3.1. Seawater Desalination Treatment Costs

The KSA is the world’s largest user of desalinated seawater, accounting for about 18% of the total global capacity [

12]. The most used desalination technology in the KSA is multi-stage flash (MSF) distillation which is very energy intensive accounting for up to 70% of the desalination costs, and these plants are expensive to maintain [

13]. In recent years, the KSA has begun to use large scale SWRO, but most commonly in hybrid facilities containing electric generation, MSF, and SWRO [

14]. In addition, many standalone SWRO and brackish water reverse osmosis (BWRO) plants, with capacities ranging between 50 m

3/d and 17,500 m

3/d, have been installed by the private sector [

12]. On the other hand, multi-effect distillation (MED) is being used to replace the MSF process in other sites in the KSA, mainly with enhanced performance using thermal vapor compression (TVC) in a hybrid MED-TVC configuration (

Table 1). It is difficult to ascertain the true cost of seawater desalination in the KSA because all utilities are subsidized by the government, and, commonly, freshwater is provided at vey low cost to the consumer [

10]. Also, there are virtually no legal restrictions on water use and legal guidelines on reclaimed water use in the KSA.

Table 1.

Water cost of different thermal desalination projects in Kingdom of Saudi Arabia (KSA), including subsidies (Global Water Intelligence/Water Desalination Report (GWI/WDR), 2009–2014).

Table 1.

Water cost of different thermal desalination projects in Kingdom of Saudi Arabia (KSA), including subsidies (Global Water Intelligence/Water Desalination Report (GWI/WDR), 2009–2014).

| Site | Capacity (m3/d) | Capital Cost (USD) | Total Water Cost ($/m3) |

|---|

| Shoaiba MSF | 880,000 and 900 MW | $2.4B | 0.95 |

| Marafiq multi-effect distillation–thermal vapor compression (MED-TVC) | 800,000 | $3.4B | 0.83 |

| Rabigh MED-TVC | 2@5000 | - | 1.15 |

Some water cost estimates can be made for the various seawater desalination facilities based upon energy consumption for the different technologies being used. These costs are truly scale dependent based on the capacity of the treatment facilities (e.g., large capacity facilities generally produce water at a generally lower unit cost compared to small facilities) [

15] (

Figure 4). Within the KSA, thermal desalination costs, including subsidies, range between $0.83 and $1.5/m

3 depending on the technology used, age of the facility, and the plant capacity. Hybrid water desalination facilities costs depend strongly on the hybrid configuration used along with the capacity. The total water cost produced by a MSF-SWRO hybrid system is 5%–10% less compared to MSF standalone plants [

16]. On the other hand, SWRO facilities (standalone) produce freshwater at a cost ranging from $0.5 to $1.5/m

3, depending on several parameters, such as feed water salinity, requested product quality (includes post-treatment), and electrical energy, land and labors costs. Water cost of some thermal desalination plants in the KSA is presented in

Table 1.

Another important factor affecting desalination water cost for rural communities is the distance of the end users from the coast or from large population centers that are served by high-capacity desalination facilities. In wadi communities located within a 50–100 km radius of a major desalination facility, the actual freshwater production cost would be the same as for the city residents, but the additional cost would be for transmission. In remote communities, the design, construction, and operation of standalone SWRO or BWRO facilities with a moderate to low capacity would likely be required and their costs might be very competitive with long water transfer from coastal desalination plants [

11]. However, the feed water sources to supply these local plants within the wadi areas are not sustainable and therefore, would not be a reliable water supply. Overall desalination costs could be quite high from these facilities, located near the user (if possible) or at the shoreline, with a probable range from $1.25–5/m

3.

Figure 4.

Investment cost/m3 for seawater reverse osmosis (SWRO) and brackish water reverse osmosis (BWRO) systems. Note the reduction as the capacity increases.

Figure 4.

Investment cost/m3 for seawater reverse osmosis (SWRO) and brackish water reverse osmosis (BWRO) systems. Note the reduction as the capacity increases.

Installation of small-scale innovative desalination processes at the shoreline, powered with solar energy, may produce water at a lower cost and would require less maintenance and chemical use [

17]. Low-energy processes, such as membrane distillation, could be the best solution for communities living in rural areas. Also, each village would be responsible for providing water storage and a distribution system where the population density permits doing so. Existing systems depend upon trucking water from a well (if available) and conveying the water to storage tanks located at each home or cluster of homes. This system also has a cost.

