1. Introduction

In recent years, the demand for micro-products has grown with the market of electronic products and micro-electro-mechanical systems, making precision and miniaturization an important direction of the manufacturing industry, and the research of micro-plastic forming technology become a hotspot. However, with the traditional micro-forming method it is difficult to meet industrial production demands, because of high cost, low processing efficiency and environmental pollution problems [

1]. With the rapid development of laser technology, the microscale laser dynamic flexible forming (µLDFF) technique has gradually become an import dynamic high-pressure loading technology. The laser has many advantages, such as good repeatability, high accuracy and flexibility. Cheng et al. [

2] had applied this technique to the micro-forming of mental foil. The results showed that high strain rate and formability was achieved by the laser-induced high-pressure shock wave forming process. Further research was conducted by Li et al. [

3,

4] to find the forming limits and fracture of the workpiece, which showed that formability increased compared with other forming processes of metal. Gao [

5] studied the effect of laser shot peening on the fatigue properties of the workpiece. The results showed that laser shot peening causes a deeper compressive residual stress field, which can improve the fatigue strength of the material more effectively than the traditional surface strengthening method.

However, the direct µLDFF has a problem: the laser acts on the surface of the workpiece directly, which ablates the surface of the workpiece and destroys the surface quality [

1]. In order to solve this problem and improve the formability of µLDFF, Wang et al. [

1] had applied the laser-driven soft punch technique, a novel laser indirect shock forming method, to micro-forming of metal foil. In that process, low impedance medium flexible rubber was utilized as a soft punch, placed between the thin metal sheet and the black paint to protect the workpiece surface from being ablated. Liu et al. applied laser shock punch to fabricate micro-gears [

6] and dish-shaped micro-parts [

7], and found that soft punch with 200 µm in thickness is beneficial to homogenize energy and propagate the shock wave. It also has been found that the soft punch is favorable for increasing formability of the mental foils during the µLDFF, and the soft punch can easily separate from the workpiece after the forming process without excessive force [

8].

It can be seen from above that the process for laser-driven soft punch forming mainly concentrates on a single-layer metal. However, with the development of industry, single-layer metals have been unable to meet the needs of industry. Therefore, many types of sheet metal laminates, composed of a plurality of layers of metal with dissimilar materials [

9], have been produced and applied in micro-forming products, which need several different kinds of superior properties at the same time. The properties of laminates can be tailored by choosing proper layers and arrangements to improve its mechanical, thermal and electrical properties on demand [

10]. Hence, the micro-forming of sheet metal laminates was studied. Hino et al. [

11] investigated the springback of sheet metal laminates (Al/SS) in draw-bending with 1.5 mm thickness, and found that the springback was strongly affected by the strength difference between the component layers. Oya et al. [

12] evaluated the formability of multilayer steel sheets with 1 mm thickness through tensile, V-bending and hemming tests. The laser bending of a SUS430/C11000/SUS430 laminated composite was investigated by Seyedkashi et al. [

13] both experimentally and numerically. Recent studies have shown that many properties of material can be dramatically improved in terms of their laminated composites, including impact behavior, wear, corrosion, fracture toughness, fatigue behavior and damping capacity. In addition, the enhanced formability or ductility of brittle materials was also improved [

14].

However, the forming behavior of sheet metal laminates is much more complicated than single-layer sheets because of dissimilar metal components. Therefore, it is important to find the technique of improving the formability to expand the application of sheet metal laminates. The laser-driven soft punch micro-bending method was applied in this paper for its advantages in improving the forming performance. In addition, a few recent studies have reported the improvement of forming performance at elevated temperature [

15], which is called warm forming. However, the studies in warm conditions are just confined to the single layer at present. Ye, Cheng et al. [

16] researched the formability of laser direct shock forming of the copper foil in warm conditions. The results showed that the forming depth can be increased by elevating forming temperature and laser energy. These effects on forming ability were also researched by Ma et al. [

15] by charactering forming depth, forming accuracy and surface quality. It was found that the optimal forming temperature was appropriately 150 °C as the forming depth and forming accuracy was improved without deterioration of the surface integrity. Jiang et al. [

17] investigated the influence of temperature on the deformability of pure copper, and found that forming temperature has important influence on the shape accuracy and metal flow behavior.

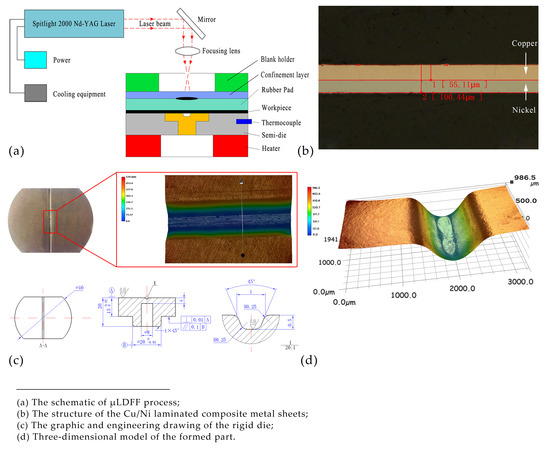

The main objective of this work is to investigate the forming performances of sheet metal laminates in warm conditions by laser-driven soft punch experiments, including the forming depth and accuracy, surface roughness and so on. Element diffusion was also involved. Influences included experimental temperature and laser energy. The micro-mold and warm platform were designed, and Cu/Ni laminated composite metal sheets were selected as the experimental material. The experiment found that formability was improved in warm conditions.

3. Results and Discussion

3.1. Forming Depth

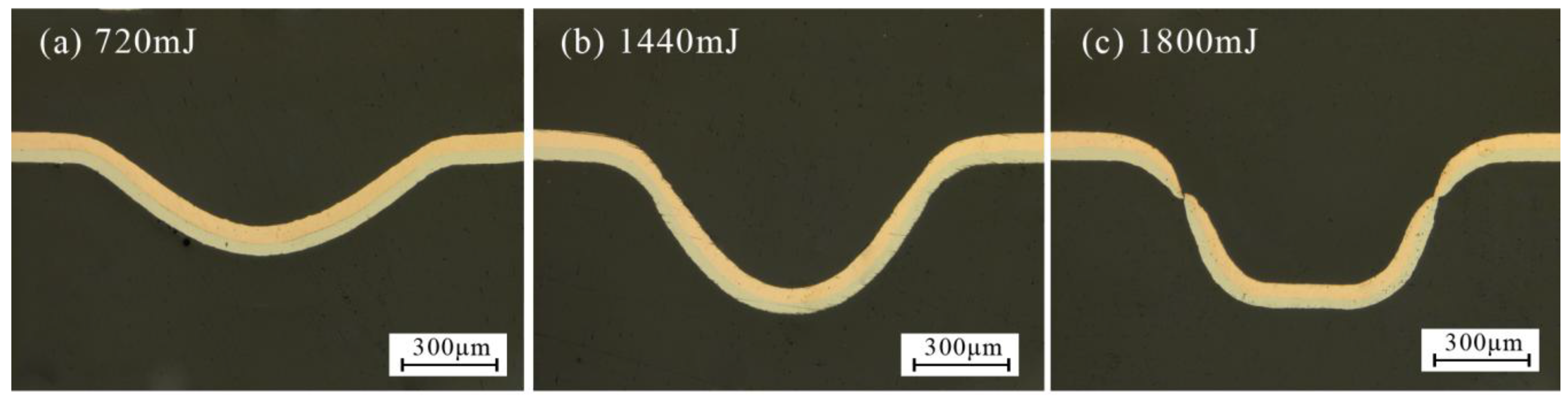

A series of experiments were conducted in warm conditions and the maximum value was defined as the forming depth at the bottom of the valley of the formed workpiece. The results are shown in

Figure 4. It was found that at room temperature (25 °C), the forming depth increased first and then decreased with laser energy, and the largest forming depth was achieved at 1440 mJ. When the laser energy reached 1440 mJ, the workpiece contacted with the bottom of the rigid die, and no longer increased, which is related to the research of Zhang et al. [

22]; when the energy was 1800 mJ, the springback of workpiece occurred because of the intense collision between the workpiece and rigid die, so the forming depth decreased, as shown in

Figure 5.

The springback can be explained as follows: First, the silicone rubber would return to the initial shape quickly after the maximum elastic deformation. However, at some parts, the plastic deformation was not complete, within the elastic deformation or between the elastic and plastic deformation; second, as the laser impact micro-forming is a rapid prototyping process, the forming depth increased with the energy and sufficient impact pressure. While the workpiece contacted with the mold, severe plastic deformation occurred with different speeds. When the surrounding has pasted the mold completely, the workpiece collided with the rigid die, resulting in springback.

