A Novel On-Chip Impedance Sensor for the Detection of Particle Contamination in Hydraulic Oil

Abstract

:1. Introduction

2. Chip Design and Fabrication

3. Detection Mode

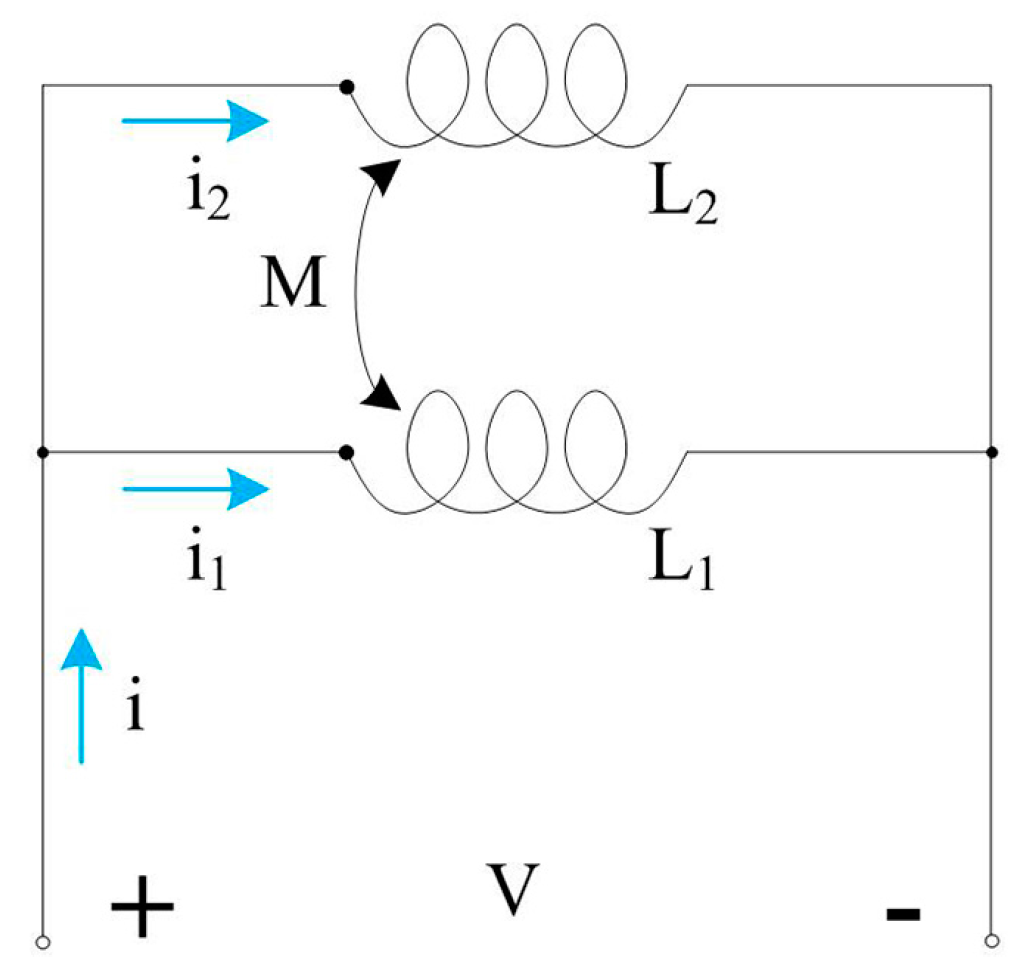

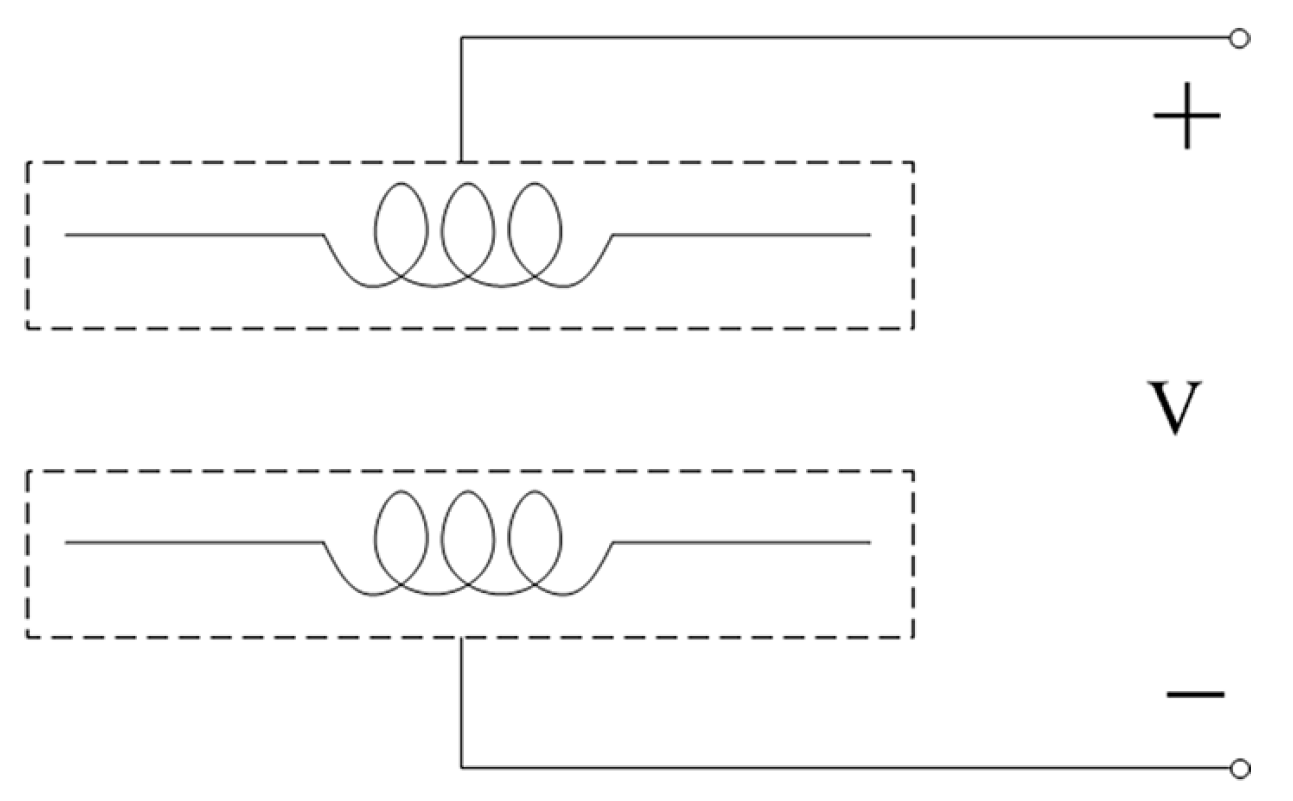

3.1. Inductance Detection Mode

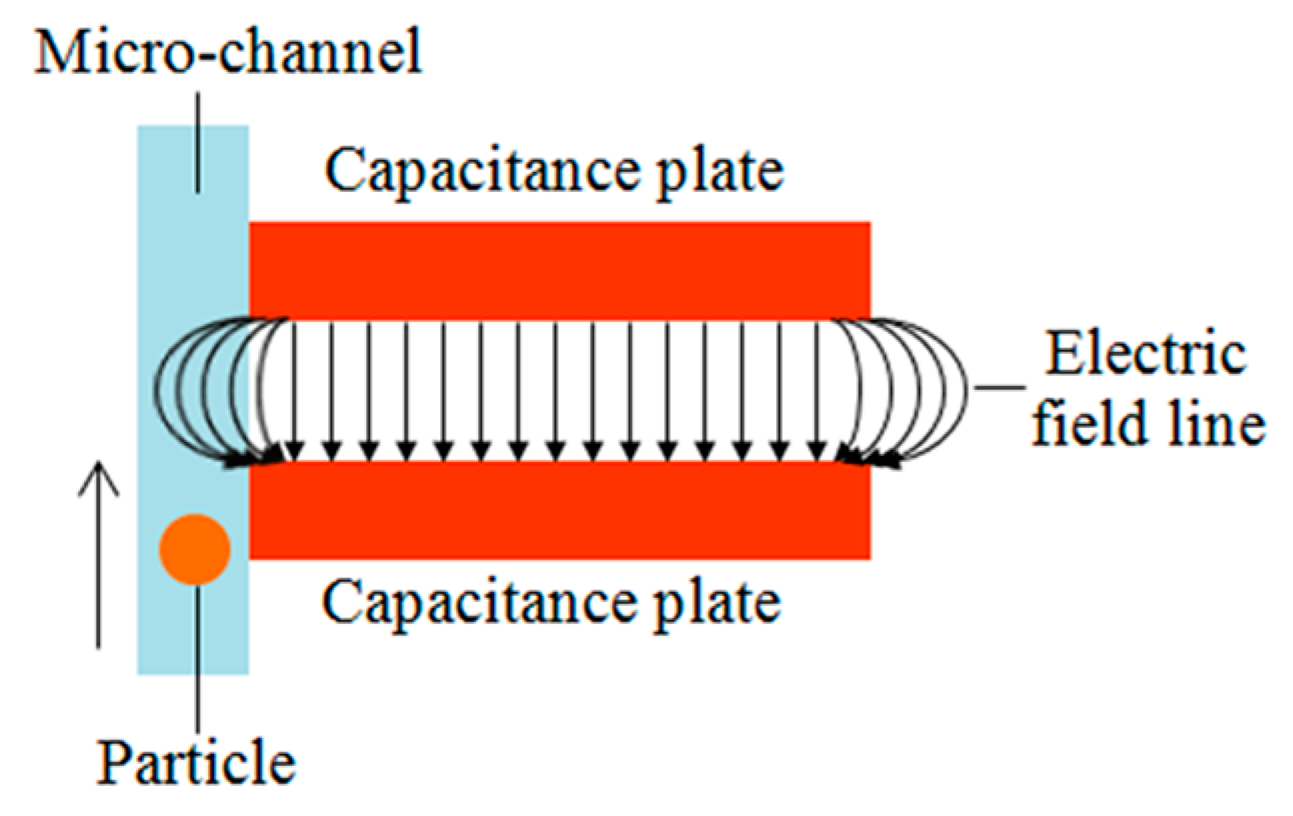

3.2. Capacitance Detection Mode

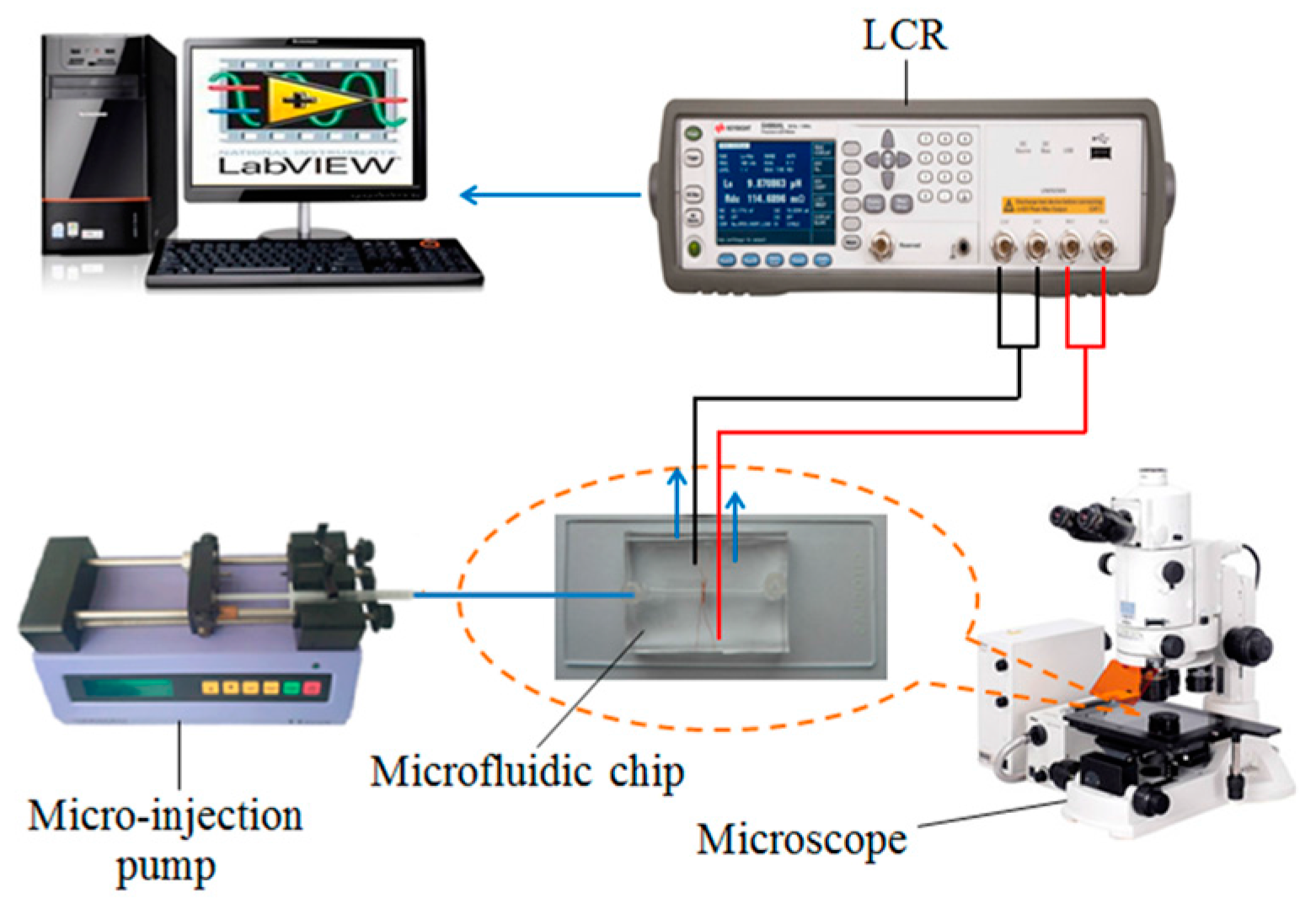

4. Experiments and Discussion

4.1. Sample Preparations

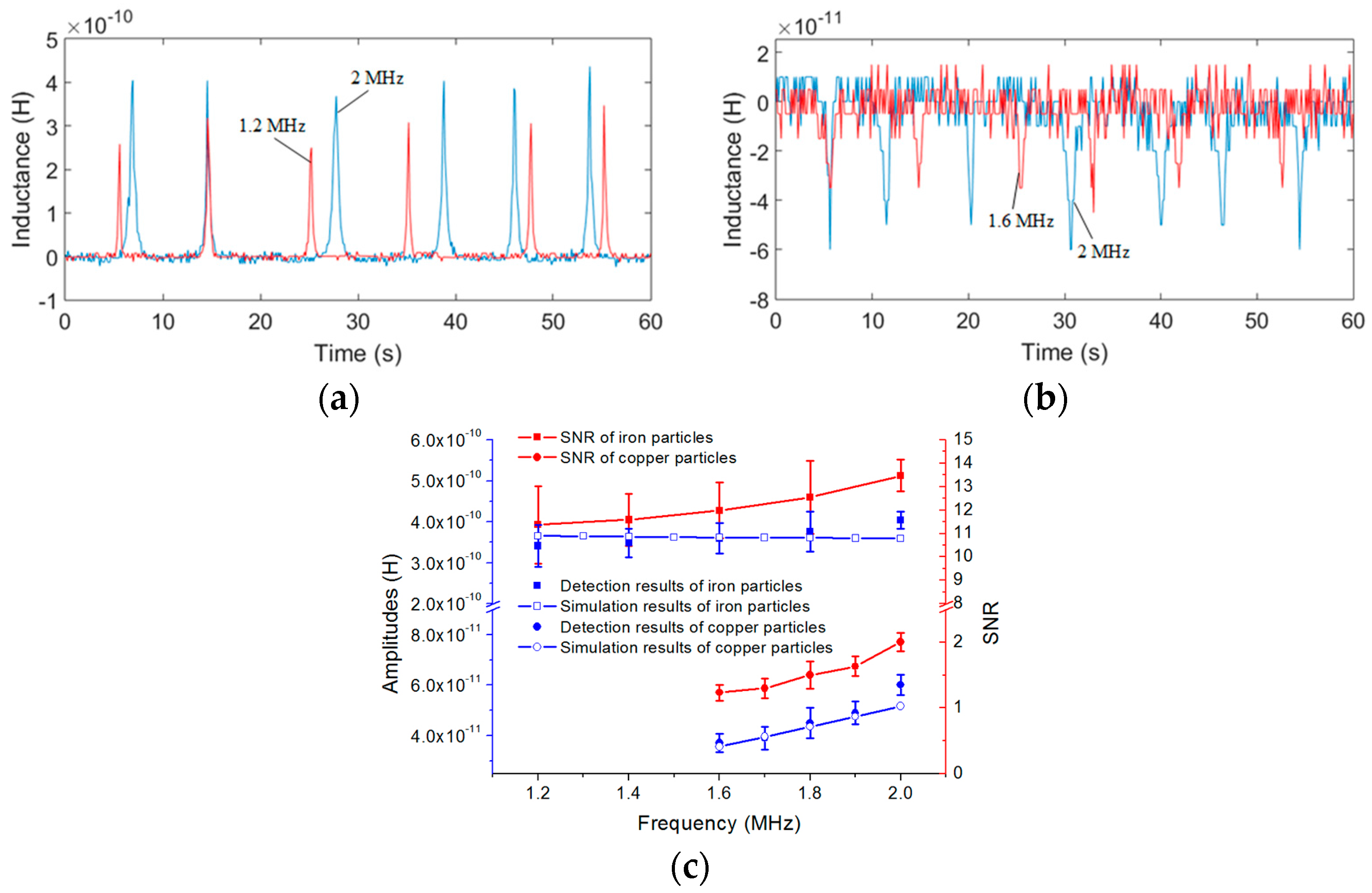

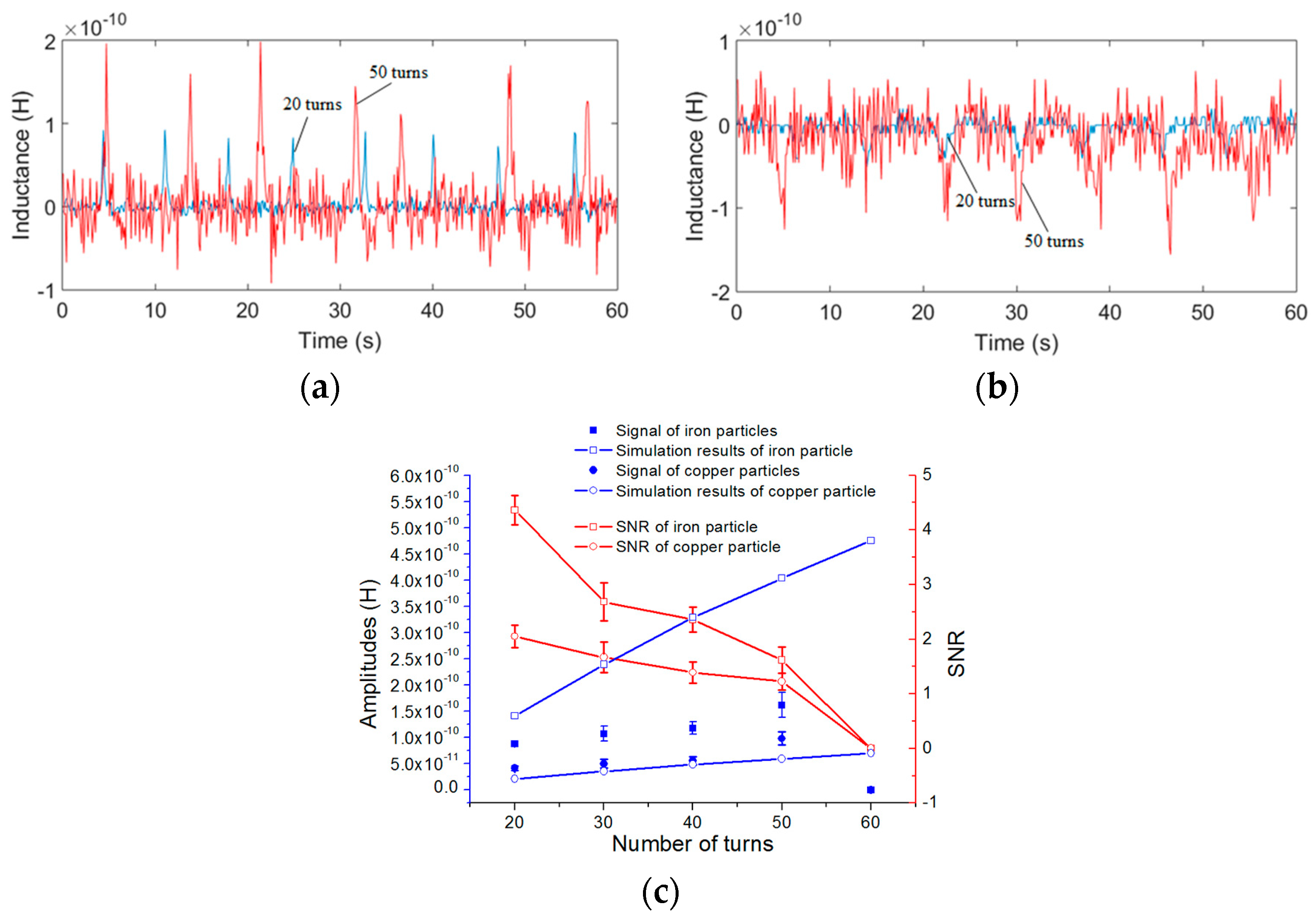

4.2. Inductance Detection Experiments

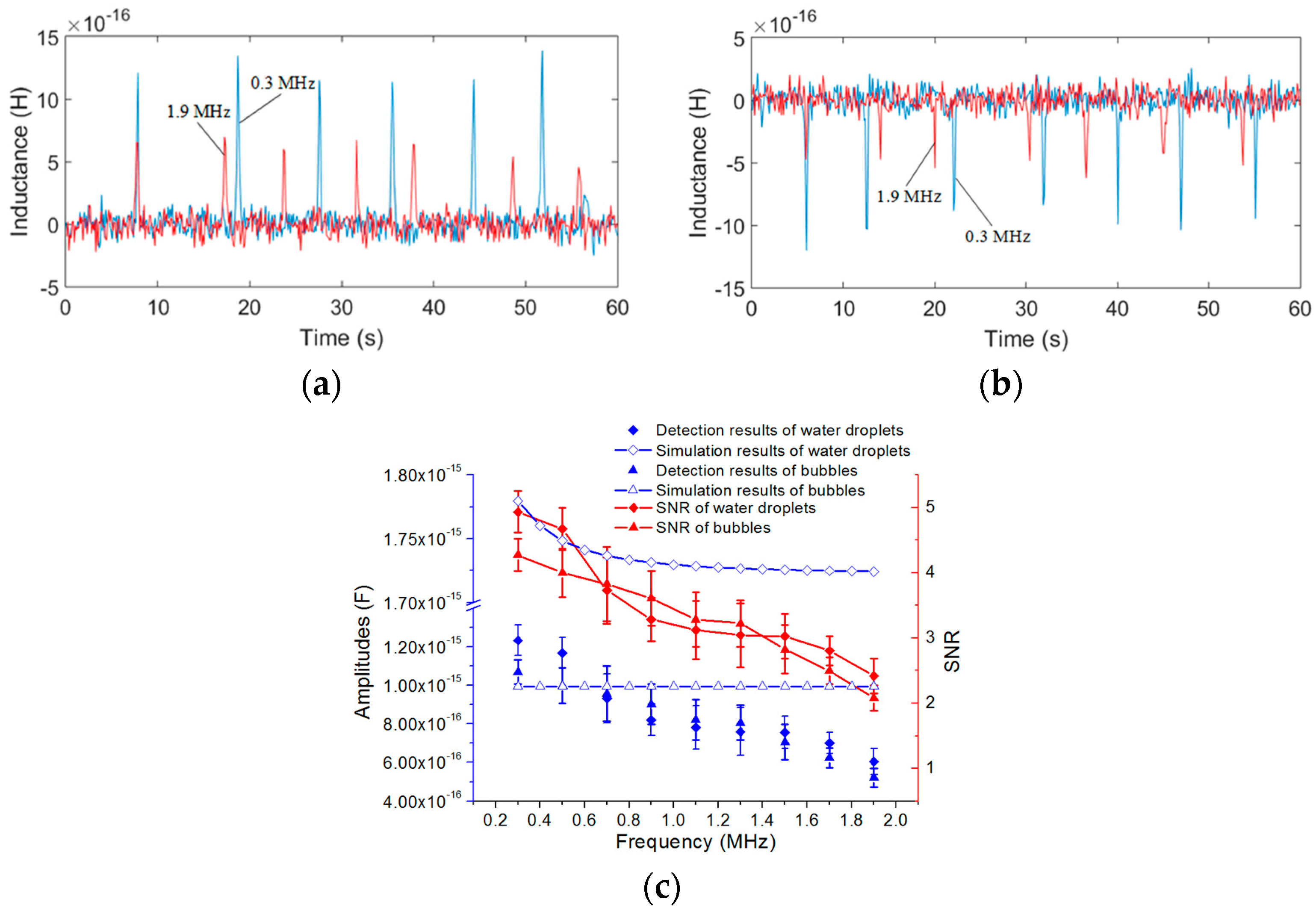

