Continuous Casting of Incoloy800H Superalloy Billet under an Alternating Electromagnetic Field

Abstract

:1. Introduction

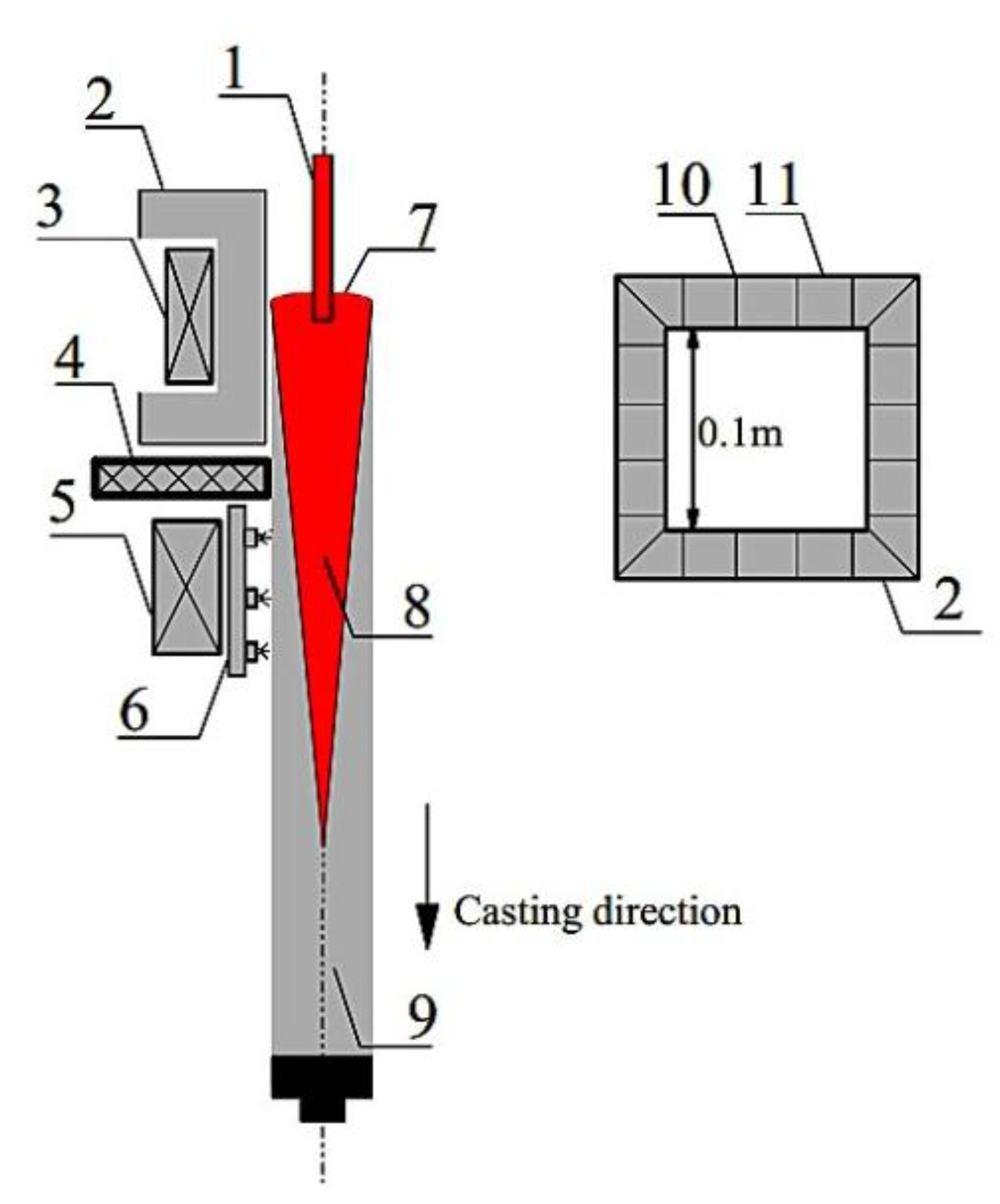

2. Experimental Procedure

| Element | Carbon | Silicon | Manganese | Phosphorus | Chromium | Nickel | Titanium | Aluminum | Iron |

