1. Introduction

Microfluidics deals with the volumes of fluids in sizes of nanoliters to picoliters [

1]. It is a multidisciplinary field that includes engineering [

2,

3,

4,

5], chemistry [

6,

7], biochemistry [

8], and biotechnology [

1,

7]. For various applications, implementing highly integrated microfluidic chips requires consideration of the performance of the chips as well as selecting on-chip components such as pumps, valves, and actuators [

9] Among the components, a compact and efficient microvalve is important to control the on-off switching of flows.

Generally, there are two kinds of microvalves: (1) normally open (NO) and (2) normally closed (NC) [

10,

11]. Many previous works have studied the two types of microvalves in terms of performance and actuation. To study the actuation process of microvalves, some researchers performed experimental analyses or fluid-structure interaction (FSI) simulations to realize the behavior of the membranes of the microvalves. In experimental analyses for large-scale integration and high throughput in fluid manipulation, NC glass microfluidic devices are fabricated using three- and four-layer device topologies, and achieved the parallel activation of the valves and pump [

12]. Afterwards, matrix-shaped microfluidic devices were fabricated using parallel channels with the orthogonally crossed elastic material polydimethylsiloxane (PDMS) to produce an automatic deflection of material while applying pressure in the channel. The experimental study was validated by using theoretical modeling [

13]. Mohan et al. performed an experimental analysis by fabricating three different shapes of pneumatically actuated microvalves (i.e., valve seats having an I-shape, V-shape, and diagonal shape), and showed that a V-shaped microvalve requires the lowest actuation pressure to open itself [

14]. Jaemin et al. fabricated and performed an experimental analysis on I- and V-shaped models (changing the shape using length/width (L/W) ratio terms) in NC microvalve models [

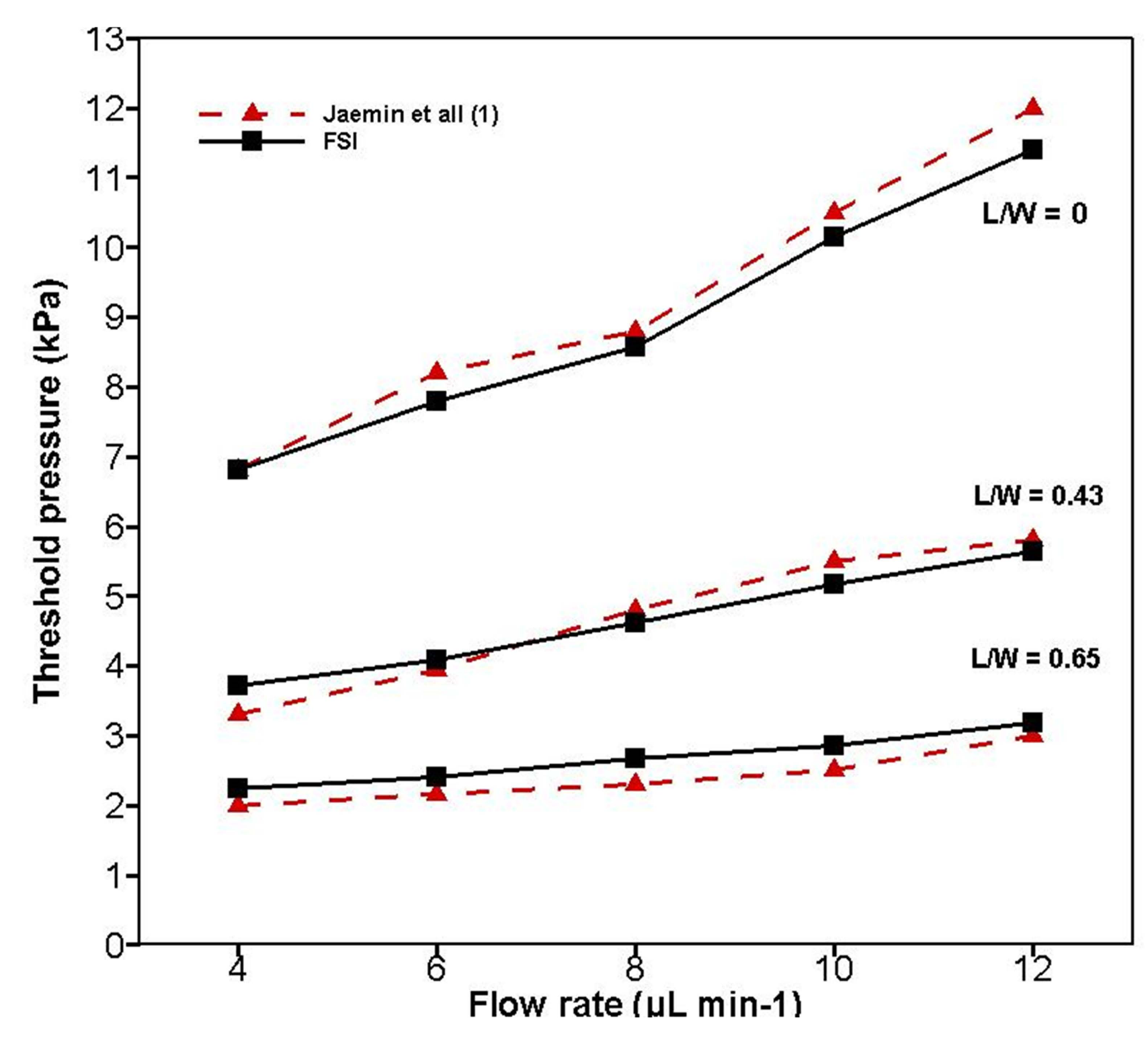

11]. This did not require an external actuation system to control the deflection of the membrane, and a low constant opening membrane pressure was achieved.

