Effects of Laser Offset and Hybrid Welding on Microstructure and IMC in Fe–Al Dissimilar Welding

Abstract

:1. Introduction

2. Experimental Procedures

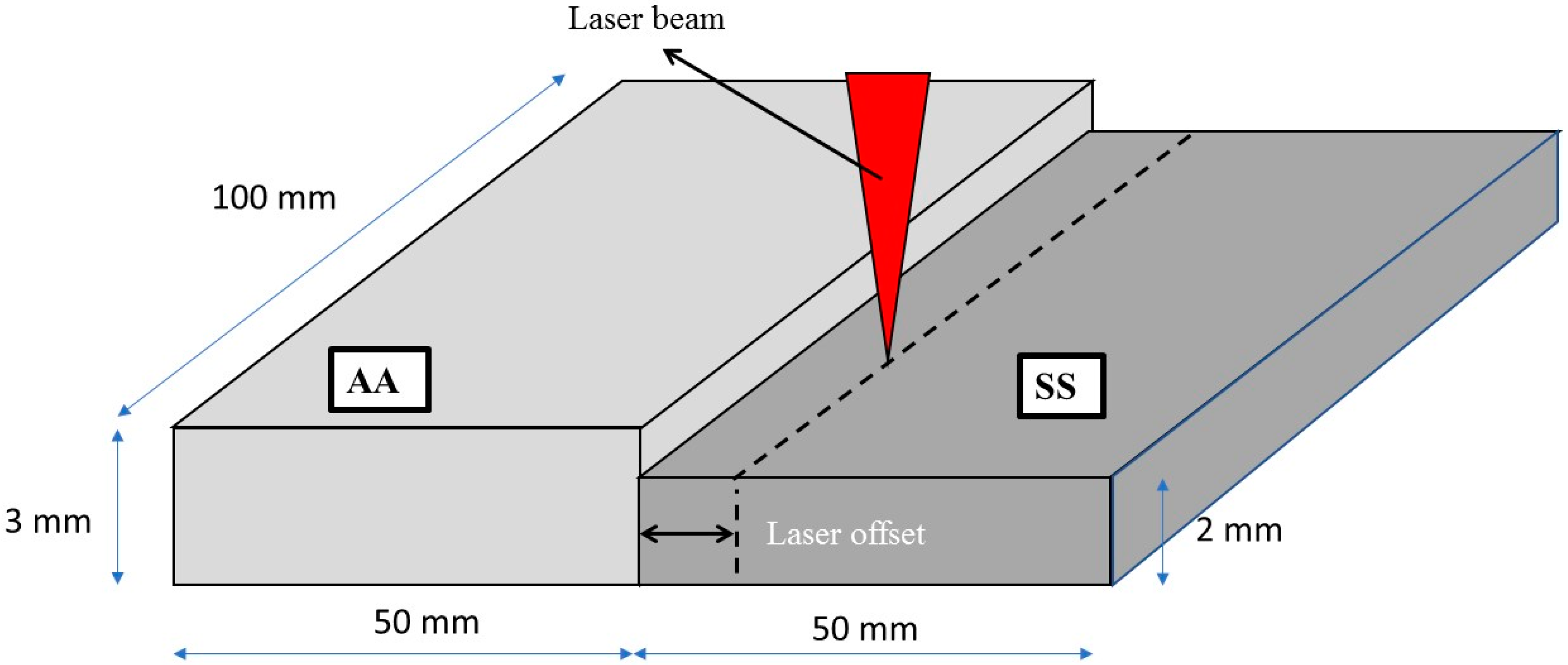

2.1. Material Properties and Weld Configuration

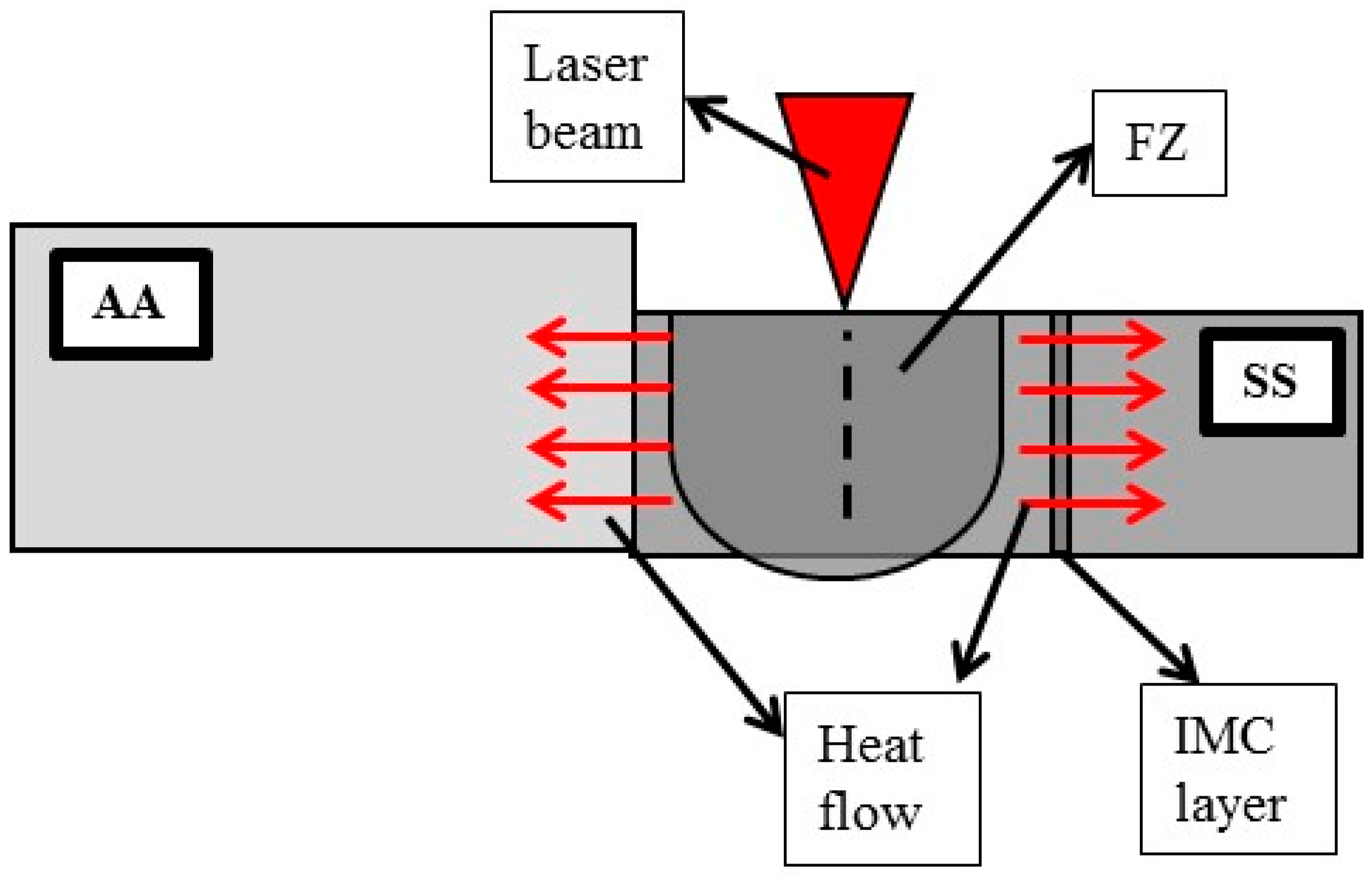

2.2. The Welding Procedures

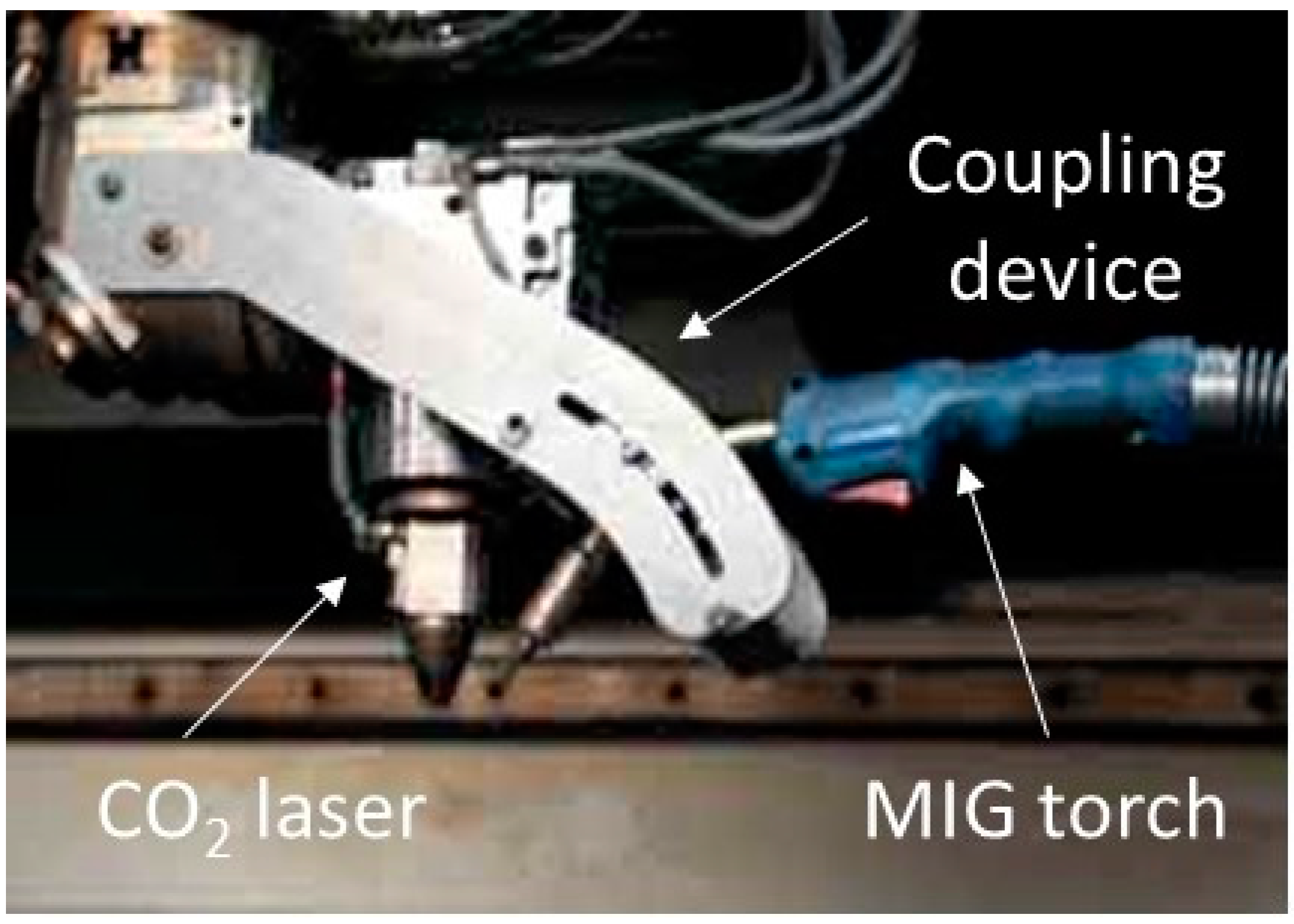

