The Evolution of Microstructures and the Properties of Bulk Metallic Glass with Consubstantial Composition Laser Welding

Abstract

:1. Introduction

2. Experimental Procedures

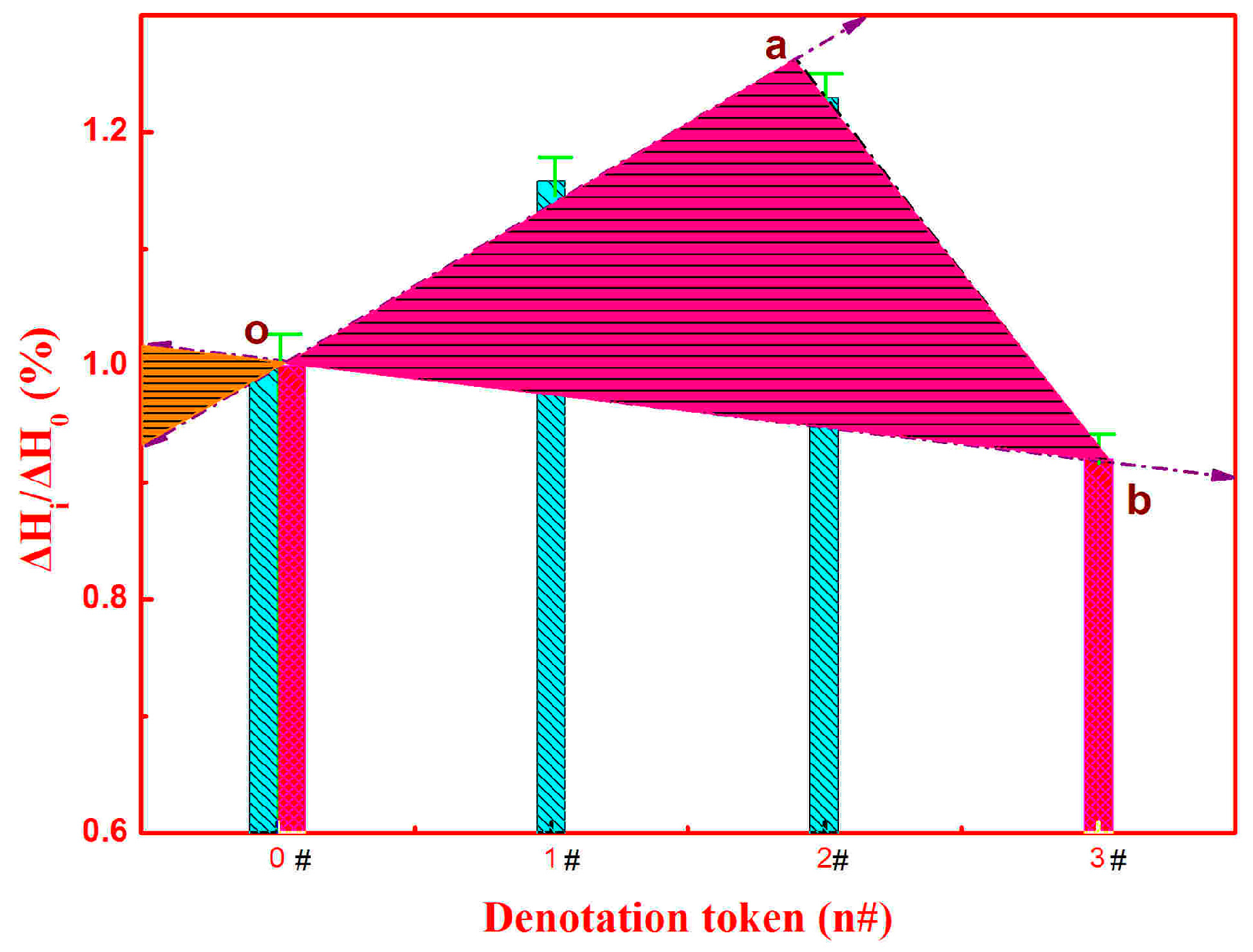

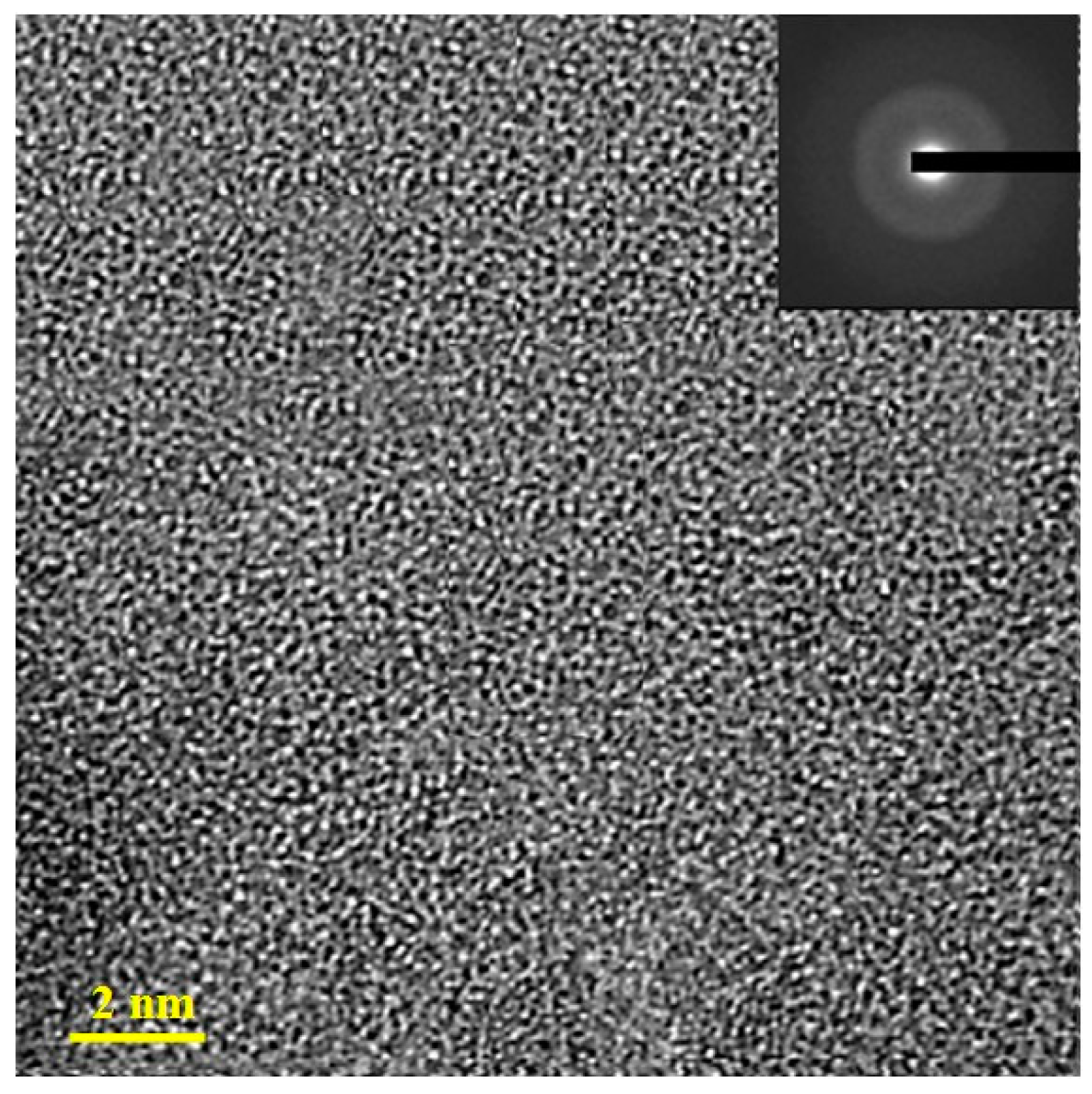

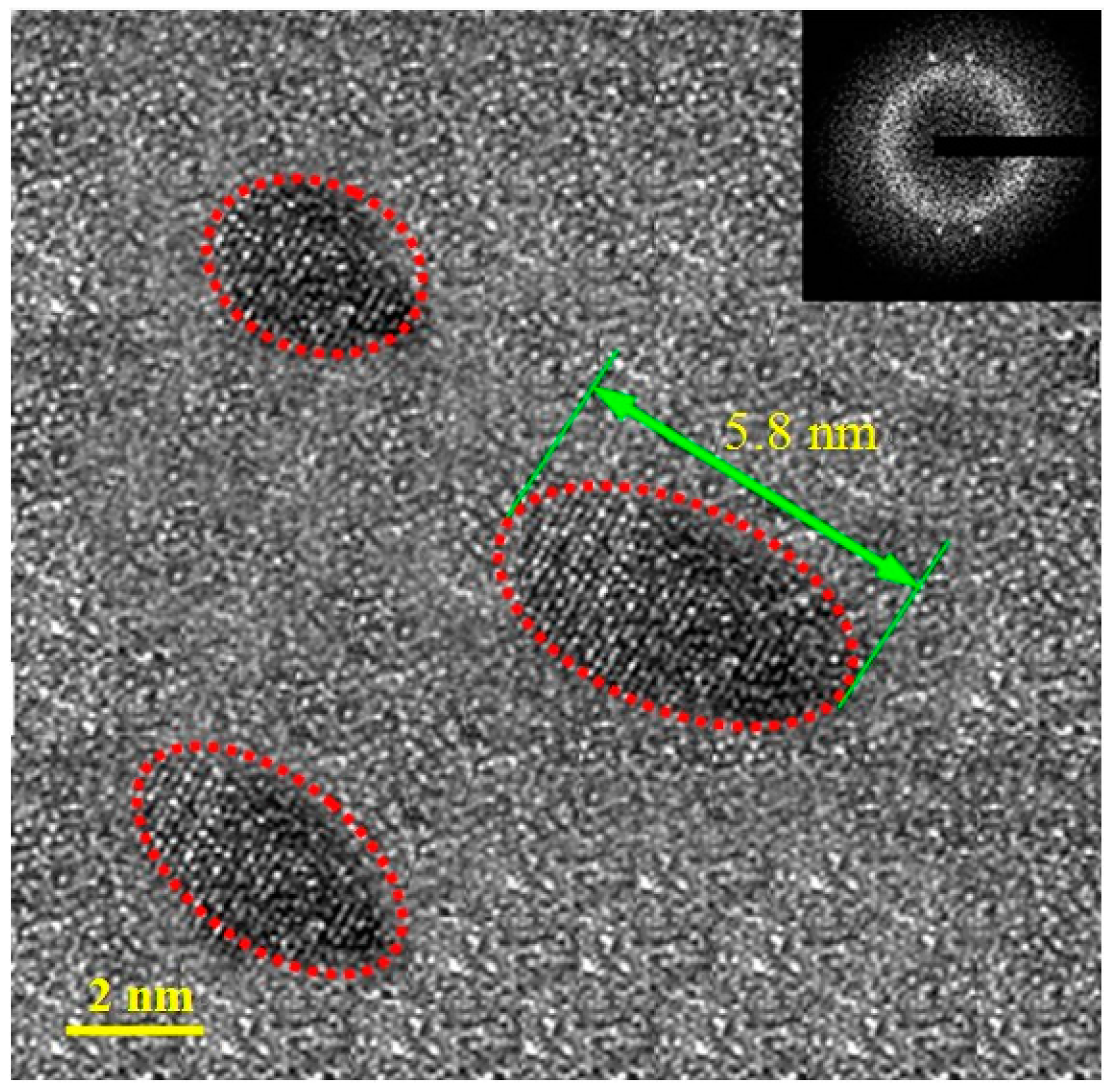

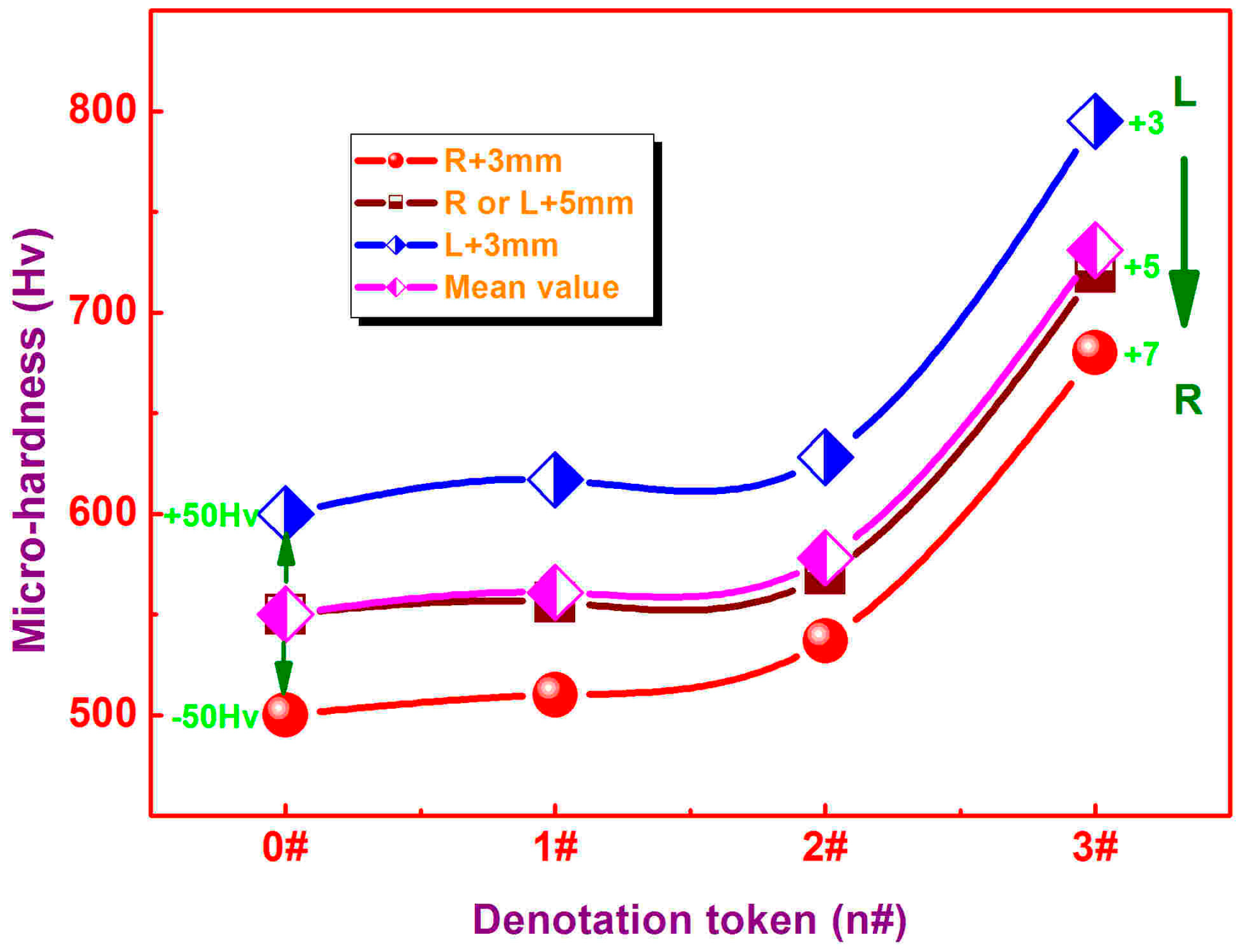

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kuwabara, J.; Yasuda, T.; Takase, N.; Kanbara, T. Effects of the Terminal Structure, Purity, and Molecular Weight of an Amorphous Conjugated Polymer on Its Photovoltaic Characteristics. ACS Appl. Mater. Interfaces 2016, 8, 1752–1758. [Google Scholar] [CrossRef] [PubMed]