Several researchers performed FSI analyses on various types of microvalves. Most of them selected a two-way FSI analysis to describe the deformation of the microvalve membrane. Yang and Kao analytically and numerically investigated the deformation of a microelectromechanical system (MEMS) diaphragm valve against the effect of fluid flow [

4]. Later, Afrasiab et al. analyzed a valveless microfluidic device actuated by a piezoelectric film using FSI governing equations [

5]. Then, finite element method (FEM) and FSI simulations were performed on a pneumatically actuated diaphragm microvalve to study fluid flow and diaphragm deflection [

3]. Afterwards, a single-channel microfluidic device was built with a PDMS flexible membrane to examine the membrane deflection and pressure drop in a microfluidic device using both experimental and FSI analyses [

2]. In the research of Sun hao et al., a three-dimensional multiphysical simulation on a microfluidic system was performed to analyze the pressure, flow velocity, and temperate distribution [

15]. However, there has been little research on the NC microvalve using FSI simulations to study performance and membrane behavior against fluid flow.

In this work, a two-way FSI analysis is performed on an NC microvalve model. This FSI analysis was performed in order to understand the fluid flow inside the microvalve, the membrane deflection against fluid flow, and changes in performance of the microvalve according to changes in parameters. Finally, results from the FSI analysis are compared with experimental data [

11]. In particular, various L/W-ratio models of the microvalve are analyzed using the FSI method to evaluate the performance and membrane behavior of the microvalve against fluid flow. Additionally, parameters such as the structural material properties of the microvalve membrane and the inlet region height are selected to check the effects of changes in parameters against performance. The results we obtained in this analysis will be helpful for designing NC microvalves.

2. Numerical Modeling of 3D Microvalve

2.1. Microvalve Design

Figure 1a illustrates a three-dimensional (3D) microvalve device. This typical microvalve device contains two layers (top and bottom), also called actuation chambers. Jaemin et al. performed a flow analysis inside a microvalve [

11]. In that analysis, to avoid external devices (i.e., the pneumatic system, cylinder, and pumps) in controlling membrane fluctuation in the microvalve, two similar NC microvalves were connected in a distinctive manner. This achieved a fluctuating fluid flow and pressure distribution in the interior regions of the microvalve to control the deflection of the structural membrane (shown in

Figure 1a

1). Typically, an NC microvalve design contains source (

), drain (

) and gate (

) regions, as shown in

Figure 1b. The source region (

) and drain region (

) are otherwise indicated as the inlet and outlet regions, respectively. The maximum deformation obtained from the microvalve’s membrane is restricted by the height of the drain region.

The microvalve design specification is taken from [

11]. These models are used to perform an FSI analysis. The dimensions of the microvalve design and the material properties of the solid and the fluid are listed in

Table 1,

Table 2 and

Table 3, respectively. To achieve a low constant opening membrane pressure, various microvalve model shapes are used, and an FSI analysis is conducted. The generated FSI results are compared with those of an experimental analysis [

11], which are shown in the sections below. To change the design and shape of the microvalve, the vertex is varied to several position lengths (L): 0

m, 50

m, 100

m, 150

m, and 200

m. This is shown in

Figure 1c. Changes in the vertex length of the microvalve models are mentioned using the parameter of the L/W ratio. Further explanation of the L/W-ratio parameter is given below.

