Thermal Treatment of Mercury Mine Wastes Using a Rotary Solar Kiln

Abstract

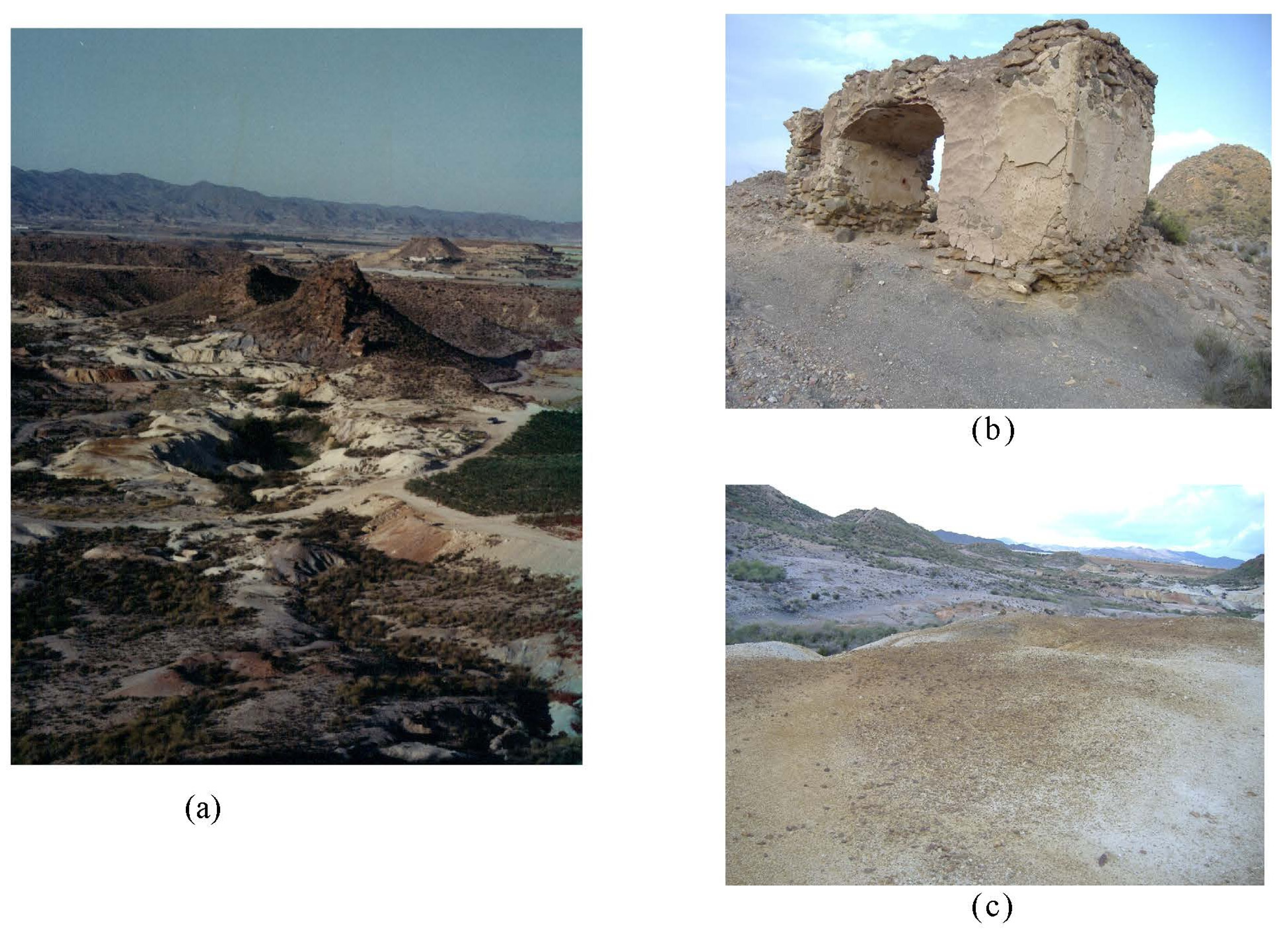

:1. Introduction

2. Materials and Methods

2.1. Characterization of Soils and Mine Wastes

| Sample | MA1 | MA3 | MA5 | MA6 | MA2 | MA4 | MA7 | IV |

|---|---|---|---|---|---|---|---|---|

| Type | MW | CS | CAL | MW | MW | CAL | CAL | --- |

| As (ppm) | 598 | 143 | 1320 | 462 | 550 | 1,550 | 477 | 55 |

| Ba (ppm) | 59,800 | 7,350 | 20,400 | 15,800 | 78,900 | 93,000 | 42,800 | 625 |

| Co (ppm) | 9 | <1 | 25 | 8 | <1 | <4 | <4 | 240 |

| Cr (ppm) | <20 | 64 | <60 | 44 | 83 | <43 | <9 | 380 |

| Fe (%) | 3.19 | 3.44 | 2.72 | 2.49 | 2.27 | 3.06 | 2.34 | --- |

| Hg (ppm) | 2,070 | 116 | <25 | 935 | 865 | 130 | 1,240 | 10 |

| Na (%) | 0.83 | 1.03 | 2.23 | 1.18 | 0.64 | 0.69 | 1.24 | --- |

| Sb (ppm) | 2,880 | 357 | >10,000 | 2,000 | 3,290 | >10,000 | 2,850 | 15 |

| Se (ppm) | <18 | <6 | <37 | <9 | <10 | <31 | <3 | 0.7 * |

| Ta (ppm) | <2.5 | <0.5 | <6.0 | <2.5 | <0.5 | <3.3 | <0.5 | 1 * |

| Th (ppm) | <2.0 | 11.6 | <7.0 | 7.2 | 6.5 | <3.8 | 4.8 | --- |

