Fabrication of Micro-Optics Elements with Arbitrary Surface Profiles Based on One-Step Maskless Grayscale Lithography

Abstract

:1. Introduction

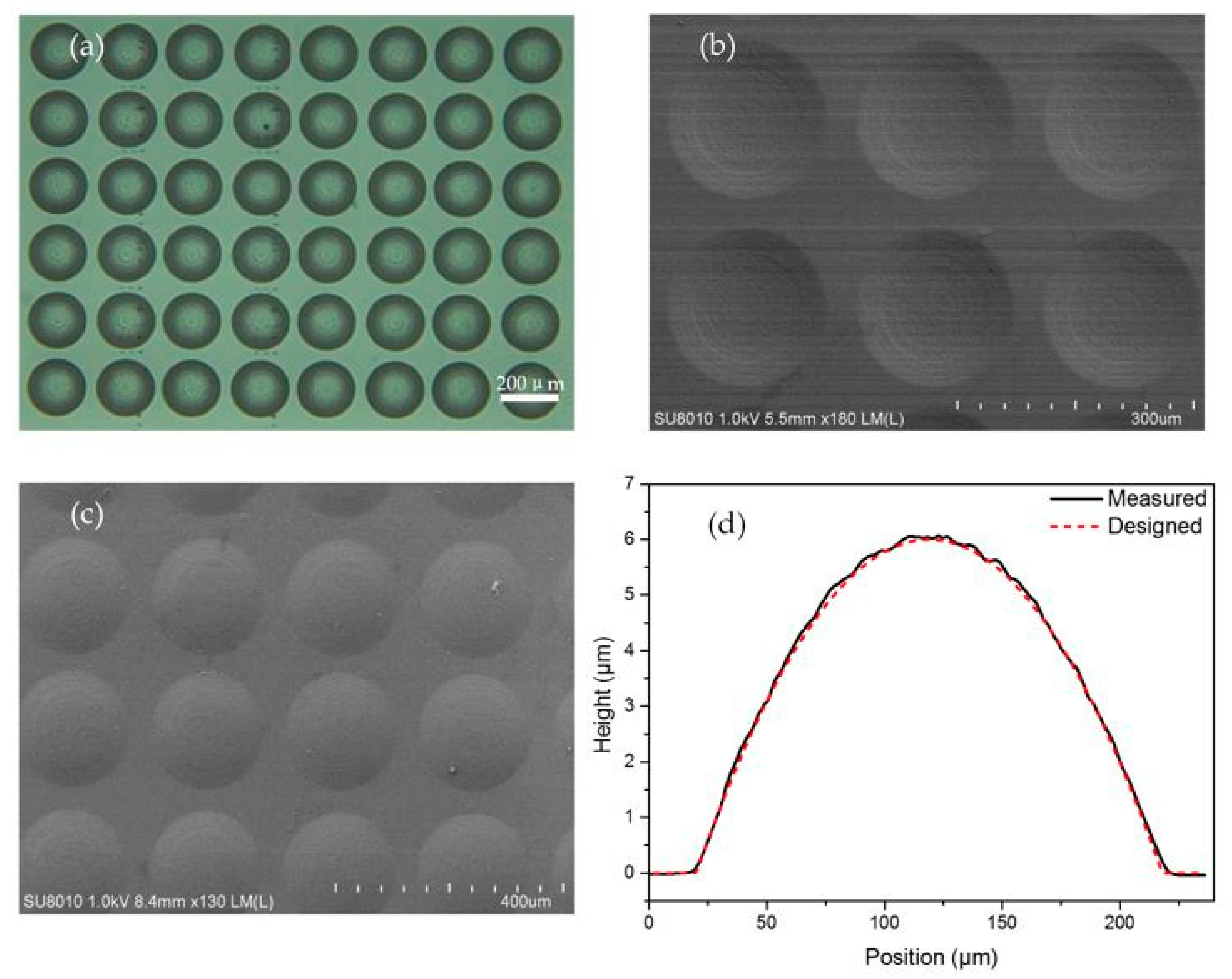