At warm conditions, the forming depth increased with temperature. By elevating the temperature from 25 °C to 250 °C, an increase of over 47 μm in forming depth was achieved, approximately 16.5%. The improved forming depth can be explained by the increased ductility and reduced flow stress. However, when the laser energy reached 1440 mJ, the temperature has little effect on the forming depth, because the workpiece contacted with the rigid die. When the laser energy changed from 1440 mJ to 1800 mJ, the depth at warm conditions was higher than that at room temperature, and the collision between the workpiece and rigid die became more moderate because the increase of temperature made the fluidity of the workpiece increased, so the springback increased too.

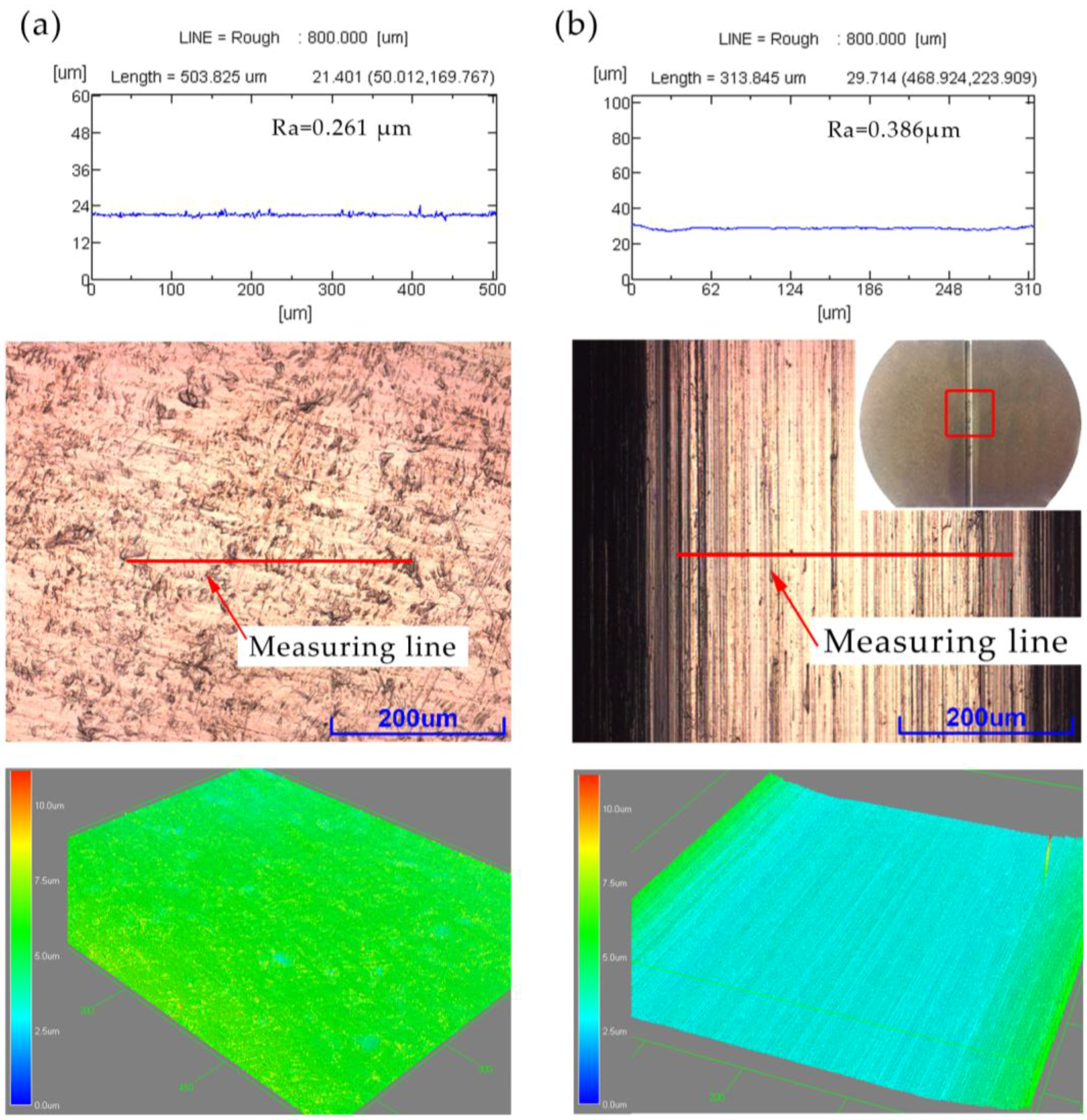

3.2. Surface Quality

It is well known that the deterioration of surface integrity can possibly lead to the failure of material. Therefore, it is necessary to research the effects on surface quality of a workpiece in warm conditions. Axio CSM 700 was employed to obtain the surface morphology and roughness of the rigid die and formed parts.

The value Ra of the formed region was measured at the bottom of the valley of the formed part to evaluate the surface roughness. The value of Ra along the length or width of the groove is different. The mold was machined along the length of the groove, a small protrusion along this direction of mold, so that the roughness variation measured along the groove is small, and the roughness level of the entire bottom of the workpiece cannot be well reflected. Therefore, the direction perpendicular to the groove was adopted in this paper, and the measurement results are accurate.

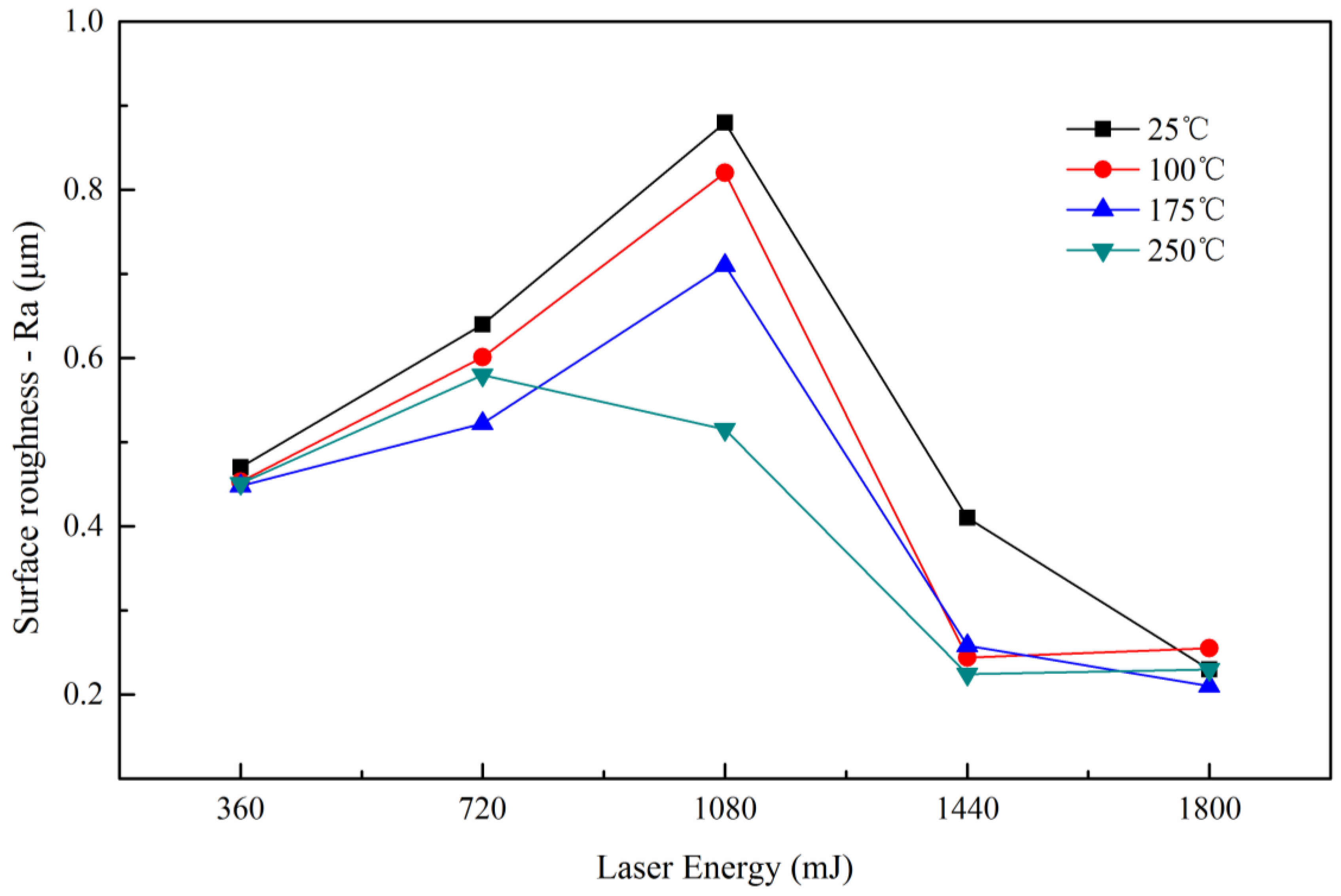

Figure 6 shows the surface roughness of raw material nickel and the rigid die. The results showed the roughness of the rigid die and nickel was 0.386 μm and 0.261 μm, respectively.