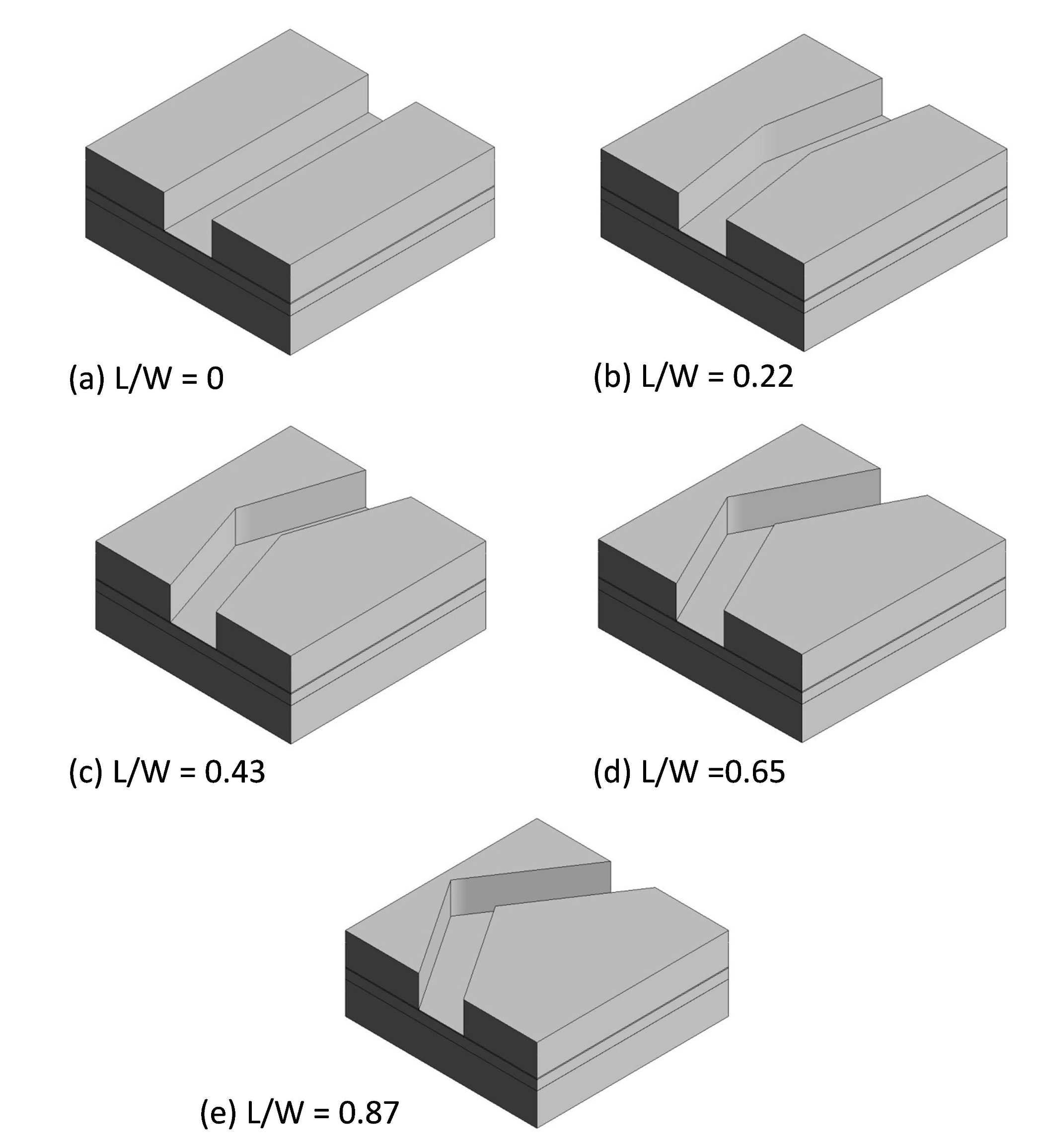

2.2. L/W Ratio in Microvalve Models

The L/W (length/width) ratio is the change in position of the valve seat and shape in a microvalve design by varying the vertex length (L). In FSI analysis, various L/W-ratio microvalve models are used to understand the behavior of membrane deflection against the fluid flow in the microvalve. The length in the L/W ratio is indicated as the vertex length (L). Width (W) is a constant value, and it is calculated by ((), where and are the widths of the valve and seat, respectively.

For example, when calculating the L/W ratio, if the vertex length (L) is 50

m and width W is 230

m (constant), the L/W ratio is 0.22. Similarly, in other models, the L/W ratios are calculated according to the above-mentioned method. This calculating procedure for the L/W ratio was inspired by Jaemin et al. [

