Figure 1.

Part-to-part gap variation and angles of elevation and depression in a simplified side-member part assembly.

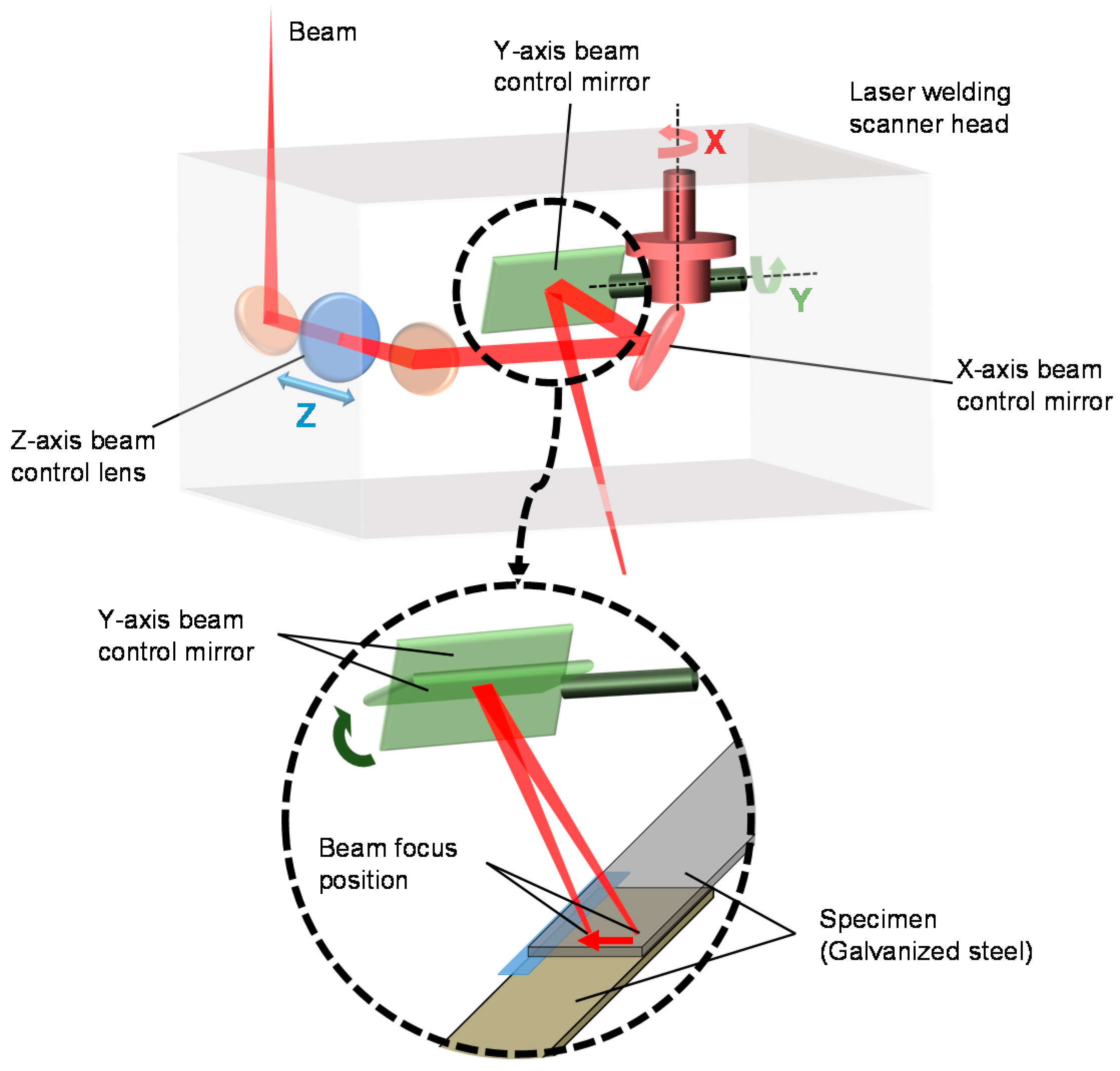

Figure 2.

A schematic illustration of a laser welding scanner head that can easily change the direction of welding.

