Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint

Abstract

1. Introduction

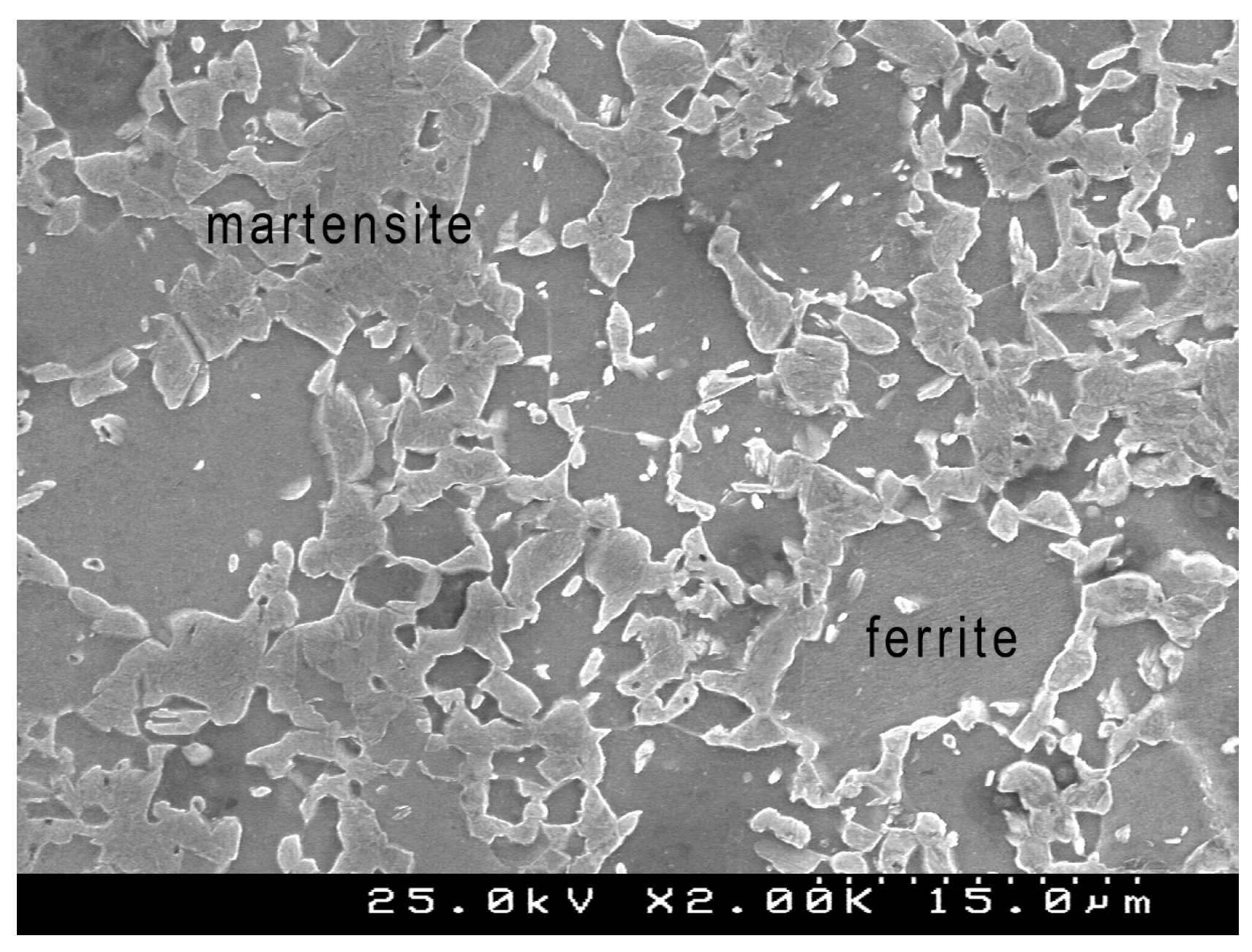

2. Base Material Characterization: DP1000 Steel

3. Experimental Procedures

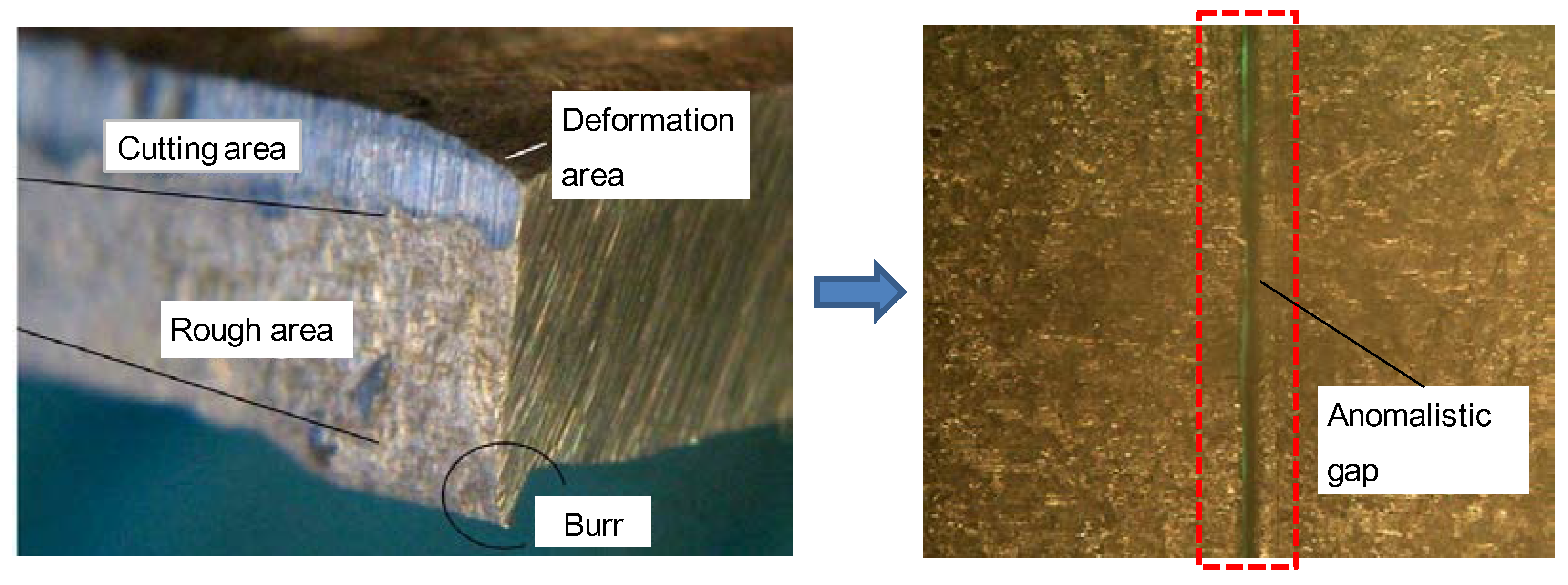

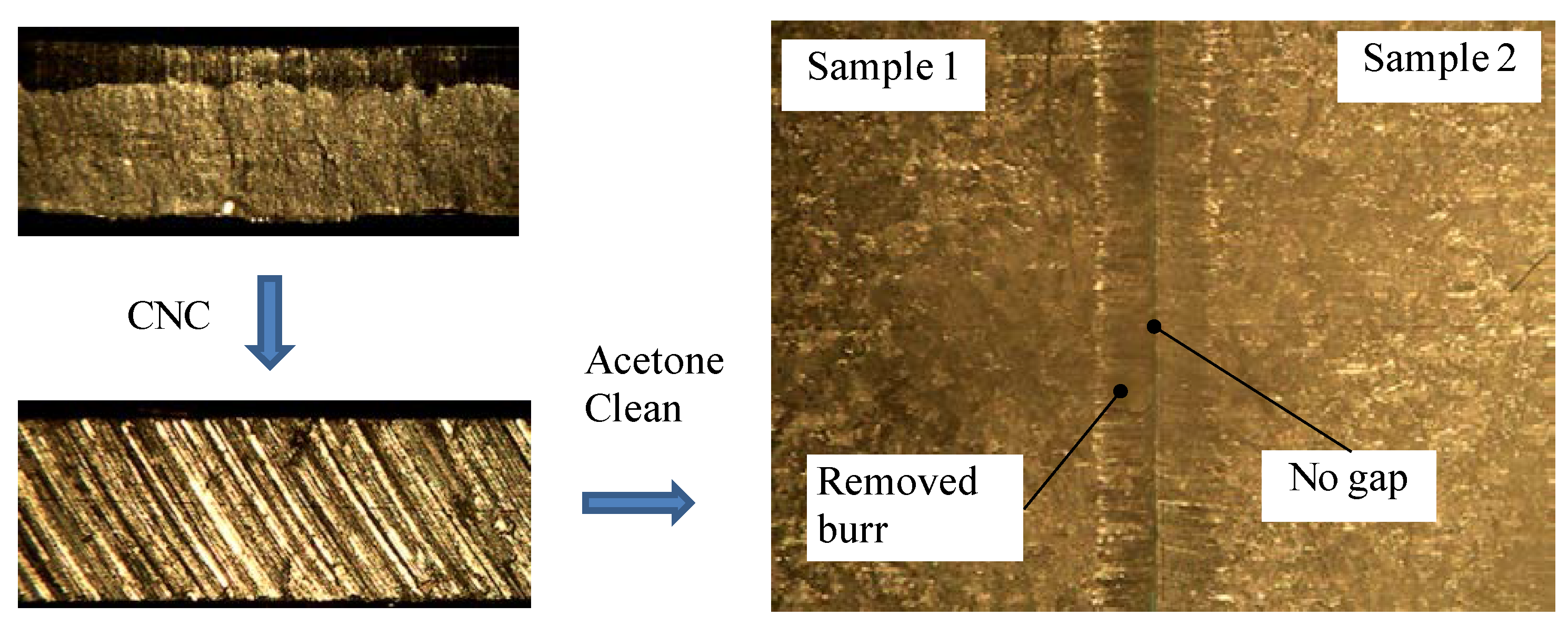

3.1. Cutting Surface Preparation for Pre-Welding Sample

3.2. Pulsed Nd:YAG Laser Welding Set-Up

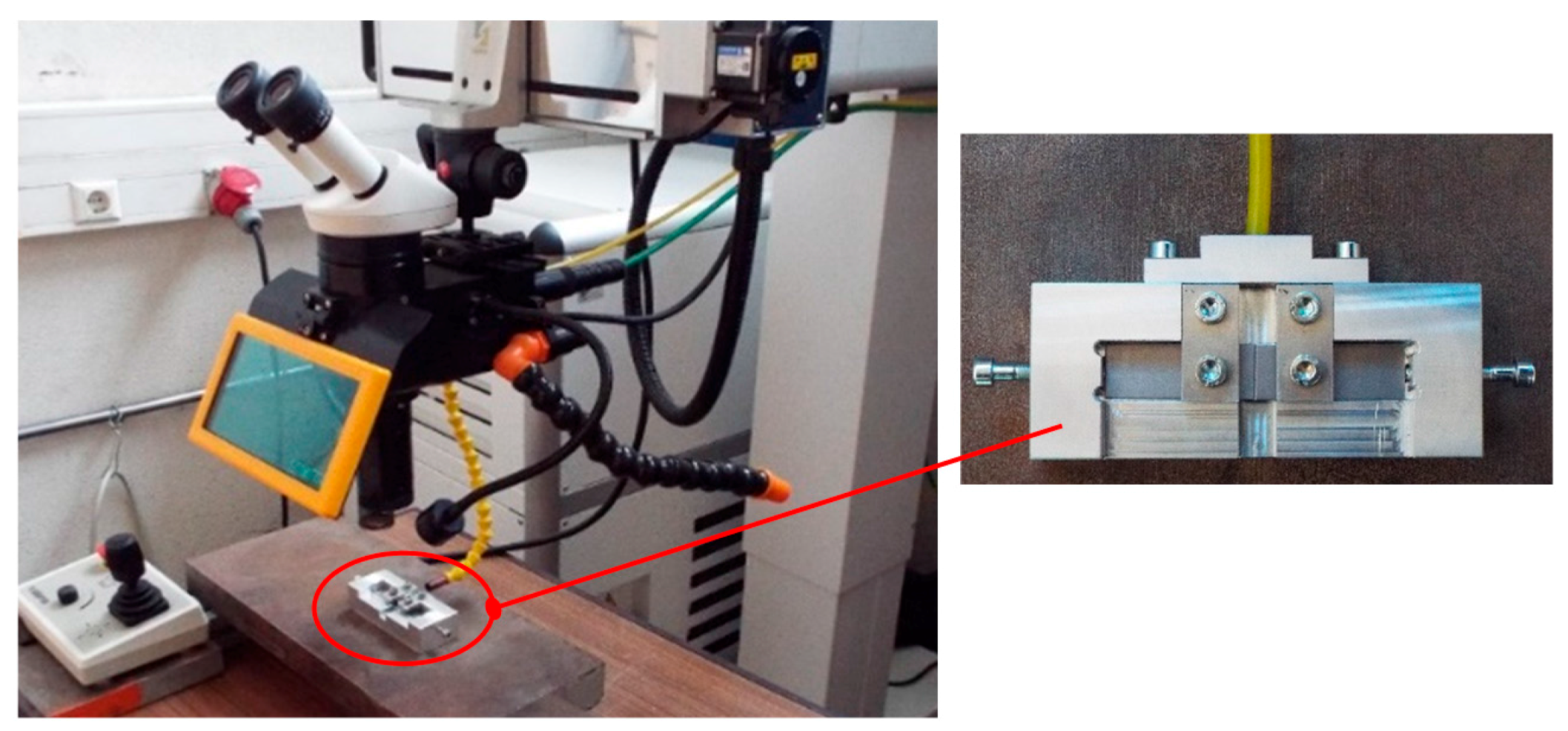

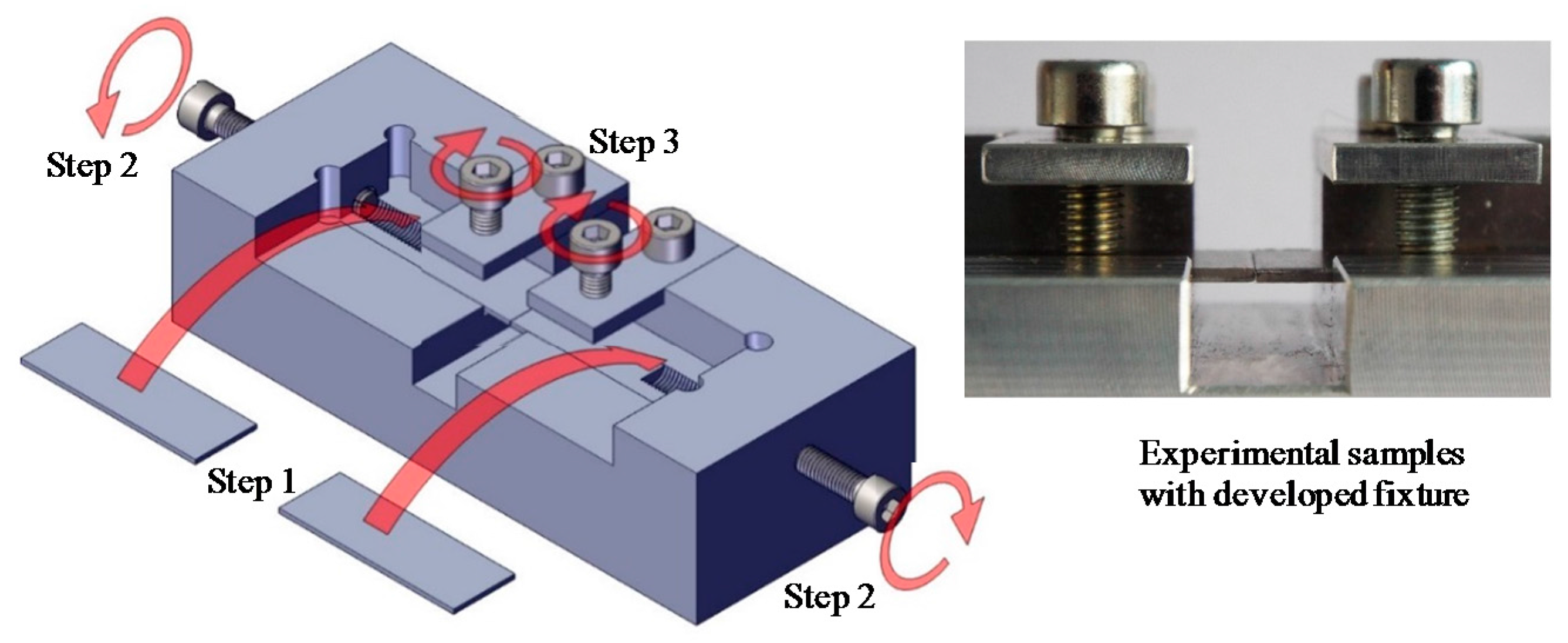

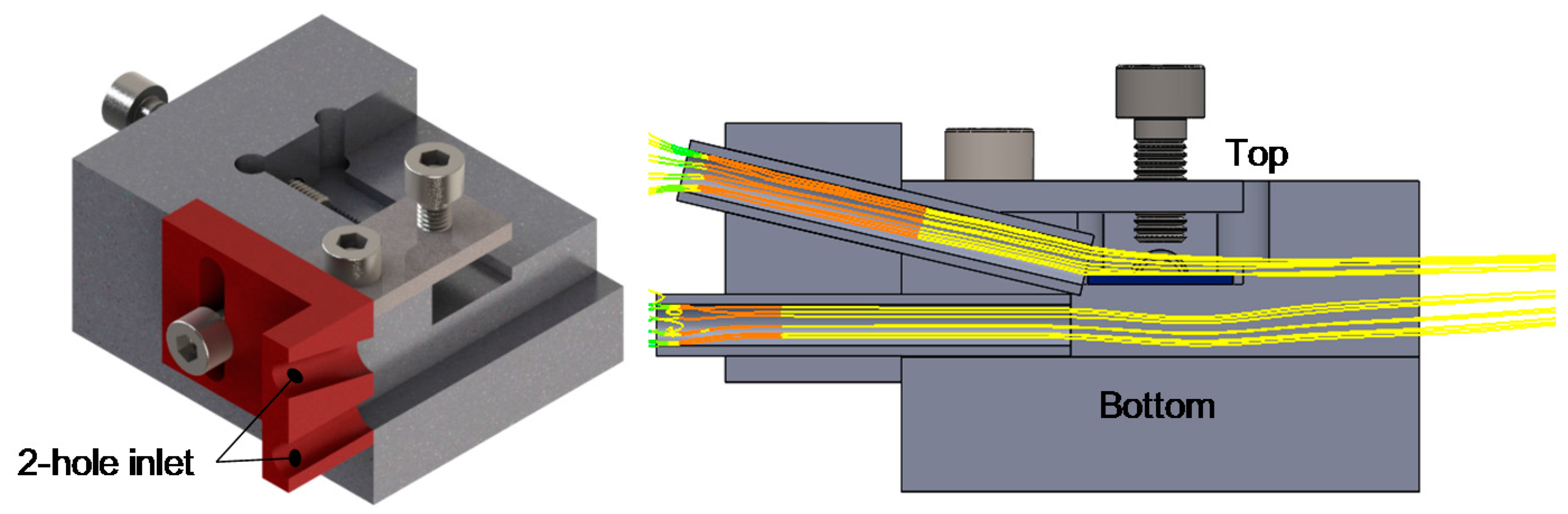

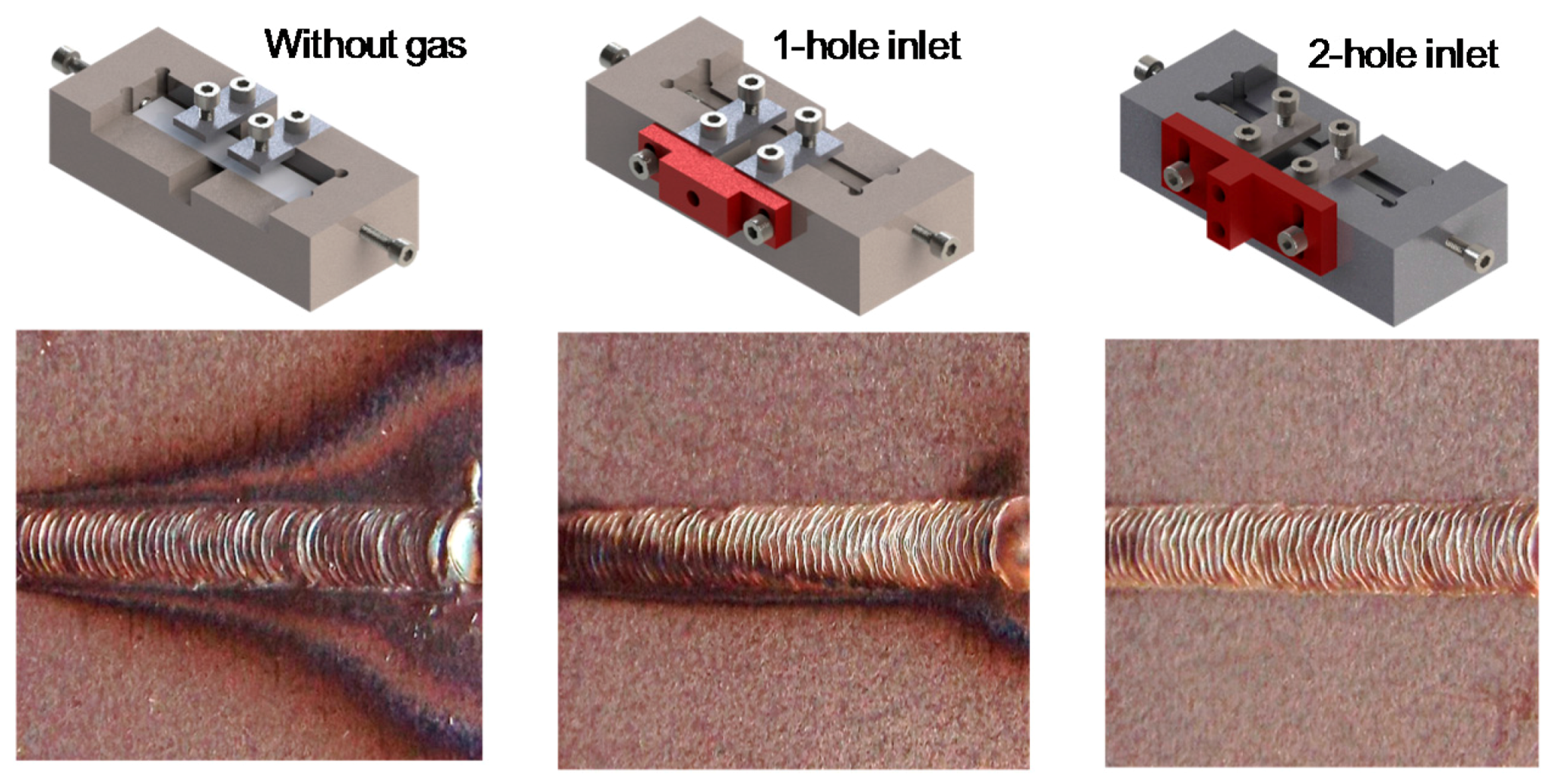

3.3. Design Optimization of Welding Sample Fixture

3.4. Microstructure and Micro-Hardness Testing

4. Process Parameter Dependent Theory

4.1. Process Parameters Relationship of General Laser Welding

4.2. Pulse Welding Parameters

4.3. Design of Experiments for Laser Welding

5. Results and Discussions

5.1. Effects of Laser Beam Parameters on Weld Penetration

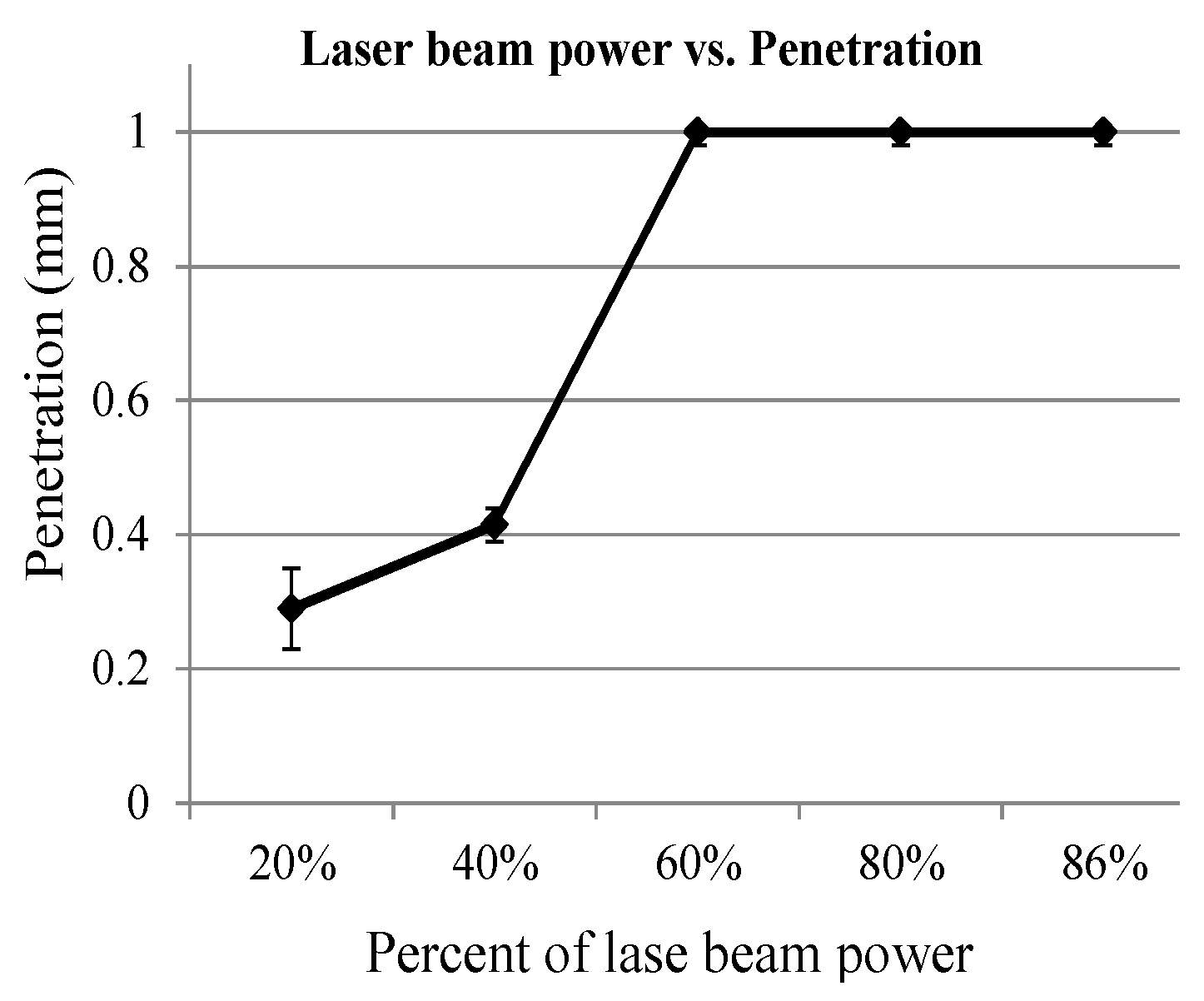

5.1.1. Effects of Laser Beam Power on Weld Penetration

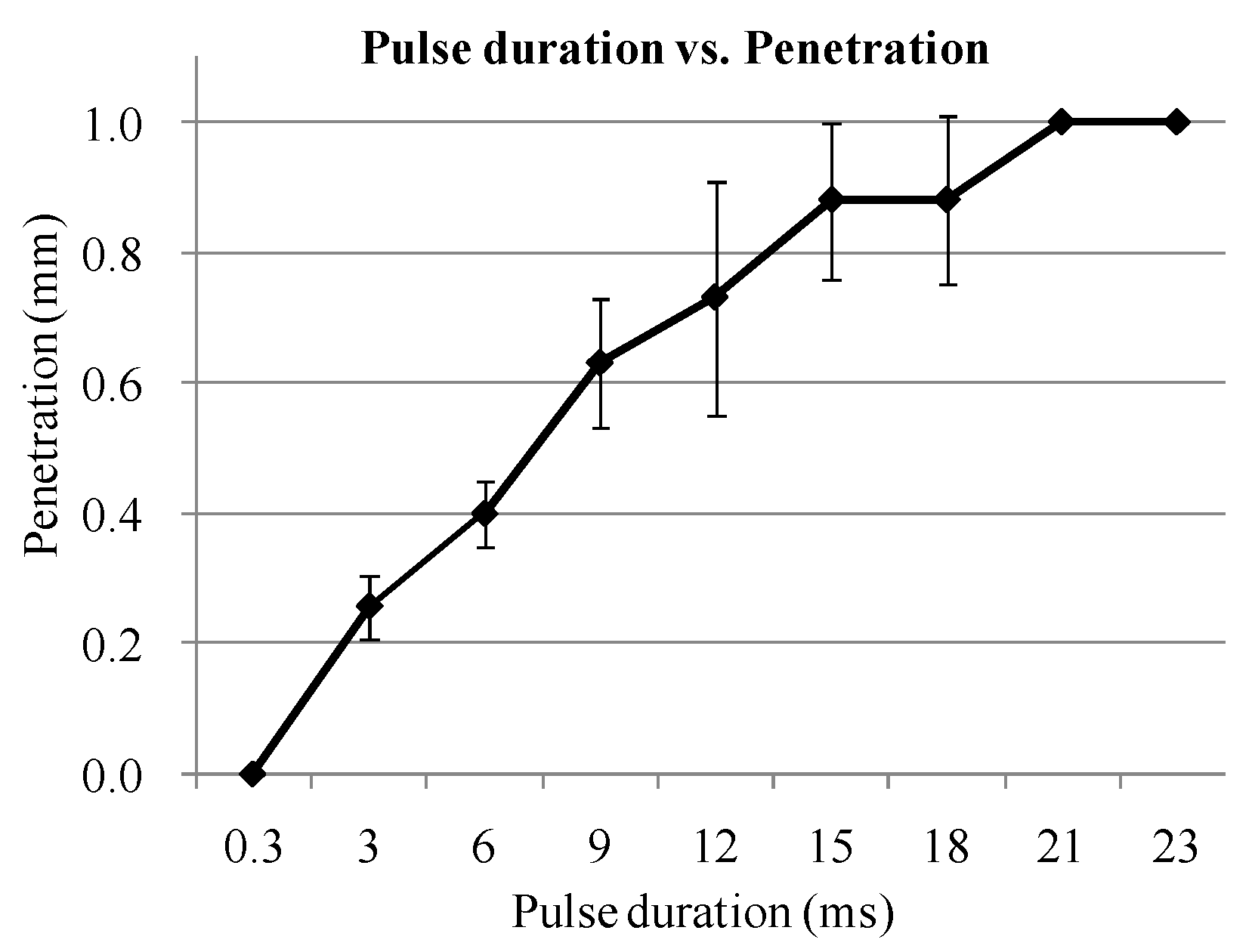

5.1.2. Effects of Pulse Duration on Weld Penetration

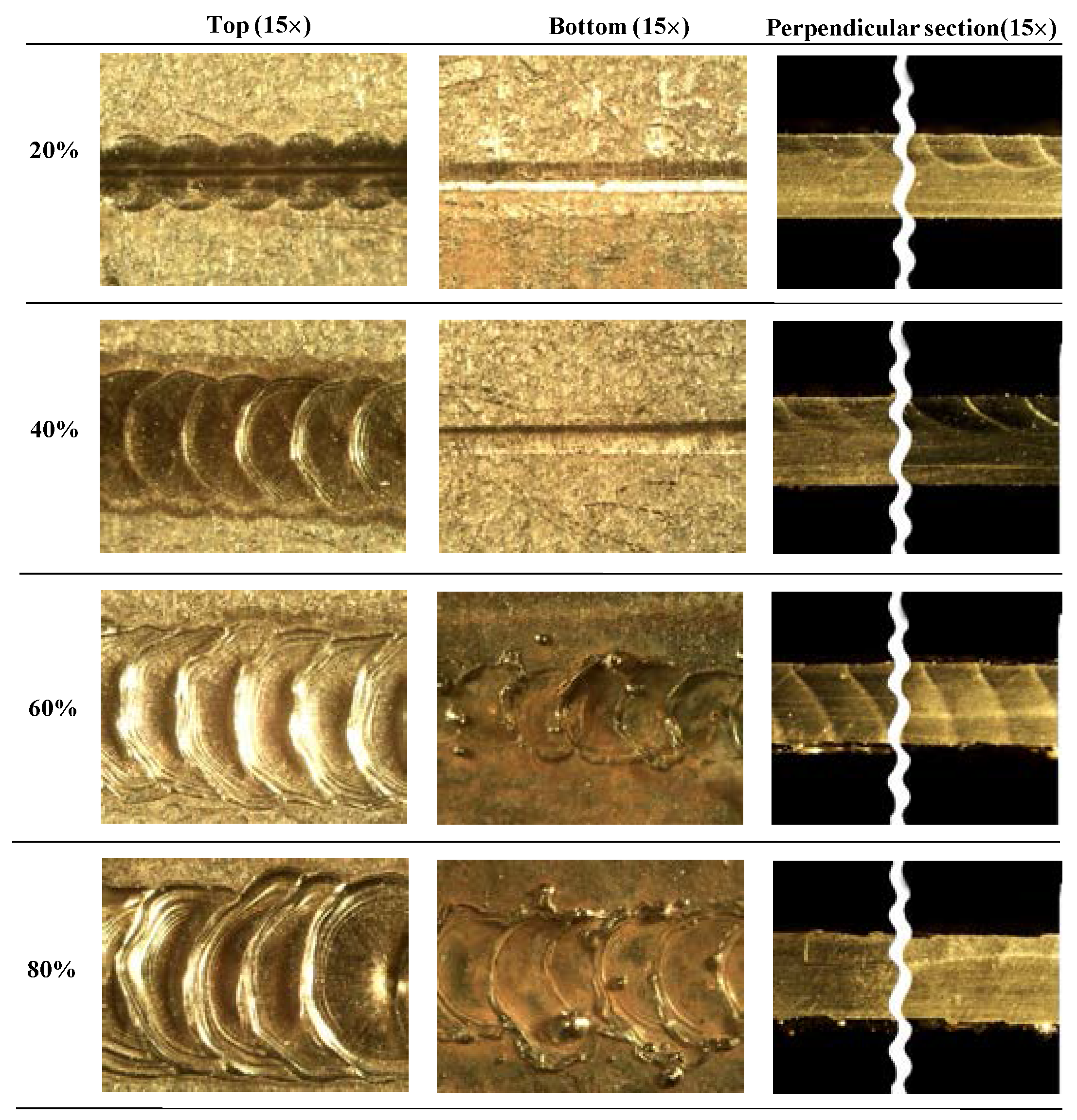

