Hot Deformation Behavior of a Spray-Deposited Al-8.31Zn-2.07Mg-2.46Cu-0.12Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

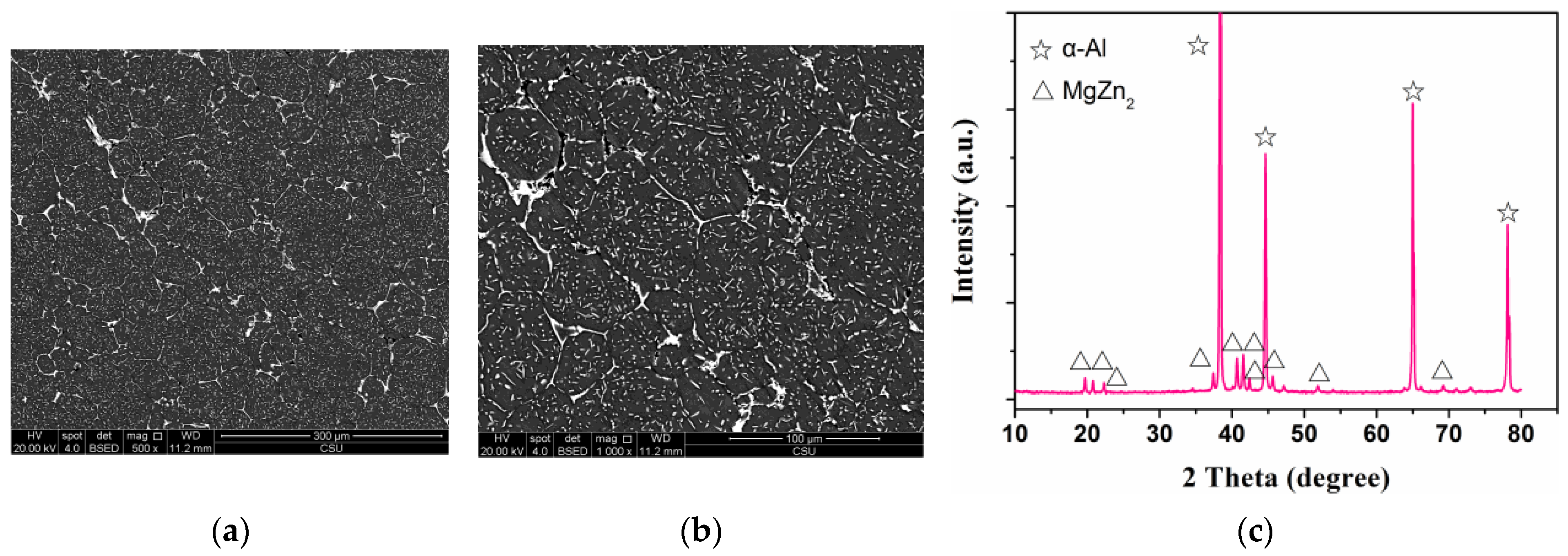

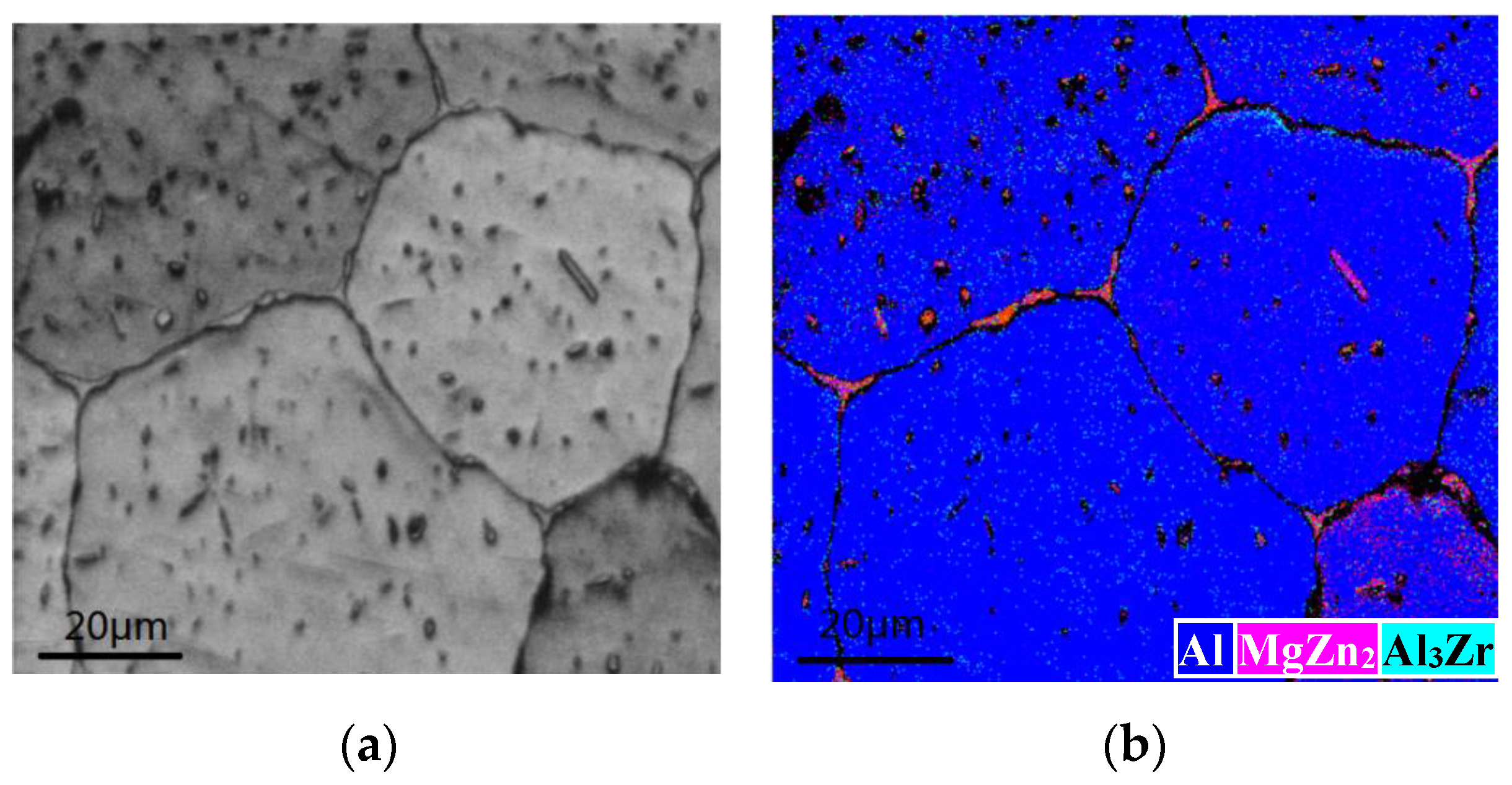

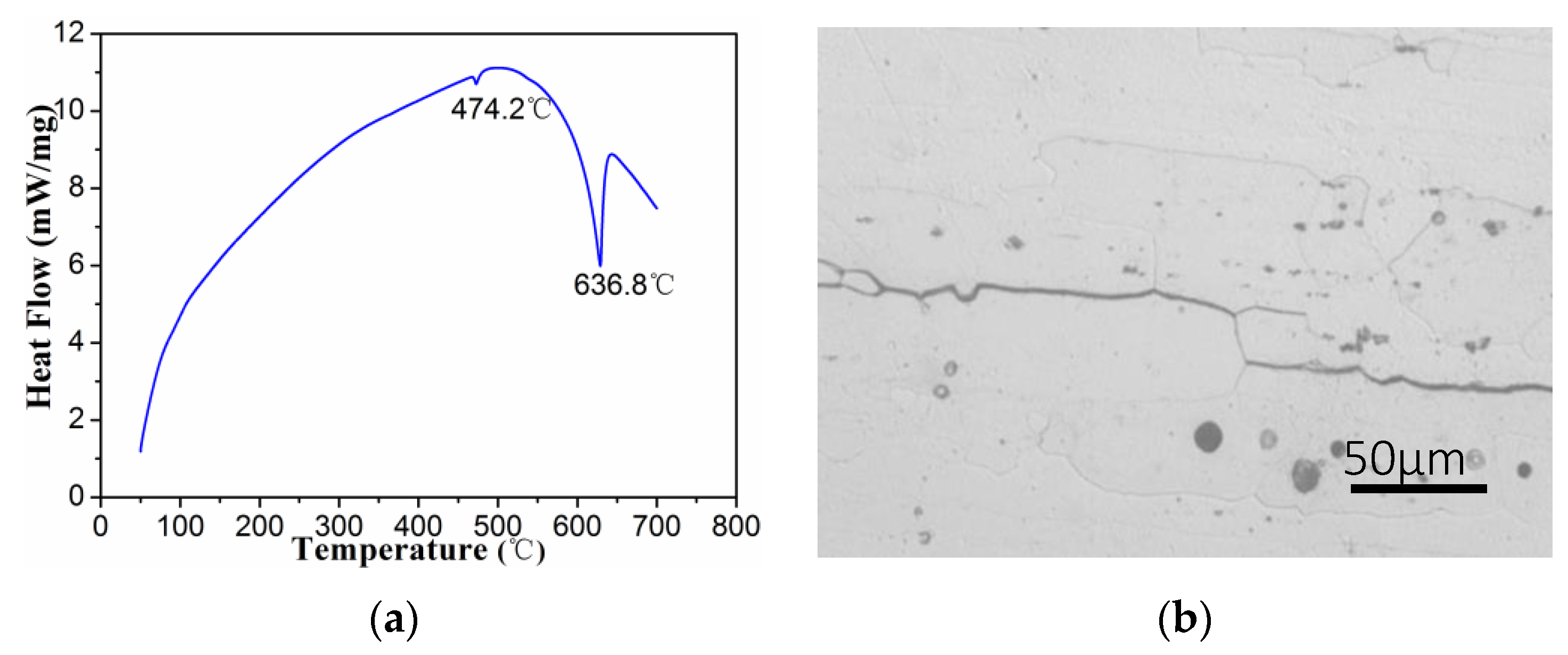

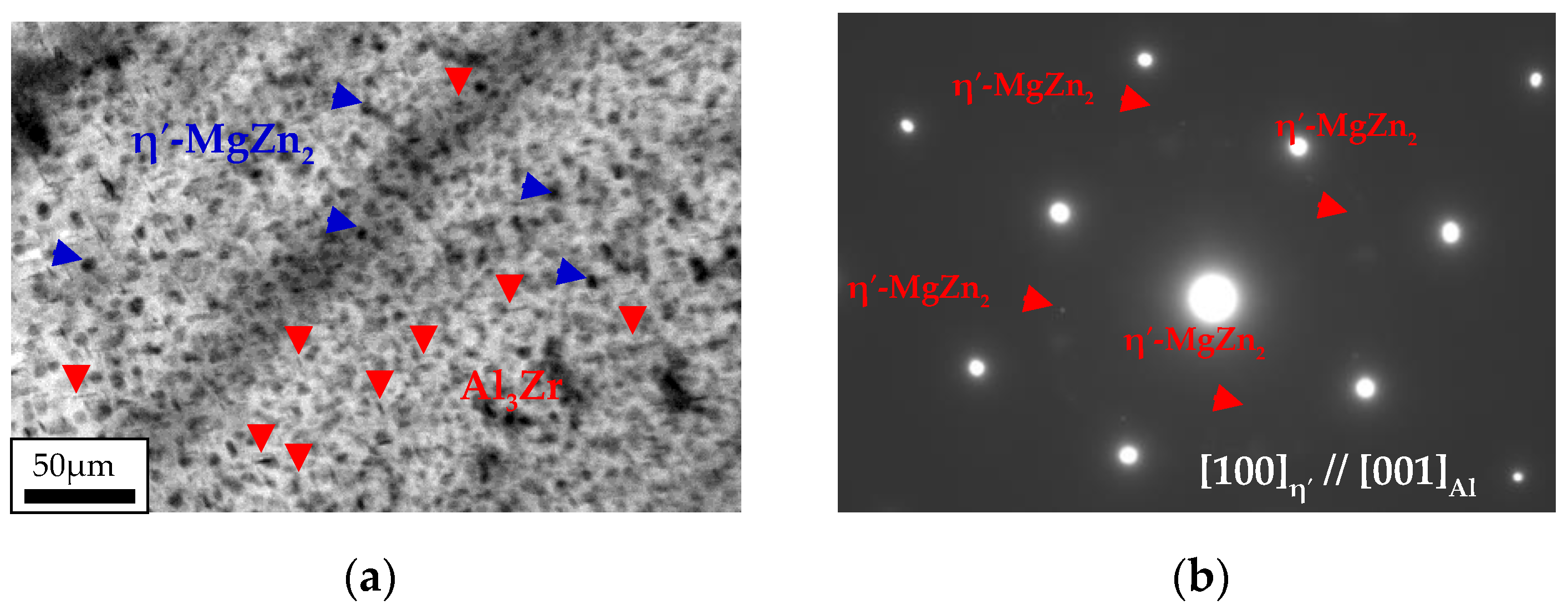

3.1. Initial Microstructure of As-Spray-Deposited Samples

3.2. Compressive Stress-Strain Curves

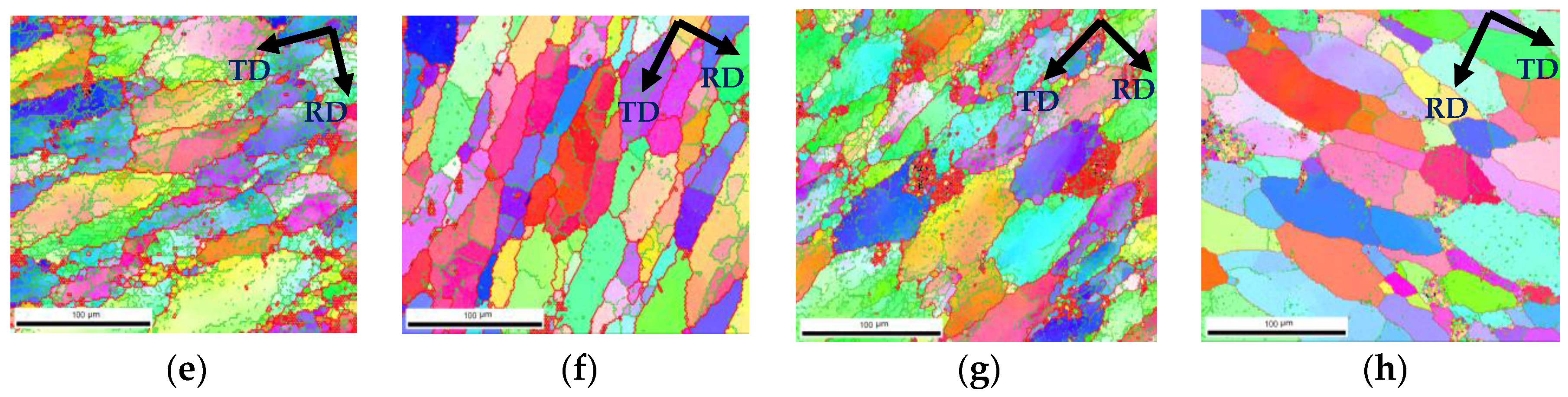

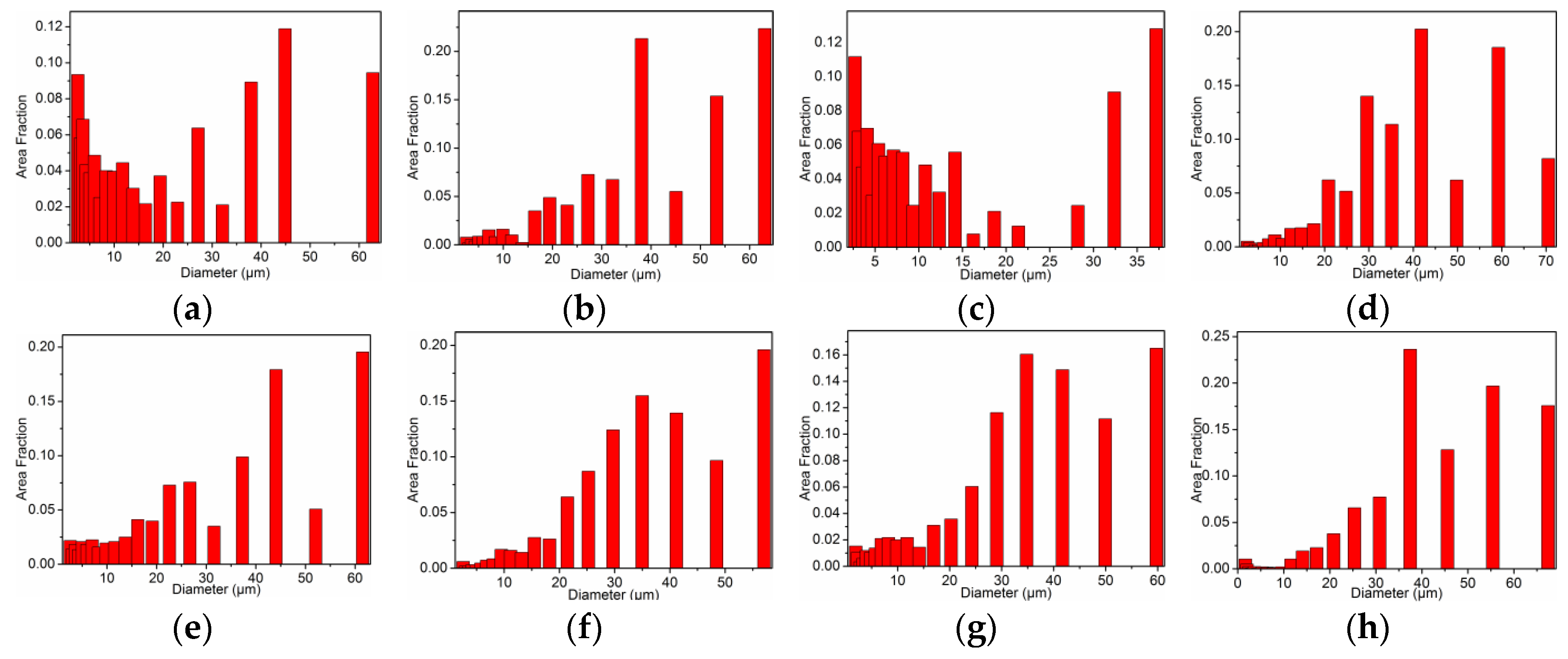

3.3. Microstructure Evolution

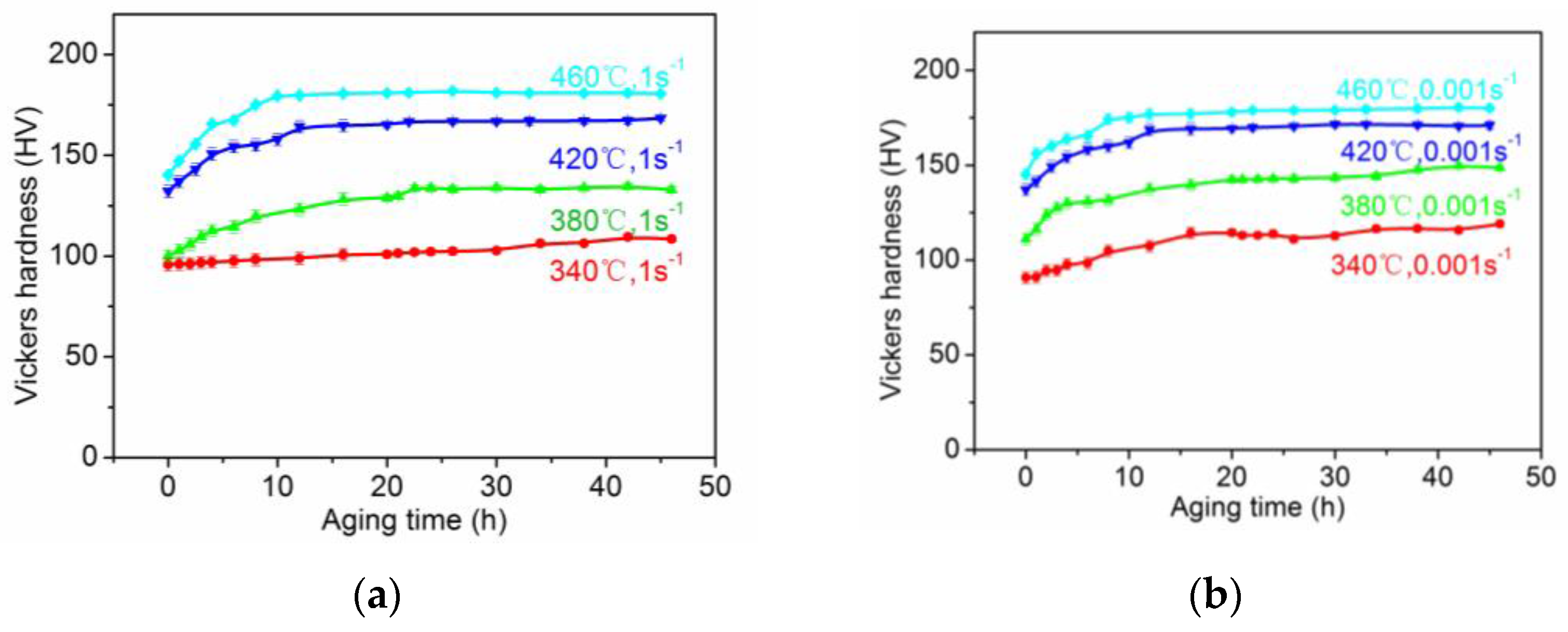

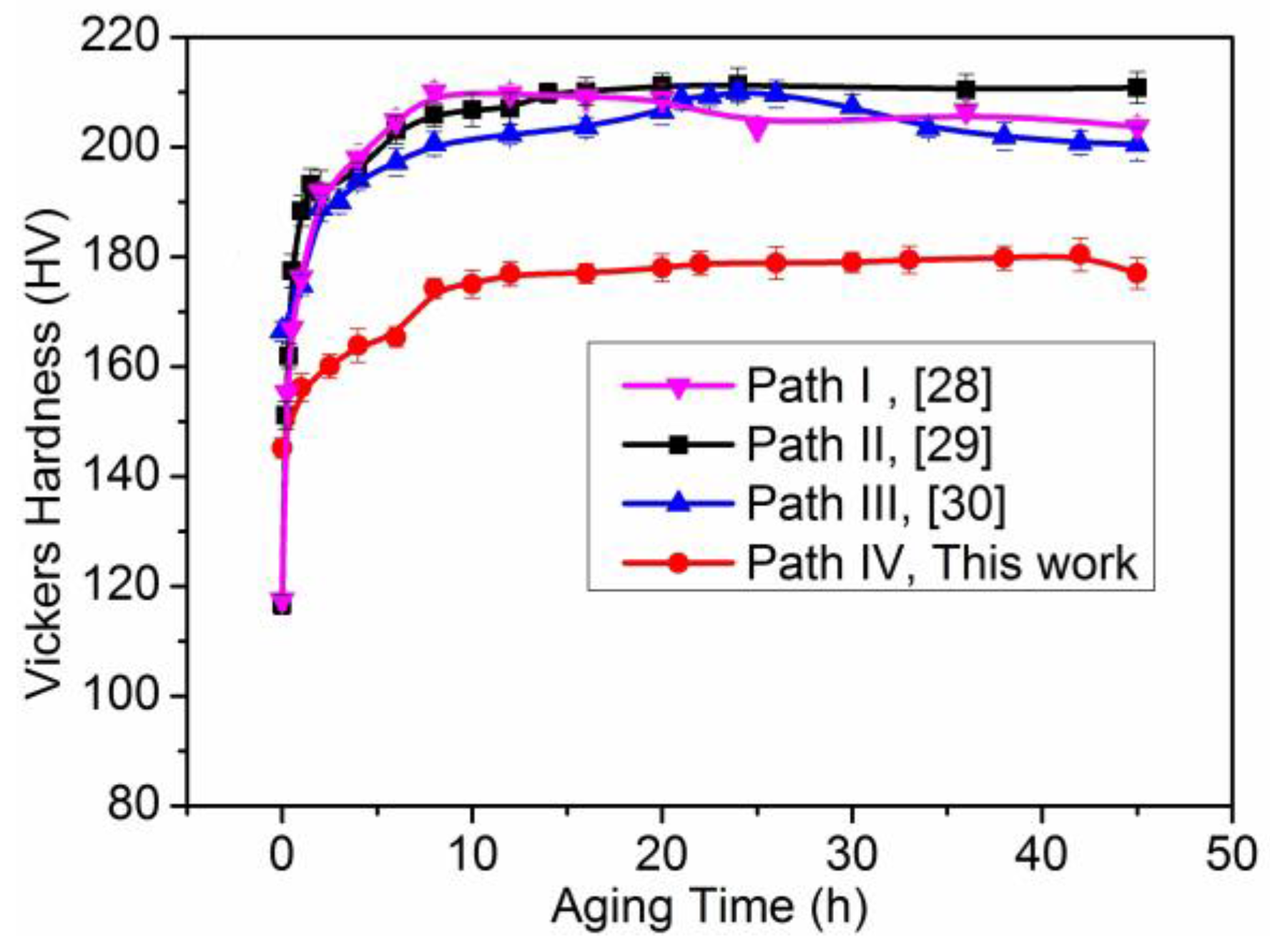

3.4. Hardness of the Compressive Samples after Age Treatments