|---|---|---|---|---|---|---|---|---|---|

| (C) | (Si) | (Mn) | (P) | (Cr) | (Ni) | (Ti) | (Al) | (Fe) | |

| wt. % | 0.08 | 0.52 | 0.8 | 0.023 | 20.13 | 30.88 | 0.52 | 0.28 | 46.76 |

| Parameters | Set I | Set II |

|---|---|---|

| EMCC current, A | 0 | 1310 |

| EMCC frequency, kHz | 0 | 20.4 |

| EMS current, A | 0 | 350 |

| EMS frequency, Hz | 0 | 5 |

| Casting speed, m/min | 0.6 | 0.6 |

| Mould oscillation frequency, cpm | 30 | 30 |

| Mould oscillation amplitude, m | 0.012 | 0.012 |

| Mould cooling water flow rate, m3/h | 6.4 | 6.4 |

| Secondary cooling water flow rate, m3/h | 3.0 | 3.0 |

| Mould dimension, m | 0.1 × 0.1 × 0.4 | 0.1 × 0.1 × 0.4 |

| Mould wall thickness, m | 0.03 | 0.03 |

| Slit number, - | 20 | 20 |

| Slit height, m | 0.4 | 0.4 |

| Slit width, m | 0.0005 | 0.0005 |

3. Results and Discussion

3.1. Surface Quality

3.2. Internal Quality

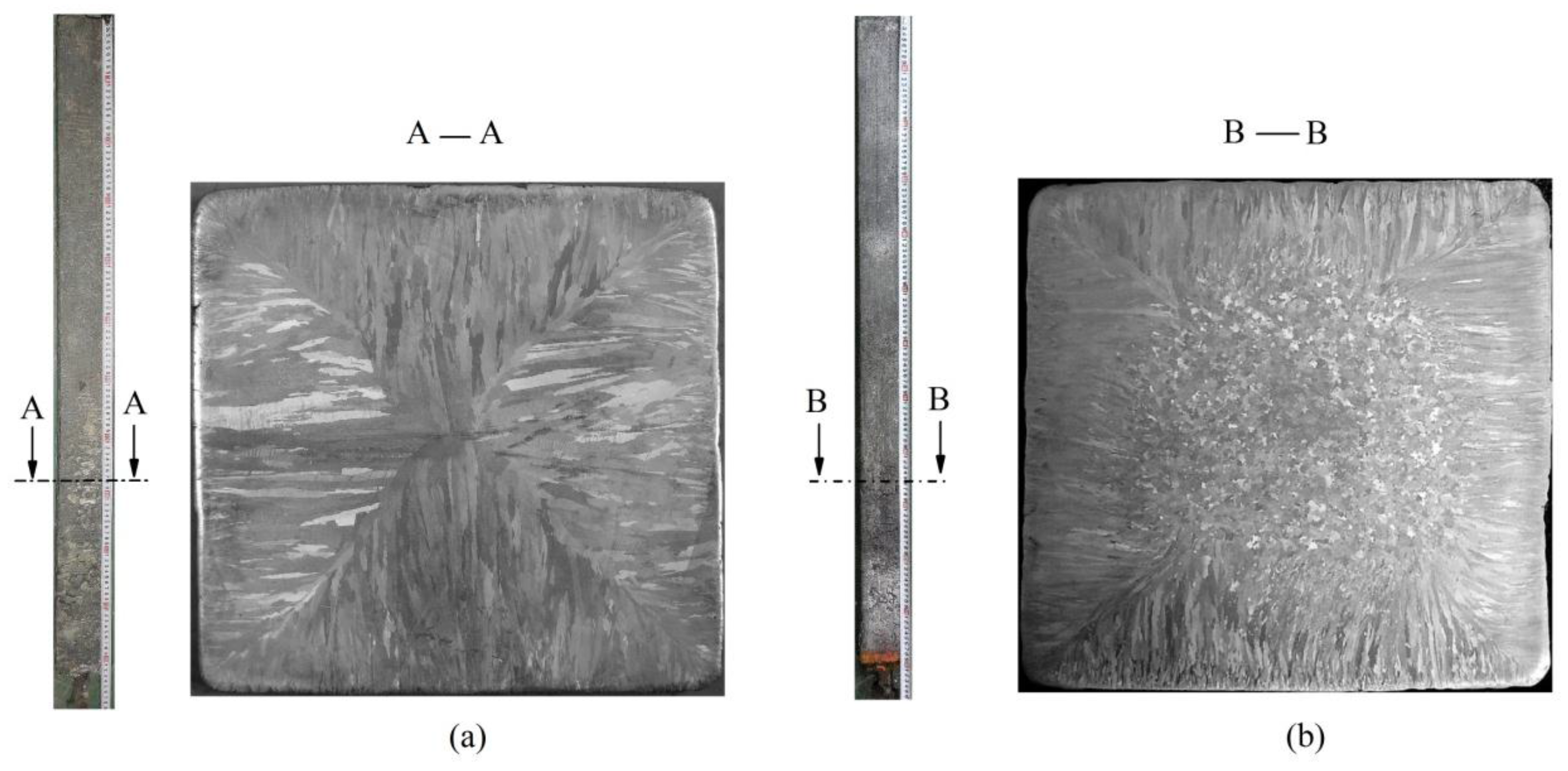

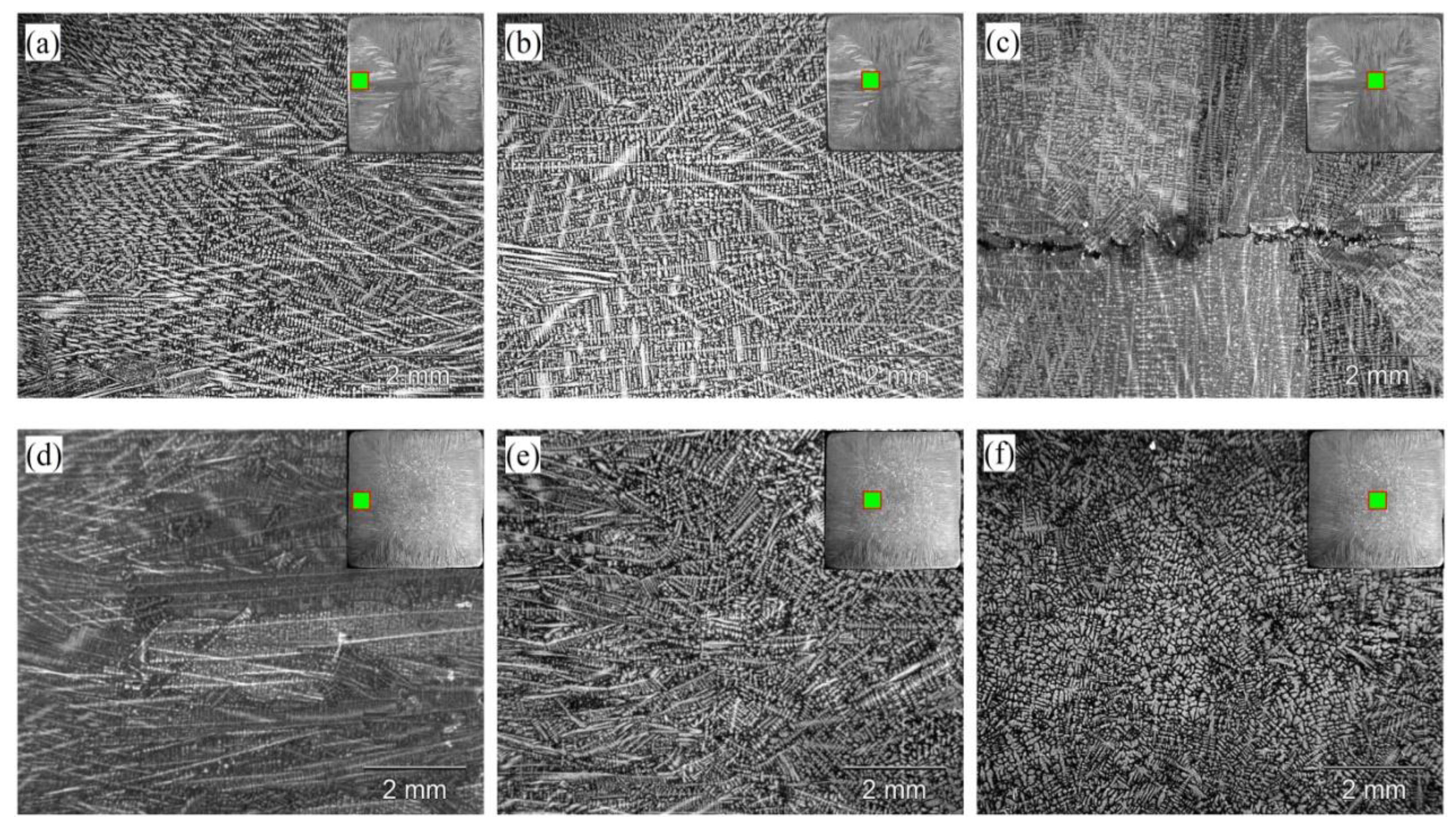

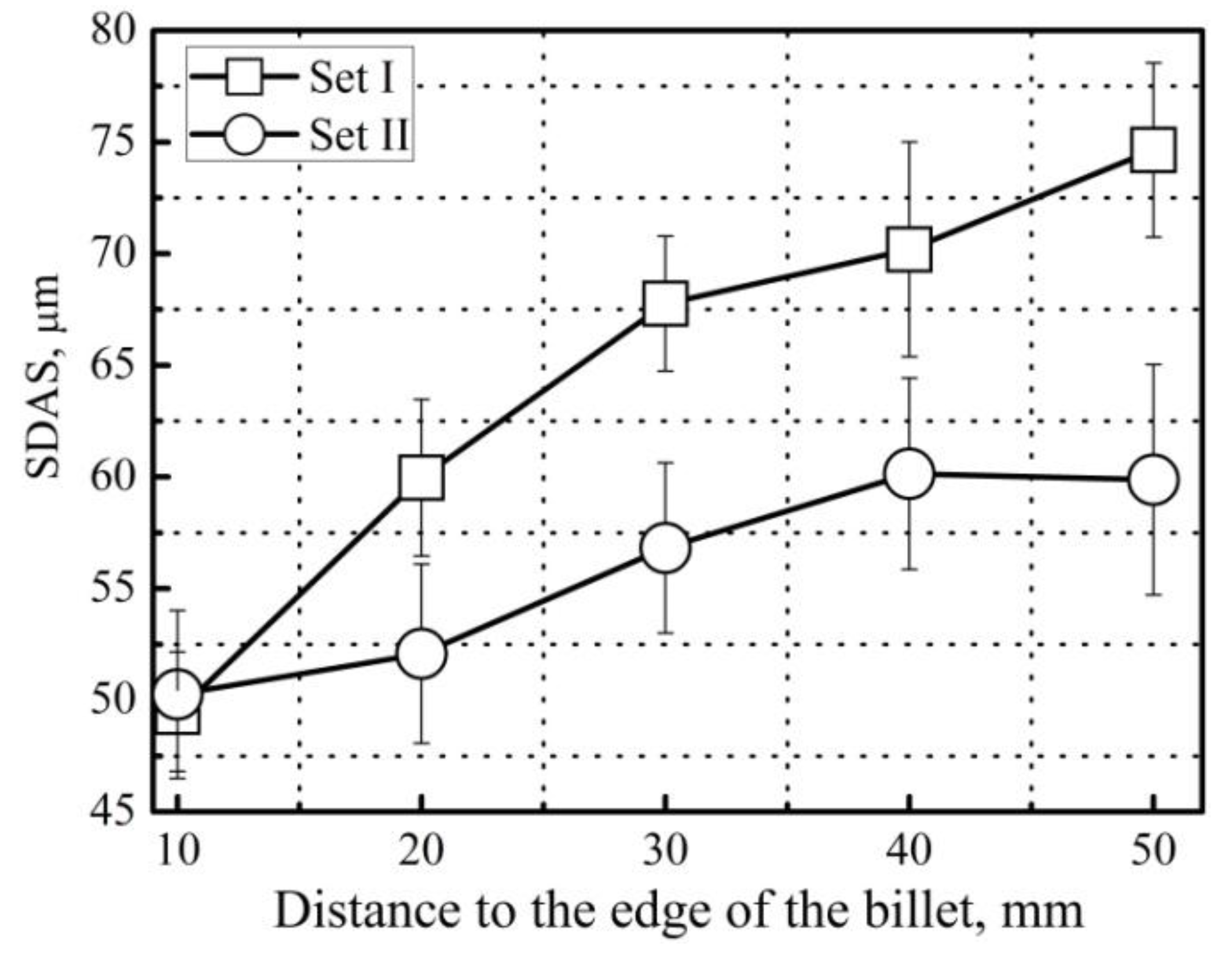

3.2.1. EMS on the Macro- and Microstructure

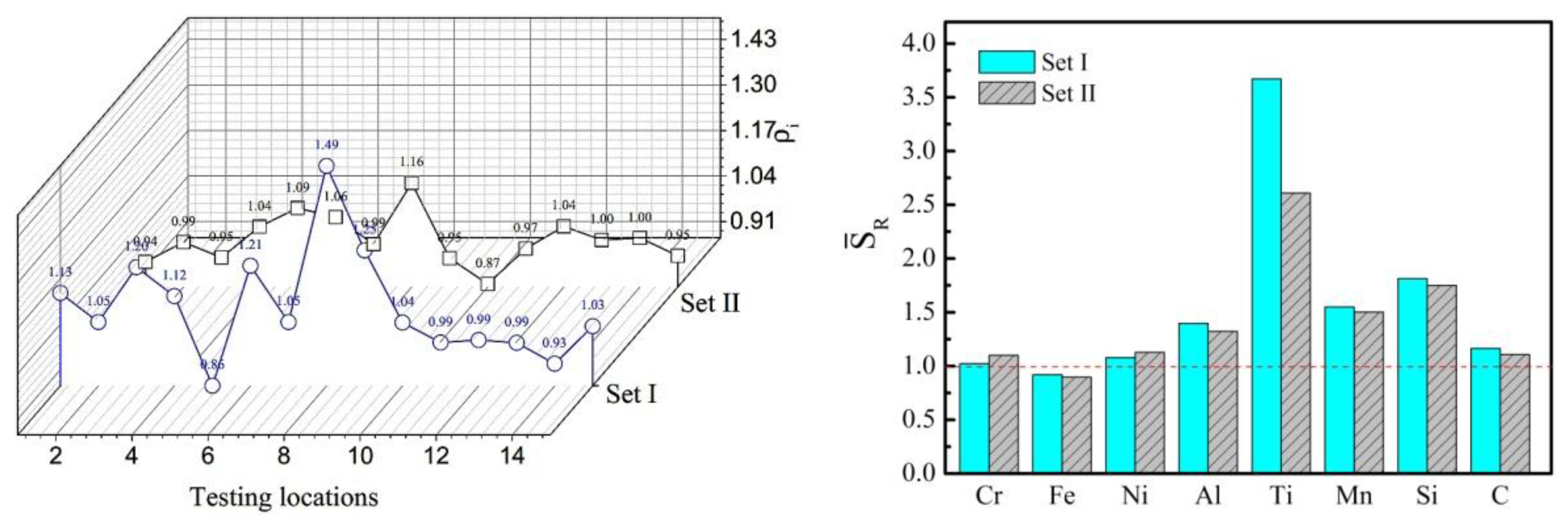

3.2.2. EMS on the Segregation

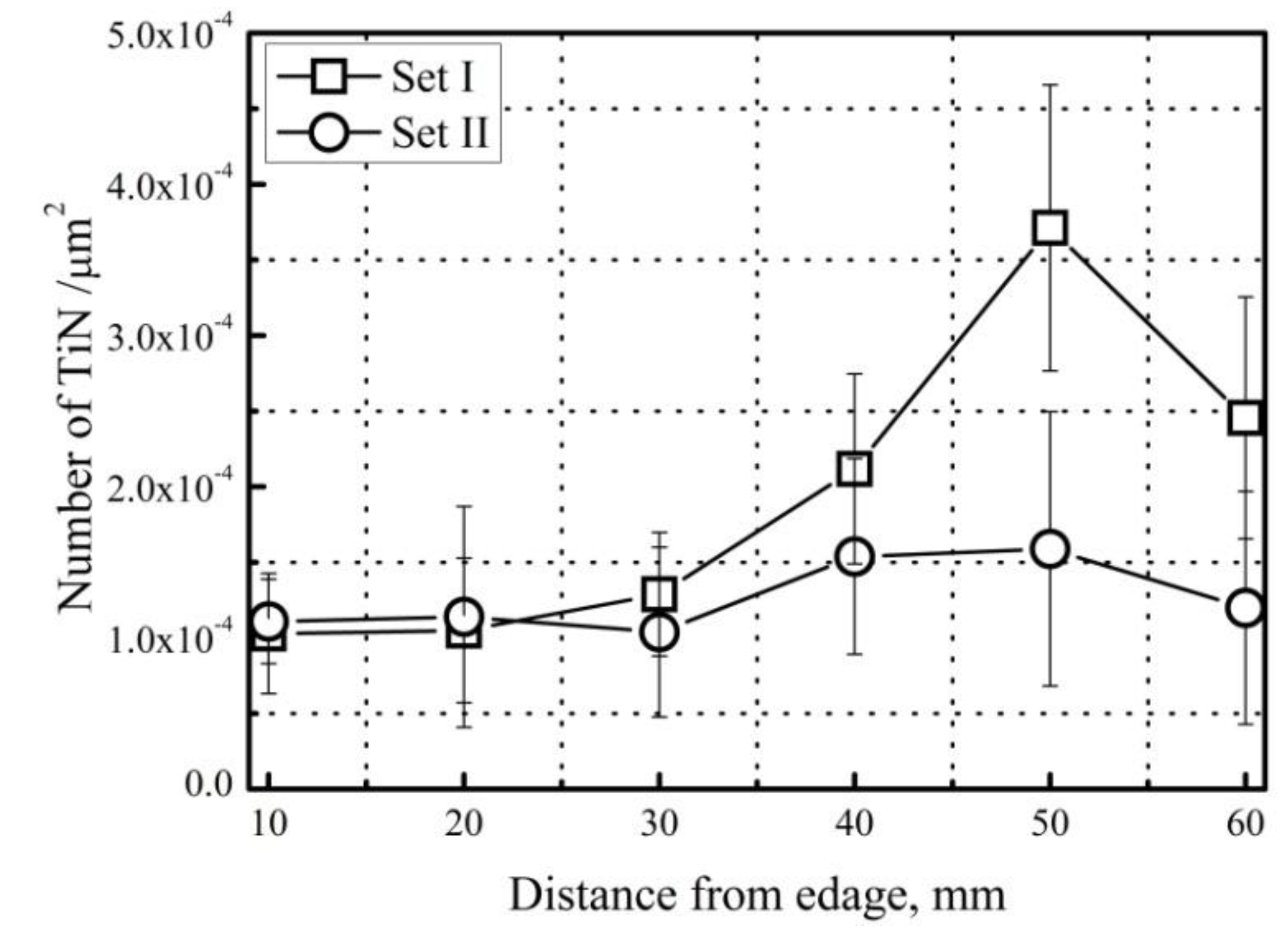