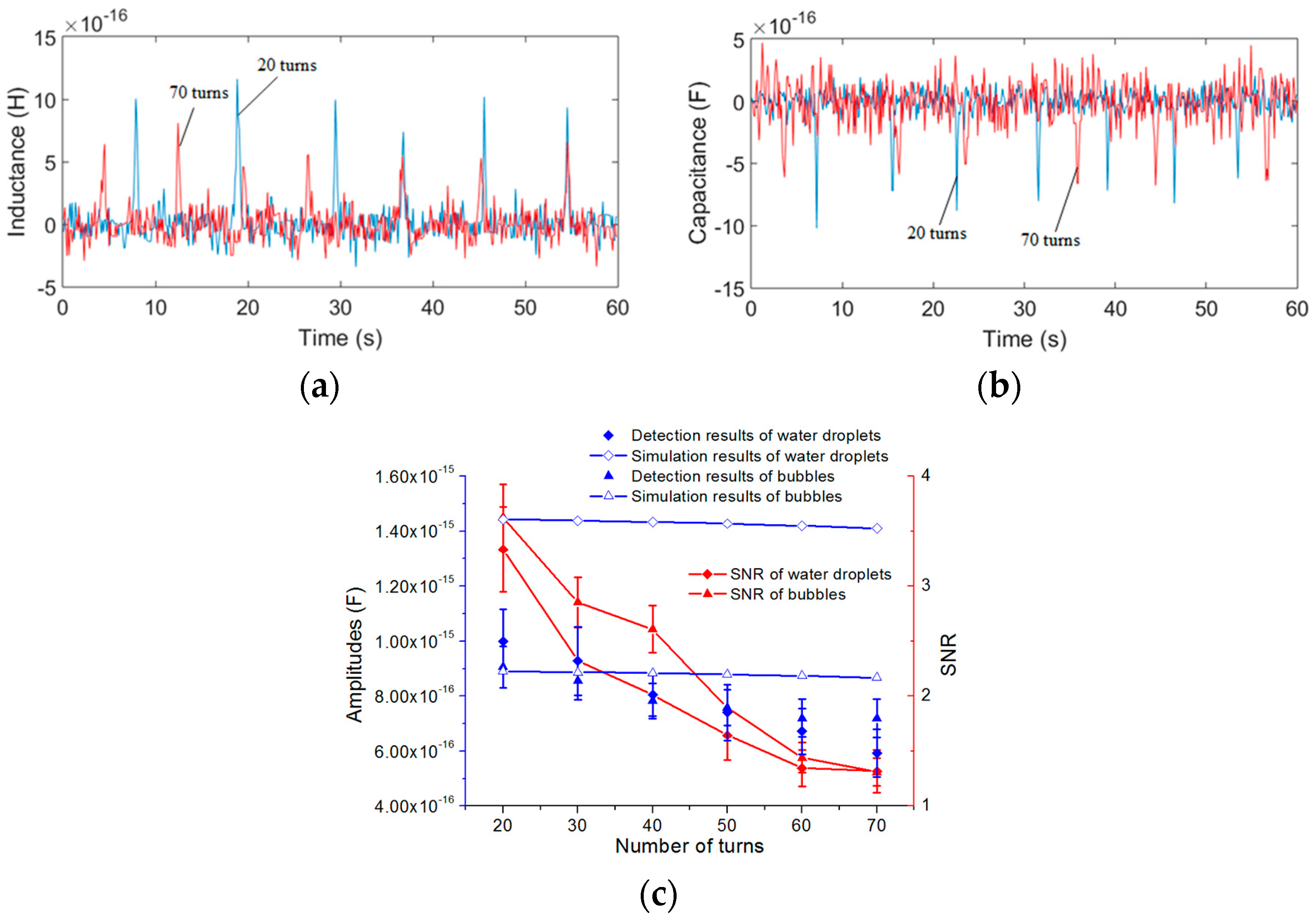

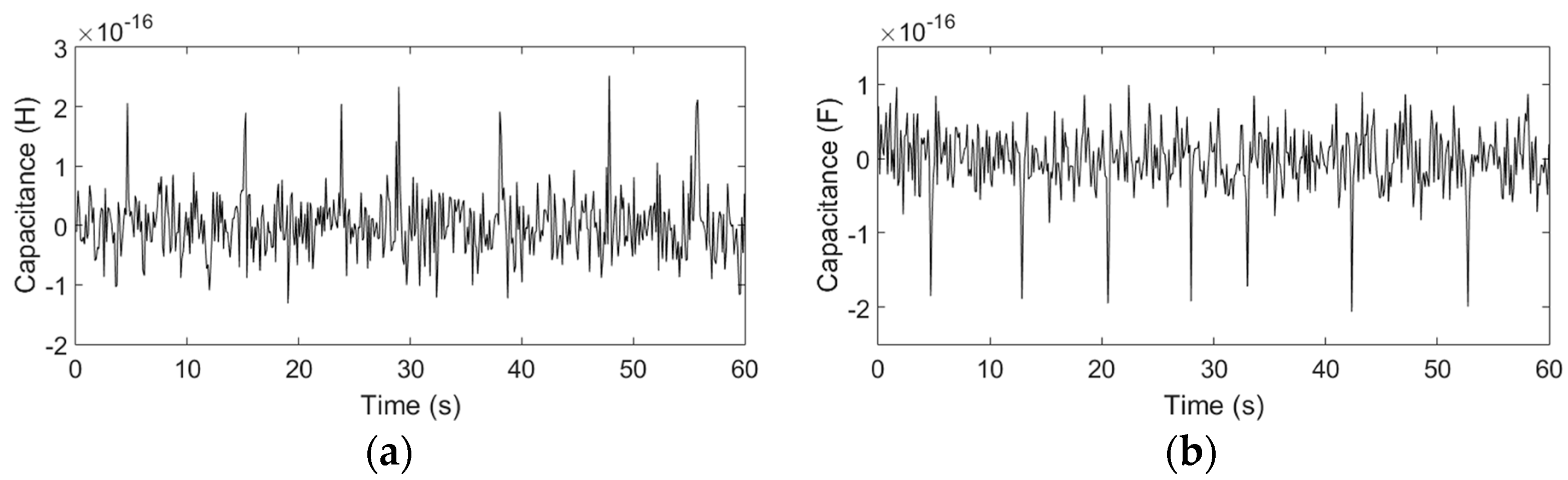

4.3. Capacitance Detection Experiments

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, H.; Huang, W.; Zhang, Y.; Shen, Y.; Li, D. Design of the microfluidic chip of oil detection. Appl. Mech. Mater. 2012, 117, 517–520. [Google Scholar] [CrossRef]

- Tucker, J.E.; Schultz, A.; Lu, C.; Sebok, T.; Holloway, C.; Tankersley, L.L.; Reintjes, J. Lasernet fines optical wear debris monitor. In Proceedings of the International Conference on Condition Monitoring, Swansea, UK, 12–15 April 1999; pp. 445–452. [Google