- Franzluebbers, A.J.; Studemann, J.A. Surface soil changes during twelve years of pasture management in the Southern Piedmont USA. Soil Sci. Soc. Am. J. 2010, 74, 2131–2141. [Google Scholar]

- Malhi, S.S.; Brandt, S.; Gill, K.S. Cultivation and grassland type effects on light fraction and total organic C and N in a Dark Brown Chernozemic soil. Can. J. Soil Sci. 2003, 83, 145–153. [Google Scholar]

- Dyer, J.A.; Verge, X.P.C.; Desjardins, R.L.; Worth, D.E.; McConkey, B.G. The impact of increased biodiesel production on the greenhouse gas emissions from field crops in Canada. Energy Sustain. Develop. 2010, 14, 73–82. [Google Scholar]

Appendix

| Cattle category | Animal used | Dayson feed | Diet Ingredient Composition (DM basis) | TDN, % | CP, % | Mid-Wt, kg | ADG, kg d−1 | DMI, kg d−1 |

|---|---|---|---|---|---|---|---|---|

| Cow-calf pairs and cows | ||||||||

| Cow-calf pairs, summer | 93–99 | 111.0 | 100% MBA pasture | 63.33 | 16.13 | 656.8 | 0.22 | 17.37 |

| Cow-calf pairs pre-weaning | 93–99 | 14.0 | 49.40% MBA pasture: 50.60% BS | 62.98 | 12.76 | 671.9 | 0.21 | 21.73 |

| Cows, post weaning | 90–110 | 21.0 | 100% BS | 60.75 | 13.02 | 674.0 | 1.15 | 10.27 |

| Cows, winter drylot | 21–42 | 125.5 | 48.17%BS:3.94%BG:2.62%OG:19.59%H:25.70%St | 57.05 | 10.78 | 719.6 | 0.52 | 12.65 |

| Cows, pre- & post-calving | 95–114 | 93.5 | 78.87%BS:15.42%BG:0.69%OG:5.03%H | 62.93 | 12.84 | 714.7 | 0.82 | 11.44 |

| Total days on feed | 365.0 | |||||||

| Herd bulls | ||||||||

| Summer grazing on-pasture | 4–5 | 108.5 | 100% MBA pasture | 63.33 | 16.13 | 866.0 | 1.03 | 21.48 |

| Fall on-pasture | 12–15 | 43.5 | 100%BS | 60.63 | 13.06 | 921.0 | 0.01 | 10.80 |

| Wintering on-pasture | 12-15 | 203.0 | 76.64%BS:20.58%BG:2.78%H | 63.32 | 13.22 | 921.0 | 0.36 | 15.25 |

| Spring pre-grazing on-pasture | 12–15 | 10.0 | 100%BS | 65.66 | 13.55 | 866.0 | 0.01 | 11.07 |

| Total days on feed | 365.0 | |||||||

| Replacement heifers | ||||||||

| On-pasture with dam | 93–99 | 137.0 | 100% MBA pasture | 63.33 | 16.13 | 168.4 | 1.17 | NA |

| Post-weaning, feedlot pen | 77–99 | 24.5 | 84.21%BS:15.79%GS | 59.97 | 13.01 | 251.3 | 0.60 | 4.35 |

| Wintering, feedlot pen | 61–72 | 105.5 | 79.14%BS:20.86%BG | 65.10 | 12.70 | 291.6 | 0.60 | 6.18 |

| Wintering, Performance Test | 61–72 | 98.0 | 77.76%BS:22.24%BG | 63.99 | 12.45 | 355.2 | 0.66 | 7.80 |

| Total days on feed | 365.0 | |||||||

| Replacement bulls | ||||||||

| On-pasture with dam | 67–69 | 126.0 | 100% MBA pasture | 63.31 | 16.12 | 179.3 | 1.07 | NA |

| Weaning to Bull Test | 67–69 | 32.0 | 100%BS | 62.85 | 12.84 | 273.1 | 0.59 | 6.79 |

| Bull Test period | 67–69 | 117.0 | 33.00%BS:60.00%BG:7.00%Ps | 78.20 | 13.64 | 369.8 | 1.49 | 9.24 |

| Wintering, Performance Test | 67–69 | 90.0 | 100%BS | 62.85 | 12.84 | 483.9 | 0.59 | 12.04 |