2.3. Set-Up of the Welding Systems

2.4. Process Parameters

2.5. Metallographic Analysis and Mechanical Testing

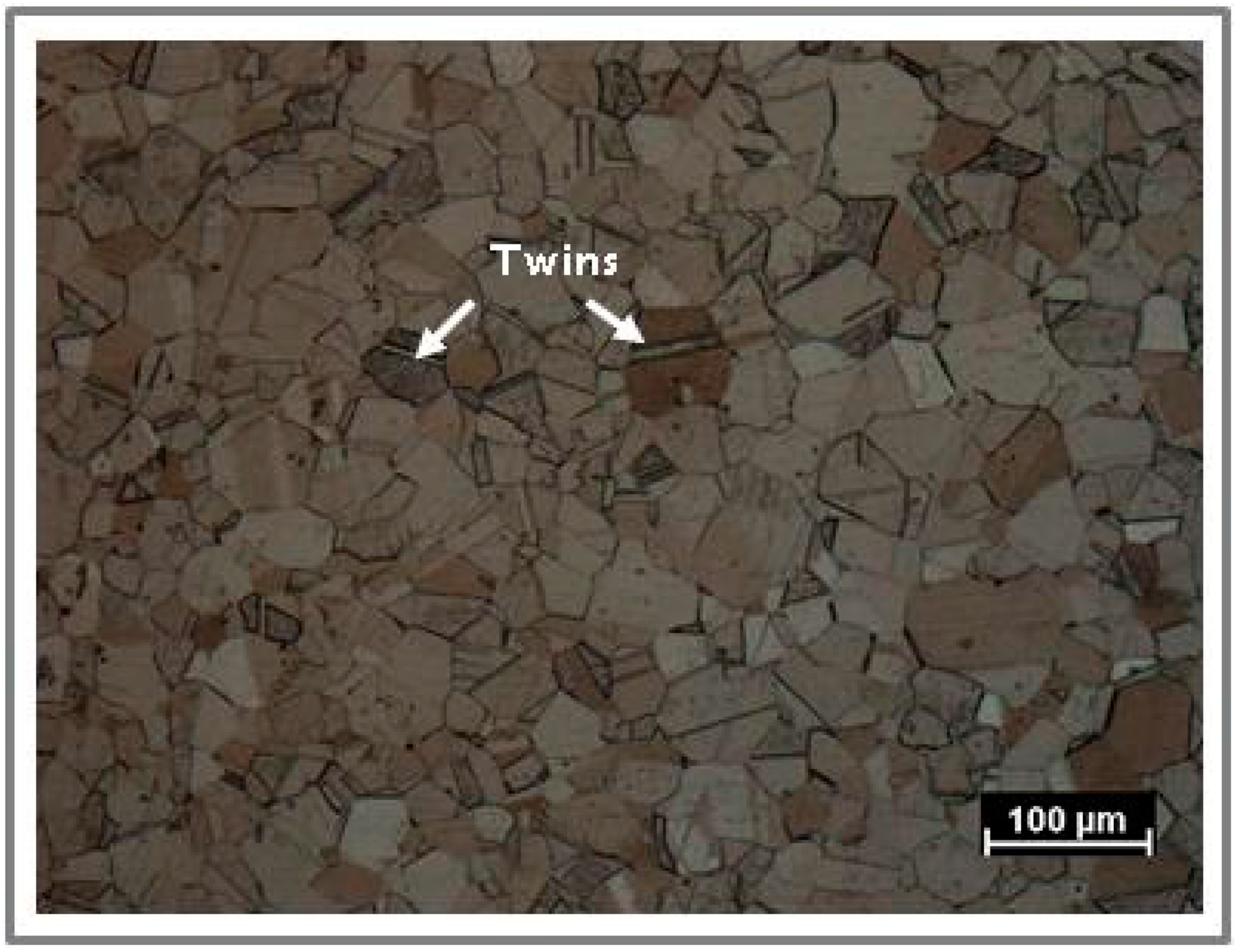

- Keller’s solution (1 mL HF, 1.5 mL HCl, 2.5 mL HNO3, and 95 mL H2O) for aluminum microstructure.

- Vilella’s solution (1 g picric acid, 5 mL HCl, 100 mL ethanol) for steel microstructure.

