1. Introduction

Generally, sediment can be classified into two groups: non-cohesive sediment such as sand and cohesive sediment such as mud. Particles of non-cohesive sediment move individually. Sediment smaller than 63 µm is generally defined as cohesive sediment [

1,

2,

3,

4]. Cohesive sediments in waters form aggregated larger particles (so-called “flocs”) by through binding together (aggregation). The flocs disaggregate into smaller micro-flocs (breakup or disaggregation) mainly due to turbulent and internal shear [

5], rather than breaking up into the single constituent grains [

6]. This series of aggregation and breakup due to cohesive properties of sediment and flow turbulence is referred to as the flocculation process. The chance of particle collisions resulting in flocculation is caused by Brownian motion, different settling velocities of particles, and turbulence. From many studies (e.g., [

7,

8,

9]), it is known that turbulent motions are the main mechanism in the flocculation process. The cohesive sediment continuously experiences changes of density and size through the flocculation process. Due to the change of density and size, the settling velocity of cohesive sediment also varies depending on many conditions such as particle properties, turbulence intensity, and sediment concentration. The settling velocity of particles is one of the most important factors in sediment suspension. Therefore, the flocculation process is of great interest when the suspension of cohesive sediment is studied. It is not simple to understand the mechanism of cohesive sediment transport because of the flocculation process.

In many studies, flocculation models are proposed under the assumption of self-similarity, the main concept of fractal theory (e.g., [

6,

9,

10,

11,

12,

13,

14,

15]). Kranenburg [

12] proposes the proportional relationship between excessive density and yield strength of floc based on experimental results of [

16,

17]. It is known from Kranenburg [

12] that the empirical proportionality constants represent the properties of material. It is also stated that the fractal dimension of floc is in the range of 1.4 (marine snow) to 2.2 (lacustrine flocs). Winterwerp [

9] developed a floc growth type flocculation model. The model of Winterwerp [

9] considers turbulence as the most dominant mechanism for floc aggregation and breakup. The empirical parameters of the model are calibrated with field data of van Leussen [

18] and simulation results are in satisfactory agreement with the field results. Khelifa and Hill [

11] propose a power law equation for the fractal dimensions of flocs by analyzing many observation results. Consequently, Khelifa and Hill [

11] suggest a settling velocity formulation for floc under the assumption of variable fractal dimension, which depends on floc size whereas that of Winterwerp [

9] is assumed to be constant. Son and Hsu [

19] propose a floc growth type flocculation model for variable fractal dimension and yield strength of floc. The model is validated with laboratory experiments of [

20,

21,

22]. The results show that a new model with variable fractal dimension and yield strength has the capability to simulate the temporal evolution of floc size reasonably well. As mentioned, properties of floc such as density and yield strength change as the floc size increases or decreases following the fractal geometry. This has a significant effect on suspension behavior of the floc because the size and density of the suspended matter (floc in this study) have a direct relationship with the settling velocity. The volumetric concentration is defined as the volume of suspended particles (flocs in this study) divided by the total volume of the fluid-particle mixture. The hindered settling effect is affected by the volumetric concentration of suspended matters. Thus, it is also known that the volumetric concentration plays an important role in calculating the settling velocity of flocs [

23,

24]. Turbulence is also affected by the volumetric concentration (see Equations (8) and (9)). Because the size and density of floc are variable through the flocculation process, the volumetric concentration also varies under the condition of constant mass concentration.

There are many methods for observing of floc concentration such as bottle sampling, pump sampling, acoustic method, and the nuclear method [

4,

25]. Among these, optical and laser diffraction systems are widely used in order to avoid disturbance of floc structure [

26]. For example, the LISST (Laser

In Situ Scattering and Transmissometry), one of the most popular instruments for floc observation, measures the volume of suspended flocs using the diffraction pattern created in a laser beam [

27]. Results obtained by the LISST are analyzed under the assumption that particles are transparent spheres [

28]. Through a comparative study, Mikkelsen

et al. [

29] find that a digital floc camera (DFC) underestimates the floc size compared to the LISST. They further conclude that an accurate measurement of floc volumetric concentration is of great importance when floc dynamics is studied. Milligan

et al. [

30] show the successive increase or decrease of concentration and median size of floc under tidal conditions. The study of Milligan

et al. [

30] focuses on the temporal variation of concentration and size rather than spatial variation, such as the vertical profile. Fox

et al. [

31] analyze field results measured in the Po River pro-delta using optical systems. The size of floc in an image is converted to the equivalent spherical diameter in order to estimate the volumetric concentration of suspended flocs. Fox

et al. [

31] find that the maximum volumetric concentration of floc is located not at the bed but above the bed. The vertical distribution of sediment mass concentration is usually represented by the Rouse profile. The Rouse profile has a continuous decrease of sediment concentration with increase in elevation from the bed. However, the volumetric concentration measured by Fox

et al. [

31] increases with elevation from the bed up to certain elevation. Fox

et al. [

31] insist that the elevated maximum of floc volumetric concentration is due to resuspension of coarse single particles near the bed under the assumption that the size of floc is larger than 125 μm. However, it is well known that the resuspension from the cohesive bed is caused mainly by aggregated flocs rather than individual particles [

32]. Dey

et al. [

33] carry out experiments to understand the turbulence structure under the condition of sediment suspension and find an increase of turbulence intensity near the bed. The increased turbulence has a significant effect on floc breakup. Therefore, the conclusion of Fox

et al. [

31] is questionable and it is necessary to investigate the elevated maximum of floc volume concentration more intensively. The elevated maximum of floc volume concentration is found in the numerical study by Son and Hsu [

34]. They find results of numerical experiments conducted by a one dimensional vertical (1DV) transport model incorporated with a floc growth type flocculation model which ensures mass conservation. Son and Hsu [

34] find that the maximum volumetric concentration of floc is located at an elevation of 0.1 to 0.6 m above the bed whereas the mass concentration of floc has a maximum value at the bed. In the case of non-cohesive sediment in Son and Hsu [

34], both the volumetric concentration and the mass concentration have maximum values at the bed. To the best of our knowledge, no numerical research except for Son and Hsu [

34] has calculated the elevated maximum of volumetric concentration so far. However, no detailed discussion of the elevated maximum of volumetric concentration is provided in the study of Son and Hsu [

34].

