1. Introduction

In the automotive industry, an emphasis on inventions, innovations and information is reflected in the constant increase of car models in the portfolio of individual automakers. On the one hand, this is due to intensification of individualism with current absolute orientation of enterprises on the customer, and, on the other hand, this is due to the models’ diversification of vehicle manufacturers in terms of marketing of various technological innovations and new vehicle concepts on the market, with the aim to occupy the greatest number of market segments. Customers also demand cars that will respect their individual needs, and it affects not only the actual increase in the number of models on offer, but also increases the complexity of the car and a separate system.

Today, it is expected in the automotive industry that, based on the material selection strategies, such products are introduced to the market, involving more intellect and less material. Materials also have a close relationship to the passive safety of vehicles. While the vehicle’s car body is the important passive safety component, the lives of the passengers and the other transport users depend on strength and deformation properties of the material. The car body designers have to choose materials with exact properties to control the deformation of each car body structural component. In the frontal deformation zones, materials able to absorb as much impact energy as possible on a larger path should be used. Otherwise, in the middle zone of the car-body, strong materials able to absorb impact energy on a shorter path (minimum deformation) should be used. The innovative potential of the thin-walled lightweight (shell) structures from aluminum alloys, magnesium alloys, composites, High Strength Steels (HSS) and Ultra High Strength Steels (UHSS) is a big challenge when looking for the right material for each deformation zone [

1,

2].

Light-weight alloy materials used in the car body structural components are undoubtedly of great potential for lightening many structural parts of the cars. However, the overall share of steel still exceeds 50% of the total weight of the mass-produced cars. The uniqueness of the position of steel in the construction of cars is determined by the combination of its properties such as strength, stiffness, deformation work, formability and recyclability [

2,

3].