Figure 7 shows the roughness of the formed parts at four temperatures. It was observed that the surface roughness showed a trend that increased first and then decreased with the laser energy. Because there were lines on the surface during the rolling process, and in laser shock process, the workpiece was deformed in all directions, making the lines and roughness become larger and larger. With the increase of laser energy, the plastic deformation of the specimen was strengthened, making the grain size of the workpiece surface roughed and leading to the increase of the surface roughness of the formed parts [

23], as shown in

Figure 8a. With further increase of energy, the workpiece copied the die lines after contacted with the rigid die, so the roughness was reduced, as shown in

Figure 8b. When the energy reached 1800 mJ, the workpiece completely pasted the rigid die, and copied the lines, making the roughness of workpiece similar with the die, about 0.386 μm, as shown in

Figure 8c.

It can also be found from

Figure 7 that the surface roughness decreased with the forming temperature. This is probably because, the fluidity and plasticity of the material was improved and the impact of line on the forming parts was alleviated, so the friction force of the workpiece between the soft punch and rigid die was reduced. Overall, the surface roughness was reduced after the forming process in warm conditions.

When the laser energy was 1080 mJ, the surface roughness increased first and then decreased. This is because when the temperature was 250 °C, the workpiece contacted with the rigid die. Finally, the surface roughness showed no obvious difference for the specimens with different temperature when the laser energy was 1800 mJ, the final roughness of the bottom mainly depended on the surface roughness of the die.

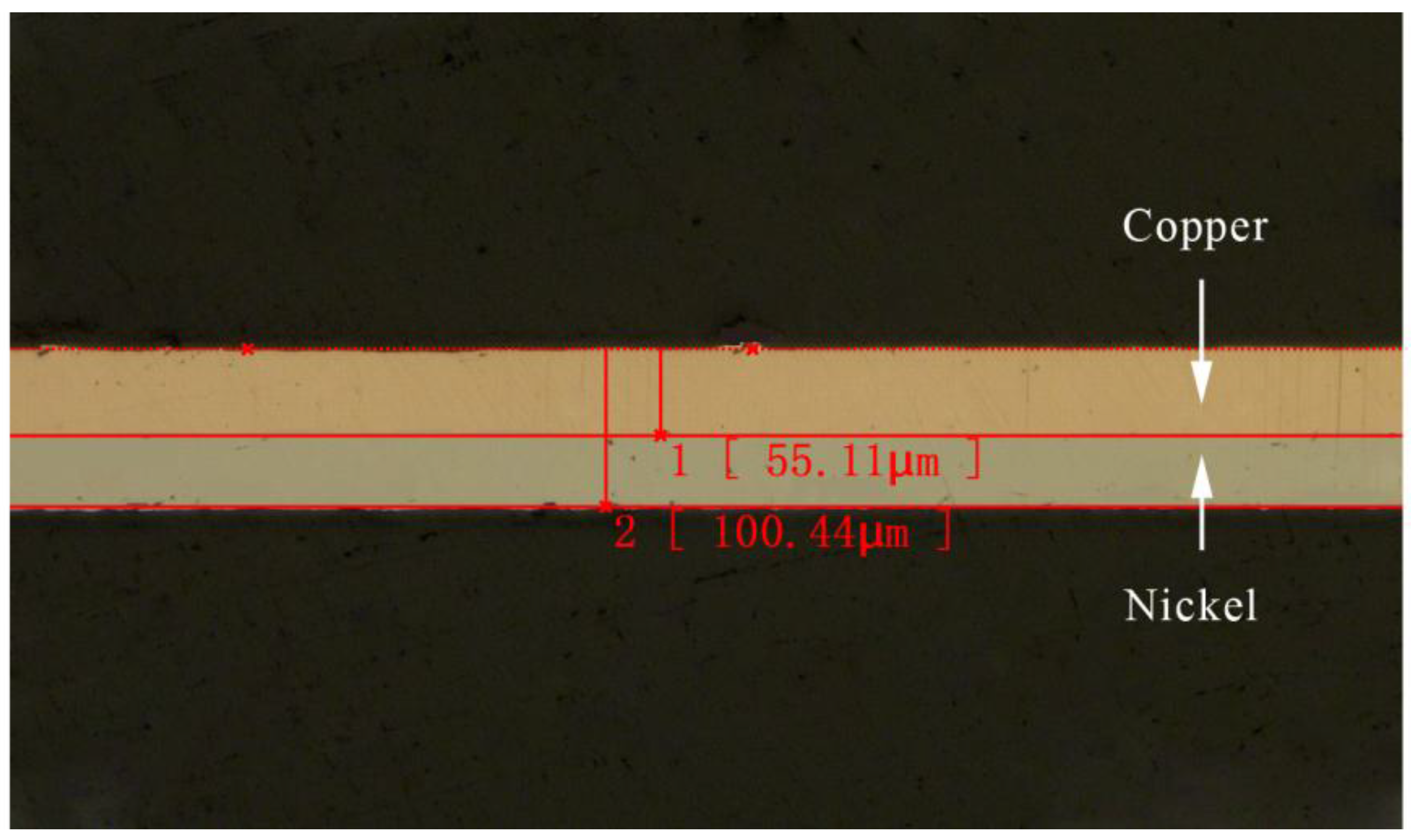

3.3. Thickness Distribution

The thickness thinning ratio of the formed parts is a significant forming property in the micro-forming process. Severe thinning of the formed parts led to compressive stress, localized necking, and even failure of the component. Therefore, the thinning ratio was characterized by using the cold-mounted process in this paper, and the mounted workpiece was grinded with 80# to 3000# sand paper and then polished. Finally, the thickness was measured as shown in

Figure 9.

The thinning ratio of the sheet and each layer was calculated respectively by Equation (1). Where

and

are the thickness before and after deformation respectively. The distribution of thickness thinning ratio with different laser energies is shown in