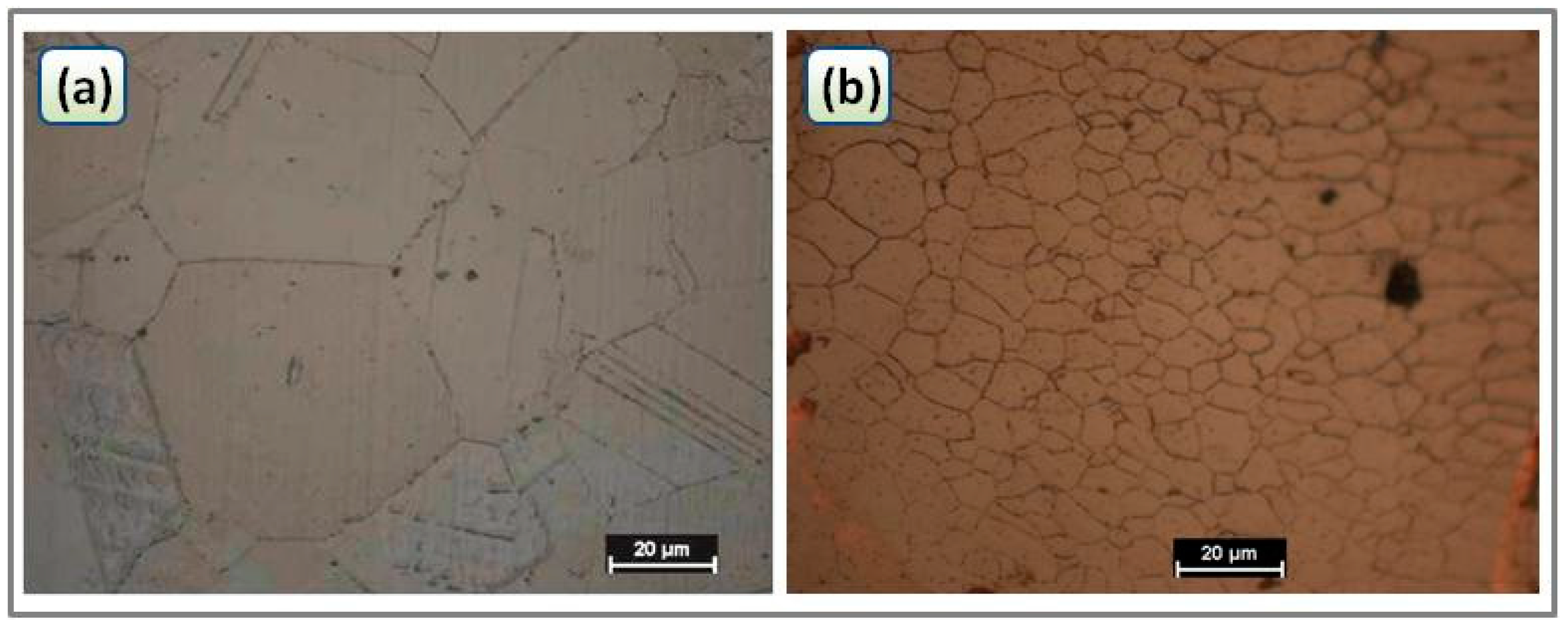

3. Base Material Characterization

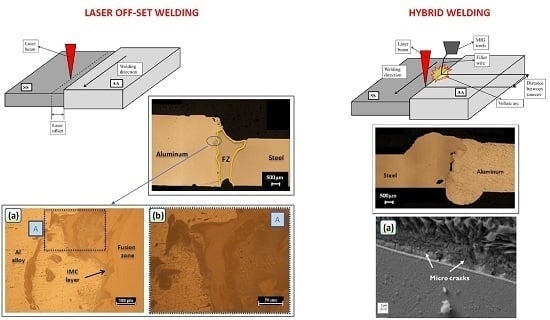

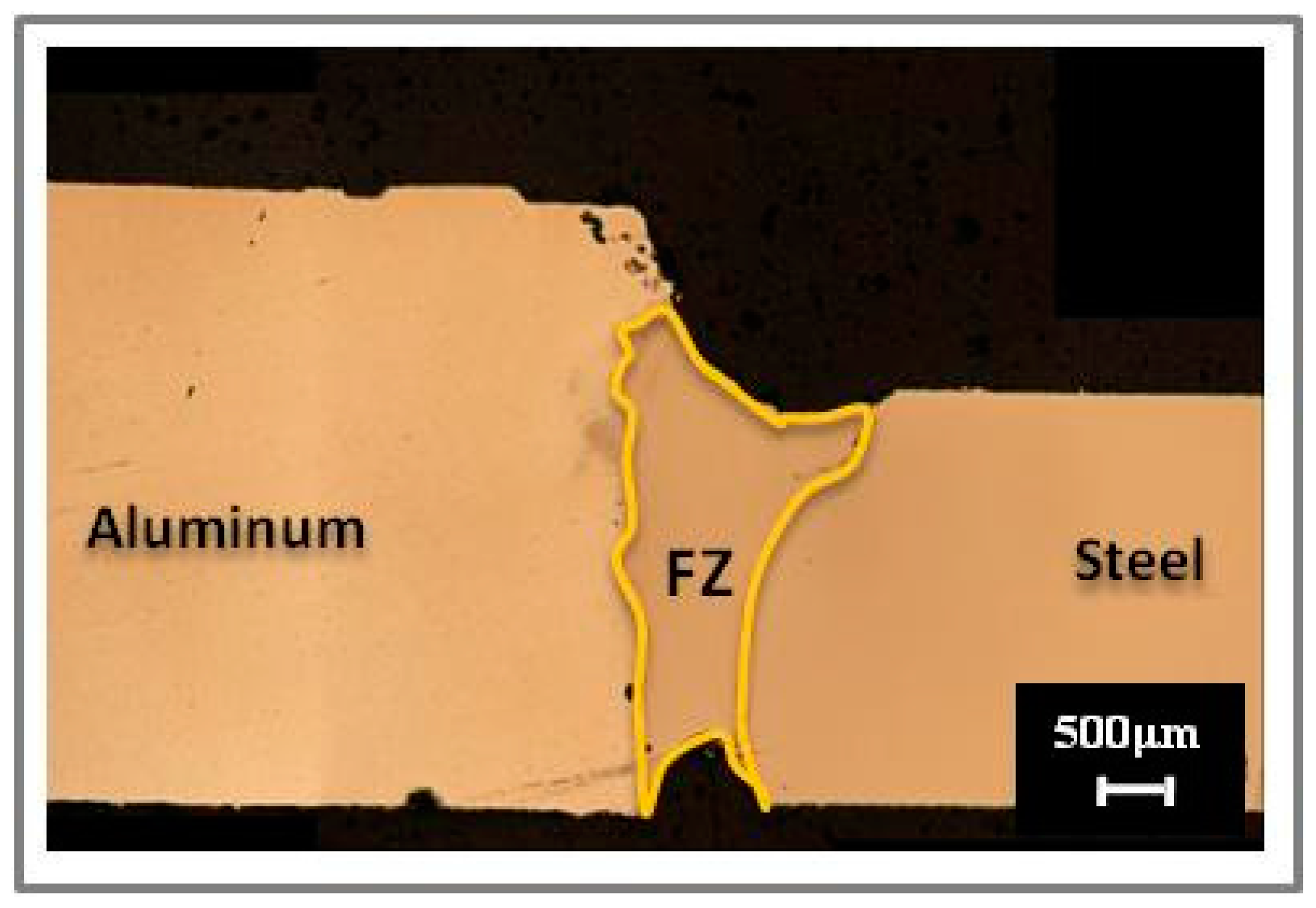

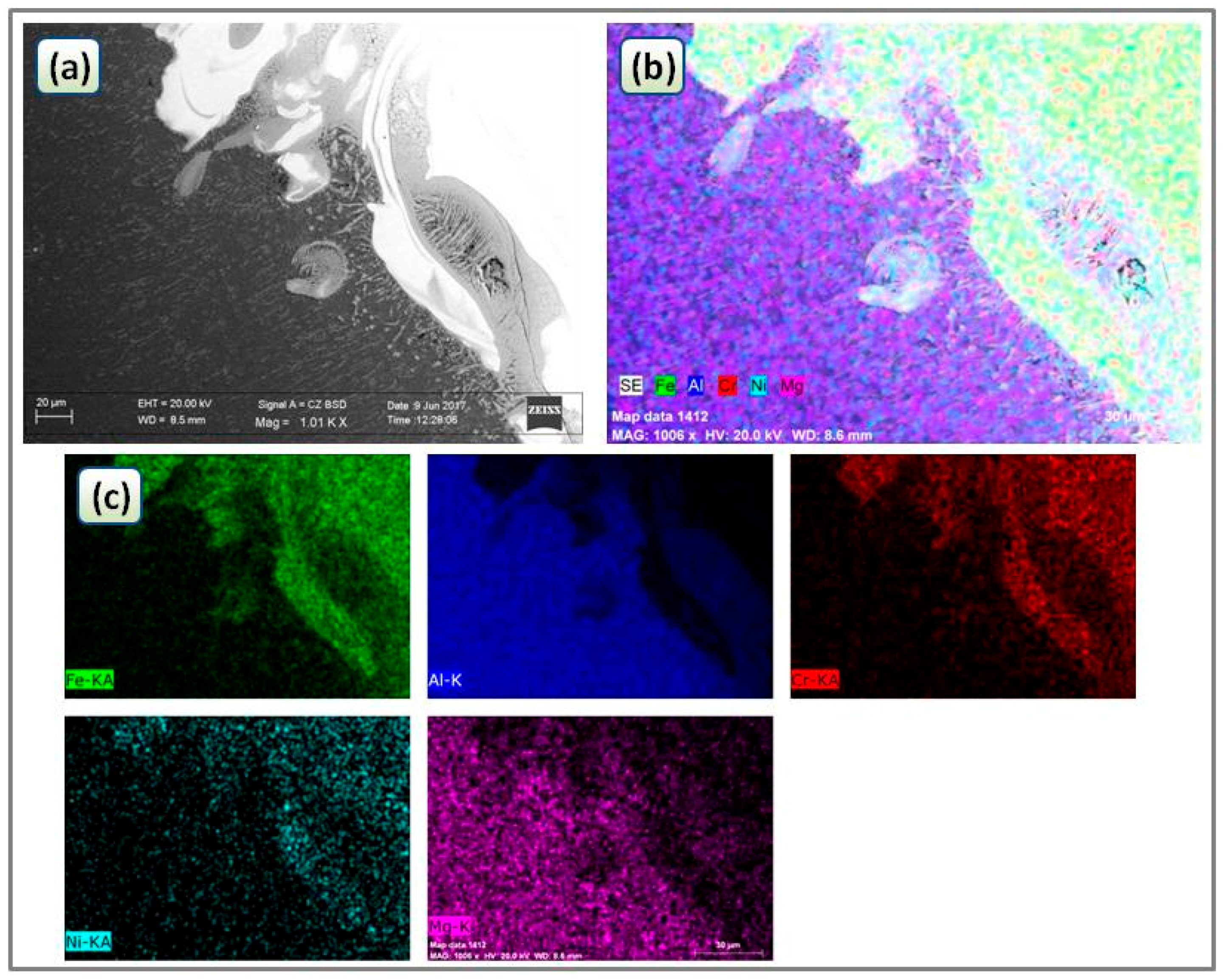

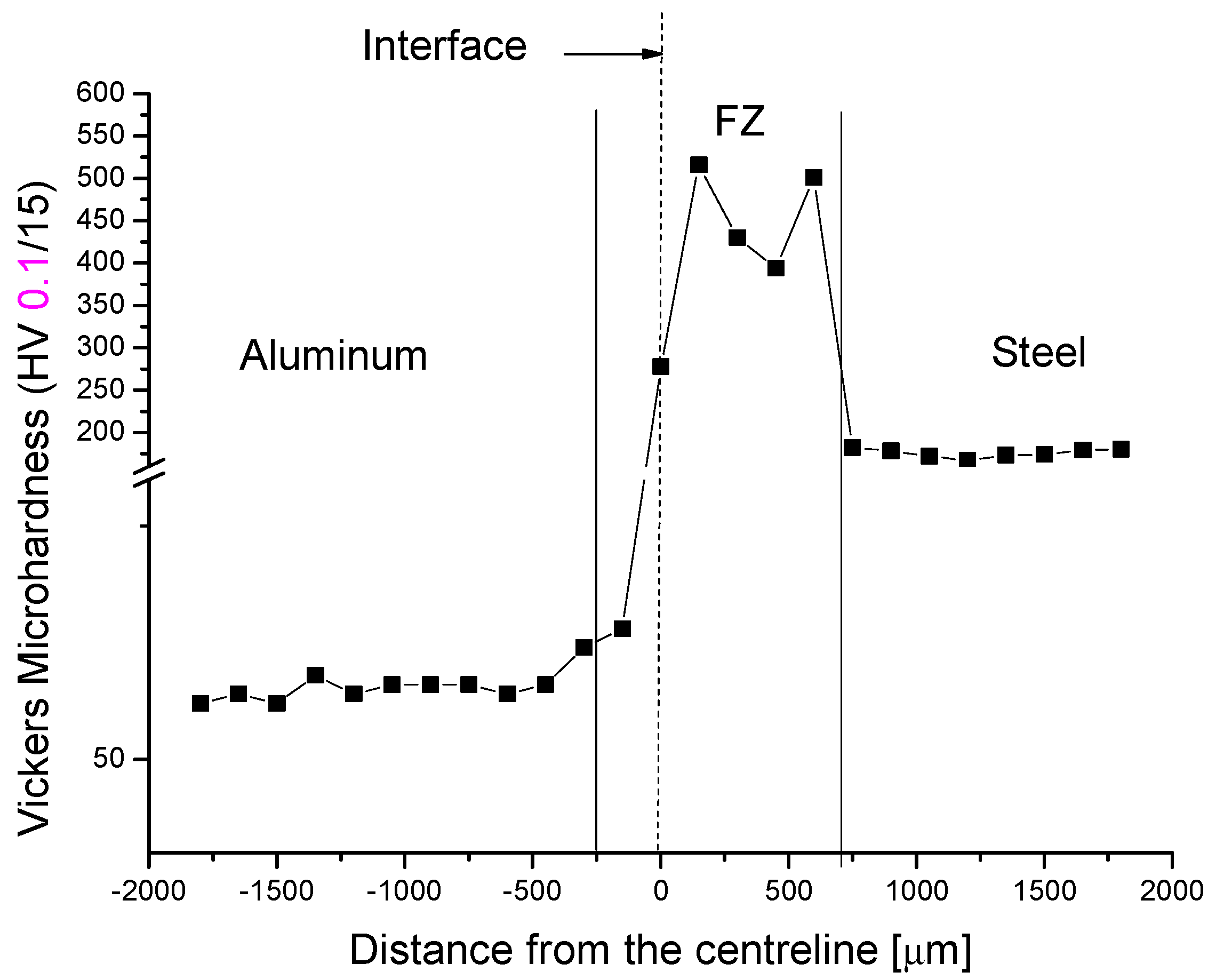

4. Laser Off-Set Welding Results

5. Laser Hybrid Welding Results

6. Conclusions

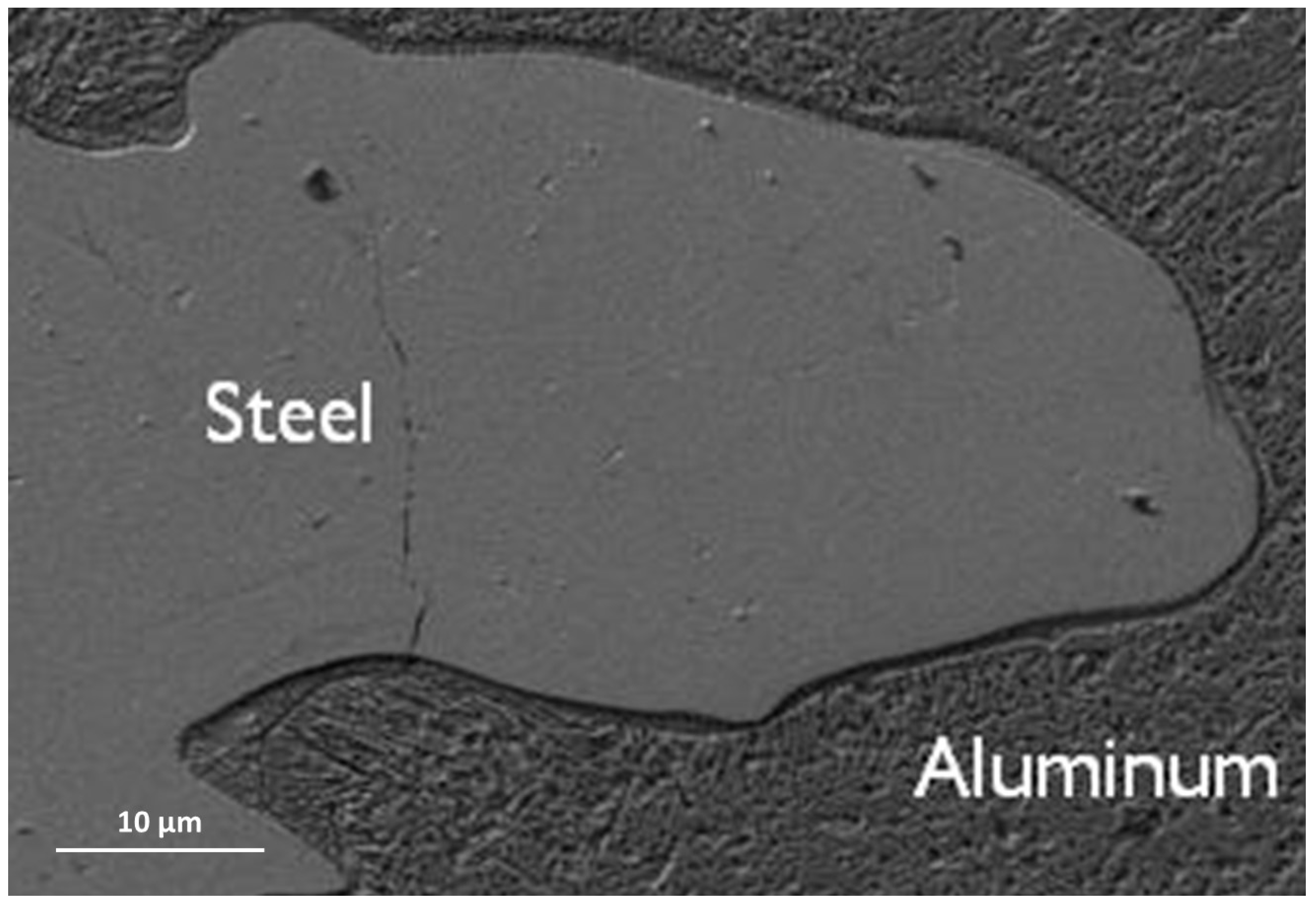

- The EDS/XRD analysis revealed the presence of FeAl2 in the laser welded joint.

- Full penetration and low defectiveness were obtained by laser offset welding. The interaction between liquid phases was restricted. Viscous forces were attenuated by optimizing the process energy balance. Moreover, the high cooling rate and low mix between the two metals enabled IMC layer growth, which was as thick as 6 µm. As stated in the literature, a thin IMC layer improves the mechanical properties of the weld. Brittle phases were detected but hot cracks were avoided.