This study aims to investigate the volumetric concentration maximum of cohesive sediment using the 1DV numerical model developed by Son and Hsu [

34]. The 1DV model of Son and Hsu [

34] has been validated with field results (e.g., [

34,

35]) and has been adopted for numerical studies of cohesive sediment suspension (e.g., [

36,

37]). A detailed description of the sediment transport model and flocculation model are given in

Section 2. In

Section 3, the results of the numerical experiments are discussed. The final conclusions of this study are drawn in

Section 4.

3. Results and Discussion

Numerical experiments are conducted here in order to study the vertical profile of volumetric concentration of flocs. The flow condition of simulation is set to be 0.5 m/s of depth-averaged velocity (

uavg) in most simulation cases of this study based on

in situ measurements of Fox

et al. [

31]. In the study of Fox

et al. [

31], the volumetric concentration has a maximum above the bed (not on the bed) when

uavg is about 0.5 m/s. In many cases, the cohesive bed has a variable critical shear stress mainly due to consolidation. However, the critical shear stress (τ

c) of cohesive bed is set to be 0.17 kPa here following the previous study of Hsu

et al. [

42] and Son and Hsu [

34,

36] because we like to exclude the effect of erodibility parameters (e.g., [

8]) on behaviors of sediment suspension. In the case of non-cohesive sediment simulation, the critical shear stress is calibrated to fit the depth-averaged concentration of non-cohesive sediment to that of cohesive sediment. The density and size of non-cohesive sediment are also determined using the average values of cohesive sediment results in order to investigate the effect of flocculation on

under the similar conditions of flow and suspension. All results discussed in this study are obtained after the equilibrium state is achieved.

The numerical experiments are carried out under two different flow conditions: pure current condition of

uavg = 0.5 m/s and oscillatory flow replicating U-tube experiments. The oscillatory flows are defined by the free-stream flow velocity (

U) for simplicity (Equation (17)). The oscillatory flow conditions are symmetric in this study.

where

uamp = orbital amplitude;

T = period of oscillation; and

t = time.

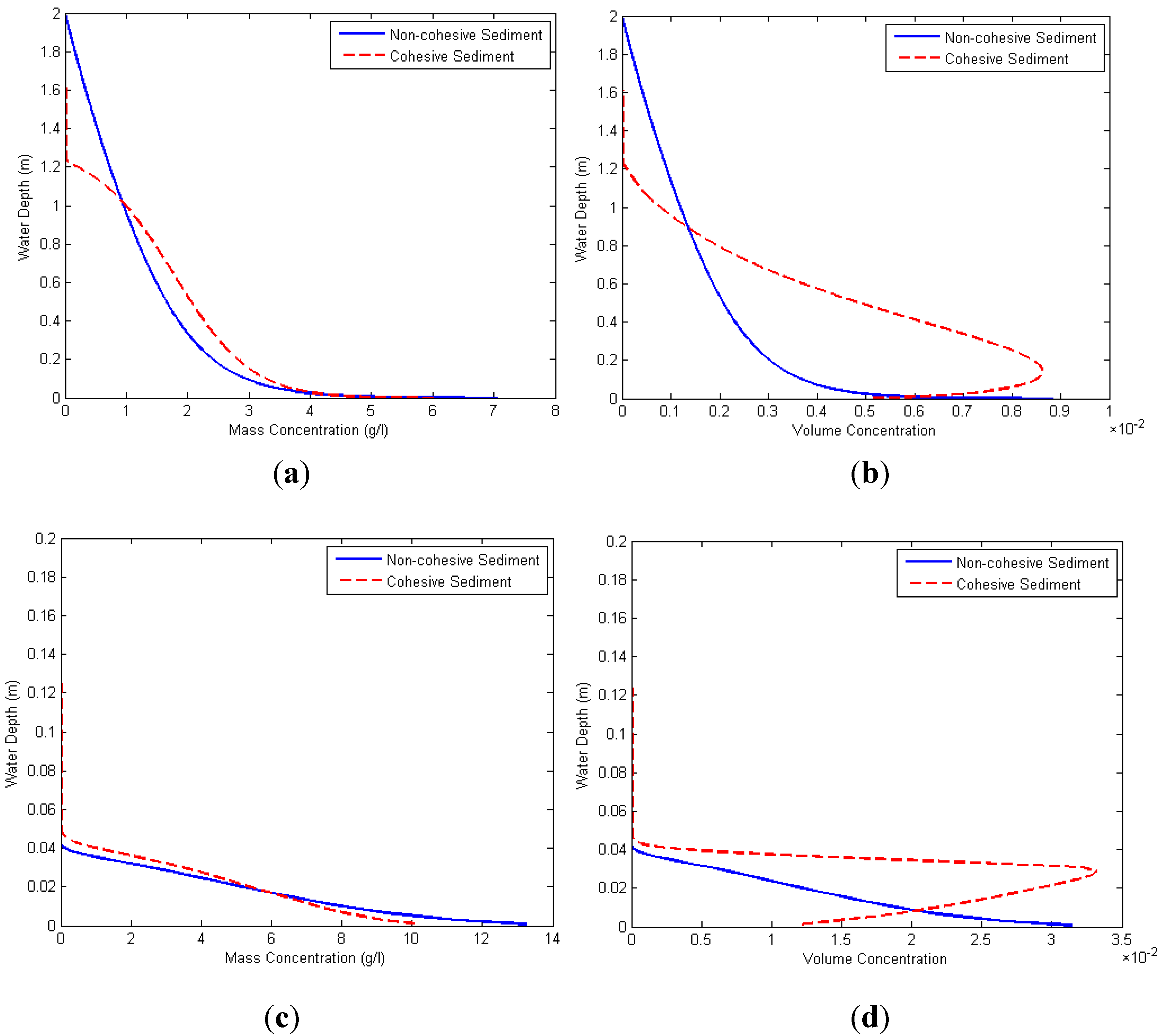

Figure 1 shows the vertical profiles of suspended sediment concentration. The solid curve and the dotted curve represent results of non-cohesive sediment and cohesive sediment, respectively.