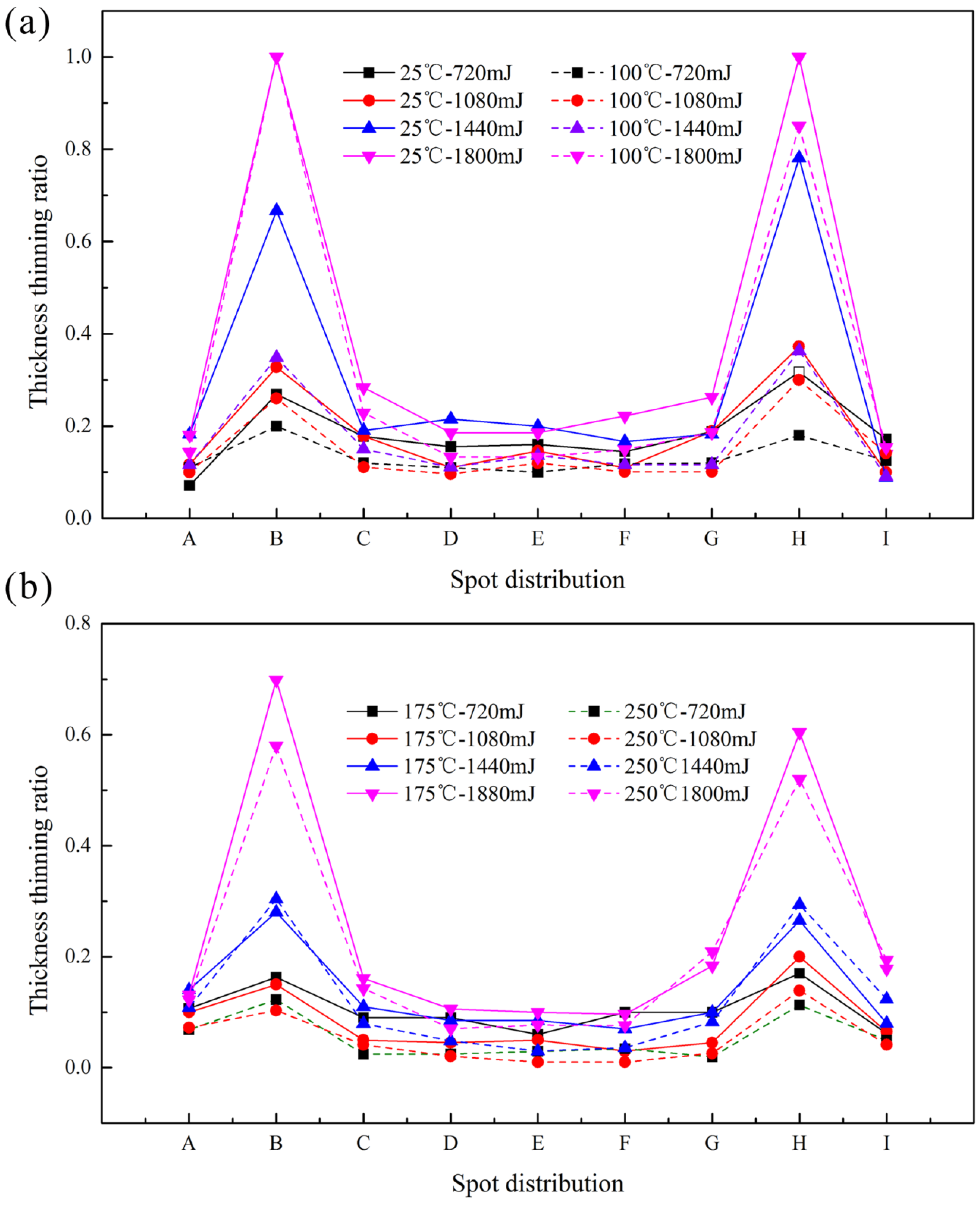

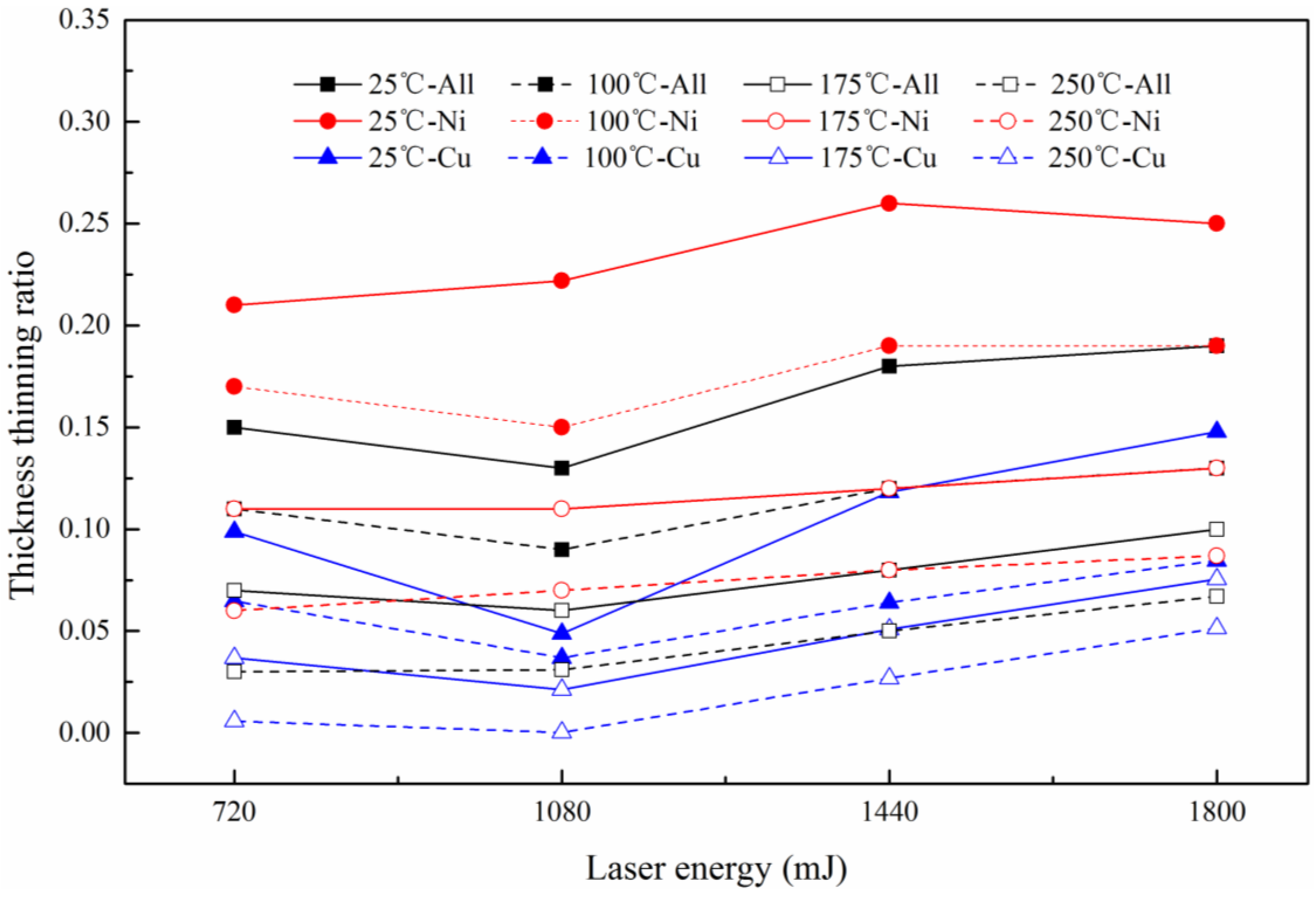

Figure 10.

It can be seen from

Figure 10 that the thinning ratio and magnitude fluctuation were small with low laser energy, and it increased with the laser energy. The maximum value was achieved at the points B and H, and even reached 1, which meant the fracture occurred. The appearance of this phenomenon is because of the short time of laser action, and the material at the chamfer did not have enough time to flow into the mold cavity. In the mold cavity, the workpiece was bent depending on the initial elastic deformation of silicone rubber. Therefore, the deformation is small.