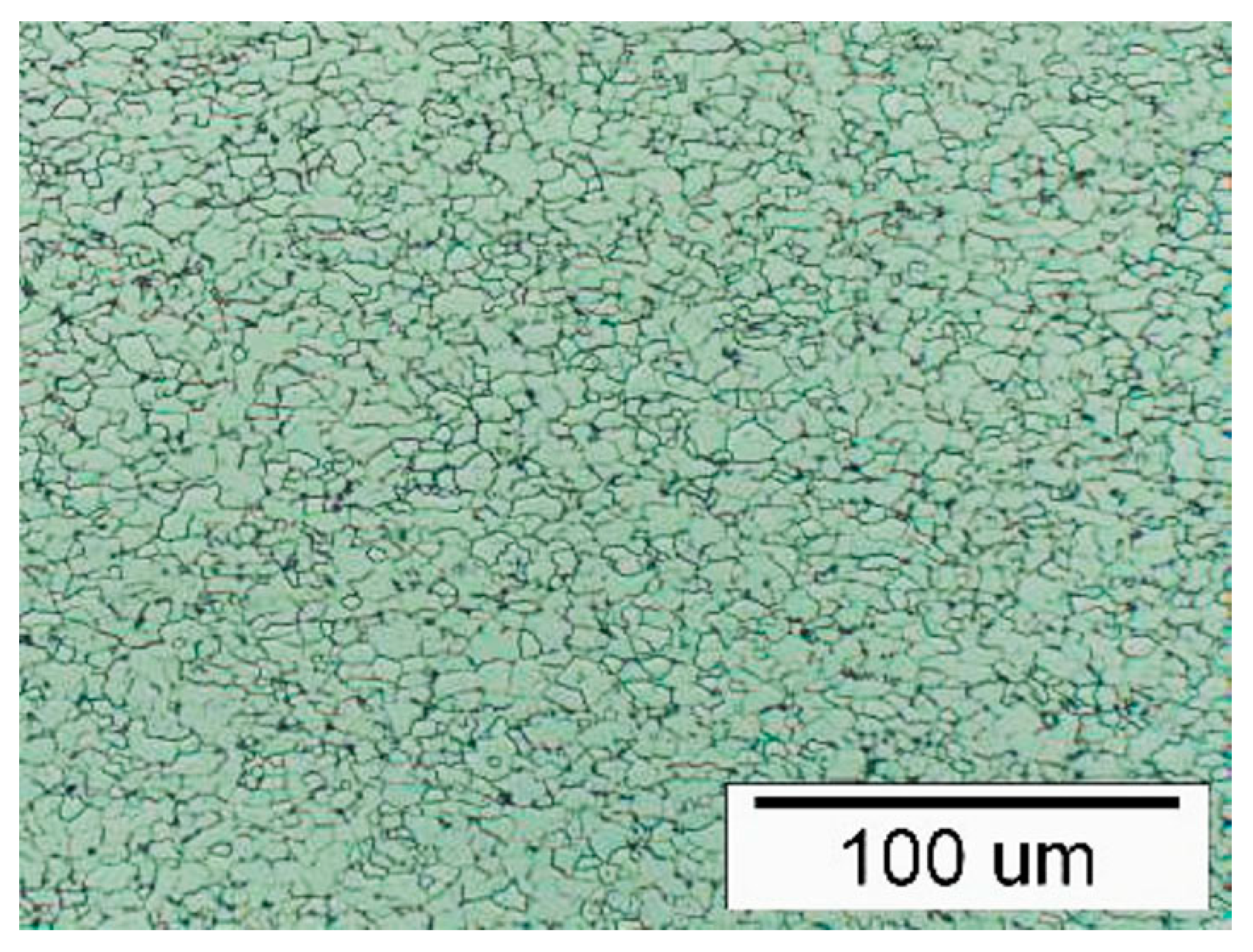

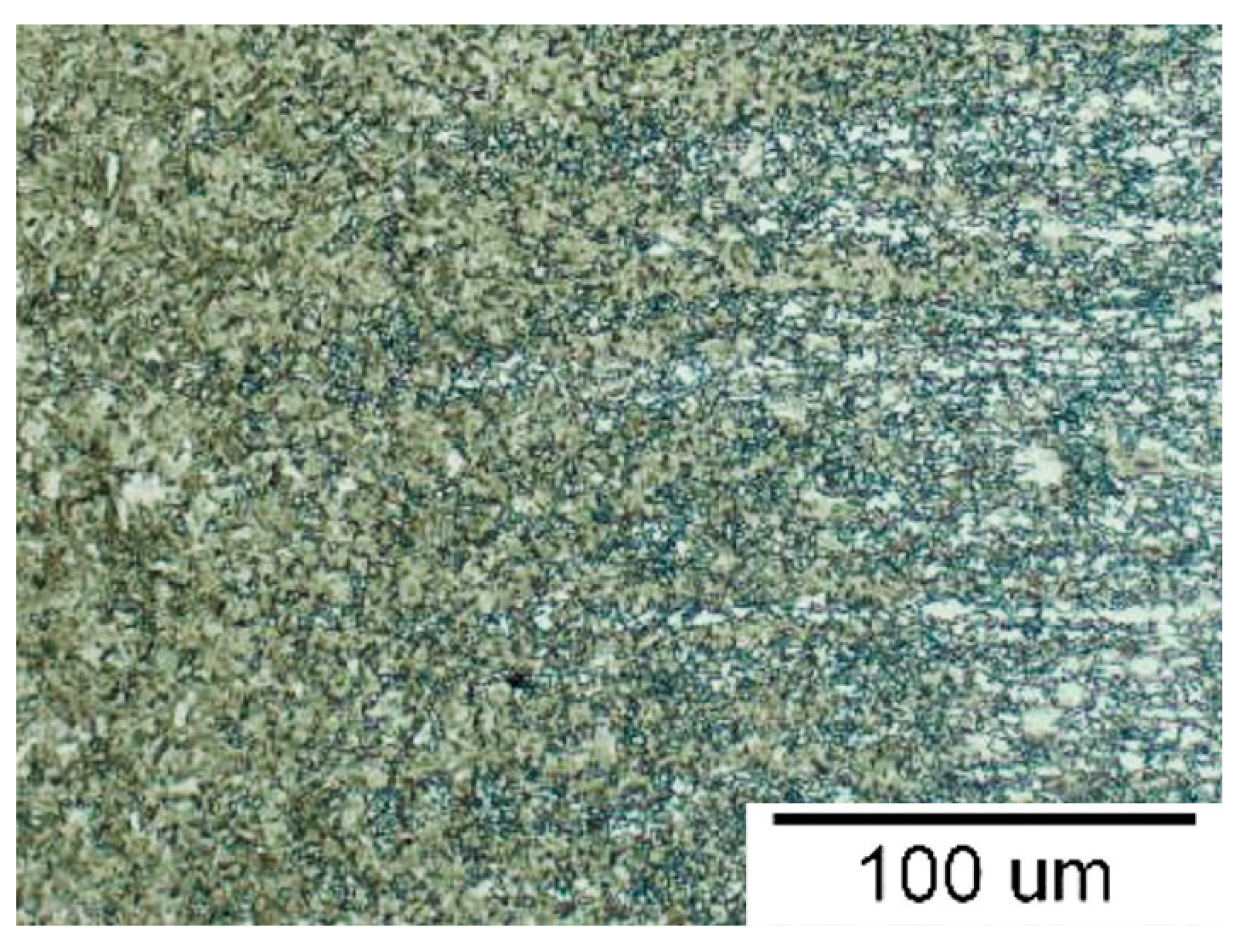

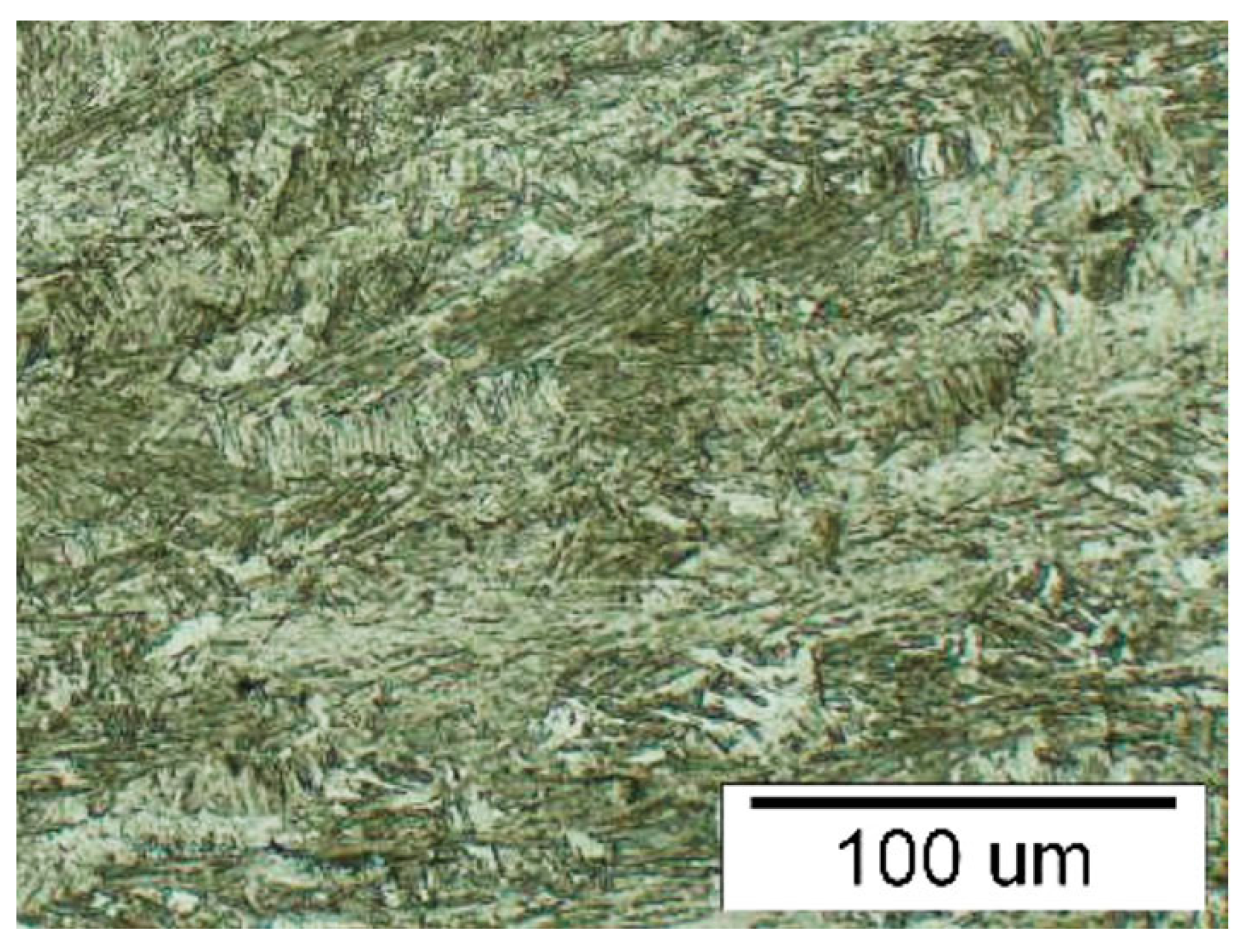

Standard low alloyed high-strength steels (IF, BH, and HSLA), advanced high-strength steels (AHSS) and ultra high-strength steels (UHSS—DP, CP, TRIP, TWIP and MS steels) commonly used in the automotive industry differ in their microstructure. Properties of steels are controlled by chemical composition and the strengthening mechanisms, such as: hardening by solid solutions, dislocation hardening, grain boundaries hardening, precipitation or transformation hardening [

4].

