Microwave Wire Interrogation Method Mapping Pressure under High Temperatures

Abstract

:1. Introduction

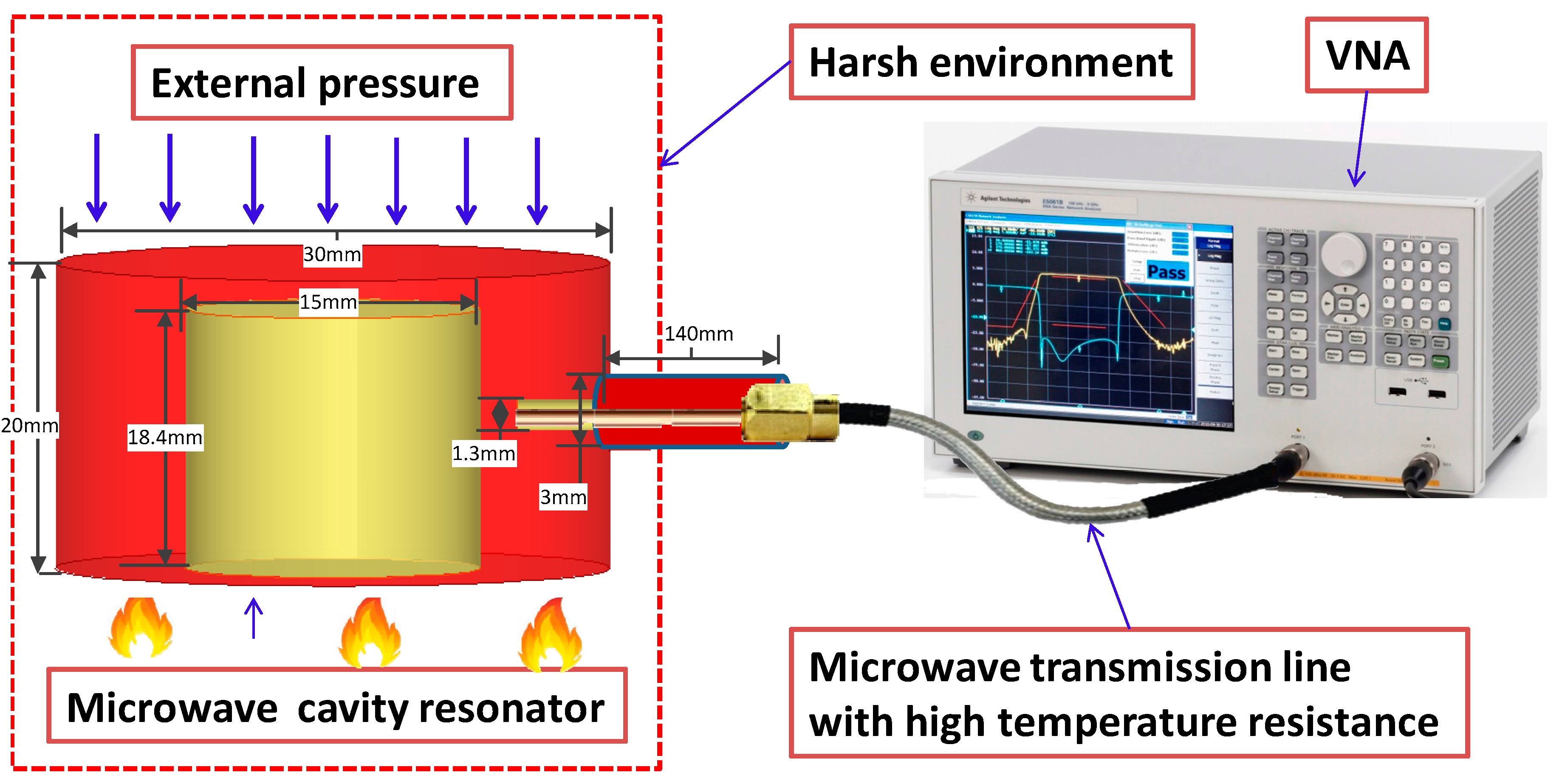

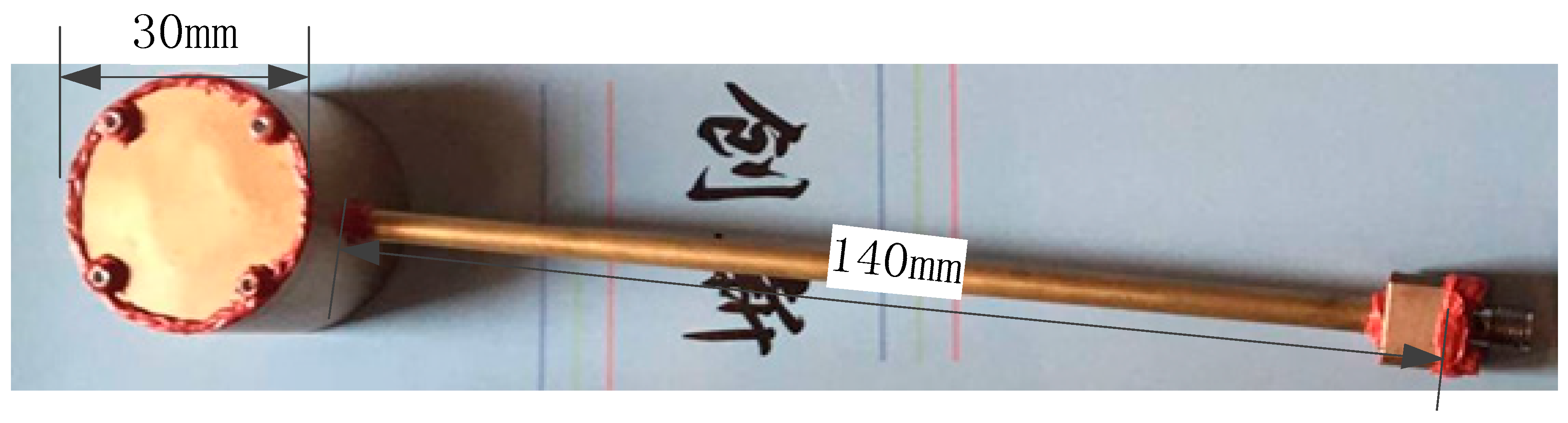

2. Pressure Detection Principle and System Description

3. Methods

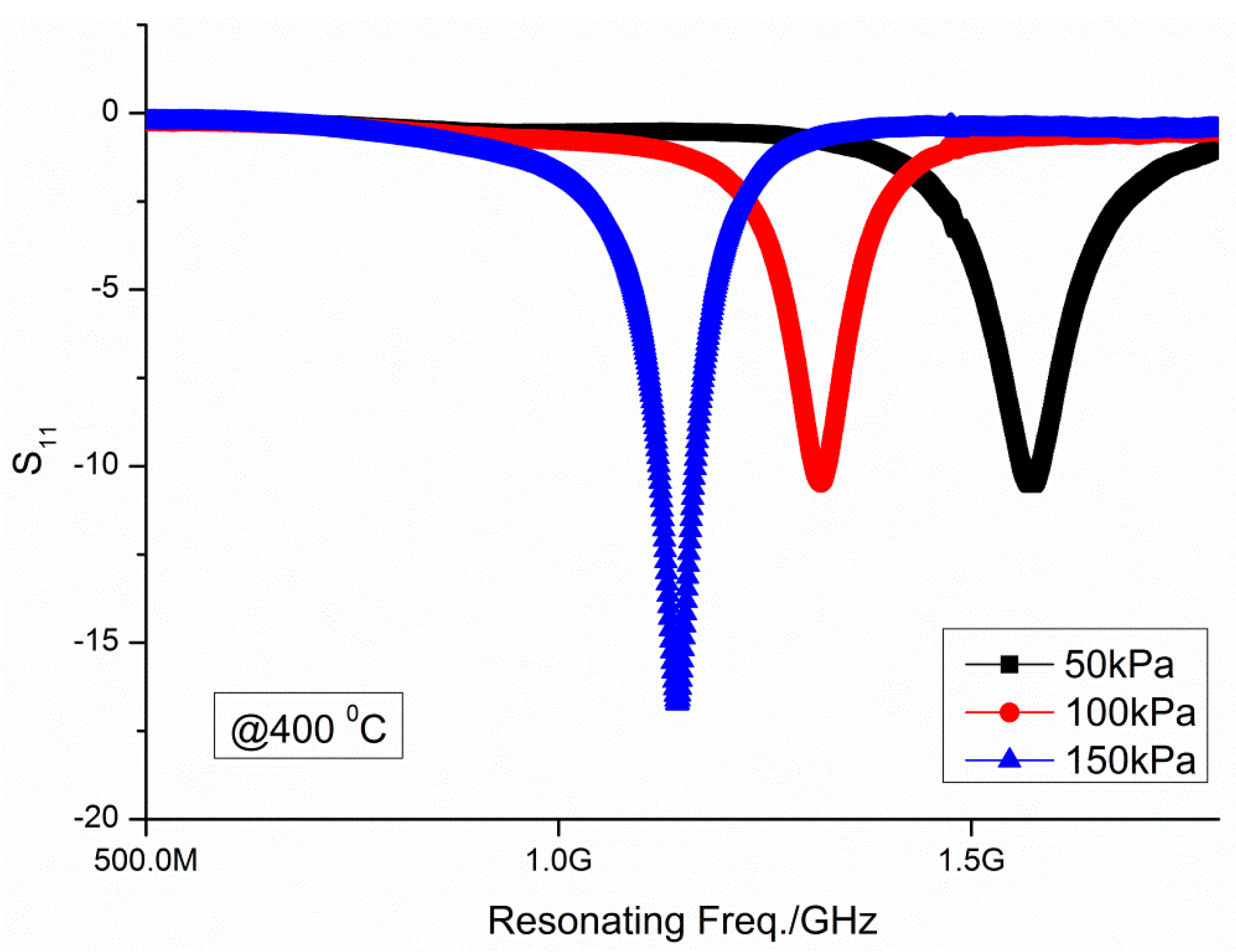

4. Experimental Results & Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Culley, D.; Garg, S.; Hiller, S.J.; Horn, W.; Kumar, A.; Mathews, H.P.; Whitney, H.; Pfoertner, H.; Rosenfeld, T.; Rybarik, P.; et al. More Intelligent Gas Turbine Engines; RTO Technical Report; Neuilly-sur-Seine Cedex: Paris, France, 2009. [Google Scholar]

