Fatigue Assessment of Ti–6Al–4V Circular Notched Specimens Produced by Selective Laser Melting

Abstract

:1. Introduction

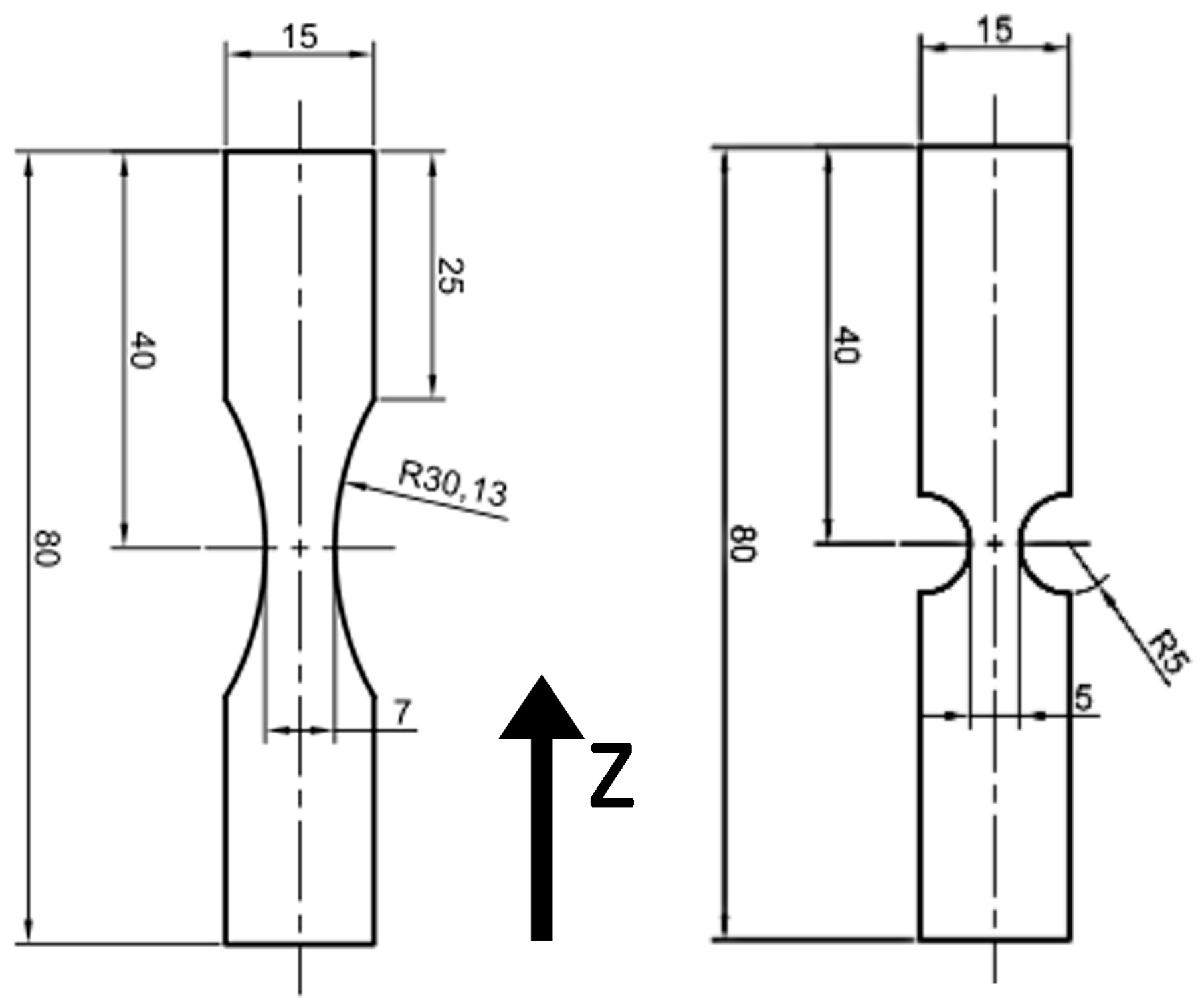

2. Material, Geometries, and Experimental Procedure

3. Results

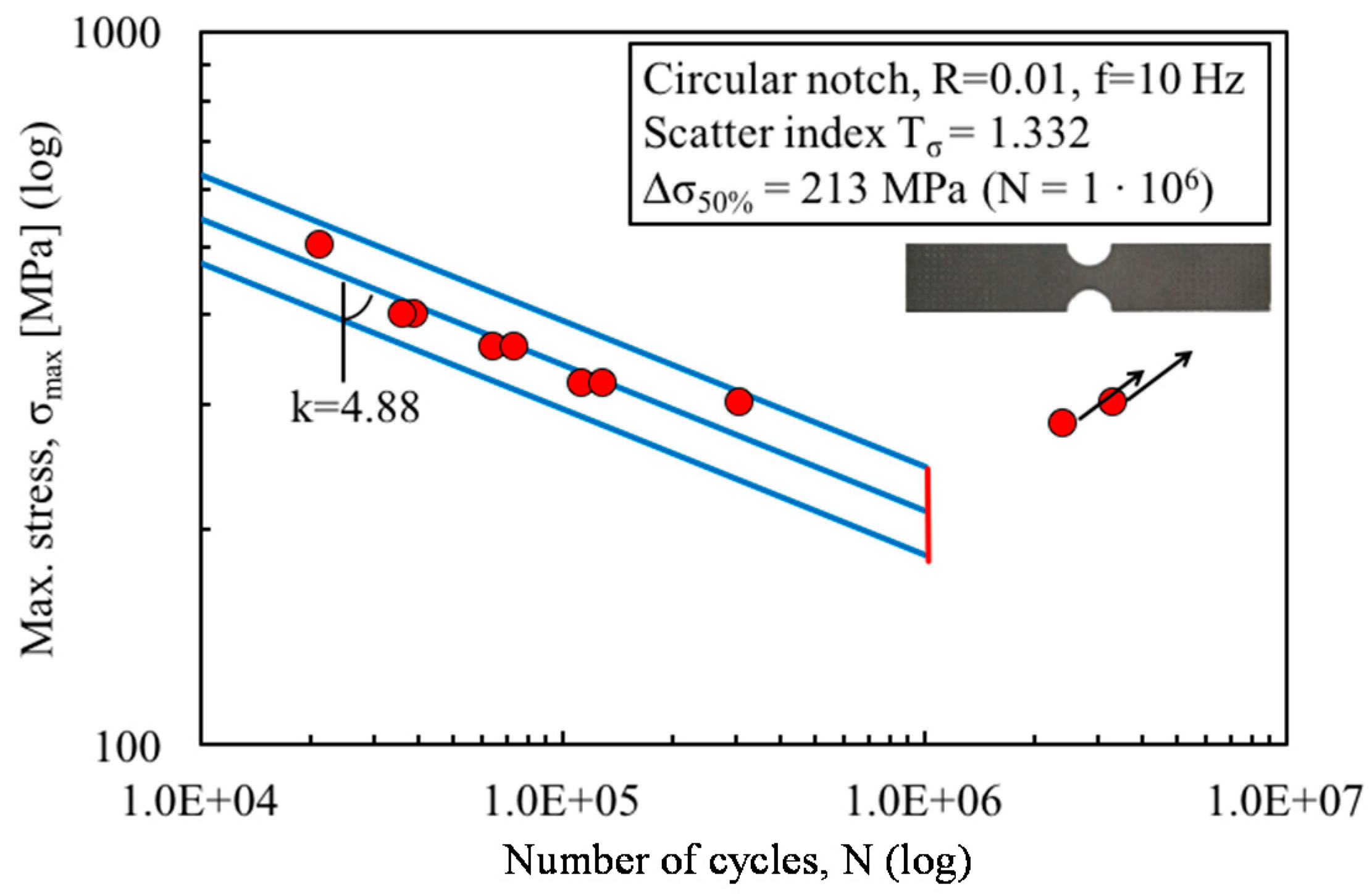

3.1. Fatigue Test Results

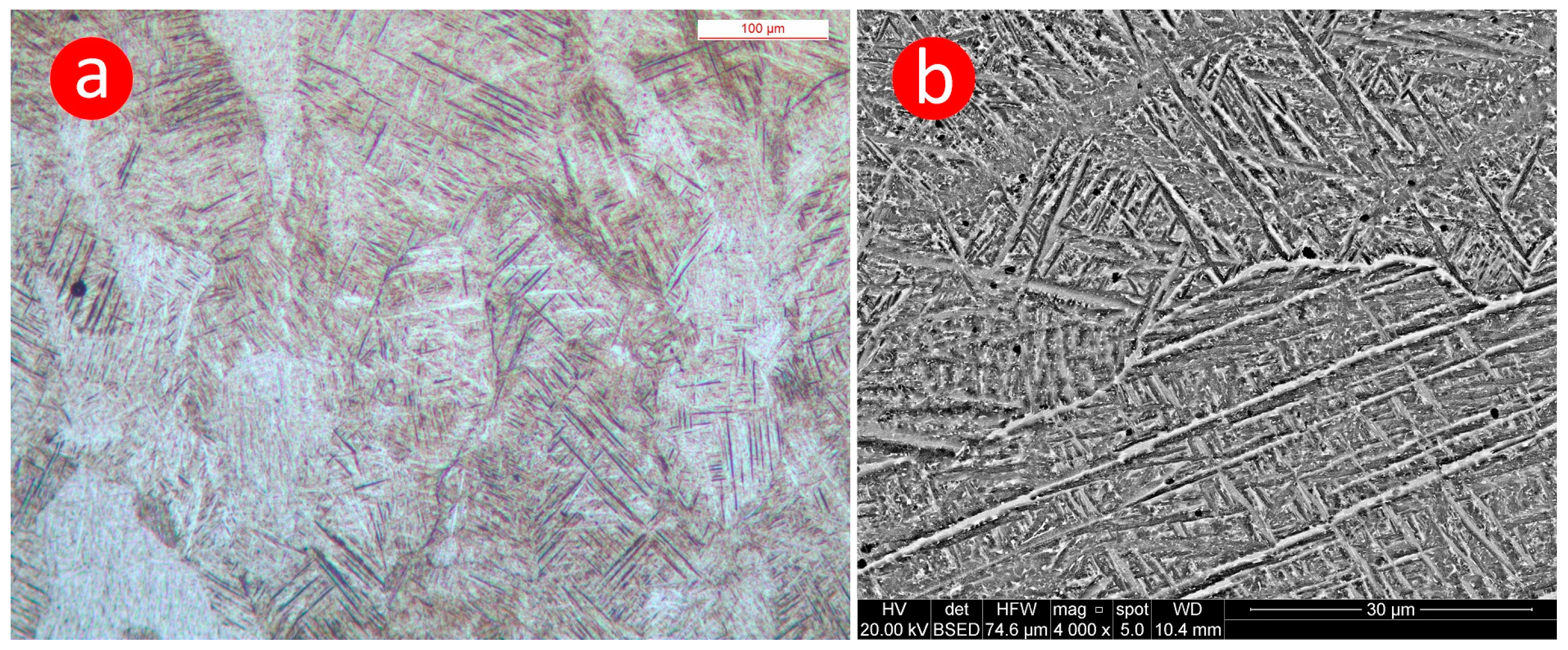

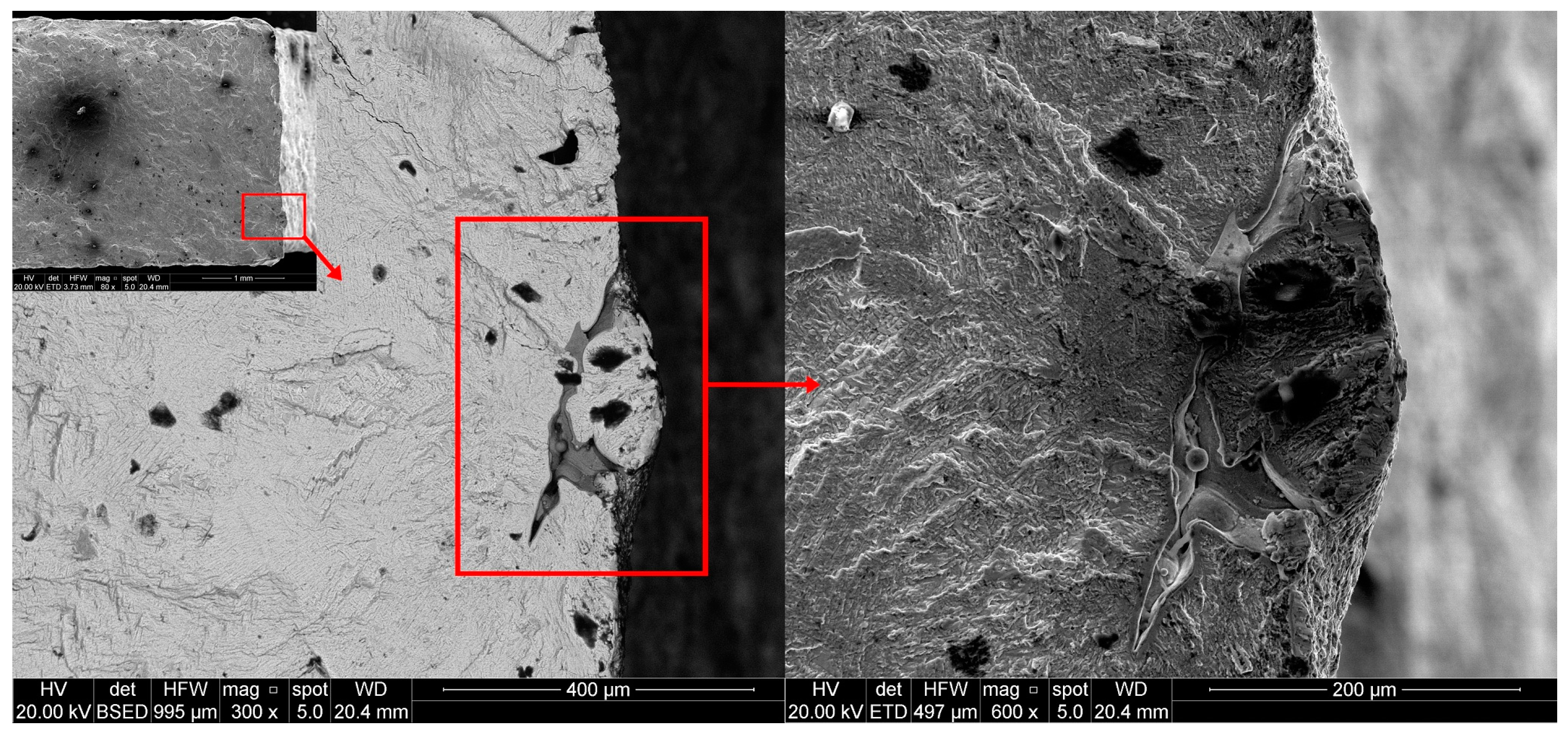

3.2. Microstructure and Fractography

4. Discussion

5. Conclusions

- Results were compared with those corresponding to smooth samples and Scanning Electron Microscopy was