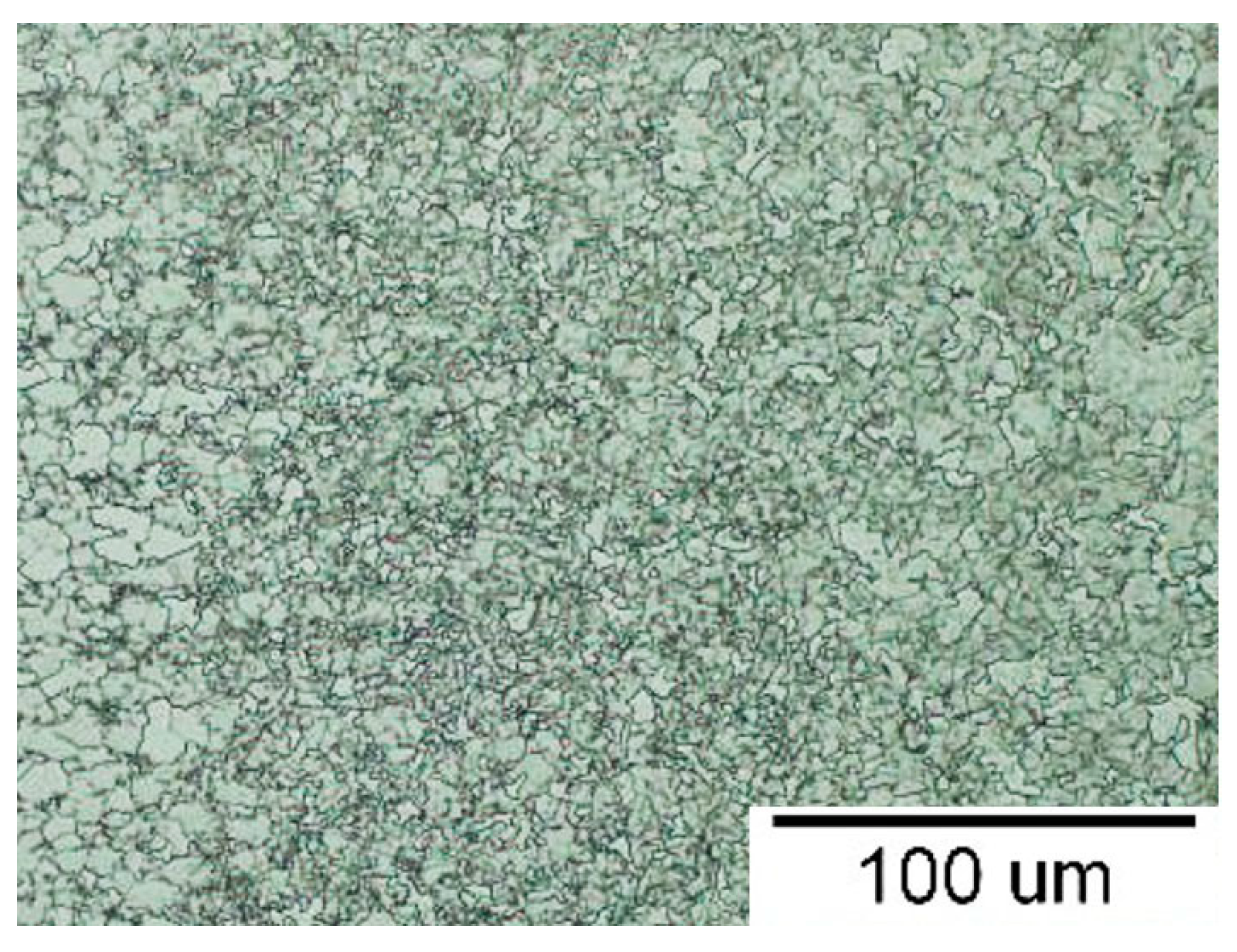

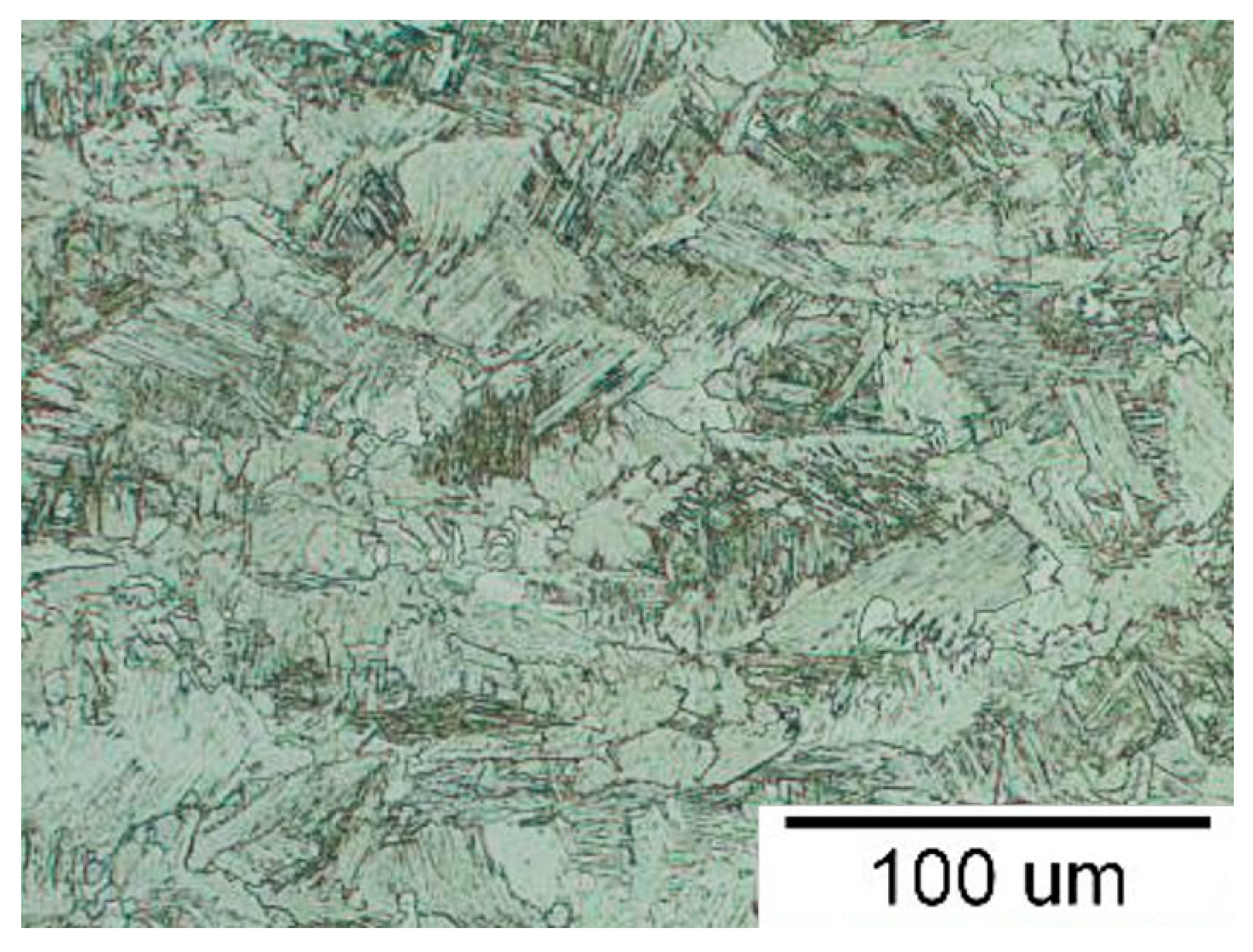

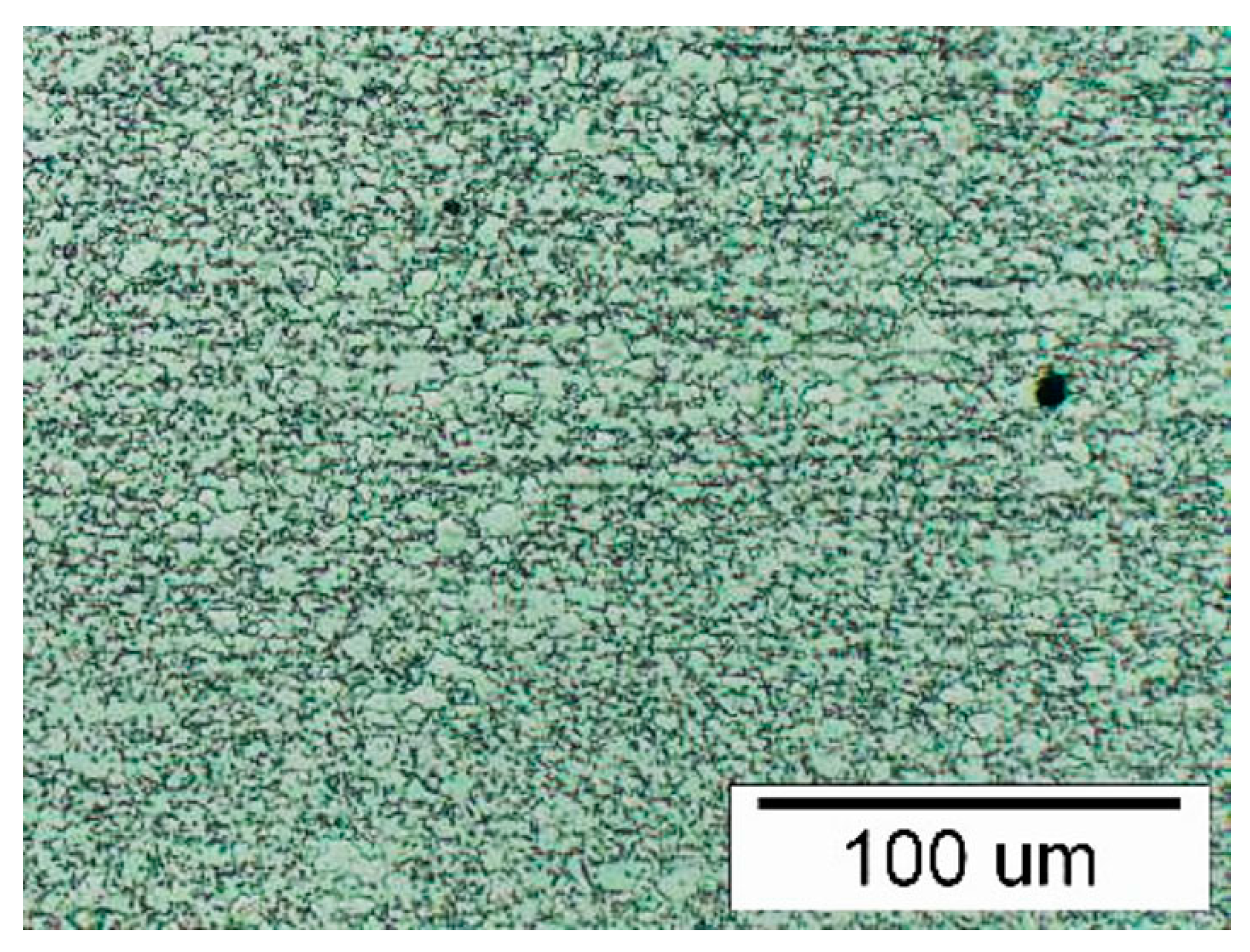

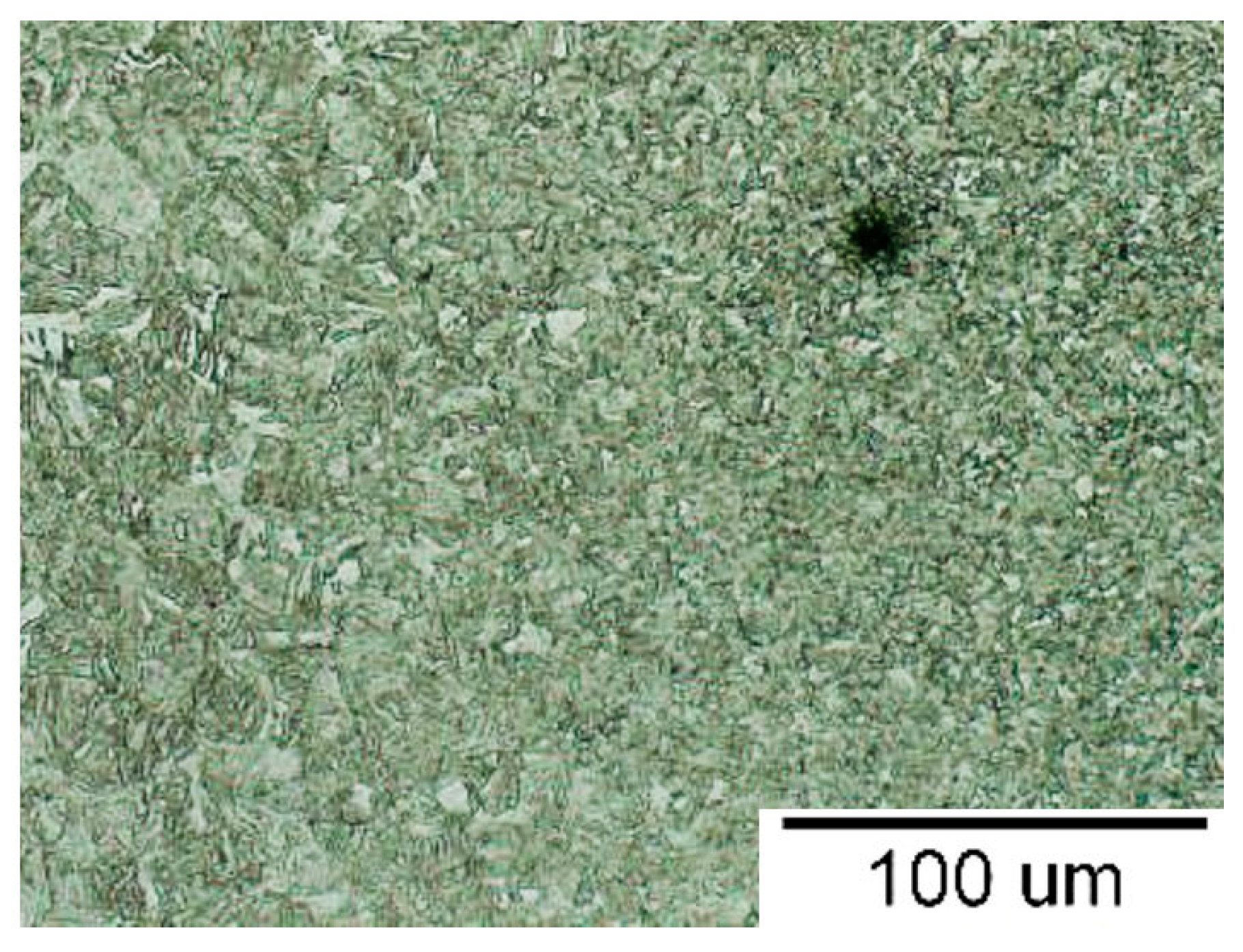

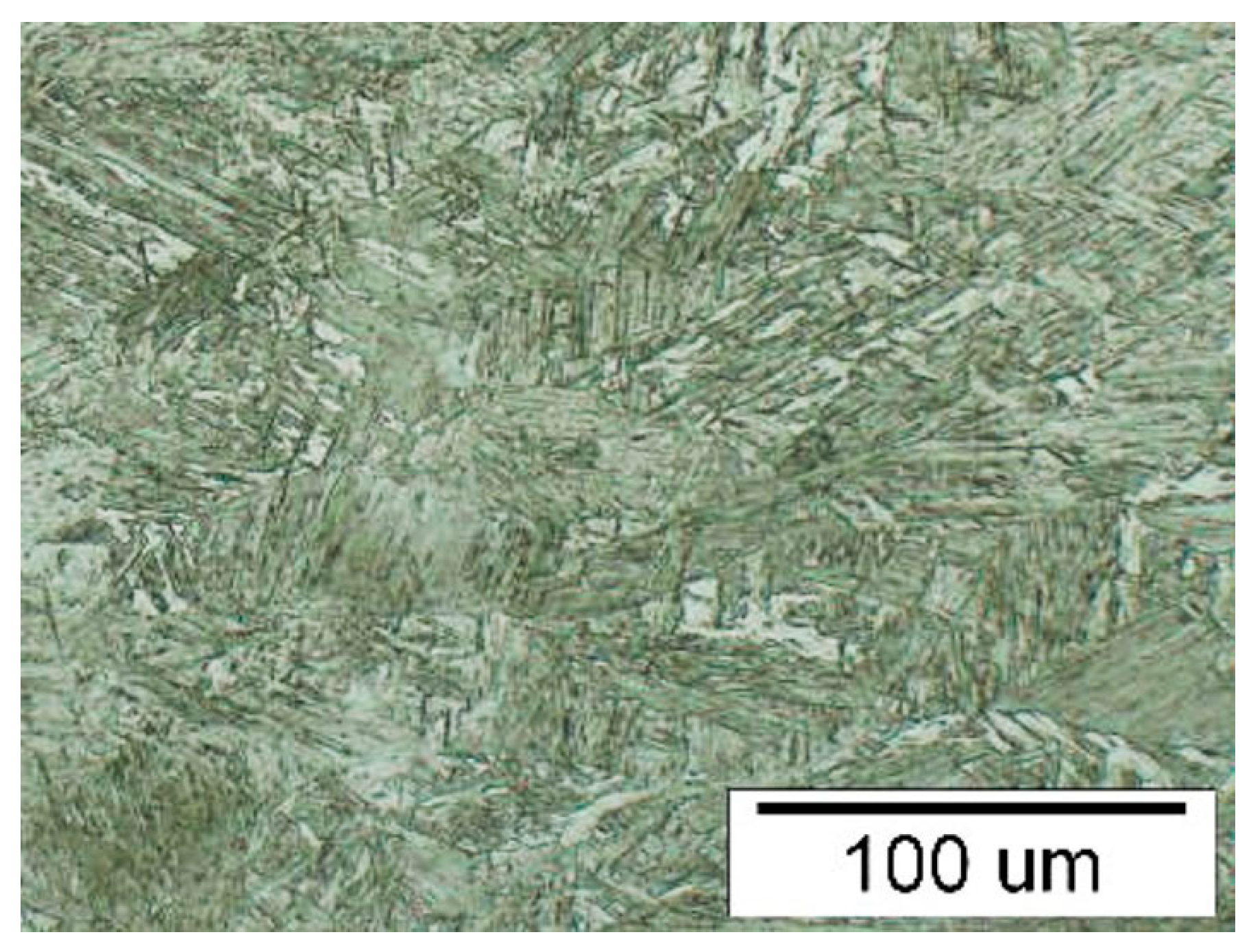

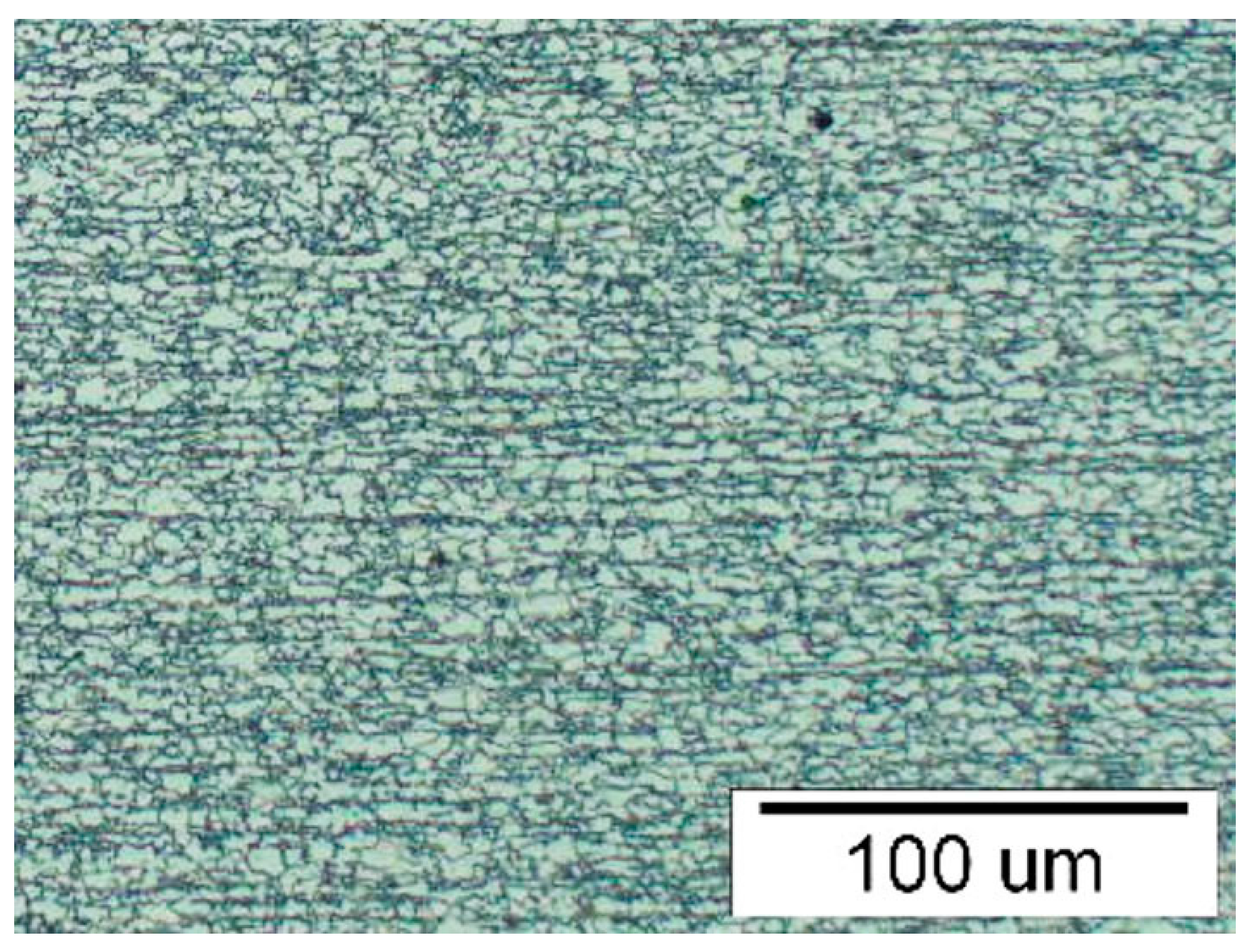

The research in the paper is focused on the high strength low alloyed steel, dual phase steel and multiphase steel. In the case of high-strength low-alloy (HSLA) steels, the increase of the ferritic matrix strength is achieved especially by microalloying elements Ti, V, and Nb, which increase strength by grain size control, precipitation hardening, or substitution hardening of structure [

4,

5]. Dual phase steels consist of a ferritic matrix with 5% to 30% martensite content. Ferrite is a soft phase with good formability. Martensite is a hard phase that gives the material its strength and hardness [

4,

6]. Transformation induced plasticity (TRIP) steels consist of retained austenite, martensite, bainite and ferrite. Residual austenite transforms to martensite during deformation, and it is situated in the polygonal ferritic matrix, which also includes bainite, preserving very good formability [