3.2.3. TiN Inclusion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tan, L.; Allen, T.T.; Yang, Y. Corrosion behavior of alloy 800H (Fe-21Cr-32Ni) in supercritical water. Corros. Sci. 2011, 53, 703–711. [Google Scholar] [CrossRef]

- Chen, W.S.; Kai, W.; Tsay, L.W.; Kai, J.J. The oxidation behavior of three different zones of welded Incoloy 800H alloy. Nucl. Eng. Design 2014, 272, 92–98. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Fang, Y.; Madigan, B.; Xu, G. Investigation of microstructures and residual stresses in laser peened Incoloy800H weldments. Opt. Laser Technol. 2014, 57, 159–164. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, S.; Wang, J.; Kelleher, J. Residual stresses determination in a 8 mm Incoloy800H weld via neutron diffraction. Mater. Design 2015, 76, 26–31. [Google Scholar] [CrossRef]

- Mizia, R.E.; Clark, D.E.; Glazoff, M.V.; Lister, T.E.; Trowbridge, T.L. Optimizing the diffusion welding process for alloy 800H: Thermodynamic, diffusion modeling, and experimental work. Metall. Mater. Trans. A 2013, 44, 154–161. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H. Research on the hot deformation behavior of a Fe-Ni-Cr alloy (800H) at temperatures above 1000 °C. J. Nucl. Mater. 2015, 465, 104–115. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.; Misra, R.D.K. The impact of aging pre-treatment on the hot deformation behavior of alloy 800H at 750 °C. J. Nucl. Mater. 2014, 452, 77–86. [Google Scholar] [CrossRef]

- Kim, D.J.; Seo, D.Y.; Tsang, J.; Yang, J.H.; Lee, J.H.; Saari, H.; Seok, C.S. The crack growth behavior of Incoloy 800H under fatigue and dwell-fatigue conditions at elevated temperature. J. Mech. Sci. Technol. 2015, 26, 2023–2027. [Google Scholar] [CrossRef]

- Tan, L.; Rakotojaona, L.; Allen, T.R.; Nanstad, R.K.; Busby, J.T. Microstructure optimization of austenitic alloy 800H (Fe-21Cr-32Ni). Mater. Sci. Eng. A 2011, 528, 2755–2761. [Google Scholar] [CrossRef]