Figure 1a,b are results under the steady current condition.

Figure 1c,d show the phase-averaged profiles under the oscillatory flow condition of

uamp = 0.5 m/s and

T = 7.0 s. In simulation results of cohesive sediment under a steady current, it is seen that the mean size and density of flocs are 73.8 μm and 1496 kg/m

3, respectively (refer to

Figure 2). In the case of oscillatory flow, those are 148 μm and 1263 kg/m

3. Based on the calculation result of cohesive sediment case, the density and size of non-cohesive sediment are fixed to be 73.8 μm and 1496 kg/m

3 under a steady current. Under the condition of oscillatory flow, those are set to be 148 μm and 1263 kg/m

3. The depth-averaged mass concentrations in the cases of current and oscillatory flow are 1.166 kg/m

3 and 0.1116 kg/m

3, respectively. The mass concentration profile of non-cohesive sediment continuously decreases in the vertical direction. The mass concentration of cohesive sediment under a steady current has a clear lutocline around 1 m above the bed. The volumetric concentration profile of non-cohesive sediment is linearly proportional to the mass concentration because the density of sediment is constant. It is found in

Figure 1b that the profile of

for cohesive sediment shows a peak value around 0.2 m above the bed under a steady current.

of cohesive sediment increases in the range of 0 m to 0.2 m from the bed whereas the mass concentration of cohesive sediment shows the typical shape of a Rouse profile (see

Figure 1a). The sediments under the oscillatory flow condition are confined near the bed similar to sheet flow. However, the maximum value of

exists at the elevation of 4 cm above the bed whereas that of the non-cohesive sediment exists at the bed. In

Figure 1, it can be seen that the elevated maximum of

is not caused by the type of flow condition because the elevated maximum is shown under both steady and oscillatory currents. The difference between profiles of mass and

result from the spatial variation of floc density and size. The density of floc decreases as the size of floc increases (see Equations (2) and (3)). Thus, it is deduced that the size of floc is large and the density is low near the elevation where the maximum value of

exists.

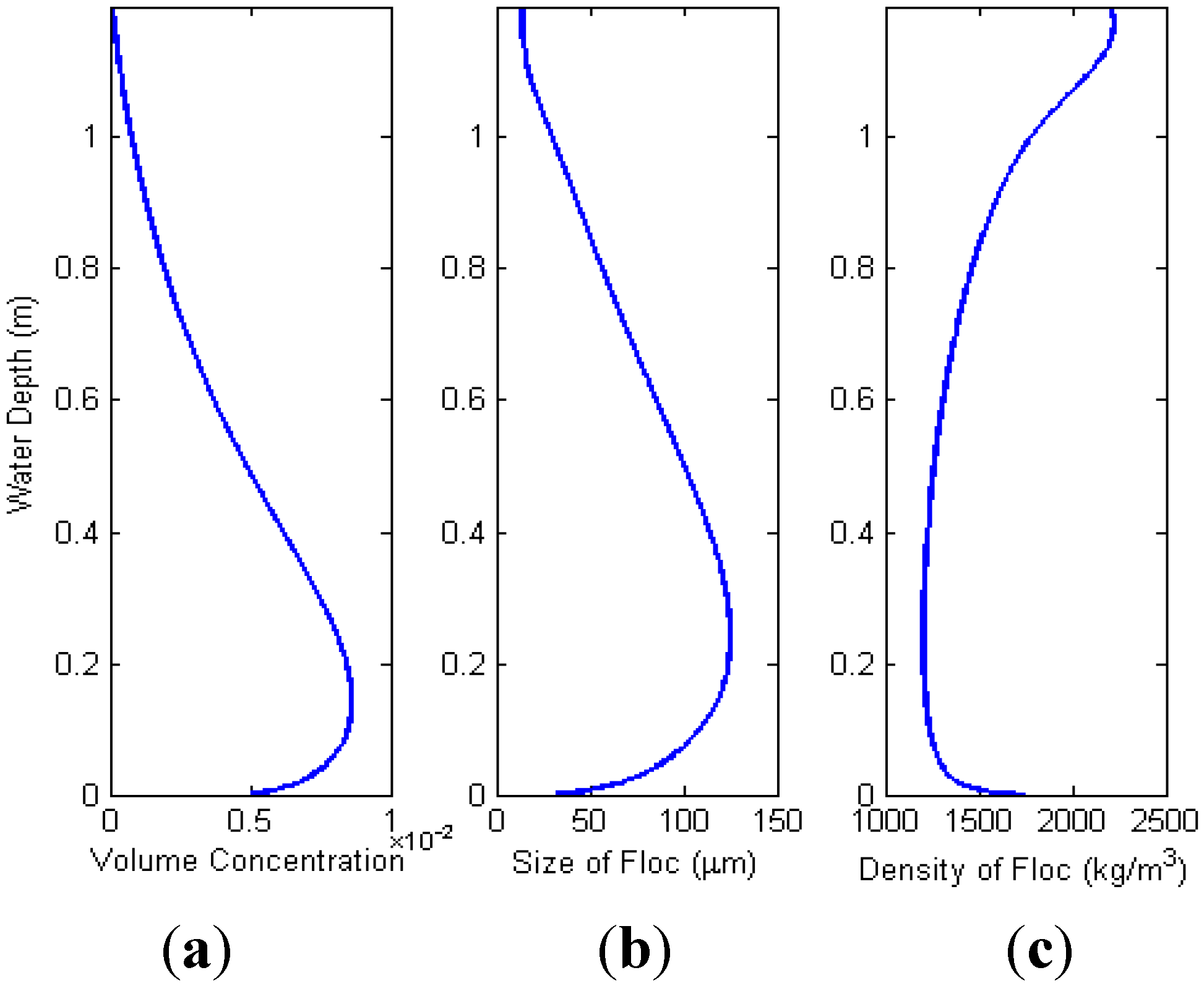

Figure 2 shows the vertical profiles of

, size, and density of floc under the steady current (

uavg = 0.5 m/s). As discussed above, the maximum size and the minimum density of floc are calculated near the elevation at which the maximum value of

is located.

