Mechanical Characterization of a Nano-ODS Steel Prepared by Low-Energy Mechanical Alloying

Abstract

:1. Introduction

2. Materials and Methods

3. Results

- (i)

- Original powders and ODS precursor;

- (ii)

- Hot extruded material;

- (iii)

- eat treated ODS steel.

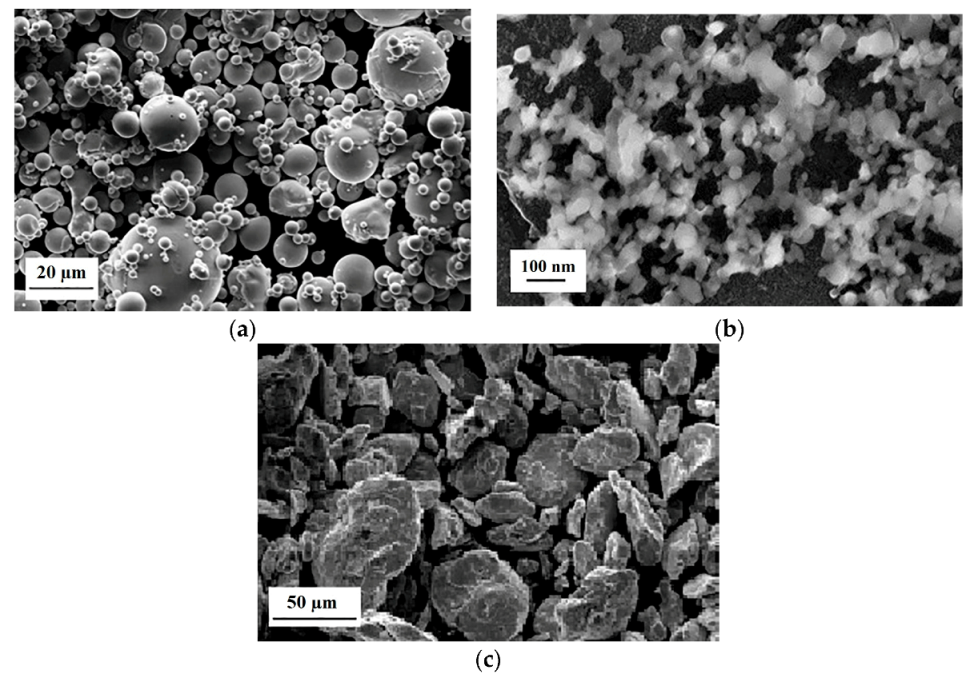