- Akhiani, H.; Nezakat, M.; Sanayei, M.; Szpunar, J. The effect of thermo-mechanical processing on grain boundary character distribution in Incoloy 800H/HT. Mater. Sci. Eng. A 2015, 626, 51–60. [Google Scholar] [CrossRef]

- Akhiani, H.; Nezakat, M.; Sonboli, A.; Szpunar, J. The origin of annealing texture in a cold-rolled Incoloy 800H/HT after different strain paths. Mater. Sci. Eng. A 2014, 626, 334–344. [Google Scholar] [CrossRef]

- Moss, T.E.; Was, G.S. Dynamic strain aging of Nickel-base alloys 800H and 690. Metall. Mater. Trans. A 2013, 43A, 3428–3431. [Google Scholar] [CrossRef]

- Kolluri, M.; Pierick, P.T.; Bakker, T. Characterization of high temperature tensile and creep-fatigue properties of alloy 800H for intermediate heat exchanger components of (V)HTRs. Nucl. Eng. Design 2015, 284, 38–49. [Google Scholar] [CrossRef]

- Busch, J.D.; Debaraadillo, J.J.; Krane, M.J.M. Flux entrapment and Titanium Nitride defects in electroslag remelting of INCOLOY alloys 800 and 825. Metall. Mater. Trans. A 2013, 44, 5295–5303. [Google Scholar] [CrossRef]

- Kanbe, Y.; Ishii, T.; Todoroki, H.; Mizuno, K. Prevention of longitudinal cracks in a continuously cast slab of Fe-Cr-Ni superalloy containing Al and Ti. Int. J. Cast Met. Res. 2009, 22, 143–148. [Google Scholar] [CrossRef]

- Todoroki, H.; Ishii, T.; Mizuno, K.; Hongo, A. Effect of crystallization behavior of mold flux on slab surface quality of a Ti-bearing Fe-Cr-Ni super alloy cast by means of continuous casing process. Mater. Sci. Eng. 2005, 413–414, 121–128. [Google Scholar] [CrossRef]

- Park, J.P.; Kim, M.G.; Yoon, U.S.; Kim, W.J. Microstructures and mechanical properties of Ma-Al-Zn-Ca alloys fabricated by high frequency electromagnetic casting method. J. Mater Sci. 2009, 44, 47–54. [Google Scholar] [CrossRef]

- Jin, W.; Li, T.; Yin, G. Research on vacuum-electromagnetic casting of IN100 superalloy ingots. Sci. Technol. Adv. Mater. 2007, 8, 1–4. [Google Scholar] [CrossRef]

- Jiang, E.; Wang, E.; Deng, A. Experimental research on solidification structure of alloy 800H by linear electromagnetic stirring. China Foundry 2014, 11, 475–480. [Google Scholar]

- Vives, C. Electromagnetic refining of aluminum alloy by the CREM process: Part I. working principle and metallurgical results. Metall. Mater. Trans. B 1988, 20B, 623–629. [Google Scholar] [CrossRef]

- Moffatt, H.K. Electromagnetic stirring. Phys. Fluids 1991, 3, 1336–1343. [Google Scholar] [CrossRef]

- Shepherd, B.F. The P-F Characteristic of Steel. Trans. Am. Soc. Met. 1934, 22, 979–1016. [Google Scholar]

- Scheidegger, A.E. The Physics of Flow Through Porous Media, 3rd ed.; University of Toronto Press: Toronto, ON, Canada, 1974. [Google Scholar]

- Poirier, D.R. Permeability for flow of interdendritic liquid in columnar-dendritic alloys. Metall. Mater. Trans. B 1987, 8, 245–255. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhang, L.; Deng, A.; Xu, X.; Wang, E. Continuous Casting of Incoloy800H Superalloy Billet under an Alternating Electromagnetic Field. Metals 2016, 6, 2. https://doi.org/10.3390/met6010002

Wang F, Zhang L, Deng A, Xu X, Wang E. Continuous Casting of Incoloy800H Superalloy Billet under an Alternating Electromagnetic Field. Metals. 2016; 6(1):2. https://doi.org/10.3390/met6010002

Chicago/Turabian StyleWang, Fei, Lintao Zhang, Anyuan Deng, Xiujie Xu, and Engang Wang. 2016. "Continuous Casting of Incoloy800H Superalloy Billet under an Alternating Electromagnetic Field" Metals 6, no. 1: 2. https://doi.org/10.3390/met6010002