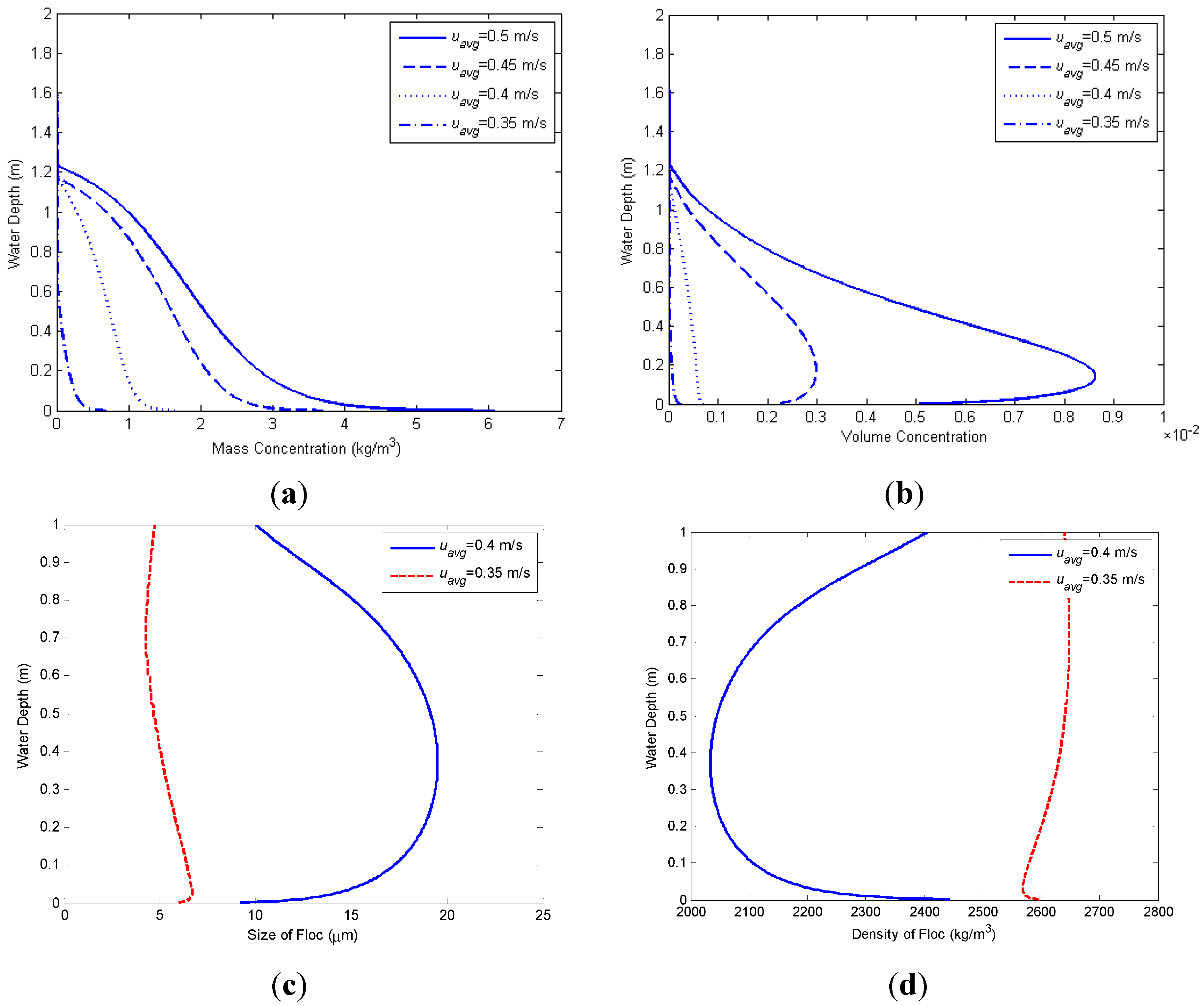

Figure 3 represents the profiles of

c,

,

D, and ρ

f under the different conditions of flow velocity. In

Figure 3, it can be seen that both depth-averaged and near-bed concentrations are decreased as

uavg decreases. The elevated maximum of

is found when

uavg is larger than 0.4 m/s. The profiles of

under the conditions of

uavg = 0.4 m/s and

uavg = 0.35 m/s are similar to those of mass concentration. The maximum size and the minimum density of floc under the conditions of

uavg = 0.4 m/s and

uavg = 0.35 m/s are also located at elevations of 0.35 m and 0.03 m, respectively (see

Figure 3c,d). Therefore, the near-bed maximum concentration in the cases of

uavg = 0.4 m/s and

uavg = 0.35 m/s is not denyed by the location of maximum floc size and the minimum floc density. The maximum floc size in the cases of

uavg = 0.4 m/s and

uavg = 0.35 m/s is calculated to be less than 20 μm. Compared to the size of the primary particle (4 μm), 20 μm of floc size is still small. This means that flocs have not experienced sufficient size evolution in the cases of

uavg = 0.4 m/s and

uavg = 0.35 m/s. As mentioned in the first paragraph of this section,

is set to be 0.17 kPa in this study. The aggregation process is affected by

c (see Equation (1)). As shown in

Figure 3a,

c under the conditions of of

uavg = 0.4 m/s and

uavg = 0.35 m/s is relatively small compared to the cases of of

uavg = 0.45 m/s and

uavg = 0.50 m/s.

Figure 3.