3.2. Domestic Wastewater Treatment Costs

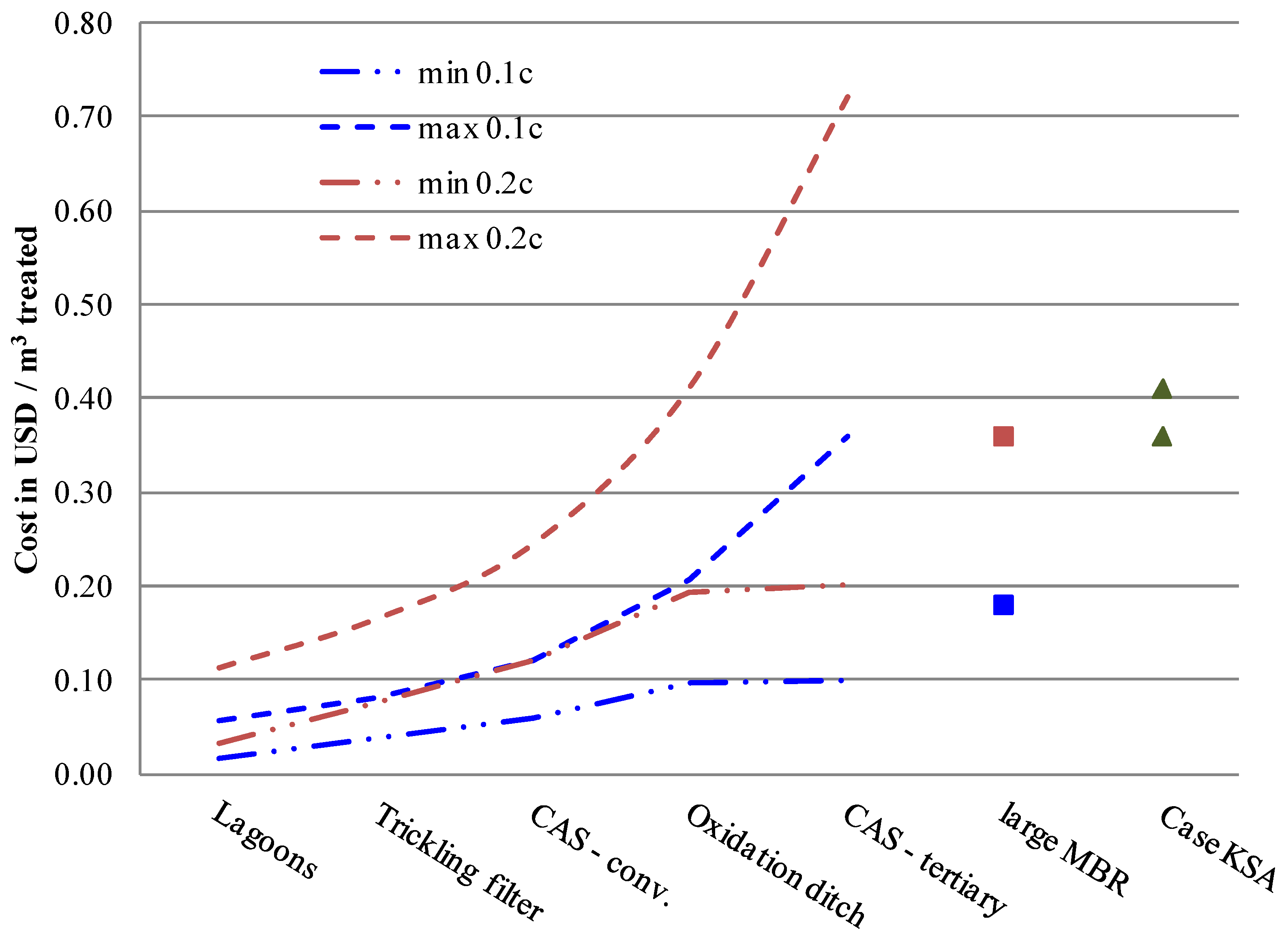

Wastewater treatment plants naturally vary in capacity as a function of the community being serviced as well as the underlying infrastructure approach used (e.g., individual households versus decentralized/satellite designs and large centralized technologies). There is also an economy of scale that generally causes larger-capacity treatment plants to operate at lower costs compared to small capacity plants. For smaller communities (e.g., villages and farms) the operating costs for a treatment system will therefore fall in the higher range of cost estimates. In addition, the type of treatment technology selected will impact both capital and operating costs. A complicating factor in such an assessment is the difference in both regional and local parameters, such as land cost (i.e., impact of plant footprint), and the unit cost for energy.