4,

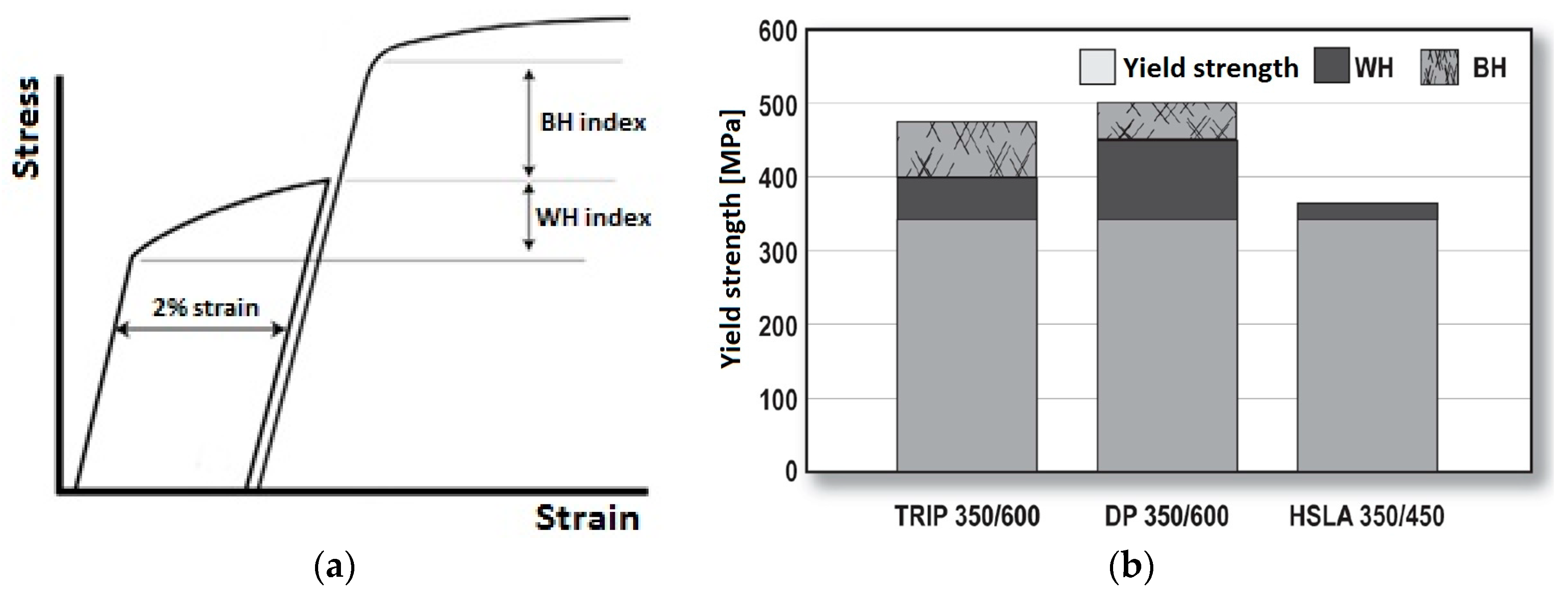

7]. Both dual phase and multi-phase steels show more work hardening (WH) and bake hardening (BH) (