Vertical profiles of floc concentration under the different conditions of current velocity. (a) c under Different Conditions of uavg; (b) ϕf under different conditions of uavg; (c) D under different condition of uavg; and (d) ρf under different condition of uavg. (a) The mass concentration shows a lutocline which is the important characteristics of cohesive sediment suspension; (b) The volumetric concentration shows the elevated maximum when the velocity exceeds 0.4 m/s; (c) The maximum size of floc in the cases of uavg = 0.40 m/s and uavg = 0.35 m/s is also located at elevations of 0.35 m and 0.03 m (not at the bed); (d) The resulting density of floc shows the maximum values not at the bed but above the bed. In (a) and (b), the solid, dashed, dotted and dash-dotted curves represent results of uavg = 0.50 m/s, uavg = 0.45 m/s, uavg = 0.40 m/s, and uavg = 0.35 m/s, respectively. In (c) and (d), the solid and dashed curves show the results of uavg = 0.40 m/s and uavg = 0.35 m/s.

Figure 3.

Vertical profiles of floc concentration under the different conditions of current velocity. (a) c under Different Conditions of uavg; (b) ϕf under different conditions of uavg; (c) D under different condition of uavg; and (d) ρf under different condition of uavg. (a) The mass concentration shows a lutocline which is the important characteristics of cohesive sediment suspension; (b) The volumetric concentration shows the elevated maximum when the velocity exceeds 0.4 m/s; (c) The maximum size of floc in the cases of uavg = 0.40 m/s and uavg = 0.35 m/s is also located at elevations of 0.35 m and 0.03 m (not at the bed); (d) The resulting density of floc shows the maximum values not at the bed but above the bed. In (a) and (b), the solid, dashed, dotted and dash-dotted curves represent results of uavg = 0.50 m/s, uavg = 0.45 m/s, uavg = 0.40 m/s, and uavg = 0.35 m/s, respectively. In (c) and (d), the solid and dashed curves show the results of uavg = 0.40 m/s and uavg = 0.35 m/s.

![Water 07 00081 g003]()

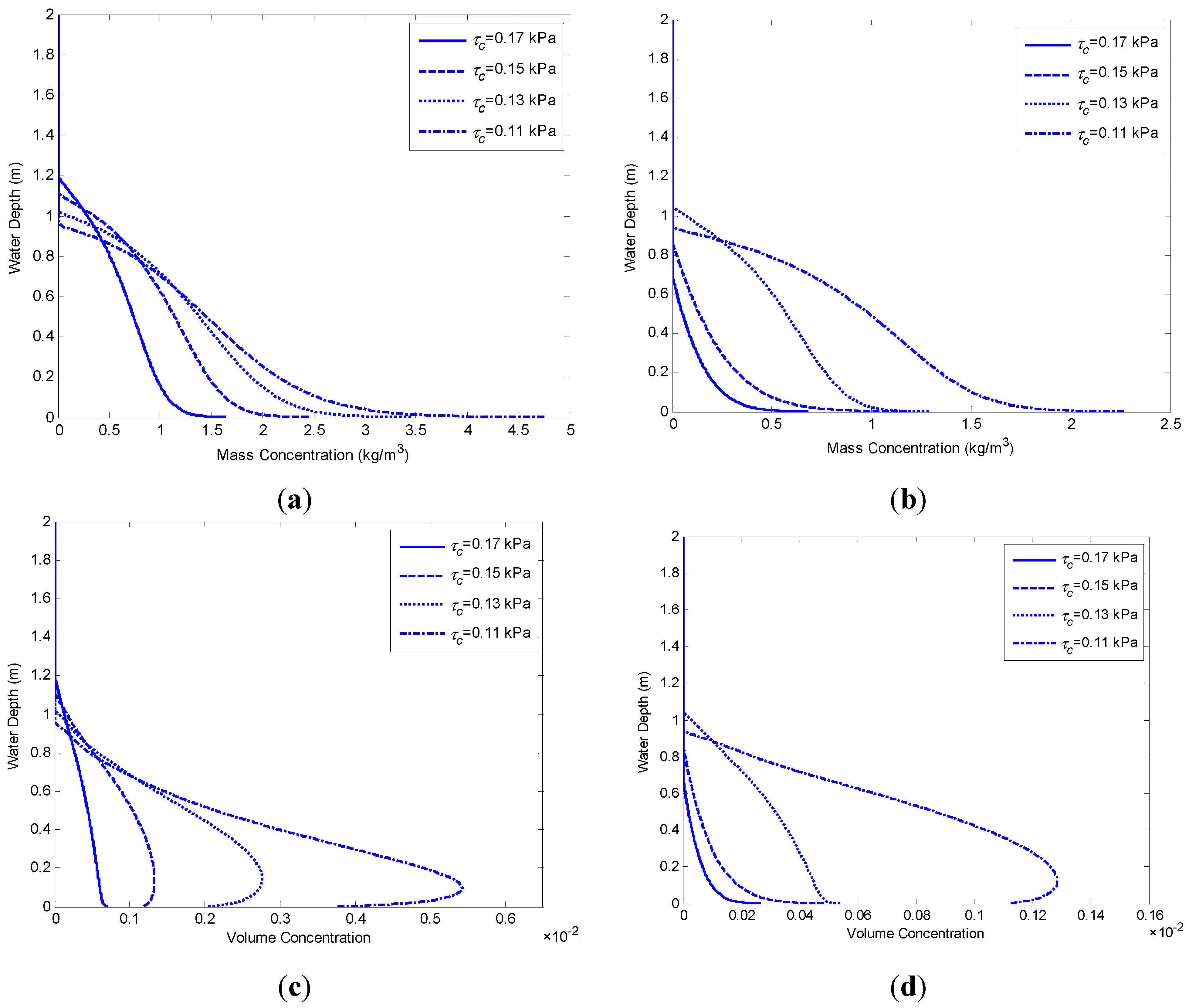

To examine the effect of mass concentration on volumetric concentration, concentration profiles calculated with different values of τ

c are plotted in

Figure 4. The solid, dashed, dotted, and dash-dotted curves represent calculation results under the conditions of τ

c = 0.17 kPa, τ

c = 0.15 kPa, τ

c = 0.13 kPa, and τ

c = 0.11 kPa, respectively. When

uavg is set to be 0.4 m/s, the elevated maximum of volumetric concentration is calculated as τ

c is decreased from 0.17 to 0.15 kPa. In the case of

uavg = 0.35 m/s, the elevated maximum is calculated with τ

c = 0.11 kPa. As shown in

Figure 4a,b, the mass concentration is increased according to decrease of τ

c. The increased mass concentration enhances the aggregation process (the first term of Equation (1)) resulting in calculating the elevated maximum of volumetric concentration.

