Comparative Study of Two Aging Treatments on Microstructure and Mechanical Properties of an Ultra-Fine Grained Mg-10Y-6Gd-1.5Zn-0.5Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure of As-Cast and ECAP Alloys

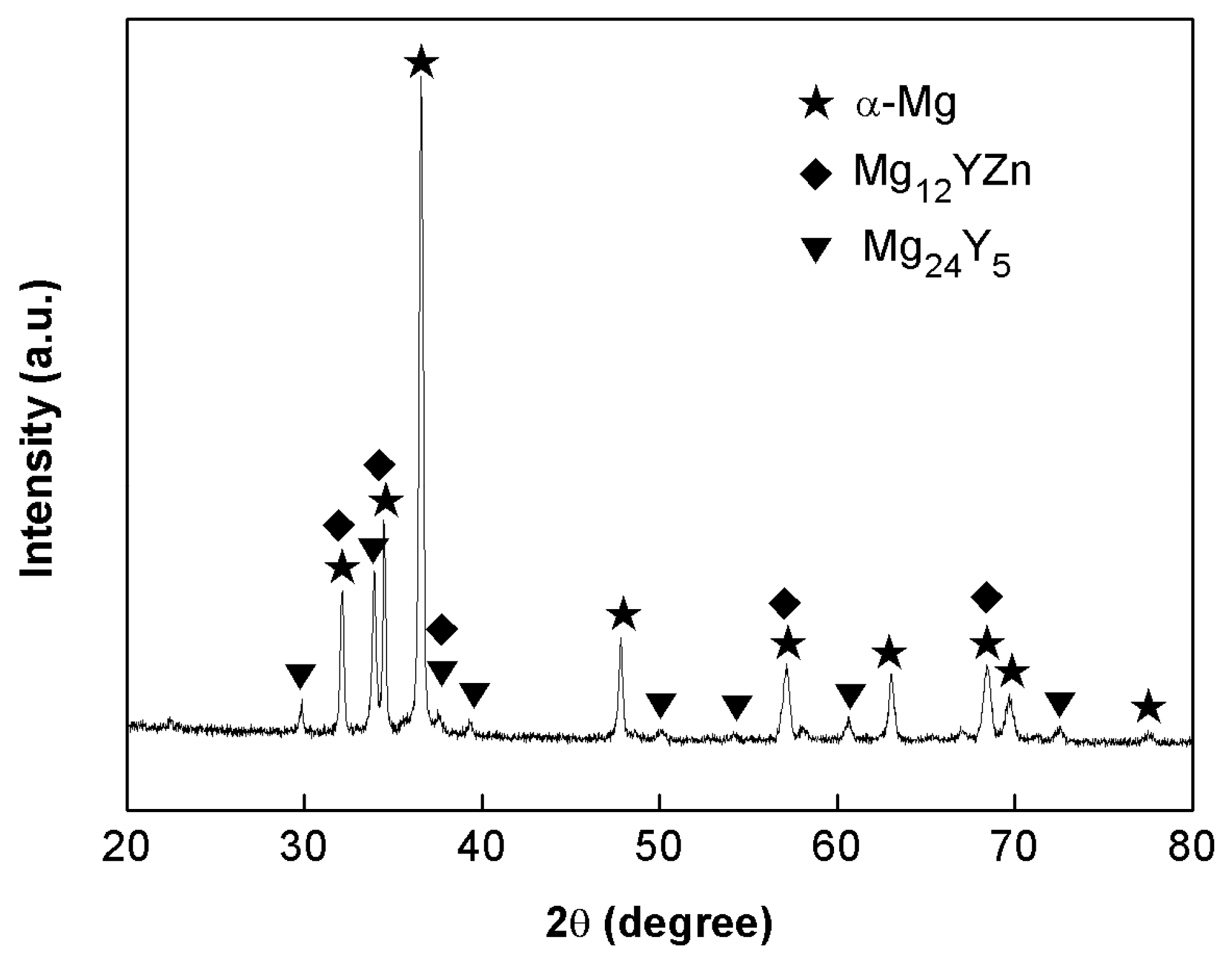

3.1.1. As-Cast Alloy

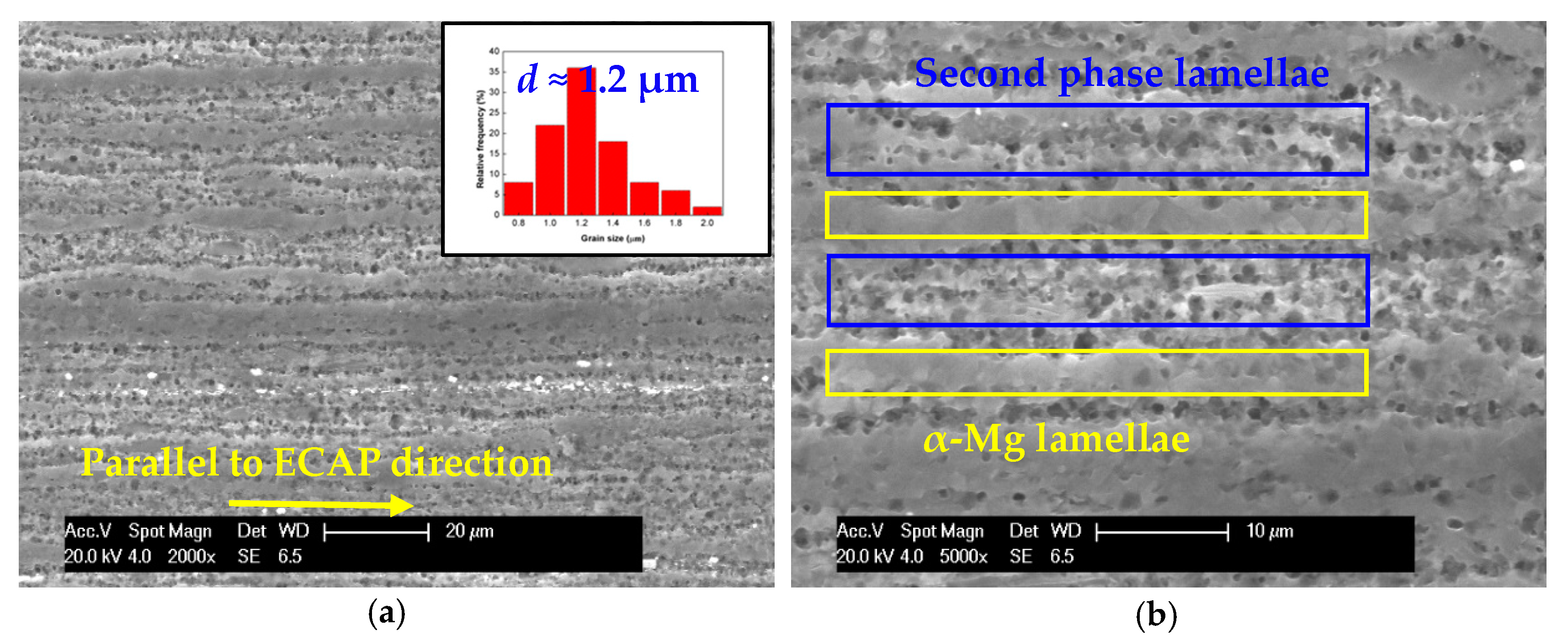

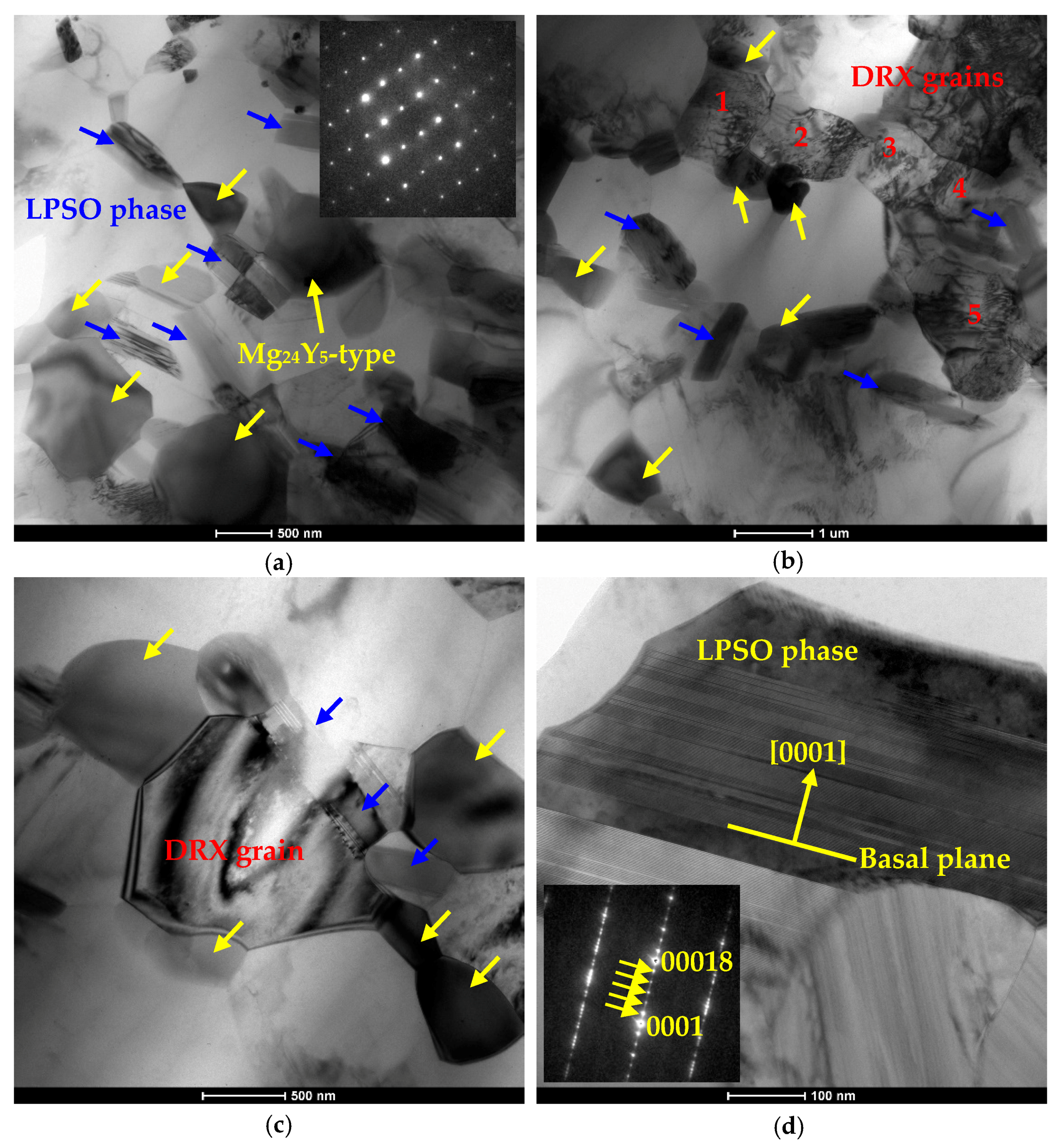

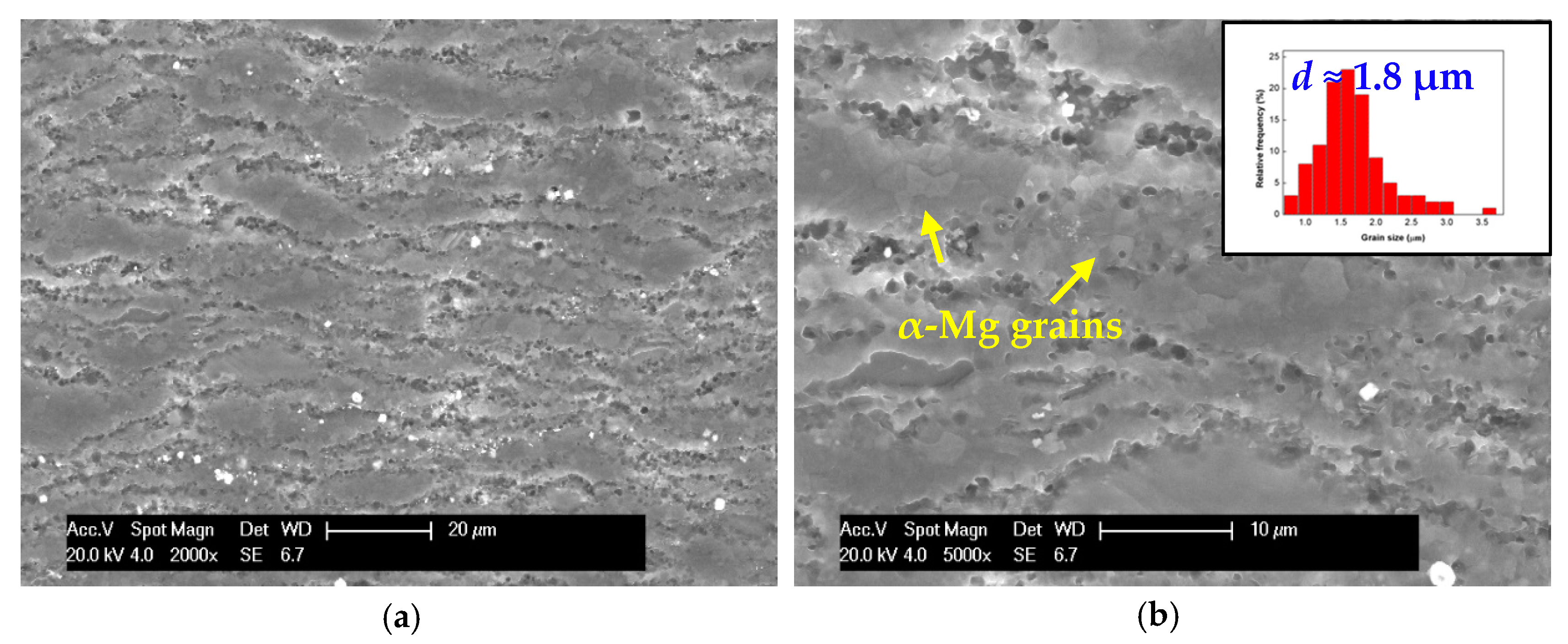

3.1.2. ECAP Alloy

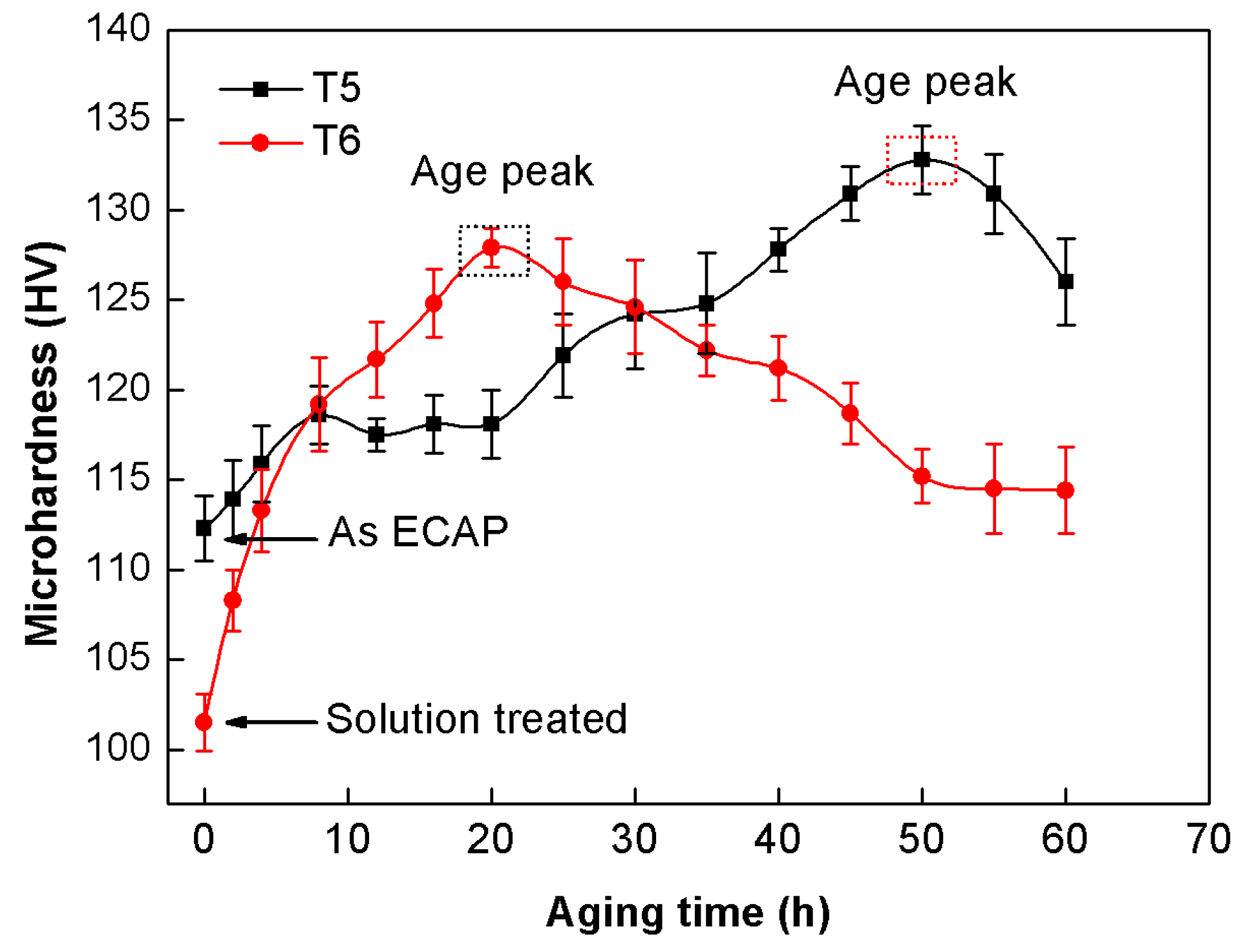

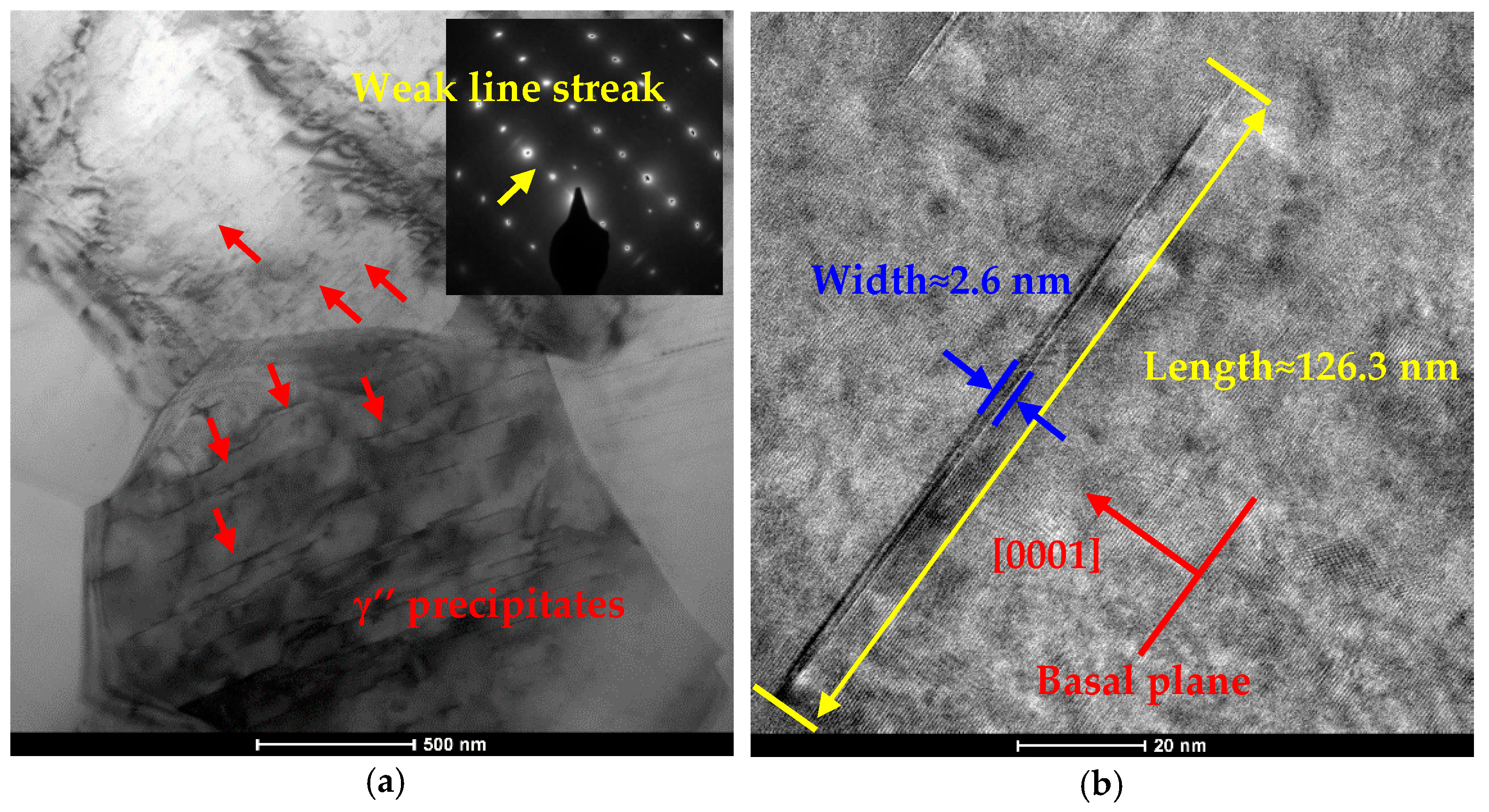

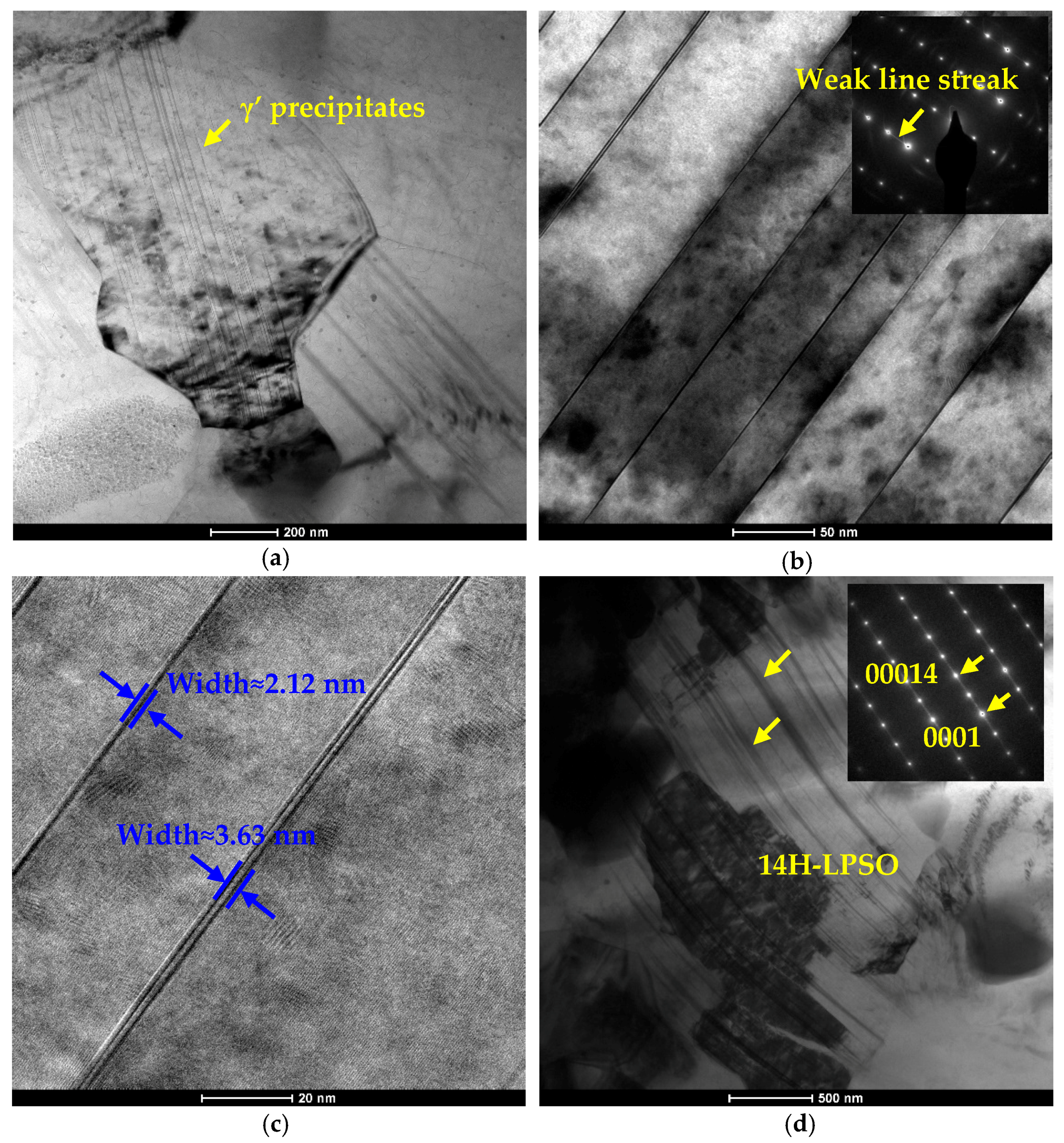