- Wilson, W.; Atkinson, G. Passive Wireless Sensor Applications for NASA’s Extreme Aeronautical Environments. IEEE Sens. J. 2014, 14, 3745–3753. [Google Scholar] [CrossRef]

- Cheng, H.; Shao, G.; Ebadi, S.; Ren, X.; Harris, K.; Liu, J.; Xu, C.; An, L.; Gong, X. Evanescent-mode-resonator-based and antenna-integrated wireless passive pressure sensors for harsh-environment applications. Sens. Actuators A Phys. 2014, 220, 22–33. [Google Scholar] [CrossRef]

- Boyce, M. Gas Turbine Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Aller, I.; Lang, C.; Schweeger, G.; Hartnagel, H.L.; Dolt, R.; Hohenberg, G. Gallium arsenide piezotransistor for dynamic pressure measurements at high temperature. Appl. Phys. Lett. 1996, 69, 403–405. [Google Scholar] [CrossRef]

- Chapin, C.A.; Miller, R.A.; Dowling, K.M.; Chen, R.; Senesky, D. InAlN/GaN high electron mobility micro-pressure sensors for high-temperature environments. Sens. Actuators A Phys. 2017, 263, 216–223. [Google Scholar] [CrossRef]

- Chapin, C.A.; Miller, R.A.; Chen, R.; Bowling, K.M.; Senesky, D. Low-temperature and pressure response of InAlN/GaN ring-shaped high electron mobility transistors. In Proceedings of the 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 786–789. [Google Scholar]