Scholar]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of precursor wear debris in lubrication systems. In Proceedings of the 2000 IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 25 March 2000; pp. 73–77. [Google Scholar]

- Toms, A.; Toms, A. Oil analysis and condition monitoring. In Chemistry and Technology of Lubricants; Springer: Dordrecht, The Netherlands, 2010; pp. 459–495. [Google Scholar]

- Abouel-Kasem, A.; Alturki, F.A.; Ahmed, S.M. Fractal analysis of cavitation eroded surface in dilute emulsions. J. Tribol. 2011, 133, 041403. [Google Scholar] [CrossRef]

- Zou, J.; Wang, C.; Fu, X. Design and experiment of on-line bubble elimination valve for hydraulic oil. Hydraul. Pneum. Seals 2012, 8, 53–55. [Google Scholar]

- Sun, W. Quantitative estimation technique for wear amounts by real time measurement of wear debris in lubricating oil. Adv. Mater. Res. 2011, 308, 647–650. [Google Scholar] [CrossRef]

- Wu, T.; Wu, H.; Du, Y.; Peng, Z. Progress and trend of sensor technology for on-line oil monitoring. Sci. China Technol. Sci. 2013, 56, 2914–2926. [Google Scholar] [CrossRef]

- Khandaker, I.I.; Glavas, E.; Jones, G.R. A fibre-optic oil condition monitor based on chromatic modulation. Meas. Sci. Technol. 1993, 4, 8–13. [Google Scholar] [CrossRef]