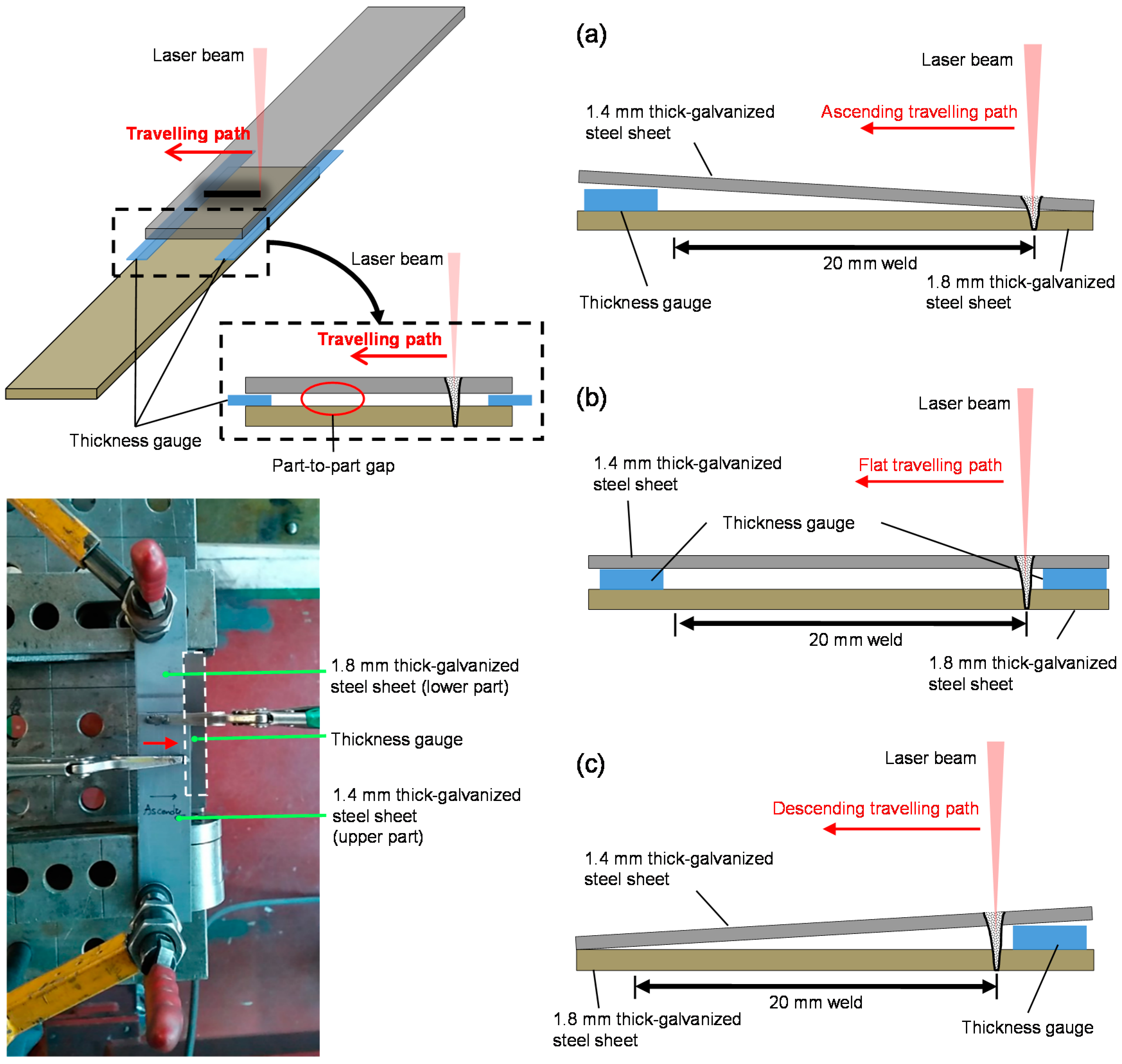

Figure 3.

Weld joint configuration clamped at the two corners and the three types of travelling paths: (a) ascending; (b) flat; (c) descending.

