Investigating the Effect of Nanosecond Laser Surface Texturing on Microstructure and Mechanical Properties of AISI 301LN

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material and Sample Preparation

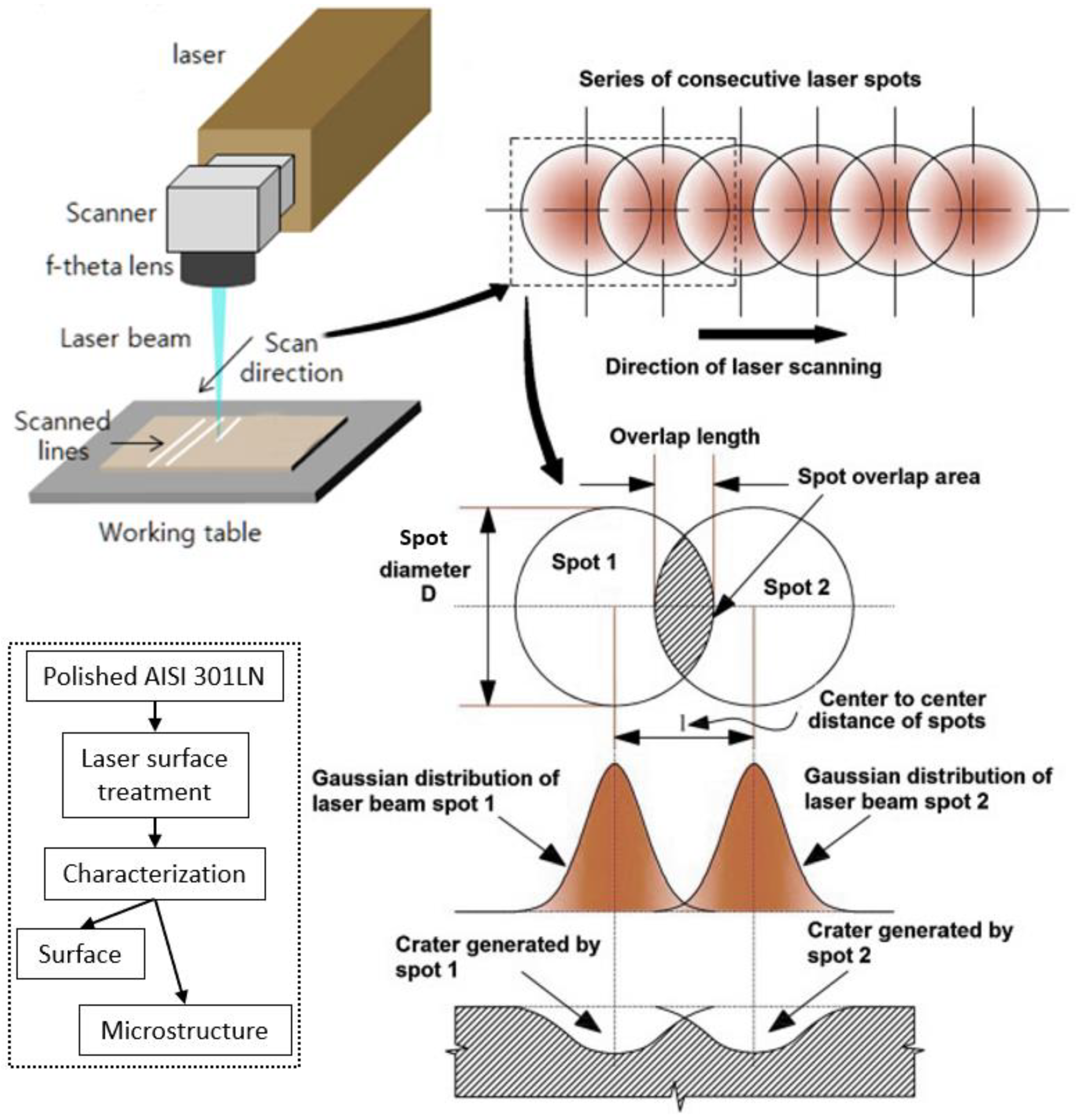

2.2. Laser Processing and Parameters

2.3. Microstructural Characterization

2.3.1. Optical and Scanning Electron Microscopy (SEM)

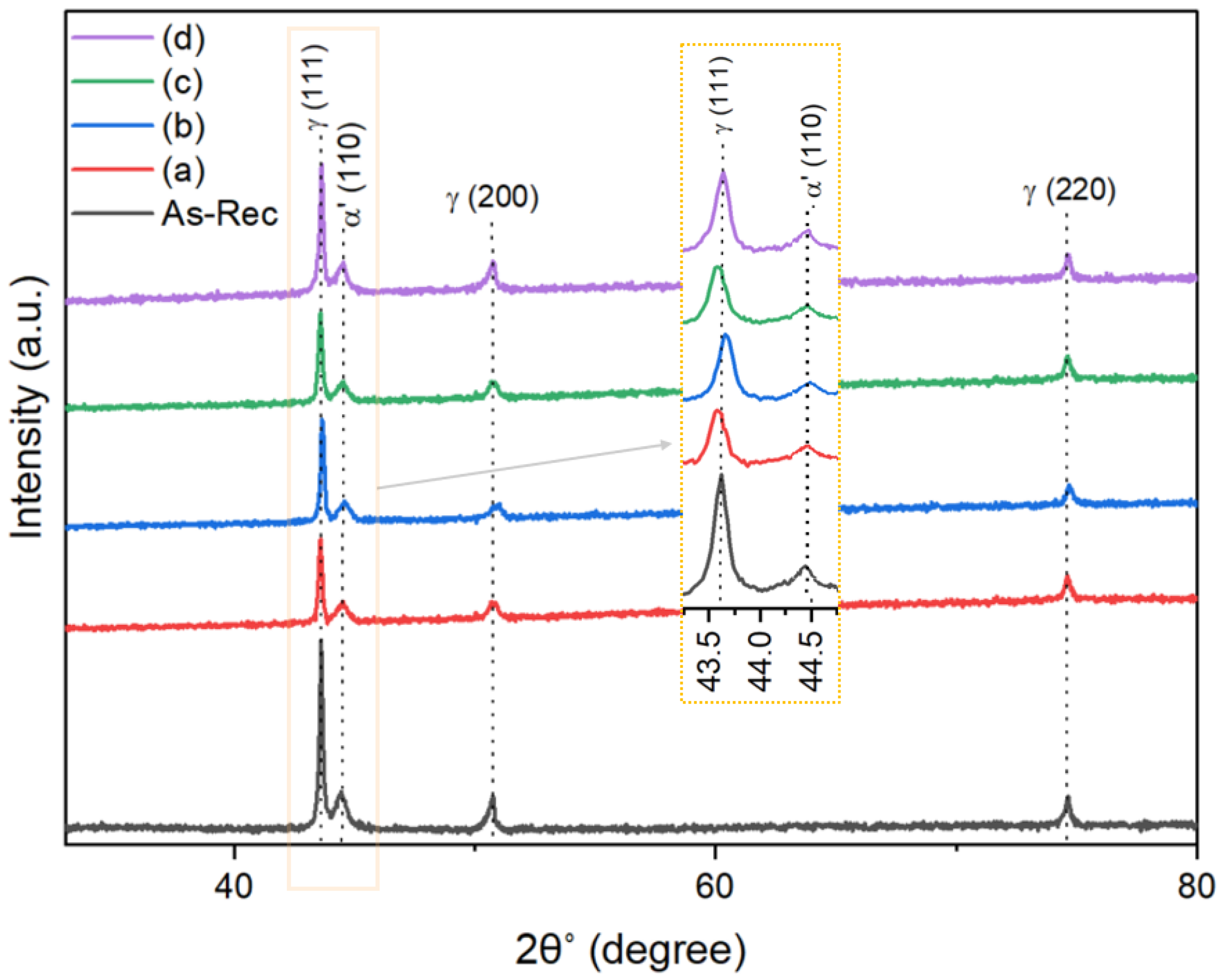

