Effect of Cold Rolling and Heat Treatment on the Mechanical Properties of GH4169 Alloy Sheet at Room Temperature

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

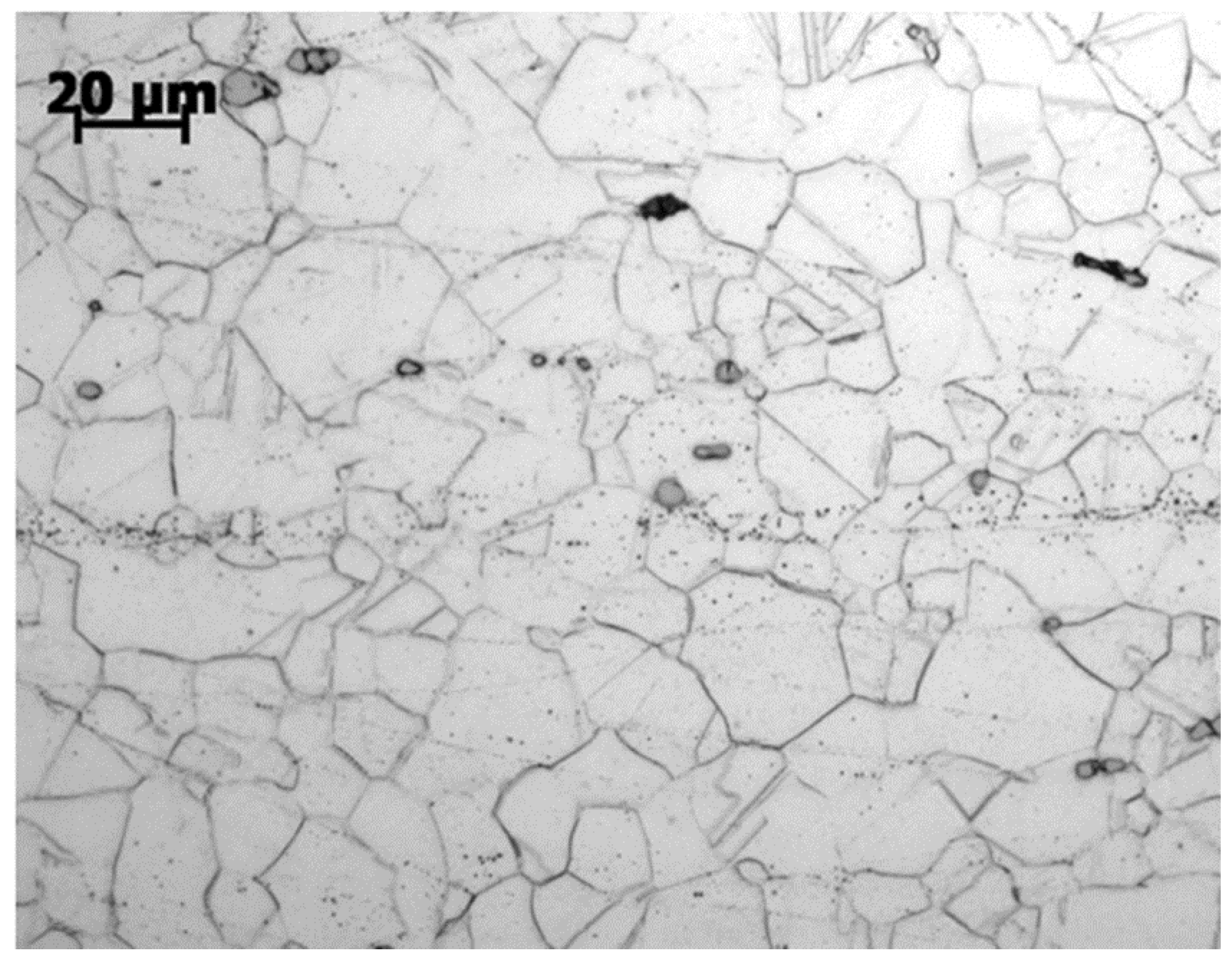

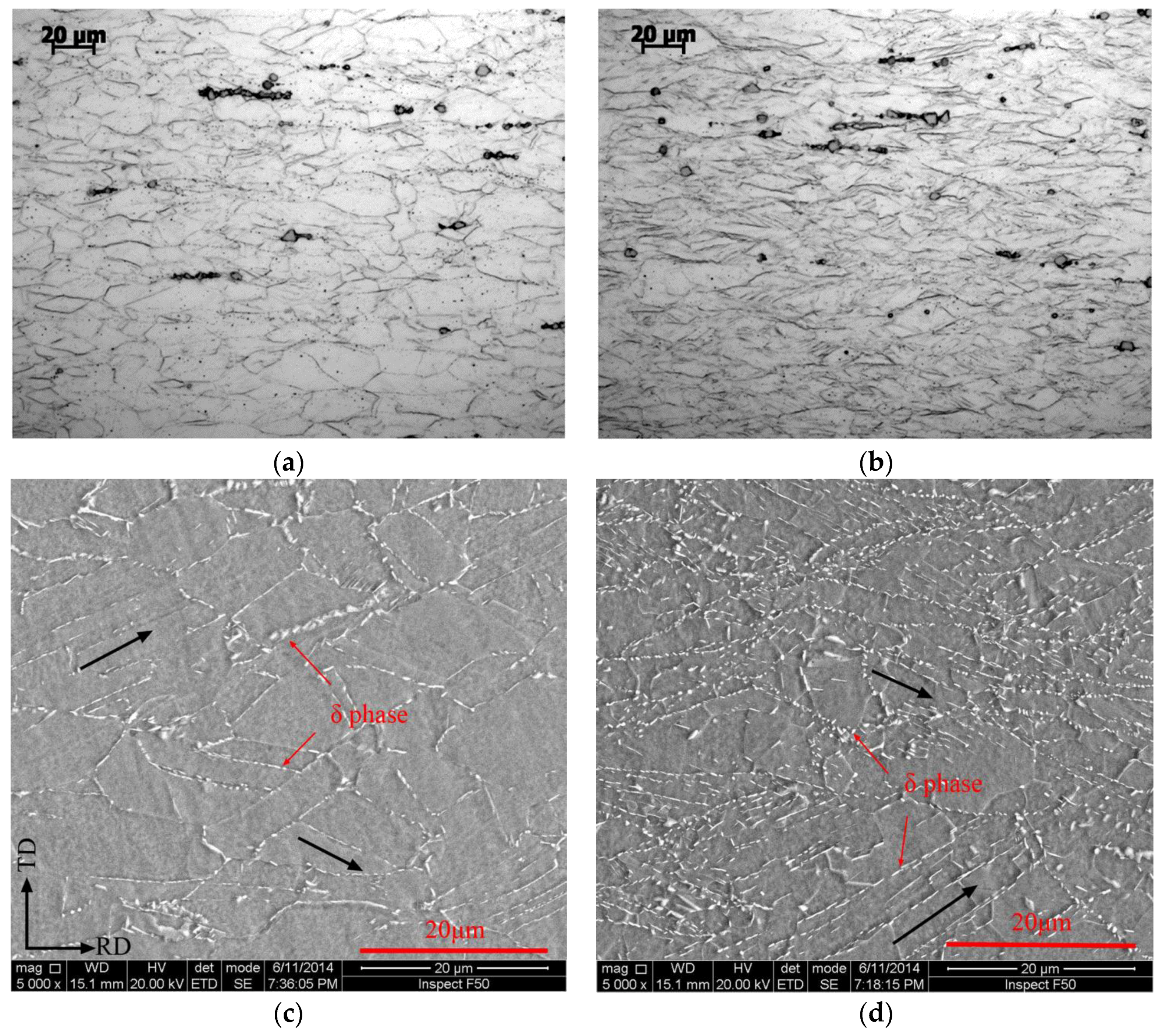

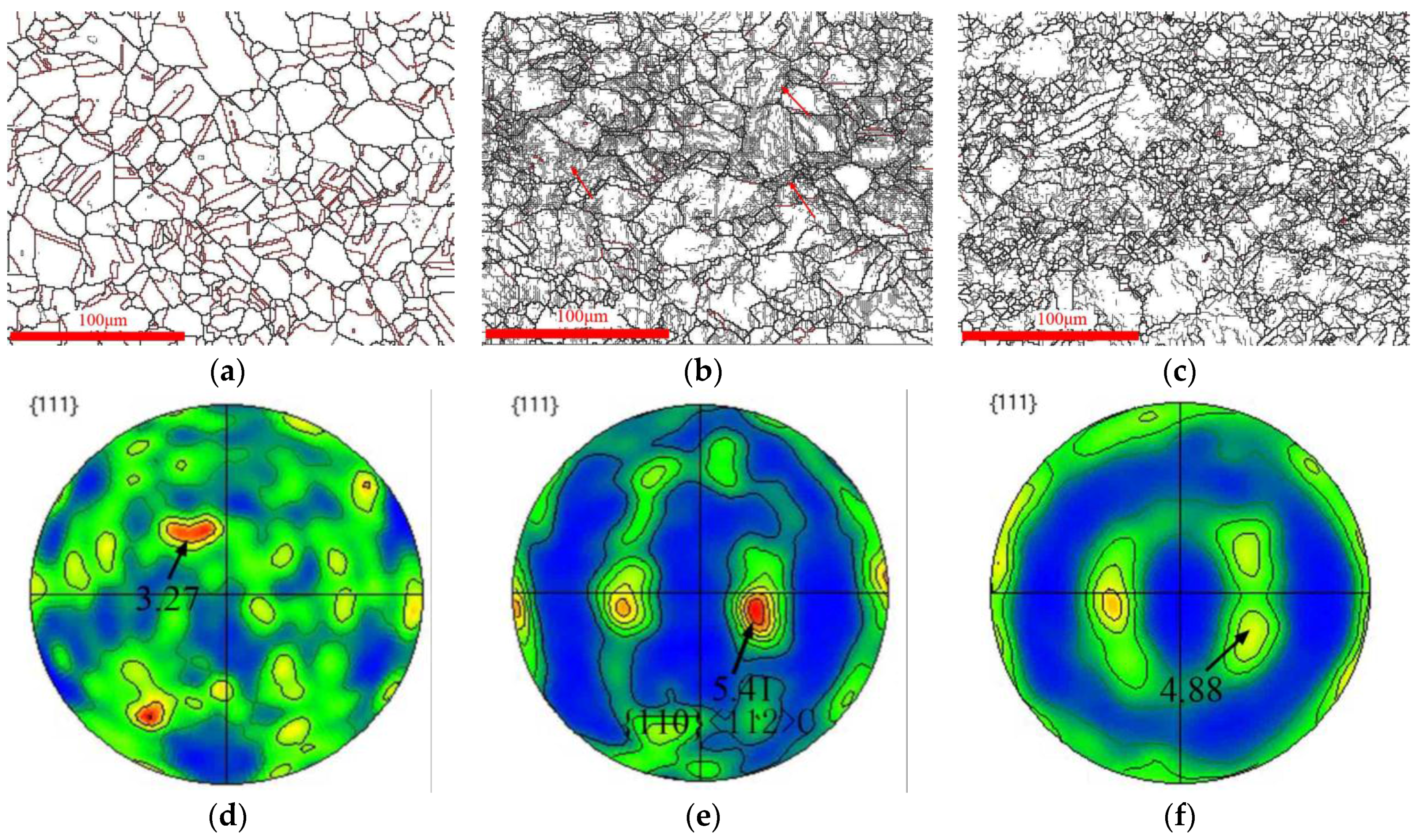