11]. As shown in

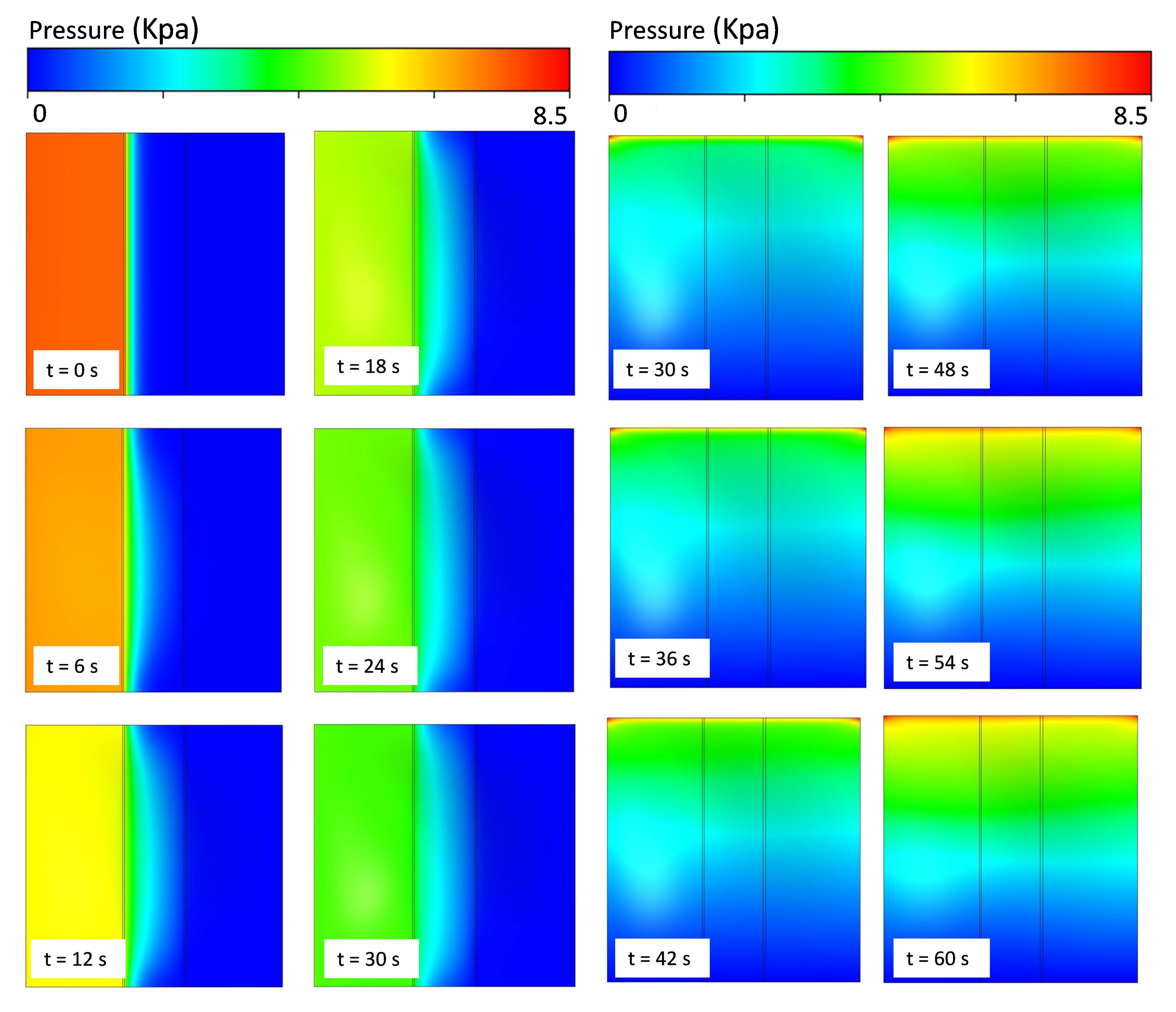

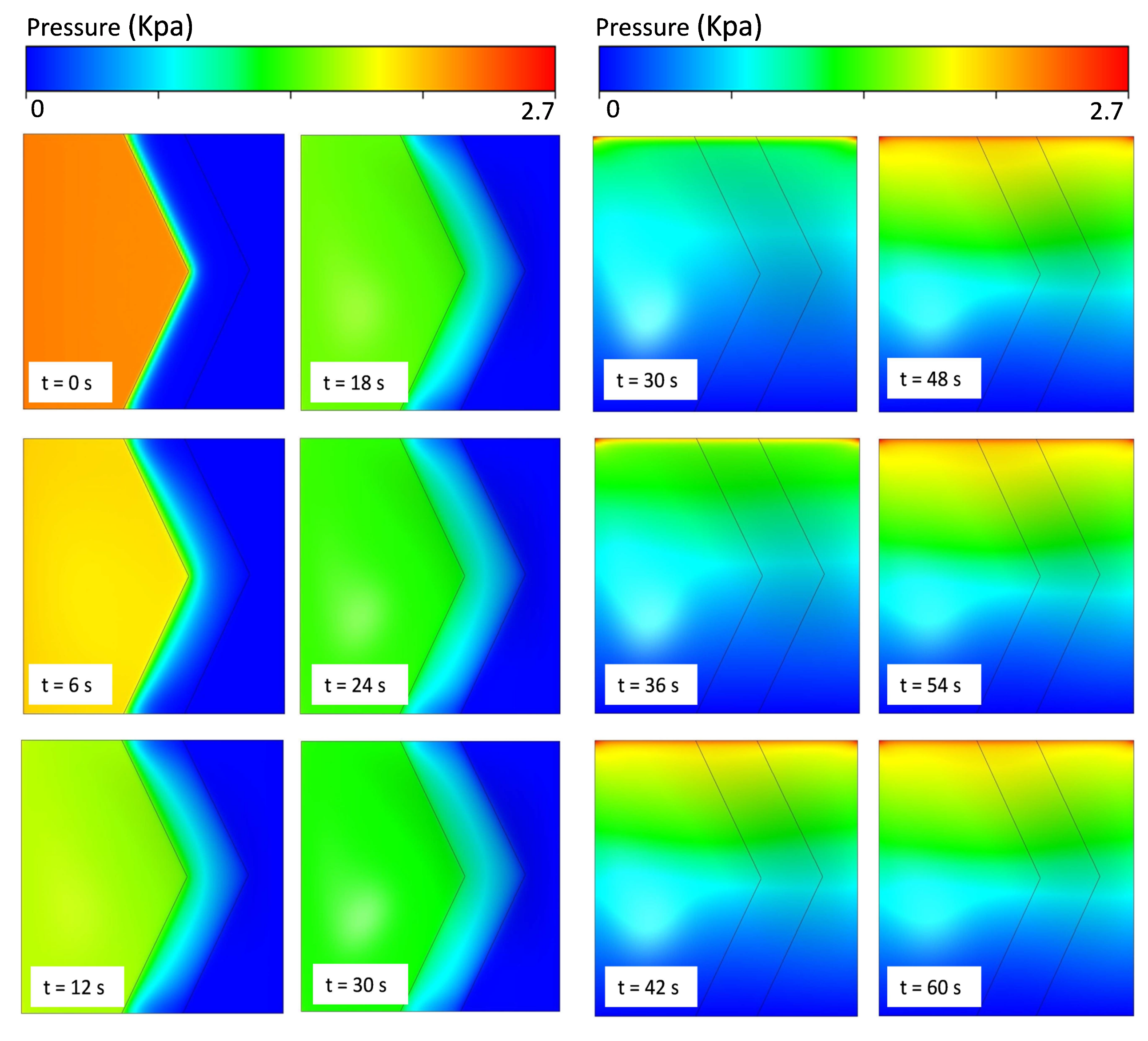

Figure 2, an increase in the L/W ratio separates the volumes of the source and drain regions. Therefore, in higher-L/W models, the source region has a large volume, and simultaneously the drain region will have a lower volume. The separation in region volumes creates a greater pressure difference in the source region; hence, quick deflection in the structural membrane is achieved.