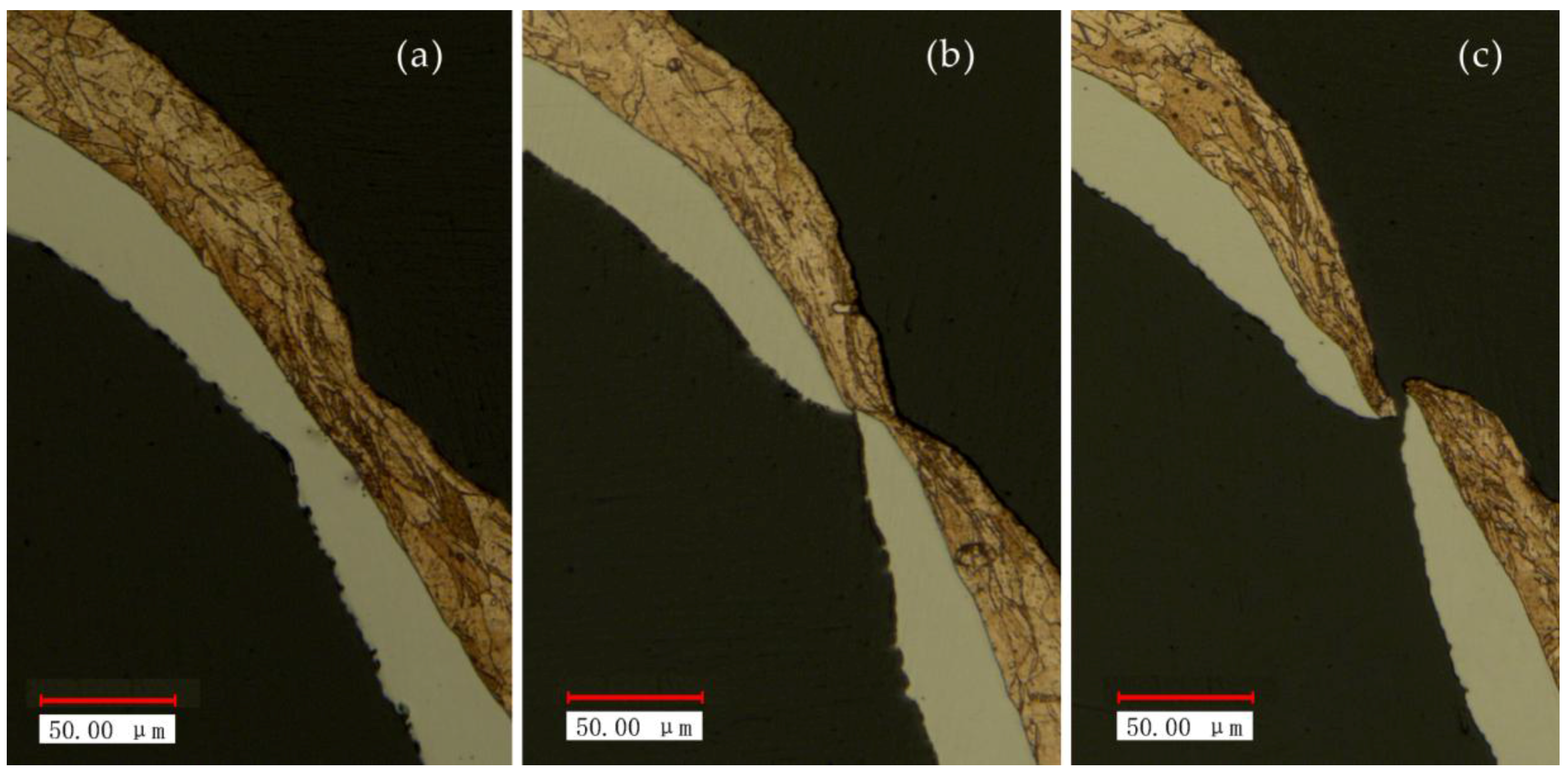

With the increase of laser energy, necking occurred in the chamfer area. Then the workpiece was squeezed into the mold cavity by the silicone rubber, making the thickness further reduced to complete the plastic deformation, the distribution was no longer uniform. When the energy reached 1800 mJ, due to the smaller thickness, the smaller number of grains was involved in deformation, and the workpiece has friction with the soft punch and rigid die, so poor mobility caused the uneven deformation, even fracture, which was the critical load point, as shown in

Figure 11.

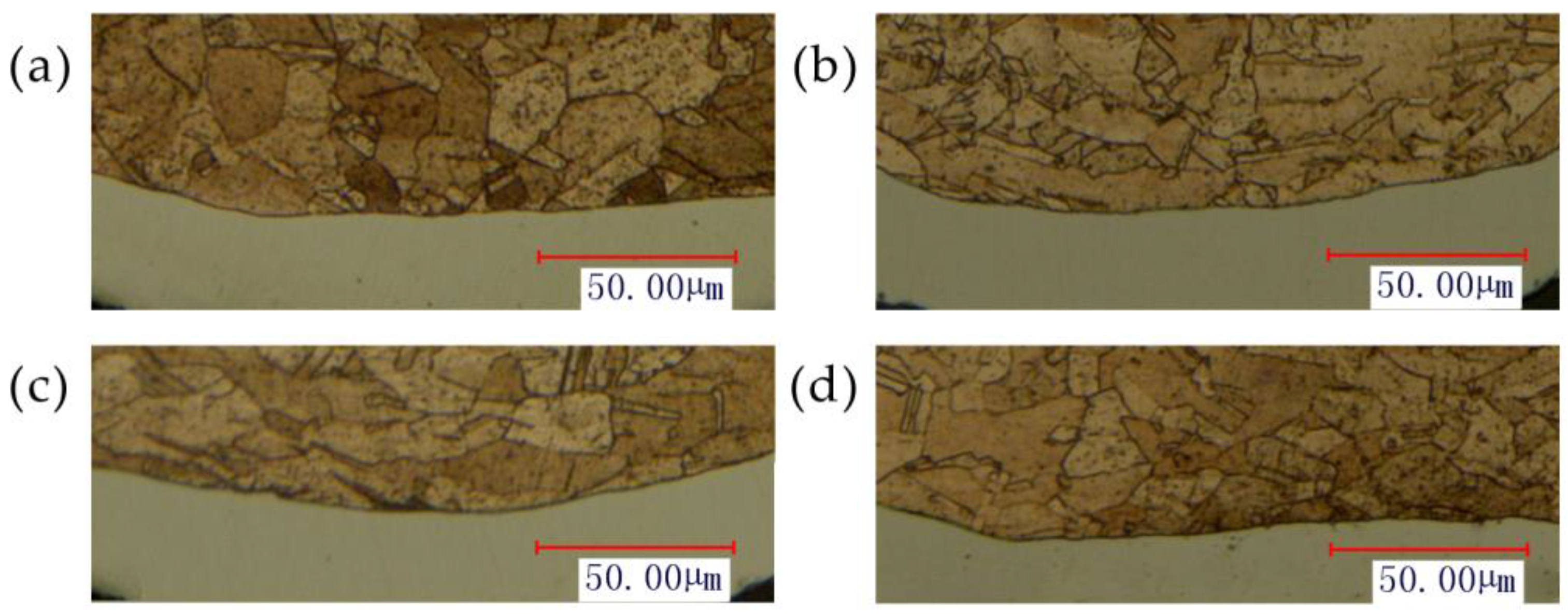

In order to verify the above reasons, the microstructure of the fracture process was observed. The metallographic etchant was prepared by the mass of 5 g FeCl

3, 15 mL HCl and 85 mL H

2O. The polished samples were immersed in the etching solution for 2 to 3 s. The microstructure achieved after etching was shown in

Figure 12. It was can be found that with the increase in energy, due to the friction and poor mobility, the grains were elongated. When the tension is greater than the binding force between the grains, fracture occurred.