3.1. Microstructure Evolution

3.2. Phase Fraction

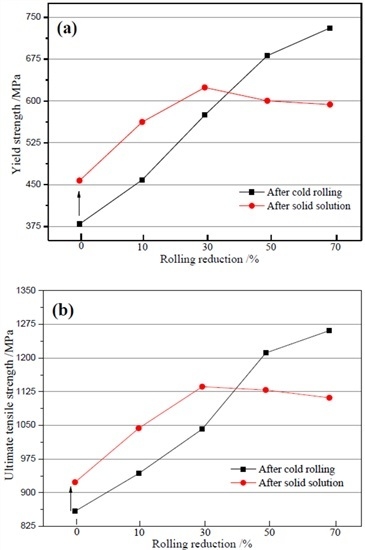

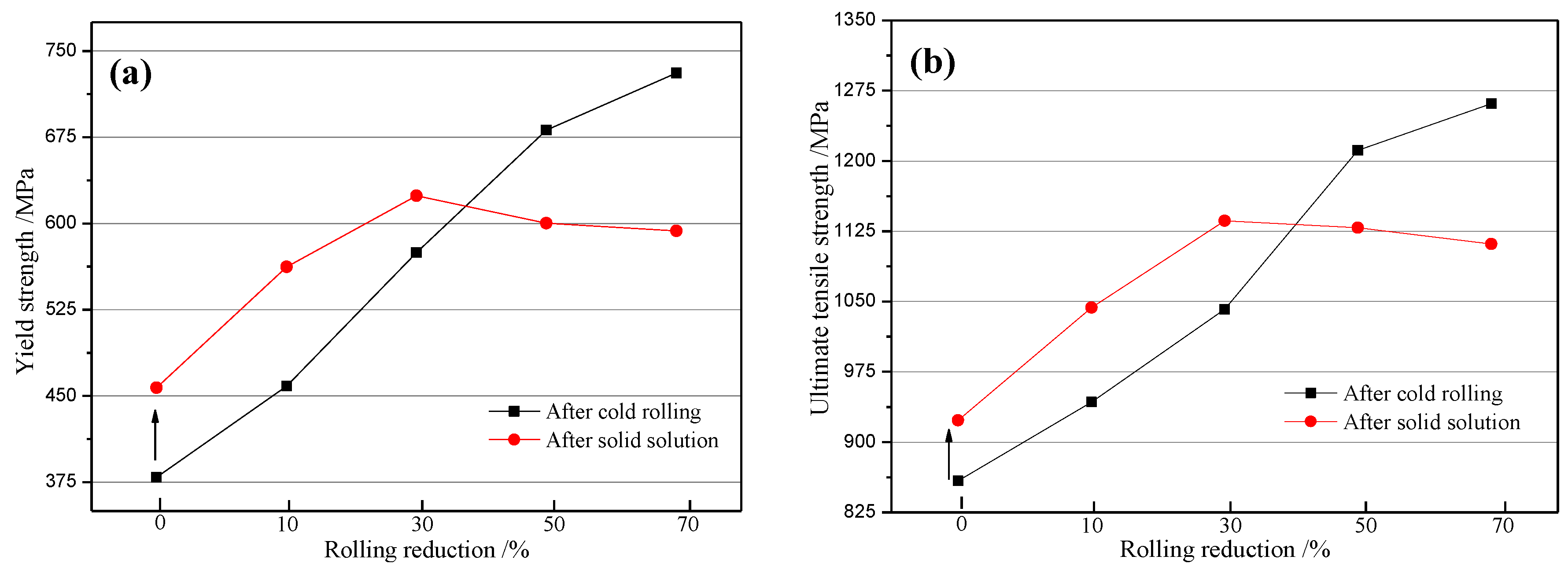

3.3. Mechanical Properties

3.4. Discussion

3.4.1. Strength Variation after Cold Rolling

| β × 10−3/rad | τi/MPa | ΔσT/Mpa | Δσc/Mpa | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0% | 30% | 50% | 0% | 30% | 50% | 0% → 30% | 30% → 50% | 0% → 30% | 30% → 50% |

| 7.1 | 11.1 | 13.3 | 130.1 | 203.0 | 243.8 | 233.4 | 109.9 | 195.2 | 155.5 |

3.4.2. Strength Variation after Solid Solution

| β × 10−3/rad | τi/MPa | ΔσT/MPa | Δσc/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0% | 30% | 50% | 0% | 30% | 50% | 0% → 30% | 30% → 50% | 0% → 30% | 30% → 50% |

| 7.3 | 9.7 | 7.5 | 134.3 | 176.8 | 137.2 | 146.2 | −131.4 | 166.8 | −30.5 |

4. Conclusions

- (1)