- Hybrid laser-arc welding resulted less effective. In fact, an excessive weld crown was observed and the weld presented a lack of penetration. The process was instable because of the significant difference in thermal- and fluid-dynamic properties of the two metals, which compromised the keyhole stability. The interface was highly irregular and non-homogeneous, due to the action of the viscous forces.

Author Contributions

Conflicts of Interest

References

- Yang, J.; Long, L.Y.; Zhang, H. Microstructure and mechanical properties of pulsed laser welded Al/steel dissimilar joint. Trans. Nonferrous Met. Soc. China 2016, 26, 994–1002. [Google Scholar] [CrossRef]

- Fridlyander, I.N.; Sister, V.G.; Grushko, O.E.; Berstenev, V.; Sheveleva, L.M.; Ivanova, L.A. Aluminium alloys: Promising materials in the automotive industry. Met. Sci. Heat Treat. 2002, 44, 365–370. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Tahamtan, S.; Sabbaghzadeh, J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser. Mater. Des. 2010, 31, 458–465. [Google Scholar] [CrossRef]

- Chen, S.; Zhai, Z.; Huang, J.; Zhao, X.; Xiong, J. Interface microstructure and fracture behavior of single/dual-beam laser welded steel-Al dissimilar joint produced with copper interlayer. Int. J. Adv. Manuf. Technol. 2016, 82, 631–643. [Google Scholar] [CrossRef]

- Hiroaki, O.; Schlesinger, M.E.; Mueller, E.M. Alloy Phase Diagrams, 3rd ed.; ASM International: Geauga County, OH, USA, 1992; ISBN 978-1-62708-070-5. [Google Scholar]

- Çam, G.; Erim, S.; Yeni, Ç.; Koçak, M. Determination of mechanical and fracture properties of laser beam welded steel joints. Weld. J. 1999, 78, 193–201. [Google Scholar]

- Çam, G.; Yeni, Ç.; Erim, S.; Ventzke, V.; Koçak, M. Investigation into properties of laser welded similar and dissimilar steel joints. Sci. Technol. Weld. Join. 1998, 3, 177–189. [Google Scholar] [CrossRef]

- Mvola, B.; Kah, P.; Martikainen, J.; Suoranta, R. Dissimilar high-strength steels: Fusion welded joints, mismatches, and challenges. Rev. Adv. Mater. Sci. 2016, 44, 146–159. [Google Scholar]

- Liu, X.; Lan, S.; Ni, J. Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater. Des. 2014, 59, 50–62. [Google Scholar] [CrossRef]

- Movahedi, M.; Kokabi, A.H.; Reihani, S.S.; Cheng, W.-J.; Wang, C.J. Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater. Des. 2013, 44, 487–492. [Google Scholar] [CrossRef]

- Habibnia, M.; Shakeri, M.; Nourouzi, S.; Givi, M.B. Microstructural and mechanical properties of friction stir welded 5050 Al alloy and 304 stainless steel plates. Int. J. Adv. Manuf. Technol. 2015, 76, 819–829. [Google Scholar] [CrossRef]

- Sahin, M. Joining of stainless-steel and aluminium materials by friction welding. Int. J. Adv. Manuf. Technol. 2009, 41, 487–497. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef]

- Ratanathavorn, W.; Melander, A.; Magnusson, H. Intermetallic compounds in friction stirred lap joints between AA5754/galvanised ultra-high strength steel. Sci. Technol. Weld. Join. 2016, 21, 653–659. [Google Scholar] [CrossRef]

- Oikawa, H.; Ohimiya, S.; Yoshimura, T.; Saitoh, T. Resistance spot welding of steel and aluminum sheet using insert metal sheet. Sci. Technol. Weld. Join. 1999, 4, 80–88. [Google Scholar] [CrossRef]