In rural communities there is a tendency to choose low-technology solutions which typically require a lot of space (on the assumption that land costs are minimal) and which will require a minimum of skilled-labor maintenance. However, for a water reclamation and reuse strategy, there is a move to more advanced treatment systems to ensure reliable, safe, and high water quality as defined by the end use. In this cost estimate, representative treatment technologies, which can be defined as low to high technology solutions, have been included in the comparison. These include ponds and lagoons, trickling filters, variations of conventional activated sludge (CAS) (e.g., secondary treatment/oxidation ditches), tertiary treatment of secondary effluent (e.g., membrane filtration/advanced oxidation), and membrane bioreactor technology (MBR) as an alternative advanced tertiary treatment system. A direct comparison of capital costs for these technologies is not straight forward, although studies in the literature can be found showing that high technology options are cost competitive to low technology alternatives [

18,

19,

20,

21].

In most studies assessing operating costs for various treatment technologies, energy is highlighted as a key parameter for defining the operating costs, typically in the range of 40%–60% of total costs [

18,

19]. The specific energy consumption for wastewater treatment is reported in the range of 0.4–1.0 kWh/m

3 of treated water [

19,

21,

22]. Breaking this down to commonly used technologies in terms of sophistication of the treatment plant gives the ranges or 0.08–0.28 kWh/m

3 for lagoons, 0.19–0.41 kWh/m

3 for trickling filter plants, 0.33–0.61 kWh/m

3 for conventional activated sludge, and 0.48–1.03 kWh/m

3 for oxidation ditches and tertiary treatment. Membrane bioreactors are perceived as being energy intensive, however recent case studies comparing average energy requirements for tertiary treatment based on conventional activated sludge compared to MBR have shown that a relatively large MBR plant consumes 0.9 kWh/m

3 compared to a range of 0.5–1.8 kWh/m

3 for the tertiary conventional activated sludge options [

18,

20,

23,

24,

25,

26,

27,

28]. On the assumption that energy costs on average are 50% of the total operating costs, energy can be estimated at 0.01–0.210/kWh/m

3, an estimate for a lower and upper range of operating costs for various wastewater treatment technologies can be compared. The results are shown in

Figure 5.

Figure 5.

Estimated cost/m3 for wastewater treatment using different technologies.

Figure 5.

Estimated cost/m3 for wastewater treatment using different technologies.

For the low technology options (e.g., lagoons, trickling filters) the treatment costs will range between $0.05–0.20/m

3 depending on the criteria chosen, however, it is debatable whether the water quality achieved is well suited for reuse. Conventional activated sludge is a more appropriate technology with respect to treated water quality and design options resulting in costs ranging between $0.10–0.50/m

3. It is interesting to note that conventional activated sludge designed as an oxidation ditch can be relatively higher in O&M costs, as exemplified by the example of case studies in the KSA [

26,

27]. Treatment of wastewater to a high quality suitable for reuse can be achieved by conventional activated sludge followed by advanced tertiary treatment, estimated at a cost ranging from $0.10–0.70/m

3 based on a series of assumptions. For this level of treatment, MBR technology is shown to be more efficient with estimated costs of less than $0.40/m

3 [

23,

24]. In recent research conducted on advanced treatment of wastewater by MBR technology, it was shown to be very competitive an as alternative to desalination options [

23,

24]. With respect to rural populations having to rely on desalination as a reliable water source, it is apparent for the simple estimations shown above that advanced treatment of wastewater for both non-potable and indirect-potable reuse is a viable and sustainable option.

3.3. Conveyance Cost

The cost to convey water from the treatment plant to the end user is quite significant, especially in the isolated rural environment. Conveyance cost can be broken down into capital and operating costs. Capital costs include the pipeline engineering and construction, the cost of the pumping stations, and some undefined costs of conveyance, such as construction of pipelines crossing roads and municipal infrastructure at large facilities. The operating costs include the electrical costs and are mostly for electricity to run the pumps. Any additional costs associated with the operation of ASR wells are considered to be minor within the overall assessment.

Wadi valley pipeline engineering design and construction are relatively simple, but require consideration of periodic flooding within the wadi channels and potential erosion of the main channel area. The soils are predominantly sands and gravels and are easy to excavate. The preferred pipeline material can be HDPE. The strength of the pipe should be 16 BAR PE 100 to prevent any damage due to movement during earthquakes and by trucks or other farm equipment. The cost for materials and installation of HDPE pipe in the wadi valleys of Saudi Arabia is given in

Table 2. The hydraulic gradient from the shoreline to the heads of the wadi valleys is not very steep and the overall elevation rise is likely not more than 70 m over a distance of about 40 km. Pumping station costs were obtained for a variety of facilities ranging in capacity from 5000 to 40,000 m

3/d. The cost for such facilities in western Saudi Arabia is roughly $500,000/5000 m

3/day of capacity (

Table 2). A preliminary assessment shows that a single pumping station can be used to transmit this range of capacities between 40 and 60 km, assuming that the overall head loss is no greater than 120 m.