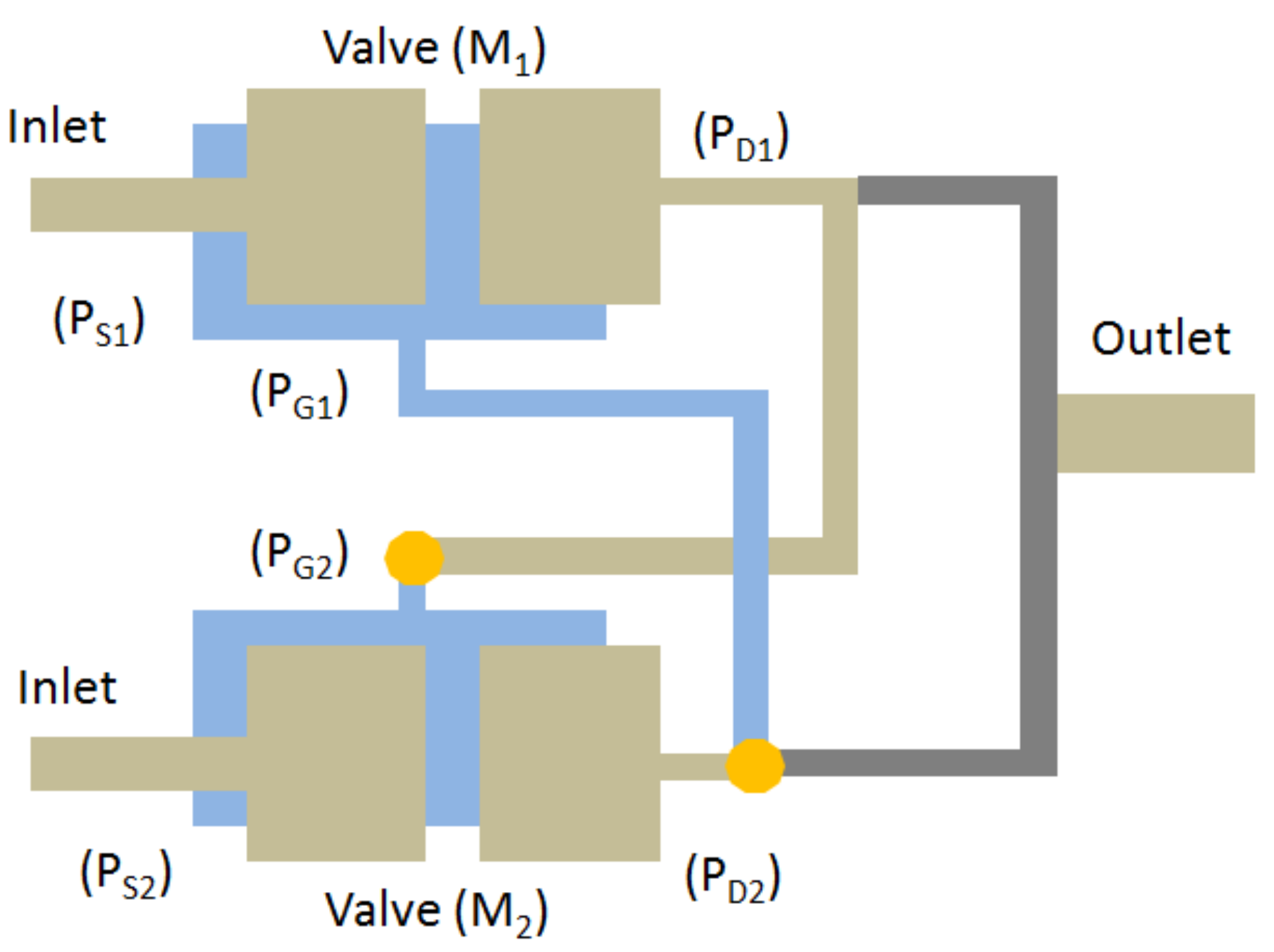

2.3. Operation of Microvalve

In an experimental analysis [

11] to achieve a low constant opening threshold pressure, the various regions of two similar microvalves are interconnected. Fluid flow between these different regions creates pressure fluctuations in the microvalve to control the structural membrane deformation. This process is performed with the microvalve in an open and closed state. For example, the source regions (PS) (inlet regions) of two similar microvalves (named

and

) are connected to the inlet fluid flow. The drain region (

) outlet of microvalve

is connected to the gate region (

) of microvalve

. Similarly, the outlet of microvalve

is connected to the gate region of microvalve

. This is shown in

Figure 3. This way of interconnecting regions creates fluctuations in the fluid flow between the two microvalves.