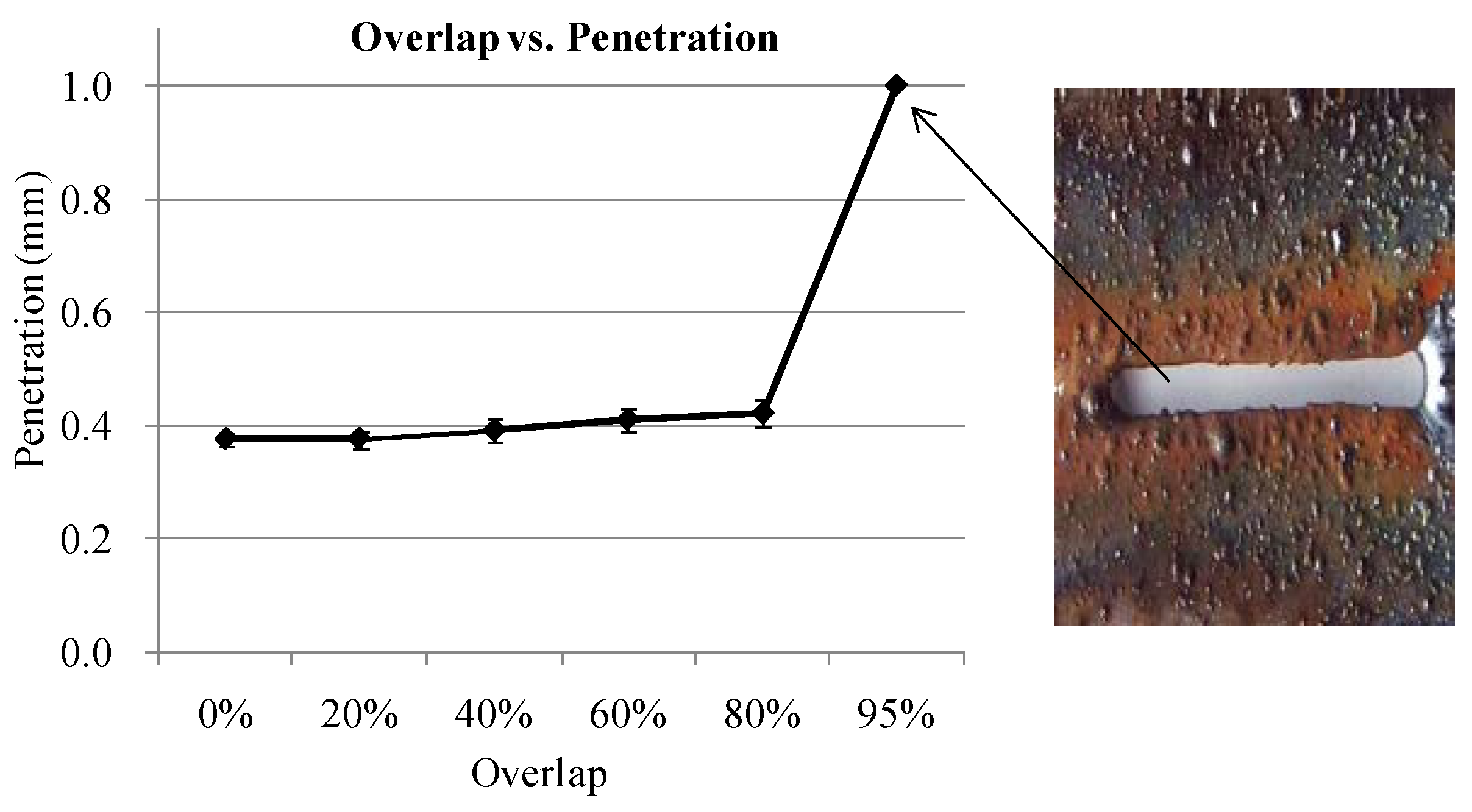

5.1.3. Effects of Overlap on Weld Penetration

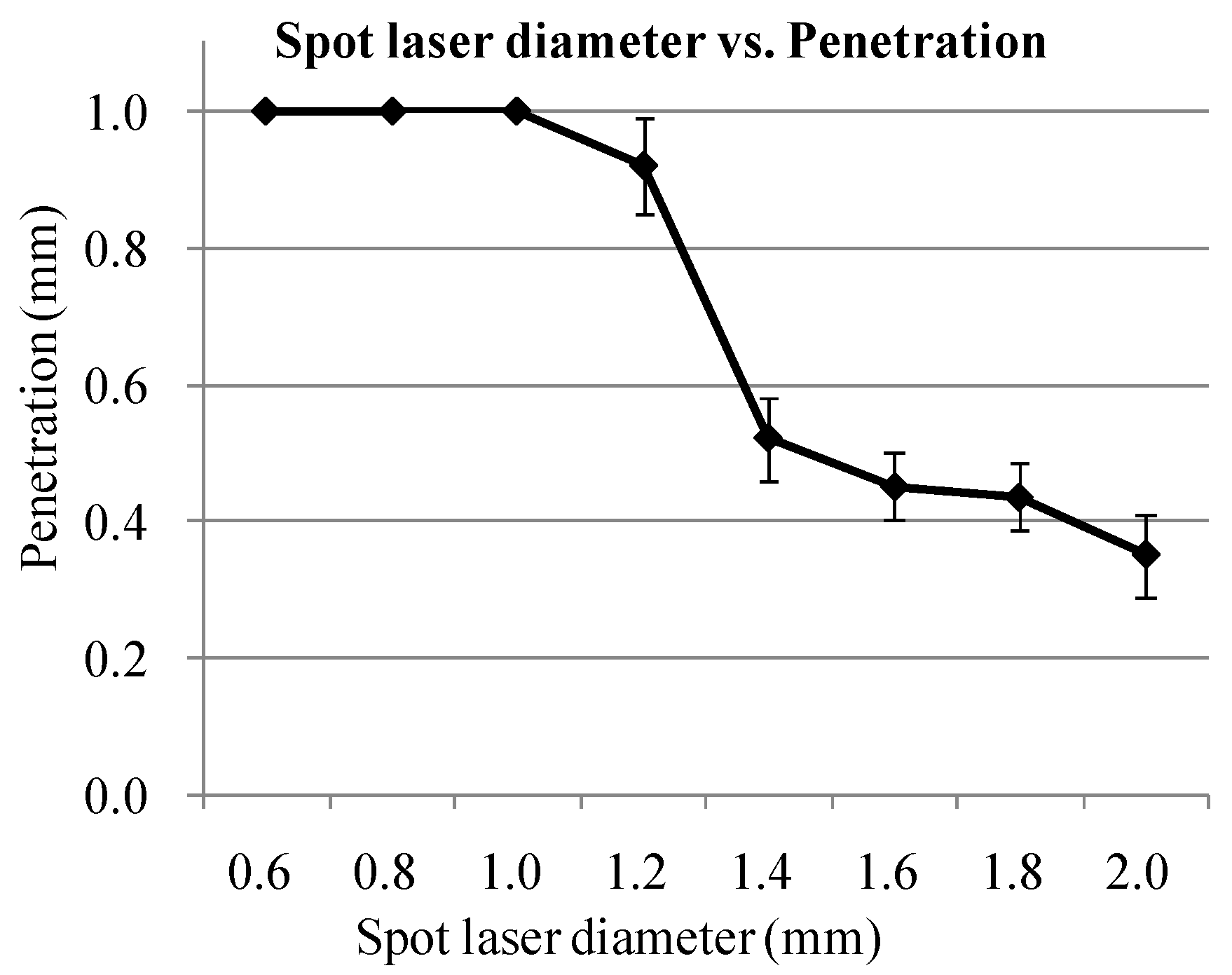

5.1.4. Effects of Spot Laser Diameter on Weld Penetration

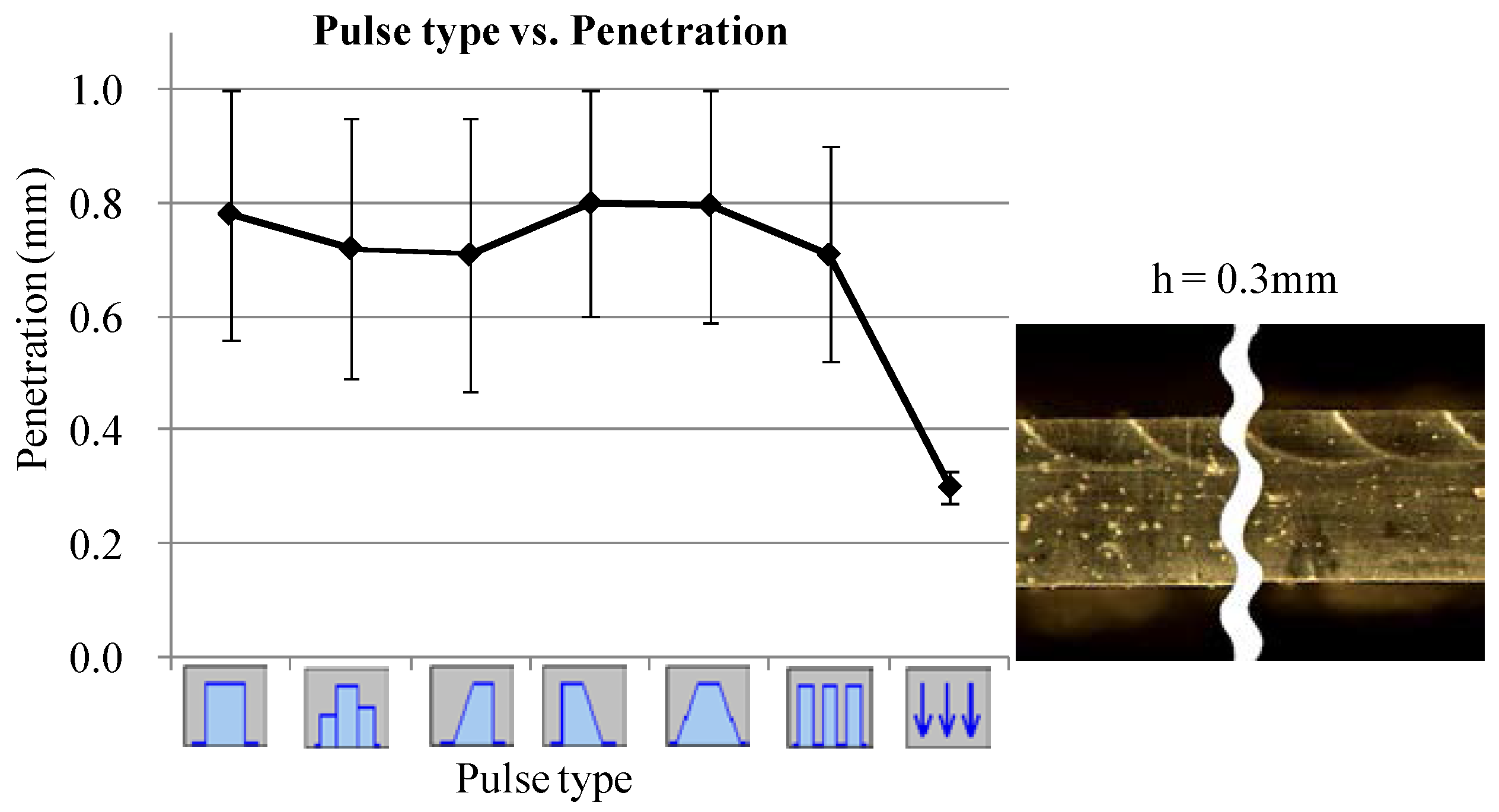

5.1.5. Effects of Pulse Type on Penetration

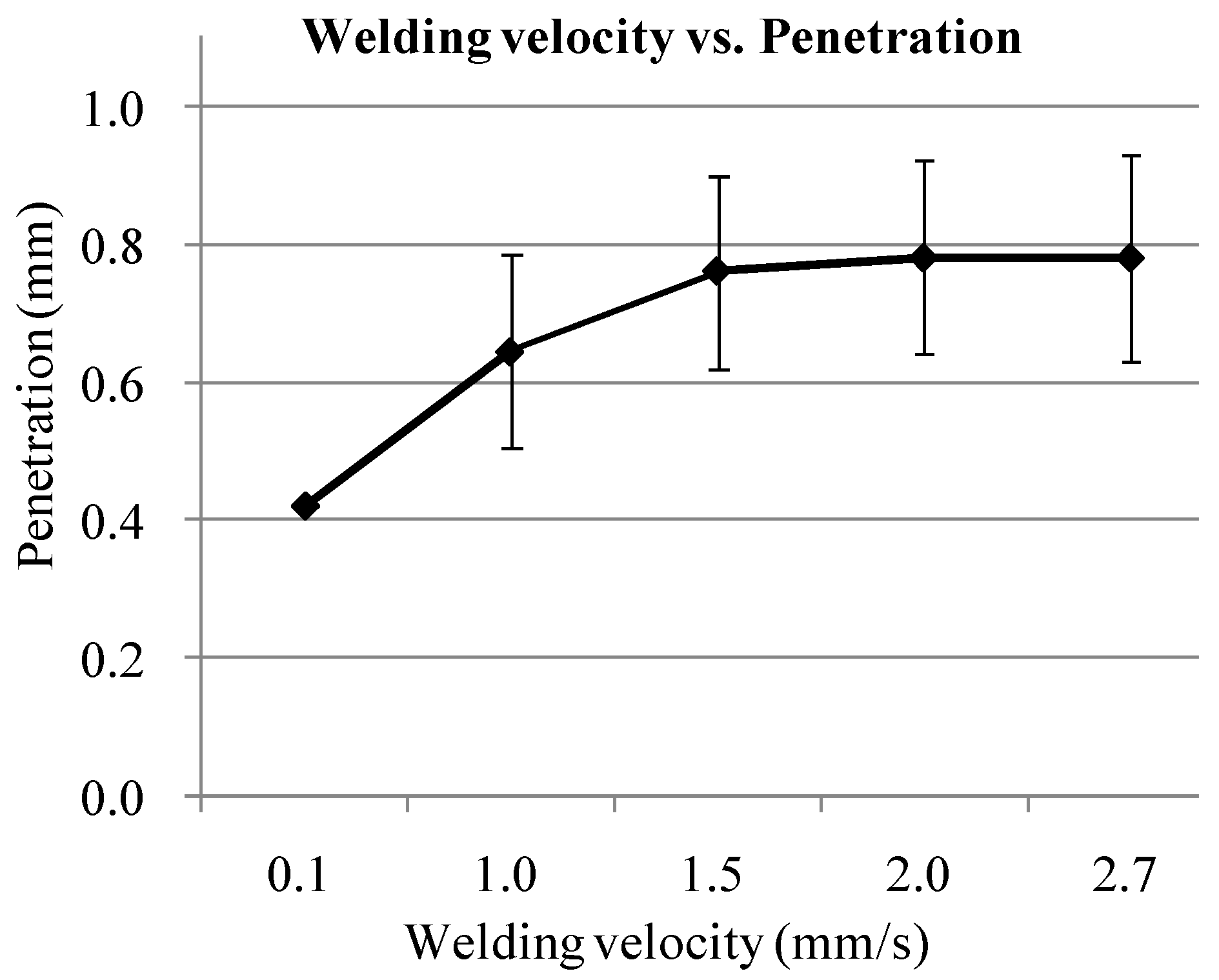

5.1.6. Effects of Welding Velocity on Weld Penetration

5.1.7. ANOVA for Quadratic Model of Weld Penetration

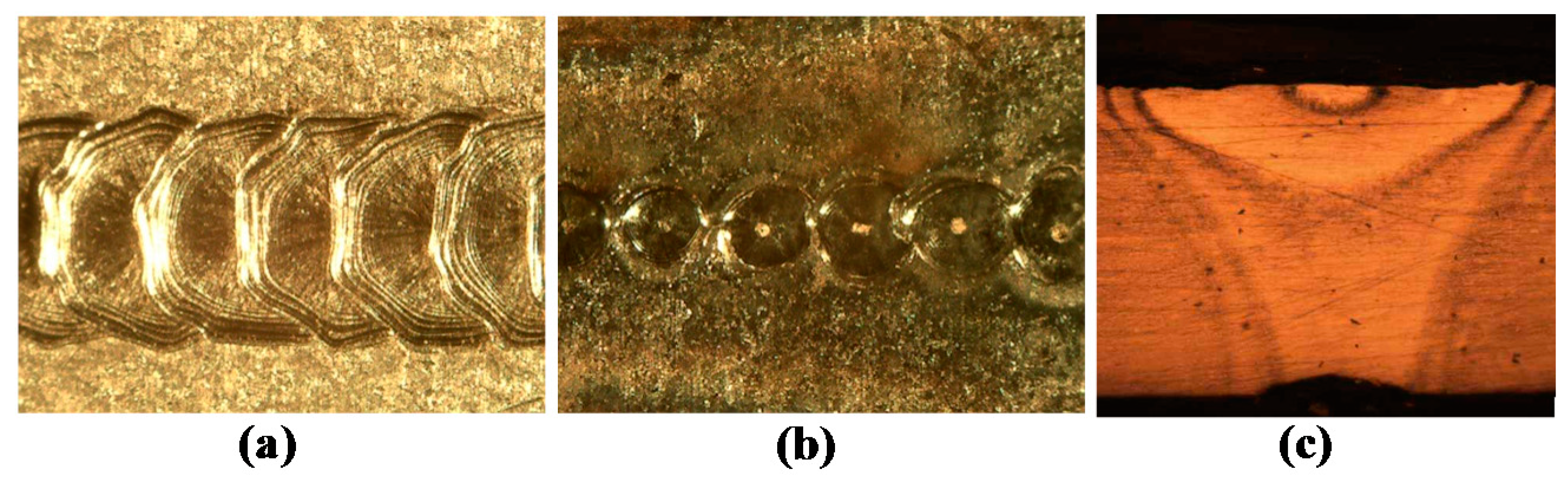

5.2. Effects of Laser Parameters on Hardness and Its Microstructure Observation

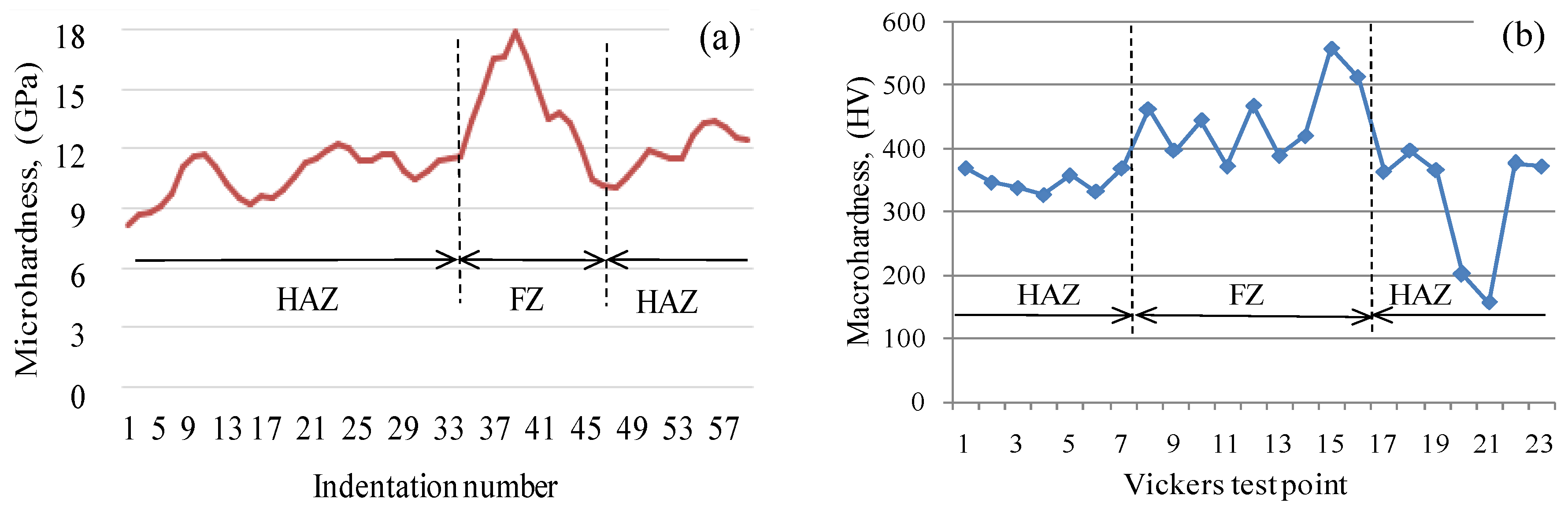

5.2.1. Microscopic and Macroscopic Hardness

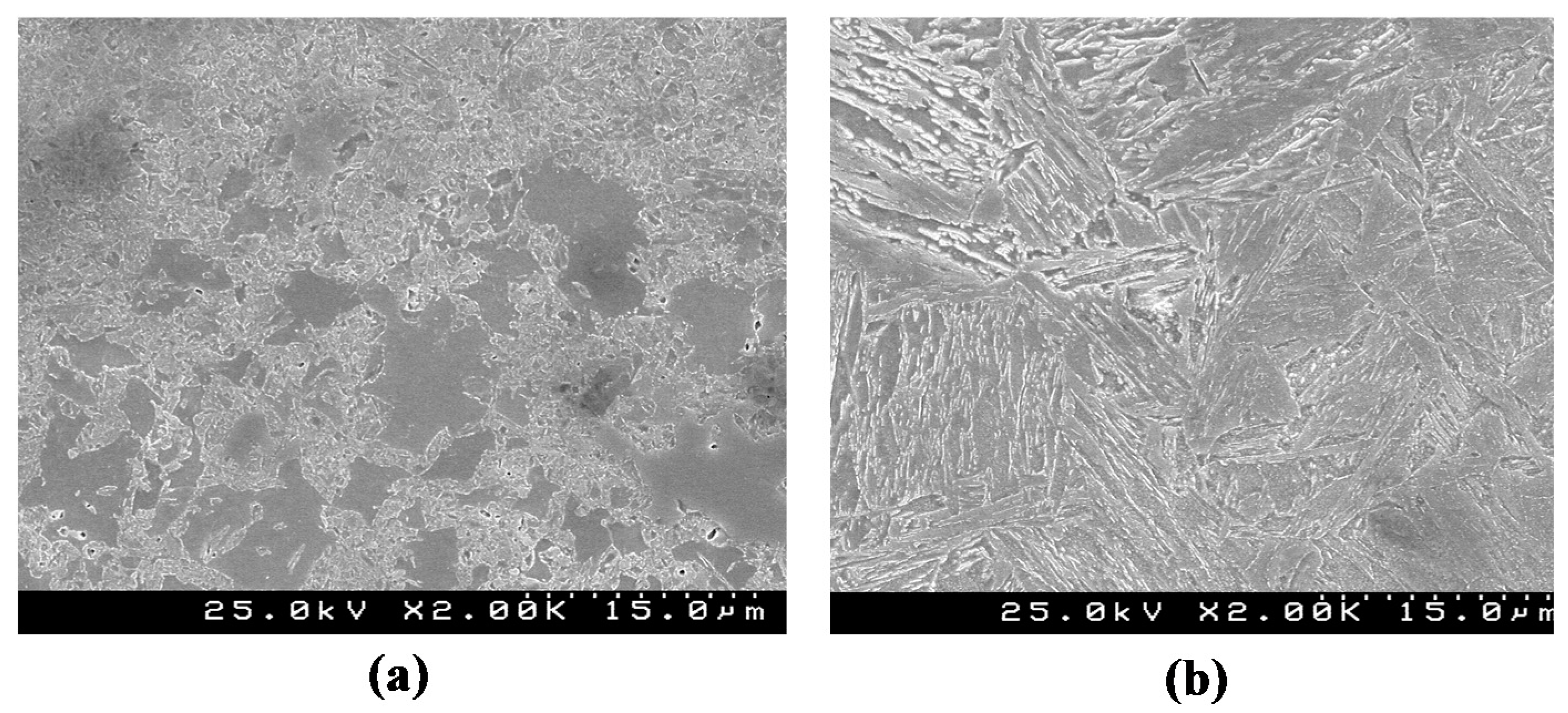

5.2.2. Microstructure Characterization of Nd:YAG Laser Welded Joint

6. Conclusions

- The ideal laser beam power for welding in the studied case should be between 40% and 60% with a sharp rise. However, the sensitivity of the weld penetration to the greater than 60% laser beam power becomes less pronounced.

- The greater the pulse duration, the deeper the weld penetration.

- The overlap seems not to affect the weld penetration, but only up to the value of 80%.

