1. Introduction

Addition of titanium-boron master alloys to molten aluminum produces fine, equiaxed grains after solidification, which otherwise tends to be coarse and columnar [

1,

2,

3,

4,

5]. A fine, equiaxed grain structure imparts to casting materials, high toughness, high yield strength, excellent formability, good surface finish and improved machinability [

6,

7]. Furthermore, a sound grain-refining practice avoids hot tearing, allows a marked increase in casting speed and improves the homogeneity of the cast structure by refining the distribution of secondary phases and micro-porosity [

8]. The use of grain refining master alloys in casting of ingots, billets and strip, has become a common practice in aluminum foundries worldwide.

The grain refinement of aluminum alloys, by melt inoculation, is generally achieved by introducing into the melt Al–Ti–B master alloys [

9,

10,

11,

12], which typically consist of TiAl

3 and TiB

2 particles in an aluminum matrix. Although Al

3Ti, TiB

2, AlB

2 and (Ti, Al)B

2 can be taken as effective heterogeneous nuclei; Al

3Ti was supposed to be the best grain refiner for Al alloys [

13]. Recent investigations show that the (0001) faces of TiB

2 particles are covered with thin Al

3Ti-like phase epitaxial layers on which α-Al is formed with epitaxial orientation. The aluminum nucleates on the basal planes of the coated TiB

2 particles led to the ‘free growth’ model. Once the radius of the nucleated solid grows beyond half of the diameter of the TiB

2 facet, it can grow freely into the melt. The necessary undercooling to achieve this state is inversely proportional to the facet diameter, the largest TiB

2 particles being the most effective [

14].

The standard method for the manufacture of Al-Ti-B involves the use of K

2TiF

6 and KBF

4 results in considerable fluoride emissions and formation of potassium aluminum fluoride salts as slag [

15]. Trials are currently in progress to minimize these effects and control pollution. Process control is somewhat difficult in flux treatment as the borides may get entrapped with the slag particles leading to less efficient grain refinement and to the introduction of slag inclusions in the solidified aluminum alloy. Other disadvantages of using fluxes include (1) their hygroscopic nature, (2) release of corrosive fumes during melting, (3) possibility of reaction with modifying agents such as Na and Sr (in Al-Si Alloys) and (4) the unpredictable recovery behavior of Ti and B [

16].

In order to improve the metallurgical quality of Al-Ti-B master alloys, a method based on SHS (self-propagating high-temperature synthesis) was developed, including the most common, Al-5%Ti-1%B [

17]. The SHS process is a powder metallurgical process for producing inorganic compounds by exothermic reactions, with low energy requirements and very high purity of final products due to the high temperatures created during the reaction. The synthesis is initiated by point-heating of a small part of the sample. Once started, a wave of exothermic reaction sweeps through the remaining material. Reactions are conducted in a vacuum and under either inert or reactive gases. The initial melt temperature, powder grade and powder ratio were shown to have a significant effect on the reaction temperature and on the structure of the synthesized grain refiner [

18]. The use of fluxes increased the SHS reaction and made it possible to reduce the initial melt temperature [

19]. Also the use of two fluxes, Na

3AlF

6 and K1

3AlF

6, during SHS, induces materials with larger particle size and lower purity [

20].

The main reactions involved in the SHS process are [

19,

20]:

or:

The aim of this work is to establish the effect of KBF4 and Na2B4O7 as raw materials and NaCl/KCl salts as flux agents to obtain an Al-Ti-B refining master alloy made by SHS using Ti and B powders with quite large particle size, impurities at different concentrations and with and without a protective atmosphere. The results presented are part of a work aimed at developing low cost refining master alloys presenting a good refining effect. The aim of the work was to validate the production of Al-5Ti-1B master alloys, using SHS, to produce master alloys that could comply with the established quality requirements.

2. Experimental Section

The composition of Al, Ti and B powders, employed as the initial materials for the preparation of master alloys, are listed in

Table 1.

Table 1.