- Giurgiutiu, V.; Xu, B.; Liu, W. Development and Testing of High-temperature Piezoelectric Wafer Active Sensors for Extreme Environments. Struct. Health Monit. 2010, 9, 513–525. [Google Scholar] [CrossRef]

- Toygur, L.; Yu, X.; Garverick, S. High-temperature, low-power 8-MegΩ by 1.2-MegHz SOI-CMOS transimpedance amplifier for MEMS-based wireless sensors. In Proceedings of the 2004 IEEE International SOI Conference (IEEE Cat. No. 04CH37573), Charleston, SC, USA, 4–7 October 2004. [Google Scholar]

- Herfurth, P.; Maier, D.; Lugani, L.; Carlin, J.F.; Rosch, R.; Men, Y.; Grandjean, N.; Kohn, E. Ultrathin Body InAlN/GaN HEMTs for High-Temperature (600) Electronics. IEEE Electron Device Lett. 2013, 34, 496–498. [Google Scholar] [CrossRef]

- Patil, A.; Fu, X.; Mehregany, M.; Garverick, S. Fully-monolithic, 600 C differential amplifiers in 6H-SiC JFET IC technology. In Proceedings of the 2009 IEEE Custom Integrated Circuits Conference, Rome, Italy, 13–16 September 2009. [Google Scholar]

- Neudeck, P.; Garverick, S.; Spry, D.; Chen, L.; Beheim, G.; Krasowski, M. Extreme temperature 6H-SiC JFET integrated circuit technology. Phys. Status Solidi 2009, 206, 2329–2345. [Google Scholar] [CrossRef]

- Sanders, J.W.; Yao, J.; Huang, H. Microstrip Patch Antenna Temperature Sensor. IEEE Sens. J. 2015, 15, 5312–5319. [Google Scholar] [CrossRef]

- Yao, J.; Xu, C.C.; Mears, A.; Jaguan, M.; Tjuatja, S.; Huang, H. Pressure sensing using low-cost microstrip antenna sensor. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 27 March 2015. [Google Scholar]

- Li, S.; Liang, T.; Wei, W.; Hong, Y.; Zheng, T.; Xiong, J. A novel SOI pressure sensor for high temperature application. J. Semicond. 2015, 36, 014014. [Google Scholar] [CrossRef]

- Fricke, S.; Friedberger, A.; Seidel, H.; Schmid, U. A robust pressure sensor for harsh environmental applications. Sens. Actuators A Phys. 2012, 184, 16–21. [Google Scholar] [CrossRef]

- Marsi, N.; Majlis, B.Y.; Hamzah, A.A.; Mohd-Yasin, F. A MEMS packaged capacitive pressure sensor employing 3C-SiC with operating temperature of 500 °C. Microsyst. Technol. 2015, 21, 9–20. [Google Scholar] [CrossRef]

- Yang, J. A harsh environment wireless pressure sensing solution utilizing high temperature electronics. Sensors 2013, 13, 2719–2734. [Google Scholar] [CrossRef] [PubMed]

- Young, D.; Du, J.; Zorman, C.; Ko, W. High-temperature single-crystal 3C-SiC capacitive pressure sensor. IEEE Sens. J. 2004, 4, 464–470. [Google Scholar] [CrossRef]

- Chen, L.; Mehregany, M. A silicon carbide capacitive pressure sensor for in-cylinder pressure measurement. Sens. Actuators A Phys. 2008, 145, 2–8. [Google Scholar] [CrossRef]

- Chen, L.; Tan, Q.; Xue, C.; Zhang, W.; Xiong, J. Wireless contactless pressure measurement of an LC passive pressure sensor with a novel antenna for high-temperature applications. Chin. Phys. B 2015, 24, 048801. [Google Scholar]

- Xiong, J.; Li, C.; Jia, P. An Insertable Passive LC Pressure Sensor Based on an Alumina Ceramic for In Situ Pressure Sensing in High-Temperature Environments. Sensors 2015, 15, 21844–21856. [Google Scholar] [CrossRef] [PubMed]