| U (ppm) | <6.0 | <0.9 | <15.0 | <3.0 | <2.9 | <8.9 | <1.9 | --- |

| W (ppm) | <5 | <1 | <13 | <4 | <1 | <6 | <1 | --- |

| Ag (ppm) | 16.5 | 1.1 | 58.7 | 15.7 | 25.7 | 34.5 | 15.3 | 15 ** |

| Cu (ppm) | 36 | 27 | 32 | 38 | 31 | 42 | 28 | 190 |

| Cd (ppm) | 3.8 | 1 | 5 | 1.4 | 10.6 | 6.6 | 0.8 | 12 |

| Mo (ppm) | 4 | <1 | <1 | 1 | 2 | <1 | <1 | 200 |

| Pb (ppm) | 213 | 134 | 1,820 | 512 | 1,210 | 1,190 | 536 | 530 |

| Ni (ppm) | 25 | 55 | 20 | 34 | 20 | 23 | 18 | 210 |

| Zn (ppm) | 1,200 | 424 | 503 | 1,330 | 3,190 | 2,230 | 854 | 720 |

| S (%) | 2.62 | 0.47 | 2.81 | 1.49 | 2.05 | 2.02 | 0.28 | --- |

| Be (ppm) | 2 | 3 | 1 | 3 | 2 | 2 | 2 | 1.1 * |

| Ca (%) | 1.7 | 2.49 | 7.33 | 2.28 | 0.27 | 3.09 | 0.12 | --- |

| K (%) | 1.86 | 1.98 | 1.14 | 2.07 | 1.87 | 1.45 | 1.49 | --- |

| Mg (%) | 0.46 | 1.28 | 0.94 | 0.69 | 0.23 | 1.16 | 0.54 | --- |

| Mn (ppm) | 83 | 823 | 64 | 108 | 53 | 171 | 31 | --- |

| V (ppm) | 51 | 91 | 25 | 63 | 57 | 30 | 53 | 42 * |

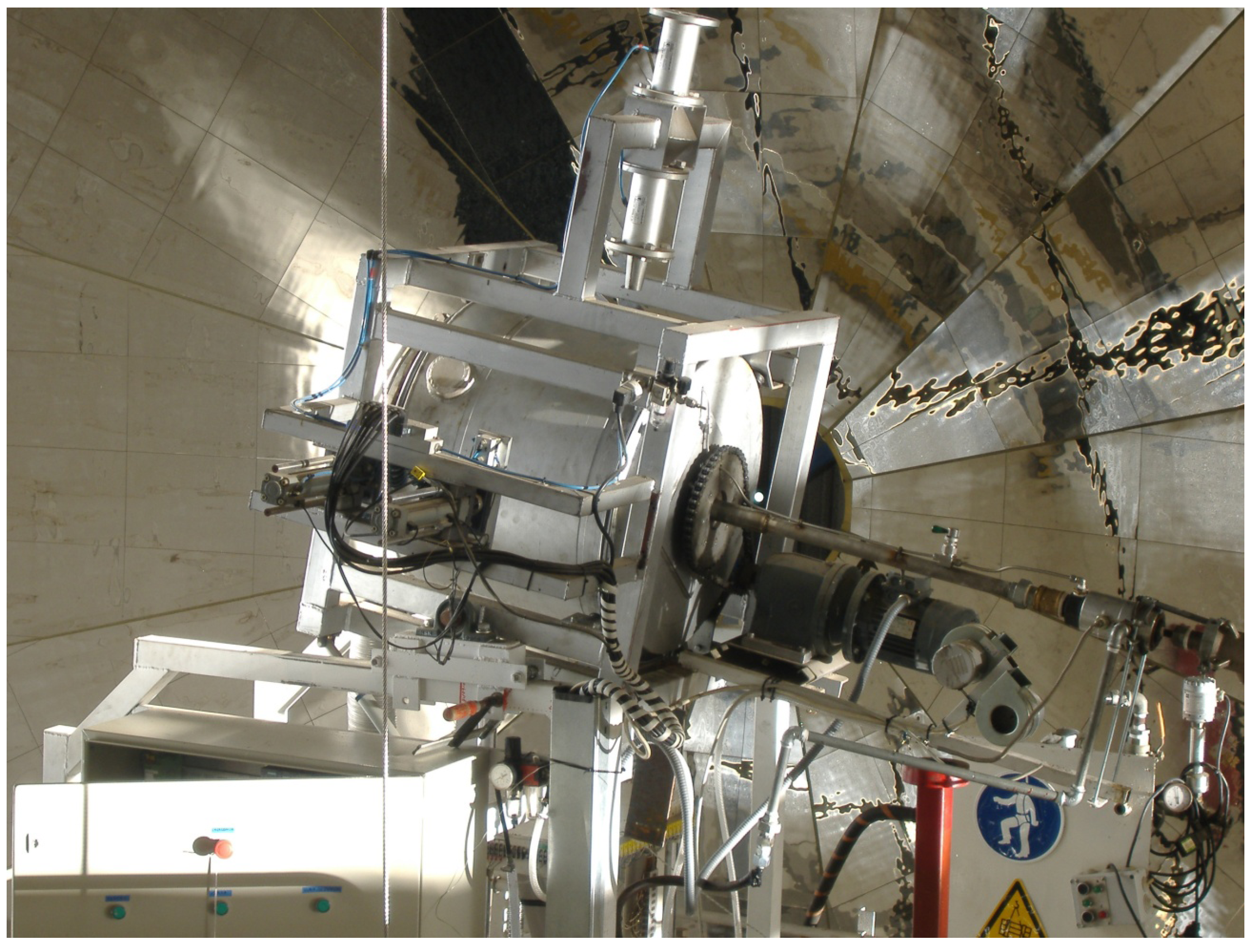