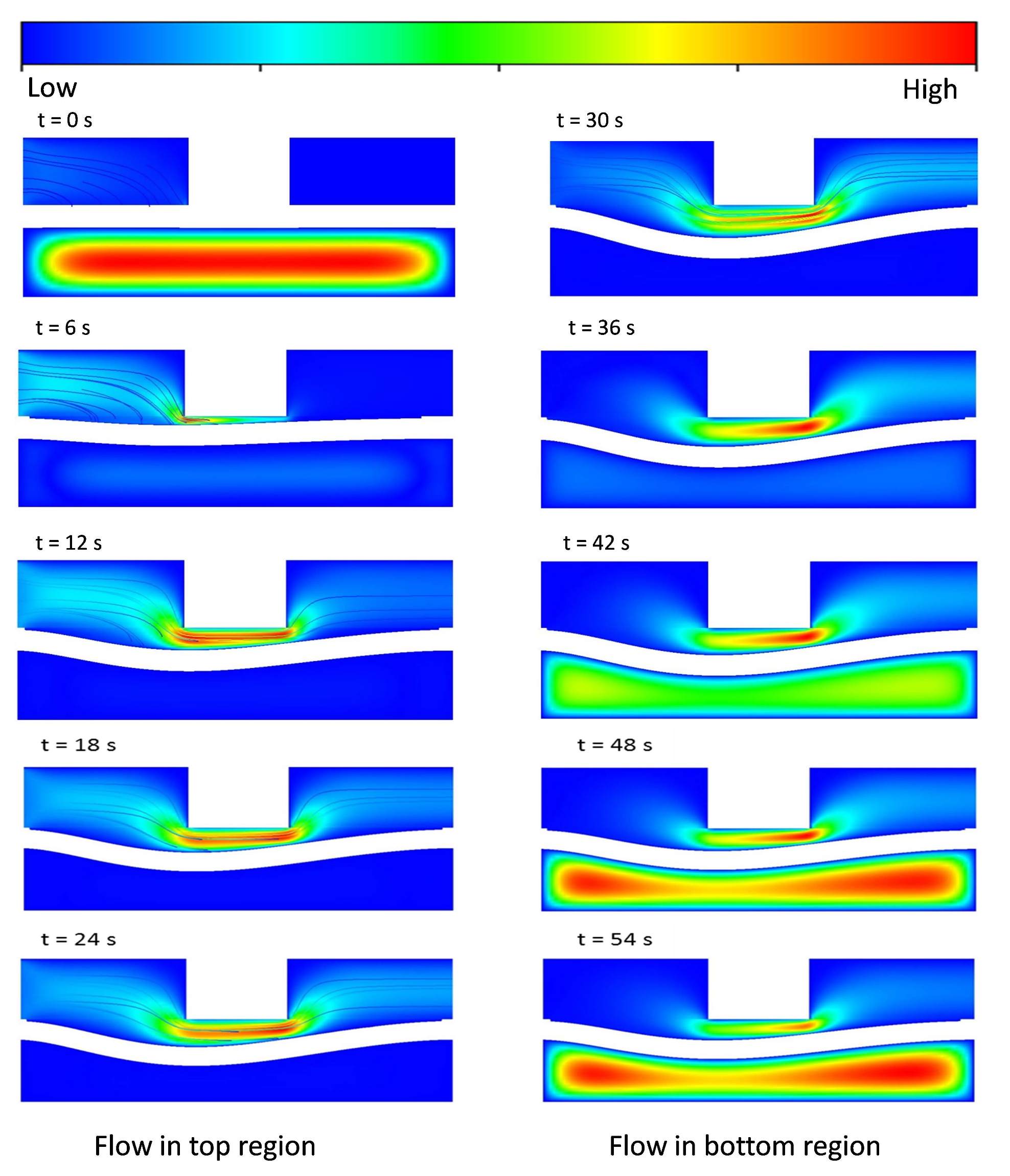

The inlet is connected to the source regions (PS) of microvalves and . The flow to these microvalves is independent. For example, if the inlet of microvalve is open, then the inlet of microvalve is closed. If the fluid flow through the input of microvalve () creates pressure in the source region, and the developed pressure in that region is applied over the upper surface of the structural membrane. Then, pressures on the surface on the membrane deflect downward and make way for fluid to flow from the inlet () to the outlet (). This phenomenon is called the open state of the microvalve. Simultaneously, per the interconnections, the flow from the drain region () outlet is connected to the gate region (). This process creates pressure in the gate region () in microvalve and forces the membrane to deflect upward. This process is called the closed state of the membrane. This interconnection method operates as a cyclic process. In FSI analysis, a working procedure identical to that above from an experimental analysis is applied. To reduce the computational overhead , just microvalve is taken and analysis is performed in complete cycle. The complete cycle takes around 60 s to transform from the open to closed state of a lone microvalve. Therefore, during the analysis, the first 30 s the inlet flow is sent to the top region of the microvalve to perform the open-state process. Similarly, the last 30 s of the flow is sent to the bottom region of the microvalve for the closed-state process. Finally, the performance of microvalve and the behavior of the structural membrane are examined, and the results are given below.

3. Fluid-Structure Interaction

In order to study a coupled field analysis of the fluid flow and structural deformation in microfluidic devices, a fluid-structure interaction was performed using commercial ANSYS software (version 16.2, ANSYS, Inc., Canonsburg, PA, USA) [

16]. The coupled-field analysis is a multidisciplinary analysis that is associated with two or more fields to solve various engineering problems. This coupling analysis can be conducted using a one-way or two-way method. For the analysis of small structural deformations, the one-way FSI method is more efficient and less time consuming. The two-way FSI coupling method is performed when structural deformations are not in the negligible range. However, if a highly elastic material is used for the structural analysis, then the deformation is large.

In the microvalve FSI analysis, elastic material is used for the structural membrane. This is shown in

Table 2. Hence, the elastic material obtains large structural deformations in the membrane. Therefore, the fluid and structure field should couple in the two-way analysis to produce more accurate results for this problem. Thus, a two-way FSI coupling analysis is used to solve microvalve problems in an iterative manner to produce accurate results. In this work, the membrane of the value is modelled as a 3D solid, which facilitates the convergence of the FSI coupling. In order to avoid the excessive element distortion in solid membrane of the value due to large deformation of the FSI interface, the elastic analogy mesh motion method is used [

3,

17,

18].

3.1. Governing Equations in FSI

Coupled two-way fluid-structure interaction problems need to consider every field, i.e., the fluid flow, structural deformations, and moving mesh. The governing equation for all these fields is referred to in [

3,

5,

19] and is given below.

3.1.1. Fluid Formulation

The conservation laws of momentum and the continuity equation of a viscous, incompressible flow comprising the Navier-Stokes equation with arbitrary Lagrangian-Eulerian (ALE) framework are used to solve the flow problem, which can be written as

Navier-Stokes equation

and the equation of continuity for incompressible flow is given by

where

denotes fluid density,

is the viscosity,

v is the velocity and

p is pressure.

and

represent the mesh velocity and body force vector, respectively. The fluid domain is indicated as

, and the time interval is denoted between

. The time derivative of ALE mesh is represented as

. The symmetric tensor

is called rate-of-deformation tensor.

For the present problem, an incompressible, viscous, constant-input mass flow rate of the fluid is applied between 4 to 12

L/min in the inlet of the microfluidic valve, and the behavior of the structural membrane is analyzed. Water is considered as the working fluid, as shown in

Table 1. Using the valve dimensions mentioned in

Table 1 and the boundary conditions of the microfluidic device, the Reynolds number is calculated as

Thus, Reynolds number of the fluid flow inside a microfluidic valve is predicted before the analysis, and the flow is considered to be laminar throughout the analysis.

