High-Temperature Compressive Resistance and Mechanical Properties Improvement of Strain-Induced Melt Activation-Processed Al-Mg-Si Aluminum Alloy

Abstract

:1. Introduction

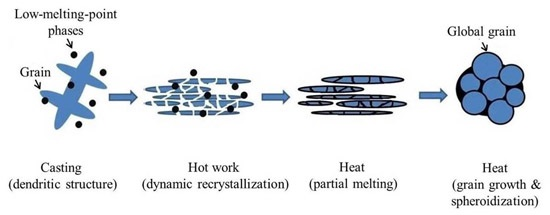

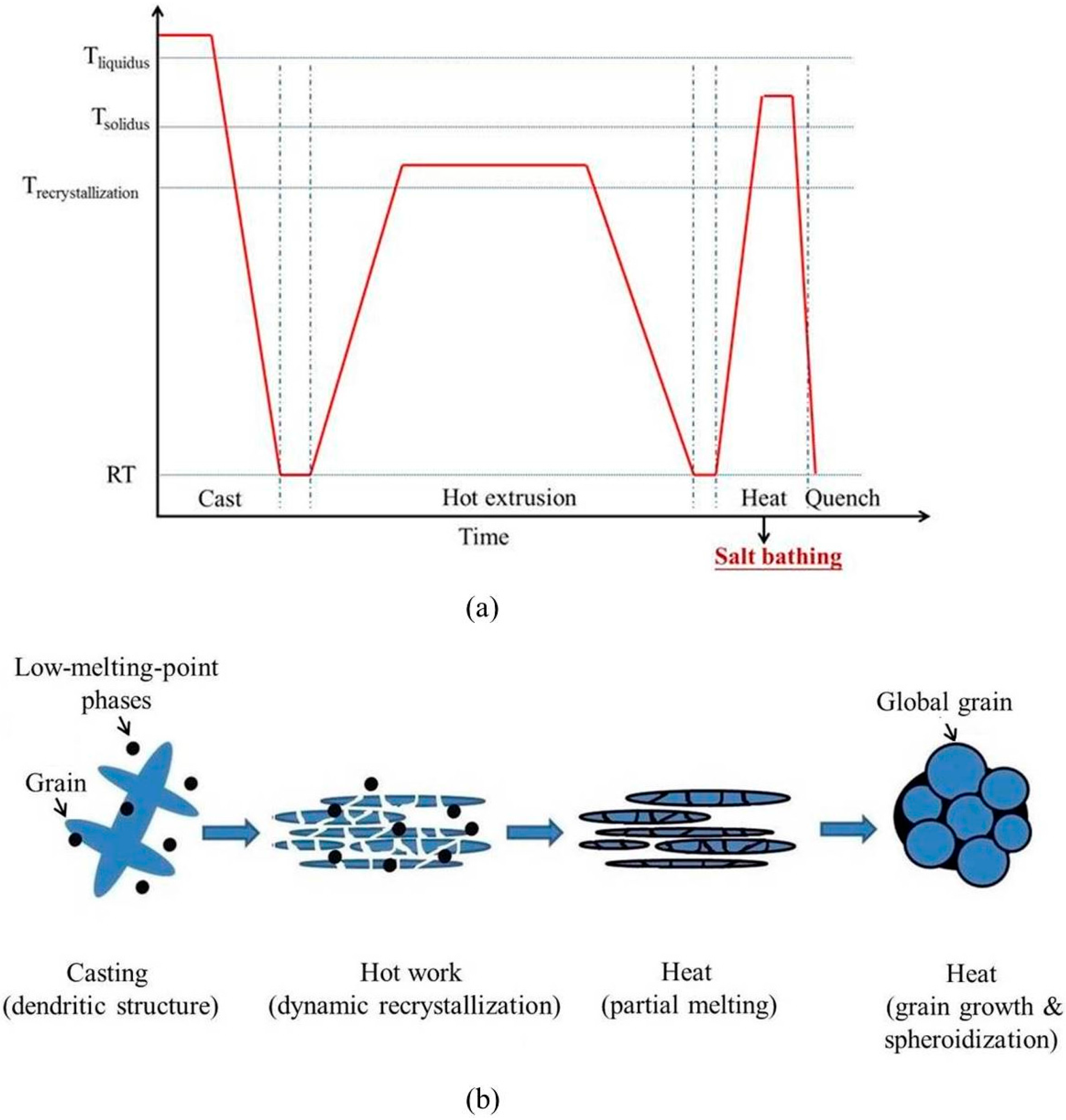

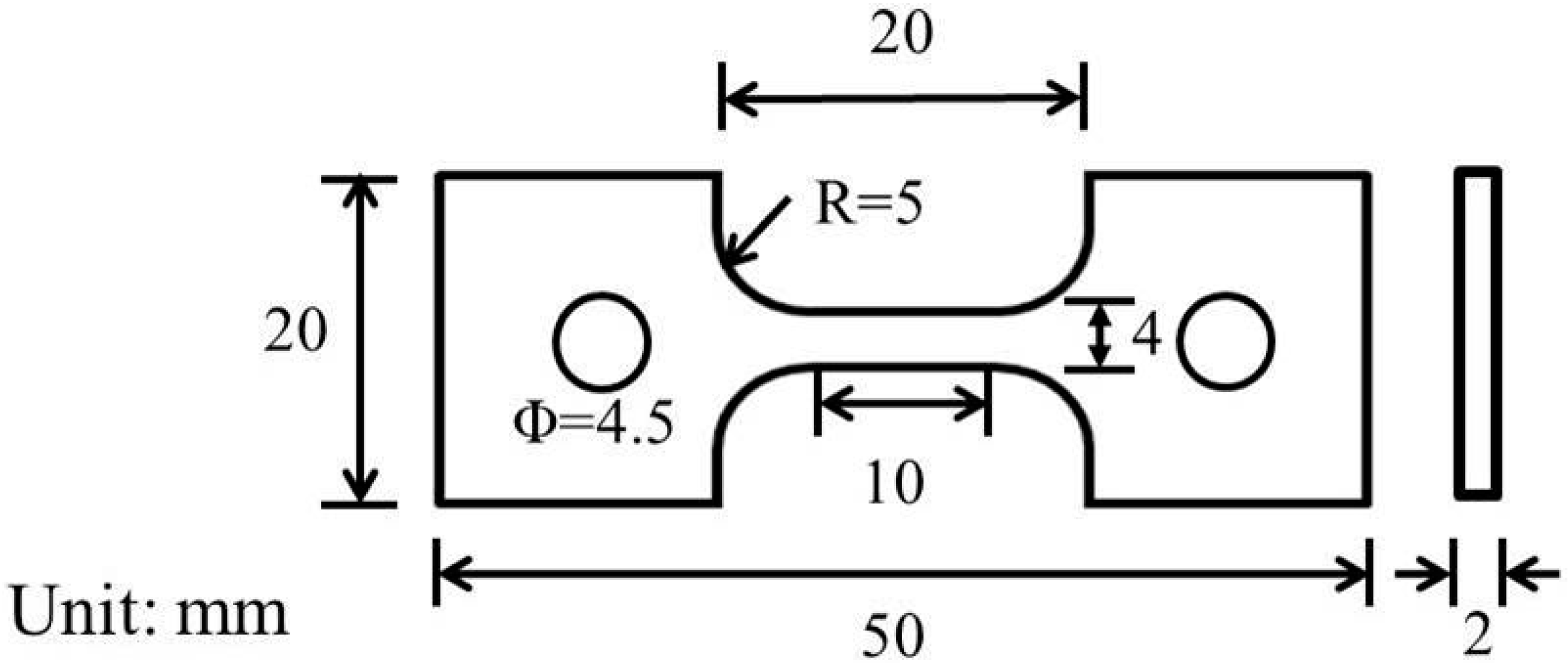

2. Materials and Methods