3.1. Original Powders and ODS Precursor

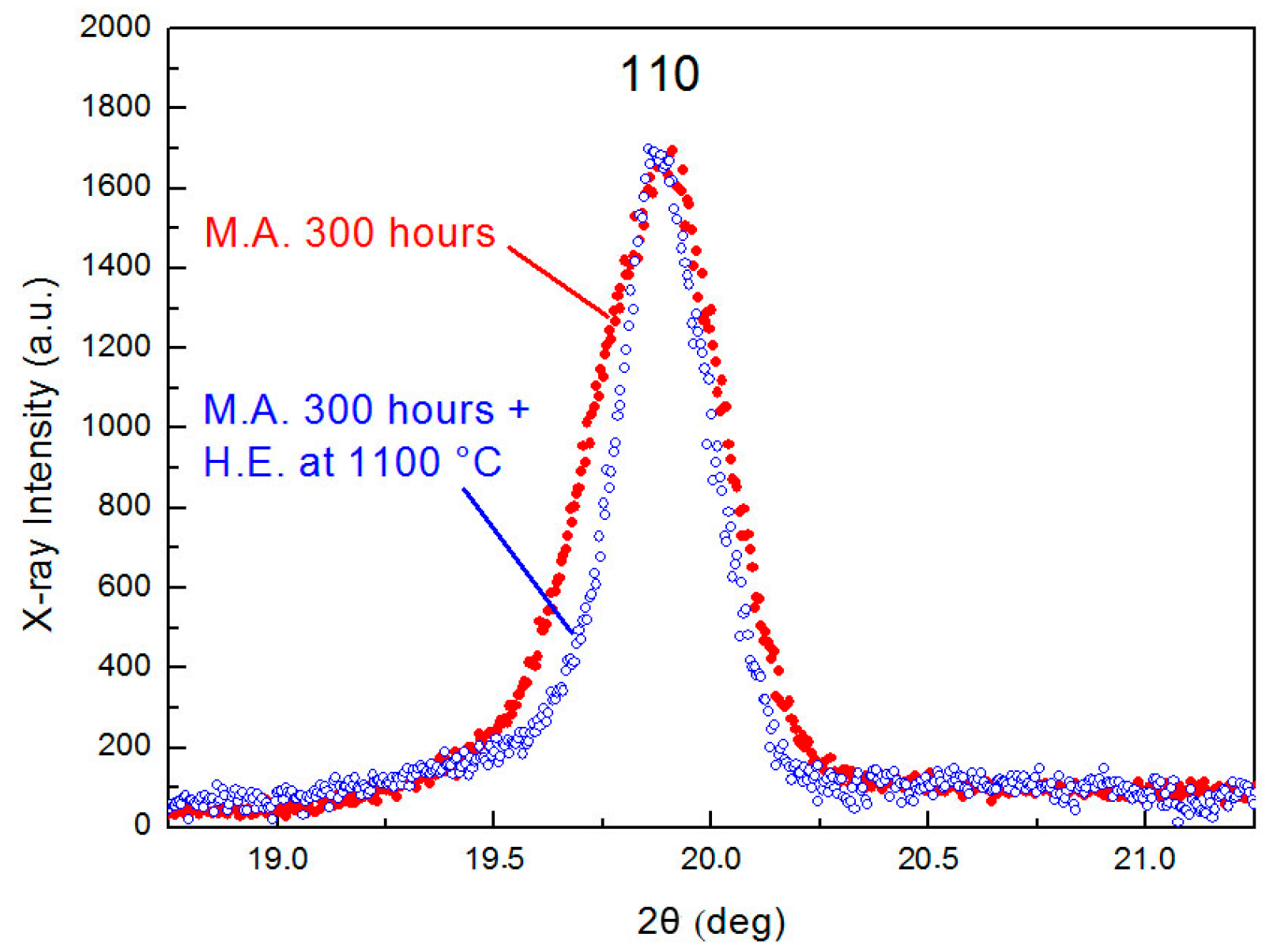

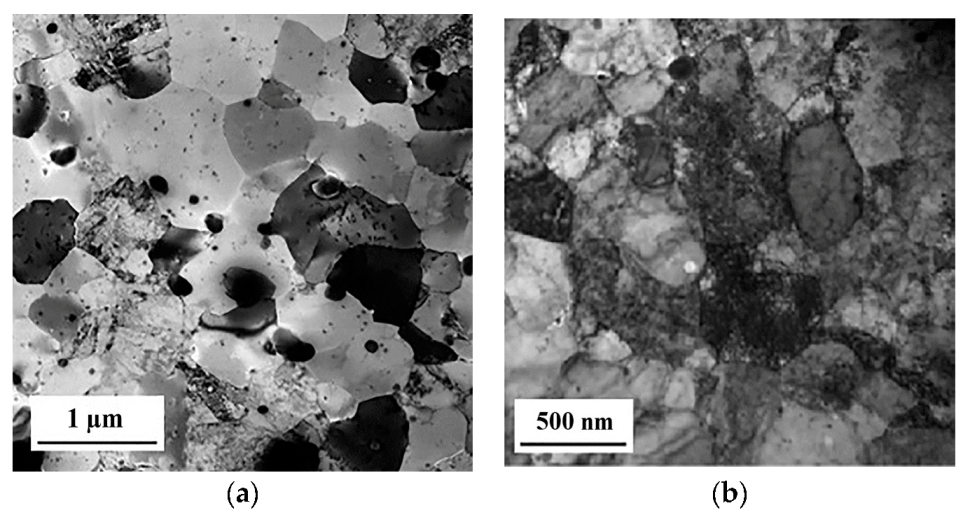

3.2. Hot Extruded Material

3.3. Heat Treated ODS Steel

4. Discussion

- (i)

- In the case of examined ODS steel the solid solution strengthening mainly depends on the amounts of Cr and W and may be evaluated as [32]:

- (ii)

