Effect of Post Heat Treatment on the Microstructure and Microhardness of Friction Stir Processed NiAl Bronze (NAB) Alloy

Abstract

:1. Introduction

2. Experimental Procedure

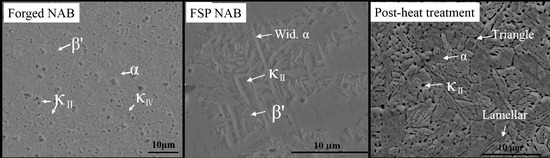

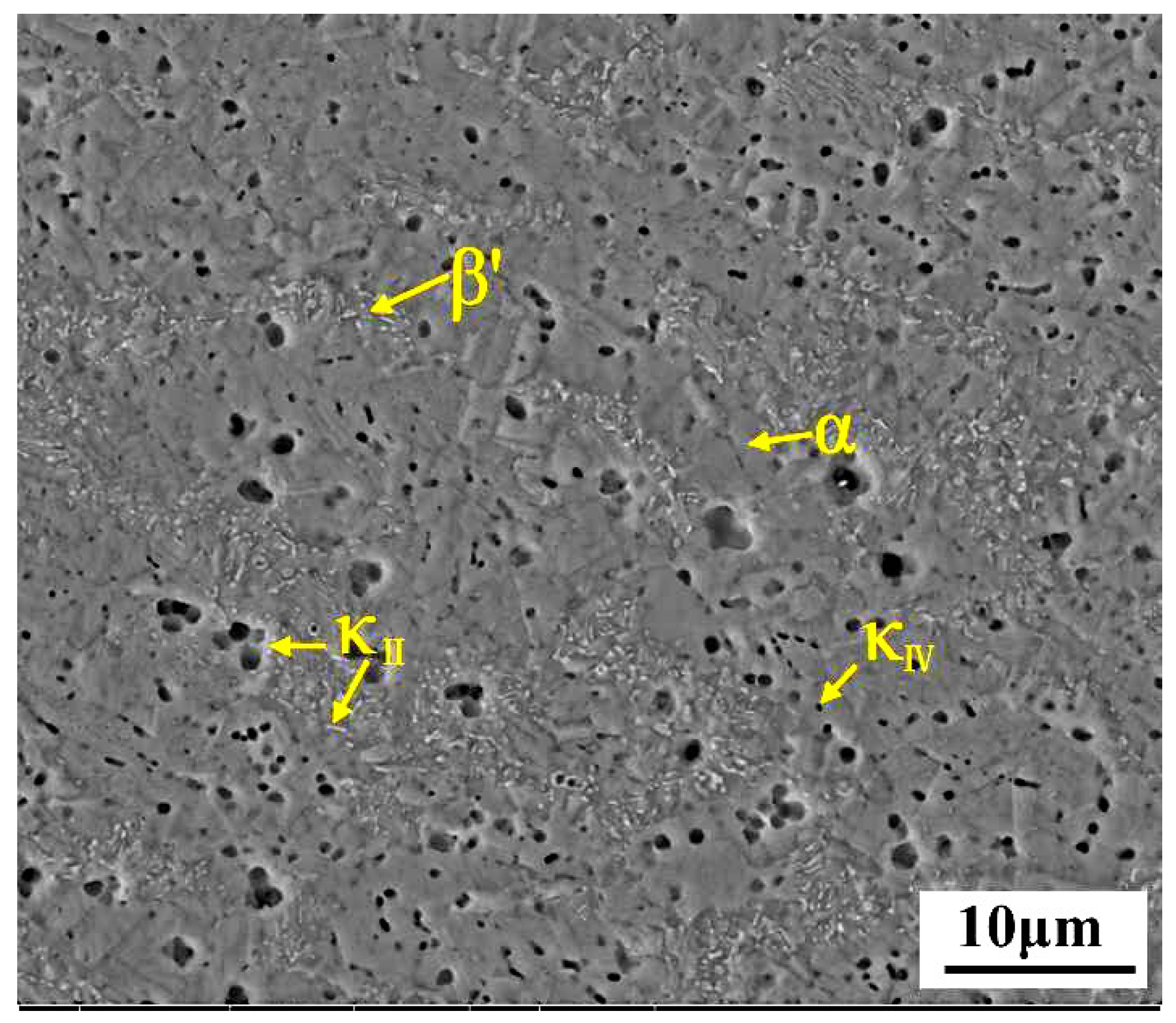

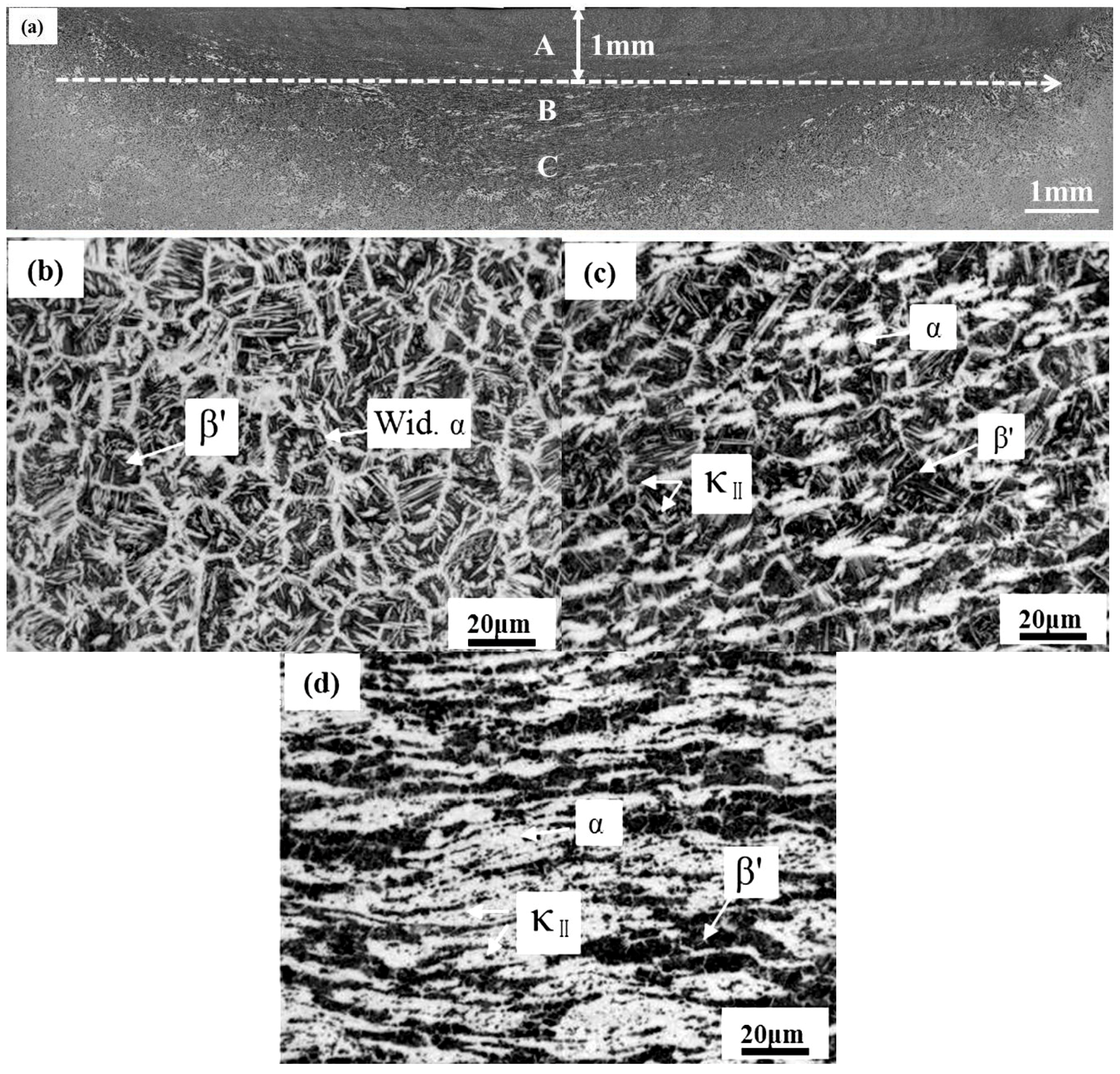

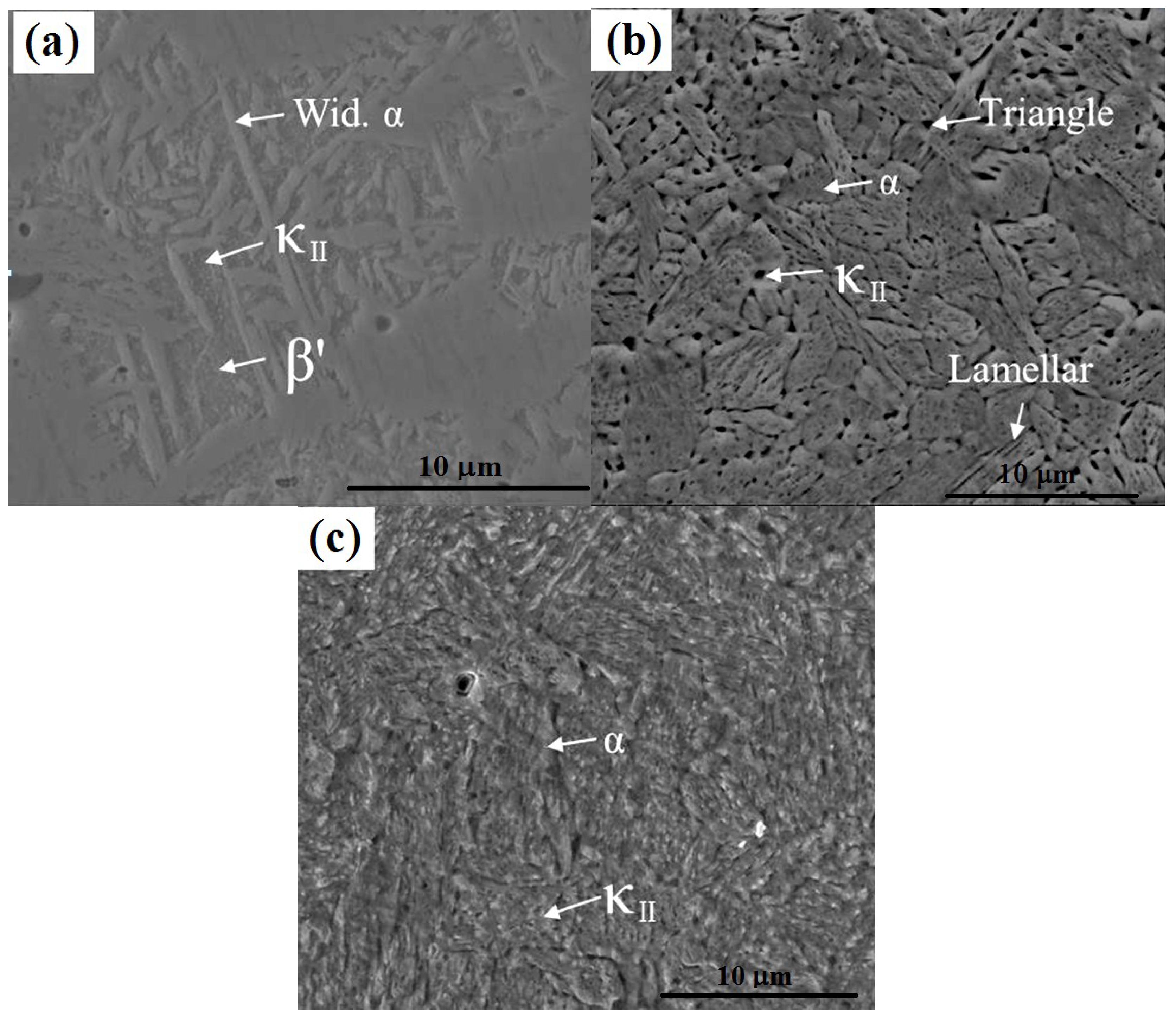

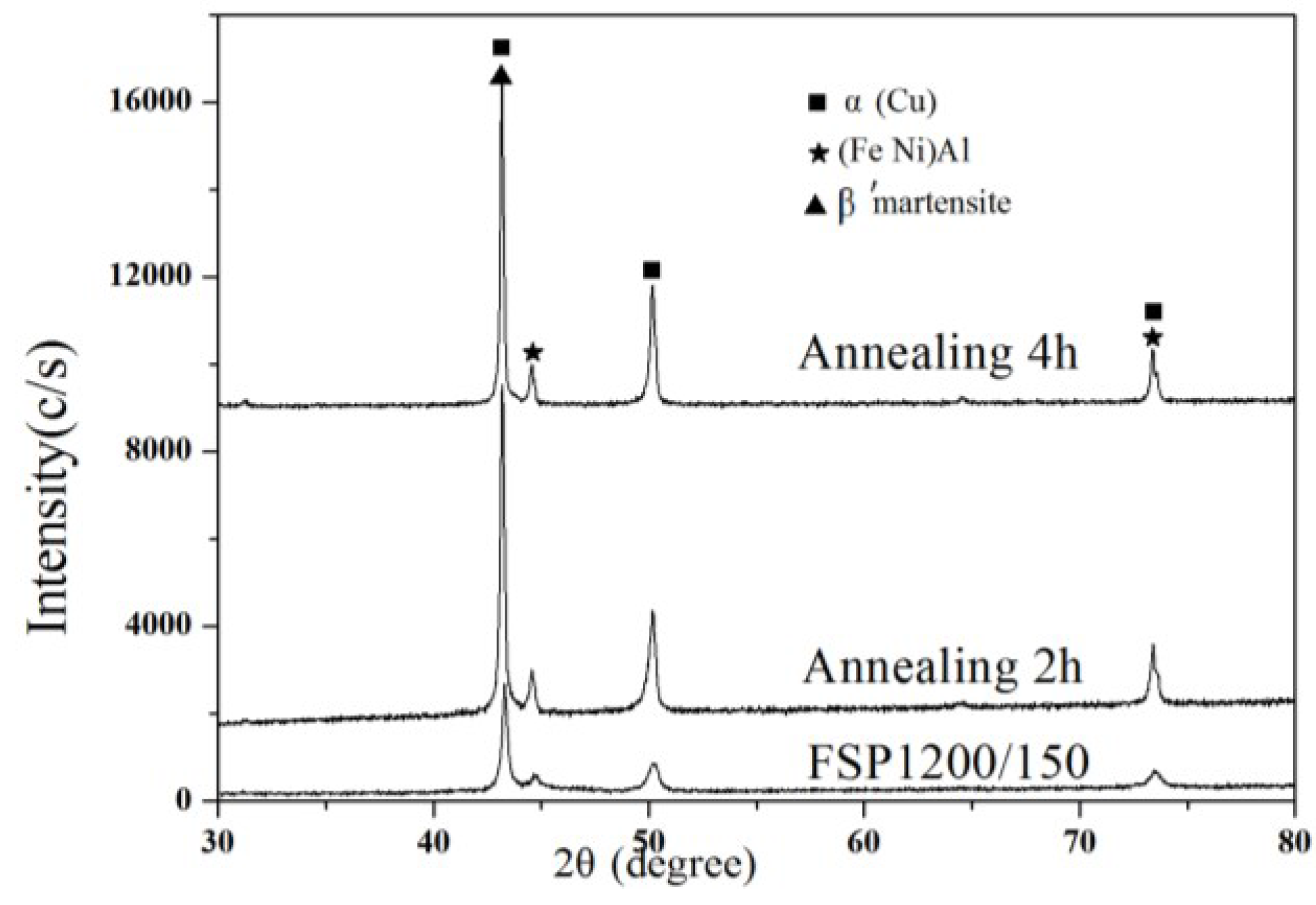