- Kwon, O.K.; Kong, H.S.; Han, H.G.; Yoon, E.S.; Myshkin, N.K.; Markova, L.V.; Semeniouk, M.S. On-line Measurement of Contaminant Level in Lubricating Oil. U.S. Patent US6151108 A, 21 November 2000. [Google Scholar]

- Zhang, J.; Drinkwater, B.W.; Dwyer-Joyce, R.S. Monitoring of lubricant film failure in a ball bearing using ultrasound. J. Tribol. 2006, 128, 612–618. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J.; Carletta, J.; Veillette, R.; Choy, F. Real-time monitoring of wear debris in lubrication oil using a microfluidic inductive Coulter counting device. Microfluid. Nanofluid. 2010, 9, 1241–1245. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A high throughput inductive pulse sensor for online oil debris monitoring. Tribol. Int. 2011, 44, 175–179. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Zhang, C.; Shen, Y.; Pan, X.; Li, D. Detection of micro debris based on spatial micro solenoid inductance. Mach. Tool Hydraul. 2012, 21, 48–50. [Google Scholar]

- Zhang, X.; Zhang, H.; Sun, Y.; Chen, H.; Zhang, Y. Research on the output characteristics of microfluidic inductive sensor. J. Nanomater. 2014, 2014, 725246. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhan, L.; Zhe, J. Improving sensitivity of an inductive pulse sensor for detection of metallic wear debris in lubricants using parallel LC resonance method. Meas. Sci. Technol. 2013, 24, 075106. [Google Scholar] [CrossRef]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Zheng, Y.; Shojaei-Baghini, E.; Wang, C.; Sun, Y. Microfluidic characterization of specific membrane capacitance and cytoplasm conductivity of singlecells. Biosens. Bioelectron. 2013, 42, 496–502. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhao, K.; Song, Y.; Pan, X. Microfluidic capacitance sensor for detecting metal wear debris in lubrication oil. Dalian Haishi Daxue Xuebao 2013, 3, 42–46. [Google Scholar]