- The weld penetration has a sharp decrease when the applied spot diameter increases from 1.2 mm to 1.4 mm.

- The pulse type has no significant effect on penetration, with the exception of the scale expanded pulse.

- The penetration seems to be directly influenced by the welding velocity, i.e., the higher the welding velocity, the deeper the weld penetration.

- The ANOVA tests applied to the individual coefficients in the regression model show that the Model F-value of weld penetration response is 12.94, which implies that the models are significant. The determination coefficient of the regression analysis results indicates that a high degree of correlation between the experimental values and empirical calculated values is obtained from the models.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| A1 | 20 | - | - | - | - | 24.0 | - | 6.3 |

| A2 | 40 | 43.5 | 3.5 | |||||

| A3 | 60 | 66.1 | 2.2 | |||||

| A4 | 80 | 91.6 | 1.6 | |||||

| A5 | 86 | 100.0 | 1.4 |

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| B1 | 50 | 0.3 | 50 | 1.3 | Simple rectangular | 1.3 | 1.4 | 10 |

| B2 | 3 | 13.0 | 10 | |||||

| B3 | 6 | 26.1 | 5.8 | |||||

| B4 | 9 | 39.1 | 3.9 | |||||

| B5 | 12 | 52.2 | 2.9 | |||||

| B6 | 15 | 65.2 | 2.3 | |||||

| B7 | 18 | 78.3 | 1.9 | |||||

| B8 | 21 | 91.3 | 1.6 | |||||

| B9 | 23 | 100.0 | 1.4 |

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| C1 | 50 | 12.5 | 0 | 1.3 | Simple rectangular | 54.3 | 0.2 | 5.5 |

| C2 | 20 | 4.4 | ||||||

| C3 | 40 | 3.3 | ||||||

| C4 | 60 | 2.2 | ||||||

| C5 | 80 | 1.1 | ||||||

| C6 | 95 | 0.2 |

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| D1 | 50 | 12.5 | 50 | 0.6 | Simple rectangular | 54.3 | 1.2 | 1.2 |

| D2 | 0.8 | 1.7 | ||||||

| D3 | 1.0 | 2.1 | ||||||

| D4 | 1.2 | 2.5 | ||||||

| D5 | 1.4 | 3.0 | ||||||

| D6 | 1.6 | 3.4 | ||||||

| D7 | 1.8 | 3.8 | ||||||

| D8 | 2.0 | 4.3 |

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| E1 | 50 | 12.5 | 50 | 1.3 |  | 54.3 | 2.6 | 2.7 |

| E2 |  | 54.5 | 2.7 | |||||

| E3 |  | 59.0 | 2.6 | |||||

| E4 |  | 59.0 | 2.6 | |||||

| E5 |  | 56.9 | 2.6 | |||||

| E6 |  | 53.4 | 2.8 | |||||

| E7 |  | 28.5 | 5.3 |

| Series | Power (%) | Duration (ms) | Overlap (%) | Diameter (mm) | Pulse Type | Energy (J) | Velocity (mm/s) | Max. Velocity (mm/s) |

|---|---|---|---|---|---|---|---|---|

| F1 | 50 | 12.5 | 50 | 1.3 | Simple rectangular | 54.3 | 0.1 | 2.7 |