- Following the increase of cold rolling reduction, the yield strength and ultimate tensile strength of GH4169 superalloy sheet were substantially increased, however, they were increased then decreased following solid solution.

- (2)

- The main reasons for yield strength changes of GH4169 superalloy are texture and work hardening, followed by the grain refinement and precipitation of δ phase. When the rolling reduction was below 30%, the influence of δ phase was greater than grain refinement and the opposite happen when the rolling reduction was larger than 50%.

- (3)

- The precipitation of δ phase promotes the improvement of yield strength and the relationship between the fraction of δ phase and the improvement of yield strength satisfies the following equation: σδ = 15.9Wδ + 59.7.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ahmadi, M.R.; Povoden-Karadeniz, E.; Whitmore, L.; Stockinger, M.; Falahati, A.; Kozeschnik, E. Yield strength prediction in Ni-base alloy 718Plus based on thermo-kinetic precipitation simulation. Mater. Sci. Eng. A 2014, 608, 114–122. [Google Scholar] [CrossRef]

- Fisk, M.; Ion, J.C.; Lindgren, L.E. Flow stress model for IN718 accounting for evolution of strengthening precipitates during thermal treatment. Comput. Mater. Sci. 2014, 82, 531–539. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.C.; Chellali, R.; Bouchikhaoui, H.; Dong, J.X. Oxidation property of powder metallurgy EP741NP Ni-based superalloy at elevated temperatures. Mater. Technol. Adv. Perform. Mater. 2013, 28, 2–128. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Wen, D.X.; Chen, M.S. A physically-based constitutive model for a typical nickel-based superalloy. Comput. Mater. Sci. 2014, 83, 282–289. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.C.; Chellali, R.; Dong, J.X. Investigations on the growing, cracking and spalling of oxides scales of powder metallurgy Rene 95 nickel-based superalloy. Appl. Surf. Sci. 2011, 257, 9762–9767. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, M.C.; Chellali, R.; Dong, J.X. Hot corrosion behavior of powder metallurgy Rene 95 nickel-based superalloy in molten NaCl-Na2SO4 salts. Mater. Des. 2011, 32, 1981–1986. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhay, P.; Banerjee, S. Precipitation of the δ-Ni3Nb phase in two Ni base superalloys. Metall. Mater. Trans. A 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Li, H.Y.; Kong, Y.H.; Chen, G.S.; Xie, L.X.; Zhu, S.G.; Sheng, X. Effect of different processing technologies and heat treatments on the microstructure and creep behavior of GH4169 superalloy. Mater. Sci. Eng. A 2013, 582, 368–373. [Google Scholar] [CrossRef]

- Yeh, A.C.; Lu, K.W.; Kuo, C.M.; Bor, H.Y.; Wei, C.N. Effect of serrated grain boundaries on the creep property of Inconel 718 Superalloy. Mater. Sci. Eng. A 2011, 530, 525–529. [Google Scholar] [CrossRef]

- Kong, Y.H.; Liu, R.Y.; Chen, G.S.; Xie, L.X.; Zhu, S.G. Effects of different heat treatments on the microstructures and creep properties of GH4169 superalloy. J. Mater. Eng. Perform. 2013, 22, 1371–1377. [Google Scholar] [CrossRef]

- Du, J.H.; Lv, X.D.; Deng, Q. Effect of heat treatment on microstructure and mechanical properties of GH4169 superalloy. Rare Metal Mater. Eng. 2014, 43, 1830–1834. [Google Scholar] [CrossRef]