3. Results and Discussion

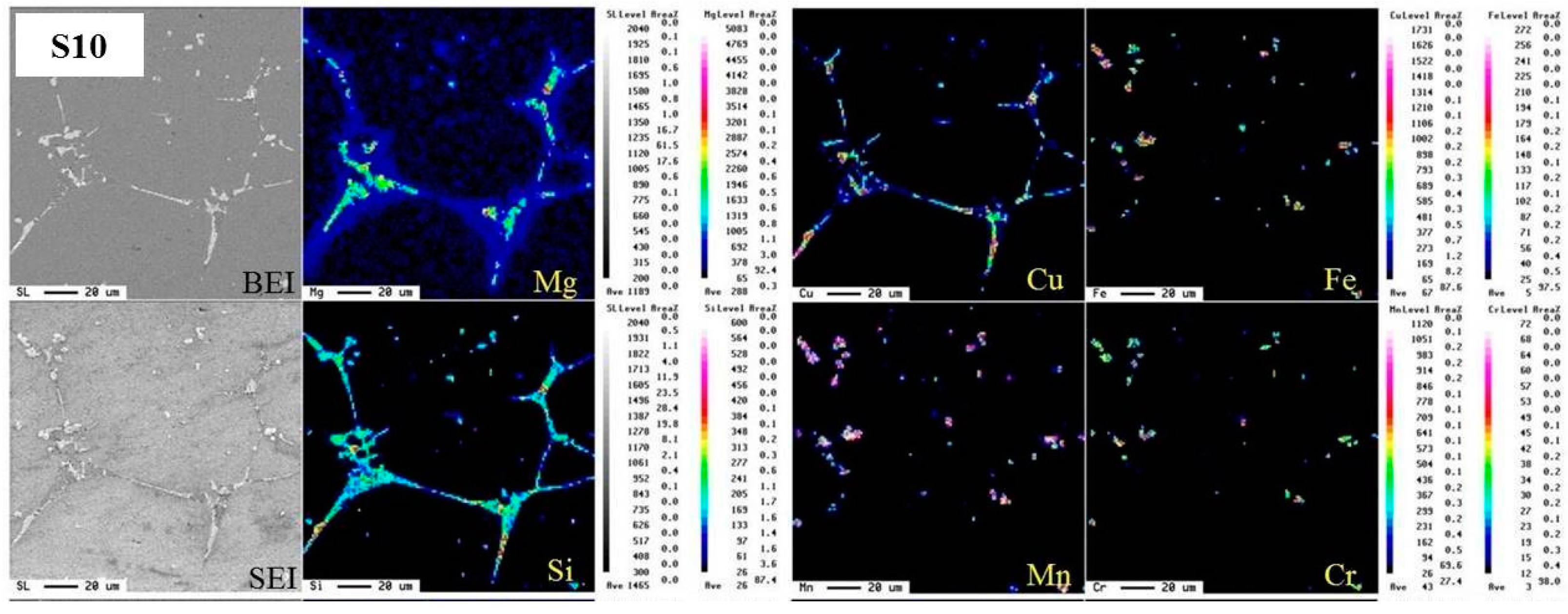

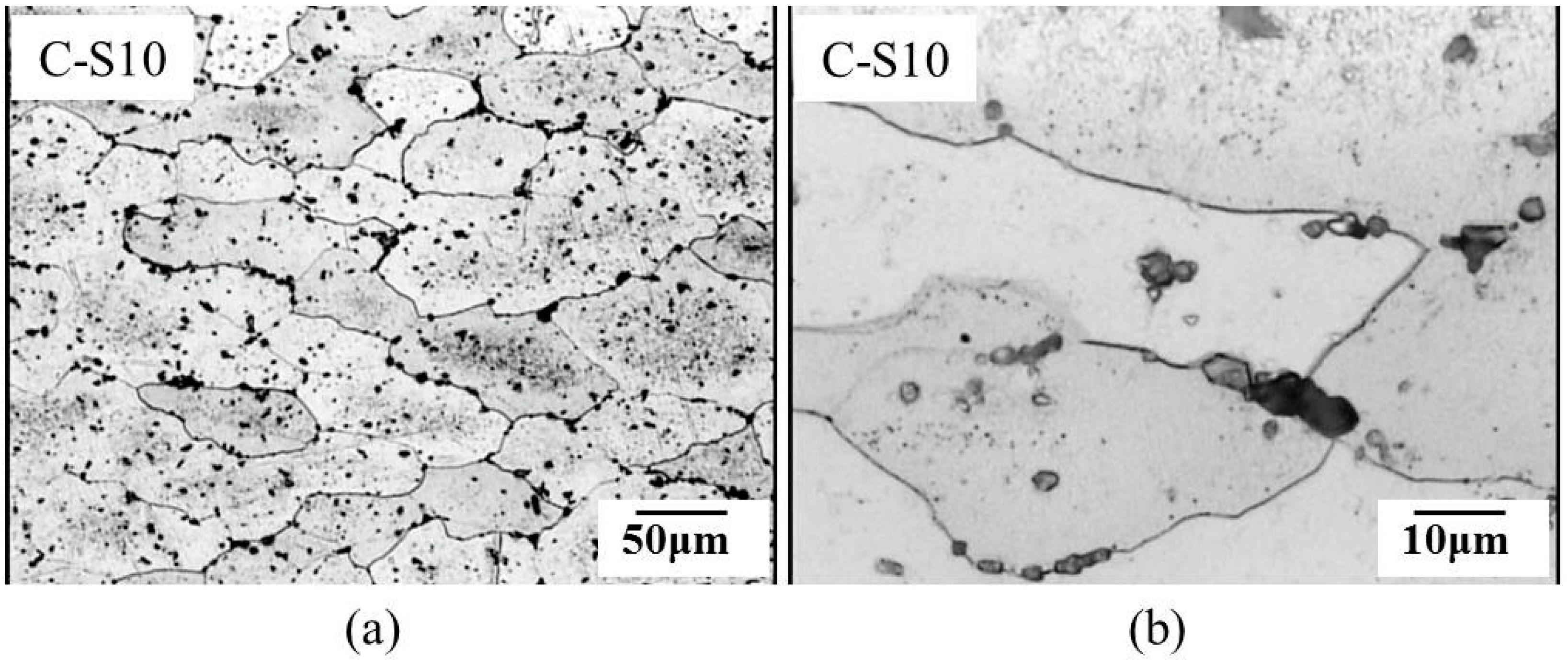

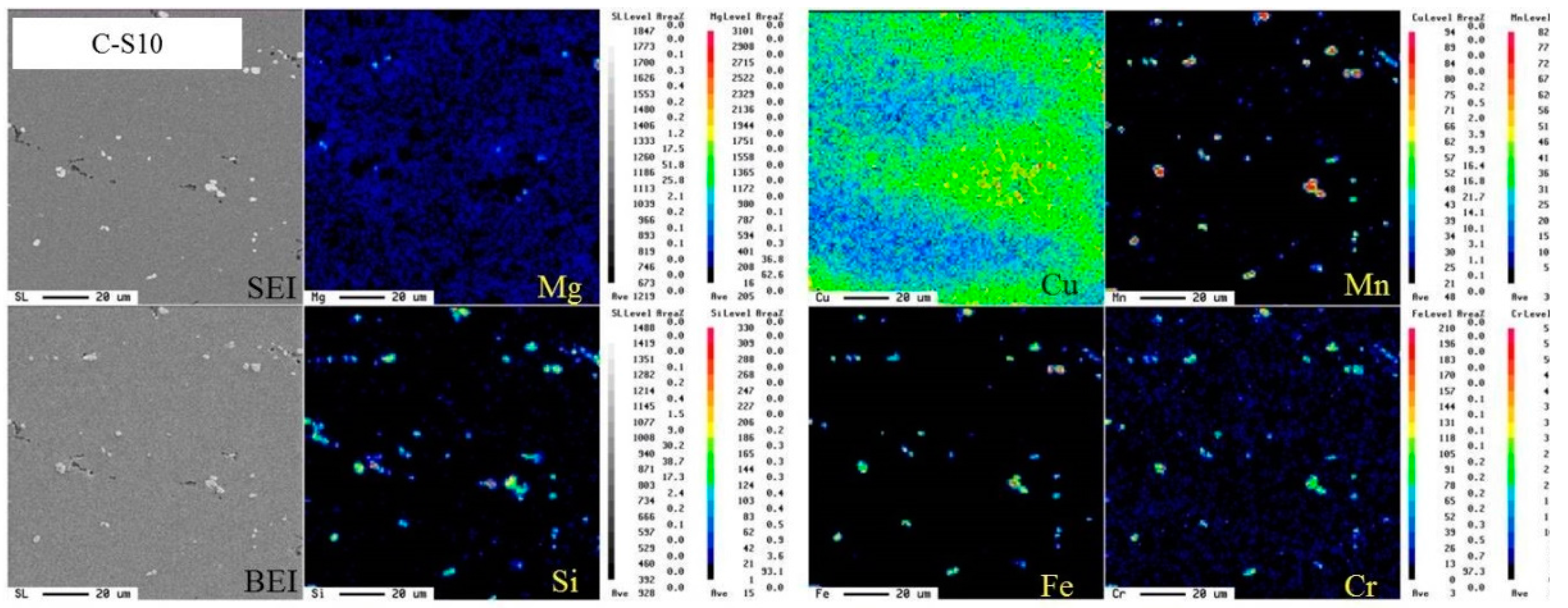