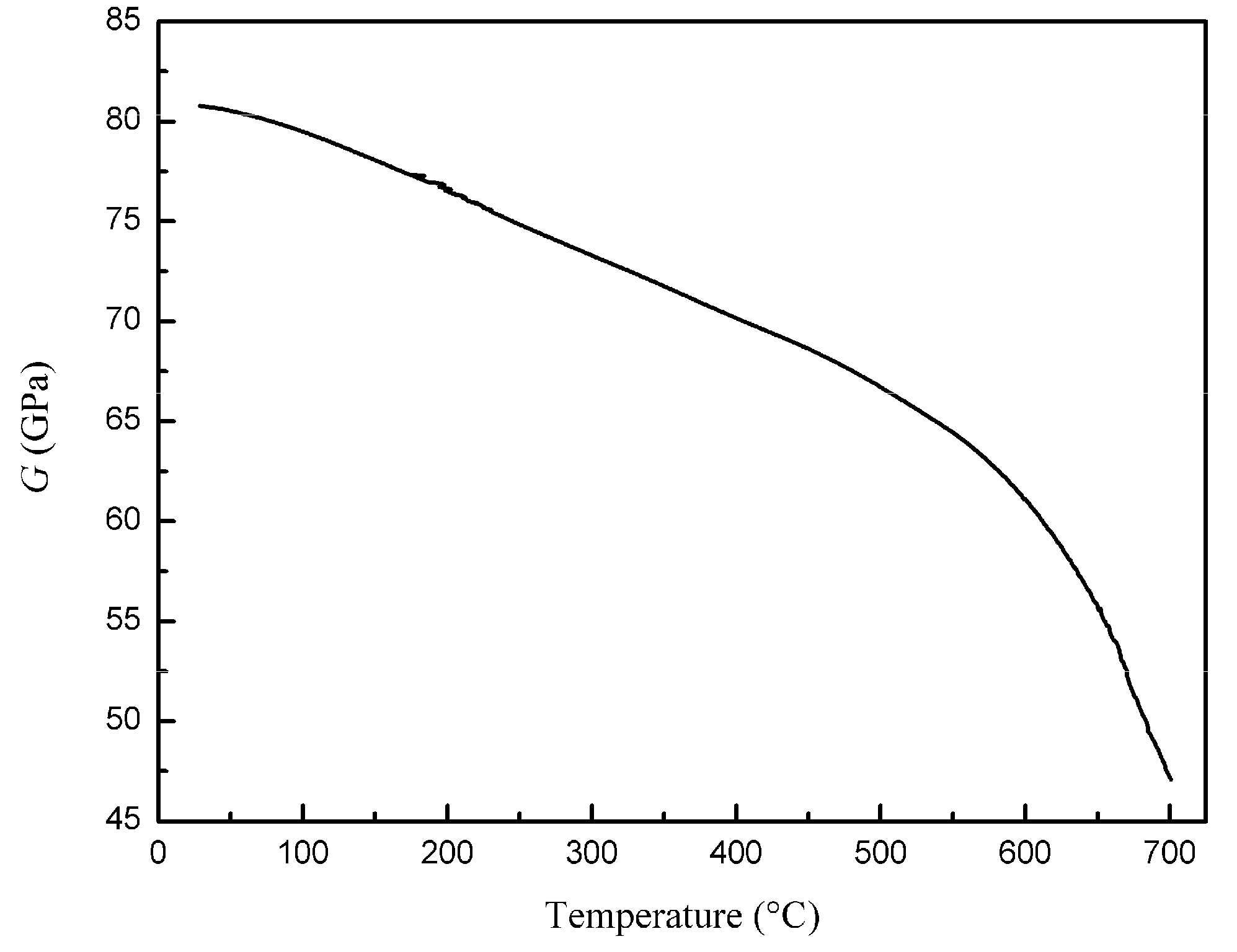

- The Bailey-Hirsch stress is expressed by the relationship:where M = 2.9 the Taylor factor for bcc metals, the parameter α = 0.24 [34], G the shear modulus, b = 0.25 nm the modulus of Burgers vector and ρ = 4 × 1012 m−2 the dislocation density determined by XRD. The shear modulus vs. temperature (G-T) curve, measured by MS, is shown in Figure 7.

- (iii)