2.3.2. X-ray Diffraction (XRD)

2.3.3. Vickers Hardness

3. Results and Discussion

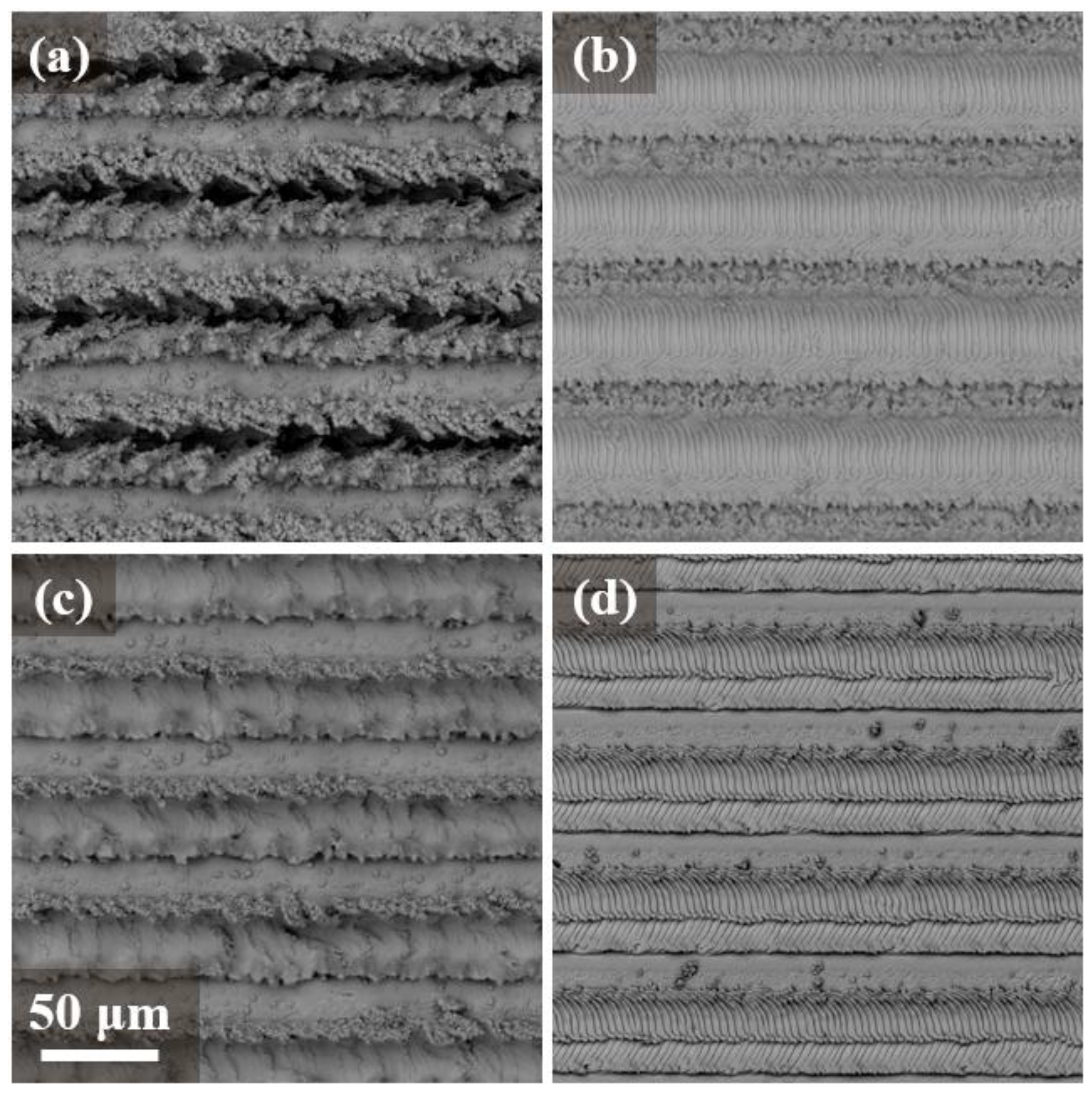

3.1. Surface Characterization

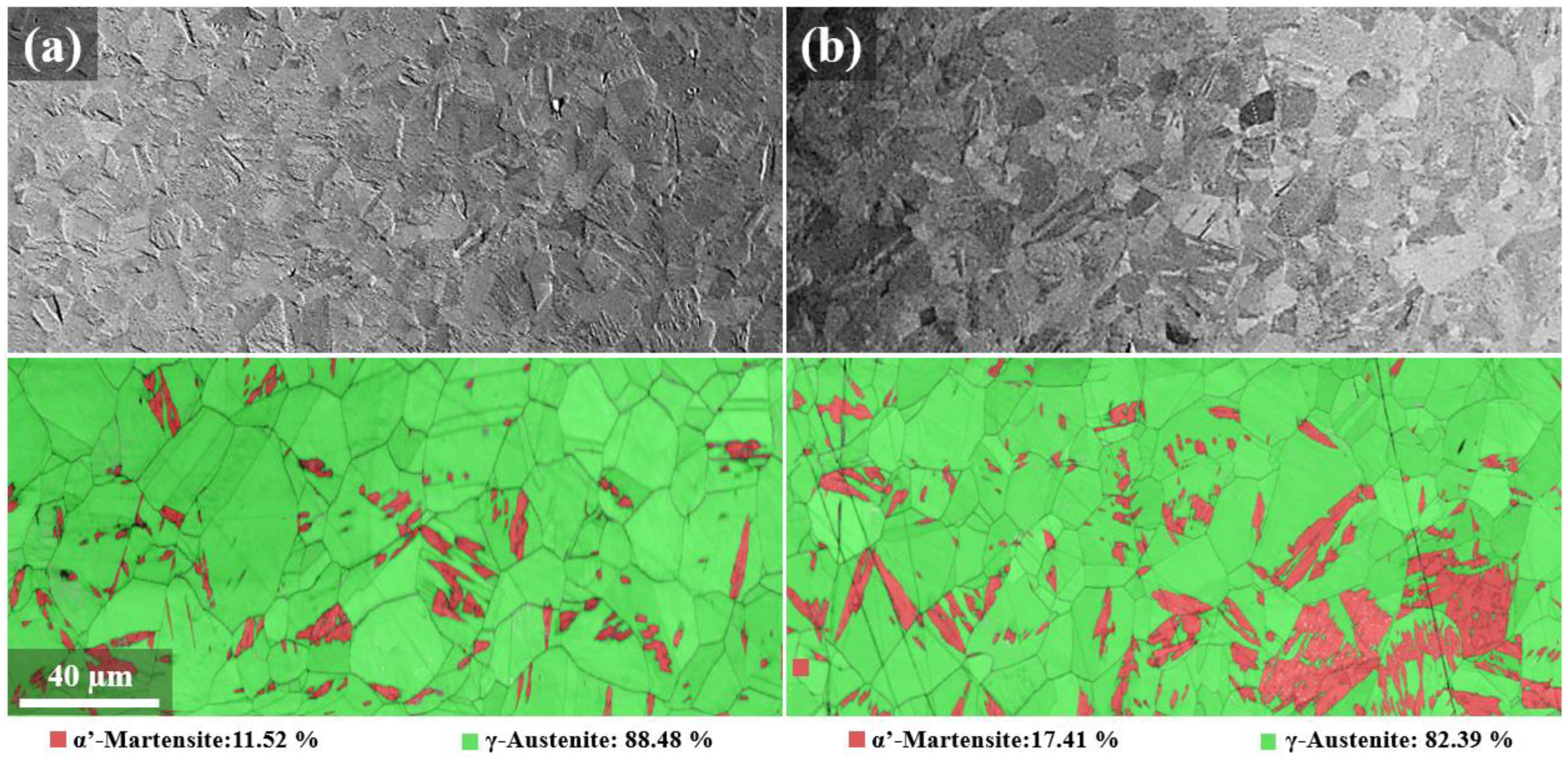

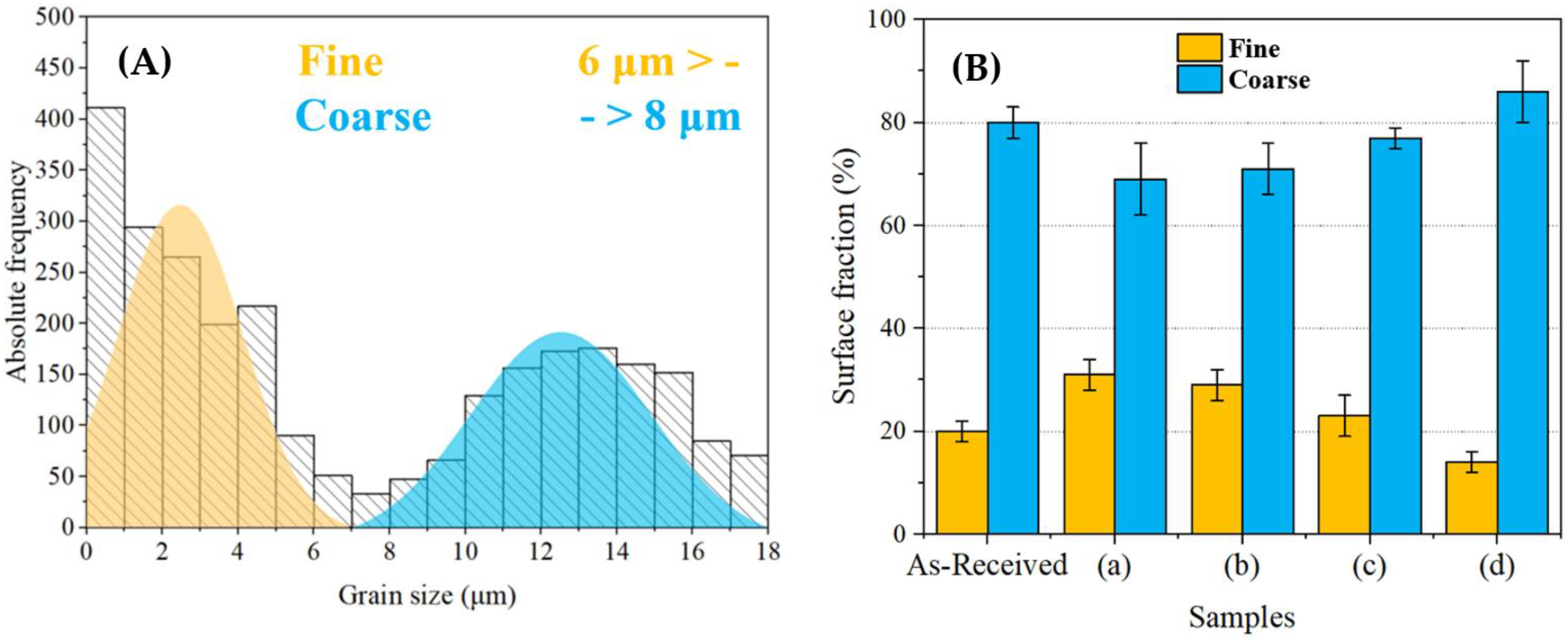

3.2. Microstructural Changes under the Surface

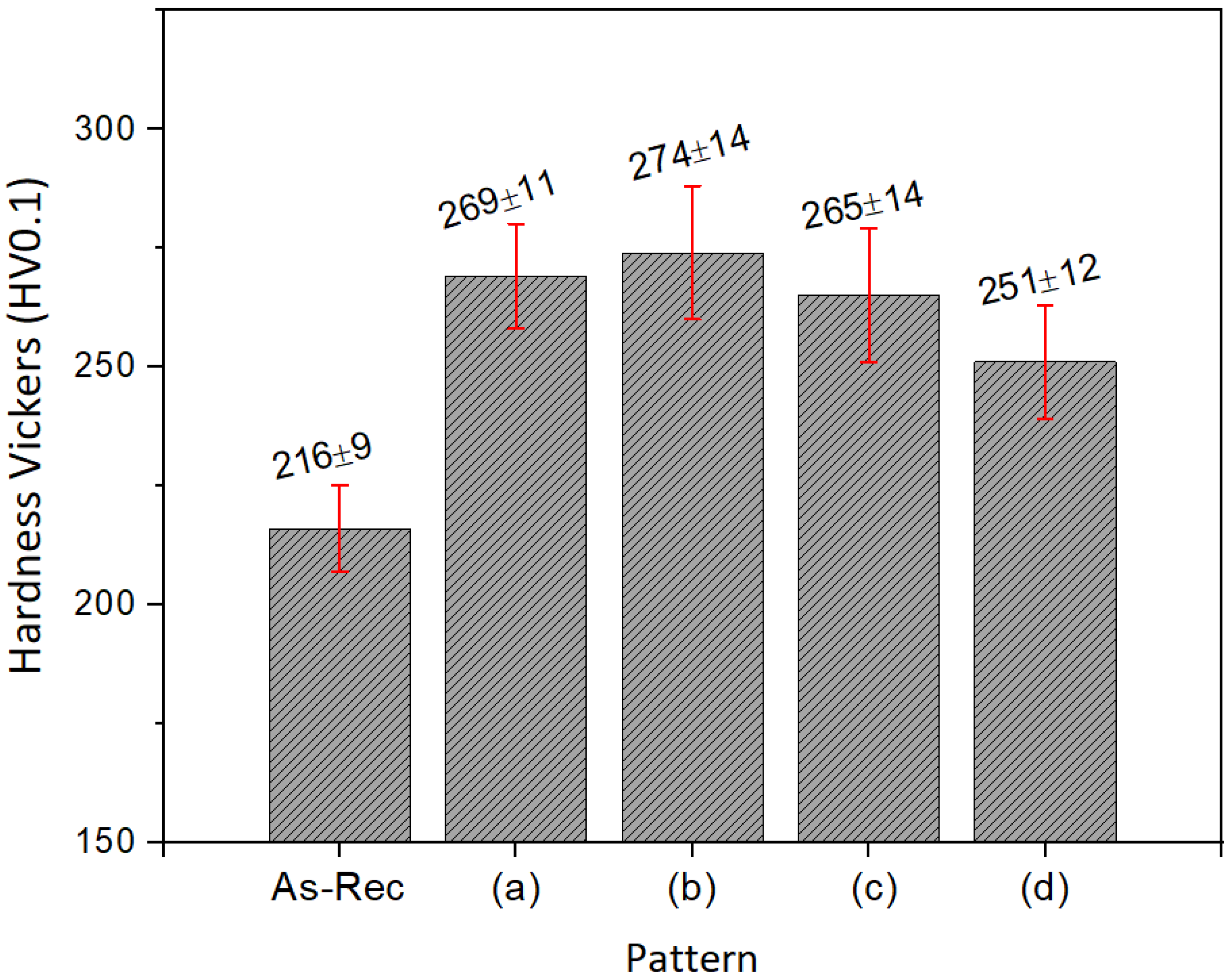

3.3. Hardness

4. Conclusions

- 1.

- The heat input from the laser significantly influences the parameters of the laser tracks and subsequently affects the roughness of the laser-textured surfaces. Higher heat input leads to increased surface roughness due to a greater amount of melted material and its subsequent resolidification.

- 2.

- The implementation of laser patterns on the surface dwells for a very short time. Accordingly, the melting and solidification take place rapidly, resulting in the formation of a fine-grained microstructure as compared with as-received samples.

- 3.

- The increase in hardness observed after laser surface texturing of 301LN steel can be attributed to the formation of a fine-grained microstructure with a high density of dislocations and defects and the formation of the α’-martensitic phase, which has a higher hardness than the austenitic phase.

5. Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MASS | Metastable austenitic stainless steels |

| TRIP | Transformation-induced plasticity |

| LST | Laser surface texturing |

| SEM | Scanning electron microscopy |

| EBSD | Electron backscatter diffraction |

| XRD | X-ray diffraction |

| RIR | Reference Intensity Ratio |

| AISI | American Iron and Steel Institute |

| μm | Micrometer |

| W | Watt |

| Hz | Hertz |

| μs | Microsecond |

| °C | Degrees Celsius |

| OPS | Silica oxide colloidal suspension |

| Nd:YLF | Neodymium-doped Yttrium Lithium Fluoride |

References

- Wu, Z.; Huang, Y. Characterization of a Metastable Austenitic Stainless Steel with Severe Plastic Distortions. Procedia Eng. 2015, 99, 1323–1329. [Google Scholar] [CrossRef]

- Schneider, M.; Liewald, M. Characterization of the Austenitic Stability of Metastable Austenitic Stainless Steel with Regard to Its Formability. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2018. [Google Scholar] [CrossRef]

- Panov, D.; Pertsev, A.; Smirnov, A.; Khotinov, V.; Simonov, Y. Metastable Austenitic Steel Structure and Mechanical Properties Evolution in the Process of Cold Radial Forging. Materials 2019, 12, 2058. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Martín, D.S.; Wang, J.; Wang, C.; Xu, W. A Review of the Thermal Stability of Metastable Austenite in Steels: Martensite Formation. J. Mater. Sci. Technol. 2021, 91, 200–214. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Yuan, S.; Wang, J.; Wang, C.; Mogucheva, A.; Xu, W. Scale-up Fabrication of Gradient AGS in Austenitic Stainless Steels Achieves a Simultaneous Increase in Strength and Toughness. Mater. Sci. Eng. A 2022, 853, 143763. [Google Scholar] [CrossRef]

- Rezayat, M.; Karamimoghadam, M.; Moradi, M.; Casalino, G.; Roa Rovira, J.J.; Mateo, A. Overview of Surface Modification Strategies for Improving the Properties of Metastable Austenitic Stainless Steels. Metals 2023, 13, 1268. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, K.Y.; Lee, Y.D. Nitrogen-Alloyed, Metastable Austenitic Stainless Steel for Automotive Structural Applications. Mater. Manuf. Process. 2004, 19, 51–59. [Google Scholar] [CrossRef]

- Smaga, M.; Boemke, A.; Daniel, T.; Skorupski, R.; Sorich, A.; Beck, T. Fatigue Behavior of Metastable Austenitic Stainless Steels in LCF, HCF and VHCF Regimes at Ambient and Elevated Temperatures. Metals 2019, 9, 704. [Google Scholar] [CrossRef]

- Fang, R.; Deng, N.; Zhang, H.; Wang, G.; Su, Y.; Zhou, H.; Gao, K.; Gu, L. Effect of Selective Laser Melting Process Parameters on the Microstructure and Properties of a Precipitation Hardening Stainless Steel. Mater. Des. 2021, 212, 110265. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Wei, S.; Ni, X.; Zhang, L.; Li, R.; Wang, L.; Man, C.; Li, X. About Metastable Cellular Structure in Additively Manufactured Austenitic Stainless Steels. Addit. Manuf. 2021, 38, 101804. [Google Scholar] [CrossRef]

- Di Schino, A.; Kenny, J.M. Grain Refinement Strengthening of a Micro-Crystalline High Nitrogen Austenitic Stainless Steel. Mater. Lett. 2003, 57, 1830–1834. [Google Scholar] [CrossRef]

- Roa, J.J.; Fargas, G.; Jiménez-Piqué, E.; Mateo, A. Deformation Mechanisms Induced under High Cycle Fatigue Tests in a Metastable Austenitic Stainless Steel. Mater. Sci. Eng. A 2014, 597, 232–236. [Google Scholar] [CrossRef]

- Sapezanskaia, I.; Roa, J.J.; Fargas, G.; Turon-Viñas, M.; Trifonov, T.; Kouitat Njiwa, R.; Redjaïmia, A.; Mateo, A. Deformation Mechanisms Induced by Nanoindentation Tests on a Metastable Austenitic Stainless Steel: A FIB/SIM Investigation. Mater. Charact. 2017, 131, 253–260. [Google Scholar] [CrossRef]

- Sun, S.C.; Mu, J.W.; Jiang, Z.H.; Ji, C.T.; Lian, J.S.; Jiang, Q. Effect of Cold Rolling on Tensile Properties and Microstructure of High Nitrogen Alloyed Austenitic Steel. Mater. Sci. Technol. 2013, 30, 146–151. [Google Scholar] [CrossRef]

- Rezayat, M.; Moradi, M.; Mateo, A. Nanosecond Pulsed Laser Surface Processing of AISI 301LN Steel: Effect on Surface Topography and Mechanical Properties. Int. J. Adv. Manuf. Technol. 2023, 128, 3025–3040. [Google Scholar] [CrossRef]

- Wahab, J.A.; Ghazali, M.J.; Yusoff, W.M.W.; Sajuri, Z. Enhancing Material Performance through Laser Surface Texturing: A Review. Trans. IMF 2016, 94, 193–198. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Zou, J.; Liu, Z.; Wang, Z.; Tian, L.; Qin, L.; Zhang, H.; Wang, Z.; Tang, B.; et al. Effect of Laser Surface Texturing (LST) on Tribological Behavior of Double Glow Plasma Surface Zirconizing Coating on Ti6Al4V Alloy. Surf. Coat. Technol. 2019, 368, 97–109. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser Surface Texturing and Related Techniques for Enhancing Tribological Performance of Engineering Materials: A Review. J. Manuf. Process 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Cep, R.; Pradhan, B.B.; Sharma, A. Laser Surface Texturing for Biomedical Applications: A Review. Coatings 2021, 11, 124. [Google Scholar] [CrossRef]

- Obilor, A.F.; Pacella, M.; Wilson, A.; Silberschmidt, V. V Micro-Texturing of Polymer Surfaces Using Lasers: A Review. Int. J. Adv. Manuf. Technol. 2022, 120, 103–135. [Google Scholar] [CrossRef]