| F2 | 1.0 | |||||||

| F3 | 1.5 | |||||||

| F4 | 2.0 | |||||||

| F5 | 2.7 |

| Source | SS | DF | MS | F-Value | p-Value | Evaluation |

|---|---|---|---|---|---|---|

| Model | 1.446 | 14 | 0.13 | 12.94 | 0.0036 | Significant |

| A | 0.115 | 1 | 0.12 | 10.37 | 0.0181 | - |

| B | 0.010 | 1 | 0.010 | 0.88 | 0.3839 | |

| C | 0.379 | 1 | 0.379 | 34.13 | 0.0011 | |

| D | 0.014 | 1 | 0.014 | 1.30 | 0.2976 | |

| E | 0.003 | 1 | 0.003 | 1.02 | 0.3505 | |

| F | 0.008 | 1 | 0.008 | 2.59 | 0.1587 | |

| AB | 0.074 | 1 | 0.074 | 6.65 | 0.0419 | |

| AC | 0.138 | 1 | 0.138 | 12.40 | 0.0125 | |

| AD | 0.003 | 1 | 0.003 | 0.28 | 0.6188 | |

| AE | 0.060 | 1 | 0.060 | 5.36 | 0.0599 | |

| AF | 0.045 | 1 | 0.045 | 4.02 | 0.0919 | |

| BC | 0.099 | 1 | 0.099 | 8.91 | 0.0245 | |

| BD | 0.073 | 1 | 0.073 | 23.42 | 0.0029 | |

| BE | 0.020 | 1 | 0.020 | 6.48 | 0.0437 | |

| BF | 0.065 | 1 | 0.065 | 20.66 | 0.0039 | |

| CD | 0.079 | 1 | 0.079 | 25.35 | 0.0024 | |

| CE | 0.040 | 1 | 0.040 | 12.73 | 0.0118 | |

| CF | 0.009 | 1 | 0.009 | 2.81 | 0.1447 | |

| DE | 0.007 | 1 | 0.007 | 2.40 | 0.1724 | |

| DF | 0.019 | 1 | 0.019 | 5.93 | 0.0508 | |