Figure 4.

Vertical profiles of concentrations under different conditions of critical shear stress. (a) The mass concentration under the condition of uavg = 0.40 m/s; (b) The mass concentration under the condition of uavg = 0.35 m/s; (c) The volumetric concentration under the condition of uavg = 0.40 m/s; (d) The volumetric concentration under the condition of uavg = 0.35 m/s. The solid, dashed, dotted, and dash-dotted curves represent results of τc = 0.17 kPa, τc = 0.15 kPa, τc = 0.13 kPa, and τc = 0.11 kPa, respectively.

Figure 4.

Vertical profiles of concentrations under different conditions of critical shear stress. (a) The mass concentration under the condition of uavg = 0.40 m/s; (b) The mass concentration under the condition of uavg = 0.35 m/s; (c) The volumetric concentration under the condition of uavg = 0.40 m/s; (d) The volumetric concentration under the condition of uavg = 0.35 m/s. The solid, dashed, dotted, and dash-dotted curves represent results of τc = 0.17 kPa, τc = 0.15 kPa, τc = 0.13 kPa, and τc = 0.11 kPa, respectively.

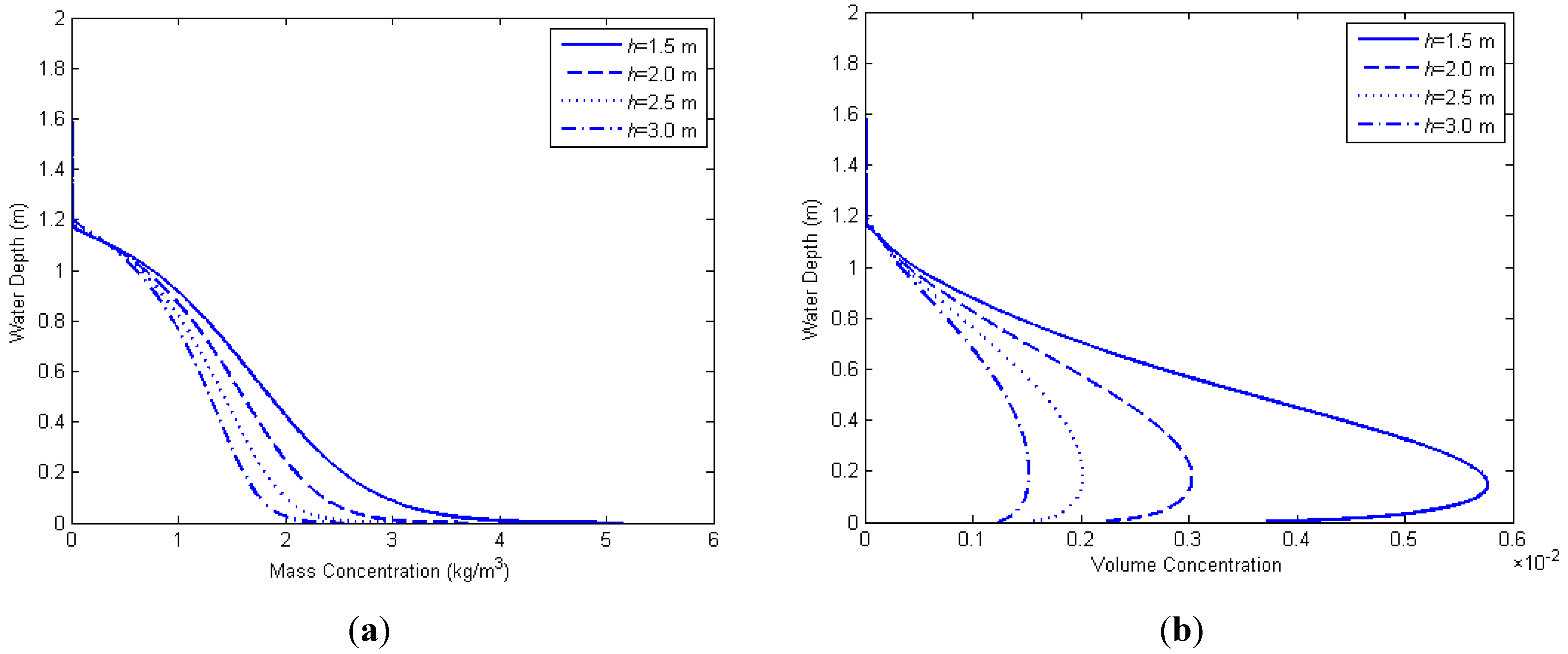

To investigate the effect of water depth (

h) on the profile of volumetric concentration, different conditions of

h are tested (

Figure 5). In all cases of

h,

uavg and τ

c are set to be 0.45 m/s and 0.17 kPa. As shown in

Figure 5a, the mass concentration is increased in accordance with decrease of

h whereas the suspension height is almost constant.

Figure 5b represents the profiles of volumetric concentration. In

Figure 5b, it is found that the vertical gradient of the volumetric concentration and the elevated maximum become more significant as

h decreases. The profiles of mass concentration and volumetric concentration under the condition of

h = 3.0 m are similar to those of

h = 2.0 m and τ

c = 0.15 kPa (see

Figure 4a,b).

Figure 5.

Vertical profiles of concentration under different conditions of water depth (h). (a) The mass concentration profiles; and (b) The volumetric concentration profiles. The solid, dashed, dotted, and dash-dotted curves represent results of h = 1.5 m, h = 2.0 m, h = 2.5 m, and h = 3.0 m, respectively.

Figure 5.