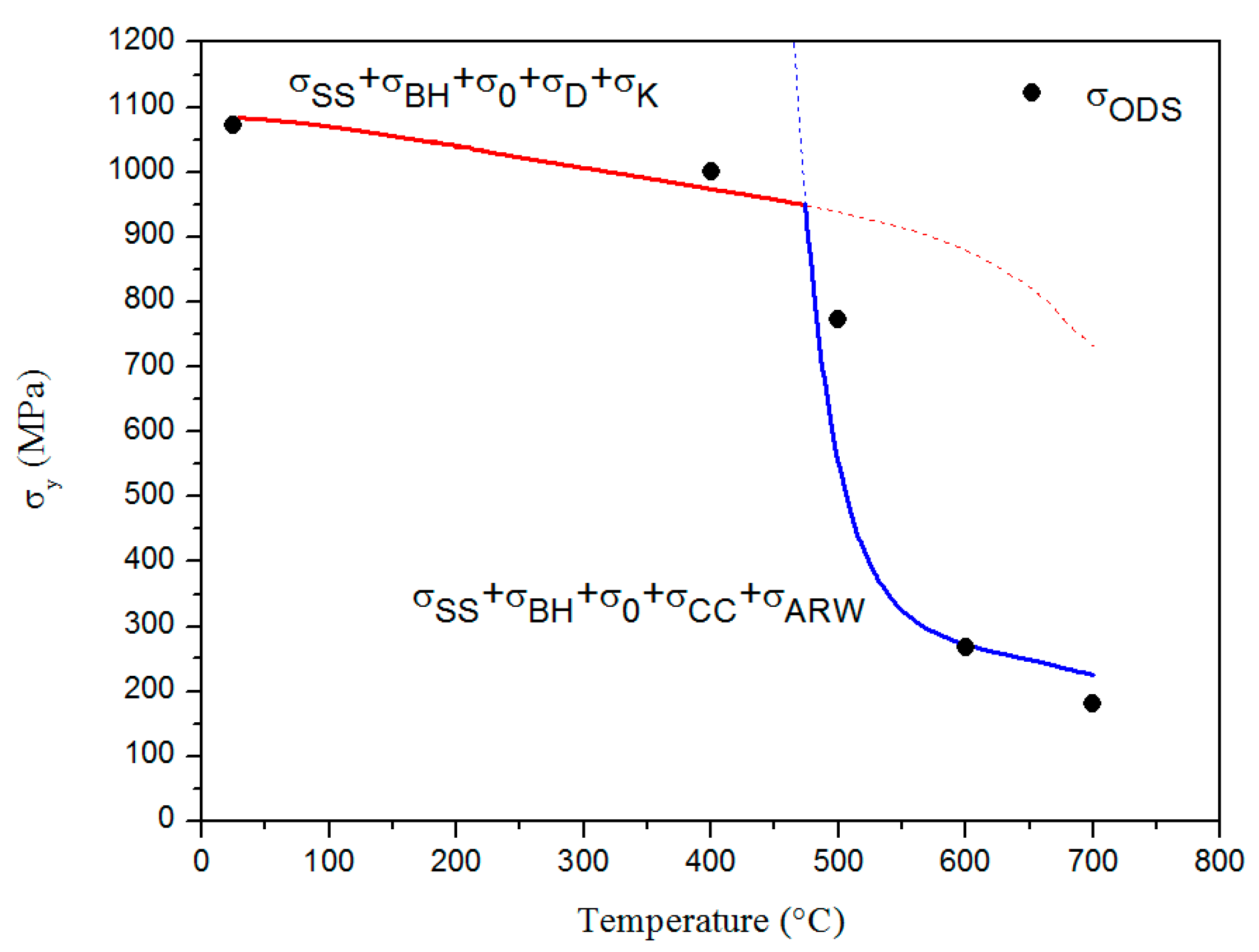

- The Hall-Petch stress (σHP) vs. temperature T is given by:where σ0 is the friction stress, i.e., the matrix yield stress for a grain of theoretically infinite size, which was evaluated to be ~13 MPa [35], K = 0.18 MPa m1/2 and the average grain size D = 400 nm. In fact, as discussed by Schneibel et al. [36], such mechanism losses his efficiency as the effect of Coble creep becomes predominant (Hall-Petch breakdown), namely when σCC < σHP. The stress σCC due to Coble creep is calculated as:where Boltzmann constant kb = 1.38 × 10−23 J/K, = 10−3 s−1, the atomic volume Ω = 1.18 × 10−29 m3, the product of grain boundary width and pre-exponential factor of grain boundary diffusion δBDB = 1.1 × 10−12 m3/s, the activation energy for grain boundary diffusion QB = 174 kJ/mol, the gas constant R = 8.31 J/mol K.

- (iv)