- Qin, G.; Su, Y.H.; Meng, X.M.; Fu, B.L. Numerical simulation on MIG arc brazing-fusion welding of aluminum alloy to galvanized steel plate. Int. J. Adv. Manuf. Technol. 2015, 78, 1917–1925. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Mei, S.W.; Wang, L.; Zeng, X.Y. Parameter optimization and mechanism of laser–arc hybrid welding of dissimilar Al alloy and stainless steel. Int. J. Adv. Manuf. Technol. 2014, 74, 199–208. [Google Scholar] [CrossRef]

- Çam, G. Friction stir welded structural materials: Beyond Al alloys. Int. Mater. Rev. 2011, 56, 1–48. [Google Scholar] [CrossRef]

- Chen, S.; Huang, J.; Ma, K.; Zhang, H.; Zhao, X. Influence of a Ni-foil interlayer on Fe/Al dissimilar joint by laser penetration welding. Mater. Lett. 2012, 79, 296–299. [Google Scholar] [CrossRef]

- Mathieu, A.; Pontevicci, S.; Viala, J.; Cicala, E.; Matteї, S.; Grevey, D. Laser brazing of a steel/aluminum assembly with hot filler wire (88% Al, 12% Si). Mater. Sci. Eng. A 2006, 435, 19–28. [Google Scholar] [CrossRef]

- Dharmendra, C.; Rao, K.; Wilden, J.; Reich, S. Study on laser welding-brazing of zinc coated steel to aluminum alloy with a zinc based filler. Mater. Sci. Eng. 2011, 528, 1497–1503. [Google Scholar] [CrossRef]

- Song, J.; Lin, S.; Yang, C.; Ma, G.; Liu, H. Spreading behavior and microstructure characteristics of dissimilar metals TIG welding brazing of aluminum alloy to stainless steel. Mater. Sci. Eng. 2009, 509, 31–40. [Google Scholar] [CrossRef]

- Choi, C.; Kim, D.; Nam, D.; Kim, Y.; Park, Y. A hybrid joining technology for aluminum/zinc coated steels in vehicles. J. Mater. Sci. Technol. 2010, 26, 858–864. [Google Scholar] [CrossRef]

- Zhang, K.; Zhenglong, L.; Chen, Y.; Liu, M.; Liu, Y. Microstructure characteristics and mechanical properties of laser-TIG hybrid welded dissimilar joints of Ti–22Al–27Nb and TA15. Opt. Laser Technol. 2015, 73, 139–145. [Google Scholar] [CrossRef]

- Thomy, C.; Vollertsen, F. Laser-Mig Hybrid Welding of Aluminium to Steel Effect of Process Parameters on Joint Properties. Weld. World 2012, 56, 124–132. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Technol. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, X.; Miao, Y.; Wu, G.; Zhao, Z. Numerical and experiment analysis of residual stress on magnesium alloy and steel butt joint by hybrid laser-TIG welding. Comput. Mater. Sci. 2011, 50, 1763–1769. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb–YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

- Rathod, M.J.; Kustuna, M. Joining of aluminum alloy 5052 and low carbon steel by laser roll welding. Weld. J. Res. Suppl. 2004, 83, 16–26. [Google Scholar]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Casalino, G.; Guglielmi, P.; Lorusso, V.D.; Mortello, M.; Peyre, P.; Sorgente, D. Laser offset welding of AZ31B magnesium alloy to 316 stainless steel. J. Mater. Process. Technol. 2017, 242, 49–59. [Google Scholar] [CrossRef]

- Miranda, R.M.; Assunção, E.; Silva, R.J.C.; Oliveira, J.P.; Quintino, L. Fiber laser welding of NiTi to Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2015, 81, 1533–1538. [Google Scholar] [CrossRef]

- Pardal, G.; Meco, S.; Ganguly, S.; Williams, S.; Prangnell, P. Dissimilar metal laser spot joining of steel to aluminium in conduction mode. Int. J. Adv. Manuf. Technol. 2014, 73, 365–373. [Google Scholar] [CrossRef]

- Kumar, S.; Nadendla, H.B.; Scamans, G.M.; Eskin, D.G.; Fan, Z. Solidification behavior of an AA5754 alloy ingot cast with high impurity content. Int. J. Mater. Res. 2012, 103, 1228–1234. [Google Scholar] [CrossRef]

- Smith, W.F. Structure and Properties of Engineering Alloys, 1st ed.; McGraw-Hill: New York, NY, USA, 1992; pp. 186–191. ISBN 0-07-59172-5. [Google Scholar]

- Davis, J.R. Aluminum and Aluminum Alloys, 1st ed.; ASM International: Geauga County, OH, USA, 1993; ISBN 978-0-87170-496-2. [Google Scholar]

- Miao, Y.G.; Han, D.F.; Yao, J.Z.; Li, F. Microstructure and interface characteristics of laser penetration brazed magnesium alloy and steel. Sci. Technol. Weld. Join. 2010, 15, 97–103. [Google Scholar] [CrossRef]

- Kobayashi, S.; Yakou, T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater. Sci. Eng. A 2002, 338, 44–53. [Google Scholar] [CrossRef]

- Sun, J.; Yan, Q.; Gao, W.; Huang, J. Investigation of laser welding on butt joints of Al/steel dissimilar materials. Mater. Des. 2015, 83, 120–128. [Google Scholar] [CrossRef]

- Qiu, R.; Shi, H.; Zhang, K.; Tu, Y.; Iwamotoc, C.; Satonaka, S. Interfacial characterization of joint between mild steel and aluminum alloy welded by resistance spot welding. Mater. Charact. 2010, 61, 684–688. [Google Scholar] [CrossRef]

- Messler, R.W. Principles of Welding: Processes, Physics, Chemistry, and Metallurgy, 1st ed.; Wiley-VCH: New York, NY, USA, 2007; pp. 406–423. ISBN 0-471-25376-6. [Google Scholar]

- Brooks, J.; Lippold, J. Welding, Brazing, and Soldering, 1st ed.; ASM International: Geauga County, OH, USA, 1993; ISBN 978-0-87170-382-8. [Google Scholar]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd:YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Sathiya, P.; Mishra, M.K.; Shanmugarajan, B. Effect of shielding gases on microstructure and mechanical properties of super austenitic stainless steel by hybrid welding. Mater. Des. 2012, 33, 203–212. [Google Scholar] [CrossRef]