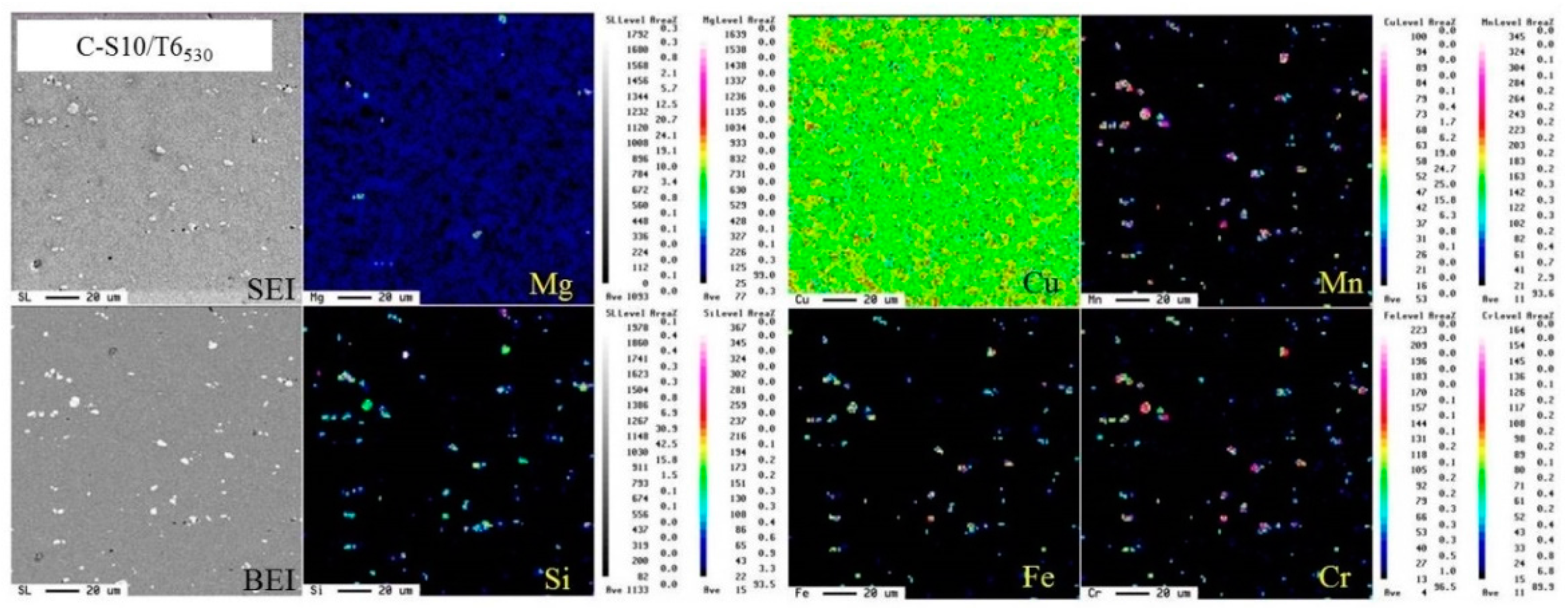

3.1. Microstructure Characteristics

3.2. High-Temperature Compressive Resistance of TS-SIMA Alloy

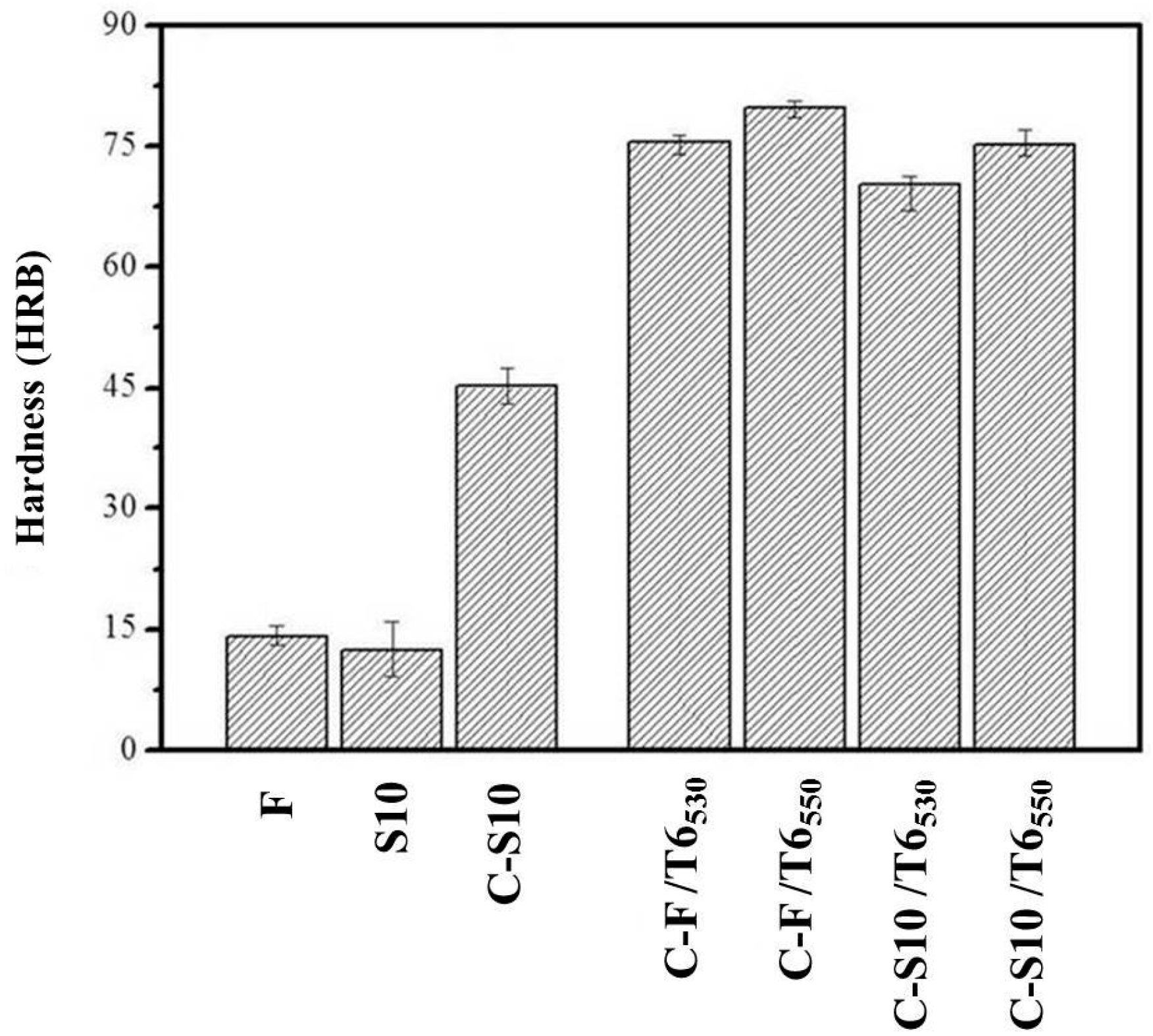