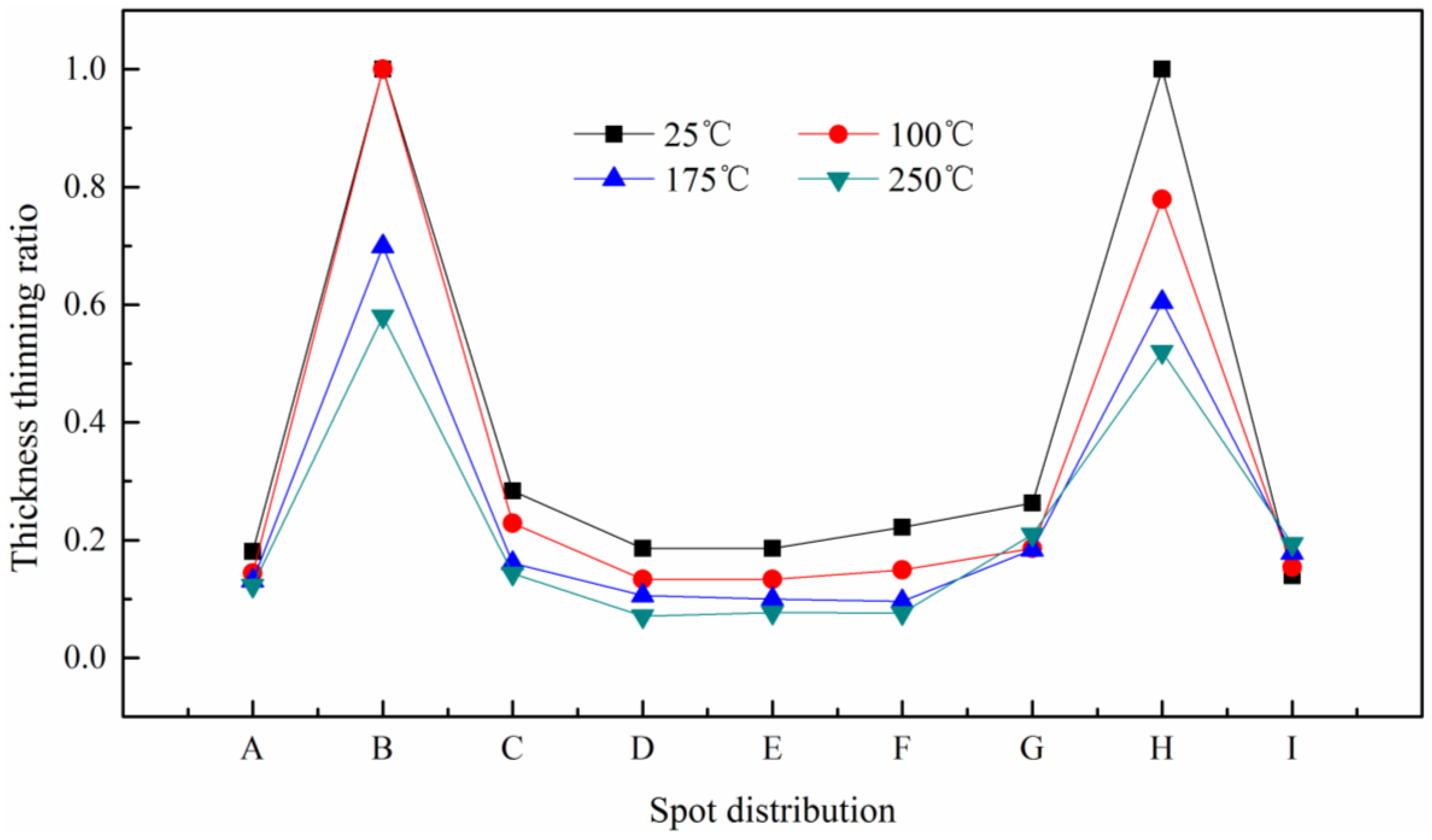

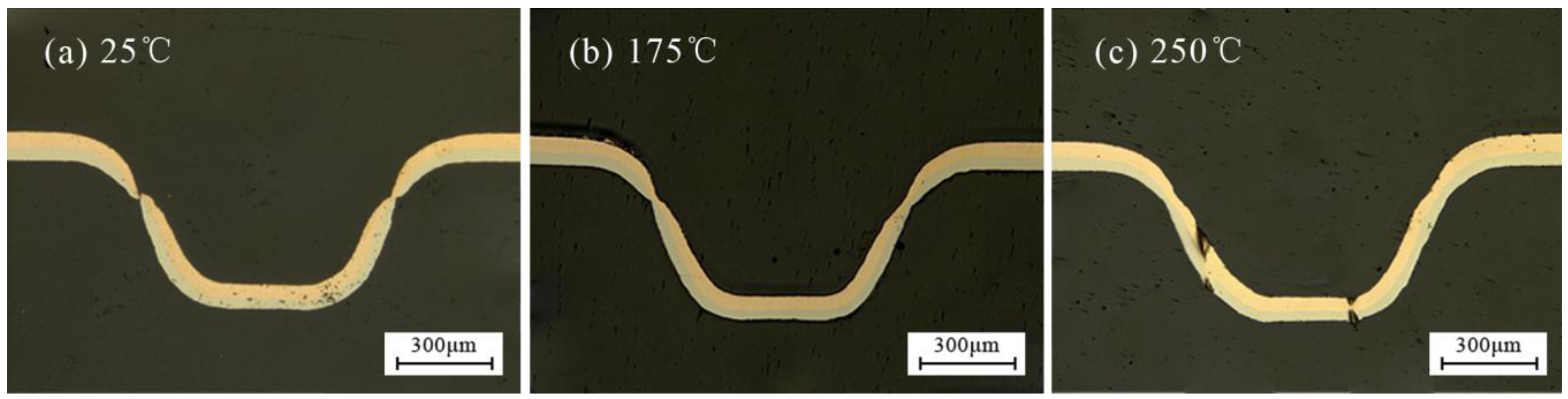

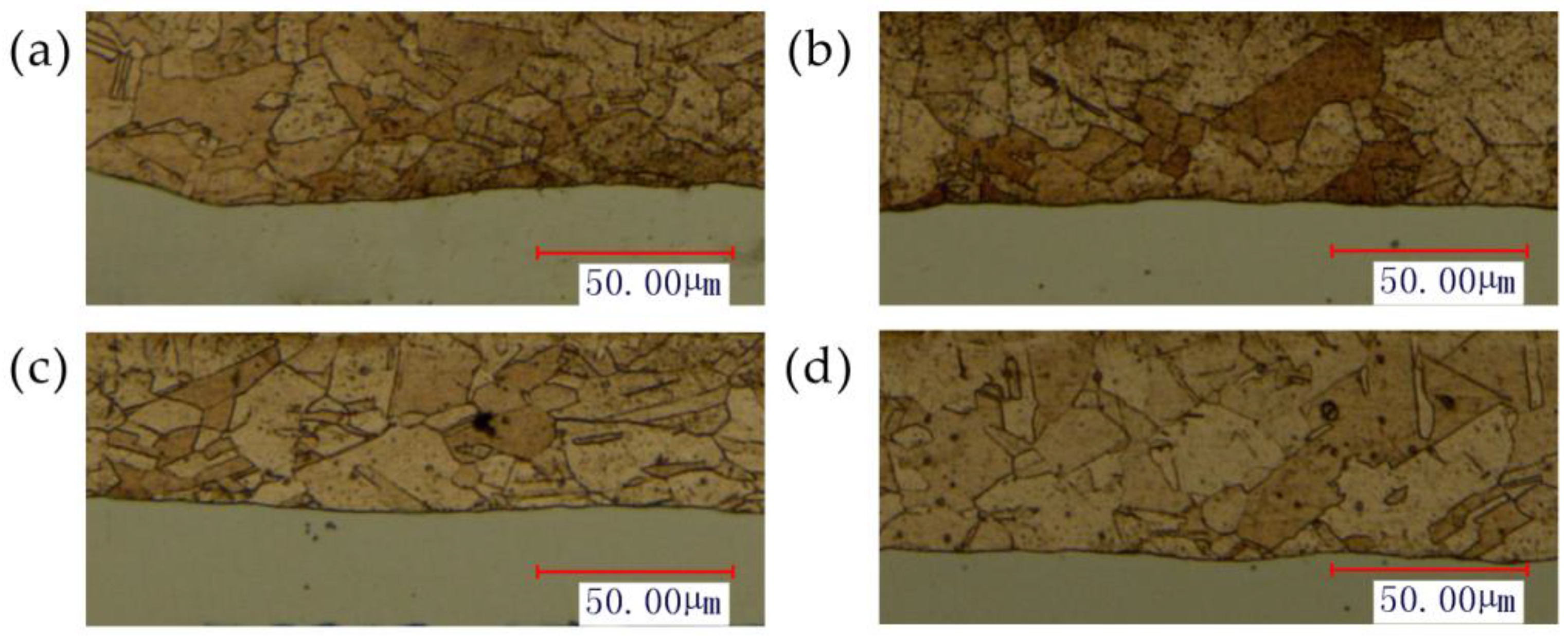

Figure 13 shows the distribution of thinning ratio with temperature. The maximum value was found at the critical load point, where the fracture occurred, as shown in

Figure 14a. The fracture disappeared with the increase of temperature to 175 °C, as shown in

Figure 14b. The necking was also alleviated by further reduced of thinning ratio with the increase of temperature to 250 °C. This is because of higher fracture strain, better ductility and improved plasticity of material compared with room temperature (25 °C), as shown in

Figure 14c.

In order to further understand the effects on thinning ratio of sheet metal laminates, the thinning ratio of each layer was also investigated.

Figure 15 shows the thinning ratio distribution of copper, nickel and composite layer, respectively. It can be seen that the thinning ratio of copper was generally smaller than nickel under the same condition, but this trend gradually became less apparent with the temperature.

This phenomenon can be related to the performance of the materials: the hardness of copper is less than nickel. In this experiment, when the workpiece was bent, the compressive stress was generated on the copper surface and the interface of copper and nickel, the tensile stress was generated on the nickel surface, as shown in

Figure 16a. This was similar with the research of Yilamu et al. [

20]. However, in this paper, the neutral lay in the weak layer, which was different from the research of Yilamu. This was because unlike the traditional pressure bending process, during the µLDFF process, all the forming areas of the workpiece were subjected to the impact pressure that produced by the plasma explosion after the laser shock, resulting in the thickness of all forming areas were reduced. With the increase of temperature, the two layers’ deformation became more uniform. This was because, the neutral layer moved toward the side of nickel layer with the temperature, as shown in

Figure 16b. Which resulting in the tensile stress of the two materials decreased, and the compressive stress increased. Therefore, the gap of thinning ratio between copper and nickel gradually became less apparent with the temperature.