| Total days on feed | 365.0 |

| Feeder Category | Animal used | Days on feed | Diet Ingredient Composition (DM basis) | TDN, % | CP, % | Mid-Wt, kg | ADG, kg d−1 | DMI, kg d−1 |

|---|---|---|---|---|---|---|---|---|

| Calf-fed, not implanted | ||||||||

| Weaning to step-up | 56 | 13.5 | 83.34%BS:16.66%GS | 59.92 | 13.01 | 263.1 | 0.79 | 4.14 |

| Step-up | 56 | 34.5 | 18.19%BS:49.85%BG:24.90%GS:7.05%Ps | 69.20 | 13.54 | 286.4 | 1.13 | 6.97 |

| Feedlot finishing, Progeny test | 56 | 83.0 | 10.38%BS:70.88%BG:9.34%GS:9.30%Ps | 74.22 | 12.84 | 369.0 | 1.50 | 8.02 |

| Feedlot finishing | 56 | 76.0 | 18.87%BS:71.62%BG:9.51%Ps | 75.06 | 14.78 | 484.1 | 1.45 | 8.55 |

| Calf-fed, implanted | ||||||||

| Weaning to step-up | 56 | 13.5 | 83.34%BS:16.66%GS | 59.92 | 13.01 | 262.9 | 0.61 | 4.14 |

| Step-up | 56 | 34.5 | 18.19%BS:49.85%BG:24.90%GS:7.05%Ps | 69.20 | 13.54 | 288.8 | 1.31 | 7.07 |

| Feedlot finishing, Progeny test | 56 | 83.0 | 10.38%BS:70.88%BG:9.34%GS:9.30%Ps | 74.22 | 12.84 | 385.4 | 1.75 | 8.52 |

| Feedlot finishing | 56 | 76.0 | 18.87%BS:71.62%BG:9.51%Ps | 75.06 | 14.78 | 519.1 | 1.67 | 9.04 |

| Yearling-fed, not implanted | ||||||||

| Weaning to fall pasture | 56 | 13.5 | 83.34%BS:16.66%GS | 59.92 | 13.01 | 261.7 | 0.71 | 4.52 |

| Fall pasture | 56 | 41.5 | 100% MBA | 55.82 | 7.95 | 267.9 | 0.18 | 3.65 |

| Winter backgrounding | 56 | 191.0 | 66.27%BS:20.55%GS:5.18%BG:2.73%OG:5.27%St | 61.76 | 12.28 | 358.8 | 0.92 | 7.80 |

| Summer pasture | 56 | 66.0 | 100% MBA | 59.39 | 12.31 | 463.8 | 0.50 | 14.83 |

| Step-up | 56 | 22.0 | 33.96%BS:60.24%BG:5.80%Protein sup. | 71.32 | 13.42 | 502.1 | 1.90 | 9.83 |

| Feedlot finishing, Progeny test | 56 | 76.5 | 16.37%BS:77.81%BG:5.82%Protein sup. | 74.57 | 12.66 | 588.3 | 1.71 | 12.50 |

| Feedlot finishing | 56 | 47.5 | 19.54%BS:74.72%BG:5.74%Protein sup. | 73.40 | 12.86 | 674.0 | 0.90 | 11.74 |

| Yearling-fed, implanted | ||||||||

| Weaning to fall pasture | 56 | 13.5 | 83.34%BS:16.66%GS | 59.92 | 13.01 | 264.3 | 1.02 | 4.52 |

| Fall pasture | 56 | 41.5 | 100% MBA | 55.82 | 7.95 | 270.3 | 0.13 | 3.65 |

| Winter backgrounding | 56 | 191.0 | 66.27%BS:20.55%GS:5.18%BG:2.73%OG:5.27%St | 61.76 | 12.28 | 366.0 | 0.99 | 8.25 |

| Summer pasture | 56 | 66.0 | 100% MBA | 59.39 | 12.31 | 479.7 | 0.55 | 13.64 |

| Step-up | 56 | 22.0 | 33.96%BS:60.24%BG:5.80%Protein sup. | 71.32 | 13.42 | 524.4 | 2.33 | 10.60 |