Vertical profiles of concentration under different conditions of water depth (h). (a) The mass concentration profiles; and (b) The volumetric concentration profiles. The solid, dashed, dotted, and dash-dotted curves represent results of h = 1.5 m, h = 2.0 m, h = 2.5 m, and h = 3.0 m, respectively.

From this finding, it is known again that the shape of volumetric concentration significantly depends on mass concentration.

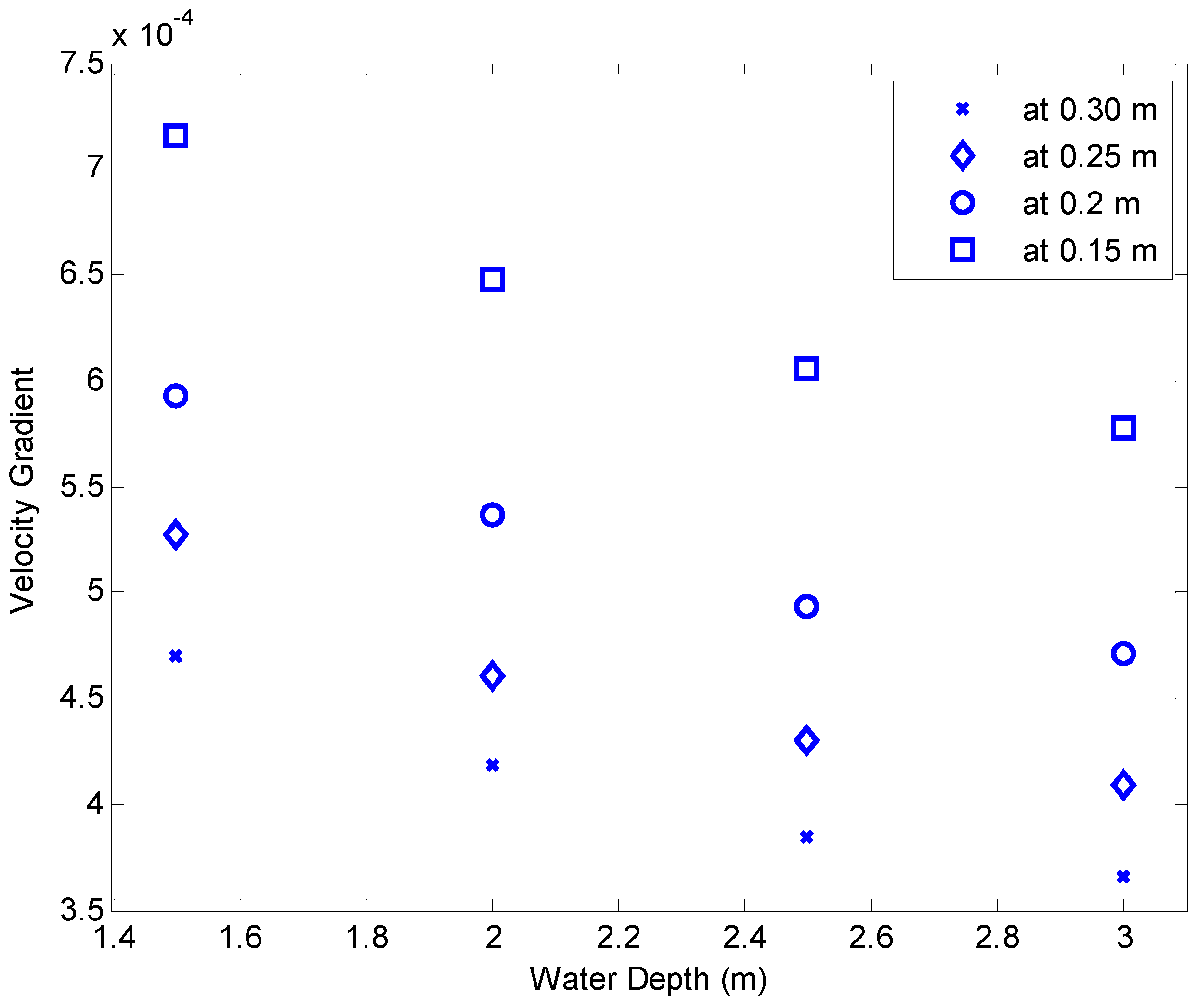

Figure 6 shows the gradient of

uavg at the elevations of 0.30 m, 0.25 m, 0.20 m, and 0.15 m under the condition of

Figure 5. It is found in

Figure 6 that the velocity gradient near the bed decreases as the water depth increases. The fluid shear stress is considered to be proportional to the velocity gradient under the assumption of Newtonian shear stress relationship. Based on Newtonian shear stress relationship, it can be seen in

Figure 6 that the fluid shear is also decreased as the water depth increases. Therefore, the sediment suspension is affected by the water depth under the constant conditions of

uavg and τ

c. However, the water depth is not considered as a dominant factor to determine the occurrence of elevated maximum because the elevated maximum of volumetric concentration is found in all cases of elevations tested in this study. This is also found in the study of Fox

et al. [

31]. In

Figure 4 of Fox

et al. [

31], the elevated maximum of volumetric concentration is found at many different elevations. However, it is also difficult to make a generalized conclusion with Fox

et al. [

31] because of the hydrodynamics changes at different locations of measurement. In addition, it is impossible to replicate the measurements of Fox

et al. [

31] using a numerical model due to limited information on the hydrodynamic conditions of the measurements.

From Equation (4), it is known that

is inversely proportional to the solid volume concentration of the primary particles within a floc,

, defined below:

where

Vf = volume of a floc;

Vs = volume of primary particles within a floc; and

= ratio of the total volume of solids in a floc to the volume of a floc.