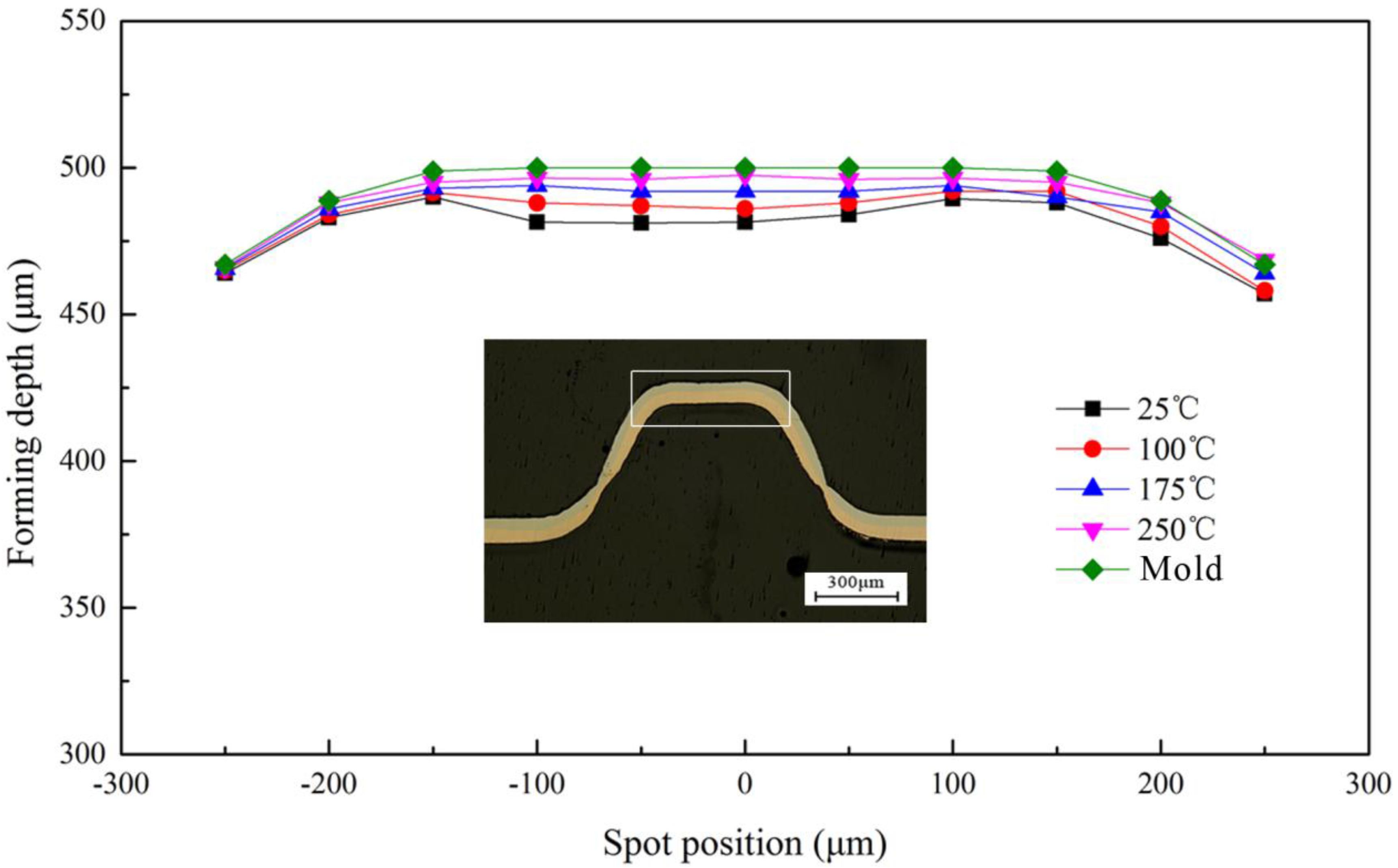

3.4. Forming Accuracy

Fitability and symmetry are the aspects to characterize the formability of accuracy, which is the ability of workpiece to obtain the shape of the rigid die during the forming process. In this paper, the 2D curves in different conditions were investigated to research the forming accuracy in

Figure 17. The dotted and solid lines in this figure represent the experimental data at different temperature, and the outside solid line is the contour curve of the rigid die. The contours of the formed parts should be symmetrical along the X axis zero because the rigid die is symmetrical and the laser employed in the experiment with Gaussian distribution beam. From

Section 3.3, it was known that with the increase of temperature, the material has higher fracture strain, better ductility and plasticity, the deformation were more uniform and forming ability was improved. Therefore, the contour aligned along the X axis zero better after the forming process with higher temperature.

When the laser energy was 1800 mJ, the regular pattern was still valid. This was because the workpiece had reached the maximum forming depth. However, the workpiece and the rigid die were not completely conformed at 25 °C for the springback; when the temperature is 250 °C, the fluidity increased and the springback decreased, resulting in the better fit between the workpiece and rigid die. In order to research the effect of springback on the fitability at different temperatures, the next experiment about fitability was conducted at 1800 mJ, as shown in

Figure 18.

According to

Section 3.1, when the energy was 1800 mJ, the springback of workpiece occurred after contacted with the rigid die, but the increase of temperature making the fluidity of the material increased, the forming depth also increased for the reduce of springback. The fitability of the workpiece was improved. In summary, with the increase of temperature, the fitability and the symmetry improved, the forming accuracy became better and better.

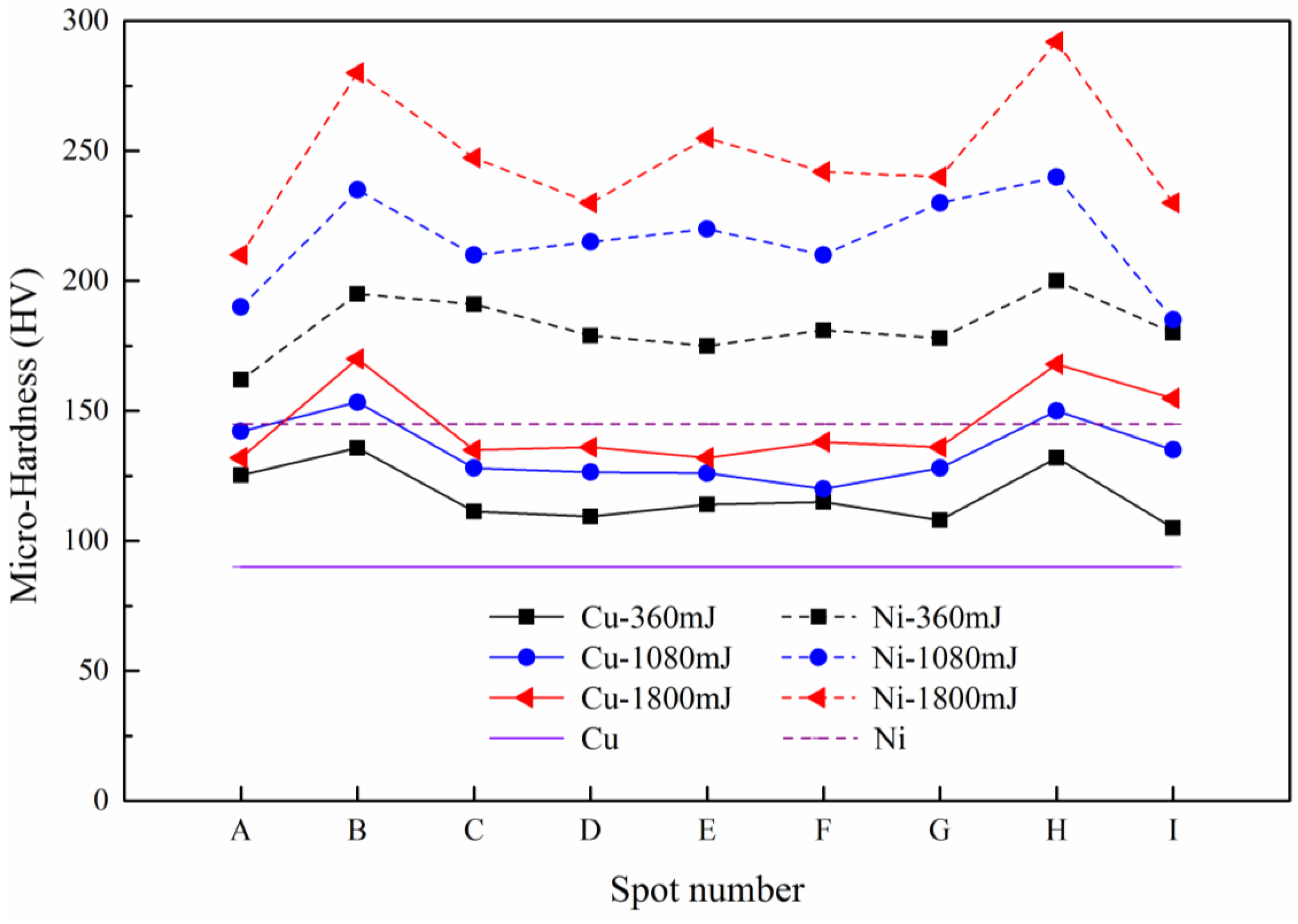

3.5. Hardness Distribution

It is well known that hardness is directly related to the strength of metals [

24]. In order to explore the mechanical property of Cu/Ni laminated metal sheet before and after micro-forming, micro-hardness was measured. In this paper, the microscopic indentation experiment mainly revealed the distribution of micro-hardness of the cross section of the forming parts, and discussed the influences of the laser energy and temperature on it. The maximum load used in the experiment was 245 mN and was maintained for 10 s when the loading force was reached and then unloaded. Nine positions of the cross section were selected as the micro-indentation test points, as shown in

Figure 19.