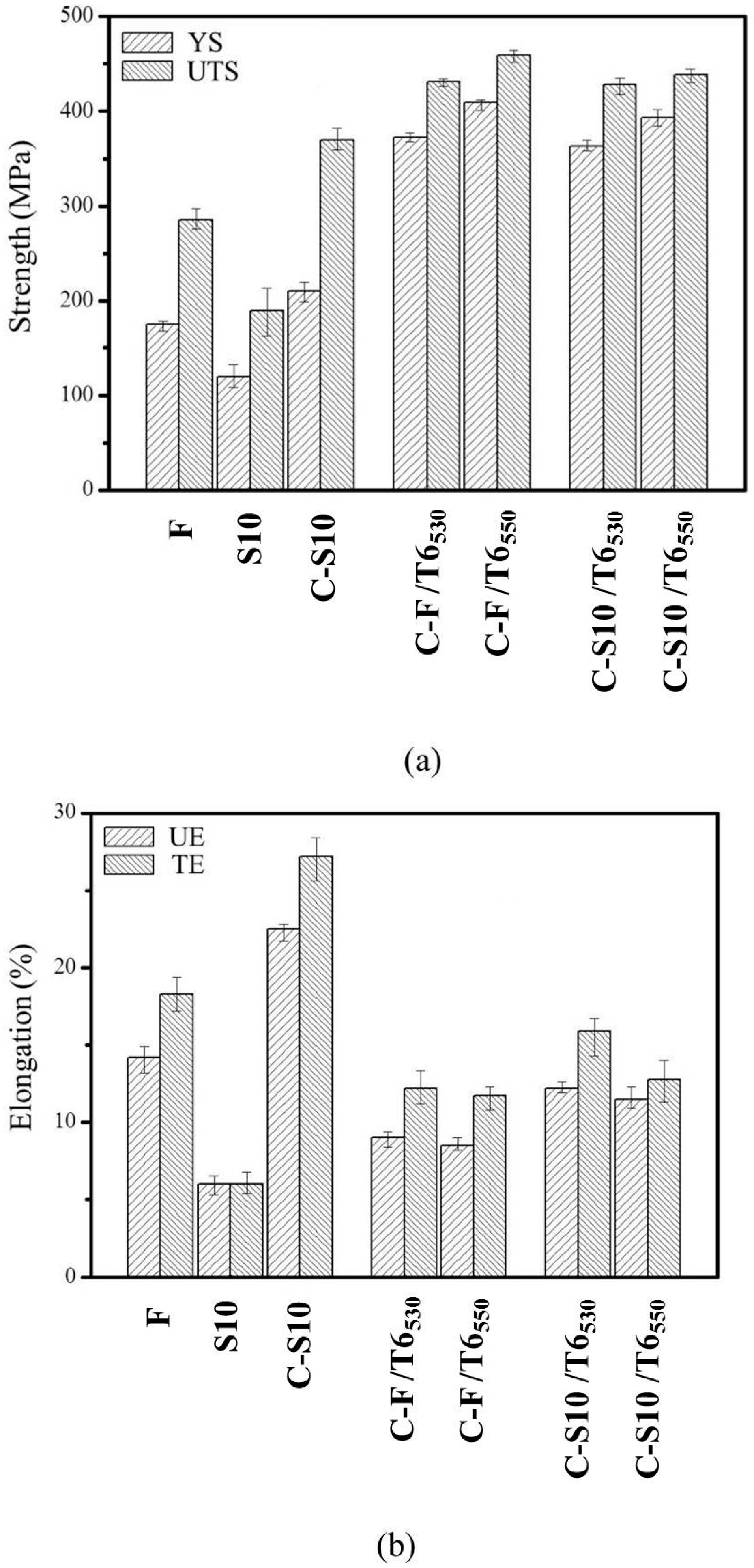

3.3. Mechanical Properties Improvement of TS-SIMA Forming Alloys

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hatch, J.E. Aluminum: Properties and Physical Metallurgy; ASM International: Materials Park, OH, USA, 1984; Volume 1, p. 50. [Google Scholar]

- Zhen, L.; Fei, W.D.; Kang, S.B.; Kim, H.W. Precipitation behavior of Al-Mg-Si alloys with high silicon content. J. Mater. Sci. 1997, 32, 1895–1902. [Google Scholar]

