Multiphysics Simulation and Experimental Investigation of Aluminum Wettability on a Titanium Substrate for Laser Welding-Brazing Process

Abstract

:1. Introduction

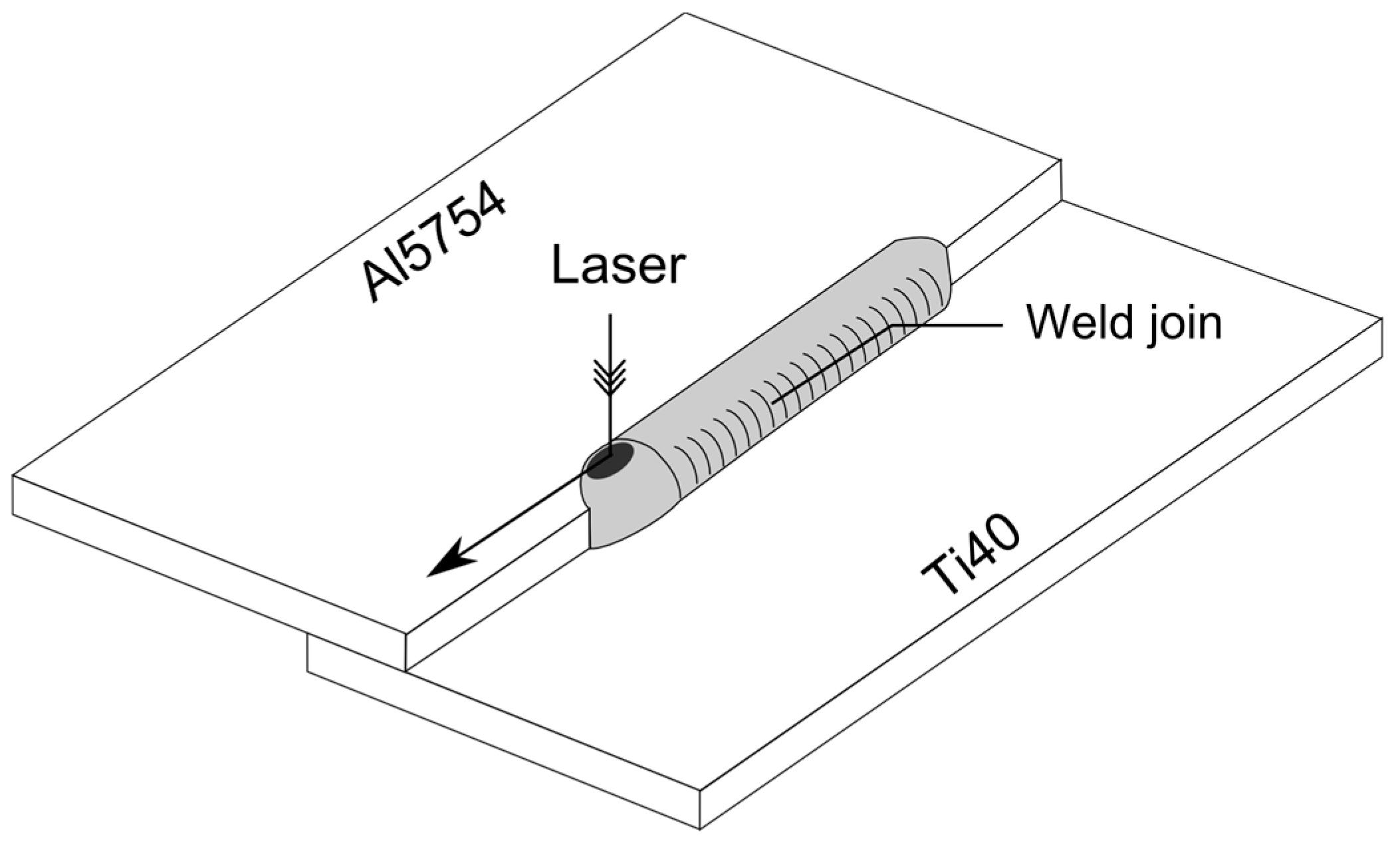

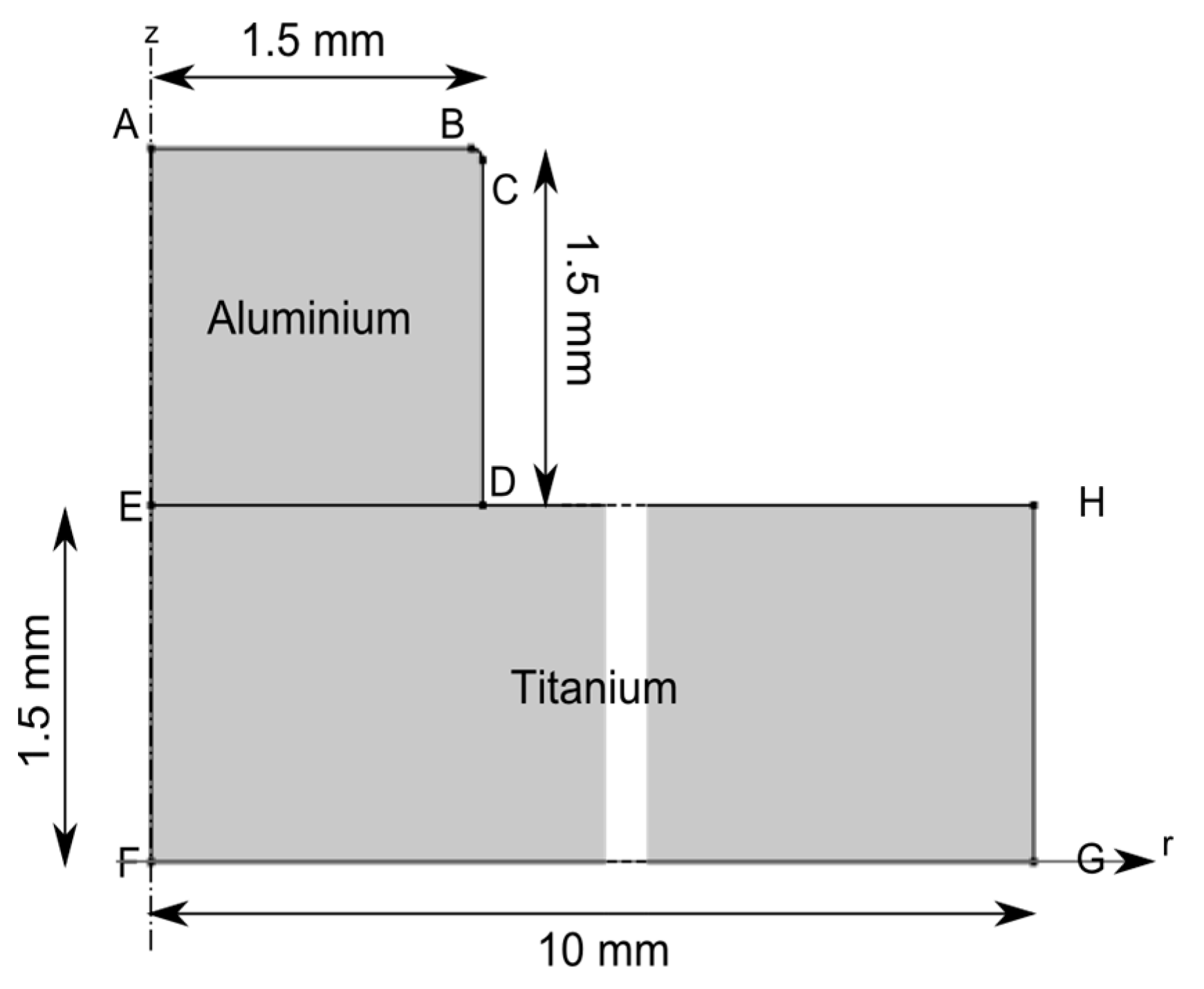

2. Experimental, Physical and Mathematical Description of the Ti/Al Reactive Wetting Assembly

2.1. Experimental Work

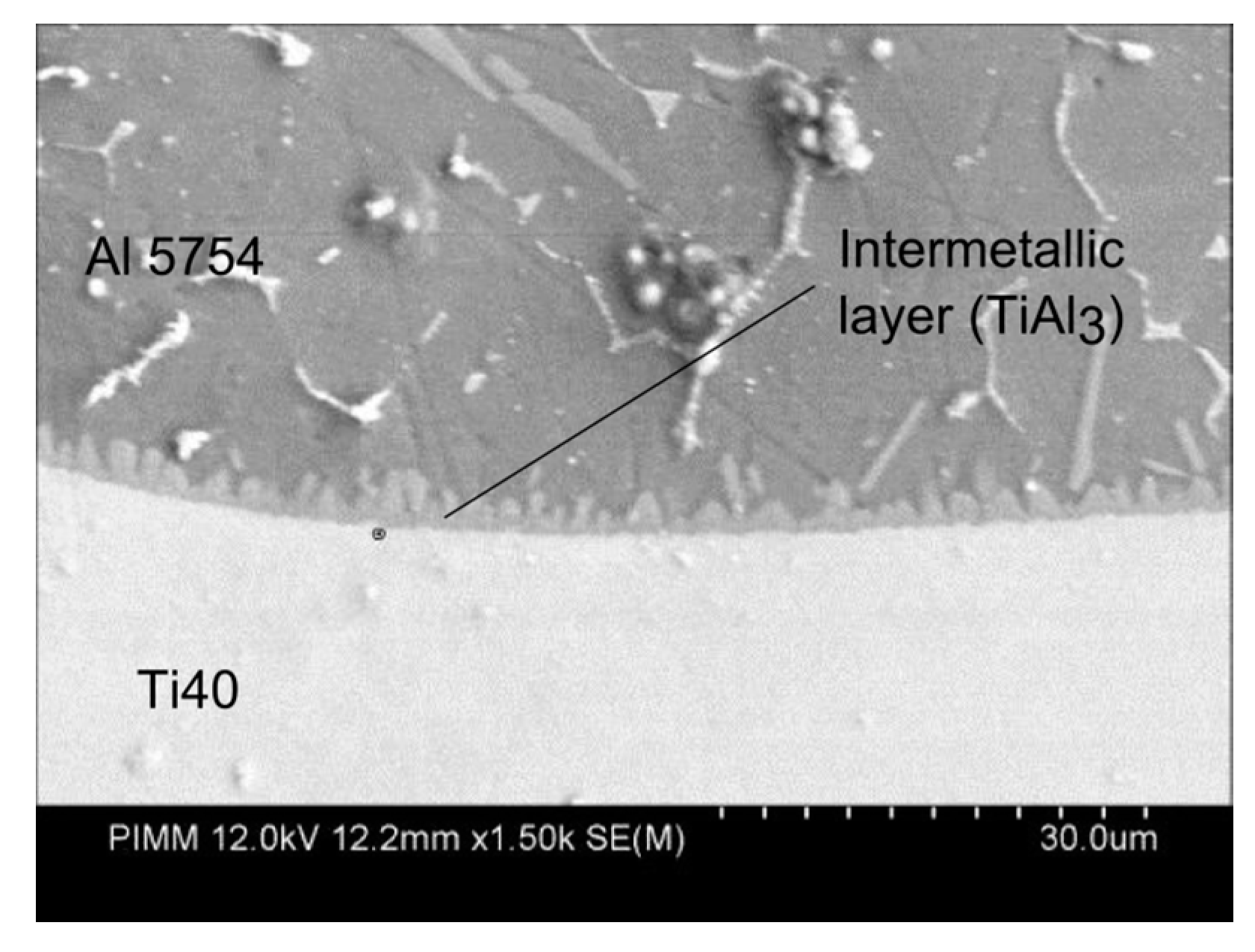

2.2. Physical Description of the Reactive Wetting Phenomenon