Only two relatively large diameter pipe sizes are listed in the table. Since wadi systems contain a series of local farms and village occurring along a linear geometry or with a series of branches, these pipeline diameters would be used as trunk lines and could be reduced in diameter from proximal to distal users. For cost estimation purposes, the larger diameters should be used because the cost of construction will likely be nearly the same for the next lower set of pipe diameters.

The electrical use for operation of the pumping stations to convey the water from the source to the use area is dependent on the required capacity (

Table 2). The kilowatt-hours of electricity per day are also given in

Table 2. The subsidies used in Saudi Arabia make the determination of real electric costs quite difficult to estimate, but the real cost likely ranges from $0.05–0.15/kw-h. An estimated cost range to convey the water 40 km is $0.45–1.50/m

3.

Since the key aspect of this research is the comparison of costs between use of desalinated water and reuse of highly treated domestic wastewater indirectly via an MAR system for potable supply and directly for irrigation use, the cost of conveyance of the water will be the same for either option. It can be calculated from the data given in the tables. If the water is conveyed from great distance, the cost of desalinated water delivery will be roughly doubled. The multiplier will be even greater for conveyance of highly treated wastewater because of its lower treatment cost.

Table 2.

Estimated cost for construction of high-density polyethylene pipe (HDPE) pipelines in wadi systems.

Table 2.

Estimated cost for construction of high-density polyethylene pipe (HDPE) pipelines in wadi systems.

| Cost Item | Cost/km |

|---|

| 1100 mm outside diameter HDPE pipe (rated 16 Bar PE 100) | $7,000 |

| 630 mm outside diameter HDPE pipe (rated 16 Bar PE 100) | $3,000 |

| Construction cost (wadi sediments, 1 m burial depth, with fittings) | |

| For 1100 mm pipe | $107,000 |

| Construction cost (wadi sediments, 1 m burial depth, with fittings) | |

| For 1100 mm pipe | $80,000 |

| HDPE Pipeline Diameter (rated 16 Bar PE 100) | Cost/km Total 1 |

| 1100 mm outside diameter | $114,000 |

| 630 mm outside diameter | $83,000 |

| Pumping Station (m3/day) (total head required = 100 m) | CAPEX | OPEX (kw-h/day) 1,2 |

| 5,000 | $500,000 | 38,000 |

| 10,000 | $1,000,000 | 76,000 |

| 20,000 | $2,000,000 | 152,000 |

| 30,000 | $3,000,000 | 228,000 |

| 40,000 | $4,000,000 | 304,000 |

3.4. Cultural and Religious Issues Involving Wastewater Reuse

A major challenge for indirect potable reuse projects is obtaining public acceptance. Public perception issues associated with reuse of reclaimed water were reviewed by Maliva and Missimer [

2]. In general, public acceptance of the reuse of reclaimed water increases with increasing “distance” or isolation from the treated wastewater. There is generally a high level of acceptance for projects with no human exposure and a much lesser support for projects with direct human contact.

The passage of water through a natural environment, such as an aquifer, also reduces its “taint” of being wastewater. Public acceptance also depends upon the recognition by the effected population of the severity of the water shortage and confidence in the agency or organization that will implement the project. Reuse of reclaimed water and even indirect potable reuse are not contrary to Islamic Law. The Council of Leading Islamic Scholars in Saudi Arabia issued a fatwa in 1978, stating that reclaimed water can be used for ablution and drinking if it is sufficiently and appropriately treated to ensure good health, but recommended avoiding use of treated wastewater for drinking purposes to avoid health problems and also in consideration of the negative public sentiment about this water. If drinking is to be avoided, it is to be merely for reasons of public health and safety, not due to any ramifications of Islamic Law [

29].

Wastewater is already being recharged to some wadi alluvial aquifers downstream of wastewater treatment plants and through on-site disposal systems, so the introduction of the more controlled upgraded wastewater treatment/ARR could, in some instances would, result in improved water quality. Nevertheless, obtaining local public support will be a critical feasibility issue, which will need to start with a public education campaign. A lack of knowledge on issues such as wastewater quality, health risks, and for farmers, impacts on soils and crops often leads to a negative perception of wastewater reuse.