| EF | 0.154 | 1 | 0.154 | 49.40 | 0.0004 | |

| A2 | 0.001 | 1 | 0.001 | 0.09 | 0.7744 | |

| B2 | 0.001 | 1 | 0.001 | 0.05 | 0.8341 | |

| C2 | 0.013 | 1 | 0.013 | 1.13 | 0.3293 | |

| D2 | 0.002 | 1 | 0.002 | 0.17 | 0.6938 | |

| E2 | 0.080 | 1 | 0.080 | 25.61 | 0.0023 | |

| F2 | 0.007 | 1 | 0.007 | 2.30 | 0.1798 | |

| Residual | 0.067 | 6 | 0.011 | - | - | |

| Total | 1.512 | 20 | - | - | - |

References

- Rossinia, M.; Spena, P.R.; Cortese, L.; Matteis, P.; Firrao, D. Investigation on dissimilar laser welding of advanced high strength steel sheets for the automotive industry. Mater. Sci. Eng. A 2014, 628, 288–296. [Google Scholar] [CrossRef]

- Blacha, S.; Weglowski, M.S.T.; Dymek, S.; Kopuscianski, M. Microstructural characterization and mechanical properties of electron beam welded joint of high strength grade S690QL. Arch. Metall. Mater. 2016, 61, 1193–1200. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.; Akkerman, R.; Wijskamp, S.; Kok, J.S.M. Weld strength assessment for tape placement. Int. J. Mater. Form. 2010, 3, 707–710. [Google Scholar] [CrossRef]