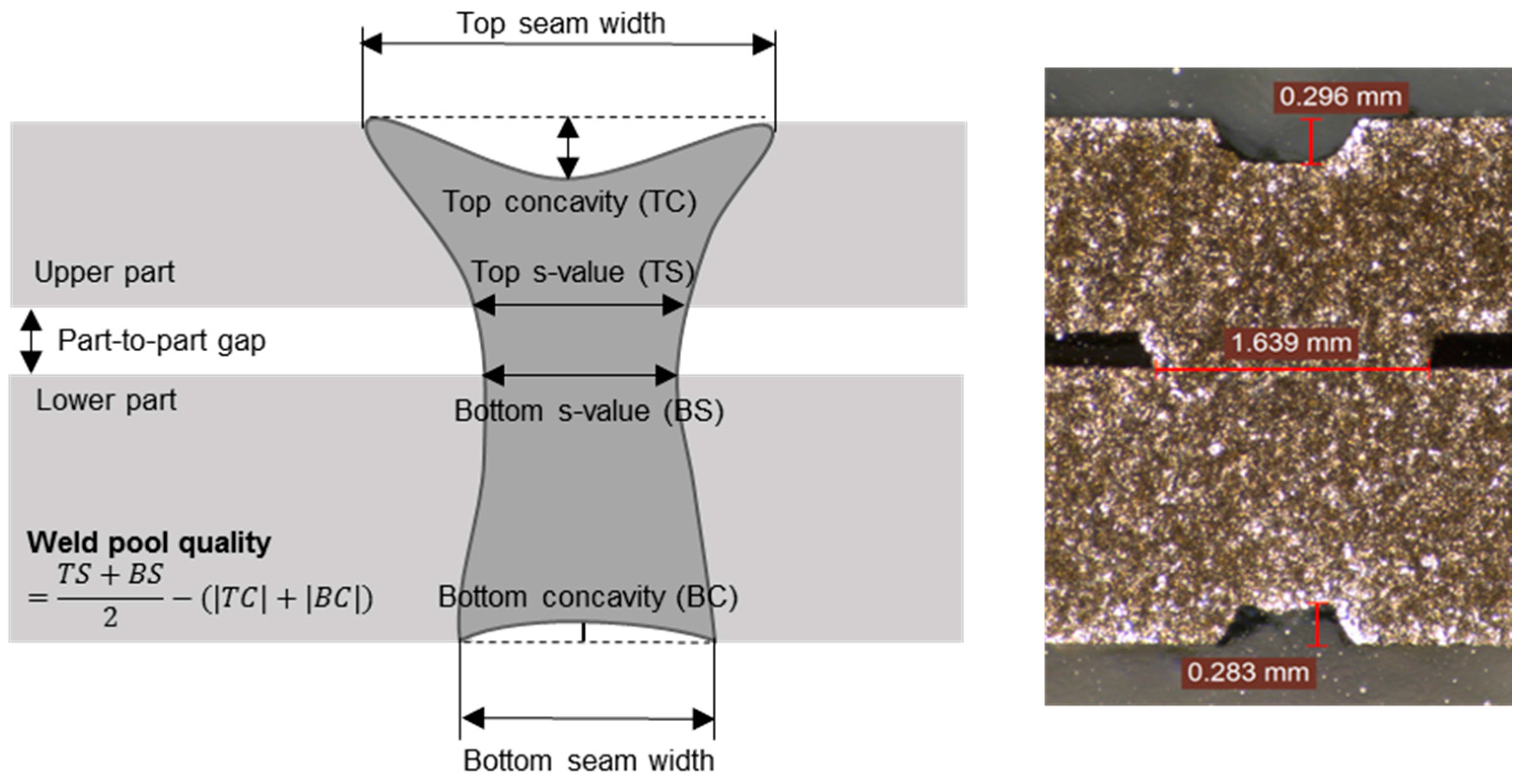

Figure 4.

Definition of weld pool quality and an example of the cross sectional view at the middle of the specimen.

Figure 5.