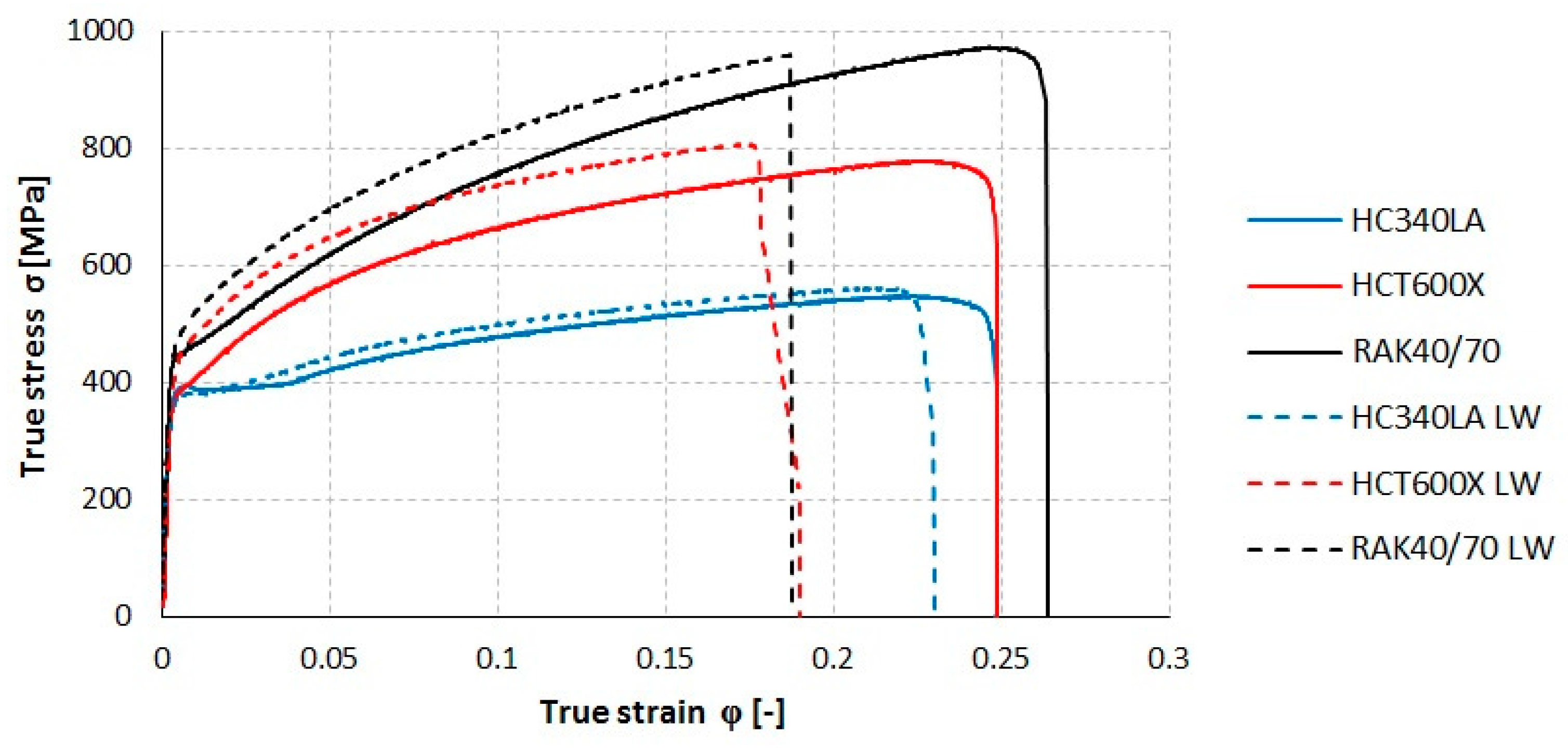

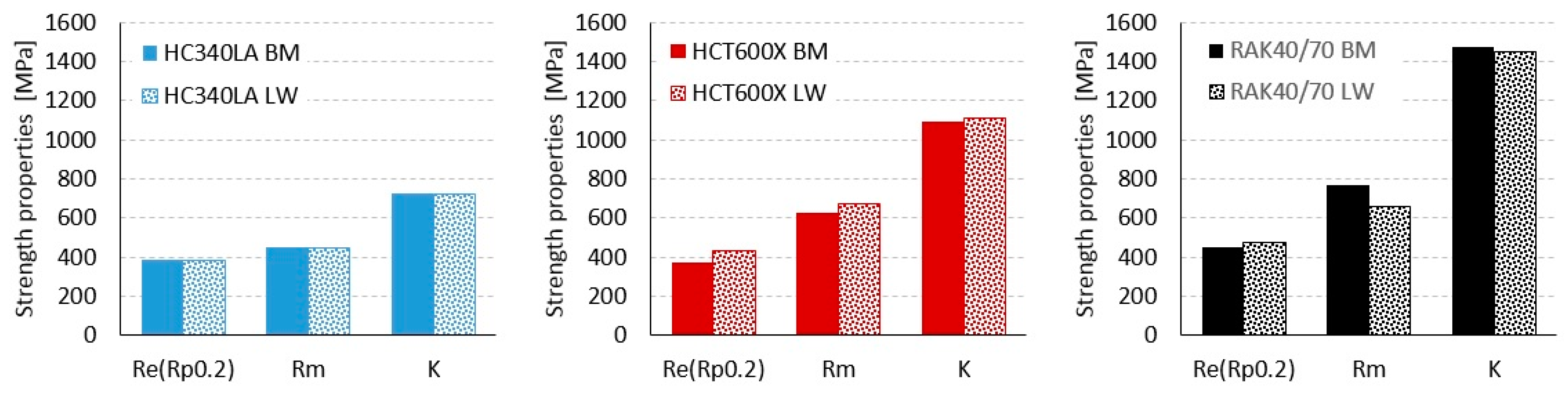

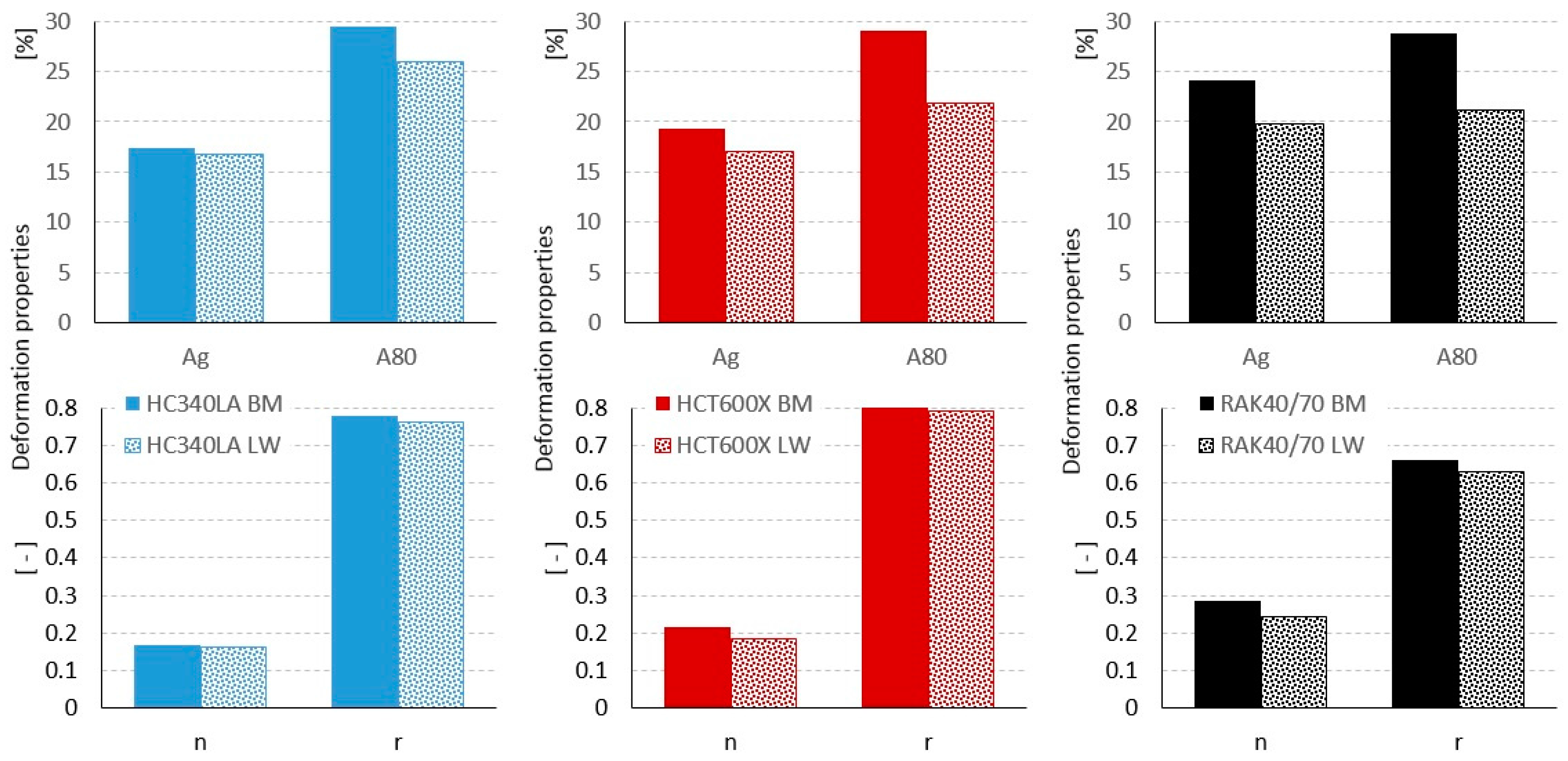

Figure 1a,b) than high strength low alloyed steel [

3].

Structural thin-walled components of security zones of cars must often meet conflicting requirements—on the one hand, the growing tendency for the reduction of the weight of stamped body parts and, on the other hand, the tendency of increasing the security (strength, stiffness, absorption capacity and programmable deformability under crash). The desired compromise between the requirements to reduce the weight of cars on the one hand and requirements for improving the safety parameters (strength, stiffness, both deformation and fatigue works), reduction of fuel consumption and emissions during operation of cars on the other hand, can be achieved by proper application of the combined tailored blanks: tailor-welded blanks (TWB), engineering blanks (EB), tailor-rolled blanks (TRB), tailor heat treated blanks (THTB) (with the same or different thickness, with different strength and deformation properties, especially in the deformation zones of thin-walled components of cars) [

8,

9,

10,

11]. The combined TWBs prepared by laser beam or electron beam welding have found the widest application.

In the areas with smaller load, the sheet metal with reduced thickness or less expensive material of less strength is applied. In the areas where greater loads occur, the material of greater thickness and higher strength is applied. Because of these advantages, combined blanks are widespread in the design of car body components and also improve their utility properties (e.g., stainless austenitic and ferritic steels for improving the corrosion resistance in the exhaust systems, the fuel tanks, etc.). According to the data of suppliers of materials for the automotive industry, their share in the structure of the car body should be increased in the coming years up to 30% [

12,

13].

Application of solid-state lasers in the industry currently comes with a significantly increasing perspective, especially due to the fact that new types of solid-state lasers such as fiber and disk lasers with their technical parameters surpass the parameters of gas CO

2 lasers [

14,

15].

The most important advantages of solid-state lasers include:

Conversion efficiency of electric energy to the energy of the laser beam being higher by 30% compared to the CO2 lasers,

Higher focusability that expands the field of industrial applicability,

Improved flexibility and stability of output parameters,

Increased dynamics of beam parameters with the possibility of shaping the rise and decay, and the tip of the laser pulse.