| Feedlot finishing, Progeny test | 56 | 76.5 | 16.37%BS:77.81%BG:5.82%Protein sup. | 74.57 | 12.66 | 626.1 | 2.00 | 14.10 |

| Feedlot finishing | 56 | 47.5 | 19.54%BS:74.72%BG:5.74%Protein sup. | 73.40 | 12.86 | 727.7 | 1.11 | 12.48 |

| Mean monthly daily mean temperature, °C | Monthly precipitation, mm | |||||||

|---|---|---|---|---|---|---|---|---|

| Month | 2008 | 2009 | 2010 | 100 years average | 2008 | 2009 | 2010 | 100 years average |

| January | −11.2 | −10.7 | −9.2 | −13.5 | 14.6 | 14.3 | 6.7 | 18.2 |

| February | −8.4 | −9.7 | −6.8 | −10.3 | 26.3 | 9.6 | 0.7 | 16.2 |

| March | −1.4 | −7.2 | 1.1 | −4.8 | 6.3 | 17.1 | 1.3 | 18.1 |

| April | 1.4 | 3.1 | 5.0 | 3.7 | 25.9 | 15.2 | 36.4 | 26.0 |

| May | 10.3 | 8.5 | 7.8 | 9.8 | 58.8 | 14.7 | 91.2 | 51.0 |

| June | 13.5 | 12.7 | 13.3 | 13.6 | 102.4 | 41.4 | 116.6 | 83.4 |

| July | 15.5 | 15.9 | 15.3 | 16.1 | 63.1 | 92.3 | 212.0 | 78.8 |

| August | 15.6 | 14.5 | 14.4 | 14.9 | 66.5 | 74.0 | 39.8 | 65.5 |

| September | 10.3 | 13.7 | 8.3 | 10.1 | 9.6 | 9.5 | 54.2 | 42.0 |

| October | 5.3 | 3.0 | 6.3 | 4.4 | 10.6 | 11.1 | 0.0 | 19.9 |

| November | 0.5 | −0.1 | −6.4 | −4.4 | 0.0 | 0.6 | 20.4 | 15.7 |

| December | −14.1 | −16.4 | −12.4 | −10.6 | 11.4 | 0.0 | 3.6 | 15.5 |

| Total | 395.5 | 299.8 | 582.9 | 450.3 | ||||

| Gas/Source | Fraction, emission factor, equation | Reference |

|---|---|---|

| CO2 machine operations (kg CO2 ha−1) | = ∑Embodied +∑Fuel+ ∑ Lubricants | [32,33] |

| CO2 Embodied (kg CO2 ha−1) | =( (MJ hr−1 equipment unit) / (43.99 (MJ L−1)) × (2.639 kg CO2 L−1) / work rate (ha h−1) | [32,33] |

| CO2 Fuel (kg CO2 ha−1) | =( MJ h−1 power unit) / (43.99 (MJ L−1diesel)) × (2.639 kg CO2 L−1) / work rate (ha h−1) | |

| CO2 Lube (kg CO2 ha−1) | = (MJ h−1Lube) / (43.99 (MJ L−1)) × (2.639 kg CO2 L−1) / work rate (ha h−1) | [32,33] |

| Work rate (ha h−1) = power unit, implement and width. Fuel use rate (L h−1) = Diesel fuel by power unit, implement and width Lube use rate = oil and grease etc. (MJ h−1) implement and power unit combination) 43.99 MJ L−1 diesel fuel 2.639 kg CO2 L−1 diesel fuel | [34] [32,33] | |

| CO2 Cropping inputs (kg CO2 ha−1) | =∑seed +∑fertilizer + ∑ herbicide | |

| CO2 Seed (kg CO2 ha−1) | = MJ kg−1 seed production / 43.99 MJ L−1 × 2.639 kg CO2 L−1 × seeding rate (kg ha−1) | [32,33] |

| CO2 Fertilizer (kg CO2 ha−1) | = MJ kg−1 nutrient / 43.99 MJ L−1 × 2.639 kg CO2 L−1 × nutrient rate (kg ha−1) | [32,33] |

| CO2 Herbicide (kg CO2 ha−1) | = MJ kg−1 herbicide / 43.99 MJ L−1 × 2.639 kg CO2 L−1 × herbicide rate (kg ha−1) | [32,35] |