- Prutsch, D.; Wilkening, M.; Hanzu, I. Long-Cycle-Life Na-Ion Anodes Based on Amorphous Titania Nanotubes-Interfaces and Diffusion. ACS Appl. Mater. Interfaces 2015, 7, 25757–25769. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk Metallic Glasses. Mater. Sci. Eng. R 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Gordon, L.M.; Cohen, M.J.; MacRenaris, K.W.; Pasteris, J.D.; Seda, T.; Joester, D. Amorphous Intergranular Phases Control the Properties of Rodent Tooth Enamel. Science 2015, 347, 746–750. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wu, C.-Y.; Franke, G. Effectiveness of Amorphous Silica Encapsulation Technology on Welding Fume Particles and Its Impact on Mechanical Properties of Welds. Mater. Des. 2014, 54, 79–86. [Google Scholar] [CrossRef]

- Fard, Z.H.; Islam, S.M.; Kanatzidis, M.G. Porous Amorphous Chalcogenides as Selective Adsorbents for Heavy Metals. Chem. Mater. 2015, 27, 6189–6192. [Google Scholar] [CrossRef]

- Pauly, S.; Gorantla, S.; Wang, G.; Kuehn, U.; Eckert, J. Transformation-mediated Ductility in CuZr-based Bulk Metallic Glasses. Nat. Mater. 2010, 9, 473–477. [Google Scholar] [CrossRef] [PubMed]

- Tao, P.J.; Yang, Y.Z.; Bai, X.J.; Mu, Z.X.; Li, G.Q.; Xie, Z.W.; Chen, X.C. Study on Implantation of Co Ions in ZrCuNiAl Bulk Metallic Glass. Surf. Coat. Technol. 2009, 203, 1656–1659. [Google Scholar] [CrossRef]

- Duan, G.; Blauwe, K.D.; Lind, M.L.; Schramm, J.P.; Johnson, W.L. Compositional Dependence of Thermal, Elastic, and Mechanical Properties in Cu-Zr-Ag Bulk Metallic Glasses. Scr. Mater. 2008, 58, 159–162. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Q.; Kalb, J.A.; Thompson, C.V. Matching Glass-Forming Ability with the Density of the Amorphous Phase. Science 2008, 322, 1816–1819. [Google Scholar] [CrossRef] [PubMed]

- Singer, J.P.; Gopinadhan, M.; Shao, Z.; Taylor, A.D.; Schroers, J.; Osuji, C.O. Nanoimprinting Sub-100 nm Features in a Photovoltaic Nanocomposite using Durable Bulk Metallic Glass Molds. ACS Appl. Mater. Interfaces 2015, 7, 3456–3461. [Google Scholar] [CrossRef] [PubMed]

- Shahabi, H.S.; Scudino, S.; Kaban, I.; Stoica, M.; Rütt, U.; Kühn, U.; Eckert, J. Structural Aspects of Elasto-plastic Deformation of a Zr-based Bulk Metallic Glass under Uniaxial Compression. Acta Mater. 2015, 95, 30–36. [Google Scholar] [CrossRef]

- Granata, D.; Fischer, E.; Loffler, J.F. Effectiveness of Hydrogen Microalloying in Bulk Metallic Glass Design. Acta Mater. 2015, 99, 415–421. [Google Scholar] [CrossRef]

- Epp, V.; Ma, Q.L.; Hammer, E.M.; Tietz, F.; Wilkening, M. Very Fast Bulk Li Ion Diffusivity in Crystalline Li1.5Al0.5Ti1.5(PO4)3 as Seen Using NMR Relaxometry. Phys. Chem. Chem. Phys. 2015, 17, 32115–32121. [Google Scholar] [CrossRef] [PubMed]