- Cao, X.; Wallace, W.; Immarigeon, J.P.; Poon, C. Research and Progress in Laser Welding of Wrought Aluminum Alloys. II. Metallurgical Microstructures, Defects, and Mechanical Properties. Mater. Manuf. Process. 2003, 18, 23–49. [Google Scholar] [CrossRef]

| Metal | C | Al | Cr | Mn | Mo | Mg | Ni | Ti | P | S | Si | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 316 | 0.08 | - | 18 | 2 | 3 | - | 14 | - | 0.045 | 0.03 | 1 | balance |

| AA5754 | - | balance | 0.30 | 0.50 | - | 3.6 | - | 0.15 | - | - | 0.40 | 0.40 |

| Metal | UTS (MPa) | YS (MPa) | E (GPa) | A% | HV | K (W/(m·K)) | TL (°C) | ρ (g/cm3) | c (J/(g·°C)) |

|---|---|---|---|---|---|---|---|---|---|

| AISI 316 | 580 | 290 | 193 | 50 | 178 | 16.3 | 1400 | 8 | 0.5 |

| AA5754 | 230 | 80 | 68 | 17 | 62 | 147 | 600 | 2.66 | 0.9 |

| Laser Power (kW) | Welding Speed (m/min) | Wire Feed Speed (m/min) | Current (A) | Voltage (V) | |

|---|---|---|---|---|---|

| Laser Offset Welding | 2.5 | 2 | - | - | - |

| Hybrid Laser-MIG Welding | 3.42 | 2 | 1.2 | 80 | 24 |

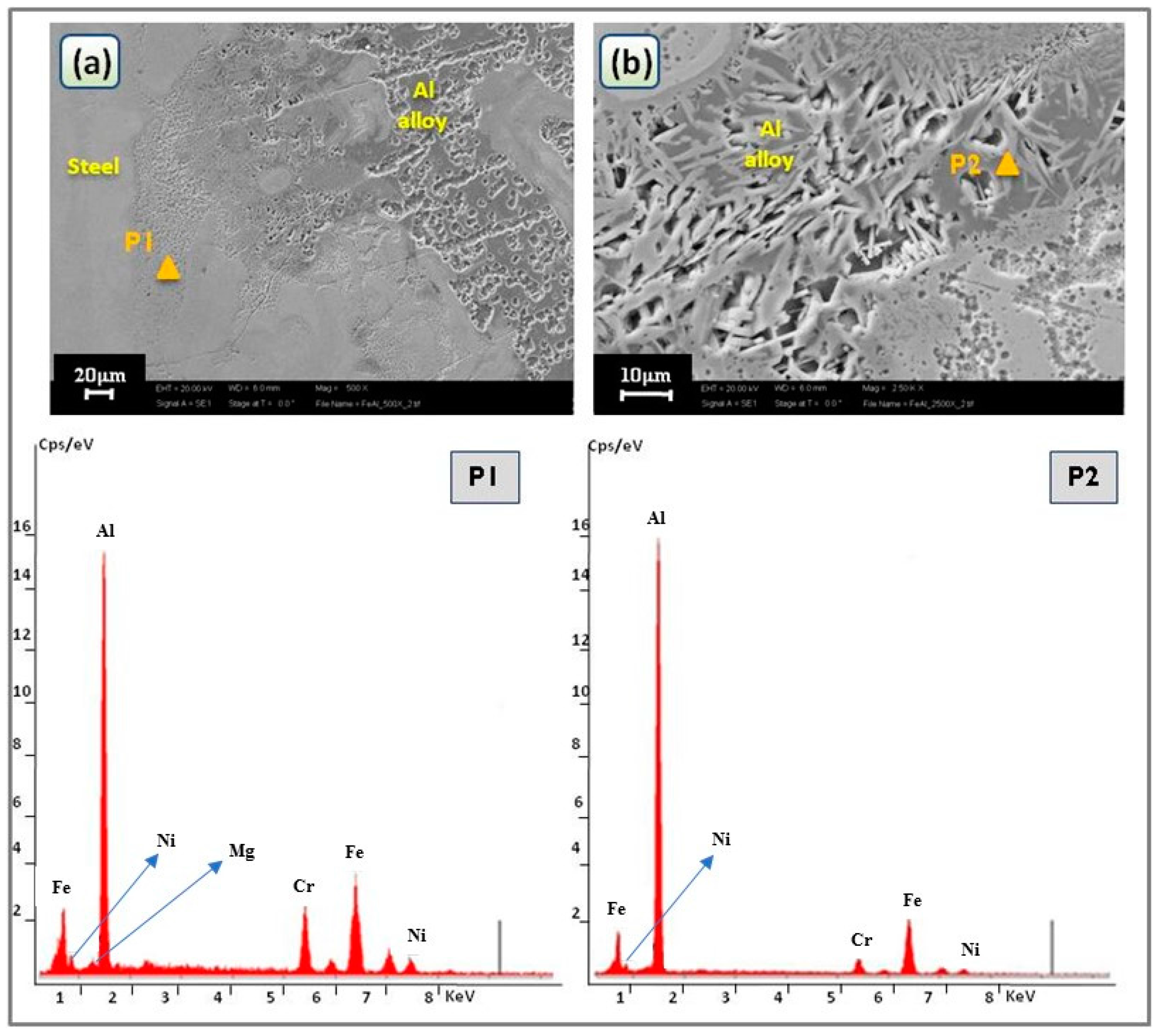

| Point No. | Al | Fe | Cr | Ni | Mg |

|---|---|---|---|---|---|

| P1 | 63.9 | 26.2 | 5.8 | 3.3 | 0.8 |

| P2 | 71.37 | 23.43 | 3.6 | 1.6 | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casalino, G.; Leo, P.; Mortello, M.; Perulli, P.; Varone, A. Effects of Laser Offset and Hybrid Welding on Microstructure and IMC in Fe–Al Dissimilar Welding. Metals 2017, 7, 282. https://doi.org/10.3390/met7080282

Casalino G, Leo P, Mortello M, Perulli P, Varone A. Effects of Laser Offset and Hybrid Welding on Microstructure and IMC in Fe–Al Dissimilar Welding. Metals. 2017; 7(8):282. https://doi.org/10.3390/met7080282

Chicago/Turabian StyleCasalino, Giuseppe, Paola Leo, Michelangelo Mortello, Patrizia Perulli, and Alessandra Varone. 2017. "Effects of Laser Offset and Hybrid Welding on Microstructure and IMC in Fe–Al Dissimilar Welding" Metals 7, no. 8: 282. https://doi.org/10.3390/met7080282