2.3. Mathematical Formulation

2.3.1. Thermal Problem

2.3.2. Fluid Flow Problem

2.3.3. Free Boundary Motion

2.3.4. Mass Transfer Problem

2.4. Material Properties

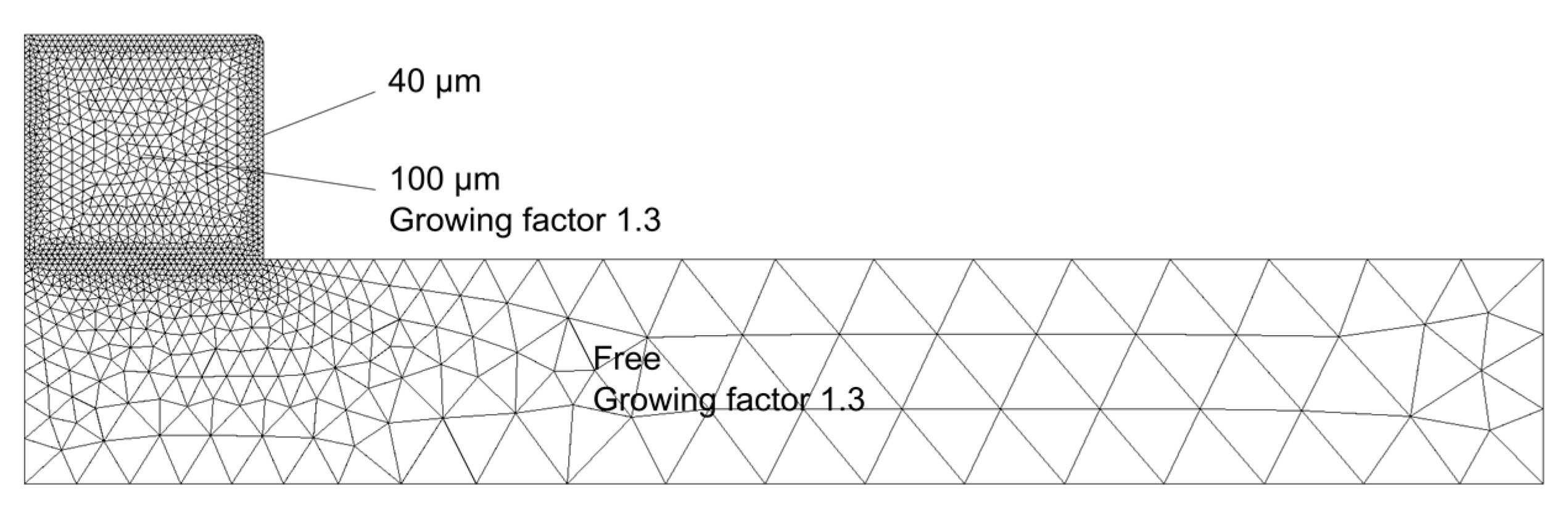

2.5. Numerical Considerations

3. Results and Discussion

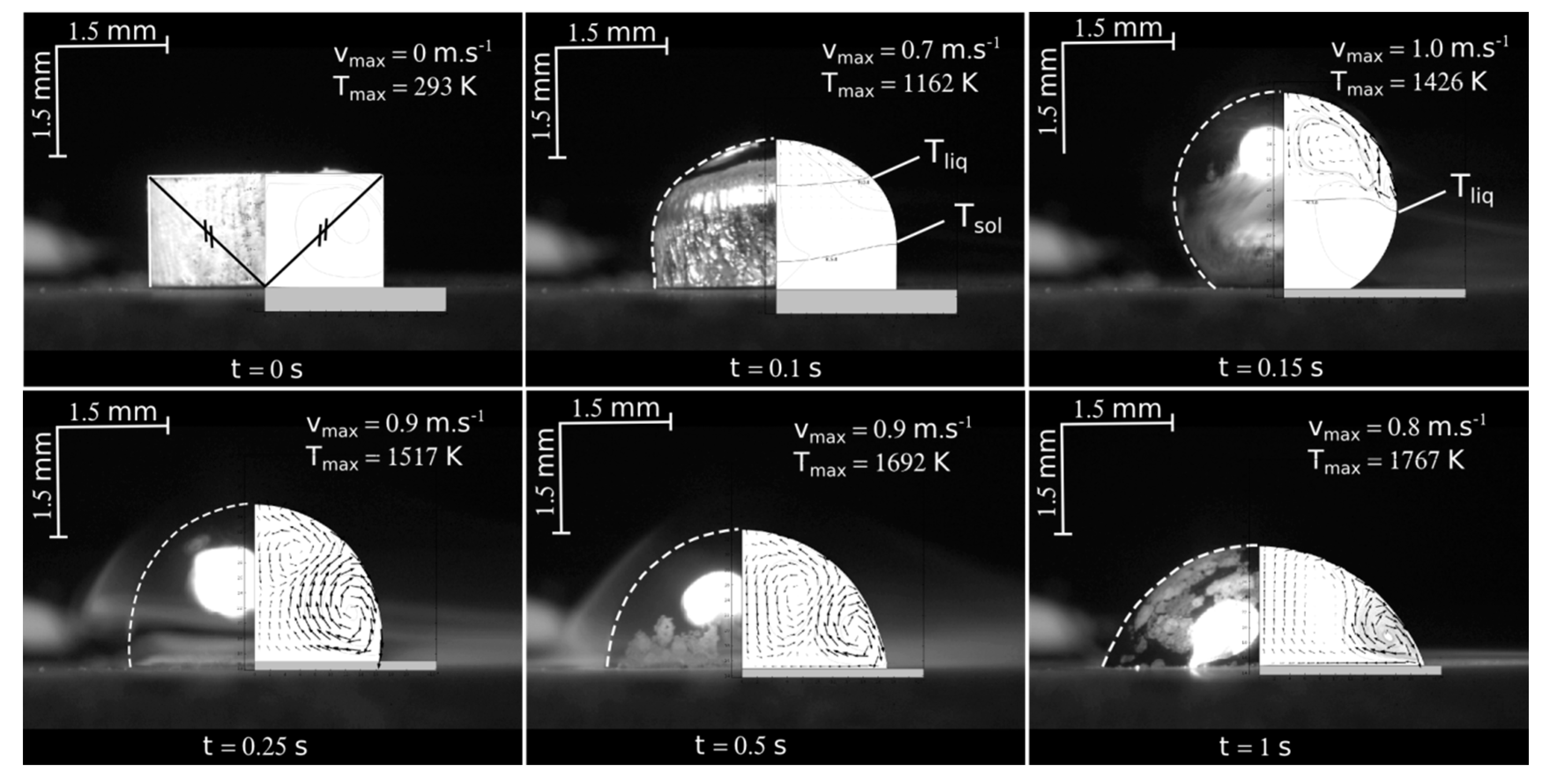

3.1. Droplet Shape Dynamics

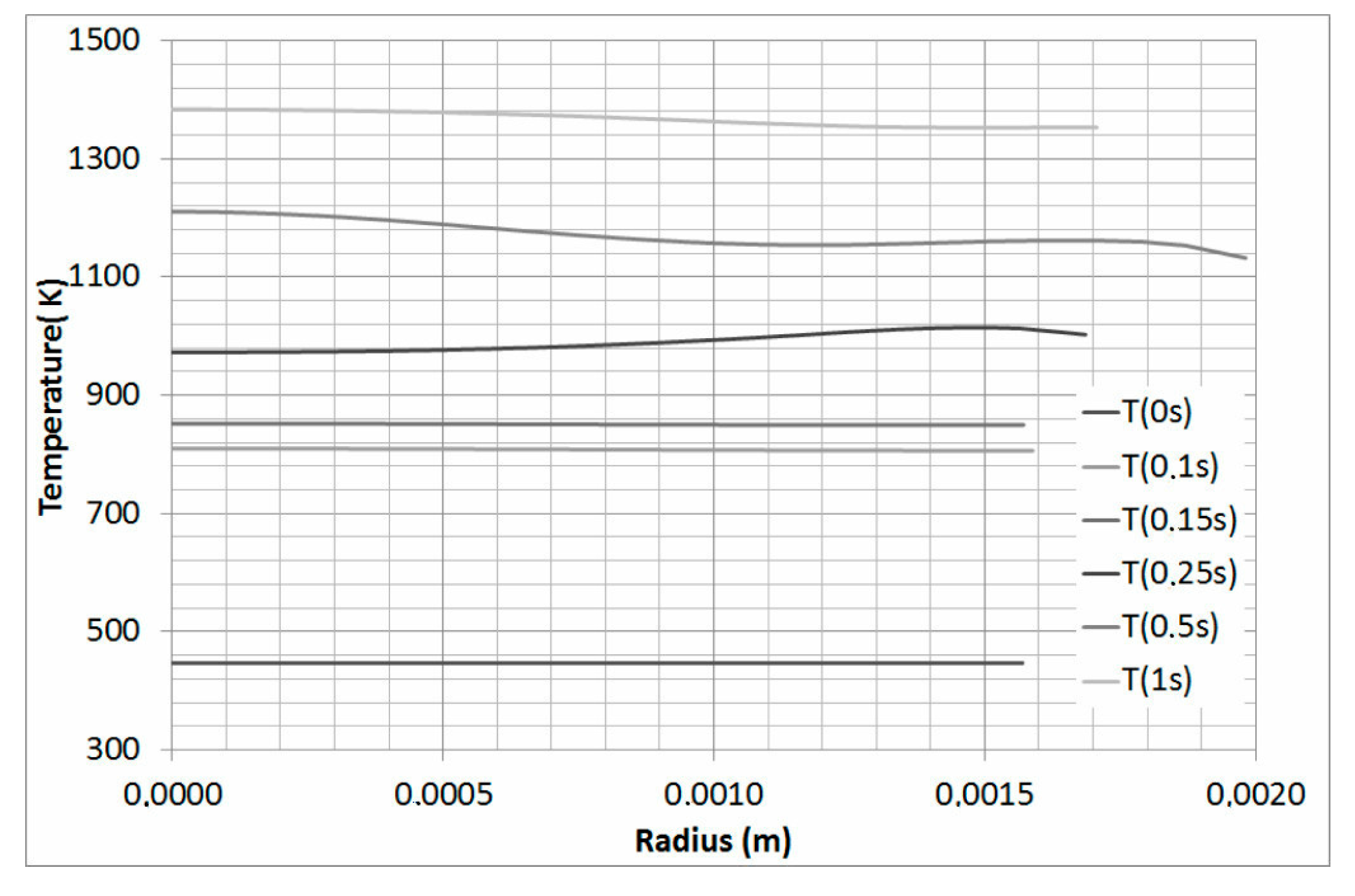

3.2. Thermal Validation

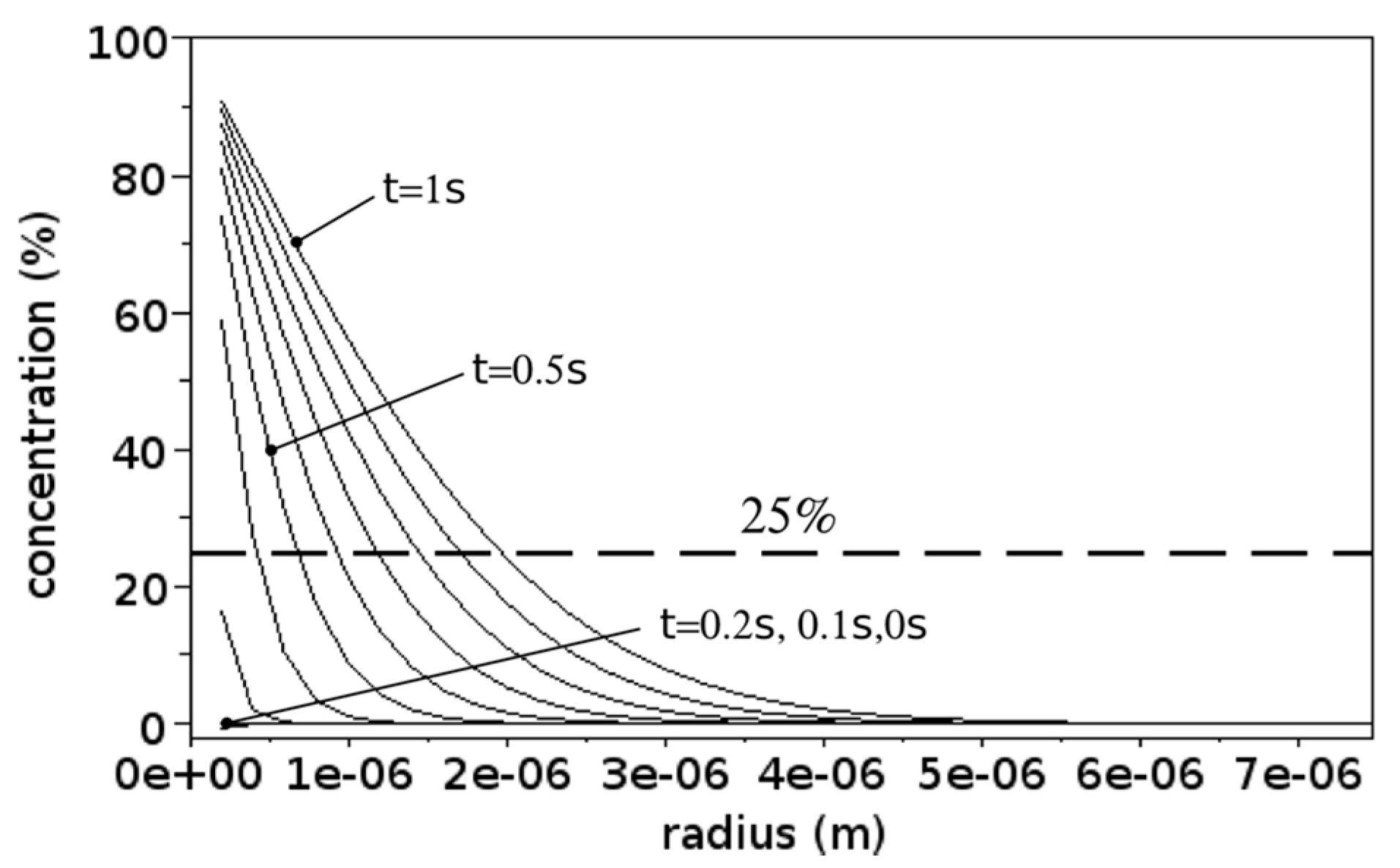

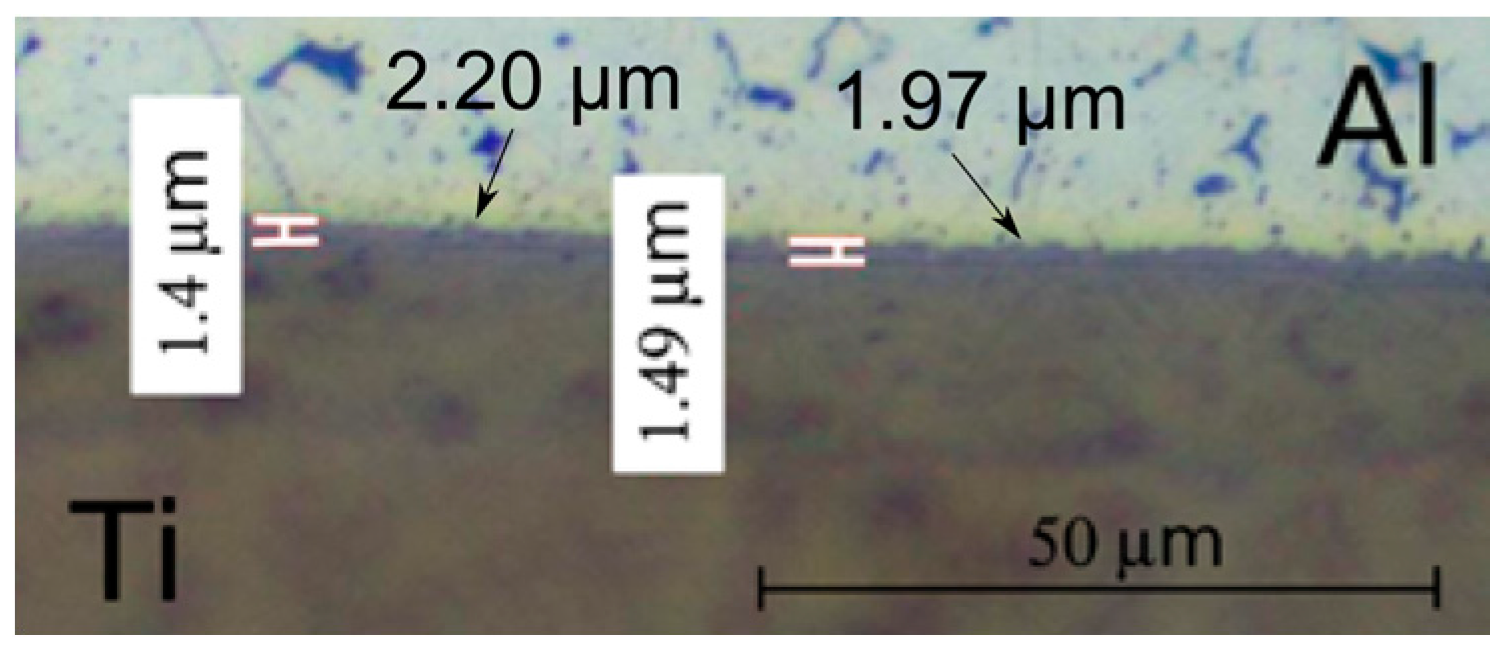