3.2. Microstructure of Aged Alloys

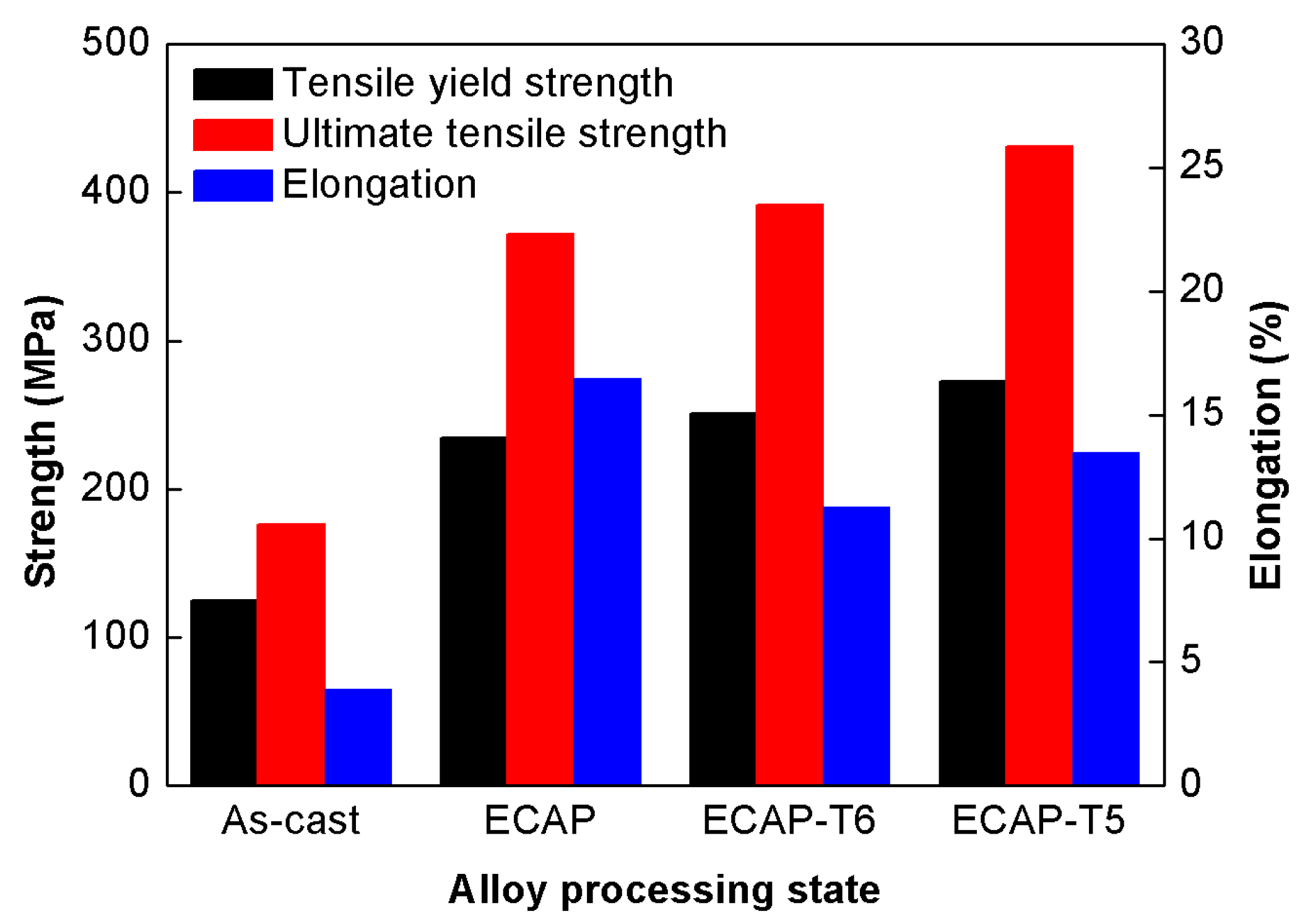

3.3. Mechanical Properties

4. Discussion

4.1. Precipitation Behavior of UFG Mg-10Y-6Gd-1.5Zn-0.5Zr Alloy

4.2. Relationship between the Microstructure and Mechanical Properties

5. Conclusions

- (1)

- The as-cast WGZ1061 alloy was composed of α-Mg matrix, network-shaped Mg24Y5-type phase, block LPSO phase and a few Y-rich particles. After sixteen passes of ECAP, the UFG microstructure with alternately arranged α-Mg lamellae and second phase lamellae was obtained.

- (2)