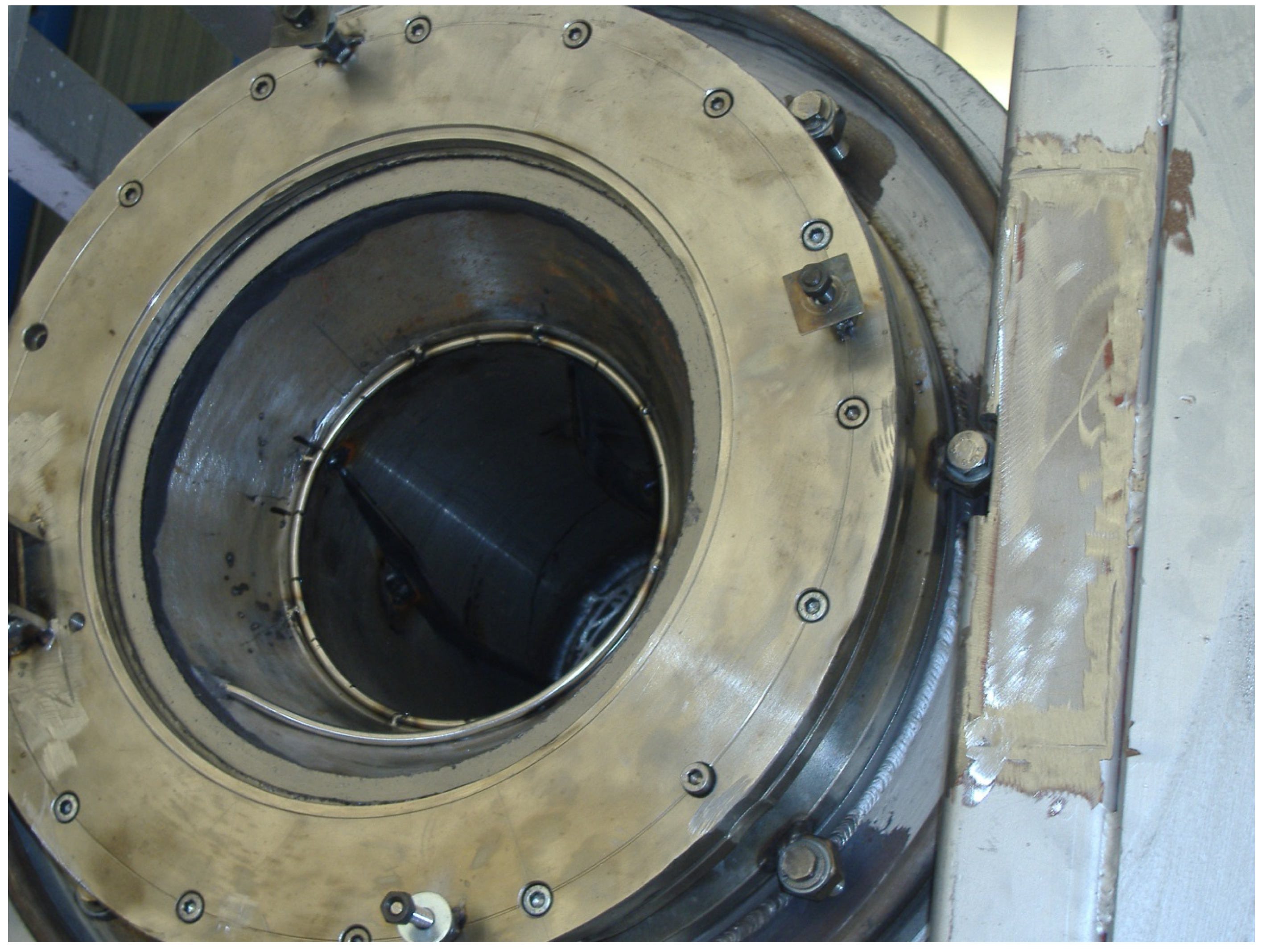

2.2. Rotary Kiln

3. Results and Discussion

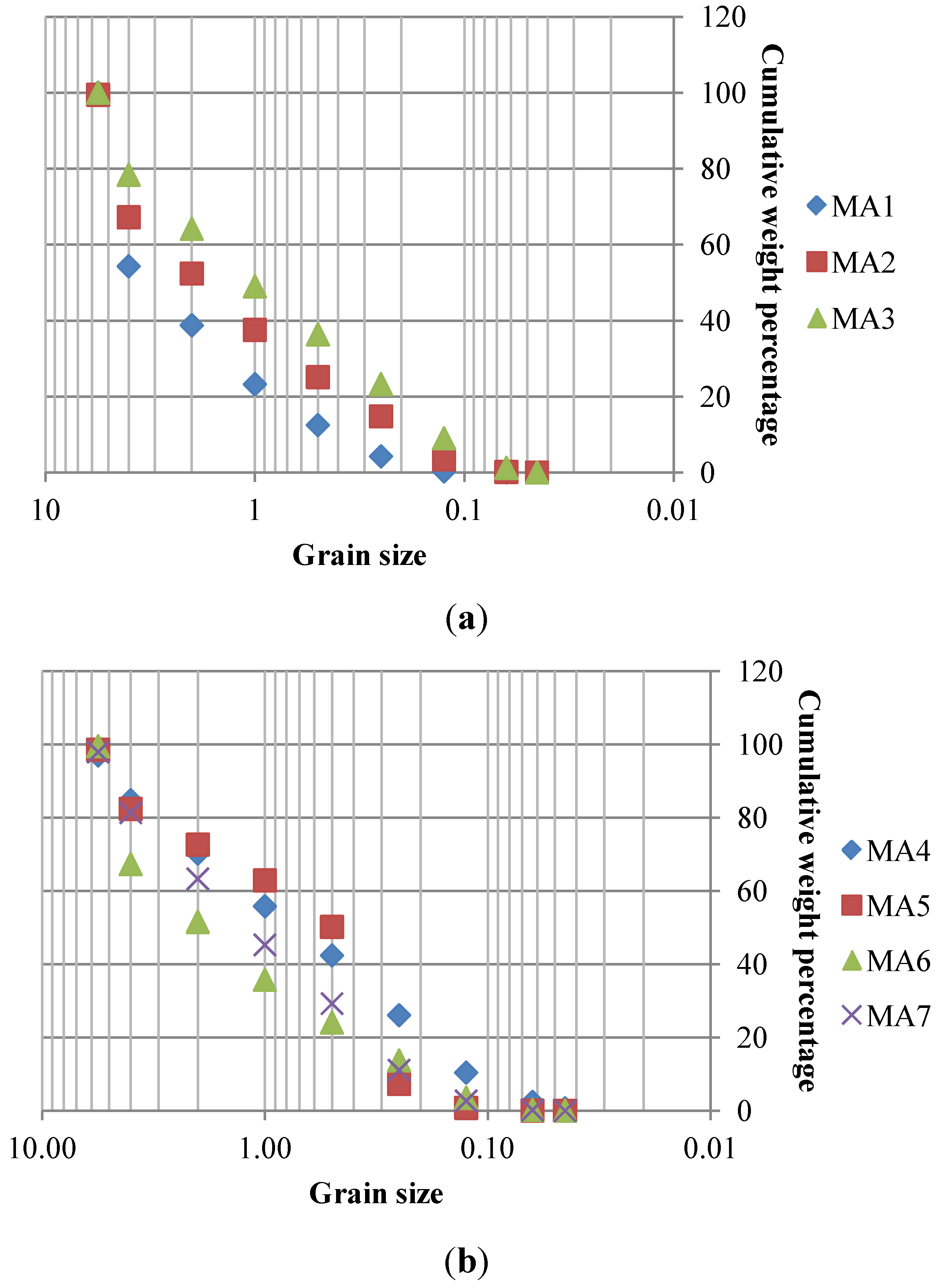

3.1. Geochemistry of Soils and Mine Wastes: Physical Characteristics

| Sample | de | ε | ρ | FC (%) |

|---|---|---|---|---|

| MA1 | 3.4 | --- | 1330 | 8 |

| MA2 | 1.8 | 0.34 | 1430 | 8 |

| MA3 | 1.0 | 0.45 | 1310 | 10 |

| MA4 | 0.8 | --- | 1410 | 10 |

| MA5 | 0.5 | --- | 1470 | 7 |

| MA6 | 1.9 | --- | 1400 | 8 |

| MA7 | 1.3 | 0.41 | 1490 | 8 |

| Minerals | Formula |

|---|---|

| Primary minerals (soils and mine wastes) | |

| Quartz * | SiO2 |

| Barite * | Ba(SO4) |

| Cinnabar * | HgS |

| Dolomite * | CaMg(CO3)2 |

| Calcite * | Ca(CO3) |

| Huntite * | Mg3Ca(CO3)4 |

| Stibnite * | Sb2S3 |

| Realgar * | AsS |

| Orpiment | As2S3 |

| Chalcopyrite | CuFeS2 |

| Arsenian pyrite * | Fe(S1-x As x)2 |

| Sphalerite | ZnS |

| Orthoclase | K(Al,Fe)Si2O8 |

| Gold | Au |

| Illite * | Al4(Si4O10)(OH)8 |

| Secondary minerals (soils and mine wastes) | |

| Hg0 | Hg |

| Metacinnabar | HgS |

| Goethite | FeOOH |