- Rezayat, M.; Aboutorabi Sani, A.; Talafi Noghani, M.; Saghafi Yazdi, M.; Taheri, M.; Moghanian, A.; Mohammadi, M.A.; Moradi, M.; Mateo, A.; Besharatloo, H. Effect of Lateral Laser-Cladding Process on the Corrosion Performance of Inconel 625. Metals 2023, 13, 367. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- du Plessis, A.; Razavi, S.M.J.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and Applications of Additively Manufactured Metallic Cellular Materials: A Review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Shamsul Baharin, A.F.; Ghazali, M.J.; Wahab, J.A. Laser Surface Texturing and Its Contribution to Friction and Wear Reduction: A Brief Review. Ind. Lubr. Tribol. 2016, 68, 57–66. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, R.; Kango, S.; Sharma, V.S. Recent Progresses and Applications in Laser-Based Surface Texturing Systems. Mater. Today Commun. 2021, 26, 101736. [Google Scholar] [CrossRef]

- Kümmel, D.; Hamann-Schroer, M.; Hetzner, H.; Schneider, J. Tribological Behavior of Nanosecond-Laser Surface Textured Ti6Al4V. Wear 2019, 422–423, 261–268. [Google Scholar] [CrossRef]

- Li, S.; Chen, H.; Luo, T.; Xiao, G.; Yi, M.; Chen, Z.; Zhang, J.; Xu, C. Tribological Properties of Laser Surface Texturing Modified GCr15 Steel under Graphene/5CB Lubrication. J. Mater. Res. Technol. 2022, 18, 3598–3611. [Google Scholar] [CrossRef]

- Soltani-Kordshuli, F.; Miller, C.; Harris, N.; Zou, M. Laser Surface Texturing of Both Thin Polytetrafluoroethylene Coatings and Stainless Steel Substrates for Improving Tribological Properties. Polym. Test. 2023, 117, 107852. [Google Scholar] [CrossRef]

- Jia, X.; Li, K.; Li, Z.; Wang, C.; Chen, J.; Cui, S. Multi-Scan Picosecond Laser Welding of Non-Optical Contact Soda Lime Glass. Opt. Laser Technol. 2023, 161, 109164. [Google Scholar] [CrossRef]

- Wang, C.; Ding, K.; Song, Y.; Jia, X.; Lin, N.; Duan, J. Femtosecond Laser Patterned Superhydrophobic Surface with Anisotropic Sliding for Droplet Manipulation. Opt. Laser Technol. 2024, 168, 109829. [Google Scholar] [CrossRef]

- Rezayat, M.; Roa, J.J.; Mateo, A. Effect of Laser Surface Texturing on Schmid Factor and Plastic Deformation Mechanisms on AISI 301LN Steel. Metals 2023, 13, 1789. [Google Scholar] [CrossRef]

- Rezayat, M.; Mateo, A.; Roa, J.J. Exploring the Effects of Laser Surface Modification on AISI 301LN Steel: A Micro-Mechanical Study. J. Manuf. Mater. Process. 2023, 7, 191. [Google Scholar] [CrossRef]

- Dywel, P.; Szczesny, R.; Domanowski, P.; Skowronski, L. Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316). Materials 2020, 13, 2168. [Google Scholar] [CrossRef] [PubMed]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The Effect of Laser Texturing of Steel Surfaces and Speed-Load Parameters on the Transition of Lubrication Regime from Boundary to Hydrodynamic. Tribol. Trans. 2004, 47, 299–307. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248. [Google Scholar] [CrossRef]

- Shi, X.; Huang, Z.; Laakso, M.J.; Niklaus, F.; Sliz, R.; Fabritius, T.; Somani, M.; Nyo, T.; Wang, X.; Zhang, M.; et al. Quantitative Assessment of Structural and Compositional Colors Induced by Femtosecond Laser: A Case Study on 301LN Stainless Steel Surface. Appl. Surf. Sci. 2019, 484, 655–662. [Google Scholar] [CrossRef]

- Rezayat, M.; Rovira, J.J.R.; García, A.M. Phase Transformation and Residual Stresses after Laser Surface Modification of Metastable Austenitic Stainless Steel. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2023; p. 020005. [Google Scholar]

- Rezayat, M.; Morales, M.; Moradi, M.; Mateo, A. Laser Wobbling Surface Texturing of AISI 301LN Steel for Enhancement of the Corrosion Resistance at High Temperature. Opt. Laser Technol. 2024, 171, 110375. [Google Scholar] [CrossRef]

- Amanov, A.; Watabe, T.; Sasaki, S. The Influence of Micro-Scale Dimples and Nano-Sized Grains on the Fretting Characteristics Generated by Laser Pulses. J. Nanosci. Nanotechnol. 2013, 13, 8176–8183. [Google Scholar] [CrossRef]

- Costil, S.; Lamraoui, A.; Langlade, C.; Heintz, O.; Oltra, R. Surface Modifications Induced by Pulsed-Laser Texturing—Influence of Laser Impact on the Surface Properties. Appl. Surf. Sci. 2014, 288, 542–549. [Google Scholar] [CrossRef]

- Pfefferkorn, F.E.; Morrow, J.D. Controlling Surface Topography Using Pulsed Laser Micro Structuring. CIRP Ann. 2017, 66, 241–244. [Google Scholar] [CrossRef]

- Mustafa, H.; Mezera, M.; Matthews, D.T.A.; Römer, G.R.B.E. Effect of Surface Roughness on the Ultrashort Pulsed Laser Ablation Fluence Threshold of Zinc and Steel. Appl. Surf. Sci. 2019, 488, 10–21. [Google Scholar] [CrossRef]

- Putignano, C.; Parente, G.; Profito, F.J.; Gaudiuso, C.; Ancona, A.; Carbone, G. Laser Microtextured Surfaces for Friction Reduction: Does the Pattern Matter? Materials 2020, 13, 4915. [Google Scholar] [CrossRef] [PubMed]

