Structural and Mechanical Evaluation of a Nanocrystalline Al–5 wt %Si Alloy Produced by Mechanical Alloying

Abstract

:1. Introduction

2. Materials and Methods

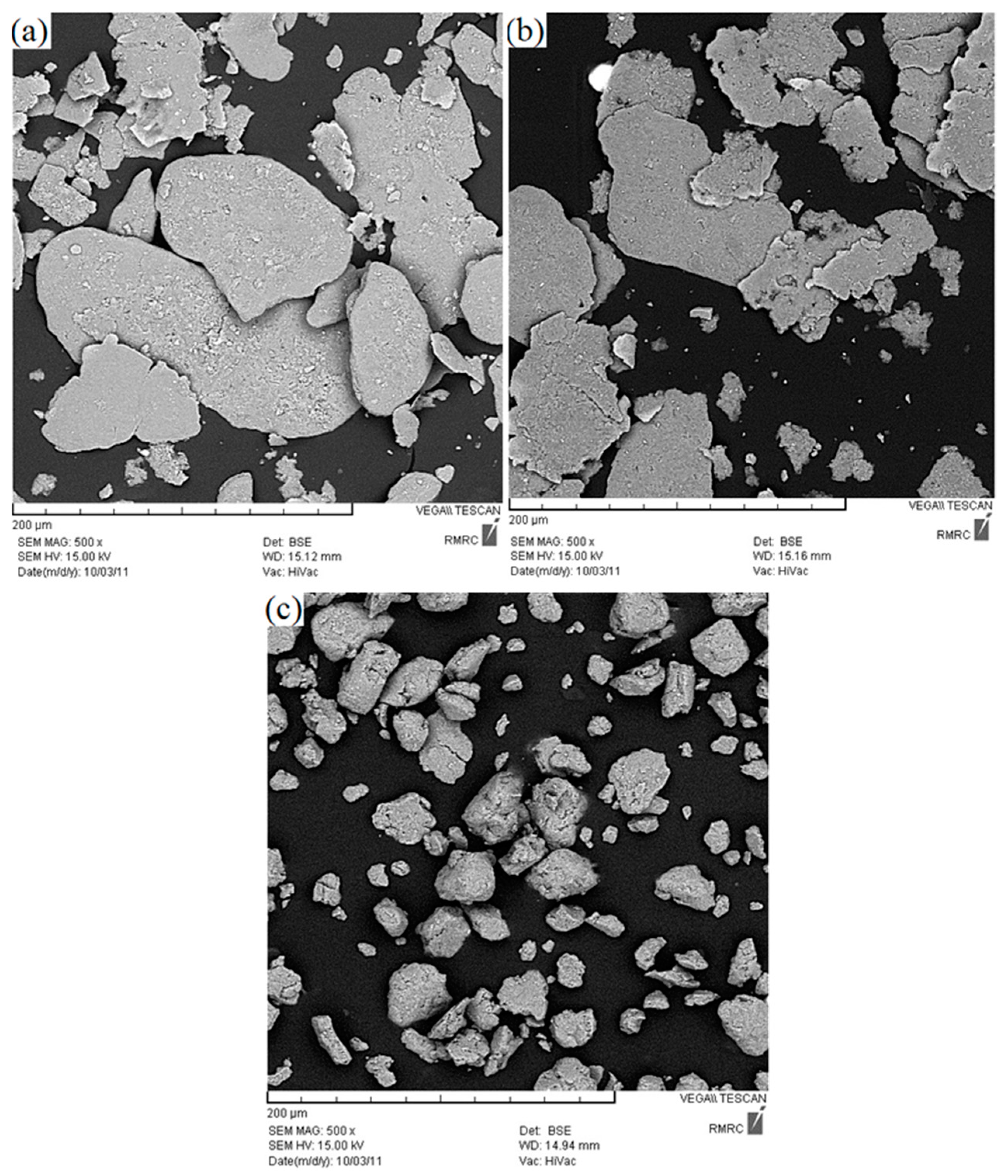

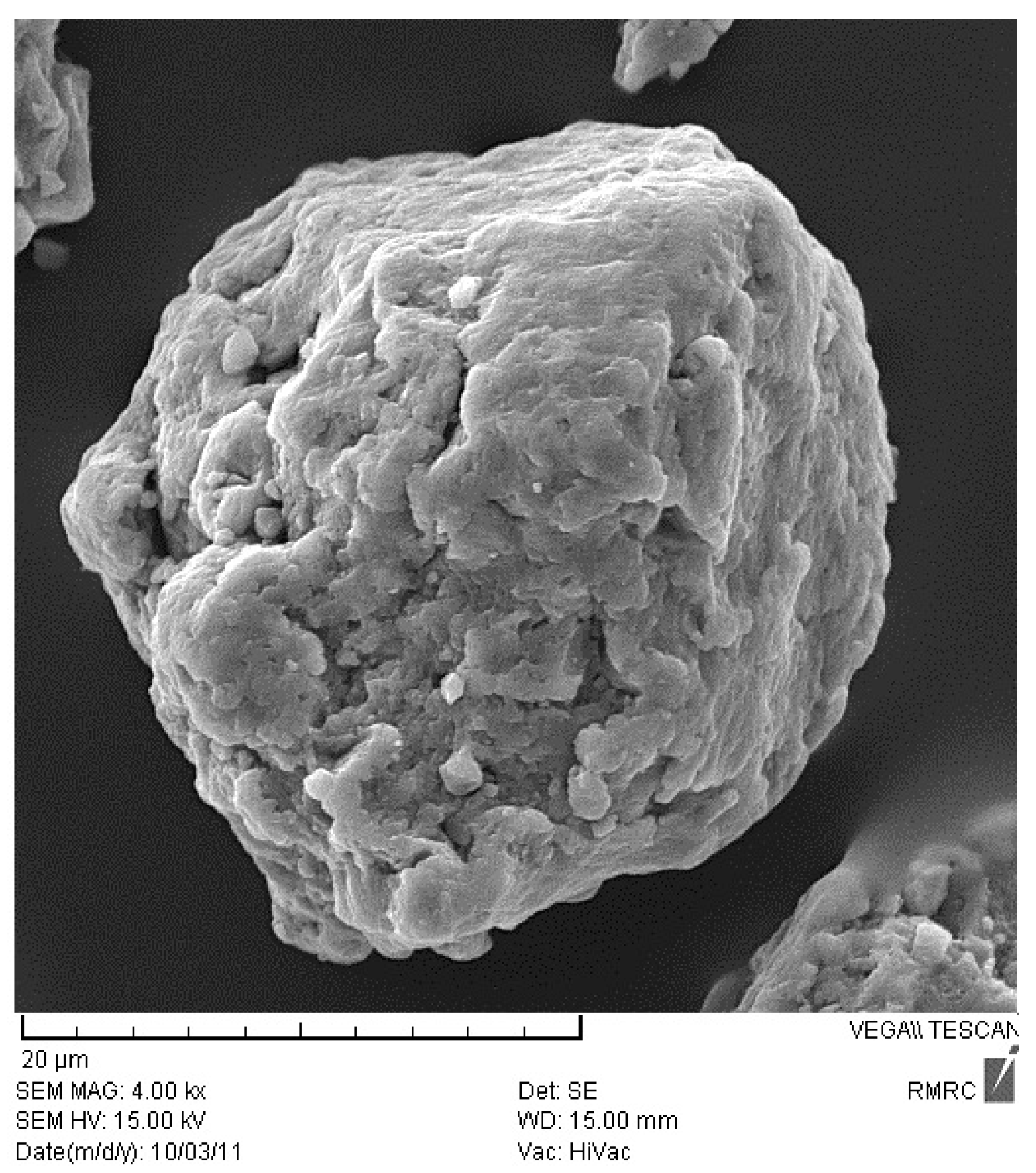

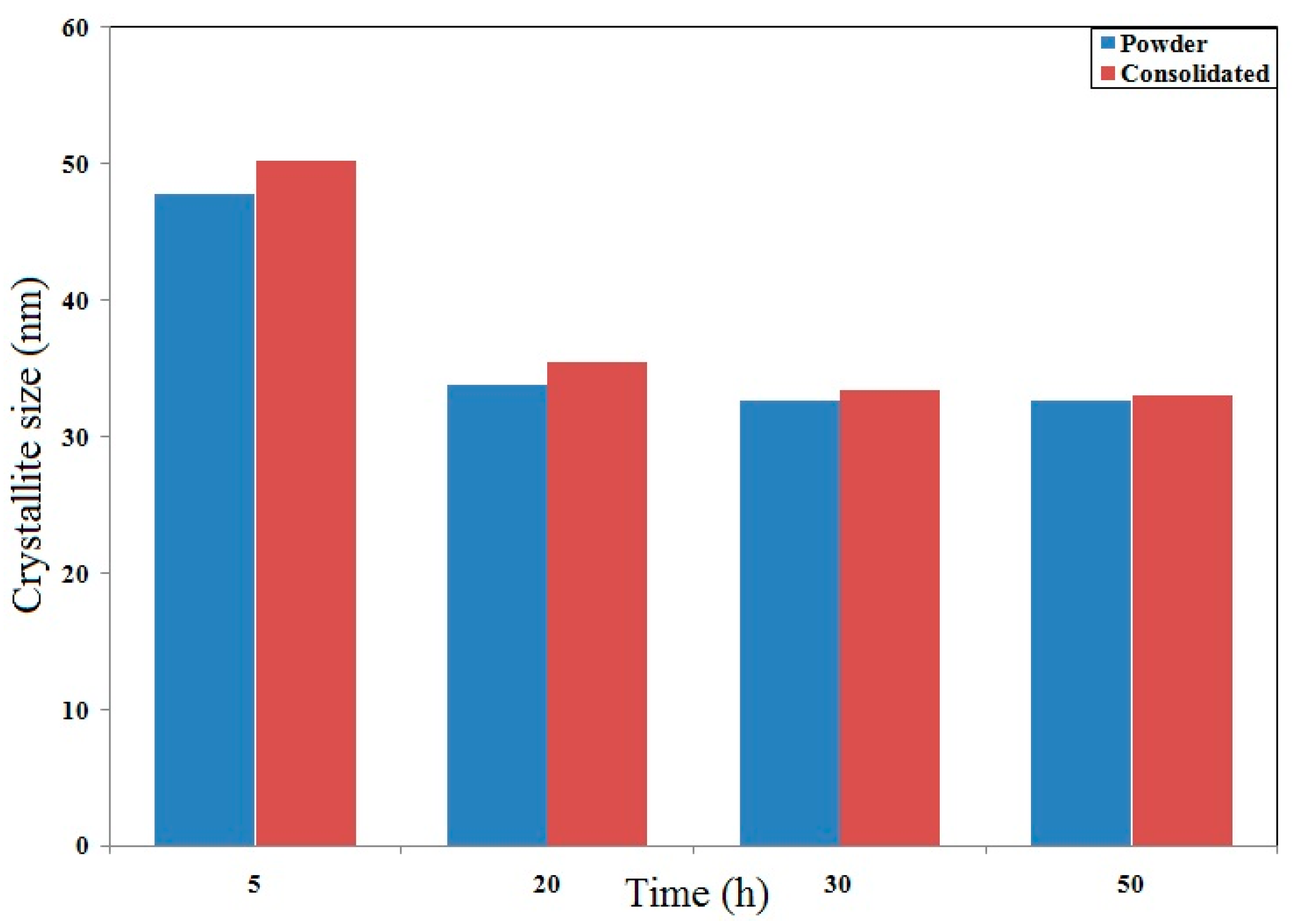

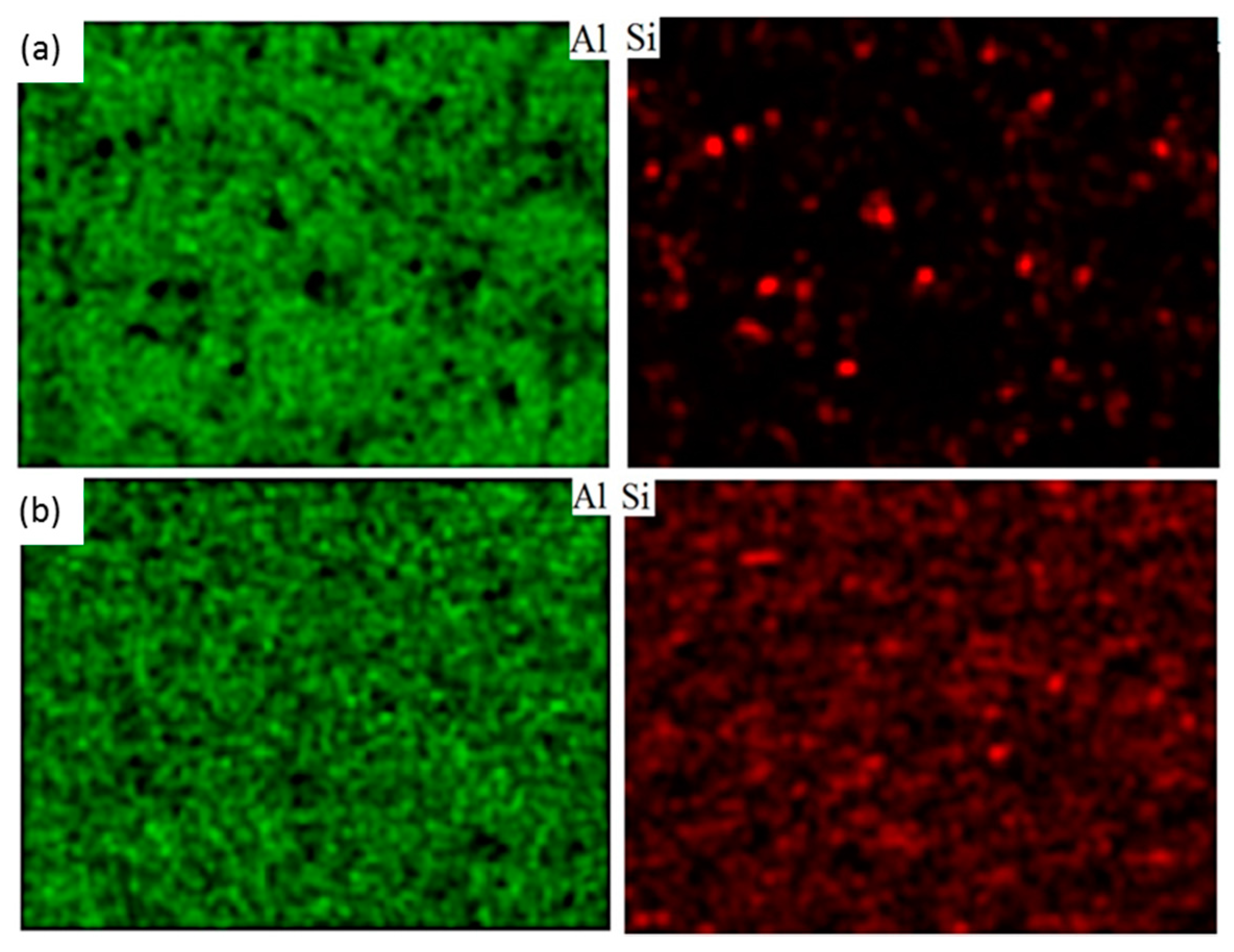

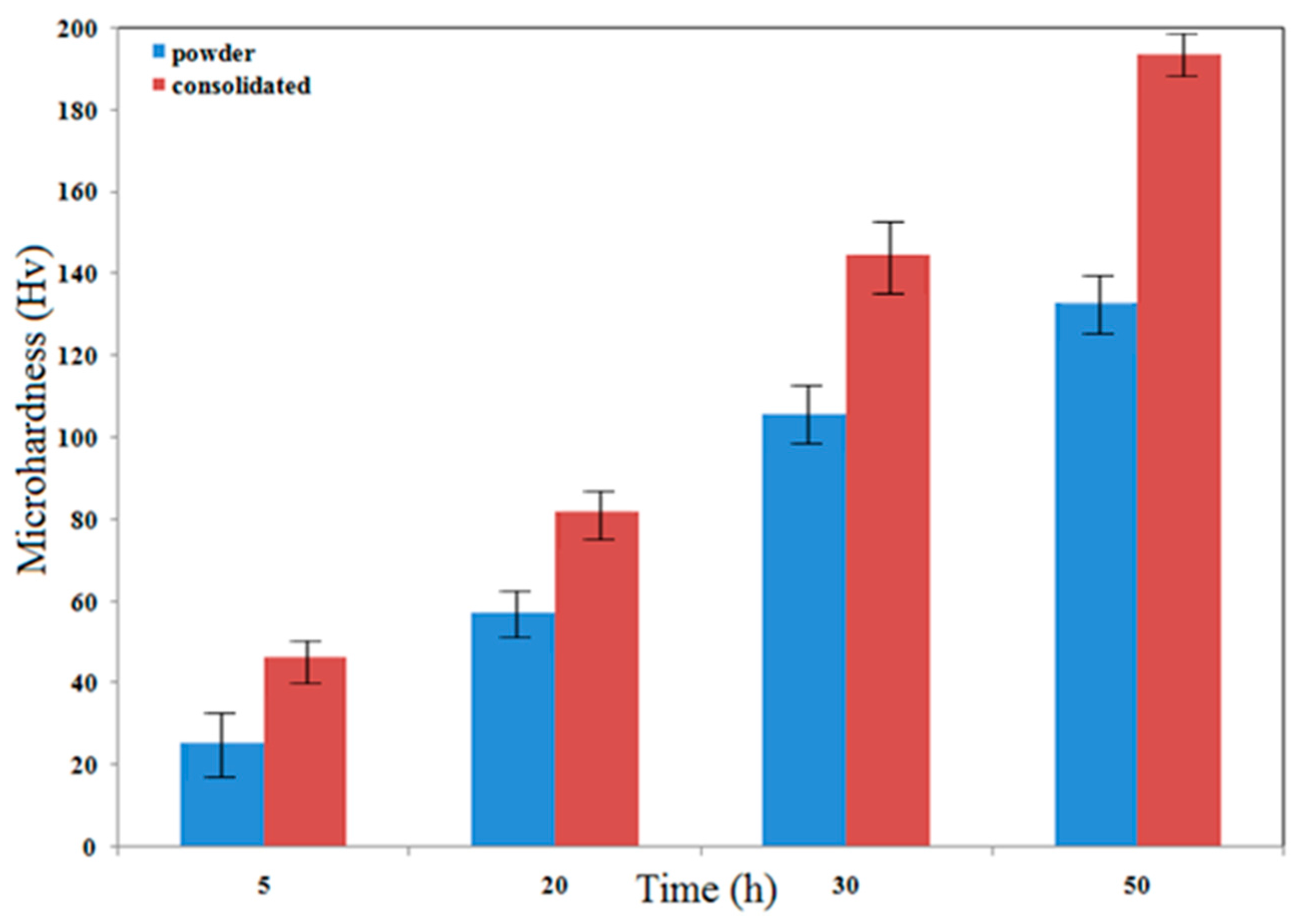

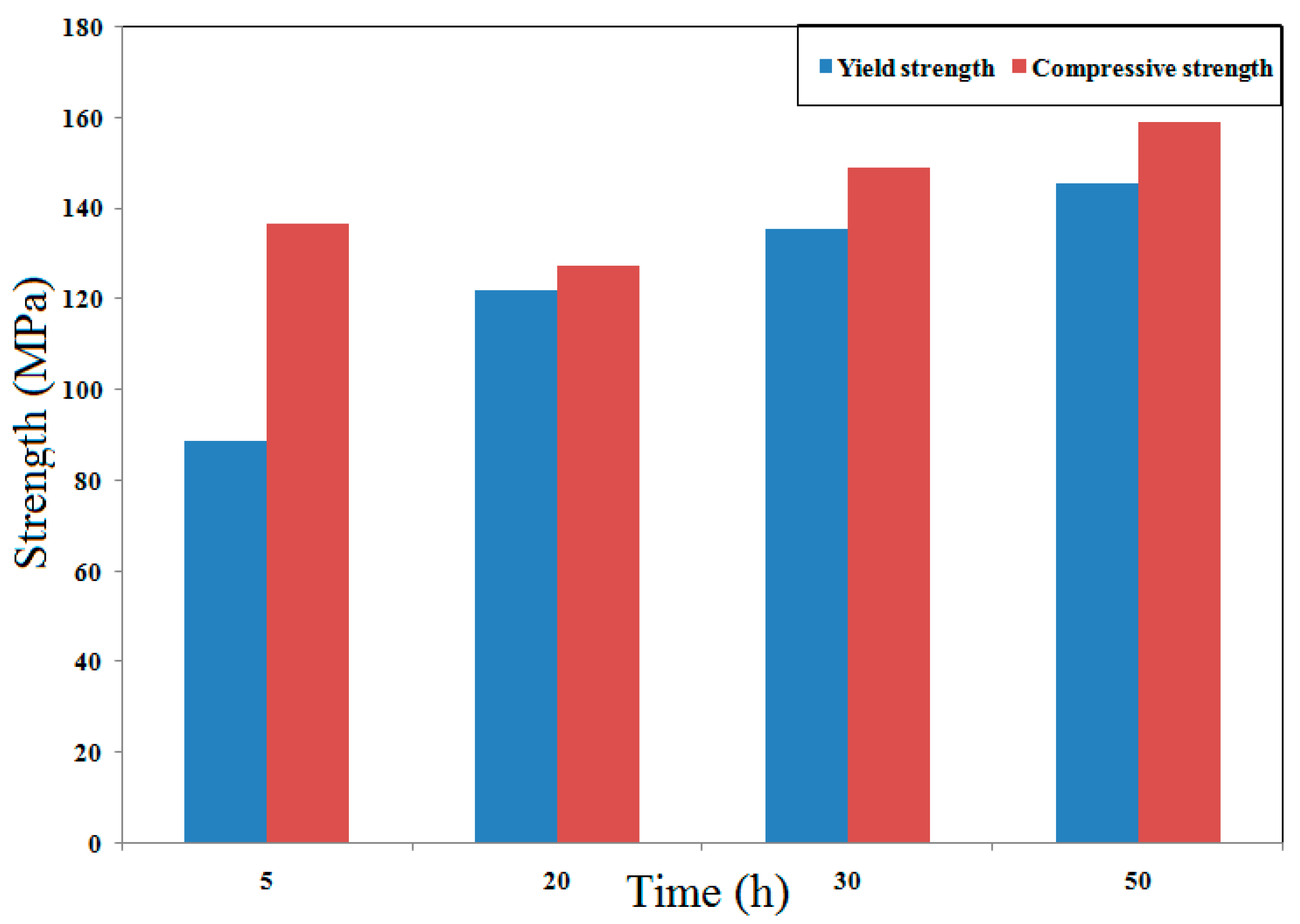