- Fan, Z. Semisolid metal processing. Int. Mater. Rev. 2002, 47, 49–85. [Google Scholar] [CrossRef]

- Song, Y.B.; Park, K.T.; Hong, C.P. Recrystallization behavior of 7175 Al alloy during modified strain-induced melt-activated (SIMA) process. Mater. Trans. 2006, 47, 1250–1256. [Google Scholar] [CrossRef]

- Tzimas, E.; Zavaliangos, A. A comparative characterization of near-equiaxed microstructures as produced by spray casting, magnetohydrodynamic casting and the stress induced, melt activated process. Mater. Sci. Eng. A 2000, 289, 217–227. [Google Scholar] [CrossRef]

- Paes, M.; Zoqui, E.J. Semi-solid Behavior of New Al-Si-Mg Alloys for Thixoforming. Mater. Sci. Eng. A 2005, 406, 63–73. [Google Scholar] [CrossRef]

- Parshizfard, E.; Shabestari, S.G. An investigation on the microstructural evolution and mechanical properties of A380 aluminum alloy during SIMA process. J. Alloy. Compd. 2011, 509, 9654–9658. [Google Scholar] [CrossRef]

- Akhlaghi1, F.; Farhood, A.H.S. Characterization of globular microstructure in NMS processed aluminum A356 alloy: The role of casting size. Adv. Mater. Res. 2011, 264–265, 1868–1877. [Google Scholar] [CrossRef]

- Tzimas, E.; Zavaliangos, A. Evolution of near-equiaxed microstructure in the semisolid state. Mater. Sci. Eng. A 2000, 289, 228–240. [Google Scholar] [CrossRef]

- Emamy, M.; Razaghian, A.; Karshenas, M. The effect of strain-induced melt activation process on the microstructure and mechanical properties of Ti-refined A6070 Al alloy. Mater. Des. 2013, 46, 824–836. [Google Scholar] [CrossRef]

- Lin, C.W.; Hung, F.Y.; Lui, T.S. High-temperature deformation resistance and forming behavior of two-step SIMA-processed 6066 alloy. Mater. Sci. Eng. A 2016, 659, 143–157. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, S.; Lim, K.R.; Hing, S.H.; Kim, K.B.; Na, Y.S. Crystallization, High temperature defroemation behavior and solid-to-solid formability of a Ti-based bulk metallic glass within supercooled liquid region. J. Alloy. Compd. 2016, 663, 270–278. [Google Scholar] [CrossRef]

- ASM International Alloy Phase Diagram and the Handbook Committees. ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 3, pp. 307–308. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel. Proc. Phys. Soc. 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Int. 1953, 174, 25–28. [Google Scholar]

| Element | Mg | Si | Cu | Mn | Fe | Cr | Al |

|---|---|---|---|---|---|---|---|

| Mass % | 1.02 | 1.29 | 0.98 | 1.02 | 0.19 | 0.18 | Bal. |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-W.; Hung, F.-Y.; Lui, T.-S. High-Temperature Compressive Resistance and Mechanical Properties Improvement of Strain-Induced Melt Activation-Processed Al-Mg-Si Aluminum Alloy. Metals 2016, 6, 183. https://doi.org/10.3390/met6080183

Lin C-W, Hung F-Y, Lui T-S. High-Temperature Compressive Resistance and Mechanical Properties Improvement of Strain-Induced Melt Activation-Processed Al-Mg-Si Aluminum Alloy. Metals. 2016; 6(8):183. https://doi.org/10.3390/met6080183

Chicago/Turabian StyleLin, Chia-Wei, Fei-Yi Hung, and Truan-Sheng Lui. 2016. "High-Temperature Compressive Resistance and Mechanical Properties Improvement of Strain-Induced Melt Activation-Processed Al-Mg-Si Aluminum Alloy" Metals 6, no. 8: 183. https://doi.org/10.3390/met6080183

APA StyleLin, C.-W., Hung, F.-Y., & Lui, T.-S. (2016). High-Temperature Compressive Resistance and Mechanical Properties Improvement of Strain-Induced Melt Activation-Processed Al-Mg-Si Aluminum Alloy. Metals, 6(8), 183. https://doi.org/10.3390/met6080183