3.1.2. Solid Formulation

The conservation law of linear momentum for a solid continuum is given with respect to spatial coordinate

x as

where

,

u,

and

are the solid density, displacement field, body force vector, and solid domain, respectively.

is the deformation gradient tensor.

3.1.3. FSI Interface Conditions

The interface conditions between solid and fluid are

where

n and

are the outer normal at the solid and the FSI interface, respectively.

3.1.4. Moving Mesh

In the ALE approach to the fluid-structure interaction (FSI) problems, the pseudo-medium’s boundary conditions are the solid deformation in the FSI interface. The governing equation of the displacement of the fluid mesh nodes is written as

where

is the Cauchy stress tensor of the pseudo-medium [5]. For every boundary

i, a Dirichlet boundary condition may be given:

where

is the boundary displacement vector.

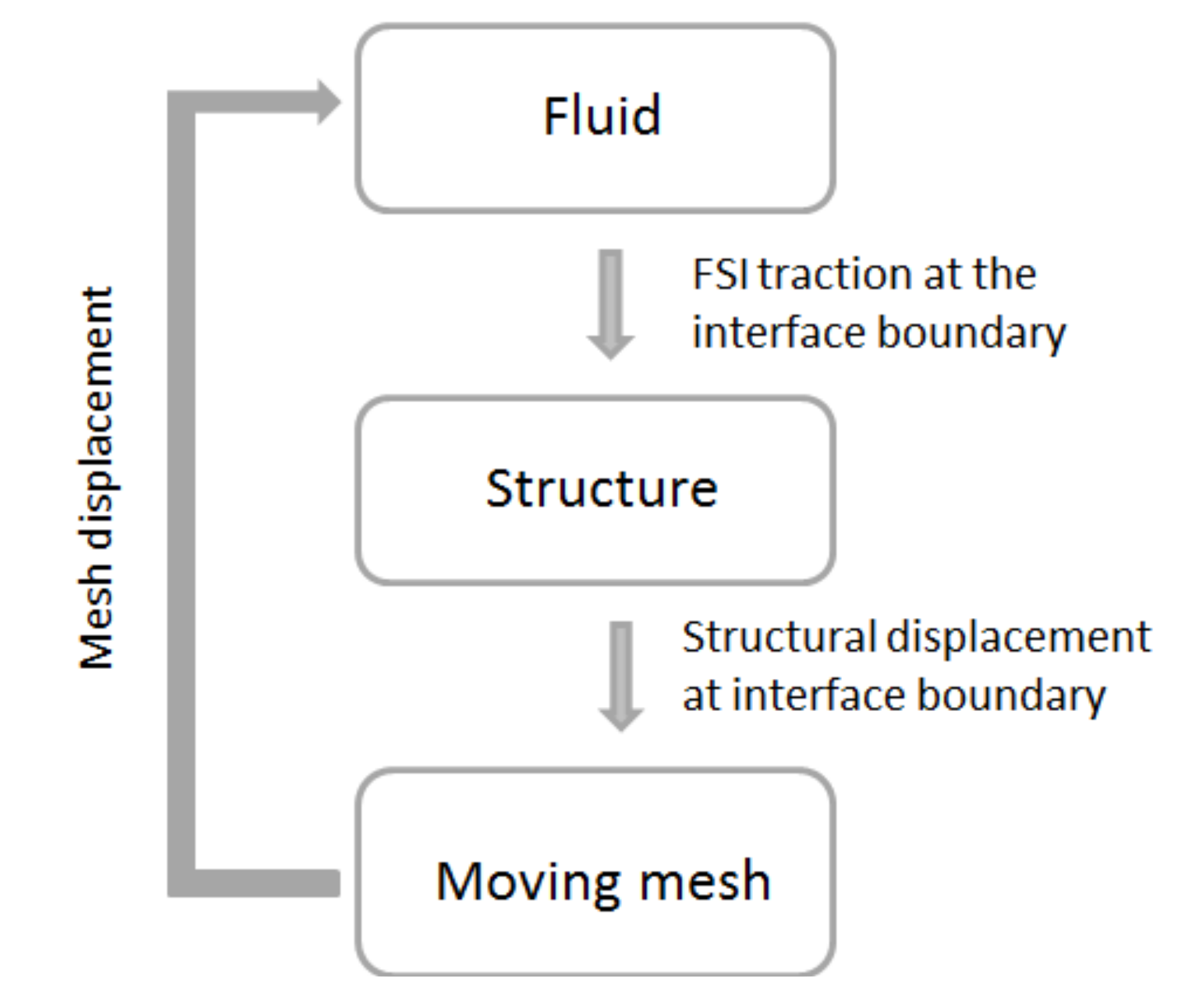

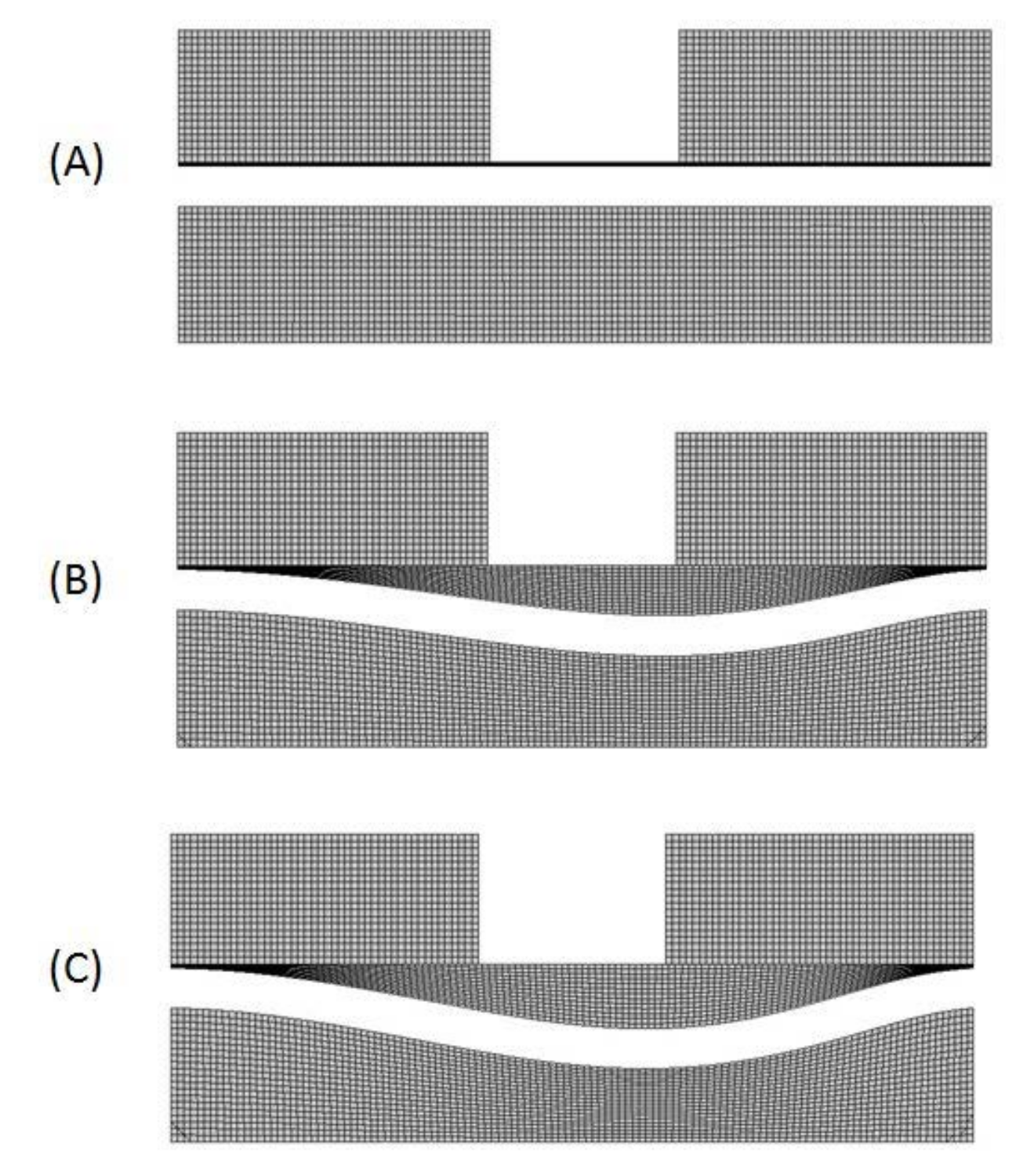

3.2. FSI Coupling Method

FSI analysis of the two-way coupling method is illustrated in

Figure 4. This coupling method is an iterative process: during each time step, both fields’ outcome data are transferred to another field, until convergence is achieved.

Initially, the fluid field is solved in ANSYS-CFX based on the given boundary conditions and are applied in the fluid domain. Later, the pressure from the fluid domain is transferred to the structural domain (ANSYS-Transient structure) through the coupling process. The transferred pressure is applied over the FSI interface surface in the structural model. Since external pressure is applied to the elastic structural membrane, it obtains a large deformation and changes its shape in the model. Furthermore, the deformed shape obtained from the solid domain sets the fluid mesh displacement equal to the solid domain deformation on the FSI interface (i.e., set

). This step will update the Dirichlet boundary condition for the fluid solver. This process continues until it reaches convergence. The initial and deformed states of the microvalve model are shown in

Figure 5.