- Salguero, J.; Sol, I.D.; Dominguez, G.; Batista, M.; Vazquez-Martinez, J.M. Tribological Wear Effects of Laser Texture Design on AISI 630 Stainless Steel under Lubricated Conditions. Metals 2022, 12, 543. [Google Scholar] [CrossRef]

- Misumi, I.; Naoi, K.; Sugawara, K.; Gonda, S. Profile Surface Roughness Measurement Using Metrological Atomic Force Microscope and Uncertainty Evaluation. Measurement 2015, 73, 295–303. [Google Scholar] [CrossRef]

- Podulka, P.; Macek, W.; Rozumek, D.; Żak, K.; Branco, R. Topography Measurement Methods Evaluation for Entire Bending-Fatigued Fracture Surfaces of Specimens Obtained by Explosive Welding. Measurement 2024, 224, 113853. [Google Scholar] [CrossRef]

- Khoshelham, K.; Altundag, D.; Ngan-Tillard, D.; Menenti, M. Influence of Range Measurement Noise on Roughness Characterization of Rock Surfaces Using Terrestrial Laser Scanning. Int. J. Rock. Mech. Min. Sci. 2011, 48, 1215–1223. [Google Scholar] [CrossRef]

- Boidi, G.; Grützmacher, P.G.; Kadiric, A.; Profito, F.J.; Machado, I.F.; Gachot, C.; Dini, D. Fast Laser Surface Texturing of Spherical Samples to Improve the Frictional Performance of Elasto-Hydrodynamic Lubricated Contacts. Friction 2021, 9, 1227–1241. [Google Scholar] [CrossRef]

- Cunha, Â.; Bartolomeu, F.; Silva, F.; Trindade, B.; Carvalho, Ó. Influence of Laser Parameters on the Texturing of 420 Stainless Steel. Materials 2022, 15, 8979. [Google Scholar] [CrossRef]

- Dahotre, N.B.; Paital, S.R.; Samant, A.N.; Daniel, C. Wetting Behaviour of Laser Synthetic Surface Microtextures on Ti–6Al–4V for Bioapplication. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 1863–1889. [Google Scholar] [CrossRef]

- Hussain, A.; Lee, H.-L.; Moon, Y.-J.; Hwang, J.Y.; Moon, S. Effect of Pulse Overlapping on Temperature Field and Physical Characteristics in Pulsed Laser Sintering of Inkjet-Printed Silver Nanoparticles. Int. J. Heat. Mass. Transf. 2023, 202, 123678. [Google Scholar] [CrossRef]

- Shivakoti, I.; Kibria, G.; Pradhan, B.B. Predictive Model and Parametric Analysis of Laser Marking Process on Gallium Nitride Material Using Diode Pumped Nd:YAG Laser. Opt. Laser Technol. 2019, 115, 58–70. [Google Scholar] [CrossRef]

- Min, D.; Shen, J.; Lai, S.; Chen, J.; Xu, N.; Liu, H. Effects of Heat Input on the Low Power Nd:YAG Pulse Laser Conduction Weldability of Magnesium Alloy AZ61. Opt. Lasers Eng. 2011, 49, 89–96. [Google Scholar] [CrossRef]

- Finger, J.; Bornschlegel, B.; Reininghaus, M.; Dohrn, A.; Nießen, M.; Gillner, A.; Poprawe, R. Heat Input and Accumulation for Ultrashort Pulse Processing with High Average Power. Adv. Opt. Technol. 2018, 7, 145–155. [Google Scholar] [CrossRef]

- Hubbard, C.R.; Snyder, R.L. RIR—Measurement and Use in Quantitative XRD. Powder Diffr. 1988, 3, 74–77. [Google Scholar] [CrossRef]

- Fawcett, T.G.; Kabekkodu, S.N.; Blanton, J.R.; Blanton, T.N. Chemical Analysis by Diffraction: The Powder Diffraction FileTM. Powder Diffr. 2017, 32, 63–71. [Google Scholar] [CrossRef]

- Fargas, G.; Roa, J.J.; Mateo, A. Influence of Pre-Existing Martensite on the Wear Resistance of Metastable Austenitic Stainless Steels. Wear 2016, 364–365, 40–47. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-Induced Martensite in Austenitic Stainless Steels: A Review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Larimian, T.; AlMangour, B.; Grzesiak, D.; Walunj, G.; Borkar, T. Effect of Laser Spot Size, Scanning Strategy, Scanning Speed, and Laser Power on Microstructure and Mechanical Behavior of 316L Stainless Steel Fabricated via Selective Laser Melting. J. Mater. Eng. Perform. 2021, 31, 2205–2224. [Google Scholar] [CrossRef]

- Al-Sayed, S.R.; Hussein, A.A.; Nofal, A.A.; Hassab Elnaby, S.I.; Elgazzar, H. Characterization of a Laser Surface-Treated Martensitic Stainless Steel. Materials 2017, 10, 595. [Google Scholar] [CrossRef]

- Richter, J.; Bartzsch, G.; Scherbring, S.; Bolender, A.; Vollmer, M.; Mola, J.; Volkova, O.; Niendorf, T. Metastable CrMnNi Steels Processed by Laser Powder Bed Fusion: Experimental Assessment of Elementary Mechanisms Contributing to Microstructure, Properties and Residual Stress. Sci. Rep. 2022, 12, 21862. [Google Scholar] [CrossRef]

- Chai, L.; Chen, B.; Wang, S.; Guo, N.; Huang, C.; Zhou, Z.; Huang, W. Microstructural Changes of Zr702 Induced by Pulsed Laser Surface Treatment. Appl. Surf. Sci. 2016, 364, 61–68. [Google Scholar] [CrossRef]

- Jafar, S.; Kadhim, M.; Faayadh, S. Effect of Laser Surface Melting on Chromium Carbide of 304 Stainless Steels. Eng. Technol. J. 2018, 36, 344–349. [Google Scholar] [CrossRef]