- Hernandez, V.H.B.; Panda, S.K.; Kuntz, M.L.; Zhou, Y. Nanoindentation and microstructure analysis of resistance spot welded dual phase steel. Mater. Lett. 2010, 64, 207–210. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of microstructure and mechanical properties of resistance spot welded DP600 Steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef]

- Huang, Y.M.; Wu, D.; Zhang, Z.F.; Chen, H.B.; Chen, S.B. EMD-based pulsed TIG welding process porosity defect detection and defect diagnosis using GA-SVM. J. Mater. Process. Technol. 2017, 239, 92–102. [Google Scholar] [CrossRef]

- Narwadkar, A.; Bhosle, S. Optimization of MIG welding parameters to control the angular distortion in Fe410WA Steel. Mater. Manuf. Process. 2015, 31, 2158–2164. [Google Scholar] [CrossRef]

- Ahmadzadeh, M.; Farshi, B.; Salimi, H.R.; Fard, A.H. Residual stresses due to gas arc welding of aluminum alloy joints by numerical simulations. Int. J. Mater. Form. 2013, 6, 233–247. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Prahl, U.; Schleser, M.; Reisgen, U.; Bleck, M. Micro-macro-characterisation and modelling of mechanical properties of gas metal arc welded (GMAW) DP600 steel. Mater. Sci. Eng. A 2014, 589, 1–14. [Google Scholar] [CrossRef]