3.3. Intermetallic Layer

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gupta, S.P. Intermetallic compounds in diffusion couples of Ti with an Al-Si eutectic alloy. Mater. Charact. 2003, 49, 321–330. [Google Scholar] [CrossRef]

- Sujata, M; Bhargava, S.; Sangal, S. On the formation of TiAl3 during reaction between solid Ti and liquid Al. J. Mater. Sci. Lett. 1997, 16, 1175–1178. [Google Scholar]

- Wang, T.; Lu, Y.X.; Zhu, M.L.; Zhang, J.S. Identification of the comprehensive kinetics of thermal explosion synthesis Ti + 3Al → TiAl3 using non-isothermal differential scanning calorimetry. Mater. Lett. 2002, 54, 284–290. [Google Scholar] [CrossRef]

- Majumdar, B.; Galun, R.G.; Weisheit, A.; Mordike, B.L. Formation of a crack-free joint between Ti alloy and Al alloy by using a high-power CO2 laser. J. Mater. Sci. 1997, 32, 6191–6200. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, S.; Li, L. Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding–brazing. Mater. Des. 2010, 31, 227–233. [Google Scholar] [CrossRef]

- Rastkar, A.R.; Parseh, P.; Darvishnia, N.; Hadavi, S.M.M. Microstructural evolution and hardness of TiAl3 and TiAl2 phases on Ti–45Al–2Nb–2Mn–1B by plasma pack aluminizing. Appl. Surf. Sci. 2013, 276, 112–119. [Google Scholar] [CrossRef]

- Liu, J.P.; Luo, L.S.; Su, Y.Q.; Xu, Y.J.; Li, X.Z.; Chen, R.R.; Guo, J.J.; Fu, H.Z. Numerical simulation of intermediate phase growth in Ti/Al alternate foils. Trans. Nonferr. Met. Soc. China 2011, 21, 598–603. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Dai, J.; Huang, J. Improving interfacial reaction nonhomogeneity during laser welding–brazing aluminum to titanium. Mater. Des. 2011, 32, 4408–4416. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Dal, M.; Pouzet, S.; Sallamand, P.; Tomashchuk, I. Generation and characterization of T40/A5754 interfaces with lasers. J. Mater. Process. Technol. 2014, 214, 1946–1953. [Google Scholar] [CrossRef]

- Dezellus, O. Contribution à L’étude des Mécanismes du Mouillage Réactif. Ph.D. Thesis, Institut National Polytechnique de Grenoble, Grenoble, France, 12 May 2000. [Google Scholar]

- Molina, J.M.; Voytovych, R.; Louis, E.; Eustathopoulos, N. The surface tension of liquid aluminium in high vacuum: The role of surface condition. Int. J. Adhes. Adhes. 2007, 27, 394–401. [Google Scholar] [CrossRef]