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Benjamin, J.S. Dispersion strengthened superalloys by mechanical alloying. Metall. Trans. 1970, 1, 2943–2951. [Google Scholar] [CrossRef]

- Lü, L.; Lai, M.O. Mechanical Alloying; Springer: New York, NY, USA, 1998. [Google Scholar]

- Wang, W.; Zhai, H.; Chen, L.; Zhou, Y.; Huang, Z.; Bei, G.; Greil, P. Sintering and properties of mechanical alloyed Ti3AlC2-Cu composites. Mater. Sci. Eng. A 2017, 685, 154–158. [Google Scholar] [CrossRef]

- Shokrollahi, H. The magnetic and structural properties of the most important alloys of iron produced by mechanical alloying. Mater. Des. 2009, 30, 3374–3387. [Google Scholar] [CrossRef]

- Polkin, I.S.; Borzov, A.B. New materials produced by mechanical alloying. Adv. Perform. Mater. 1995, 2, 99–109. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Mukhopadhyay, N.K.; Khoshkhoo, M.S.; Mishra, B.K.; Eckert, J. Effect of particle dispersion on the mechanical behavior of Al-based metal matrix composites reinforced with nanocrystalline Al–Ca intermetallics. J. Alloys Compd. 2012, 536, S134–S137. [Google Scholar] [CrossRef]

- Caballero, E.S.; Cintas, J.; Cuevas, F.G.; Montes, J.M.; Herrera-García, M.; Oral, A.Y.; Bahşi, Z.B.; Özer, M.; Sezer, M.; Aköz, M.E. High temperature behavior of nanostructured Al powders obtained by mechanical alloying under NH3 flow. AIP Conf. Proc. 2015, 1653, 20025. [Google Scholar] [CrossRef]

- Fogagnolo, J.; Velasco, F.; Robert, M.; Torralba, J. Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powders. Mater. Sci. Eng. A 2003, 342, 131–143. [Google Scholar] [CrossRef]

- Kang, W.-K.; Yılmaz, F.; Kim, H.-S.; Koo, J.-M.; Hong, S.-J. Fabrication of Al–20 wt %Si powder using scrap Si by ultra high-energy milling process. J. Alloys Compd. 2012, 536, S45–S49. [Google Scholar] [CrossRef]

- Khan, A.S.; Farrokh, B.; Takacs, L. Effect of grain refinement on mechanical properties of ball-milled bulk aluminum. Mater. Sci. Eng. A 2008, 489, 77–84. [Google Scholar] [CrossRef]

- Chen, C.; Lu, C.; Feng, X.; Shen, Y. Effects of annealing on Al–Si coating synthesised by mechanical alloying. Surf. Eng. 2017, 33, 548–558. [Google Scholar] [CrossRef]