Main effect plots of the average s-value and weld pool quality in terms of the travelling path for experiment (a) #1-1 (laser power: 1.6, 1.8, and 2 kW, part-to-part gap: 0.3 mm) and (b) #1-2 (laser power: 4, 5, and 6 kW, part-to-part gap: 0.3 mm).

Figure 6.

Main effect plots of the average s-value and weld pool quality in terms of the travelling path for experiment (a) #2-1 (laser power: 2 kW, part-to-part gap: 0.5 mm) and (b) #2-2 (laser power: 4, 5, and 6 kW, part-to-part gap: 0.5 mm).

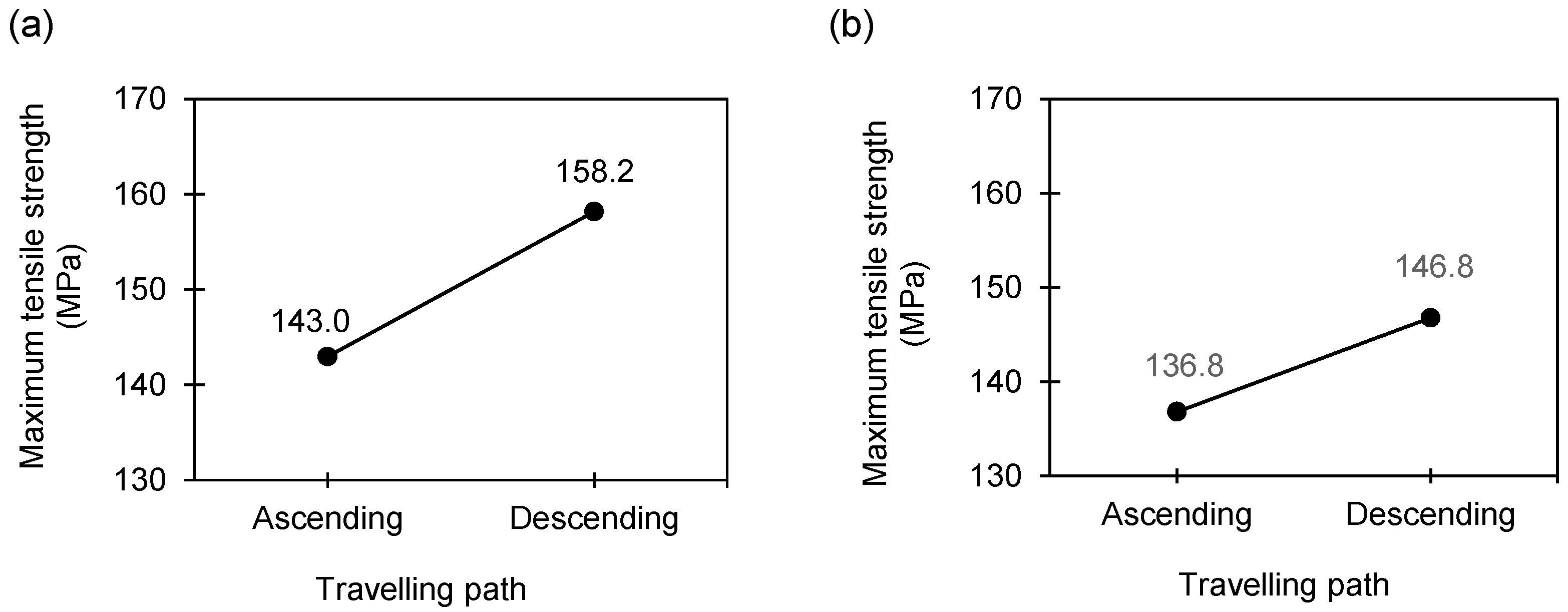

Figure 7.

Main effect plots of maximum tensile strength in terms of the travelling paths for experiment (a) #3-1 (laser power: 2 kW, part-to-part gap: 0.3 mm) and (b) #3-2 (laser power: 4, 4.5, 5.5, and 6 kW, part-to-part gap: 0.3 mm).