Composition of elemental Ti and B powders.

| Powders | Purity (%) | Average particle size (≤µm) |

|---|

| Aluminum William Rowland (Fine) | 99.50 | 25 |

| Titanium Bostlan (Large) | 99.50 | 1000 |

| Boron amorphous Bostlan | 96.06 | 0.6 |

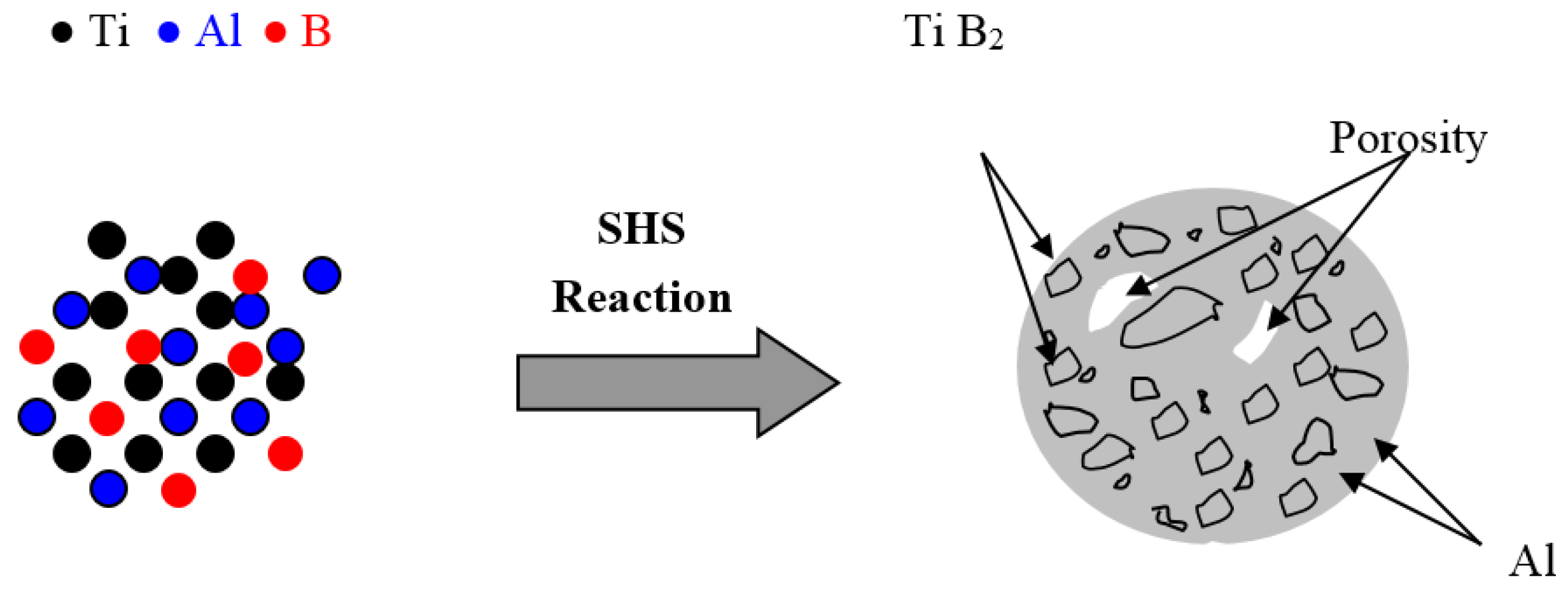

Figure 1.

Schematic self-propagating high-temperature synthesis (SHS) Reaction with initial reactive powders and obtained phase products.

The SHS equipment is composed of a mixer, a briquetting tool, a SHS reactor and generator, and a ball-milling device. The production process can be resumed as follows: (1) elemental powders are mixed in a mixer, for a specific concentration, during 2 h at 69 rpm, (2) elemental powders are cold pressed to 200 bar in order to obtain a 25 mm diameter briquette which is then placed in the reaction chamber, (3) a vacuum is made inside the reactor and then filled with high purity argon, (4) an electric generator gives the necessary electrical discharge in order to start the SHS reaction, (5) a master alloy is obtained for a temperature in a range of 680 to 720 °C and (6) a master alloy is finally milled (for Al-TiB

2 master alloy different grain size can be obtained depending on milling conditions) (cf.

Figure 1)).

Figure 2 shows a master alloy ingot (1) during the SHS reaction and (2) after SHS reaction, where oxidation of the external ingot surface can be observed.

Figure 2.

Reaction process and obtained SHS product without reactor.

Several trials have been developed in order to obtain the master alloy with optimized structural characteristics and cheaper price. The experimental parameters used are listed below:

(1) Commercial Titanium with a size up to 1.000 µm and commercial Boron with an average particle size of 0.6 μm;

(2) Reaction without reactor in air or with argon supply in order to eliminate the reactor and the high vacuum process;

(3) The use of NaCl/ KCl in order to improve homogeneous dissolution;

(4) The introduction of KBF4 and Na2B4O7 as an economical boron source.