- Kainer, K.U. Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Bose, A.; Eisen, W.B. Hot Consolidation of Powders and Particulates; Metal Powder Industries Federation: Princeton, NJ, USA, 2003. [Google Scholar]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Hryha, E.; Zubko, P.; Dudrová, E.; Pešek, L.; Bengtsson, S. An application of universal hardness test to metal powder particles. J. Mater. Proc. Technol. 2009, 209, 2377–2385. [Google Scholar] [CrossRef]

- Abdoli, H.; Salahi, E.; Farnoush, H.; Pourazrang, K. Evolutions during synthesis of Al–AlN-nanostructured composite powder by mechanical alloying. J. Alloys Compd. 2008, 461, 166–172. [Google Scholar] [CrossRef]

- Milligan, J.; Vintila, R.; Brochu, M. Nanocrystalline eutectic Al–Si alloy produced by cryomilling. Mater. Sci. Eng. A 2009, 508, 43–49. [Google Scholar] [CrossRef]

- Miraghaei, S.; Abachi, P.; Madaah-Hosseini, H.R.; Bahrami, A. Characterization of mechanically alloyed Fe100−xSix and Fe83.5Si13.5Nb3 nanocrystalline powders. J. Mater. Process. Technol. 2008, 203, 554–560. [Google Scholar] [CrossRef]

- Safari, J.; Akbari, G.H.; Shahbazkhan, A.; Delshad Chermahini, M. Microstructural and mechanical properties of Al-Mg/Al2O3 nanocomposite prepared by mechanical alloying. J. Alloys Compd. 2011, 509, 9419–9424. [Google Scholar] [CrossRef]

- Mhadhbi, M.; Khitouni, M.; Azabou, M.; Kolsi, A. Characterization of Al and Fe nanosized powders synthesized by high energy mechanical milling. Mater. Charact. 2008, 59, 944–950. [Google Scholar] [CrossRef]

- Sivasankaran, S.; Sivaprasad, K.; Narayanasamy, R.; Satyanarayana, P.V. X-ray peak broadening analysis of AA 6061100−x–x wt % Al2O3 nanocomposite prepared by mechanical alloying. Mater. Charact. 2011, 62, 661–672. [Google Scholar] [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E. Mechanical properties and wear behavior of Al–2 wt %Cu alloy composites reinforced by B4C nanoparticles and fabricated by mechanical milling and hot extrusion. Mater. Charact. 2012, 67, 119–128. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Poirier, D.; Drew, R.A.; Trudeau, M.L.; Gauvin, R. Fabrication and properties of mechanically milled alumina/aluminum nanocomposites. Mater. Sci. Eng. A 2010, 527, 7605–7614. [Google Scholar] [CrossRef]

| Time (h) | d (W-H ) | ε (W-H ) |

|---|---|---|

| 5 | 47.8 | 2.2 × 10−3 |

| 20 | 33.8 | 2.8 × 10−3 |

| 30 | 32.6 | 2.8 × 10−3 |

| 50 | 32.6 | 4.3 × 10−3 |

| Time (h) | d (W-H) | ε (W-H) |

|---|---|---|

| 5 | 50.2 | 1.5 × 10−3 |

| 20 | 35.43 | 2.0 × 10−3 |

| 30 | 33.4 | 2.1 × 10−3 |

| 50 | 33.0 | 2.7 × 10−3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dayani, D.; Shokuhfar, A.; Vaezi, M.R.; Jafarpour Rezaei, S.R.; Hosseinpour, S. Structural and Mechanical Evaluation of a Nanocrystalline Al–5 wt %Si Alloy Produced by Mechanical Alloying. Metals 2017, 7, 332. https://doi.org/10.3390/met7090332

Dayani D, Shokuhfar A, Vaezi MR, Jafarpour Rezaei SR, Hosseinpour S. Structural and Mechanical Evaluation of a Nanocrystalline Al–5 wt %Si Alloy Produced by Mechanical Alloying. Metals. 2017; 7(9):332. https://doi.org/10.3390/met7090332

Chicago/Turabian StyleDayani, Davood, Ali Shokuhfar, Mohammad Reza Vaezi, Seyed Reza Jafarpour Rezaei, and Saman Hosseinpour. 2017. "Structural and Mechanical Evaluation of a Nanocrystalline Al–5 wt %Si Alloy Produced by Mechanical Alloying" Metals 7, no. 9: 332. https://doi.org/10.3390/met7090332