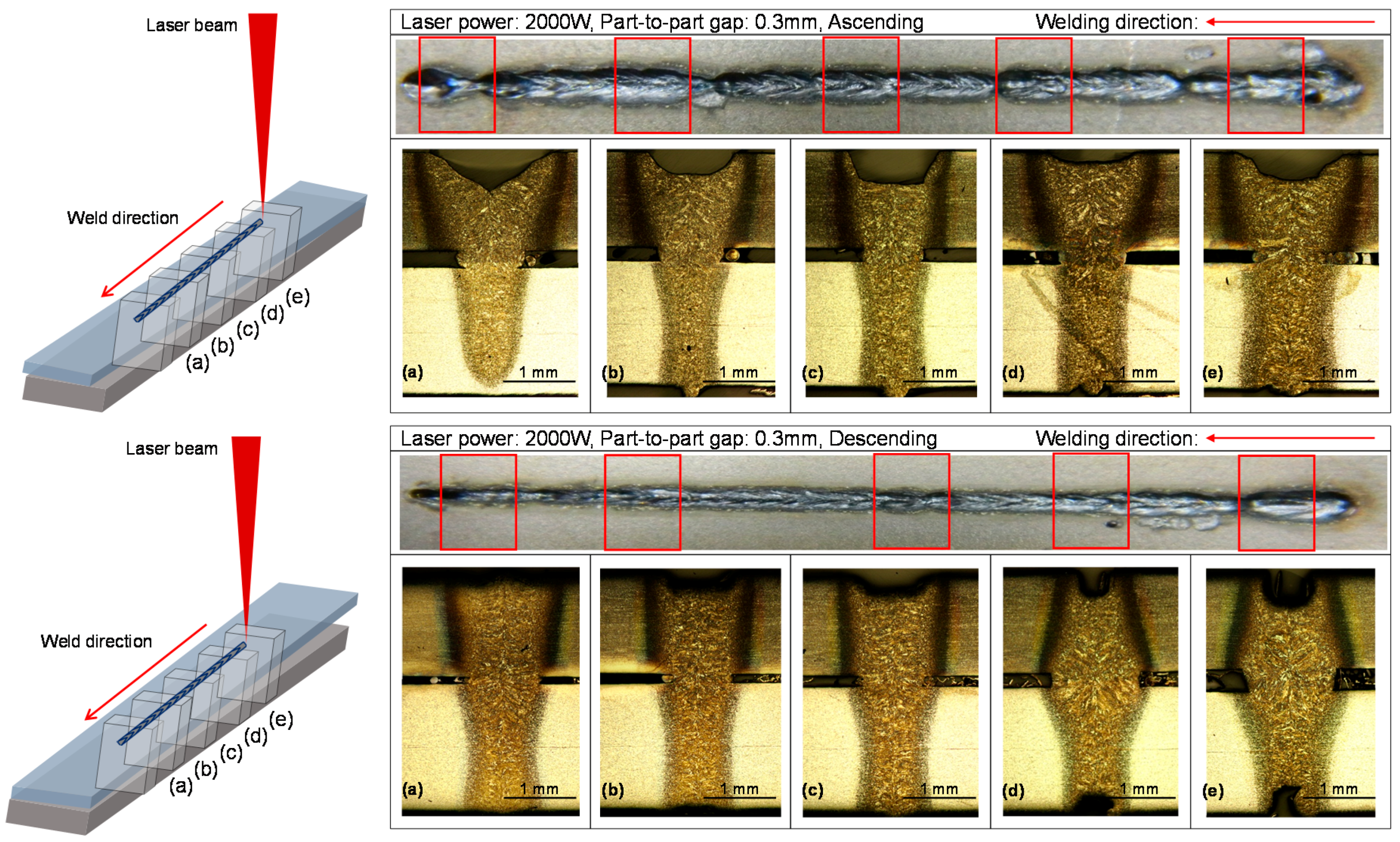

Figure 8.

The lateral images of weld joints in the cases of ascending (top) and descending (bottom) travelling paths.

Table 1.