4. Discussion

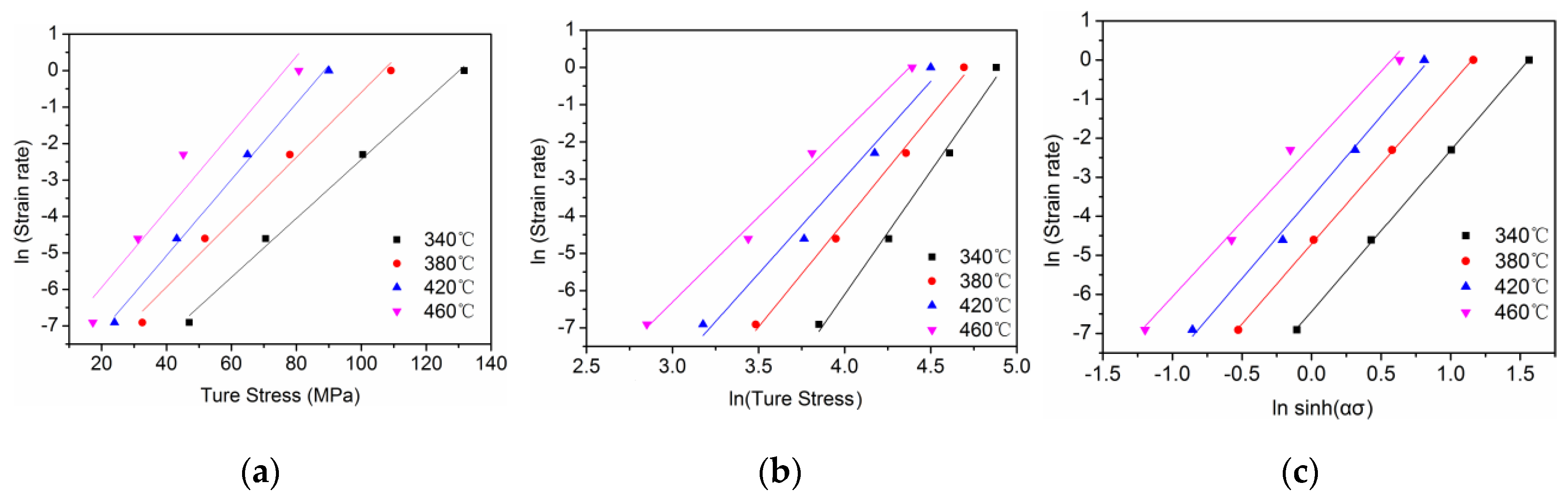

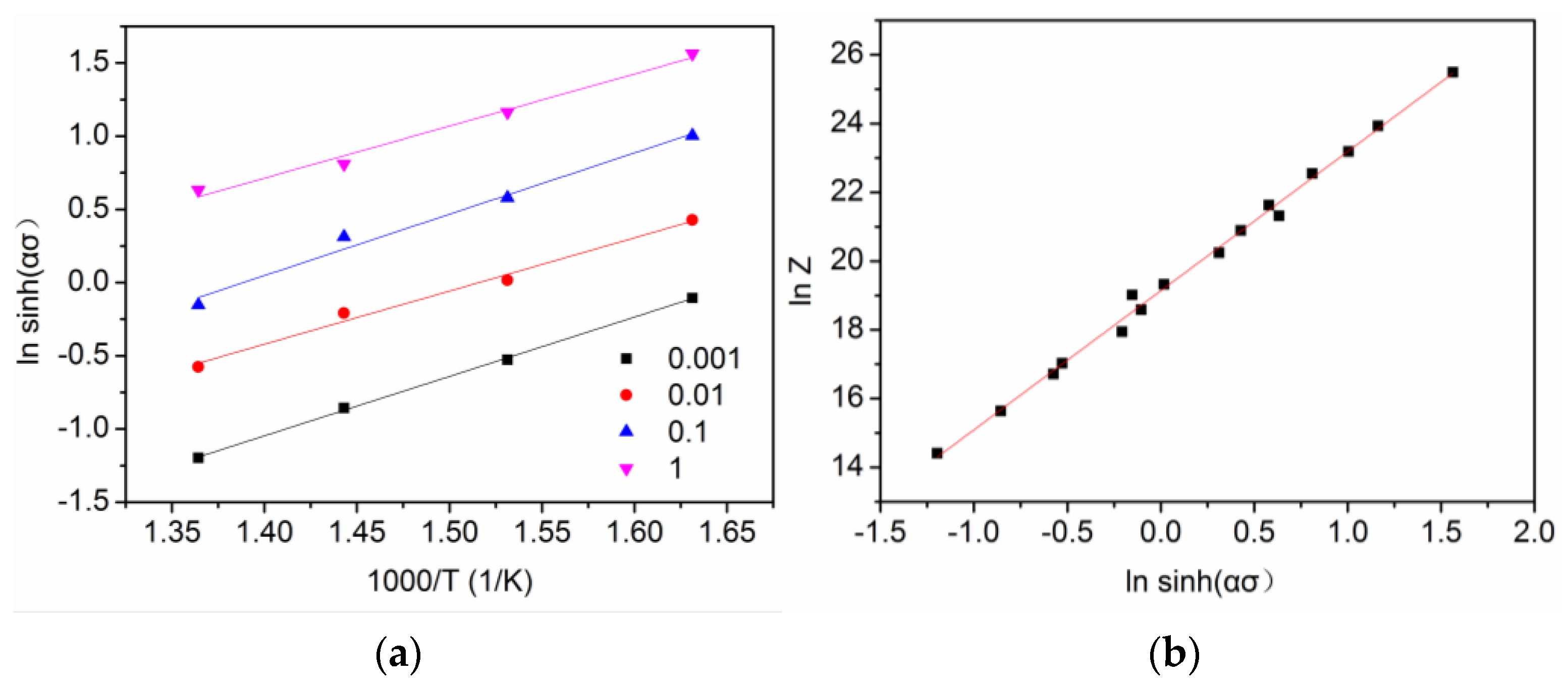

4.1. Constitutive Equation

4.2. Hot Deformation Behavior

4.3. Shortening the Production Process

4.4. Strengthening Mechanism

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ferguson, J.B.; Schultz, B.F.; Mantas, J.C.; Shokouhi, H.; Rohatgi, P.K. Effect of Cu, Zn, and Mg concentration on heat treating behavior of squeeze cast Al-(10 to 12)Zn-(3.0 to 3.4)Mg-(0.8 to 1)Cu. Metals 2014, 4, 314–321. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Zhan, L.H. Effect of creep aging process on microstructures and properties of the retrogressed Al-Zn-Mg-Cu alloy. Metals 2016, 6, 189. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Ma, S.M.; Sun, Y.H.; Wang, H.Y.; Lü, X.S.; Qian, M.; Ma, Y.L.; Zhang, C.; Liu, B.C. Effect of a minor Sr modifier on the microstructures and mechanical properties of 7075 T6 Al alloys. Metals 2017, 7, 13. [Google Scholar] [CrossRef]

- Zhao, H.L.; Yao, D.M.; Qiu, F.; Xia, Y.M.; Jiang, Q.C. High strength and good ductility of casting Al-Cu alloy modified by PrxOy and LaxOy. J. Alloys Compd. 2011, 509, 43–46. [Google Scholar] [CrossRef]

- Lang, Y.J.; Zhou, G.X.; Hou, L.G.; Zhang, J.S.; Zhuang, L.Z. Significantly enhanced the ductility of the fine-grained Al-Zn-Mg-Cu alloy by strain-induced precipitation. Mater. Des. 2015, 88, 625–631. [Google Scholar] [CrossRef]

- Yuan, W.H.; Zhang, J.; Zhang, C.C.; Chen, Z.H. Processing of ultra-high strength SiCp/Al-Zn-Mg-Cu composites. J. Mater. Process. Technol. 2009, 209, 3251–3255. [Google Scholar] [CrossRef]

- Krasilnikov, N.A.; Sharafutdiniv, A. High strength and ductility of nanostructured Al-based alloy, prepared by high-pressure technique. Mater. Sci. Eng. A 2007, 463, 74–77. [Google Scholar] [CrossRef]

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys. Acta Mater. 2010, 58, 248–260. [Google Scholar] [CrossRef]