3.6. Indirect Reuse and Irrigation Use Using MAR Treatment of Domestic Wastewater for Wadi Communities in the KSA: Special Circumstances

The economic analyses developed in this research suggest that the use of treated domestic wastewater combined with ARR polishing for indirect potable use is the most economical solution to meet the rural water supply requirements, but it is still costly. However, there are extenuating circumstances that greatly affect the economics of water reuse which include the current practice of disposal of the treated or untreated wastewater and its adverse environmental effects on the marine environment and some inland aquifer water quality.

Only about 10% of the wastewater generated in the KSA is reused in a beneficial manner. Partial treatment and discharge to tidal water or into channels transmitting into the desert with no users are not economically beneficial. Therefore, a real cost comparison between use of desalinated water and wastewater should consider that there is zero cost for treatment of the wastewater if it is being discharged to waste. In fact, environmental damage caused by inappropriate wastewater disposal practices produces a negative economic impact, which must be considered in this analysis.

Wastewater discharges to tide adversely affect the fringing reef of the Red Sea as occurs in all coral reef ecosystems [

30,

31,

32], which in turn, adversely affects fisheries and the potential recreational aspects of the reef ecosystem. Coral reef ecosystems provide a diverse variety of goods and services to humanity [

33,

34]. Goods and services of all natural systems of the Earth affect the human economy and well-being [

35]. Anthropogenic impacts on coral reefs have a direct economic impact on the recreational value of reefs that can be measured [

36]. Economic assessments by Cesar [

37] and Berg

et al. [

38] found that losses to coral reef tourism caused by the destruction of 1 km

2 of reef ranged between $27,900 and $100,800 USD and $5500 and $368,000 USD, respectively. A loss of $40 million USD over a 10-year period was estimated by Hodgson and Dixon [

39] for tourism and fisheries declines in a coastal area of the Philippines. While the Red Sea of KSA does not have a well-developed ecotourism industry, it is greatly dependent on the fisheries, which may generate an event larger overall economic impact.

There is a negative cost impact on the disposal of each 1 m3 of wastewater discharged to tidal water in the vicinity of a coral reef system. This cost depends on the concentration of nutrients within the wastewater, the degree of treatment for removal of solids and organic carbon, the proximity of the discharge to the reef, and the nearshore current patterns. A crude estimate of this cost range is $0.05–0.20 USD/m3 for the economic losses associated with marine pollution. The range of loss associated with discharge to wadi aquifers and contamination of groundwater cannot really be estimated for areas where there is no significant water use.

3.7. Long-Term Sustainability of Seawater Desalination to Meet Rural Water Demands: Subsidies

In any economic analysis, the issue of sustainability must be raised within the context of the water supply options being assessed. Based on the economic return of the relatively small population and the farms within the wadi valleys, the cost of supplying desalinated seawater to these areas would have to be subsidized by the government to bring economic viability to the residents and farmers. This issue raises questions concerning the long-term viability of a fully subsidized water supply within the context of the Saudi Arabian economy. However, there may be some mitigating economic issues with regard to food security which cannot be evaluated within the context of this research.

Electricity, fuel, and utilities are all nearly fully subsidized in KSA. The root of economic prosperity in the KSA is the income received from the international sale of petroleum [

40]. In 2009, 25% of the petroleum produced in the KSA was consumed domestically and with population growth, this percentage will likely continue to rise [

41]. This means that as domestic petroleum consumption rises, the petroleum available for export sale declines, and overall revenue income will decline with time. Also, the rate of domestic energy consumption in the KSA is greater than the United States. Declining revenue raises the question whether significant water use that provides little or no economic return can be maintained.

All other subsidies, including water supply and wastewater treatment are also subsidized to a nearly full degree. However, water and wastewater tariffs are being assessed to a limited degree in an attempt to recover some costs of providing utility service to the public and industry. There has been considerable push-back by the general population and industry that have grown comfortable with free utility services. Ramady [

40] suggests that continuation of subsidies is a great challenge that is part of greater economic reform, which will be required in the future. Krane [

41] has suggested that most economists believe that continued maintenance of utility subsidies threatens the stability of the Saudi Arabian economy. Therefore, the long-term economic sustainability of providing desalinated water to small villages and farms for drinking and irrigation water is debatable and questionable. This suggests that choosing the low cost water supply alternative, despite religious and cultural questions, may be the only viable long-term water supply option.