In FSI analysis, converting from the open to closed state of the microvalve creates pressure instability and initiates the contact between the membrane surface and the wall. This contact happens mainly due to the low bending stiffness of the membrane. This type of contact analysis is not appropriate for a two-way FSI problem. This may be attributed to the instability and distortion in the mesh when membrane contacts with the wall during the two-way FSI analysis. Afrasiab et al. reported a similar problem related to this analysis [

3,

4]. Hence, in this study, the mass flow was fixed in the range of 4

L/min to 12

L/min to avoid membrane contact with the wall and the FSI analyses were performed.

The coupled fluid-structure model was solved by the commercial software ANSYS workbench. Finite volume in fluid and finite element in solids was solved in the ANSYS-CFX and ANSYS-Transient structure, respectively. Hexahedral elements were used for both domains and the full Newton numerical method is used to solve this problem.

5. Conclusions

The complex fluid-structure interaction between deformable microvalve structural membrane behavior against the fluid flow inside the valves was studied using an FSI model. Using the model, it was observed that an increase in L/W ratio increases the volume in the source region and decreases the volume in the drain region of the microvalve. In addition, an increase in L/W ratio separates the membrane surface area within those regions. Interestingly, the separation completely alters the nature of fluid flow and the behavior of membrane deflection inside the microvalve.

Compared with lower-L/W-ratio models, higher-L/W-ratio models exhibit better performance in terms of membrane deflection and low opening threshold pressure. A higher-L/W-ratio model favors a higher volume in the source region, which enables more rapid structural membrane deflection than the lower L/W ratio models. L/W = 0.65 or higher ratio models can deflect the membrane in lower pressure regime favoring the fluid flow than other lower ratio models.

Finally, using an FSI simulation, selected parameters such as the material properties of the structural membrane and the inlet region height were analyzed for better rapid deflection and low opening threshold pressure. This creates a new step in understanding better fluid flow inside a microvalve.