| Jarosite | KFe3(SO4)2(OH)6 |

| Hematite | Fe2O3 |

| Inyoite | CaB3O3(OH)5·4H2O |

| Ferrihydrite | Fe(OH)3 |

| Kaolinite | KAl2Si3AlO10(OH)2·3H2O |

| Gypsum | Ca(SO4)·2H2O |

| Secondary minerals (soils and mine wastes) | |

| Schuetteite | Hg3(SO4)O2 |

| Tiemannite | HgSe |

| Corderoite | Hg3S2Cl2 |

| Shakhovite | Hg4SbO5(OH)3 |

| Calomel | Hg2Cl2 |

| Kuzminite | Hg2(Br,Cl)2 |

| Sample | Dominant Hg-mineral phase |

| MA1 (mining wastes) | Hg matrix, cinnabar |

| MA2 (mining wastes) | Hg matrix |

| MA3 (contaminated soil) | Hg matrix, cinnabar |

| MA4 (calcine) | Hg matrix |

| MA5 (calcine) | Hg matrix |

| MA6 (mining wastes) | Hg matrix, cinnabar |

| MA7 (calcine) | Hg matrix |

3.2. Thermal Desorption Experiments

| Sample | Hg (US) (ppm) | Hg (TS) (ppm) | RE (%) | T (°C) |

|---|---|---|---|---|

| MA1 | 2070 | <10 | 99.5 | 550 |

| MA3 | 116 | <1 | 99.1 | 750 |

| MA5 | <25 | <25 | ---- | 790 |

| MA6 | 935 | <5 | 99.4 | 700 |

| MA2 | 865 | <5 | 99.4 | 700–800 |

| MA4 | 130 | <15 | 88.4 | 700–800 |

| MA7 | 1240 | <5 | 99.6 | 700–800 |

