Effect of Al2O3 Nanoparticles as Reinforcement on the Tensile Behavior of Al-12Si Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results

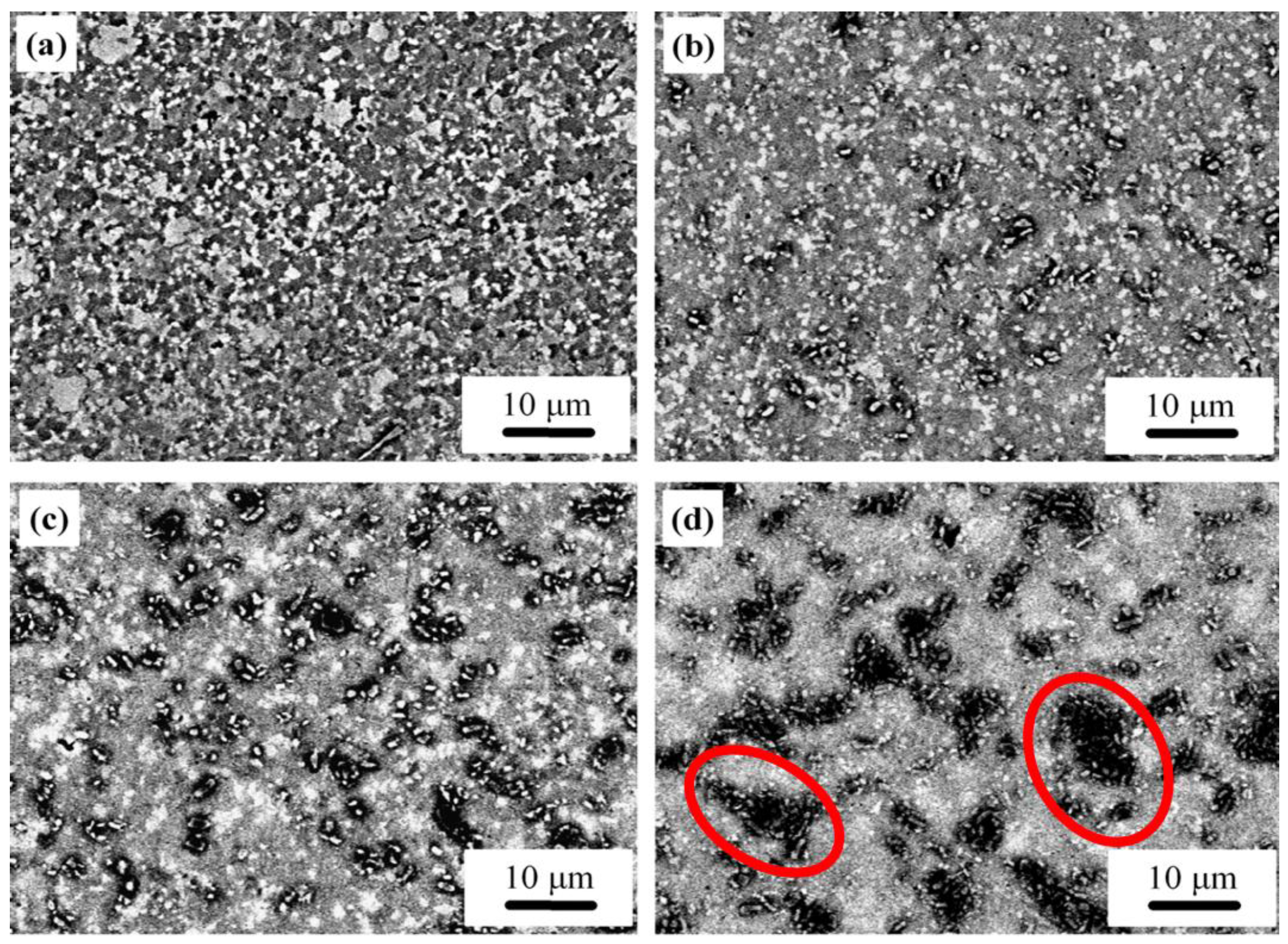

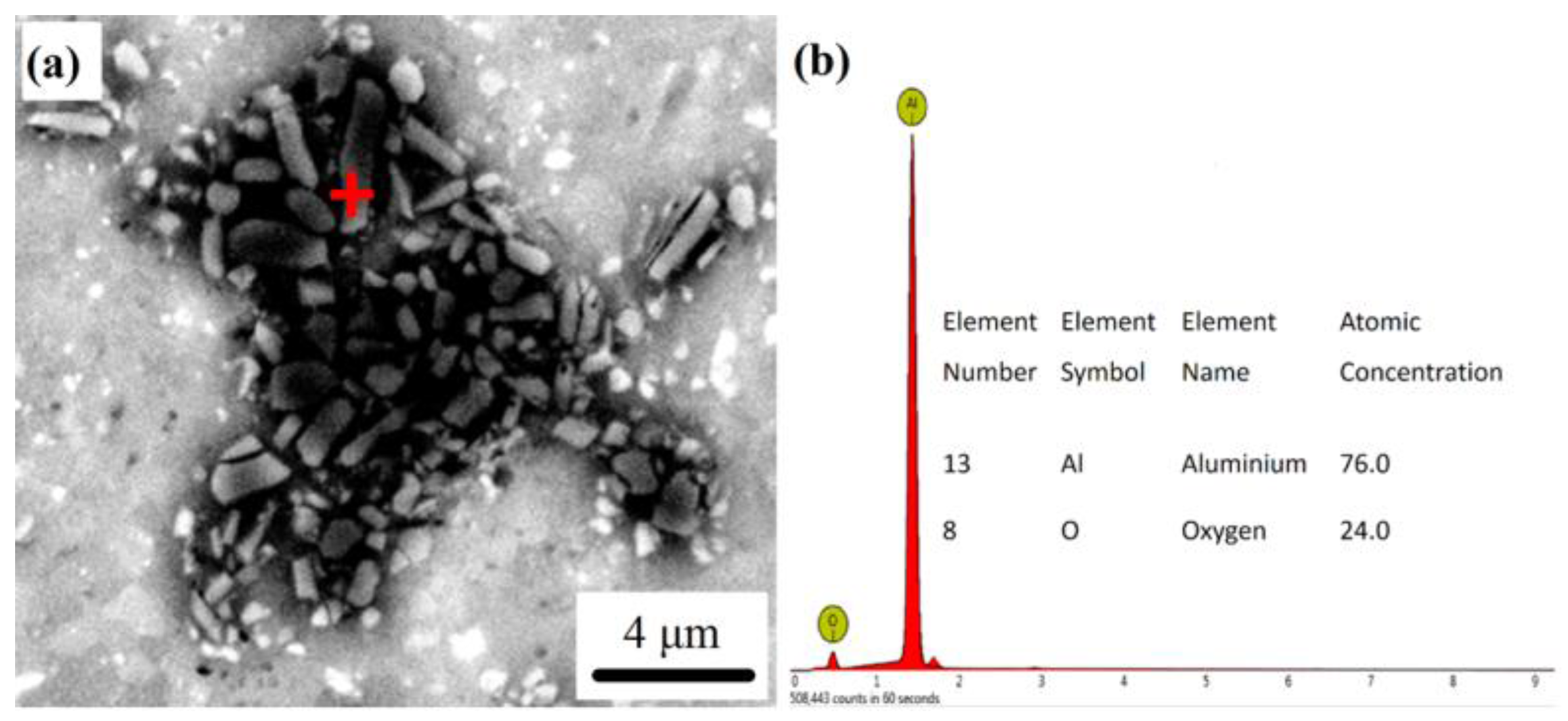

3.1. Microstructure Analysis and Phase Identification

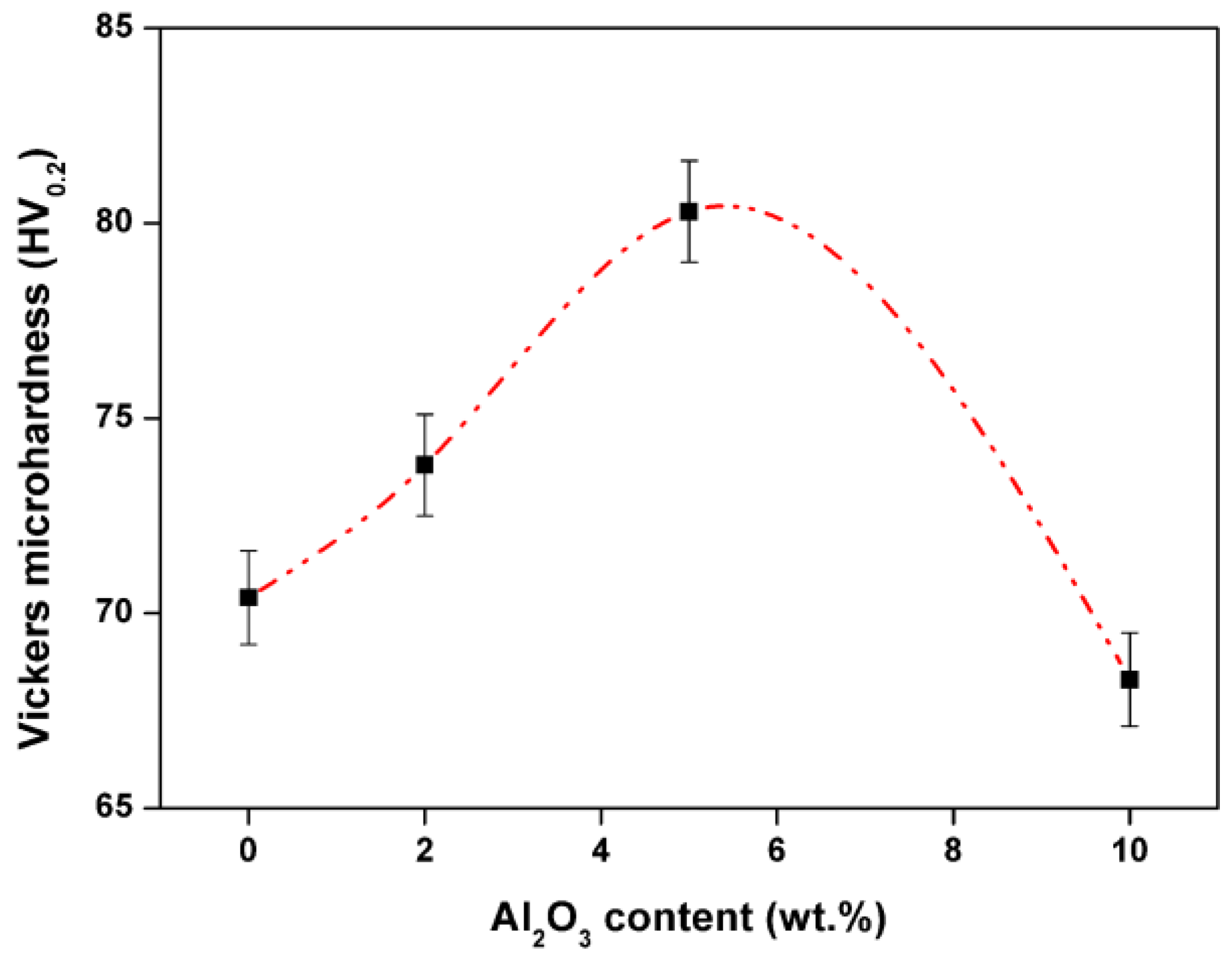

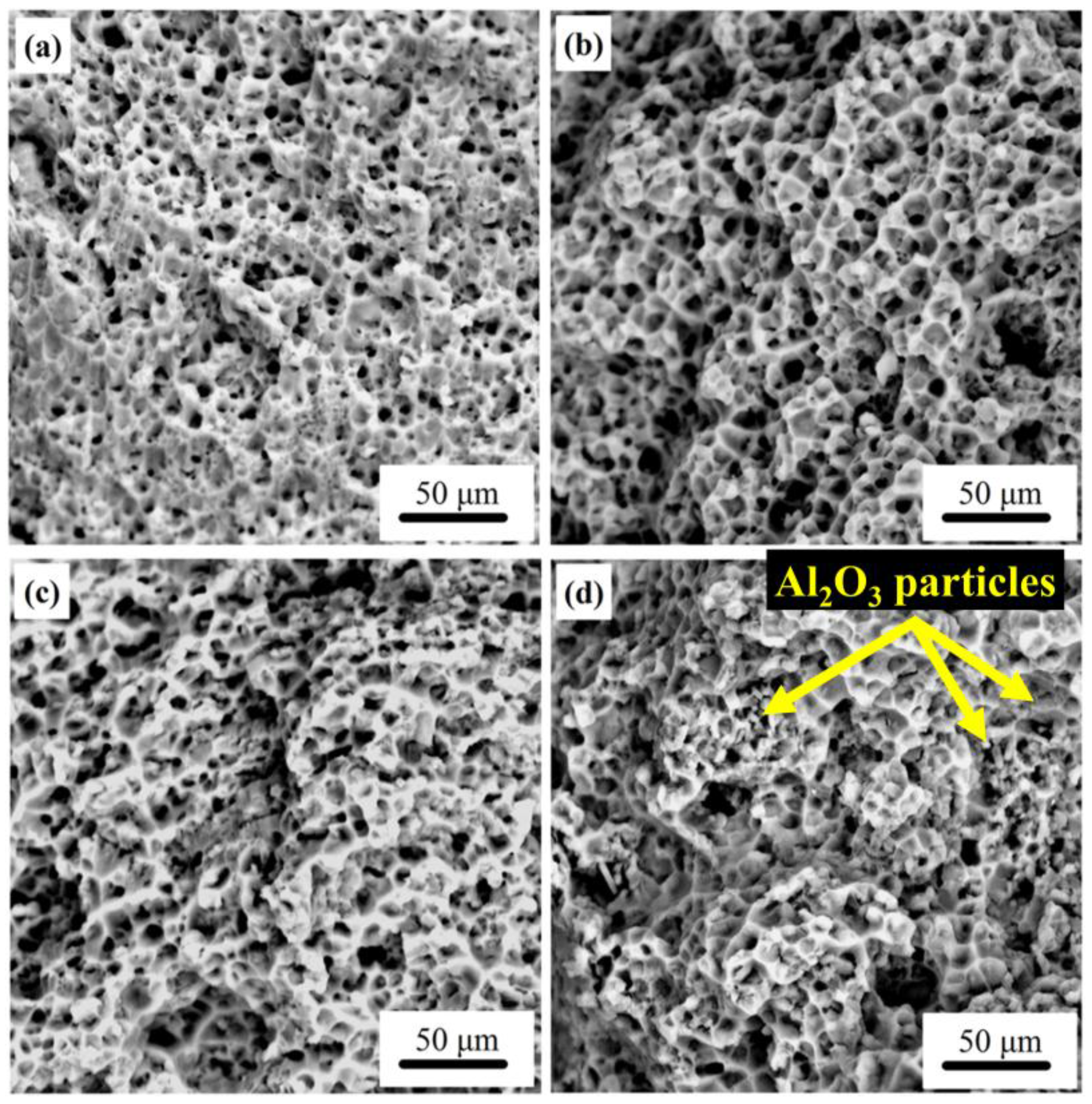

3.2. Physical and Mechanical Properties