- Ratzke, K.; Zollmer, V.; Bartsch, A.; Meyer, A.; Faupel, F. Diffusion in Bulk-metallic Glass-forming Pd-Cu-Ni-P alloys: From the Glass to the Equilibrium Melt. J. Non-Cryst. Solids 2007, 353, 3285–3289. [Google Scholar] [CrossRef]

- Jin, K.; Loffler, J.F. Bulk metallic glass formation in Zr-Cu-Fe-Al alloys. Appl. Phys. Lett. 2005. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, T.; Nishiyama, N.; Ohba, K.; Masumoto, T. Preparation of 16 mm Diameter Rod of Amorphous Zr65Al7.5Ni10Cu17.5 Alloy. Mater. Trans. 1993, 34, 1234–1237. [Google Scholar] [CrossRef]

- Tao, P.; Yang, Y. Effect of Aspect-ratio Alterations on Plastic-deformation-behavior of a Large-plastic Bulk Metallic Glass. Mater. Des. 2015, 73, 10–14. [Google Scholar] [CrossRef]

- Wang, H.S.; Chiou, M.S.; Chen, H.G.; Jang, J.S.C. The effects of Initial Welding Temperature and Welding Parameters on the Crystallization Behaviors of Laser Spot Welded Zr-based Bulk Metallic Glass. Mater. Chem. Phys. 2011, 129, 547–552. [Google Scholar] [CrossRef]

- Shin, H.S.; Park, J.S.; Jung, Y.C.; Ahn, J.H.; Yokoyama, Y.; Inoue, A. Similar and Dissimilar Friction Welding of Zr-Cu-Al Bulk Glassy Alloys. J. Alloy. Compd. 2009, 483, 182–185. [Google Scholar] [CrossRef]

- Wang, D.; Xiao, B.L.; Ma, Z.Y.; Zhang, H.F. Friction Stir Welding of Zr55Cu30Al10Ni5 Bulk Metallic Glass to Al-Zn-Mg-Cu Alloy. Scr. Mater. 2009, 60, 112–115. [Google Scholar] [CrossRef]

- Kim, J.; Kawamura, Y. Dissimilar Welding of Zr41Be23Ti14Cu12Ni10 Bulk Metallic Glass and Stainless Steel. Scr. Mater. 2011, 65, 1033–1036. [Google Scholar] [CrossRef]

- Cheung, T.L.; Shek, C.H. Thermal and mechanical properties of Cu-Zr-Al bulk metallic glasses. J. Alloy. Compd. 2007, 434–435, 71–74. [Google Scholar] [CrossRef]

- Bian, Z.; Wang, R.J.; Wang, W.H. Carbon-nanotube-reinforced Zr-based Bulk Metallic Glass Composites and Their Properties. Adv. Funct. Mater. 2004, 14, 55–63. [Google Scholar] [CrossRef]