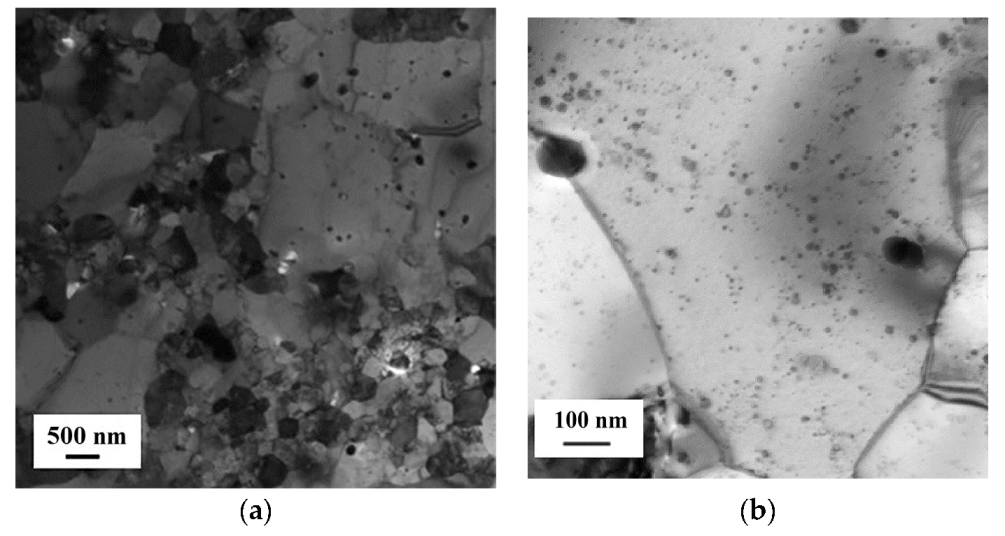

- ν = 0.3 is the Poisson’s ratio, L = 63 nm and d = 18 nm are the mean spacing between particles and particle size, respectively, determined from TEM observations (average values of 20 micrographs).

- (v)

- The Arzt-Rősler-Wilkinson stress (σARW), connected to the process of dislocation climb over hard particles, can be written according to the equation proposed by Reppich [37] as:where R = 0.77 represents the decrease of line tension of a pinned dislocation segment.

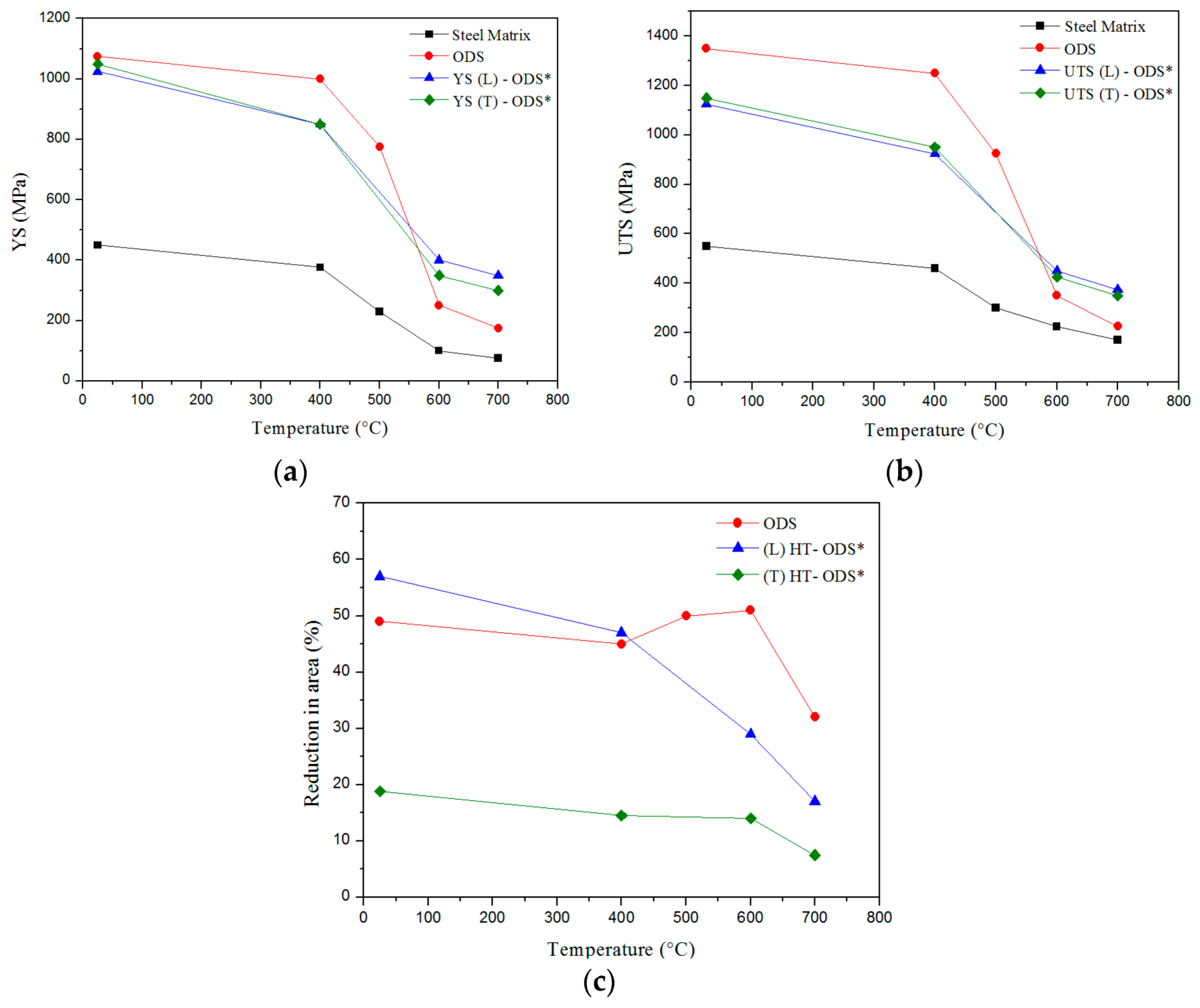

5. Conclusions

- (i)

- The method permits treatment of large amounts of powder in the order of kilograms.