- Sharma, M.M.; Amateau, M.F.; Eden, T.J. Aging response of Al-Zn-Mg-Cu spray formed alloys and their metal matrix composites. Mater. Sci. Eng. A 2006, 424, 87–96. [Google Scholar] [CrossRef]

- Dong, J.; Cui, J.Z.; Yu, F.X.; Zhao, Z.H.; Zhuo, Y.B. A new way to cast high-alloyed Al-Zn-Mg-Cu-Zr for super-high strength and toughness. J. Mater. Process. Technol. 2006, 171, 399–404. [Google Scholar] [CrossRef]

- Roy, S.B.Y.; Nataraj, B.R.; Suwas, S.; Kumar, S.; Chattopadhyay, K. Accumulative roll bonding of aluminum alloys 2219/5086 laminates: Microstructural evolution and tensile properties. Mater. Des. 2012, 36, 529–539. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R.; Park, J.K. Microstructure and mechanical properties of Al-7075 alloy processed by equal channel angular pressing combined with aging treatment. Mater. Des. 2014, 57, 250–257. [Google Scholar] [CrossRef]

- Sun, N.; Apelian, D. Friction stir processing of aluminum cast alloys for high performance applications. J. Miner. Metal. Mater. Soc. 2011, 63, 44–50. [Google Scholar] [CrossRef]

- Naeem, H.T.; Mohammed, K.S.; Ahmad, K.R. Effect of friction stir processing on the microstructure and hardness of an aluminum-zinc-magnesium-copper alloy with nickel additives. Strength Plast. 2015, 116, 1035–1046. [Google Scholar] [CrossRef]

- Sharma, M.M.; Amateau, M.F.; Eden, T.J. Hardening mechanisms of spray formed Al-Zn-Mg-Cu alloys with scandium and other elemental additions. J. Alloys Compd. 2006, 416, 135–142. [Google Scholar] [CrossRef]

- Dorward, R.C.; Beerntsen, D.J. Grain structure and quench-rate effects on strength and toughness of AA7050 Al-Zn-Mg-Cu-Zr alloy plate. Metall. Mater. Trans. A 1995, 26, 2481–2484. [Google Scholar] [CrossRef]

- Sharma, M.M.; Amateau, M.F.; Eden, T.J. Mesoscopic structure control of spray formed high strength Al-Zn-Mg-Cu alloys. Acta Mater. 2005, 53, 2919–2924. [Google Scholar] [CrossRef]