The hardness results of Cu/Ni at room temperature are shown in

Figure 20. It can be seen that the hardness of Cu and Ni are both improved: compared with unformed parts, the hardness of Cu and Ni improved about 20% under the laser shock at 360 mJ. The tendency of experimental results in agreement with Cheng et al. [

2]: the hardness of the workpiece increased by 6 to 8 times after the dynamic impact of the laser. Further increased the laser energy, the hardness of Cu and Ni increased, and the hardness value of point B and H were the largest, which was similar with the distribution of thinning ratio in

Figure 10. This was because in cold process, the greater plastic deformation, the higher local hardness [

25]: It can be found in

Figure 11 and

Figure 20 that, with the increase of energy, plastic deformation increased. The workpiece were subjected to tensile or compressive stress, causing strain hardening in these areas. In addition, the µLDFF was adiabatic high strain rate plastic deformation, which making the microstructure of the workpiece was refined, mechanical properties was also been improved. Contrast

Figure 12 and

Figure 21, it can be found that the filaments at the fillet were subjected to more tensile stress, and local plastic strain occurred. So the hardness of the workpiece at the fillet was greater than at the bottom of the workpiece.

In order to understand the effect of temperature on the hardness, the variation of Cu and Ni hardness at different temperatures were investigated at 1800 mJ. The experimental results are shown in

Figure 22. It can be seen that after adding the temperature, the hardness of Cu and Ni showed a downward trend. The reason can be surmised that with the increases of temperature, the fluidity of material was improved, and the material gradually softened. It can be seen from

Figure 23 that the grain size increases slightly with temperature, the number of grain boundaries decreased, grain boundary strengthening effect is weakened. Therefore, the surface hardness of workpiece was decreased. As the temperature continued to increase, the ratio of decrease of hardness slowed down, and the hardness of points B and H were consistent with other points. This was similar to

Figure 13, where the thinning ratio varied with temperature. This was because with the increase of temperature, the material became soft, and the plastic deformation decreased. Overall the forming became more uniform, and the hardness of the material decreased in warm conditions.

3.6. Element Diffusion

Interface bonding strength is an important indicator to evaluate the performance of metal. In this investigation, two layers of the workpiece, fabricated by press and cold roll bonding, bite each other to form a mechanical combination because of the friction between two layers, but this combination of strength is relatively low. According to the research of Jain et al. [

26], after annealed, the metal compound produced by the diffusion of elements will be formed on the interface of the sheet metal laminates, which realized the excess of metal from mechanical bonding to metallurgy bonding strength of the bonding surface.

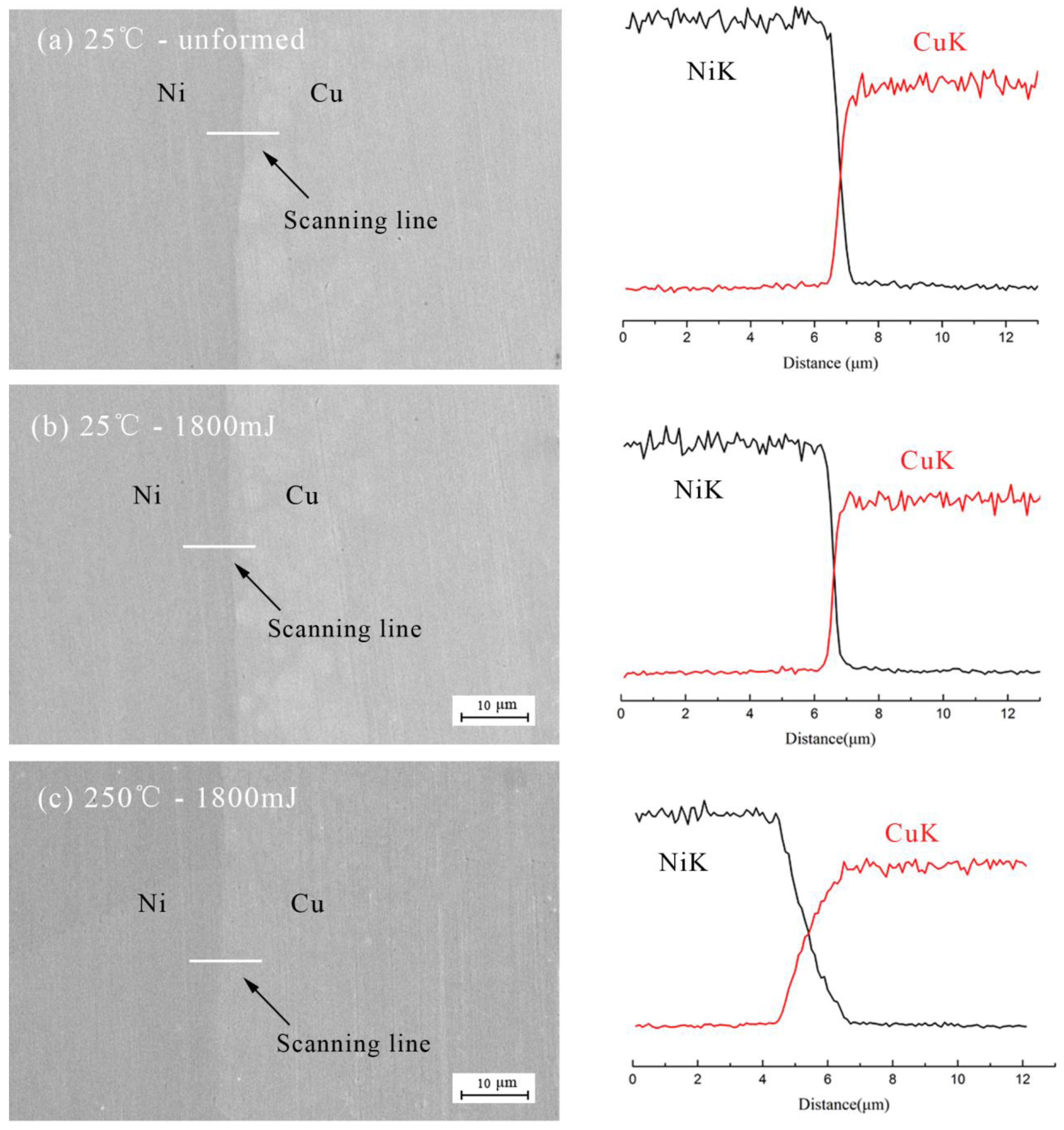

In this paper, different energy and temperature were used as factors to study the effects on the diffusion of Cu/Ni, the analysis of diffusion in

Figure 24 was carried. The results were obtained by EDX line scan analysis of a 12 μm line perpendicular to the Cu/Ni interface and the results are shown in

Figure 25. The “NiK” and “CuK” mean the K line of nickel and copper, respectively. The black and red curves indicate the changes of element content of Ni and Cu, respectively.

Figure 25a,b show the composition profile across the Cu/Ni interface before and after forming process at 25 °C, respectively. It can be seen that element content (Cu and Ni) varied sharply in the weld interface. The results showed that apparent element diffusion did not occurr across the weld interface with increased energy [

27]. This was because no severe plastic deformation was imposed during the forming process. According to the deformation induced inter-diffusion process [

28,

29], no intermetallic phase was formed in the Cu/Ni interface with no diffusion of the two elements.

Figure 25b,c show the composition profile before and after warm forming process at 1800 mJ, respectively. The diffusion slope in

Figure 25c was smaller than that in

Figure 25b, which indicated that intermixing of the two elements at the interface has already occurred, and intermetallic phase islands grow along interface by the diffusion of the two elements with temperature [

26]. This may be because with the increase of the forming temperature, the energy of the atoms in the copper and nickel element increase and the motion is more active, so that the stability of the element decreases with the increase of the temperature, and the diffusion between the elements becomes easier. In addition, as the temperature increases further, this trend will increase, that is, the diffusion will be strengthened and the thickness of the intermediate layer will increase [

30]. However, due to differences in the energy conditions of the atoms on the surface, no significant compound layer was formed, that is, the interface between the two elements did not changed significantly of the interface, the affected area of the bonding zone only about 2 μm. Which can be found by compared the graphics in

Figure 25b,c.