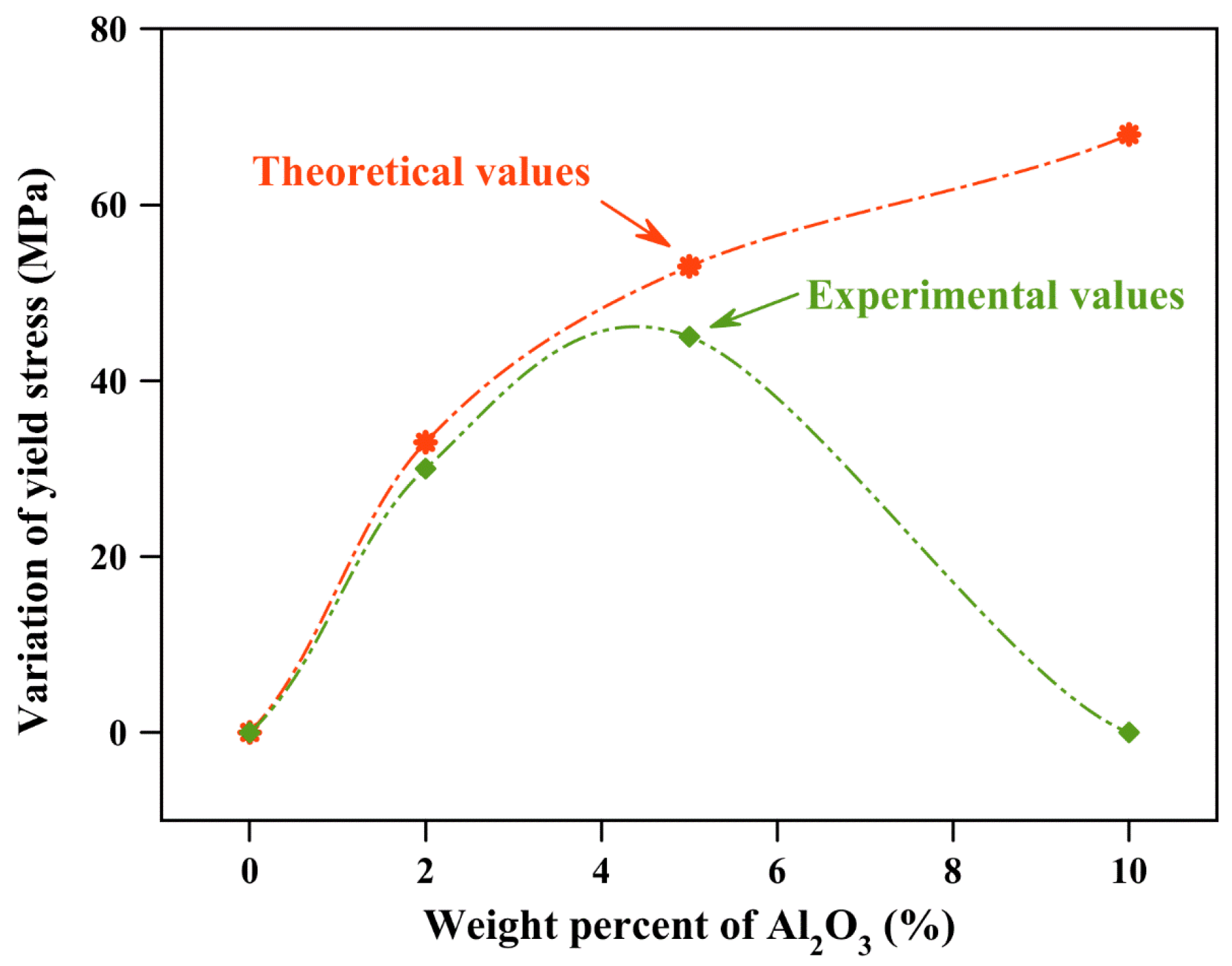

3.3. Strengthening Mechanism

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surreddi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Hunt, W.; Herling, D.R. Aluminum Metal Matrix Composites. Adv. Mater. Process. 2004, 162, 39–44. [Google Scholar]

- Wang, Z.; Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Sordelet, D.J.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Tensile properties of Al matrix composites reinforced with in-situ devitrified Al84Gd6Ni7Co3 glassy particles. J. Alloy. Compd. 2014, 586, S419–S422. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Lober, L.; Wang, P.; Attar, H.; Schimansky, F.; Pyczak, F.; Eckert, J. Processing of Al-12Si–TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Sun, B.A.; Scudino, S.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Fabrication and mechanical properties of Al-based metal matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater. Sci. Eng. A 2014, 600, 53–58. [Google Scholar] [CrossRef]

- Mazahery, A.; Abdizadeh, H.; Baharvandi, H.R. Development of high- performance A356/nano-Al2O3 composites. Mater. Sci. Eng. A 2009, 518, 61–64. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustaf, S.F. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Mirzaee, O.; Baharvandi, H.R. Fabrication and study on mechanical properties and fracture behavior of nanometric Al2O3 particle- reinforced A356 composites focusing on the parameters of vortex method. Mater. Des. 2013, 46, 199–205. [Google Scholar] [CrossRef]