- Zhou, N.; Lv, D.C.; Zhang, H.L.; McAllister, D.; Zhang, F.; Mills, M.J.; Wang, Y. Computer simulation of phase transformation and plastic deformation in IN718 superalloy: Microstructural evolution during precipitation. Acta Mater. 2014, 65, 270–286. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.Q.; Luo, J.; Li, C. Effect of the δ phase on the deformation behavior in isothermal compression of superalloy GH4169. Mater. Sci. Eng. A 2011, 528, 4723–4731. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Zhang, S.H.; Cheng, M.; Li, Z.X. Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy. Mater. Charact. 2010, 61, 49–53. [Google Scholar] [CrossRef]

- Liu, W.C.; Chen, Z.L.; Xiao, F.R.; Yao, M.; Jiang, Z.Q.; Wang, S.G. Effect of cold rolling on the precipitation behavior of δ phase and γ″ phase in Inconel 718. Acta Aeronaut. Astronaut. Sin. 1999, 20, 279–282. [Google Scholar] [CrossRef]

- Hansen, N. Polycrystalline strengthening. Metall. Trans. A 1985, 16A, 2167–2190. [Google Scholar] [CrossRef]

- Liu, W.C.; Xiao, F.R.; Yao, M. Quantitative phases analysis of GH4169 by X-ray diffraction. J. Mater. Sci. 1997, 16, 769–771. [Google Scholar]

- Liu, W.C.; Xiao, F.R.; Yao, M. Relationship between the lattice constant of γ phase and the content of δ phase, γ″ and γ′ phases in Inconel 718. Scr. Mater. 1997, 37, 59–64. [Google Scholar] [CrossRef]

- Li, R.B.; Yao, M.; Liu, W.C.; He, X.C. Isolation and determination for δ, γ″ and γ′ phases in Inconel 718 alloy. Scr. Mater. 2002, 46, 635–638. [Google Scholar] [CrossRef]

- Cai, D.Y.; Liu, W.C.; Li, R.B.; Zhang, W.H.; Yao, M. On the accurancy of the X-ray diffraction quantitative phases analysis method in GH4169. J. Mater. Sci. 2004, 39, 719–721. [Google Scholar]

- Rauch, E.F.; Gracio, J.J.; Barlet, F. Work-hardening model for polycrystalline metals under strain reversal at large strain. Acta Meterialia 2007, 55, 2030–2948. [Google Scholar] [CrossRef]

- Wang, X.Q.; Cui, F.K.; Yan, G.P.; Li, Y.X. Study on the dislocation density change during cold roll-beating of 40Cr. China Mech. Eng. 2013, 24, 2248–2256. [Google Scholar]

- Ye, N.Y.; Cheng, M.; Zhang, S.H.; Song, H.W.; Zhou, H.W.; Wang, P.B. Effect of δ Phase on Mechanical Properties of GH4169 Alloy at Room Temperature. J. Iron Steel Res. Int. 2015, 22, 752–756. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.-H.; Ye, N.-Y.; Cheng, M.; Song, H.-W.; Zhou, H.-W.; Wang, P.-B. Effect of Cold Rolling and Heat Treatment on the Mechanical Properties of GH4169 Alloy Sheet at Room Temperature. Metals 2016, 6, 1. https://doi.org/10.3390/met6010001

Zhang S-H, Ye N-Y, Cheng M, Song H-W, Zhou H-W, Wang P-B. Effect of Cold Rolling and Heat Treatment on the Mechanical Properties of GH4169 Alloy Sheet at Room Temperature. Metals. 2016; 6(1):1. https://doi.org/10.3390/met6010001

Chicago/Turabian StyleZhang, Shi-Hong, Neng-Yong Ye, Ming Cheng, Hong-Wu Song, Hong-Wei Zhou, and Ping-Bo Wang. 2016. "Effect of Cold Rolling and Heat Treatment on the Mechanical Properties of GH4169 Alloy Sheet at Room Temperature" Metals 6, no. 1: 1. https://doi.org/10.3390/met6010001