- (ii)

- The material has equiaxed grains (mean size of 400 nm) and a dislocation density of 4 × 1012 m−2. Two types of second phase particles were observed: (i) round or irregular-shaped Y-Ti-oxides with different contents of titanium; (ii) cubic or rectangular fine precipitates of few nanometers. Therefore, low-energy MA decomposes Y2O3 into Y and O atoms, which are then bonded with Ti and precipitate to form extremely fine Y-Ti-O complex oxides during HE. Nano-oxides are stable up to 800 °C and guarantee the stability of microstructure and mechanical properties.

- (iii)

- With respect to the conventional preparation route fine equiaxed grains are observed instead of a bimodal grain size distribution. This microstructure involves better mechanical properties up to 500 °C, however, the precipitate distribution in the matrix is not so homogeneous as that obtained from high-energy MA, thus at higher temperature, where the Petch-Hall contribution breakdowns and the role played by precipitate in strengthening is dominant, YS and UTS remarkably decrease and are a little lower than those of conventional ODS steels.

- (iv)

- ODS steel heat treated above 1000 °C exhibits defect recovery and partial grain growth that can be also ascribed to the not homogeneous original distribution of Y2O3 particles.

- (v)

- In conclusion the examined method seems promising but a longer time of MA seems necessary for achieving a more homogeneous distribution of nano-oxides and consequently further enhancing mechanical properties at high temperature.

Author Contributions

Conflicts of Interest

References

- Ukai, S.; Harada, M.; Okada, H.; Inoue, M.; Nomura, S.; Shikakura, S.; Asabe, K.; Nishida, T.; Fujiwara, M. Alloying design of oxide dispersion strengthened ferritic steel for long life FBRs core materials. J. Nucl. Mater. 1993, 204, 65–73. [Google Scholar] [CrossRef]

- Ukai, S.; Fujiwara, M. Perspective of ODS alloys application in nuclear environments. J. Nucl. Mater. 2002, 307–311, 749–757. [Google Scholar] [CrossRef]

- Klueh, R.L.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Odette, G.R.; Van der Schaaf, B.; Victoria, M. Ferritic/martensitic steels—Overview of recent results. J. Nucl. Mater. 2002, 307–311, 455–465. [Google Scholar] [CrossRef]

- Unifantowicz, P.; Fikar, J.; Spätig, P.; Testani, C.; Maday, F.; Baluc, N.; Tran, M.Q. Optimisation of Production Method of a Nanostructured ODS Ferritic Steels. In Proceedings of the 24th IAEA Fusion Energy Conference, San Diego, CA, USA, 8–13 October 2012; p. 421. [Google Scholar]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- De Castro, V.; Leguey, T.; Auger, M.A.; Lozano-Perez, S.; Jenkins, M.L. Analytical characterization of secondary phases and void distributions in an ultrafine-grained ODS Fe-14Cr model alloy. J. Nucl. Mater. 2011, 417, 217–220. [Google Scholar] [CrossRef] [Green Version]

- De Castro, V.; Leguey, T.; Muñoz, A.; Monge, M.A.; Fernández, P.; Lancha, A.M.; Pareja, R. Mechanical and microstructural behavior of Y2O3 ODS EUROFER 97. J. Nucl. Mater. 2007, 367–370, 196–201. [Google Scholar] [CrossRef]

- Brodrick, J.; Hepburn, D.J.; Ackland, G.J. Mechanism for radiation damage resistance in yttrium oxide dispersion strengthened steels. J. Nucl. Mater. 2014, 445, 291–297. [Google Scholar] [CrossRef]

- Kimura, A. Current Status of Reduced-Activation Ferritic/Martensitic Steels R&D for Fusion Energy. Mater. Trans. 2005, 46, 394–404. [Google Scholar]

- Klueh, R.L.; Ehrlich, K.; Abe, F. Ferritic/martensitic steels: Promises and problems. J. Nucl. Mater. 1992, 191–194, 116–124. [Google Scholar]