The major process parameters in the laser lap welding of galvanized steel from literature.

| Major Process Parameters | Laser Welding Quality | References |

|---|

| Laser power, focal position, welding speed | Heat input and weld bead geometry (i.e., penetration depth, widths of welded zone, and heat-affected zone) | Benyounis et al. [2], Wu et al. [3] |

| Part-to-part gap | Weld depth, weld width, and concavity | Zhao et al. [9] |

| Laser power, welding speed, focal position, and shielding gases | Static tensile strength | Mei et al. [10] |

| Shielding gases | Tensile strength and widths of heat-affected zone | Chen et al. [11], Yang et al. [12] |

| Clamp pressure | Lap shear strength and weld seam width | Acherjee et al. [13], Anawa et al. [14] |

Table 2.

Technical parameters of the laser welding systems.

| Parameters | Unit | Fiber Laser | Disk Laser |

|---|

| YLS-2000AC | TruDisk6602 |

|---|

| Max. laser power | kW | 2.0 | 6.6 |

| Beam quality | mm × mrad | 6.0 | 8.0 |

| Fiber diameter | µm | 600 | 200 |

| Emission wavelength | nm | 1070 | 1030 |

| Focal length | mm | 278 | 533 |

Table 3.

Chemical composition (weight %) of the test materials.

| Tested Materials | Dimension (mm) (length × width × thickness) | Zinc Coating (g/m2) | C (%) | Si (%) | Mn (%) | P (%) | S (%) |

|---|

| SGARC440 (Lower part) | 130 × 30 × 1.8 | 45.5 | 0.12 | 0.5 | 1.01 | 0.021 | 0.004 |

| SGAFC590DP (Upper part) | 130 × 30 × 1.4 | 45.4 | 0.09 | 0.26 | 1.79 | 0.03 | 0.003 |

Table 4.

Mechanical properties of the test materials.

| Tested Material | Tensile Test |

|---|

| Yield Strength (N/m2) | Max-Tensile Strength (N/m2) | Elongation (%) |

|---|

| SGARC440 (Lower part) | 327.5 | 451.1 | 38 |

| SGAFC590DP (Upper part) | 413.8 | 625.7 | 28 |

Table 5.

Experimental design.

| Experiments | Experimental Factors | Part-to-Part Gap (mm) | Welding Speed (mm/min) |

|---|

| Laser Power (W) | Type of Travelling Path |

|---|

| #1-1 | 1600 | Ascending | 0.3 (in-tolerance) | 800 |

| 3 levels × 2 levels with 2 replicates (2 kW fiber) | 1800 | Descending | 1000 |

| 2000 | | 1250 |

| #1-2 | 4000 | Ascending | 0.3 (in-tolerance) | 4000 |

| 3 levels × 2 levels with 5 replicates (6.6 kW disk) | 5000 | Descending | 5000 |

| 6000 | | 6000 |

| #2-1 | 2000 | Ascending | 0.5 (out-of-tolerance) | 900 |

| 3 levels with 10 replicates (2 kW fiber) | | Flat | |

| | Descending | |

| #2-2 | 4000 | Ascending | 0.5 (out-of-tolerance) | 3000 |

| 3 levels × 3 levels with 4 replicates (6.6 kW disk) | 5000 | Flat | 4000 |

| 6000 | Descending | 4000 |

Table 8.

ANOVA table for experiment #1-1 (2-kW fiber laser welding system).

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | P-Value |

|---|

| Blocks | 1 | 0.00165 | 0.00165 | 0.05 | 0.828 |

| Laser power | 2 | 0.01256 | 0.00628 | 0.2 | 0.824 |

| Travelling path | 1 | 0.26895 | 0.26895 | 8.6 | 0.033 |

| Laser power × Travelling path | 2 | 0.01281 | 0.00641 | 0.2 | 0.821 |

| Error | 5 | 0.15628 | 0.03126 | | |

| Total | 11 | 0.45224 | | | |

Table 9.

ANOVA table for experiment #1-2 (6.6-kW disk laser welding system).

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | P-Value |

|---|

| Block | 4 | 0.0479 | 0.0120 | 1.34 | 0.291 |

| Laser power | 2 | 0.0666 | 0.0333 | 3.71 | 0.043 |

| Travelling path | 1 | 0.0072 | 0.0072 | 0.81 | 0.380 |

| Laser Power × Travelling path | 2 | 0.0373 | 0.0187 | 2.08 | 0.151 |

| Error | 20 | 0.1793 | 0.0090 | | |

| Total | 29 | 0.3383 | | | |

Table 12.