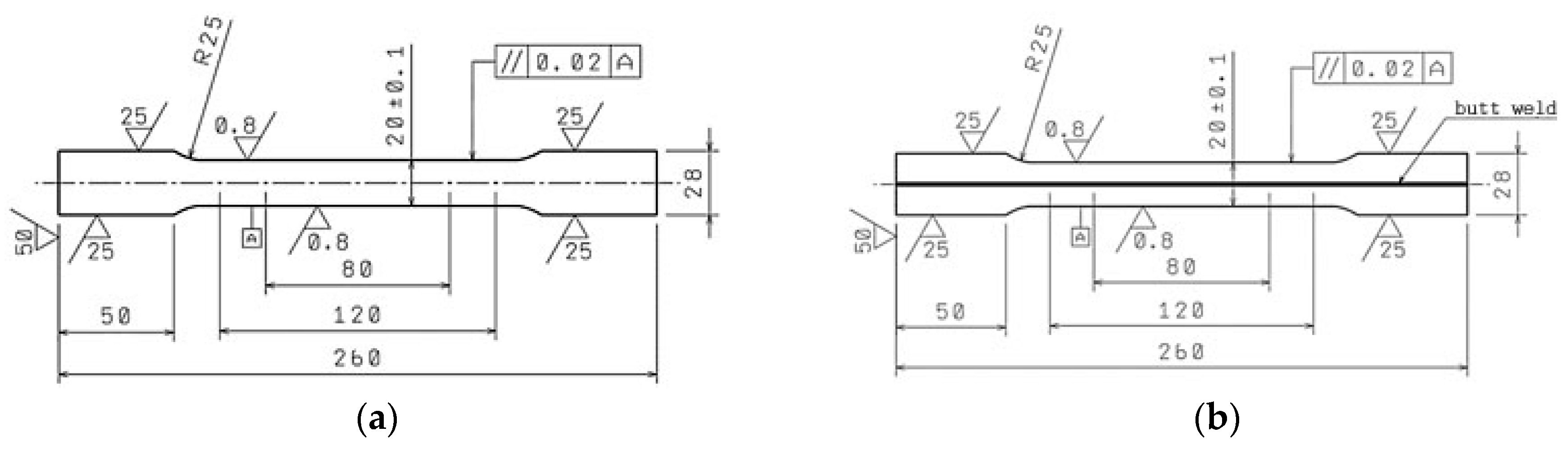

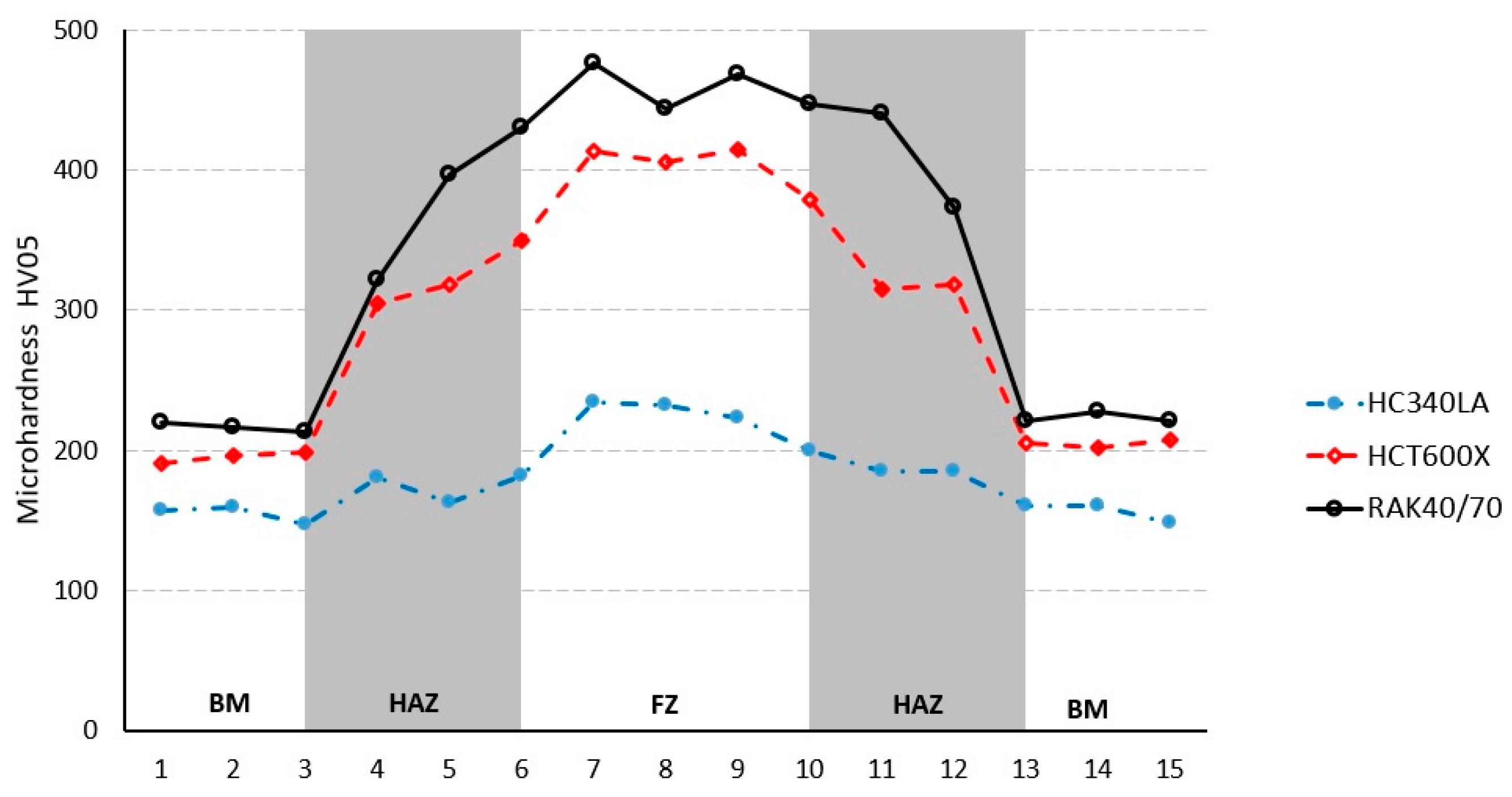

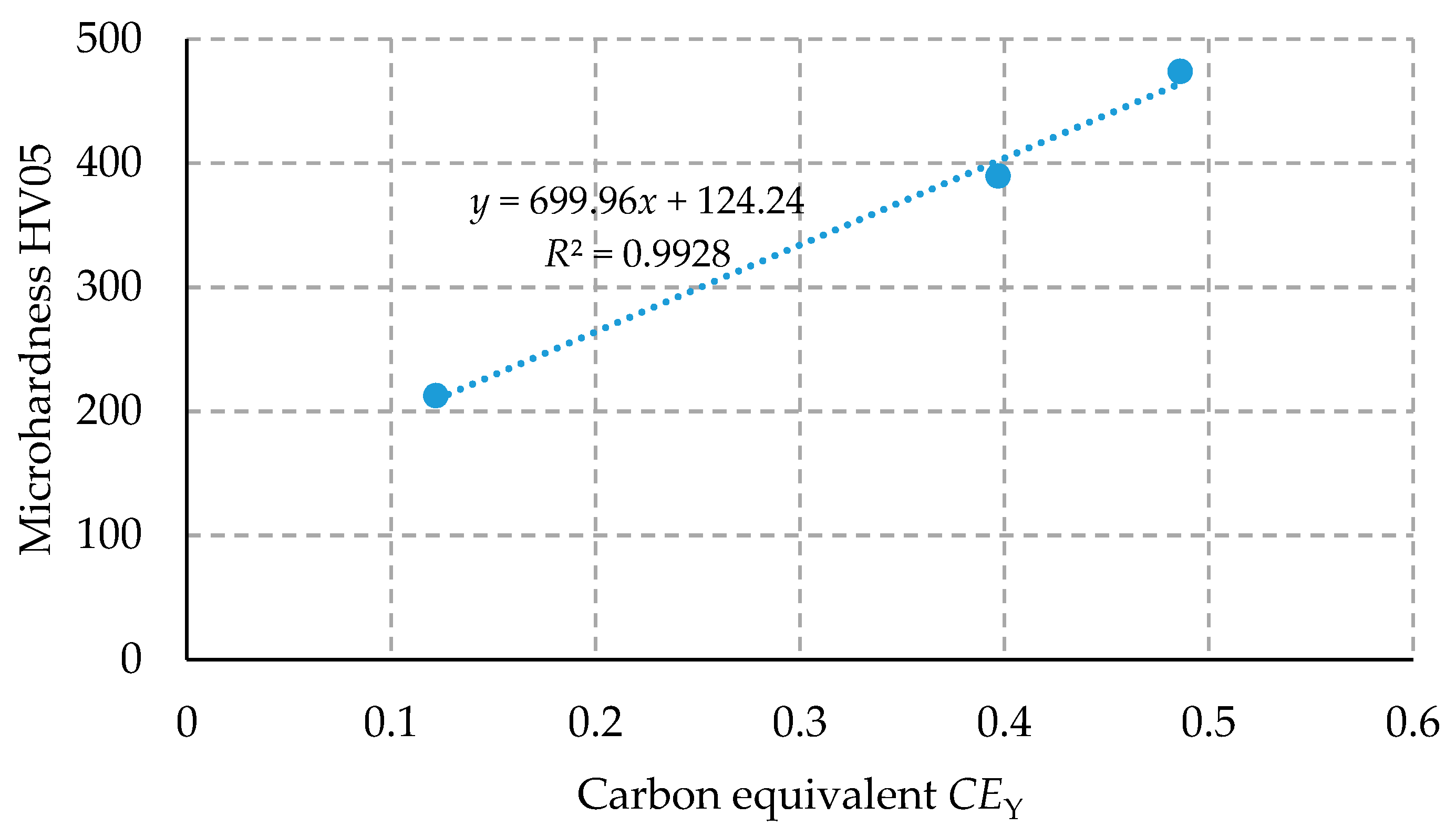

Research results of weldability and formability indicate that influence of welded joints on the material plastic flow in the joint area is examined and analyzed by the same kind of tests as are used for evaluation of weldability and formability of base materials, when used for TWBs: tensile tests; braking tests; technological tests (cup drawing tests, Erichsen tests, the Swift method, hydraulic bulge tests, hole expanding test, limit dome height tests and three- or four-point bending tests); macro and microstructure analyses of individual zones of welded joints; hardness tests and Vickers micro-hardness in zones of welded joints and the base material [

16,

17].