The different master alloys fabricated during this study are presented in

Table 2.

Table 2.

Composition of tested master alloys.

| Sample number | Size of Ti | %Ti | %B | %Al | %NaCl/ KCl | KBF4 | Na2B4O7 | Reactor |

|---|

| 1 | Fine | 48.2 | 21.8 | 30 | | | | No |

| 2 | Large | 48.2 | 21.8 | 30 | | | | No |

| 3 | Fine | 69.0 | 31 | 0 | | | | No |

| 4 | Large | 69.0 | 31 | 0 | | | | No |

| 5 | Fine | 34.5 | 15.5 | 50 | | | | No |

| 6 | Fine | 69.0 | 31 | 0 | | | | Yes |

| 7 | Large | 48.2 | 21.8 | 30 | | | | Yes |

| 8 | Large | 47.7 | 21.6 | 29.7 | 1 | | | Yes |

| 9 | Fine | 47.7 | 21.6 | 29.7 | 1 | | | Yes |

| 10 | Fine | 18.2 | 4.1 | 30 | | 47.7 | | Yes |

| 11 | Fine | 34.5 | 15.5 | 50 | | | | Yes |

| 12 | Fine | 20.7 | 9.3 | 70 | | | | Yes |

| 13 | Fine | 22.4 | 5 | 30 | | | 42.6 | Yes |

| 14 | Fine | 28.5 | 6.4 | 38.1 | | | 27 | Yes |

The master alloys were analyzed by Bruker D8 advance X-ray diffraction (XRD, Bruker, Karlsruhe, Germany) with Cu Kα radiation. The microstructure was examined with and Nikon Eclipse MA-200 x500 optical microscopy (OM, Nikon, Tokyo, Japan) and Jeol JSM-5910LV scanning electron microscopy (SEM, JEOL Ltd., Tokyo, Japan). Chemical analyses were done by energy dispersive spectroscopy with an X-act INCA 300 (SEM-EDS, Oxford instruments, Abingdom, Great Britain). The microstructural characteristics of TiB2 and TiO2 phases were determined using ImageJ as image analysis system (Public domain software). In order to have a statistical consistency, at least 10 different areas where selected to determine the average value of the particle size.

3. Results

Table 3 shows the samples that react during the SHS process and their composition obtained by SEM-EDS analysis. Samples N°5, N°12, N°13 and N°14 did not react during tests and are therefore not listed in the table.

Figure 3 and

Figure 4 show corresponding SEM micrographs of master alloys produced without and with reactor, respectively.

Table 3.

Average TiB2 particle size of the fabricated master alloys.

| Sample number | TiB2 size (µm) | Composition |

|---|

| 1 | 1.7 | Formation by oxidation of Al2TiO5, Gibbsite Al2O3·3H20, Ti5O5 and TiB2. Huge amount of Titanium oxide is also detected. Aluminum is dispersed in the ceramic matrix. TiB2 particle average size is close to 1.7 μm. |

| 2 | 2.8 | Formation by oxidation of Rutile (Ti0.992O2), Aluminum Titanium oxide (Al2TiO5) and TiB2. Aluminum is dispersed in the ceramic matrix. TiB2 particle average size is close to 2.8 μm. |

| 3 | 1.5 | Formation of TiB2 matrix with some TiB and Rutile (Ti0.992O2). TiB2 particle average grain size is close to 1.5 μm. |

| 4 | 4.6 | Formation of TiB2 with free Boron and rutile (TiO2). TiB2 particle average size is close to 4.6 μm. |

| 6 | 9.5 | Formation of a TiB2 matrix with bimodal distribution. TiB2 particle average size is close to 9.5 μm. |

| 7 | 1.3 | Formation of TiB2, Al and Al3Ti. TiB2 particle average size is close to 1.3 μm. |

| 8 | 1.3 | Formation of TiB2, Al and Al3Ti. Quite big aluminum particles covered with ceramics. TiB2 particle average size is close to 1.3 μm. |

| 9 | 1.1 | Formation of TiB2, Al and Al3Ti. Quite big aluminum particles coated with ceramics. TiB2 particle average size is close to 1.1 μm. |

| 10 | 1.9 | TiB2, Al, and Al3Ti particles are analyzed. Aluminum particles are coated with TiB2 particles. TiB2 particle average size is close to 1.9 μm and same areas present fused salts. Not salt compounds are detected in the RX diffraction analysis. |

| 11 | 1.3 | Aluminum and TiB2 are observed. No Al3Ti is detected. TiB2 particle average size is close to 1.8 μm. Some plates like structures are detected (probably deformed Aluminum grains). |

Figure 3.