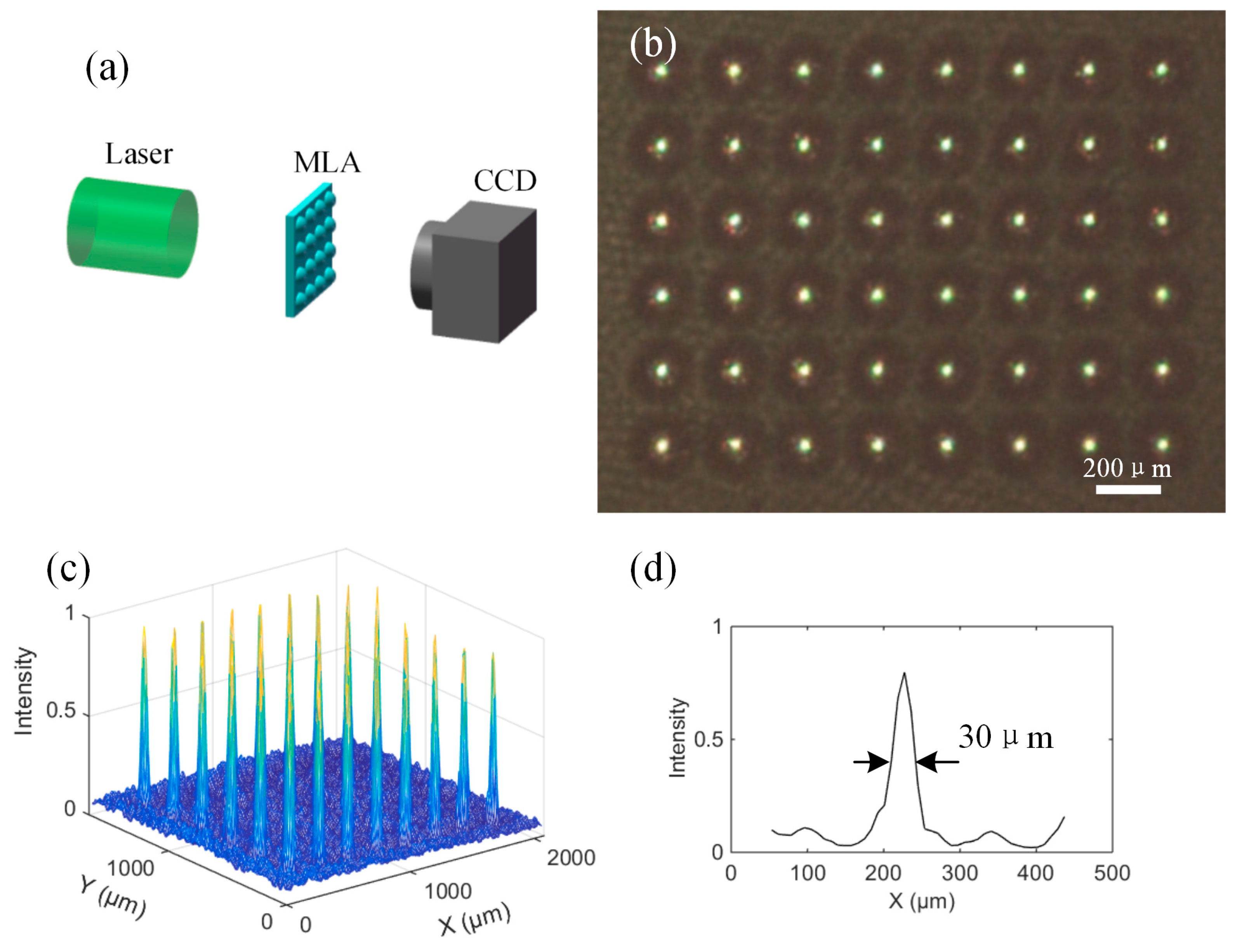

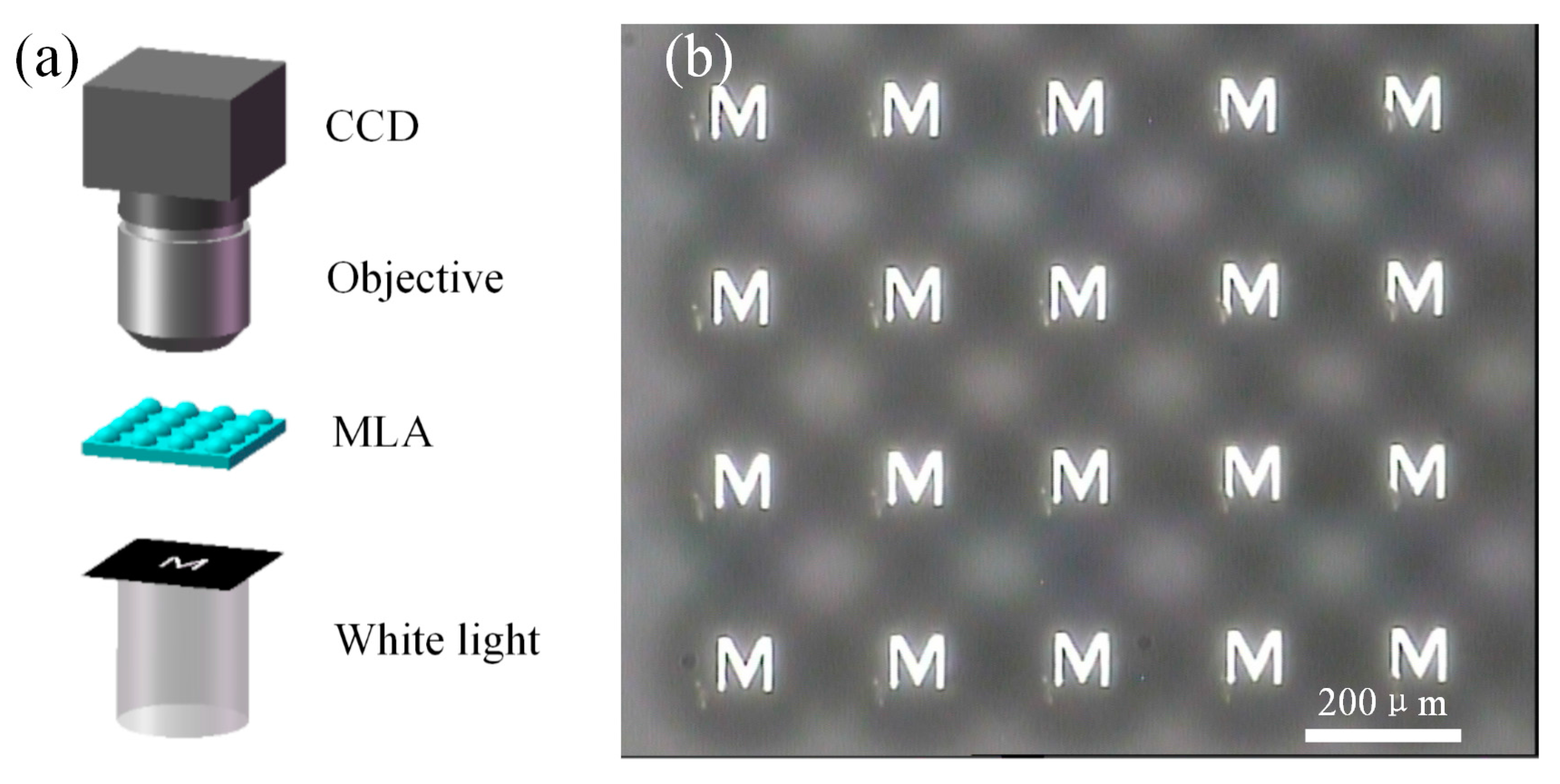