| Seed production MJ kg−1 energy to produce 1 kg seed for purposes of crop seeding Nutrient = 53 MJ kg−1 urea-N; 14 MJ kg−1 P2O5; 9 MJ kg−1 K2O manufacture and transportation Herbicide = 373 MJ kg−1 ai Glyphosate and 104.5 MJ kg−1 ai Dicamba and 2,4-D amine and Mecoprop | [33] [36] [35] | |

| Gas/Source | Fraction, emission factor, equation | Reference |

|---|---|---|

| Nitrous oxide Sources | ||

| N2O direct cropping (kg CO2 ha−1) | = ((∑Fert-N + ∑ (Residue + Root-N) ( kg N ha−1)) x EFeco (kg N2O-N kg−1 N) x (44/28) | [37] |

| N2O indirect cropping (kg CO2 ha−1) | = ∑Leach + ∑Volatilization | [22] |

| N2O indirect leaching (kg CO2 ha−1) | = (∑Fert-N + ∑ (Residue + Root-N) ( kg N ha−1)) x Frac Leach x EF Leach (kg N2O-N kg−1 N) x (44/28)) | |

| N2O indirect volatilization (kg CO2 ha−1) | = (∑Fert-N ( kg N ha−1)) x Frac vol. x EF vol. (kg N2O-N kg−1 N) x (44/28) | [22] |

| ∑ (Residue + Root-N) Represents all residue and root-N determined and measured for annuals and 10% of residue and root-N for perennials, annually. | [39] | |

| EF eco for Ecodistrict 737 = 0.0095 (kg N2O-N kg N) | [38] | |

| Frac Leach for Ecodistrict 737 = 0.19 (kg N ha−1) | [38] | |

| EF Leach = 0.0075 (kg N2O-N kg N) | [22] | |

| Frac vol. = 0.10 (kg Fert. N ha−1) | [22] | |

| EF vol. = 0.01 (kg N2O-N kg N) | [22] | |

| Crop Type | 2008–09 | 2009–10 | ||

|---|---|---|---|---|

| Energy CO2 | Crop N2O | Energy CO2 | Crop N2O | |

| Summer pasture, cow-calf pair, kg CO2e hd.d−1 | 0.11643 | 1.26118 | 1.78865 | 3.27245 |

| Summer pasture, herd bull, kg CO2e hd.d−1 | 0.11168 | 1.20976 | 1.74362 | 3.19006 |

| Fall pasture + straw, weaned calf, kg CO2e hd.d−1 | 0.10576 | 0.18609 | 0.09688 | 0.18268 |

| Summer pasture, yearling, kg CO2e hd.d−1 | 1.71257 | 2.18789 | 1.91910 | 2.87737 |

| Barley silage, kg CO2e kg−1 DM | 0.08731 | 0.08258 | 0.08080 | 0.07322 |

| Barley grain, kg CO2e kg−1 DM | 0.07737 | 0.07066 | 0.06933 | 0.06044 |

| Oat grain, kg CO2e kg−1 DM | 0.12109 | 0.10597 | NA | NA |

| Meadow brome alfalfa hay, kg CO2e kg−1 DM | 0.10581 | 0.07763 | NA | NA |

| Meadow brome alfalfa silage, kg CO2e kg−1 DM | 0.09858 | 0.07763 | NA | NA |

| Barley straw, kg CO2e kg−1 DM | 0.09570 | 0.07362 | 0.08809 | 0.06038 |

| Protein supplement plus mineralsz, kg CO2e kg−1 DM | 0.06600 | 0.05400 | 0.06600 | 0.05400 |

| Barley straw for bedding, kg CO2e kg−1 DM | 0.05604 | 0.07362 | 0.05131 | 0.06038 |

| Cattle category | Productive cows | Herd Bullsz | Repl. heifers | Fall cull cows | Spring cull cows | Repl. bulls | Calf-fed NI | Calf-fed IMP | Year-fed NI | Year-fed IMP |

|---|---|---|---|---|---|---|---|---|---|---|

| Number of cattle | 142 | 6 | 24 | 16 | 8 | 6 | 112 | 112 | 112 | 112 |

| Period, d | 365 | 365 | 365 | 112 | 365 | 365 | 207 | 207 | 454 | 454 |

| Live slaughter weight, kg hd−1 | NA | 866 | NA | 651 | 651 | NA | 518.3 | 557.5 | 668.8 | 725.3 |