- Garcia-Cordovilla, C.; Louis, E.; Pamies, A. The surface tension of liquid pure aluminium and aluminium-magnesium alloy. J. Mater. Sci. 1986, 21, 2787–2792. [Google Scholar] [CrossRef]

- De Gennes, P.G.; Brochard-Wyart, F.; Quéré, D. Gouttes, Bulles, Perles et Ondes; Belin: Paris, France, 2005; p. 254. [Google Scholar]

- Laurent, V.; Rado, C.; Eustathopoulos, N. Wetting kinetics and bonding of Al and A1 alloys on α-SiC. Mater. Sci. Eng. 1996, A205, 1–8. [Google Scholar] [CrossRef]

- Luo, J.G.; Acoff, V.L. Interfacial Reactions of Titanium and Aluminum during Diffusion Welding. Weld. J. 2000, 79, 239–243. [Google Scholar]

- Bonaccina, C.; Comini, G.; Fasano, A.; Primicerio, M. Numerical solution of phase-change problems. Int. J. Heat Mass Transf. 1973, 16, 1825–1832. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Cambridge, UK, 2002; p. 246. [Google Scholar]

- Duan, Y.H.; Sun, Y.; Lu, L. Thermodynamic properties and thermal conductivities of TiAl3-type intermetallics in Al–Pt–Ti system. Comput. Mater. Sci. 2013, 68, 229–233. [Google Scholar] [CrossRef]

- Teyssèdre, H.; Gillormini, P. Extension of the natural element method to surface tension and wettability for the simulation of polymer flows at the micro and nano scales. J. Non-Newtonian Fluid Mech. 2013, 200, 9–16. [Google Scholar] [CrossRef]

- Champion, J.A.; Keene, B.J.; Sillwood, J.M. Wetting of Aluminium Oxide by Molten Aluminium and Other Metals. J. Mater. Sci. 1969, 4, 39–49. [Google Scholar] [CrossRef]

- Han, D.S.; Jones, H.; Atkinson, H.V. The wettability of silicon carbide by liquid aluminium: The effect of free silicon in the carbide and of magnesium, silicon and copper alloy additions to the aluminium. J. Mater. Sci. 1993, 28, 2654–2658. [Google Scholar] [CrossRef]

- Hirt, C.W.; Amsden, C.C.; Cook, J.L. An arbitrary lagrangian-eulerian computing method for all flow speeds. J. Comput. Phys. 1997, 135, 203–216. [Google Scholar] [CrossRef]

- Multiphysics, C. Comsol Multiphysics Reference Manual; COMSOL: Grenoble, France, 2013; p. 1084. [Google Scholar]

- Mishin, Y.; Herzig, C. Diffusion in the Ti-Al system. Acta Mater. 2000, 48, 589–623. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.Y. Diffusion coefficients of some solutes in FCC and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. 2003, A363, 140–151. [Google Scholar] [CrossRef]

| Properties | Values/References |

|---|---|

| Thermal conductivity (Al-Ti) | λ(T) [18] |

| Specific heat (Al-Ti) | (T) [18] |

| Density (Al-Ti) | (T) [18] |

| Convective coefficient | hcv = 15 W·m−2·K−1 |

| Aluminum Absorptivity | = 0.18 |

| Aluminum Emissivity | = 0.18 |

| Titanium Emissivity | = 0.5 |

| Latent heat of fusion | Lm = 2.6 × 105 J·kg–1 |

| Stefan-Boltzmann constant | = 5.67 × 10−8 W·m–2·K–4 |

| Aluminium melting range | 815–913 K |

| Titanium melting range | 1921–1941 K |

| Reference surface tension | [25] |

| Surface tension variation | = −1.44 × 10−5 N·m–1·K–1 |

| Aluminium Dynamic viscosity | = 0.0011 Pa·s |

| Contact resistance | Rc = 1 × 10–4 K·m–2·W–1 |

| Solid fraction | fsol(T) [18] |

| Laser power | 1250 W |

| Beam diameter | 2.4 mm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dal, M.; Peyre, P. Multiphysics Simulation and Experimental Investigation of Aluminum Wettability on a Titanium Substrate for Laser Welding-Brazing Process. Metals 2017, 7, 218. https://doi.org/10.3390/met7060218

Dal M, Peyre P. Multiphysics Simulation and Experimental Investigation of Aluminum Wettability on a Titanium Substrate for Laser Welding-Brazing Process. Metals. 2017; 7(6):218. https://doi.org/10.3390/met7060218

Chicago/Turabian StyleDal, Morgan, and Patrice Peyre. 2017. "Multiphysics Simulation and Experimental Investigation of Aluminum Wettability on a Titanium Substrate for Laser Welding-Brazing Process" Metals 7, no. 6: 218. https://doi.org/10.3390/met7060218