ANOVA table of the s-value for experiment #2-1 (2-kW fiber laser welding system).

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | p-Value |

|---|

| Travelling path | 2 | 0.0630 | 0.0315 | 1.06 | 0.361 |

| Error | 27 | 0.8026 | 0.0297 | | |

| Total | 29 | 0.8656 | | | |

Table 13.

ANOVA table for experiment #2-2 (6-kW disk laser welding system).

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | p-Value |

|---|

| Blocks | 3 | 0.0437 | 0.0146 | 1.62 | 0.212 |

| Laser power | 2 | 0.0507 | 0.0254 | 2.81 | 0.08 |

| Travelling path | 2 | 1.6103 | 0.8051 | 89.33 | 0.00 |

| Laser power × Travelling path | 4 | 0.4616 | 0.1154 | 12.8 | 0.00 |

| Error | 24 | 0.2163 | 0.0090 | | |

| Total | 35 | 2.3826 | | | |

Table 14.

The laser welding experimental data of experiment #3-1 (laser power: 2 kW, part-to-part gap: 0.3 mm) and experiment #3-2 (laser power: 4, 4.5, 5.5, and 6 kW, part-to-part gap: 0.3 mm)

| Experiment #3-1 | Experiment #3-2 |

|---|

| Laser Power | Maximum Tensile Strength (MPa) | Laser Power | Maximum Tensile Strength (MPa) |

|---|

| Ascending | Descending | Ascending | Descending |

|---|

| 2 kW | 143.150 | 138.044 | 4 kW | 130.195 | 154.848 |

| 157.330 | 161.804 | 132.497 | 174.842 |

| 157.330 | 142.091 | 137.479 | 141.421 |

| 167.639 | 175.656 | 4.5 kW | 143.150 | 146.920 |

| 125.989 | 151.240 | 128.442 | 139.133 |

| 177.610 | 113.757 | 126.111 | 170.180 |

| 124.059 | 155.150 | 5.5 kW | 162.380 | 133.611 |

| 139.451 | 166.041 | 138.745 | 142.645 |

| 156.543 | 167.844 | 122.292 | 157.112 |

| | | 6 kW | 152.604 | 145.174 |

| | | 163.173 | 145.174 |

| | | 163.173 | 122.911 |

Table 15.

ANOVA table of the tensile strength for experiment #3-1 (2-kW fiber laser welding system).

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | p-Value |

|---|

| Travelling path | 1 | 1037 | 1037 | 5.44 | 0.033 |

| Error | 16 | 3053 | 191 | | |

| Total | 17 | 4090 | | | |

Table 16.

ANOVA table of the tensile strength for experiment #3-2 (6.6-kW disk laser welding system).

| Source | Degree of Freedom | Sum of Square | Mean Square | F-Ratio | p-Value |

|---|

| Laser power | 3 | 419 | 139.7 | 0.62 | 0.612 |

| Travelling path | 1 | 552.9 | 552.9 | 2.45 | 0.137 |

| Laser power × Travelling path | 3 | 1200.7 | 400.2 | 1.78 | 0.192 |

| Error | 16 | 3603.5 | 225.2 | | |

| Total | 23 | 5776.1 | | | |

Table 17.

Summary of the four experiments.

| Experiments | Part-to-Part Gap (mm) | Significance of Welding Direction |

|---|

| #1-1 (2-kW fiber) 3 levels × 2 levels with 2 replicates | 0.3 (in-tolerance) | Descending ≥ Ascending |

| #1-2 (6.6-kW disk) 3 levels × 2 levels with 5 replicates | 0.3 (in-tolerance) | X |

| #2-1 (2-kW fiber) 3 levels with 10 replicates | 0.5 (out-of-tolerance) | X |

| #2-2 (6.6-kW disk) 3 levels × 3 levels with 4 replicates | 0.5 (out-of-tolerance) | X |