| Phase | Desorption temperature (°C) |

|---|---|

| Hg0 | <100 |

| Hg2 Cl2 | 170 |

| HgCl2 | <250, 220 |

| HgO | 420–550 |

| HgSO4 | 450–500 |

| HgS (cinnabar) | 310–330 |

| Hg in pyrite | >450 |

| Hg in Sphalerite | 600 |

| Hg matrix | 200–300 |

| Sample | Pb (US) (ppm) | Pb (TS) (ppm) | RE (%) | T (°C) |

|---|---|---|---|---|

| MA1 | 213 | 245 | --- | 550 |

| MA3 | 134 | 69 | 48.5 | 750 |

| MA5 | 1820 | 795 | 56.3 | 790 |

| MA6 | 512 | 260 | 49.2 | 700 |

| MA2 | 1210 | 745 | 38.4 | 700–800 |

| MA4 | 1190 | 130 | 89.0 | 700–800 |

| MA7 | 536 | 68 | 87.3 | 700–800 |

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- U.S. Environmental Protection Agency. Treatment Technologies for Mercury in Soil, Waste and Water; EPA-542-R-07-003; Office of Superfund Remediation and Technology Innovation, U.S. Environmental Protection Agency: Washington, DC, USA, 2007. [Google Scholar]

- Mulligan, C.N.; Yong, R.N.; Gibbs, B.F. Remediation technologies for metal-contaminated soils and groundwater: An evaluation. Eng. Geol. 2001, 60, 193–207. [Google Scholar] [CrossRef]