| Carcass weight, kg hd−1 | NA | 493.6 | NA | 371 | 371 | NA | 302.0 | 328.9 | 395.2 | 432.4 |

| Total live weight sold, kg | 0 | 1,730 | 0 | 10,416 | 5,208 | 0 | 58,045 | 62,435 | 74,911 | 81,233 |

| Total carcass weight sold, kg | 0 | 986 | 0 | 5,936 | 2,968 | 0 | 33,827 | 36,840 | 44,258 | 48,427 |

| Greenhouse gas emissions from enteric fermentation and manure handling, storage and land application from beef herd | ||||||||||

| Enteric CH4, kg CO2e hd−1 period−1 | 2,530.24 | 2,976.78 | 754.52 | 955.70 | 2,530.24 | 1,180.61 | 541.84 | 566.97 | 1,871.31 | 1,936.36 |

| Manure CH4, kg CO2e hd−1 period−1 | 58.91 | 66.08 | 16.33 | 21.10 | 58.91 | 21.93 | 221.81 | 232.64 | 535.57 | 574.71 |

| Manure N2O, kg CO2e hd−1 period−1 | 1,038.68 | 1,465.65 | 280.40 | 485.60 | 1,038.68 | 467.86 | 180.60 | 189.27 | 591.40 | 604.34 |

| Sub-total, kg CO2e hd−1 period−1 | 3,627.83 | 4,508.51 | 1,051.25 | 1,462.45 | 3,627.83 | 1,670.40 | 944.24 | 988.87 | 2,998.28 | 3,115.41 |

| Enteric CH4, kg CO2e period−1 | 359,294 | 17,861 | 18,109 | 15,291 | 20,242 | 7,084 | 60,686 | 63,500 | 209,586 | 216,873 |

| Manure CH4, kg CO2e period−1 | 8,365 | 397 | 392 | 338 | 471 | 132 | 24,843 | 26,055 | 59,984 | 64,367 |

| Manure N2O, kg CO2e period−1 | 147,493 | 8,794 | 6,730 | 7,770 | 8,309 | 2,807 | 20,227 | 21,198 | 66,237 | 67,686 |

| Sub-total, kg CO2e period−1 | 515,151 | 27,051 | 25,230 | 23,398 | 29,023 | 10,022 | 105,755 | 110,754 | 335,807 | 348,926 |

| Greenhouse gas emissions from energy use and cropping | ||||||||||

| Energy use CO2, kg CO2e period−1 | 56,530 | 2,585 | 3,144 | 1,707 | 3,185 | 1,182 | 14,845 | 15,504 | 46,483 | 48,764 |

| Cropping N2O, kg CO2e period−1 | 74,169 | 3,300 | 2,939 | 4,062 | 4,179 | 1,093 | 13,555 | 14,134 | 49,417 | 51,440 |

| Sub-total, kg CO2e period−1 | 130,700 | 5,885 | 6,083 | 5,769 | 7,363 | 2,276 | 28,400 | 29,639 | 95,900 | 100,204 |

| Total live weight sold, kg | 75,399 | 79,789 | 92,265 | 98,587 | ||||||

| Total carcass weight sold, kg | 43,717 | 46,731 | 54,148 | 58,317 | ||||||

| Total enteric CH4, kg CO2e | 498,566 | 501,380 | 647,466 | 654,752 | ||||||

| Total manure CH4, kg CO2e | 34,936 | 36,149 | 70,078 | 74,461 | ||||||

| Total manure N2O, kg CO2e | 202,129 | 203,101 | 248,139 | 249,588 | ||||||

| Total energy CO2, kg CO2e | 83,178 | 83,838 | 114,816 | 117,098 | ||||||

| Total crop N2O, kg CO2e | 103,297 | 103,877 | 139,160 | 141,182 | ||||||

| Total GHG emissions, kg CO2e | 922,107 | 928,344 | 1,219,659 | 1,237,082 | ||||||

| GHG Intensity, kg CO2e kg−1 live weight | 12.23 | 11.63 | 13.22 | 12.55 | ||||||