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hasan, F.; Jahanafrooz, A.; Lorimer, G.W.; Ridley, N. The morphology, crystallography and chemistry of phases in as cast nickel aluminum bronze. Metall. Mater. Trans. A 1982, 13, 1337–1345. [Google Scholar] [CrossRef]

- Jahanafrooz, A.; Hasan, F.; Lorrmer, G.W.; Ridley, N. Microstructural development in complex nickel aluminum bronzes. Metall. Mater. Trans. A 1982, 14, 1951–1956. [Google Scholar] [CrossRef]

- Nakhaie, D.; Davoodi, A.; Imani, A. The role of constituent phases on corrosion initiation of NiAl bronze in acidic media studied by SEM–EDS, AFM and SKPFM. Corros. Sci. 2014, 80, 104–110. [Google Scholar] [CrossRef]

- Wharton, J.A.; Stokes, K.R. The influence of nickel–aluminium bronze microstructure and crevice solution on the initiation of crevice corrosion. Electrochim. Acta 2008, 53, 2463–2473. [Google Scholar] [CrossRef]

- Gao, L.L.; Cheng, X.H. Microstructure and dry sliding wear behavior of Cu–10%Al–4%Fe alloy produced by equal channel angular extrusion. Wear 2008, 265, 986–991. [Google Scholar] [CrossRef]