- Su, H.; Gao, W.L.; Feng, Z.H.; Lu, Z. Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Des. 2012, 36, 590–596. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H. Microstructure and mechanical properties of Al-Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Torabi Parizi, M. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Chou, S.N.; Huang, J.L.; Lii, D.F.; Lu, H.H. The mechanical properties of Al2O3/aluminum alloy A356 composite manufactured by squeeze casting. J. Alloys Compd. 2006, 419, 98–102. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Niroumand, B. Effects of reinforcement distribution on low and high temperature tensile properties of Al356/SiCp cast composites produced by a novel reinforcement dispersion technique. Mater. Sci. Eng. A 2011, 528, 7186–7195. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Baharvandi, H.R.; Mirzaee, O. Fabrication of nano-sized Al2O3 reinforced casting aluminum composite focusing on preparation process of reinforcement powders and evaluation of its properties. Compos. Part B. 2013, 55, 426–432. [Google Scholar] [CrossRef]

- Li, S.F.; Sunb, B.; Imaia, H.; Mimotob, T.; Kondoha, K. Powder metallurgy titanium metal matrix composites reinforced with carbon nanotubes and graphite. Compos. Part A 2013, 48, 57–66. [Google Scholar] [CrossRef]

- Kallip, K.; Kishore Babu, N.; AlOgab, K.A.; Kollo, L.; Maeder, X.; Arroyo, Y.; Leparoux, M. Microstructure and mechanical properties of near net shaped aluminium/alumina nanocomposites fabricated by powder metallurgy. J. Alloys Compd. 2017, 714, 133–143. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Murty, B.S. Production, kinetic study and properties of Fe-based glass and its composites. Mater. Manuf. Processes. 2010, 25, 592–597. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Scudino, S.; Sun, B.A.; Qu, R.T.; He, J.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Mechanical behavior of Al-based matrix composites reinforced with Mg58Cu28.5Gd11Ag2.5 metallic glass. Adv. Powder technol. 2014, 25, 635–639. [Google Scholar] [CrossRef]

- Marko, D.; Prashanth, K.G.; Scudino, S.; Wang, Z.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Al-based metal matrix composites reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 glassy powder: Mechanical behavior under tensile loading. J. Alloys Compd. 2014, 615, S382–S385. [Google Scholar] [CrossRef]

- Tabandeh Khorshid, M.; Jenabali Jahromi, S.A.; Moshksar, M.M. Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron sized Al2O3 particulates developed by wet attrition milling and hot extrusion. Mater. Des. 2010, 31, 3880–3884. [Google Scholar] [CrossRef]

- Razavi, H.Z.; Hafizpour, H.R.; Simchi, A. An investigation on the compressibility of aluminum/nano-alumina composite powder prepared by blending and mechanical milling. Mater. Sci. Eng. A 2007, 454–455, 89–98. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Debalina, B.; Wang, Z.; Gostin, P.; Gebert, A.; Calin, M.; Kühn, U.; Kamaraj, M.; Scudino, S.; Eckert, J. Triobological and corrosion properties of Al-12Si produced by selective laser melting. J. Mater. Res. 2014, 29, 2044–2054. [Google Scholar] [CrossRef]

- Li, C.D.; Wang, X.J.; Liu, W.Q.; Wu, K.; Shi, H.L.; Ding, C.; Hu, X.S.; Zheng, M.Y. Microstructure and strengthening mechanism of carbon nanotubes reinforced magnesium matrix composite. Mater. Sci. Eng. A 2014, 597, 264–269. [Google Scholar] [CrossRef]

- Zhang, D.; Zhan, Z. Preparation of graphene nanoplatelets-copper composites by a modified semi-powder method and their mechanical properties. J. Alloys Compd. 2016, 654, 226–233. [Google Scholar] [CrossRef]

- Li, M.Q.; Zhai, H.X.; Huang, Z.Y.; Liu, X.H.; Zhou, Y.; Li, S.B.; Li, C.W. Tensile behavior and strengthening mechanism in ultrafine TiC0.5 particle reinforced Cu-Al matrix composites. J. Alloys Compd. 2015, 628, 186–194. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon. 2015, 95, 690–698. [Google Scholar] [CrossRef]