- Verdejo, H.; Castro, P.; Concepción, R.; Ferrada, M.; Alfaro, M.; Alcaíno, M. Comparison of a radiofrequency-based wireless pressure sensor to swan-ganz catheter and echocardiography for ambulatory assessment of pulmonary artery pressure in heart failure. J. Am. Coll. Cardiol. 2007, 50, 2375–2382. [Google Scholar] [CrossRef] [PubMed]

- Thai, T.T.; DeJean, G.R.; Tentzeris, M.M. A novel front-end radio frequency pressure transducer based on a dual-band resonator for wireless sensing. In Proceedings of the 2009 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009. [Google Scholar]

- Salpavaara, T.J.; Verho, J.; Kumpulainen, P. Performance of a Near-Field Radio-Frequency Pressure Sensing Method in Compression Garment Application, in Wireless Mobile Communication and Healthcare; Springer: Berlin, Germany, 2011; pp. 322–328. [Google Scholar]

- Tan, Q.; Kang, H.; Xiong, J.; Qin, L.; Zhang, W.; Li, C. A Wireless Passive Pressure Microsensor Fabricated in HTCC MEMS Technology for Harsh Environments. Sensors 2013, 13, 9896–9908. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Li, Y.; Hong, Y.; Zhang, B.; Cui, T.; Tan, Q. Wireless LTCC-based capacitive pressure sensor for harsh environment. Sens. Actuators A Phys. 2013, 197, 30–37. [Google Scholar] [CrossRef]

- Su, S.; Lu, F.; Wu, G.; Wu, D.; Tan, Q.; Dong, H. Slot Antenna Integrated Re-Entrant Resonator Based Wireless Pressure Sensor for High-Temperature Applications. Sensors 2017, 17, 1963. [Google Scholar] [CrossRef] [PubMed]

- Thai, T.T.; Mehdi, J.M.; Chebila, F.; Aubert, H.; Pons, P.; Dejean, G. Design and development of a novel passive wireless ultrasensitive RF temperature transducer for remote sensing. IEEE Sens. J. 2012, 12, 2756–2766. [Google Scholar] [CrossRef]

- Boccard, J.M.; Aftab, T.; Hoppe, J.; Yousaf, A.; Hütter, R.; Reindl, L. High-Resolution, Far-Field, and Passive Temperature Sensing up to 700 °C Using an Isolated ZST Microwave Dielectric Resonator. IEEE Sens. J. 2016, 16, 715–722. [Google Scholar] [CrossRef]

- Cheng, H.; Ebadi, S.; Ren, X.; Gong, X. Wireless passive high-temperature sensor based on multifunctional reflective patch antenna up to 1050 degrees centigrade. Sens. Actuators A Phys. 2015, 222, 204–211. [Google Scholar] [CrossRef]

- Yao, J.; Tchafa, F.M.; Jain, A.; Tjuatja, S.; Huang, H. Far-Field Interrogation of Microstrip Patch Antenna for Temperature Sensing Without Electronics. IEEE Sens. J. 2016, 16, 7053–7060. [Google Scholar] [CrossRef]

- Yao, J.; Tjuatja, S.; Huang, H. Real-Time Vibratory Strain Sensing Using Passive Wireless Antenna Sensor. IEEE Sens. J. 2015, 15, 4338–4345. [Google Scholar] [CrossRef]

- Yi, X.; Cho, C.; Wang, Y.; Tentzeris, M.M.; Cook, B.; Leon, R.T. Design and simulation of a slotted patch antenna sensor for wireless strain sensing. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 11 April 2013. [Google Scholar]

- Benchirouf, A.; Zichner, R.; Müller, C.; Kanoun, O. Electromagnetic Simulation of Flexible Strain Sensor based Microstrip Patch Antenna. Int. J. Microw. Opt. Technol. 2015, 10, 397. [Google Scholar]

- Xu, X.; Huang, H. Multiplexing passive wireless antenna sensors for multi-site crack detection and monitoring. Smart Mater. Struct. 2012, 21, 015004. [Google Scholar] [CrossRef]