used to investigate the fracture surface of broken samples in order to identify crack initiation points and fracture mechanisms.

- Despite the surface treatment and heat treatment of the AM samples, some defects due to manufacturing process were observed on the fracture surface of the tested samples.

- Despite the fatigue specimens being weakened by the sharp circular notch, a very low notch sensitivity was measured.

- Low notch sensitivity of the tested specimens was attributed both to the hexagonal crystal lattice of tempered alpha prime grains and to the high roughness detected on sample surfaces.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Todai, M.; Nakano, T.; Liu, T.; Yasuda, H.Y.; Hagihara, K.; Cho, K.; Ueda, M.; Takeyama, M. Effect of building direction on the microstructure and tensile properties of Ti–48Al–2Cr–2Nb alloy additively manufactured by electron beam melting. Addit. Manuf. 2017, 13, 61–70. [Google Scholar] [CrossRef]

- Domashenkov, A.; Plotnikova, A.; Movchan, I.; Bertrand, P.; Peillon, N.; Desplanques, B.; Saunier, S.; Desrayaud, C. Microstructure and physical properties of a Ni/Fe-based superalloy processed by Selective Laser Melting. Addit. Manuf. 2017, 15, 66–77. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef]

- Lindgren, L.E.; Lundbäck, A.; Fisk, M.; Pederson, R.; Andersson, J. Simulation of additive manufacturing using coupled constitutive and microstructure models. Addit. Manuf. 2016, 12, 144–158. [Google Scholar] [CrossRef]

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.S.; Voice, W. Microstructures of laser-deposited Ti–6Al–4V. Mater. Des. 2014, 25, 137–144. [Google Scholar] [CrossRef]