| GHG Intensity, kg CO2e kg−1 carcass weight | 21.09 | 19.87 | 22.52 | 21.21 | ||||||

| GHG Intensityy, kg CO2e kg−1 live weight yr−1 | 13.10 | 12.46 | 23.07 | 21.90 | ||||||

| GHG Intensityy, kg CO2e kg−1 carcass weight yr−1 | 22.60 | 21.28 | 39.31 | 37.02 | ||||||

| Cattle category | Productive cows | Herd bullsy | Repl. heifers | Fall cull cows | Spring cull cows | Repl. bulls | Calf-fed NI | Calf-fed IMP | Year-fed NI | Year-fed IMP |

|---|---|---|---|---|---|---|---|---|---|---|

| Number of cattle | 142 | 6 | 24 | 16 | 8 | 6 | 112 | 112 | 112 | 112 |

| Period, d | 365 | 365 | 365 | 112 | 365 | 365 | 207 | 207 | 454 | 454 |

| Feed resources used for beef herd averaged over two years | ||||||||||

| Fresh forage x, head.d | 16,744 | 651 | 0 | 1,792 | 943 | 0 | 0 | 0 | 12,040 | 12,040 |

| Fresh forage, kg DM period−1 | 295,774 | 13,968 | 0 | 30,868 | 16,663 | 0 | 0 | 0 | 123,740 | 116,249 |

| Barley silage, kg DM period−1 | 279,762 | 17,713 | 28,827 | 0 | 15,761 | 9,946 | 32,237 | 33,650 | 148,788 | 159,470 |

| Barley grain, kg DM period−1 | 33,714 | 3,836 | 7,306 | 0 | 1,899 | 3,892 | 117,280 | 123,556 | 152,629 | 167,570 |

| Oat grain, kg DM period−1 | 8,049 | 0 | 0 | 0 | 453 | 0 | 0 | 0 | 4,905 | 5,083 |

| MBA hay, kg DM period−1 | 59,974 | 518 | 0 | 0 | 3,379 | 0 | 0 | 0 | 36,987 | 38,329 |

| Grass silage, kg DM period−1 | 0 | 0 | 418 | 0 | 0 | 0 | 13,207 | 13,605 | 1,263 | 1,263 |

| Barley straw, kg DM period−1 | 48,166 | 0 | 0 | 0 | 2,714 | 0 | 0 | 0 | 7,921 | 8,587 |

| Protein suppl., kg DM period−1 | 0 | 0 | 0 | 0 | 0 | 454 | 15,694 | 16,534 | 11,126 | 12,244 |

| Straw for bedding, kg DM period−1 | 52,343 | 2,607 | 2,517 | 0 | 2,949 | 578 | 23,355 | 23,355 | 52,014 | 52,014 |

| Feed resources used to produce calf-fed and yearling-fed steers from birth to slaughter averaged over two years | ||||||||||

| Total fresh forage x, head.d | 20,130 | 20,130 | 32,170 | 32,170 | ||||||

| Total fresh forage, kg DM | 357,274 | 357,274 | 481,014 | 473,523 | ||||||

| Total barley silage y, kg DM | 384,247 | 385,660 | 500,797 | 511,480 | ||||||

| Total barley grain y, kg DM | 167,928 | 174,204 | 203,277 | 218,218 | ||||||

| Total oat grain y, kg DM | 8,503 | 8,503 | 13,408 | 13,585 | ||||||

| Total MBA hay y, kg DM | 63,871 | 63,871 | 100,858 | 102,200 | ||||||

| Total MBA silage y, kg DM | 13,625 | 14,022 | 1,680 | 1,680 | ||||||

| Total barley straw y, kg DM | 50,879 | 50,879 | 58,800 | 59,466 | ||||||

| Total protein suppl. y, kg DM | 16,148 | 16,988 | 11,580 | 12,698 | ||||||

| Total straw for bedding y, kg DM | 84,349 | 84,349 | 113,007 | 113,007 | ||||||

| Total all feed, t DM | 1,147 | 1,156 | 1,484 | 1,506 | ||||||

| Land requirements, ha | 318.5 | 319.7 | 403.4 | 407.3 | ||||||

| Land productivity, ha t−1 live weight | 236.7 | 249.5 | 228.7 | 242.1 | ||||||

| Land productivity z, ha t−1 live weight yr−1 | 253.6 | 267.3 | 399.1 | 422.4 | ||||||