- Jang, S.D.; Kim, J. Passive wireless structural health monitoring sensor made with a flexible planar dipole antenna. Smart Mater. Struct. 2012, 21, 027001. [Google Scholar] [CrossRef]

- Fonseca, M.; English, J.; Arx, M.; Allen, M. Wireless micromachined ceramic pressure sensor for high-temperature applications. J. Microelectron. Syst. 2002, 11, 337–343. [Google Scholar] [CrossRef]

- Birdsell, E.D.; Park, J.; Allen, M.G. Wireless ceramic sensors operating in high temperature environments. In Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Fort Lauderdale, FL, USA, 11–14 July 2004. [Google Scholar]

- Zhang, H.; Hong, Y.; Liang, T.; Zhang, H.; Tan, Q.; Xue, C. Phase Interrogation Used for a Wireless Passive Pressure Sensor in an 800 °C High-Temperature Environment. Sensors 2015, 15, 2548–2564. [Google Scholar] [CrossRef] [PubMed]

- Chebila, F.; Pons, P.; Aubert, H. Working principle description of the wireless passive EM transduction pressure sensor. Eur. Phys. J. Appl. Phys. 2011, 56, 13702. [Google Scholar]

- Jatlaoui, M.; Pons, P.; Aubert, H. Radio frequency pressure transducer. In Proceedings of the 2007 European Microwave Conference, Munich, Germany, 9–12 October 2007. [Google Scholar]

- Senior, D.; Cheng, X.; Jao, P.; Kim, C.; Kim, J.; Yoon, Y. Wireless passive sensing application using a cavity loaded evanescent mode half mode substrate integrated waveguide resonator. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Pozar, D.M. Microwave Engineering 3e; Wiley Interscience: Hoboken, NJ, USA, 2005. [Google Scholar]

- Zhao, Y.; Kim, S.H.; Li, Y.; Pan, B.; Wu, X.; Tentzeris, M. A micromachined airflow sensor based on RF evanescent-mode cavity resonator. In Proceedings of the 2008 IEEE MTT-S International Microwave Symposium Digest, Atlanta, GA, USA, 15–20 June 2008. [Google Scholar]

- Mahmood, A.; Sigmarsson, H.; Joshi, H.; Chappell, W.; Peroulis, D. An evanescent-mode cavity resonator based thermal sensor. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007. [Google Scholar]

- Guo, G.; Li, E.; Li, Z.; Zhang, Q.; He, F. A test system for complex permittivity measurements of low-loss materials at high temperatures up to 2000 °C. Meas. Sci. Technol. 2011, 22, 045707. [Google Scholar] [CrossRef]

| Cases | Working Principle | Sensors Materials | Highest Working Temperature (°C) | Highest Working Pressure (kPa) | Sensitivity (MHz/kPa) |

|---|---|---|---|---|---|

| [38] | LC Resonator | LTCC and silver | 400 | 700 | 0.00141 |

| [27] | LC Resonator | LTCC and silver | 600 | 360 | 0.00344 |

| [26] | LC Resonator | HTCC and platinum | 600 | 300 | 0.0000086 |

| [3] a | Evanescent-mode resonator | PDC and platinum | 800 | 52.6 | 3.6 |

| [28] | Re-entrant resonator | HTCC and silver | 800 | 120 | 0.73125 |

| This work | Evanescent-mode resonator | Copper | 400 | 150 | 4.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Yan, D.; Hong, Y.; Liang, T.; Xiong, J. Microwave Wire Interrogation Method Mapping Pressure under High Temperatures. Micromachines 2018, 9, 11. https://doi.org/10.3390/mi9010011

Chen X, Yan D, Hong Y, Liang T, Xiong J. Microwave Wire Interrogation Method Mapping Pressure under High Temperatures. Micromachines. 2018; 9(1):11. https://doi.org/10.3390/mi9010011

Chicago/Turabian StyleChen, Xiaoyong, Dan Yan, Yingping Hong, Ting Liang, and Jijun Xiong. 2018. "Microwave Wire Interrogation Method Mapping Pressure under High Temperatures" Micromachines 9, no. 1: 11. https://doi.org/10.3390/mi9010011