- Wycisk, E.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Fatigue performance of laser additive manufactured Ti–6A–4V in very high cycle fatigue regime up to 109 cycles. Front. Mater. 2015, 2. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti–6Al–4V alloy processed by selective laser melting. Metall. Mater. Trans. 2011, 42A, 3190–3199. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Romboust, M. Binding mechanism in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Humbeeck, J.V. Heat treatment of T6Al4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Cherolis, N.E. Fatigue in the Aerospace Industry: Striations. J. Fail. Anal. Prev. 2008, 8, 255–258. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Niinomi, M.; Nakai, M.; Liu, Y.; Zhu, M. Microstructure and fatigue behaviors of a biomedical Ti–Nb–Ta–Zr alloy with trace CeO2 additions. Mater. Sci. Eng. 2014, 619, 112–118. [Google Scholar] [CrossRef]

- Sun, Z.; Chemkhi, M.; Kanoute, P.; Retraint, D. Fatigue properties of a biomedical 316L steel processed by surface mechanical attrition. Mater. Sci. Eng. 2014, 63. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of Ti–6Al–4V processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Berto, F.; Barati, E. Fracture assessment of U-notches under three point bending by means of local energy density. Mater. Des. 2011, 32, 822–830. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P.; Ayatollahi, M.R. Brittle fracture of sharp and blunt V-notches in isostatic graphite under pure compression loading. Carbon 2013, 63, 101–116. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P.; Marangon, C. Fatigue strength of notched specimens made of 40CrMoV13.9 under multiaxial loading. Mater. Des. 2014, 54, 57–66. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Ayatollahi, M.R.; Sommitsch, C.; Moser, C. Retardation of fatigue crack growth in high strength steel S690 using a modified stop-hole technique. Eng. Fract. Mech. 2017, 169, 226–237. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Razavi, S.M.J.; Sommitsch, C.; Moser, C. Fatigue life extension by crack repair using double stop-hole technique. Mater. Sci. Forum 2017, 879, 3–8. [Google Scholar] [CrossRef]

- Blattmeier, M.; Witt, G.; Wortberg, J.; Eggert, J.; Toepker, J. Influence of surface characteristics on fatigue behaviour of laser sintered plastics. Rapid Prototyp. J. 2012, 18, 161–171. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; de Lacalle, L.N.L.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for Specimen Manufacturing in Tensile Testing of Steel Plates. Exp. Tech. 2016. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Goodridge, R.D.; Christie, S.D.; Edmondson, S.; Hague, R.J.M. Surface modification of selective laser melted structures using self-assembled monolayers for biomedical applications, Polishing. In Proceedings of the Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Yadroitsev, I.; Smurov, I. Surface morphology in selective laser melting of metal powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef]

- Yang, L.; Gu, H.; Lassell, A. Surface treatment of Ti6al4V parts made by powder bed fusion additive manufacturing processes using electropolishing. In Proceedings of the Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- De Lacalle, L.N.L.; Lamikiz, A.; Sanchez, J.A.; Arana, J.L. Improving the surface finish in high speed milling of stamping dies. J. Mater. Proc. Tech. 2002, 123, 292–302. [Google Scholar] [CrossRef]

- Hosseini, S. Fatigue of Ti–6Al–4V. In Biomedical Engineering—Technical Applications in Medicine; Hudak, R., Penhaker, M., Majernik, J., Eds.; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0733-0. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razavi, S.-M.-J.; Ferro, P.; Berto, F. Fatigue Assessment of Ti–6Al–4V Circular Notched Specimens Produced by Selective Laser Melting. Metals 2017, 7, 291. https://doi.org/10.3390/met7080291

Razavi S-M-J, Ferro P, Berto F. Fatigue Assessment of Ti–6Al–4V Circular Notched Specimens Produced by Selective Laser Melting. Metals. 2017; 7(8):291. https://doi.org/10.3390/met7080291

Chicago/Turabian StyleRazavi, Seyed-Mohammad-Javad, Paolo Ferro, and Filippo Berto. 2017. "Fatigue Assessment of Ti–6Al–4V Circular Notched Specimens Produced by Selective Laser Melting" Metals 7, no. 8: 291. https://doi.org/10.3390/met7080291