- De Carlan, Y.; Bechade, J.-L.; Dubuisson, P.; Seran, J.-L.; Billot, P.; Bougault, A.; Cozzika, T.; Doriot, S.; Hamon, D.; Henry, J.; et al. CEA developments of new ferritic ODS alloys for nuclear applications. J. Nucl. Mater. 2009, 386–388, 430–432. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Z.; Sun, H.; Hu, H.; Li, S. Microstructural observation and tensile properties of ODS-304 austenitic steel. Mater. Sci. Eng. A 2013, 559, 287–292. [Google Scholar] [CrossRef]

- Kawahara, M.; Kim, H.; Tokita, M. Fabrication of Nano-Materials by the Spark Plasma Sintering (SPS) Method. In Proceedings of the Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November 2000; pp. 741–744. [Google Scholar]

- Zhang, H.W.; Gopalan, R.; Mukai, T.; Hono, K. Fabrication of bulk nanocrystalline Fe-C alloy by spark plasma sintering of mechanically milled powder. Scr. Mater. 2005, 53, 863–868. [Google Scholar] [CrossRef]

- Cabibbo, M.; Deodati, P.; Libardi, S.; Molinari, A.; Montanari, R.; Ucciardello, N. Damping of FeMo alloys obtained from SPS sintering of nanostructured powders. Mater. Sci. Forum 2009, 604–605, 203–211. [Google Scholar] [CrossRef]

- Ji, G.; Grosdidier, T.; Bozzolo, N.; Launois, S. The mechanisms of microstructure formation in a nanostructured oxide dispersion strengthened FeAl alloy obtained by spark plasma sintering. Intermetallics 2007, 15, 108–118. [Google Scholar] [CrossRef]

- Boulnat, X.; Fabregue, D.; Perez, M.; Mathon, M.-H.; De Carlan, Y. High-temperature tensile properties of nano-oxide dispersion strengthened ferritic steels produced by mechanical alloying and spark plasma sintering. Metall. Mater. Trans. A 2013, 44, 2461–2465. [Google Scholar] [CrossRef]

- Kasada, R.; Lee, S.G.; Isselin, J.; Lee, J.H.; Omura, T.; Kimura, A.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; et al. Anisotropy in tensile and ductile-brittle transition behavior of ODS ferritic steels. J. Nucl. Mater. 2011, 417, 180–184. [Google Scholar] [CrossRef]

- Hilger, I.; Boulnat, X.; Hoffmann, J.; Testani, C.; Bergner, F.; De Carlan, Y.; Ferraro, F.; Ulbricht, A. Fabrication and characterization of oxide dispersion strengthened (ODS) 14Cr steels consolidated by means of hot isostatic pressing, hot extrusion and spark plasma sintering. J. Nucl. Mater. 2016, 472, 206–214. [Google Scholar] [CrossRef]

- Magini, M.; Iasonna, A. Energy Transfer in Mechanical Alloying (Overview). Mater. Trans. JIM 1995, 36, 123–133. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1974. [Google Scholar]

- Williamson, G.K.; Smallman, R.E. III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Amadori, S.; Campari, E.G.; Fiorini, A.L.; Montanari, R.; Pasquini, L.; Savini, L.; Bonetti, E. Automated resonant vibrating-reed analyzer apparatus for a non-destructive characterization of materials for industrial applications. Mater. Sci. Eng. A 2006, 442, 543–546. [Google Scholar] [CrossRef]

- Okuda, T.; Fujiwara, M. Dispersion behavior of oxide particles in mechanically alloyed ODS steel. J. Mater. Sci. Lett. 1995, 14, 1600–1603. [Google Scholar] [CrossRef]

- Dawson, K.; Tatlock, G.J. Characterisation of nanosized oxides in ODM401 oxide dispersion strengthened steel. J. Nucl. Mater. 2014, 444, 252–260. [Google Scholar] [CrossRef]

- Oka, K.; Ohnuki, S.; Yamashita, S.; Akasaka, N.; Ohtsuka, S.; Tanigawa, H. Structure of Nano-Size oxides in ODS Steels and Its Stability under Electron Irradiation. Mater. Trans. 2007, 48, 2563–2566. [Google Scholar] [CrossRef]

- Alamo, A.; Lambard, V.; Averty, X.; Mathon, M.H. Assessment of ODS-14%Cr ferritic alloy for high temperature applications. J. Nucl. Mater. 2004, 329–333, 333–337. [Google Scholar] [CrossRef]

- Serrano, M.; Hernández-Mayoral, M.; García-Junceda, A. Microstructural anisotropy effect on the mechanical properties of a 14Cr ODS steel. J. Nucl. Mater. 2012, 428, 103–109. [Google Scholar] [CrossRef]

- Kocks, U.F. The theory of an obstacle-controlled yield strength-Report after an international workshop. Mater. Sci. Eng. A 1977, 27, 291–298. [Google Scholar] [CrossRef]