- Mei, L.F.; Chen, G.Y.; Jin, X.Z.; Zhang, Y.; Wu, Q. Research on laser welding of high-strength galvanized automobile steel sheets. Opt. Lasers Eng. 2009, 47, 1117–1124. [Google Scholar] [CrossRef]

- Sharma, R.S.; Molian, P. Yb:YAG laser welding of TRIP780 steel with dual phase and mild steels for use in tailor welded blanks. Mater. Des. 2009, 30, 4146–4155. [Google Scholar] [CrossRef]

- Xu, W.; Westerbaan, D.; Nayak, S.S.; Chen, D.L.; Goodwin, F.; Zhou, Y. Tensile and fatigue properties of fiber laser welded high strength low alloy and DP980 dual-phase steel joints. Mater. Des. 2013, 43, 373–383. [Google Scholar] [CrossRef]

- Ghaini, F.M.; Hamedi, M.J.; Torkamany, M.J.; Sabbaghzadeh, J. Weld metal microstructural characteristics in pulsed Nd:YAG laser welding. Scr. Mater. 2007, 56, 955–958. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T. Scanning speed and powder flow rate influence on the properties of laser metal deposition of titanium alloy. Int. J. Adv. Manuf. Technol. 2017, in press. [Google Scholar] [CrossRef]

- Hazratinezhad, M.; Arab, N.B.M.; Sufizadeh, A.R.; Torkamany, M.J. Mechanical and metallurgical properties of pulsed neodymium-doped yttrium aluminum garnet laser welding of dual phase steels. Mater. Des. 2012, 33, 83–87. [Google Scholar] [CrossRef]

- Mirakhorli, F.; Malek Ghaini, F.; Torkamany, M.J. Development of weld metal microstructures in pulsed laser welding of duplex stainless steel. J. Mater. Eng. Perform. 2012, 21, 2173–2176. [Google Scholar] [CrossRef]

- Seang, C.; David, A.K.; Ragneau, E. Effect of Nd:YAG laser welding parameters on the hardness of lap joint: Experimental and numerical approach. Phys. Proc. 2013, 41, 38–40. [Google Scholar] [CrossRef]

- Sun, Q.; Di, H.S.; Li, J.C.; Wang, X.N. Effect of pulse frequency on microstructure and properties of welded joints for dual phase steel by pulsed laser welding. Mater. Des. 2016, 105, 201–211. [Google Scholar] [CrossRef]

- Wang, J.F.; Yang, L.J.; Sun, M.S.; Liu, T.; Li, H. A study of the softening mechanisms of laser-welded DP1000 steel butt joints. Mater. Des. 2016, 97, 118–125. [Google Scholar] [CrossRef]

- Tzeng, Y.F. Effects of operating parameters on surface quality for the pulsed laser welding of zinc-coated steel. J. Mater. Process. Technol. 2000, 100, 163–170. [Google Scholar] [CrossRef]

- Xia, M.S.; Biro, E. Effects of heat input and martensite on HAZ softening in laser welding of dual phase steels. ISIJ Int. 2008, 48, 809–814. [Google Scholar] [CrossRef]

- Dong, D.Y.; Liu, Y.; Yang, Y.L.; Li, J.F.; Ma, M.; Jiang, T. Microstructure and dynamic tensile behavior of DP600 dual phase steel joint by laser welding. Mater. Sci. Eng. A 2014, 594, 17–25. [Google Scholar] [CrossRef]

- Baghjari, S.H.; Akbari Mousavi, S.A.A. Effects of pulsed Nd:YAG laser welding parameters and subsequent post-weld heat treatment on microstructure and hardness of AISI 420 stainless steel. Mater. Des. 2013, 43, 1–9. [Google Scholar] [CrossRef]

- Farabia, N.; Chen, D.L.; Zhou, Y. Microstructure and mechanical properties of laser welded dissimilar DP600/DP980 dual-phase steel joints. J. Alloys Compd. 2011, 509, 982–989. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.H.; Kwon, H.S.; Kim, G.S.; Lee, C.S. Laser, tungsten inert gas, and metal active gas welding of DP780 steel: Comparison of hardness, tensile properties and fatigue resistance. Mater. Des. 2014, 64, 559–565. [Google Scholar] [CrossRef]

- Reisgen, U.; Schleser, M.; Mokrov, O.; Ahmed, E. Shielding gas influences on laser weldability of tailored blanks of advanced automotive steels. Appl. Surf. Sci. 2010, 257, 1401–1406. [Google Scholar] [CrossRef]

- Schemmann, L.; Zaefferer, S.; Raabe, D.; Friedel, F.; Mattissen, D. Alloying effects on microstructure formation of dual phase steels. Acta Mater. 2015, 95, 386–398. [Google Scholar] [CrossRef]

- Wang, X.N.; Chen, C.J.; Wang, H.S.; Zhang, S.H.; Zhang, M.; Luo, X. Microstructure formation and precipitation in laser welding of microalloyed C-Mn steel. J. Mater. Process. Technol. 2015, 226, 106–114. [Google Scholar] [CrossRef]

- Liao, J.; Sousa, J.A.; Lopes, A.B.; Xue, X.; Barlat, F.; Pereira, A.B. Mechanical, microstructural behaviour and modelling of dual phase steels under complex deformation paths. Int. J. Plast. 2017, 93, 269–290. [Google Scholar] [CrossRef]

- Xue, X.; Liao, J.; Vincze, G.; Pereira, A.B.; Barlat, F. Experimental assessment of nonlinear elastic behaviour of dual-phase steels and application to springback prediction. Int. J. Mech. Sci. 2016, 117, 1–15. [Google Scholar] [CrossRef]

- ARAMIS—3D Motion and Deformation Sensor. Available online: http://www.gom.com/metrology-systems/aramis.html (accessed on 30 July 2017).

- Tasan, C.C.; Diehl, M.; Yan, D.; Zambaldi, C.; Shanthraj, P.; Roters, F.; Raabe, D. Integrated experimental-simulation analysis of stress and strain partitioning in multiphase alloys. Acta Mater. 2014, 81, 386–400. [Google Scholar] [CrossRef]

- Ghadbeigi, H.; Pinna, C.; Celotto, S. Quantitative strain analysis of the large deformation at the scale of microstructure: Comparison between digital image correlation and micro grid techniques. Exp. Mech. 2012, 52, 1483–1492. [Google Scholar] [CrossRef]

- Alharbi, K.; Ghadbeigi, H.; Efthymiadis, P.; Zanganeh, M.; Celotto, S.; Dashwood, R.; Pinna, C. Damage in dual phase steel DP1000 investigated using digital image correlation and microstructure simulation. Model. Simul. Mater. Sci. 2015, 23, 085005. [Google Scholar] [CrossRef]

- Duley, W.W. Laser Welding; John Wiley & Sons: Hoboken, NJ, USA, 1998; ISBN 978-0-471-24679-4. [Google Scholar]

| C | Si | Mn | P | S | N | Cr | Ni | Cu | Al | V | B | Nb | Cekv |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.14 | 0.20 | 1.46 | 0.013 | 0.003 | 0.002 | 0.03 | 0.03 | 0.01 | 0.051 | 0.01 | 0.0004 | 0.014 | 0.39 |

| Cekv = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15 | |||||||||||||

| Direction | Elastic Modulus, E (GPa) | Poisson’ Ratio υ | Yield Stress σy (MPa) | Ultimate Stress σu (MPa) | Elongation e (%) | Hardness HV0.5 |

|---|---|---|---|---|---|---|

| RD | 210 | 0.3 | 779 | 1125 | 9.35 | 382 |

| Series | Parameters | Variation of Single Factor |

|---|---|---|

| A | Power percent (%) | 20, 40, 60, 80, 86 |

| B | Duration (ms) | 0.3, 3, 6, 9, 12, 15, 18, 21, 23 |

| C | Overlap (%) | 0, 20, 40, 60, 80, 95 |

| D | Laser beam diameter (mm) | 0.6, 0.8, 1.0, 1.2, 1.4, 1.6, 1.8, 2.0 |

| E | Pulse type |  |

| F | Velocity (mm/s) | 0.1, 1.0, 1.5, 2.0, 2.7 |

| Material | Power (%) | Pulse Duration (ms) | Overlap (%) | Diameter (mm) | Velocity (mm/s) | Energy (J) | Pulse Type |

|---|---|---|---|---|---|---|---|

| DP1000 | 57 | 9.0 | 60 | 0.6 | 0.3 | 45 | Rec. |

| Material Tested | Micro-Indentation | Vickers |

|---|---|---|

| Base DP 1000 steel | 425 HV (10.7 GPa) | 382 HV |

| Heat-affected zone | 372 HV (9.36 GPa) | 316 HV |

| Fusion zone of weld | 504 HV (14.5 GPa) | 449 HV |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Pereira, A.B.; Amorim, J.; Liao, J. Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint. Metals 2017, 7, 292. https://doi.org/10.3390/met7080292

Xue X, Pereira AB, Amorim J, Liao J. Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint. Metals. 2017; 7(8):292. https://doi.org/10.3390/met7080292

Chicago/Turabian StyleXue, Xin, António B. Pereira, José Amorim, and Juan Liao. 2017. "Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint" Metals 7, no. 8: 292. https://doi.org/10.3390/met7080292

APA StyleXue, X., Pereira, A. B., Amorim, J., & Liao, J. (2017). Effects of Pulsed Nd:YAG Laser Welding Parameters on Penetration and Microstructure Characterization of a DP1000 Steel Butt Joint. Metals, 7(8), 292. https://doi.org/10.3390/met7080292