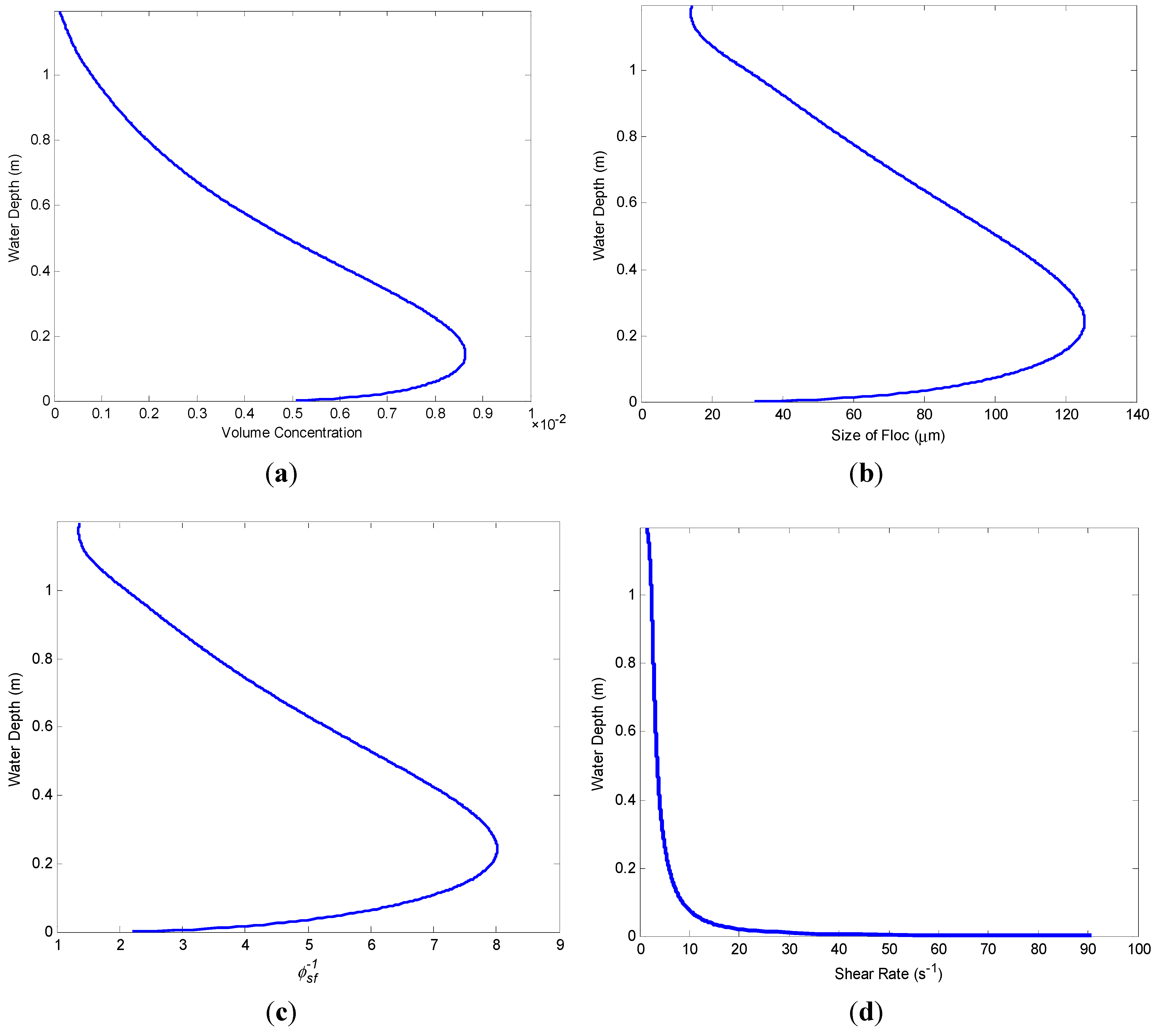

Figure 7 shows the vertical profiles of

,

,

D, and

G when the elevated maximum of

occurs. It is found in

Figure 7 that

and

D have the same shape and elevation of maximum values. The elevation of maximum

and

D is slightly higher than that of

. The elevated maximum of

means that larger flocs of which

is low exist near the location of the concentration maximum (see

Figure 7a,b). From the low values of

and

D near the bed, it is also known that small and dense flocs, which have a large yield stress (see [

38]), exist near the bed. A floc has a high density and a small size when the turbulence intensity is strong. Therefore, the intensity of turbulence near the elevation of the maximum value of

is expected to be low whereas the turbulence intensity near the bed has a high value.

Figure 7d shows the profile of

G, which is a measure of turbulence intensity.

G near the bed is about 90 s

−1 whereas

G near the elevation of the maximum value of

is about 5 s

−1. The strong turbulence near the bed enhances the breakup process of flow resulting in a small and dense floc. The low intensity of turbulence near the elevation of maximum

causes growth of flocs having a low density and a large size. Mikkelsen

et al. [

46] measure the volumetric concentration at four different locations by estimating a proxy for current stress based on the squared current velocity. It is found in Mikkelsen

et al. [

46] that the volumetric concentration increases at the location where the current stress is high. It is also concluded in Mikkelsen

et al. [

46] find that the strong turbulence causes the erosion of micro-flocs (not primary particles) from the bed. This conclusion is consistent with the findings of this study. The floc size is calculated to be small near the bed due to the high intensity of turbulence (see

Figure 7).

Figure 6.

Variation of velocity gradients under different conditions of water depth. The asterisk, diamond, circle, and square symbols represent results at elevations of 0.3 m, 0.25 m, 0.2 m, and 0.15 m, respectively. The experimental condition is consistent with

Figure 5.

Figure 6.

Variation of velocity gradients under different conditions of water depth. The asterisk, diamond, circle, and square symbols represent results at elevations of 0.3 m, 0.25 m, 0.2 m, and 0.15 m, respectively. The experimental condition is consistent with

Figure 5.

Figure 7.

Vertical profiles of ϕ

f,

D,

, and

G. In

Figure 7c, the inverse of ϕ

sf is plotted for convenience. (

a) Volumetric concentration; (

b) Floc size; (

c) Solid volume concentration within a floc; and (

d) Shear rate.

Figure 7.

Vertical profiles of ϕ

f,

D,

, and

G. In

Figure 7c, the inverse of ϕ

sf is plotted for convenience. (

a) Volumetric concentration; (

b) Floc size; (

c) Solid volume concentration within a floc; and (

d) Shear rate.