- Arzt, E.; Wilkinson, D.S. Threshold stresses for dislocation climb on hard particles: The effect of an attractive interaction. Acta Metall. 1986, 34, 1893–1898. [Google Scholar] [CrossRef]

- Arzt, E.; Rösler, J. The kinetics of dislocation climb over hard particles-II. Effects of an attractive particle-dislocation interaction. Acta Metall. 1988, 36, 1053–1060. [Google Scholar] [CrossRef]

- Li, Q. Modeling the microstructure-mechanical property relationship for a 12Cr-2W-V-Mo-Ni power plant steel. Mater. Sci. Eng. A 2003, 361, 385–391. [Google Scholar] [CrossRef]

- Shen, J.; Li, Y.; Li, F.; Yang, H.; Zhao, Z.; Kano, S.; Matsukawa, Y.; Satoh, Y.; Abe, H. Microstructural characterization and strengthening mechanisms of a 12Cr-ODS steel. Mater. Sci. Eng. A 2016, 673, 624–632. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Takaki, S.; Akama, D.; Nakada, N.; Tsuchiyama, T. Effect of grain boundary segregation of interstitial elements on Hall-Petch coefficient in steels. Mater. Trans. 2014, 55, 28–34. [Google Scholar] [CrossRef]

- Schneibel, J.H.; Heilmaier, M. Hall-petch breakdown at elevated temperatures. Mater. Trans. 2015, 55, 44–51. [Google Scholar] [CrossRef]

- Reppich, B. On the attractive particle-dislocation interaction in dispersion-strengthened material. Acta Mater. 1998, 46, 61–67. [Google Scholar] [CrossRef]

- Steckmeyer, A.; Praud, M.; Fournier, B.; Malaplate, J.; Garnier, J.; Béchade, J.L.; Tournié, I.; Tancray, A.; Bougault, A.; Bonnaillie, P. Tensile properties and deformation mechanisms of a 14Cr ODS ferritic steel. J. Nucl. Mater. 2010, 405, 95–100. [Google Scholar] [CrossRef]

| Sample | Temperature (°C) | Time (min) | Hardness HV |

|---|---|---|---|

| HE | No | No | 447 ± 5 |

| HE + 1050 °C/30 min | 1050 | 30 | 315 ± 6 |

| HE + 1100 °C/30 min | 1100 | 30 | 327 ± 10 |

| HE + 1150 °C/30 min | 1150 | 30 | 305 ± 4 |

| Intensities of the Most Strong Reflections | HE | A (HE + 1050 °C/30 min) | B (HE + 1100 °C/30 min) | C (HE + 1150 °C/30 min) |

|---|---|---|---|---|

| I110 | 100 | 100 | 100 | 100 |

| I200 | 37 | 41 | 36 | 49 |

| I211 | 43 | 61 | 50 | 59 |

| Strengthening Contributions to Yield Stress (MPa) | Temperature (°C) | ||||

|---|---|---|---|---|---|

| 25 | 400 | 500 | 600 | 700 | |

| σSS | 100 | 100 | 100 | 100 | 100 |

| σBH | 28 | 24 | 23 | 21 | 16 |

| σ0 | 13 | 13 | 13 | 13 | 13 |

| σD | 285 | 265 | 259 | - | - |

| σK | 657 | 571 | 543 | - | - |

| σARW | - | - | 133 | 122 | 94 |

| σCC | - | - | 285 | 16 | 2 |

| σSS + σBH + σ0 + σD + σK (ODS steel) | 1083 | 973 | 938 | - | - |

| σSS + σBH + σ0 + σCC + σARW (ODS steel) | - | - | 554 | 272 | 225 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanctis, M.D.; Fava, A.; Lovicu, G.; Montanari, R.; Richetta, M.; Testani, C.; Varone, A. Mechanical Characterization of a Nano-ODS Steel Prepared by Low-Energy Mechanical Alloying. Metals 2017, 7, 283. https://doi.org/10.3390/met7080283

Sanctis MD, Fava A, Lovicu G, Montanari R, Richetta M, Testani C, Varone A. Mechanical Characterization of a Nano-ODS Steel Prepared by Low-Energy Mechanical Alloying. Metals. 2017; 7(8):283. https://doi.org/10.3390/met7080283

Chicago/Turabian StyleSanctis, Massimo De, Alessandra Fava, Gianfranco Lovicu, Roberto Montanari, Maria Richetta, Claudio Testani, and Alessandra Varone. 2017. "Mechanical Characterization of a Nano-ODS Steel Prepared by Low-Energy Mechanical Alloying" Metals 7, no. 8: 283. https://doi.org/10.3390/met7080283