SEM microstructures of master alloys produced without reactor.

Figure 4.

SEM microstructures of master alloys produced with reactor.

(a) It can be observed that the average equivalent length size for the TiB2 particles increases when the size of the titanium particles increases (Pairs of samples N°1–2; N°3–4 and N°8–9), the average equivalent length size for the TiB2 particles decreases when using a reactor (Pair of sample N°2–7). The shape of TiB2 particles is very similar in all the cases (hexagonal or tetragonal).

(b) Regarding to oxidation behavior of the different samples, in direct reaction (without using a reactor with a protective gas), the total quantity of oxides is greater in the peripheral area compared to the manufacture of the compound in an inert reactor (Samples N°1 to 4). The total amount of oxides is higher when we employ fine Titanium (Pairs of samples N°1–2 and N°3–4) and the oxide layer is smaller when Aluminum is used in the master alloy (Samples N°1–2 in comparison with samples N°3–4).

(c) For the microstructure point of view, it can be observed that the grain size is bigger when aluminum powders are not used in the master alloy (Sample 6), KBF4 increases the grain size, compared with the use of Ti, B and aluminum powders (Sample 10) and finally a small addition of a 1 wt.% of NaCl/KCl do not affect significantly TiB2 grain size (Samples 7 and 8).

4. Discussion

Due to the fact that specific surface area is greater in smaller particles than in larger ones, the use of small particles as precursors induces a decrease in the average final grain size of the TiB2 particles, compared to the use of larger particles as precursors.

The main difference between the two manufacturing processes, with or without reactor, seems to be associated with the oxygen content. Indeed, for the process without reactor, the high oxygen content allows an exothermic reaction and so an increase of the temperature inside the crucible; this oxidation reaction is not observed for the reactor processes due to the absence of oxygen. This difference of temperature with and without reactor is then finally linked with the size of the TiB2 particles: TiB2 particles are smaller for the reactor process (lower temperature) than for the non-reactor one. Whatever the process, final TiB2 particles are formed with a hexagonal (more stable configuration) and/or tetragonal shape.

For the non-reactor process, the oxidation phenomenon of some external areas of the samples have to be associated with the high reactivity of the processing materials with oxygen and also with higher processing temperatures (exothermic reaction) with respect to the reactor process. Similarly, the higher surface area-to-volume ratio of finer Ti powders, in comparison with large one, promotes a larger surface area that can react with oxygen, and therefore a higher processing temperature and a final larger TiB2 particle size.

The decrease of the TiB2 grain size when adding aluminum powders can be associated with two different processes. In the first one, the use of Aluminum in the master alloy can reduce the oxidation process, and therefore the reaction temperature, due to the fact that part of the Ti particles react with Aluminum to form TiAl and Al3Ti. The second one should be more linked with volume restriction. Indeed, the growth of the two TiAl and Al3Ti intermetallics will disable the growth of the TiB2 particles and therefore decrease its grain size.

The increase of the grain size when using KBF4 in the master alloy can be correlated with the decrease of the reaction temperature that is linked with the presence of Boron and Titanium. The use of NaCl/KCl salts reduces reaction temperature, but a small percentage (1% by weight) has no significant influence over the final grain size.

5. Conclusions

Low cost SHS master alloys have been fabricated using commercial standard raw materials, with lower purity and higher grain size without a reactor or protective gas. Different master alloy compositions and morphologies are being developed.

We have shown that a larger titanium powder size can produce an aluminum master alloy with a maximum of 30% of aluminum without reactor. In comparison, the SHS reaction is much more difficult when using fine titanium powders. Chemical decomposition of KBF4 during SHS reaction leads to the formation of large TiB2 particles. TiB2 final particles are bigger when we use a larger Ti particles size and an inert atmosphere during SHS reaction inside a reactor. Ti and Ti-Al oxides are mainly formed in the peripheral area if a reactor is not employed. In the case of fine titanium powders, the total amount of oxides is much smaller than when we employ larger titanium powder. However, in the master alloy, the use of Aluminum reduces oxides concentration in the final products.