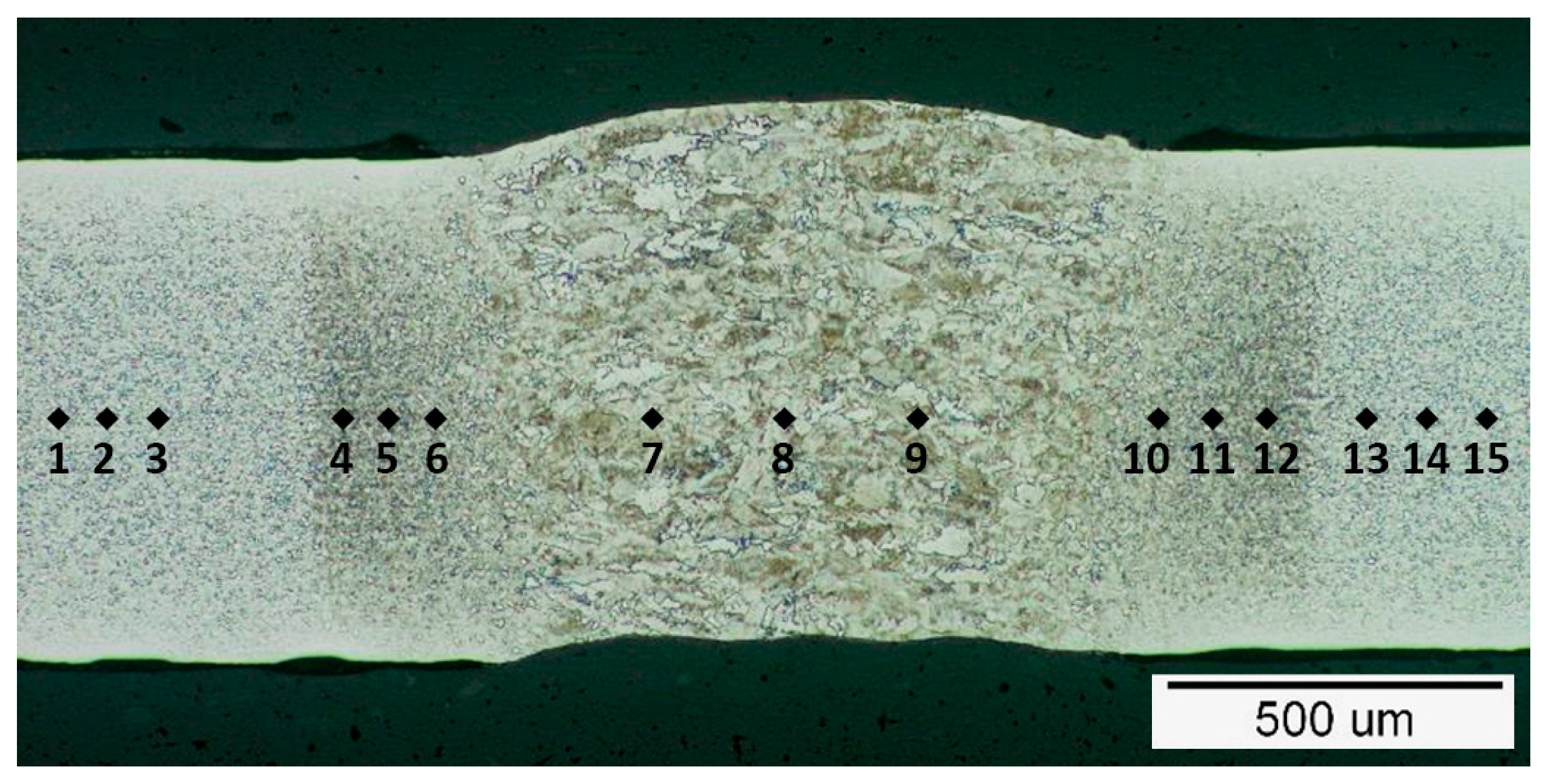

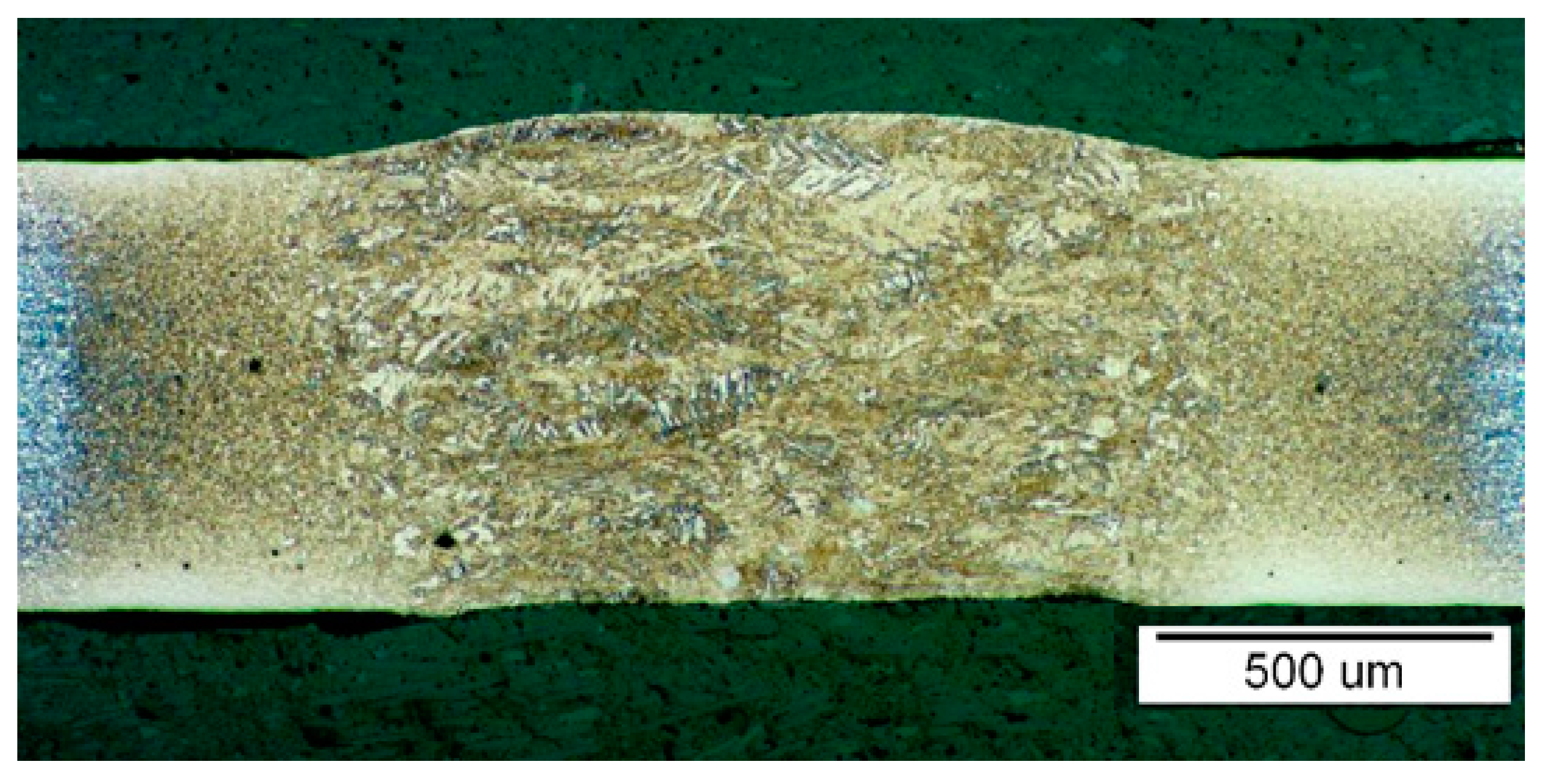

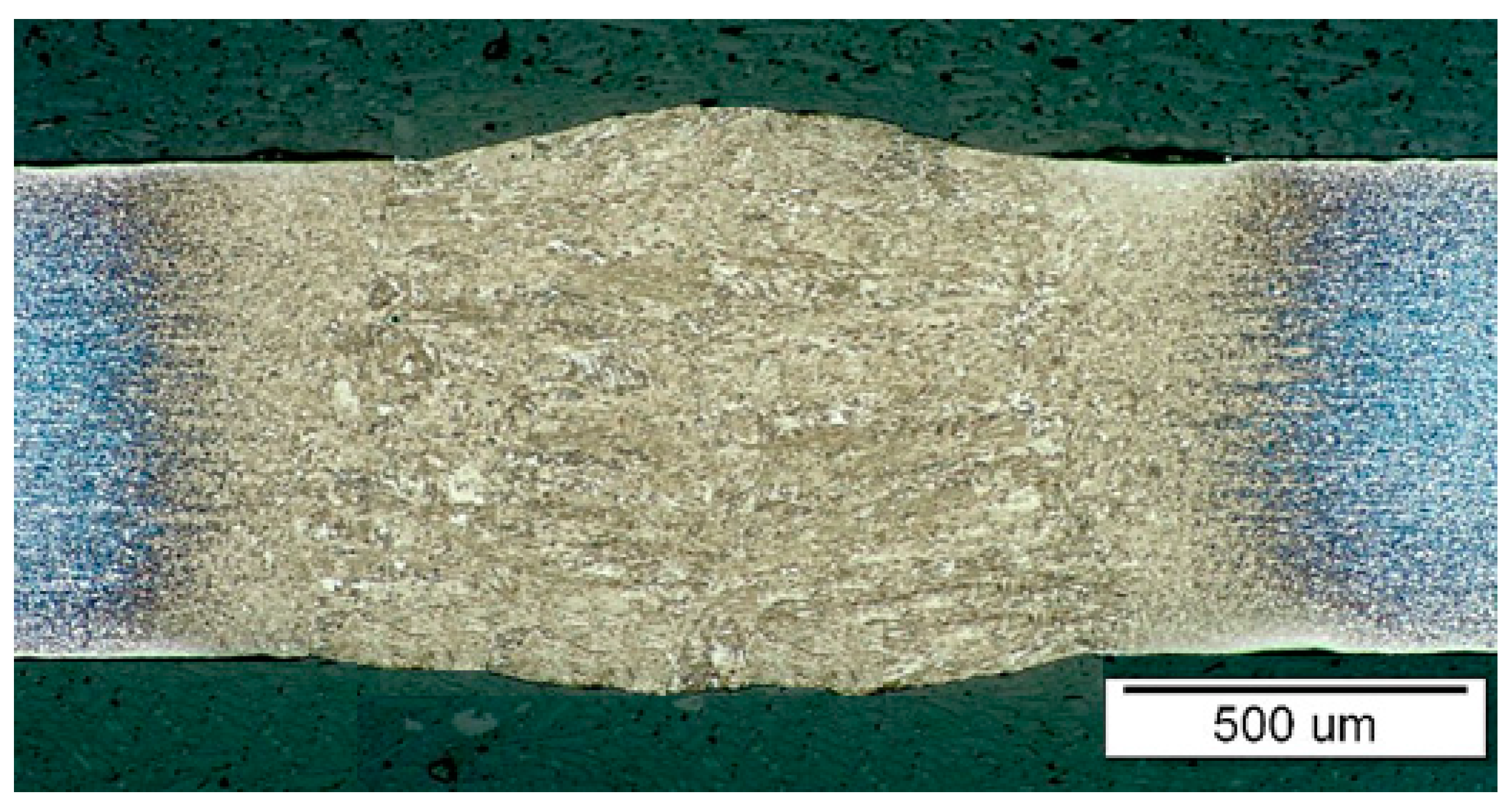

The aim of the paper is to assess the impact of laser welding on the mechanical properties of selected AHSS materials for TWBs, used in the automotive industry for structural components of the car body. The study is focused on the measurement of strength and deformation properties for base material and laser welded by a solid-state fiber laser. Many authors have investigated the influence of laser welding on the tensile properties on specimens with transverse weld [

5,

6,

18,

19,

20]. Thus, the research was focused on the specimens with longitudinal butt laser weld, as it is used for tailored TWBs. It is supposed that the longitudinal weld is more sensitive to the stress–strain distribution when a tensile test is performed. In addition, the microstructural changes and microhardness in the heat affected zone and fusion zone were examined.