- Wang, J.; Feng, X.; Anderson, C.W.N.; Xing, Y.; Shang, L. Remediation of mercury contaminated sites—A review. J. Hazard. Mater. 2012, 221–222, 1–18. [Google Scholar]

- Khan, F.I.; Husain, T.; Hejazi, R. An overview and analysis of site remediation technologies. J. Environ. Manag. 2004, 71, 95–122. [Google Scholar] [CrossRef]

- Matsuyama, A.; Iwasaki, H.; Higaki, K.; Yabuta, H.; Sano, T.; Akagi, H. Basic Study on the Remediation Technology of Mercury Compound-Contaminated Soil by Low-Temperature Thermal Treatment; Ebinghaus, R., Turner, R.R., de Lacerda, L.D., Vasiliev, O., Salomons, W., Eds.; Springer-Verlag: Berlin, Germany, 1999. [Google Scholar]

- Chang, T.C.; Yen, J.H. On-site mercury-contaminated soils remediation by using thermal desorption technology. J. Hazard. Mater. 2006, 128, 208–217. [Google Scholar] [CrossRef]

- Kunkel, A.M.; Seibert, J.J.; Elliot, L.J.; Ricci, K.; Lynn, E.K.; Pope, G.A. Remediation of elemental mercury using in situ thermal desorption (ISTD). Environ. Sci. Technol. 2006, 40, 2384–2389. [Google Scholar] [CrossRef]

- Kucharski, R.; Zielonka, U.; Sas-Nowosielska, A.; Kuperberg, J.M.; Worsztynowicz, A.; Szdzuj, J. A method of mercury removal from topsoil using low-thermal application. Environ. Monit. Assess. 2005, 104, 341–351. [Google Scholar] [CrossRef]

- Lesa, B.; Aneggi, E.; Rossi, G.; Comuzzi, C.; Goi, D. Bench-scale tests on ultrasound-assisted acid washing and thermal desorption of mercury from dredging sludge and other solid matrices. J. Hazard. Mater. 2009, 171, 647–653. [Google Scholar] [CrossRef]

- Careghini, A.; Dastoli, S.; Ferrari, G.; Saponaro, S.; Bonomo, L.; De Propris, L.; Gabellini, M. Sequential solidification/stabilization and thermal process under vacuum for the treatment of mercury in sediments. J. Soils Sediments 2010, 10, 1646–1656. [Google Scholar]

- Busto, Y.; Cabrera, X.; Tack, F.M.G.; Verloo, M.G. Potential of thermal treatment for decontamination of mercury containing wastes from chlor-alkali industry. J. Hazard. Mater. 2011, 186, 114–118. [Google Scholar] [CrossRef]