- Patel, M.N.; Qiu, D.; Wang, G.; Gibson, M.A.; Prasad, A.; StJohn, D.H.; Easton, M.A. Understanding the Refinement of Grains in Laser Surface Remelted Al–Cu Alloys. Scr. Mater. 2020, 178, 447–451. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C.; Oane, M.; Chioibasu, D.; Popescu-Pelin, G.; Ristoscu, C.; Mihailescu, I.N. Grain Refinement and Mechanical Properties for AISI304 Stainless Steel Single-Tracks by Laser Melting Deposition: Mathematical Modelling versus Experimental Results. Results Phys. 2021, 22, 103880. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, M.; Zhang, T.; Xie, J.; Wei, K.; Wang, S.; Yin, L.; He, P. Grain Refinement and Mechanical Properties Improvement of Inconel 625 Alloy Fabricated by Ultrasonic-Assisted Wire and Arc Additive Manufacturing. J. Alloys Compd. 2022, 910, 164957. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Pavlov, M.; Smurov, I. Residual Stresses at Laser Surface Remelting and Additive Manufacturing. Phys. Procedia 2011, 12, 248–254. [Google Scholar] [CrossRef]

- Zhidkov, M.V.; Smirnov, N.A.; Chen, J.; Kudryashov, S.I.; Goncharov, I.Y. Residual Stresses in Ti6Al4V Alloy after Surface Texturing by Femtosecond Laser Pulses. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 862, p. 022060. [Google Scholar] [CrossRef]

- Jia, Z.; Ye, T.; Ma, J.; Cao, X.; Liu, W.; Yu, W.; Gao, J. Effect of Process Parameters on the Hardness of Laser Surface Textured 5A06 Aluminum Alloy. J. Mater. Eng. Perform. 2021, 30, 5858–5867. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Karjalainen, P.; Hietala, M. Enhancing Mechanical Properties and Formability of AISI 301LN Stainless Steel Sheet by Local Laser Heat Treatment. Key Eng. Mater. 2013, 554–557, 885–892. [Google Scholar] [CrossRef]

- Liu, J.; Chen, C.; Feng, Q.; Fang, X.; Wang, H.; Liu, F.; Lu, J.; Raabe, D. Dislocation Activities at the Martensite Phase Transformation Interface in Metastable Austenitic Stainless Steel: An in-Situ TEM Study. Mater. Sci. Eng. A 2017, 703, 236–243. [Google Scholar] [CrossRef]

- Luo, C.; Zeng, W.; Sun, J.; Yuan, H. Plasticity Modeling for a Metastable Austenitic Stainless Steel with Strain-Induced Martensitic Transformation under Cyclic Loading Conditions. Mater. Sci. Eng. A 2020, 775, 138961. [Google Scholar] [CrossRef]

- Besharatloo, H.; Carpio, M.; Cabrera, J.-M.; Mateo, A.M.; Fargas, G.; Wheeler, J.M.; Roa, J.J.; Llanes, L. Novel Mechanical Characterization of Austenite and Ferrite Phases within Duplex Stainless Steel. Metals 2020, 10, 1352. [Google Scholar] [CrossRef]

- Besharatloo, H.; Wheeler, J.M. Influence of Indentation Size and Spacing on Statistical Phase Analysis via High-Speed Nanoindentation Mapping of Metal Alloys. J. Mater. Res. 2021, 36, 2198–2212. [Google Scholar] [CrossRef]

| Elements | Cr | Ni | Mn | Si | N | Mo | C | Fe |

|---|---|---|---|---|---|---|---|---|

| Wt% | 17.6 | 6.50 | 1.13 | 0.42 | 0.17 | 0.04 | 0.02 | Bal. |

| Pattern | Laser Power (W) | Scanning Speed (mm/s) | Pulse Energy (µJ) | Heat Input (J/mm2) | Laser Spot Overlap (%) |

|---|---|---|---|---|---|

| a | 63.3 | 1.2 | 126.6 | 44.8 | 93 |

| b | 63.3 | 6 | 126.6 | 8.9 | 68 |

| c | 53.6 | 1.2 | 107.2 | 37.9 | 93 |

| d | 53.6 | 6 | 107.2 | 7.5 | 68 |

| Pattern | Ra (μm) | Width of Laser Track (μm) | Depth of Laser Track (μm) |

|---|---|---|---|

| As-received | 0.59 ± 0.17 | - | - |

| (a) | 1.92 ± 0.07 | 66.21 ± 1.12 | 29.67 ± 1.37 |

| (b) | 0.99 ± 0.12 | 61.22 ± 1.34 | 24.85 ± 1.23 |

| (c) | 1.62 ± 0.04 | 57.26 ± 0.91 | 19.91 ± 0.88 |

| (d) | 0.74 ± 0.11 | 47.12 ± 1.09 | 17.11 ± 1.17 |

| Sample | Austenite γ (%) | α’-Martensite (%) |

|---|---|---|

| As-received | 88.48 ± 0.12 | 11.52 ± 0.23 |

| (a) | 81.56 ± 0.13 | 18.44 ± 0.19 |

| (b) | 82.39 ± 0.13 | 17.41 ± 0.10 |

| (c) | 85.43 ± 0.16 | 14.57 ± 0.14 |

| (d) | 86.44 ± 0.11 | 13.56 ± 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezayat, M.; Besharatloo, H.; Mateo, A. Investigating the Effect of Nanosecond Laser Surface Texturing on Microstructure and Mechanical Properties of AISI 301LN. Metals 2023, 13, 2021. https://doi.org/10.3390/met13122021

Rezayat M, Besharatloo H, Mateo A. Investigating the Effect of Nanosecond Laser Surface Texturing on Microstructure and Mechanical Properties of AISI 301LN. Metals. 2023; 13(12):2021. https://doi.org/10.3390/met13122021

Chicago/Turabian StyleRezayat, Mohammad, Hossein Besharatloo, and Antonio Mateo. 2023. "Investigating the Effect of Nanosecond Laser Surface Texturing on Microstructure and Mechanical Properties of AISI 301LN" Metals 13, no. 12: 2021. https://doi.org/10.3390/met13122021