- The UFG WGZ1061 alloy exhibited obvious age hardening effects during two aging treatments. The average grain size increased form 1.2 μm to 4.3 μm after T6 peak aging and abundant nanosized γ’’ plates were precipitated. With further over aging, γ’’ phases were gradually transformed to γ’ plates and 14H-LPSO lamellae. In T5 peak aged situation, the grain sizes of α-Mg changed not obviously and abundant finer γ’’ plates were generated.

- (3)

- Both T5 and T6 aging treatments significantly promoted the strength of the ECAP alloy, together with slight decreases in ductility. The T5 peak aged alloy exhibited the superior comprehensive mechanical properties with ultimate strength of 431 MPa and elongation of 13.5%, suggesting great application potential and feasibility of manipulating nanosized precipitates on LPSO-contained UFG magnesium alloy. In future studies, the detailed precipitation sequences and their influences on UFG/FG Mg-RE-Zn alloys shall be investigated.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys? J. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Feng, B.; Xin, Y.C.; Guo, F.L.; Yu, H.H.; Wu, Y.; Liu, Q. Compressive mechanical behavior of Al/Mg composite rods with different types of Al sleeve. Acta Mater. 2016, 120, 379–390. [Google Scholar] [CrossRef]

- Yu, H.H.; Li, C.; Xin, Y.C.; Chapuis, A.; Huang, X.X.; Liu, Q. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater. 2017, 128, 313–326. [Google Scholar] [CrossRef]

- Pan, F.S.; Yang, M.B.; Chen, X.H. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Wei, J.; Huang, G.H.; Yin, D.D.; Li, K.N.; Wang, Q.D.; Zhou, H. Effects of ECAP and annealing treatment on the microstructure and mechanical properties of Mg-1Y (wt.%) binary alloy. Metals 2017, 7, 119. [Google Scholar] [CrossRef]

- Liu, H.; Bai, J.; Yan, K.; Yan, J.L.; Ma, A.B.; Jiang, J.H. Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg-Y-Zn alloys during annealing at 773 K. Mater. Des. 2016, 93, 9–18. [Google Scholar] [CrossRef]

- Pan, H.C.; Ren, Y.P.; Fu, H.; Zhou, H.; Wang, L.Q.; Meng, X.Y.; Qin, G.W. Recent developments in rare-earth free wrought magnesium alloys having high strength: A review. J. Alloys Compd. 2016, 663, 321–331. [Google Scholar] [CrossRef]