- Jia, Y.D.; Cao, F.Y.; Ning, Z.L.; Guo, S.; Ma, P.; Sun, J.F. Influence of second phases on mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy. Mater. Des. 2012, 40, 536–540. [Google Scholar] [CrossRef]

- Liu, S.D.; Zhang, X.M.; Chen, X.M.; You, J.H.; Zhang, X.Y. Effect of Zr content on quench sensitivity of AlZnMgCu alloys. Trans. Nonferr. Met. Soc. China 2007, 17, 787–792. [Google Scholar] [CrossRef]

- Cai, Y.H.; Liang, R.G.; Su, Z.P.; Zhang, J.S. Microstructure of spray formed Al-Zn-Mg-Cu alloy with Mn addition. Trans. Nonferr. Met. Soc. China 2011, 21, 9–14. [Google Scholar] [CrossRef]

- Li, F.X.; Liu, Y.Z.; Jiang, Y.; Luo, X. Effect of processing parameters on the relative density of spray rolling 7050 aluminum alloy strip. Int. J. Adv. Manuf. Technol. 2013, 67, 2771–2778. [Google Scholar] [CrossRef]

- Yu, H.C.; Wang, M.P.; Sheng, X.F.; Li, Z.; Chen, L.B.; Lei, Q.; Chen, C.; Jia, Y.L.; Xiao, Z.; Chen, W.; et al. Microstructure and tensile properties of large-size 7055 aluminum billets fabricated by spray forming rapid solidification technology. J. Alloys Compd. 2013, 578, 208–214. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Medina, S.F.; Hernandez, C.A. General expression of the Zener-Hollomon parameter as a function of the chemical composition of low alloy and microalloyed steels. Acta Mater. 1996, 44, 137–148. [Google Scholar] [CrossRef]

- Kolb, G.K.H.; Scheiber, S.; Antrekowitsch, H.; Uggowitzer, P.J.U.; Pöschmann, D.; Pogatscher, S. Differential scanning calorimetry and thermodynamic predictions—A comparative study of Al-Zn-Mg-Cu alloys. Metals 2016, 6, 180. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, L.X.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Wang, Z.A.; Wang, M.P.; Yang, W.C.; Zhang, Q. Ageing precipitation and hardening behavior of 1973 high strength and high toughness aluminum alloy. Chin. J. Nonferr. Met. 2011, 21, 522–528. [Google Scholar]

- Yu, H.C. Microstructure and Mechanical Properties of Spray-Deposition 7055 High Strength Aluminum Alloys. Ph.D. Thesis, Central South University, Changsha, China, May 2015. (In Chinese). [Google Scholar]

- Liu, B.; Wang, M.P.; Lei, Q.; Daun, Y.L.; Liu, L.X.; Yu, H.C. Microstructure and properties of Al-Zn-Mg-Cu-Zr alloy prepared by spray deposition method. Chin. J. Nonferr. Met. 2015, 25, 1773–1780. [Google Scholar]

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminum; Marcel Dekker, Inc.: New York, NY, USA, 2003; Volume 1, pp. 287–288. ISBN 0824704940. [Google Scholar]

- Mabuchi, M.; Higashi, K. Strengthening mechanism of Mg-Si alloys. Acta Mater. 1996, 44, 4611–4618. [Google Scholar] [CrossRef]

- Lee, J.S.; Jung, J.Y.; Lee, E.K.; Park, W.J.; Ahn, S.; Nack, J.K. Microstructure and properties of titanium boride dispersed Cu alloys fabricated by spray forming. Mater. Sci. Eng. A 2000, 277, 274–283. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Song, K.X.; Xing, J.D.; Zhang, Y.M. Precipitation behavior and properties of aged Cu-0.23Be-0.84Co alloy. J. Alloys Compd. 2016, 658, 920–930. [Google Scholar] [CrossRef]

- Yang, G.; Li, Z.; Yuan, Y.; Qian, L. Microstructure, mechanical properties and electrical conductivity of Cu-0.3Mg-0.05Ce alloy processed by equal channel angular pressing and subsequent annealing. J. Alloys Compd. 2015, 640, 347–354. [Google Scholar] [CrossRef]

- Zheng, Z.Q. Fundamentals of Materials Science; Central South University Press: Changsha, China, 2005; pp. 302–306. ISBN 978-7-5487-0948-0. (In Chinese) [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, X.; Lei, Q.; Xiao, Z.; Wang, M. Hot Deformation Behavior of a Spray-Deposited Al-8.31Zn-2.07Mg-2.46Cu-0.12Zr Alloy. Metals 2017, 7, 299. https://doi.org/10.3390/met7080299

Sheng X, Lei Q, Xiao Z, Wang M. Hot Deformation Behavior of a Spray-Deposited Al-8.31Zn-2.07Mg-2.46Cu-0.12Zr Alloy. Metals. 2017; 7(8):299. https://doi.org/10.3390/met7080299

Chicago/Turabian StyleSheng, Xiaofei, Qian Lei, Zhu Xiao, and Mingpu Wang. 2017. "Hot Deformation Behavior of a Spray-Deposited Al-8.31Zn-2.07Mg-2.46Cu-0.12Zr Alloy" Metals 7, no. 8: 299. https://doi.org/10.3390/met7080299