| Crop Complex | Age Z yr | Calf-Fed | Yearling-Fed | Gain or loss ha−1 | |||

|---|---|---|---|---|---|---|---|

| Non implanted | Implanted | Non implanted | Implanted | Sequestration rate, Mg ha−1 yr−1 | |||

| Land area utilized by systems, ha | |||||||

| C | CO2 | ||||||

| Hay & Haylage | 5 < 10 | 9.68 | 9.68 | 12.82 | 12.99 | 0.2 | 0.730 |

| Old pasture | 110–20 | 237.40 | 237.40 | 237.40 | 237.40 | 0.2 | 0.730 |

| New pasture | <10 | 0.00 | 0.00 | 62.14 | 62.14 | 0.5 | 1.830 |

| Silage (loss) | 5–15 | 41.20 | 41.25 | 53.56 | 54.70 | 0.3 | −1.098 |

| Grain(loss) | 5−15 | 30.32 | 30.37 | 37.47 | 40.05 | 0.3 | −1.098 |

| Total | 318.60 | 318.70 | 403.39 | 407.28 | |||

| Crop Complex | Calf-Fed | Yearling-Fed | ||

|---|---|---|---|---|

| Non implanted | Implanted | Non implanted | Implanted | |

| kg CO2 yr−1 | ||||

| Hay and Haylage | 7,086 | 7,086 | 9,384 | 9,509 |

| Old pasture | 173,777 | 173,777 | 173,777 | 173,777 |

| New pasture | 0.0 | 0.0 | 113,716 | 113,716 |

| Silage (loss) | −45,238 | −45,293 | −58,809 | −60,061 |

| Grain(loss) | −33,291 | −34,444 | −41,142 | −43,975 |

| Total system net sequestration | 102,334 | 101,126 | 196,926 | 192,966 |

| System Net Emission (kg CO2 yr−1) | 819,773 | 827,218 | 1,022,733 | 1,044,116 |

| System Net Emission/ ha (kg CO2 yr−1 ha−1) | 2,573 | 2,596 | 2,535 | 2,564 |

| Live wt. (kg ) | 75,399 | 79,789 | 92,265 | 98,587 |

| Carcass wt. (kg) | 43,717 | 46,731 | 54,148 | 58,317 |

| Live wt. (kg ha−1) | 236.7 | 250.4 | 228.7 | 242.1 |

| Carcass wt. (kg ha−1) | 137.2 | 146.6 | 134.2 | 143.1 |

| GHG Intensity, kg CO2 kg−1 live weight | 10.9 | 10.4 | 11.1 | 10.6 |

| GHG Intensity, kg CO2 kg−1 carcass weight | 18.8 | 17.7 | 18.9 | 17.9 |

| GHG Intensity, kg CO2 kg−1 live weight yr−1 | 11.7 | 11.1 | 19.4 | 18.5 |

| GHG Intensity, kg CO2 kg−1 carcass weight yr−1 | 20.2 | 19.0 | 33.0 | 31.2 |

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Basarab, J.; Baron, V.; López-Campos, Ó.; Aalhus, J.; Haugen-Kozyra, K.; Okine, E. Greenhouse Gas Emissions from Calf- and Yearling-Fed Beef Production Systems, With and Without the Use of Growth Promotants. Animals 2012, 2, 195-220. https://doi.org/10.3390/ani2020195

Basarab J, Baron V, López-Campos Ó, Aalhus J, Haugen-Kozyra K, Okine E. Greenhouse Gas Emissions from Calf- and Yearling-Fed Beef Production Systems, With and Without the Use of Growth Promotants. Animals. 2012; 2(2):195-220. https://doi.org/10.3390/ani2020195

Chicago/Turabian StyleBasarab, John, Vern Baron, Óscar López-Campos, Jennifer Aalhus, Karen Haugen-Kozyra, and Erasmus Okine. 2012. "Greenhouse Gas Emissions from Calf- and Yearling-Fed Beef Production Systems, With and Without the Use of Growth Promotants" Animals 2, no. 2: 195-220. https://doi.org/10.3390/ani2020195