- Gao, L.L.; Cheng, X.H. Microstructure and mechanical properties of Cu–10%Al–4%Fe alloy produced by equal channel angular extrusion. Mater. Des. 2008, 29, 904–908. [Google Scholar] [CrossRef]

- Tang, C.H.; Cheng, F.T.; Man, H.C. Effect of laser surface melting on the corrosion and cavitation erosion behaviors of a manganese–nickel–aluminium bronze. Mater. Sci. Eng. A 2004, 373, 195–203. [Google Scholar] [CrossRef]

- Tang, C.H.; Cheng, F.T.; Man, H.C. Improvement in cavitation erosion resistance of a copper-based propeller alloy by laser surface melting. Surf. Coat. Technol. 2004, 182, 300–307. [Google Scholar] [CrossRef]

- Hanke, S.; Fischer, A.; Beyer, M.; Santos, J.D. Cavitation erosion of NiAl-bronze layers generated by friction surfacing. Wear 2011, 273, 32–37. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Nandan, R.; Debroy, T.; Bhadeshia, H. Recent advances in friction stir welding process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Swaminathan, S.; Oh-Ishi, K.; Zhilyaev, A.P.; Fuller, C.B.; London, B.; Mahoney, M.W.; Mcnelley, T.R. Peak Stir Zone Temperatures during Friction Stir Processing. Metall. Mater. Trans. A 2009, 41, 631–640. [Google Scholar] [CrossRef]

- Oh-ishi, K.; Mcnelley, T.R. Microstructural modification of as-cast Ni Al bronze stir processing. Metall. Mater. Trans. A 2004, 35, 2951–2960. [Google Scholar] [CrossRef]

- Su, J.; Swaminthan, S.; Menon, S.K.; Mcnelley, T.R. The effect of concurrent straining on phase transformations in NiAl bronze during the friction stir processing thermomechanical Cycle. Metall. Mater. Trans. A 2011, 42, 2420–2430. [Google Scholar] [CrossRef]

- Ni, D.R.; Xiao, B.L.; Ma, Z.Y.; Qiao, Y.X.; Zheng, Y.G. Corrosion properties of friction stir processed cast NiAl bronze. Corros. Sci. 2010, 52, 1610–1617. [Google Scholar] [CrossRef]

- Song, Q.N.; Zheng, Y.G.; Ni, D.R.; Ma, Z.Y. Studies of the nobility of phases using scanning Kelvin probe microscopy and its relationship to corrosion behaviour of Ni–Al bronze in chloride media. Corro. Sci. 2014, 92, 95–103. [Google Scholar] [CrossRef]

- Lenard, D.R.; Bayley, C.J. Electrochemical monitoring of selective phase corrosion of NiAl bronze in Seawater. Corrosion 2008, 64, 764–772. [Google Scholar] [CrossRef]

- Anantapong, J.; Uthaisangsuk, V.; Suranuntchai, S.; Manonukul, A. Effect of hot working on microstructure evolution of as-cast Nickel Aluminum Bronze alloy. Mater. Des. 2014, 60, 233–243. [Google Scholar] [CrossRef]

- Ni, D.R.; Xue, P.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Inhomogeneous microstructure and mechanical properties of friction stir processed NiAl bronze. Mater. Sci. Eng. A 2009, 524, 119–128. [Google Scholar] [CrossRef]

- Ni, D.R.; Xue, P.; Ma, Z.Y. Effect of Multiple-Pass Friction Stir Processing Overlapping on Microstructure and Mechanical Properties of As-Cast NiAl Bronze. Metall. Mater. Trans. A 2011, 42, 2125–2135. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Wang, L.; Xu, X.; Lu, W. Effect of Post Heat Treatment on the Microstructure and Microhardness of Friction Stir Processed NiAl Bronze (NAB) Alloy. Metals 2015, 5, 1695-1703. https://doi.org/10.3390/met5031695

Lv Y, Wang L, Xu X, Lu W. Effect of Post Heat Treatment on the Microstructure and Microhardness of Friction Stir Processed NiAl Bronze (NAB) Alloy. Metals. 2015; 5(3):1695-1703. https://doi.org/10.3390/met5031695

Chicago/Turabian StyleLv, Yuting, Liqiang Wang, Xiaoyan Xu, and Weijie Lu. 2015. "Effect of Post Heat Treatment on the Microstructure and Microhardness of Friction Stir Processed NiAl Bronze (NAB) Alloy" Metals 5, no. 3: 1695-1703. https://doi.org/10.3390/met5031695