- Huang, Y.T.; Hseu, Z.-Y.; Hsi, H.H. Influences of termal decontamination on mercury removal, soil properties, and repartitioning of coexisting heavy metals. Chemosphere 2011, 84, 1244–1249. [Google Scholar] [CrossRef]

- Comuzzi, C.; Lesa, B.; Aneggi, E.; Dolcetti, G.; Goi, D. Salt-assisted thermal desorption of mercury from contaminated dredging sludge. J. Hazard. Mater. 2011, 193, 177–182. [Google Scholar] [CrossRef]

- Hua, J.M.; Wei, K.M.; Zheng, Q. Thermal desorption of mercury from gold-loaded granule activated carbon and its effect on gold elution. Hydrometallurgy 2012, 117–118, 86–92. [Google Scholar]

- Navarro, A.; Cañadas, I.; Martínez, D.; Rodríguez, J.; Mendoza, J.L. Application of solar thermal desorption to remediation of mercury-contaminated soils. Sol. Energy 2009, 83, 1405–1414. [Google Scholar] [CrossRef]

- Navarro, A.; Biester, H.; Mendoza, J.L.; Cardellach, E. Mercury speciation and mobilization in contaminated soils of the valle del azogue Hg mine (SE, Spain). Environ. Geol. 2006, 49, 1089–1101. [Google Scholar] [CrossRef]

- Biester, H.; Scholz, C. Determination of mercury binding forms in contaminated soils: Mercury pyrolysis versus sequential extractions. Environ. Sci. Technol. 1996, 31, 233–239. [Google Scholar] [CrossRef]

- Ministry of Housing, Spatial Plannin and the Environment. Circular on Target Values and Intervention Values for Soil Remediation; Ministry of Housing, Spatial Plannin and the Environment: The Hague, The Netherlands, 2000. [Google Scholar]

- Román, R.; Cañadas, I.; Rodríguez, J.; Hernández, M.T.; González, M. Solar sintering of alumina ceramics: Microstructural development. Sol. Energy 2008, 82, 893–902. [Google Scholar] [CrossRef]

- Viladevall, M.; Font, X.; Navarro, A. Geochemical mercury survey in the Azogue Valley (Betic area, SE Spain). J. Geochem. Explor. 1999, 66, 27–35. [Google Scholar] [CrossRef]

- Biester, H.; Gosar, M.; Müller, G. Mercury speciation in tailings of the Idrija mercury mine. J. Geochem. Explor. 1999, 65, 195–204. [Google Scholar] [CrossRef]

- Navarro, A.; Cañadas, I.; Rodríguez, J.; Martínez, D. Leaching characteristics of mercury mine wastes before and after solar thermal desorption. Environ. Eng. Sci. 2012, 29, 915–928. [Google Scholar] [CrossRef]

- Navarro, A.; Cardellach, E.; Cañadas, I.; Rodríguez, J. Solar thermal vitrification of mining contaminated soils. Int. J. Miner. Process. 2013, 119, 65–74. [Google Scholar] [CrossRef]

- Taube, F.; Pommer, L.; Larsson, T.; Shchukarev, A.; Nordin, A. Soil remediation-mercury speciation in soil and vapor phase during thermal treatment. Water Air Soil Pollut. 2008, 193, 155–163. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Navarro, A.; Cañadas, I.; Rodríguez, J. Thermal Treatment of Mercury Mine Wastes Using a Rotary Solar Kiln. Minerals 2014, 4, 37-51. https://doi.org/10.3390/min4010037

Navarro A, Cañadas I, Rodríguez J. Thermal Treatment of Mercury Mine Wastes Using a Rotary Solar Kiln. Minerals. 2014; 4(1):37-51. https://doi.org/10.3390/min4010037

Chicago/Turabian StyleNavarro, Andrés, Inmaculada Cañadas, and José Rodríguez. 2014. "Thermal Treatment of Mercury Mine Wastes Using a Rotary Solar Kiln" Minerals 4, no. 1: 37-51. https://doi.org/10.3390/min4010037