- Liu, H.; Ju, J.; Bai, J.; Sun, J.P.; Song, D.; Yan, J.L.; Jiang, J.H.; Ma, A.B. Preparation, microstructure evolutions, and mechanical property of an ultra-fine grained Mg-10Gd-4Y-1.5Zn-0.5Zr alloy. Metals 2017, 7, 398. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Chiu, C.; Liu, H.C. Mechanical properties and corrosion behavior of WZ73 Mg Alloy/SiCp composite fabricated by stir casting method. Metals 2018, 8, 424. [Google Scholar] [CrossRef]

- Xu, D.K.; Han, E.H.; Xu, Y.B. Effect of long-period stacking ordered phase on microstructure, mechanical property and corrosion resistance of Mg alloys: A review. Prog. Nat. Sci. Mater. Int. 2016, 26, 117–128. [Google Scholar] [CrossRef]

- Shao, X.H.; Yang, Z.Q.; Ma, X.L. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure. Acta Mater. 2010, 58, 4760–4771. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical properties of magnesium-rare earth alloy systems: A review. Metals 2015, 5, 1–39. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef]

- Itoi, T.; Seimiya, T.; Kawamura, Y.; Hirohashi, M. Long period stacking structures observed in Mg97Zn1Y2 alloy. Scr. Mater. 2004, 51, 107–111. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Morton, A.J.; Nie, J.F. Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys. Acta Mater. 2012, 60, 6562–6572. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Morton, A.J.; Nie, J.F. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys. Acta Mater. 2010, 58, 2936–2947. [Google Scholar] [CrossRef]

- Liu, H.; Xue, F.; Bai, J.; Sun, Y.S. Effect of heat treatments on the microstructure and mechanical properties of an extruded Mg95.5Y3Zn1.5 alloy. Mater. Sci. Eng. A 2013, 585, 261–267. [Google Scholar] [CrossRef]

- Yamasaki, M.; Hashimoto, K.; Hagihara, K.; Kawamura, Y. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy. Acta Mater. 2011, 59, 3646–3658. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.S.; Wei, L.Y.; Xu, C.X.; Zong, X.M.; Hao, J.Q. Extensive dynamic recrystallized grains at kink boundary of 14H LPSO phase in extruded Mg92Gd3Zn1Li4 alloy. Mater. Sci. Eng. A 2017, 681, 97–102. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.Q.; Hu, W.Y.; Le, Q.C.; Bao, L.; Cui, J.Z. Effects of extrusion speed on the microstructure and mechanical properties of Mg-9Gd-3Y-1.5Zn-0.8Zr alloy. J. Mater. Sci. Technol. 2016, 32, 313–319. [Google Scholar] [CrossRef]

- Xu, C.; Nakata, T.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Kamado, S. Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy. Sci. Rep. 2017, 7, 40846. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, C.; Nakata, T.; Qiao, X.G.; Zheng, M.Y.; Wu, K.; Kamado, S. Ageing behavior of extruded Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr (wt.%) alloy containing LPSO phase and γ′ precipitates. Sci. Rep. 2017, 7, 43391. [Google Scholar] [CrossRef] [PubMed]

- Rong, W.; Wu, Y.J.; Zhang, Y.; Sun, M.; Chen, J.; Peng, L.M.; Ding, W.J. Characterization and strengthening effects of γ′ precipitates in a high-strength casting Mg-15Gd-1Zn-0.4Zr (wt.%) alloy. Mater. Charact. 2017, 126, 1–9. [Google Scholar] [CrossRef]

- Lapovok, R.; Gao, X.; Nie, J.F.; Estrin, Y.; Mathaudhu, S.N. Enhancement of properties in cast Mg-Y-Zn rod processed by severe plastic deformation. Mater. Sci. Eng. A 2014, 615, 198–207. [Google Scholar] [CrossRef]

- Yu, Z.J.; Huang, Y.D.; Mendis, C.L.; Hort, N.; Meng, J. Microstructural evolution and mechanical properties of Mg-11Gd-4.5Y-1Nd-1.5Zn-0.5Zr alloy prepared via pre-ageing and hot extrusion. Mater. Sci. Eng. A 2015, 624, 23–31. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Longdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 7, 881–981. [Google Scholar] [CrossRef]

- Liu, H.; Ju, J.; Yang, X.W.; Yan, J.L.; Song, D.; Jiang, J.H.; Ma, A.B. A two-step dynamic recrystallization induced by LPSO phases and its impact on mechanical property of severe plastic deformation processed Mg97Y2Zn1 alloy. J. Alloys Compd. 2017, 704, 509–517. [Google Scholar] [CrossRef]

- Lu, F.M.; Ma, A.B.; Jiang, J.H.; Yang, D.H.; Yuan, Y.C.; Zhang, L.Y. Formation of profuse long period stacking ordered microcells in Mg-Gd-Zn-Zr alloy during multipass ECAP process. J. Alloys Compd. 2014, 601, 140–145. [Google Scholar] [CrossRef]

- Zeng, Z.R.; Nie, J.F.; Xu, S.W.; Davies, C.H.J.; Birbilis, N. Super-formable pure magnesium at room temperature. Nat. Commun. 2017, 8, 972. [Google Scholar] [CrossRef] [PubMed]