- Bisht, A.; Srivastava, M.; Manoj Kumar, R.; Lahir, I.; Lahiri, D. Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering. Mater. Sci. Eng. A 2017, 695, 20–28. [Google Scholar] [CrossRef]

- Nardone, V.C.; Prewo, K.M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scripta Metall. 1986, 20, 43–48. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

- Ma, F.C.; Zhou, J.J.; Liu, P.; Li, W.; Liu, X.K.; Pan, D.; Lu, W.J.; Zhang, D.; Wu, L.Z.; Wei, X.Q. Strengthening effects of TiC particles and microstructure refinement in insitu TiC-reinforced Ti matrix composites. Mater. Charact. 2017, 127, 27–34. [Google Scholar] [CrossRef]

- Sree Manu, K.M.; Arun Kumar, S.; Rajan, T.P.D.; Riyas Mohammed, M.; Pai, B.C. Effect of alumina nanoparticle on strengthening of Al-Si alloy through dendrite refinement, interfacial bonding and dislocation bowing. J. Alloys Compd. 2017, 712, 394–405. [Google Scholar] [CrossRef]

- Li, J.; Liu, B.; Fang, Q.H.; Huang, Z.W.; Liu, Y.W. Atomic-scale strengthening mechanism of dislocation-obstacle interaction in silicon carbide particle- reinforced copper matrix nanocomposites. Ceram. Int. 2017, 43, 3839–3846. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, C.; Tieu, A.K.; Pei, L.Q.; Zhang, L.; Cheng, K.Y.; Huang, M.H. Strengthening mechanisms and dislocation processes in <111> textured nanotwinned copper. Mater. Sci. Eng. A 2016, 676, 474–486. [Google Scholar] [CrossRef]

| Weight Percent of Al2O3 (%) | Theoretical Density (g/cc) | Measured Density (g/cc) | Relative Density (%) |

|---|---|---|---|

| 0 | 2.61 | 2.60 | 99.6 |

| 2 | 2.63 | 2.61 | 99.2 |

| 5 | 2.66 | 2.64 | 99.5 |

| 10 | 2.70 | 2.65 | 98.1 |

| Weight Percent of Al2O3 (%) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 0 | 198 ± 2 | 228 ± 2 | 23 ± 2 |

| 2 | 228 ± 2 | 256 ± 3 | 24 ± 2 |

| 5 | 245 ± 2 | 286 ± 3 | 30 ± 3 |

| 10 | 195 ± 2 | 221 ± 2 | 19 ± 1 |

| Weight Percent of Al2O3 (%) | △σLoad (MPa) | △σOrowan (MPa) | △σCTE (MPa) | △σC (MPa) |

|---|---|---|---|---|

| 2 | 1.50 | 3.85 | 27.94 | 33.19 |

| 5 | 4.14 | 6.13 | 42.47 | 52.74 |

| 10 | 6.65 | 8.75 | 53.49 | 68.89 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, P.; Jia, Y.; Konda Gokuldoss, P.; Yu, Z.; Yang, S.; Zhao, J.; Li, C. Effect of Al2O3 Nanoparticles as Reinforcement on the Tensile Behavior of Al-12Si Composites. Metals 2017, 7, 359. https://doi.org/10.3390/met7090359

Ma P, Jia Y, Konda Gokuldoss P, Yu Z, Yang S, Zhao J, Li C. Effect of Al2O3 Nanoparticles as Reinforcement on the Tensile Behavior of Al-12Si Composites. Metals. 2017; 7(9):359. https://doi.org/10.3390/met7090359

Chicago/Turabian StyleMa, Pan, Yandong Jia, Prashanth Konda Gokuldoss, Zhishui Yu, Shanglei Yang, Jian Zhao, and Chonggui Li. 2017. "Effect of Al2O3 Nanoparticles as Reinforcement on the Tensile Behavior of Al-12Si Composites" Metals 7, no. 9: 359. https://doi.org/10.3390/met7090359