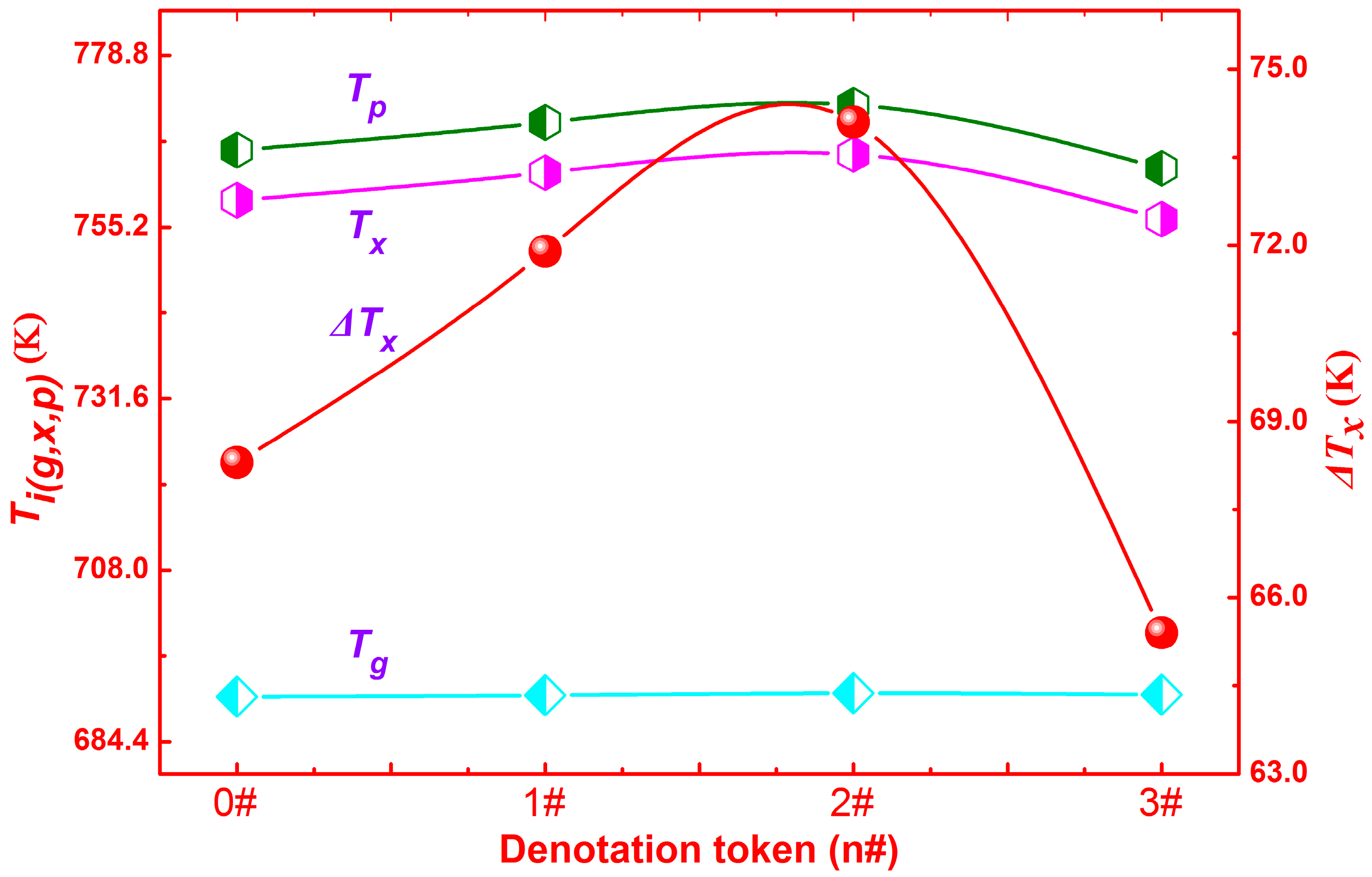

| BMG | Tg/K | Tx/K | Tp/K | ∆Tx/K |

|---|---|---|---|---|

| 0# | 690.6 | 758.9 | 765.8 | 68.3 |

| 1# | 690.8 | 762.7 | 769.6 | 71.9 |

| 2# | 691.1 | 765.2 | 772.0 | 74.1 |

| 3# | 690.9 | 756.3 | 763.3 | 65.4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, P.; Zhang, W.; Tu, Q.; Yang, Y. The Evolution of Microstructures and the Properties of Bulk Metallic Glass with Consubstantial Composition Laser Welding. Metals 2016, 6, 233. https://doi.org/10.3390/met6100233

Tao P, Zhang W, Tu Q, Yang Y. The Evolution of Microstructures and the Properties of Bulk Metallic Glass with Consubstantial Composition Laser Welding. Metals. 2016; 6(10):233. https://doi.org/10.3390/met6100233

Chicago/Turabian StyleTao, Pingjun, Wenwu Zhang, Qi Tu, and Yuanzheng Yang. 2016. "The Evolution of Microstructures and the Properties of Bulk Metallic Glass with Consubstantial Composition Laser Welding" Metals 6, no. 10: 233. https://doi.org/10.3390/met6100233