- Trang, T.T.T.; Zhang, J.H.; Kim, J.H.; Zargaran, A.; Hwang, J.H.; Suh, B.C.; Kim, N.J. Designing a magnesium alloy with high strength and high formability. Nat. Commun. 2018, 9, 2522. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.T.; Xu, C.; Qiao, X.G.; Zheng, M.Y.; Kamado, S.; Gao, N.; Starink, M.J. Evolution of microstructure and mechanical properties of an as-cast Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr alloy processed by high pressure torsion. Mater. Sci. Eng. A 2017, 700, 312–320. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.J.; Xu, C.; Meng, J.; Zhang, X.H.; Kamado, S. Effects of pre-annealing on microstructure and mechanical properties of as-extruded Mg-Gd-Y-Zn-Zr alloy. J. Alloys Compd. 2017, 729, 627–637. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Z.J.; Yan, K.; Yan, J.L.; Bai, J.; Jiang, J.H.; Ma, A.B. Effect of multi-pass equal channel angular pressing on the microstructure and mechanical properties of a heterogeneous Mg88Y8Zn4 alloy. J. Mater. Sci. Technol. 2016, 32, 1274–1281. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.H.; Leng, Z.; Liu, S.J.; Yang, Q.; Wu, R.Z.; Zhang, M.L. Microstructure and mechanical properties of high-performance Mg-Y-Er-Zn extruded alloy. Mater. Des. 2014, 54, 256–263. [Google Scholar] [CrossRef]

- Hagihara, K.; Kinoshita, A.; Sugino, Y.; Yamasaki, M.; Kawamura, Y.; Yasuda, H.Y.; Umakoshi, Y. Effect of long-period stacking ordered phase on mechanical properties of Mg97Zn1Y2 extruded alloy. Acta Mater. 2010, 58, 6282–6293. [Google Scholar] [CrossRef]

- Kawamura, Y.; Yamasaki, M. Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure. Mater. Trans. 2007, 48, 2986–2992. [Google Scholar] [CrossRef]

- Nie, J.F.; Oh-ishi, K.; Gao, X.; Hono, K. Solute segregation and precipitation in a creep-resistant Mg-Gd-Zn alloy. Acta Mater. 2008, 56, 6061–6076. [Google Scholar] [CrossRef]

- Nishijima, M.; Yubuta, K.; Hiraga, K. Characterization of β′ precipitate phase in Mg-2 at% Y alloy aged to peak hardness condition by high-angle annular detector dark-field scanning transmission electron microscopy (HAADF-STEM). Mater. Trans. 2007, 48, 84–87. [Google Scholar] [CrossRef]

- Nishijima, M.; Hiraga, K. Structural changes of precipitates in an Mg-5 at% Gd alloy studied by transmission electron microscopy. Mater. Trans. 2007, 48, 10–15. [Google Scholar] [CrossRef]

- Yamasaki, M.; Sasaki, M.; Nishijima, M.; Hiraga, K.; Kawamura, Y. Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg-Zn-Gd alloys during isothermal aging at high temperature. Acta Mater. 2007, 55, 6798–6805. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Morton, A.J.; Weyland, M.; Nie, J.F. Characterization of planar features in Mg-Y-Zn alloys. Acta Mater. 2010, 58, 464–475. [Google Scholar] [CrossRef]

- Zhu, Y.M.; Weyland, M.; Morton, A.J.; Oh-ishi, K.; Hono, K.; Nie, J.F. The building block of long-period structures in Mg-RE-Zn alloys. Sci. Mater. 2009, 60, 980–983. [Google Scholar] [CrossRef]

| Alloy Series | Precipitation Sequence | Reference |

|---|---|---|

| Mg-Y binary alloys | SSSS → G.P. → β’’(D019) → β’(Mg7Y) → β(Mg24Y5) | [39] |

| Mg-Gd binary alloys | SSSS → G.P. → β’’(D019) → β’(Mg7Gd) → β1(Mg3Gd) → β(Mg5Gd) | [40] |

| Mg-Gd-Zn alloys | SSSS → β1(Mg3Gd) → β(Mg5Gd) SSSS→SF (→14H LPSO) SSSS → γ’’(Mg70Gd15Zn15) → γ’(MgGdZn)→γ (14H LPSO) | [41] [41] [38] |

| Mg-Y-Zn alloys | SSSS → I2 stacking fault → γ’(MgYZn) → γ (14H LPSO) | [41,43] |

| Processing States | Average α-Mg Grain Size (μm) | Average Particle Size (μm) | Volume Fraction of Particles (%) |

|---|---|---|---|

| As-cast | 68 ± 9.7 | - | ~33% |

| ECAP | 1.24 ± 0.26 | 0.89 ± 0.28 | ~28% |

| ECAP-T5 | 1.83 ± 0.47 | 0.83 ± 0.30 | ~26% |

| ECAP-T6 | 4.30 ± 1.02 | 0.70 ± 0.25 | ~22% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Huang, H.; Wang, C.; Ju, J.; Sun, J.; Wu, Y.; Jiang, J.; Ma, A. Comparative Study of Two Aging Treatments on Microstructure and Mechanical Properties of an Ultra-Fine Grained Mg-10Y-6Gd-1.5Zn-0.5Zr Alloy. Metals 2018, 8, 658. https://doi.org/10.3390/met8090658

Liu H, Huang H, Wang C, Ju J, Sun J, Wu Y, Jiang J, Ma A. Comparative Study of Two Aging Treatments on Microstructure and Mechanical Properties of an Ultra-Fine Grained Mg-10Y-6Gd-1.5Zn-0.5Zr Alloy. Metals. 2018; 8(9):658. https://doi.org/10.3390/met8090658

Chicago/Turabian StyleLiu, Huan, He Huang, Ce Wang, Jia Ju, Jiapeng Sun, Yuna Wu, Jinghua Jiang, and Aibin Ma. 2018. "Comparative Study of Two Aging Treatments on Microstructure and Mechanical Properties of an Ultra-Fine Grained Mg-10Y-6Gd-1.5Zn-0.5Zr Alloy" Metals 8, no. 9: 658. https://doi.org/10.3390/met8090658