- Zhu, X.; Du, L.; Zhe, J. An integrated lubricant oil conditioning sensor using signal multiplexing. J. Micromech. Microeng. 2014, 25, 015006. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Zeng, L.; Chen, H.; Sun, Y. Determination of metal particles in oil using a microfluidic chip-based inductive sensor. Instrum. Sci. Technol. 2016, 44, 259–269. [Google Scholar] [CrossRef]

- Liu, B. Measuring core and ferrite saturable inductance. Foreign Electron. Meas. Technol. 2013, 32, 63–66. [Google Scholar]

- Zhou, D.; Wang, J.; Zhang, Q.; Wu, J.; Zhang, H. Research on sensing mechanism of ferromagnetic component flaw using pulsed eddy current testing. Yiqi Yibiao Xuebao 2013, 36, 989–995. [Google Scholar]

- Zhang, X. Study on Metal Particle Magnetization in Harmonic Field. Ph.D. Thesis, Dalian Maritime University, Dalian, China, 2014. [Google Scholar]

- Fan, H.; Zhang, Y.; Cheng, Y.; Ren, G. Effect of the radial distribution of the wear debris position on the testing results of inductive wear debris sensor. Chin. J. Sens. Actuators 2010, 23, 958–962. [Google Scholar]

- Liu, E. Research on the Detection of Various Pollutants in Marine Hydraulic Oil in an Integrated Chip. Master Thesis, Dalian Maritime University, Dalian, China, 2017. [Google Scholar]

- Palmer, H.B. The capacitance of a parallel-plate capacitor by the Schwartz-Christoffel transformation. Electr. Eng. 1937, 56, 363–368. [Google Scholar] [CrossRef]

- Hosseini, M.; Zhu, G.; Peter, Y.A. A new formulation of fringing capacitance and its application to the control of parallel-plate electrostatic micro actuators. Analog Integr. Circuits Signal Process. 2007, 53, 119–128. [Google Scholar] [CrossRef]

- Kambali, P.N.; Pandey, A.K. Capacitance and force computation due to direct and fringing effects in MEMS/NEMS arrays. IEEE Sens. J. 2016, 16, 375–382. [Google Scholar] [CrossRef]

- Nishiyama, H.; Nakamura, M. Capacitance of disk capacitors. IEEE Trans. Compon. Hybrids Manuf. Technol. 1993, 16, 360–366. [Google Scholar] [CrossRef]

- Morgan, H.; Sun, T.; Holmes, D.; Gawad, S.; Green, N.G. Single cell dielectric spectroscopy. J. Phys. D Appl. Phys. 2006, 40, 61–70. [Google Scholar] [CrossRef]

| Parameters | N = 20 | N = 30 | N = 40 | N = 50 | N = 60 |

|---|---|---|---|---|---|

| L (μH) | 1.4030 | 2.8435 | 5.3643 | 9.5557 | 15.8967 |

| Leq (μH) | 1.1037 | 2.5144 | 5.0266 | 9.0852 | 15.4097 |

| M (μH) | 0.8044 | 2.1835 | 4.6889 | 8.6147 | 14.9227 |

| M/L | 0.5733 | 0.7679 | 0.8741 | 0.9015 | 0.9387 |

| Iron Particle Sizes (μm) | Average Amplitude (H) | Copper particle Sizes (μm) | Average Amplitude (H) |

|---|---|---|---|

| 40 to 50 | 4.4 × 10−11 | 110 to 120 | 3.8 × 10−11 |

| 70 to 80 | 8.7 × 10−11 | 120 to 130 | 4. 1× 10−11 |

| 100 to 110 | 4.04 × 10−10 | 140 to 150 | 5.9 × 10−11 |

| Water Droplet Sizes (μm) | Average Amplitude (H) | Bubble Sizes (μm) | Average Amplitude (H) |

|---|---|---|---|

| 100 to 110 | 2.1 × 10−16 | 180 to 200 | 1.9 × 10−16 |

| 190 to 200 | 1.02 × 10−15 | 260 to 280 | 7.7 × 10−16 |

| 210 to 120 | 1.23 × 10−15 | 280 to 300 | 9.6 × 10−16 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zeng, L.; Teng, H.; Zhang, X. A Novel On-Chip Impedance Sensor for the Detection of Particle Contamination in Hydraulic Oil. Micromachines 2017, 8, 249. https://doi.org/10.3390/mi8080249

Zhang H, Zeng L, Teng H, Zhang X. A Novel On-Chip Impedance Sensor for the Detection of Particle Contamination in Hydraulic Oil. Micromachines. 2017; 8(8):249. https://doi.org/10.3390/mi8080249

Chicago/Turabian StyleZhang, Hongpeng, Lin Zeng, Huaibo Teng, and Xingming Zhang. 2017. "A Novel On-Chip Impedance Sensor for the Detection of Particle Contamination in Hydraulic Oil" Micromachines 8, no. 8: 249. https://doi.org/10.3390/mi8080249