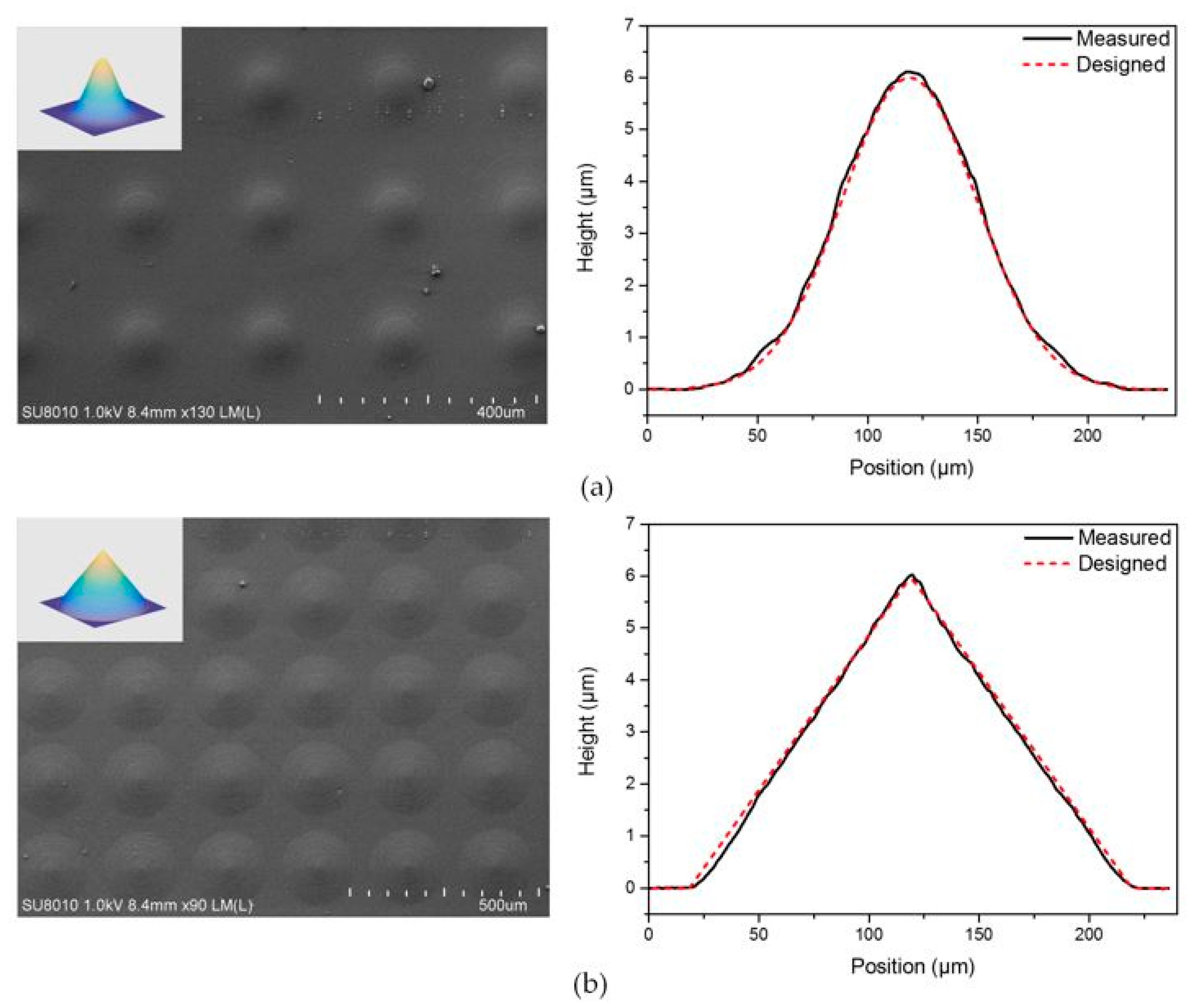

2. Experiment Setup and Methods

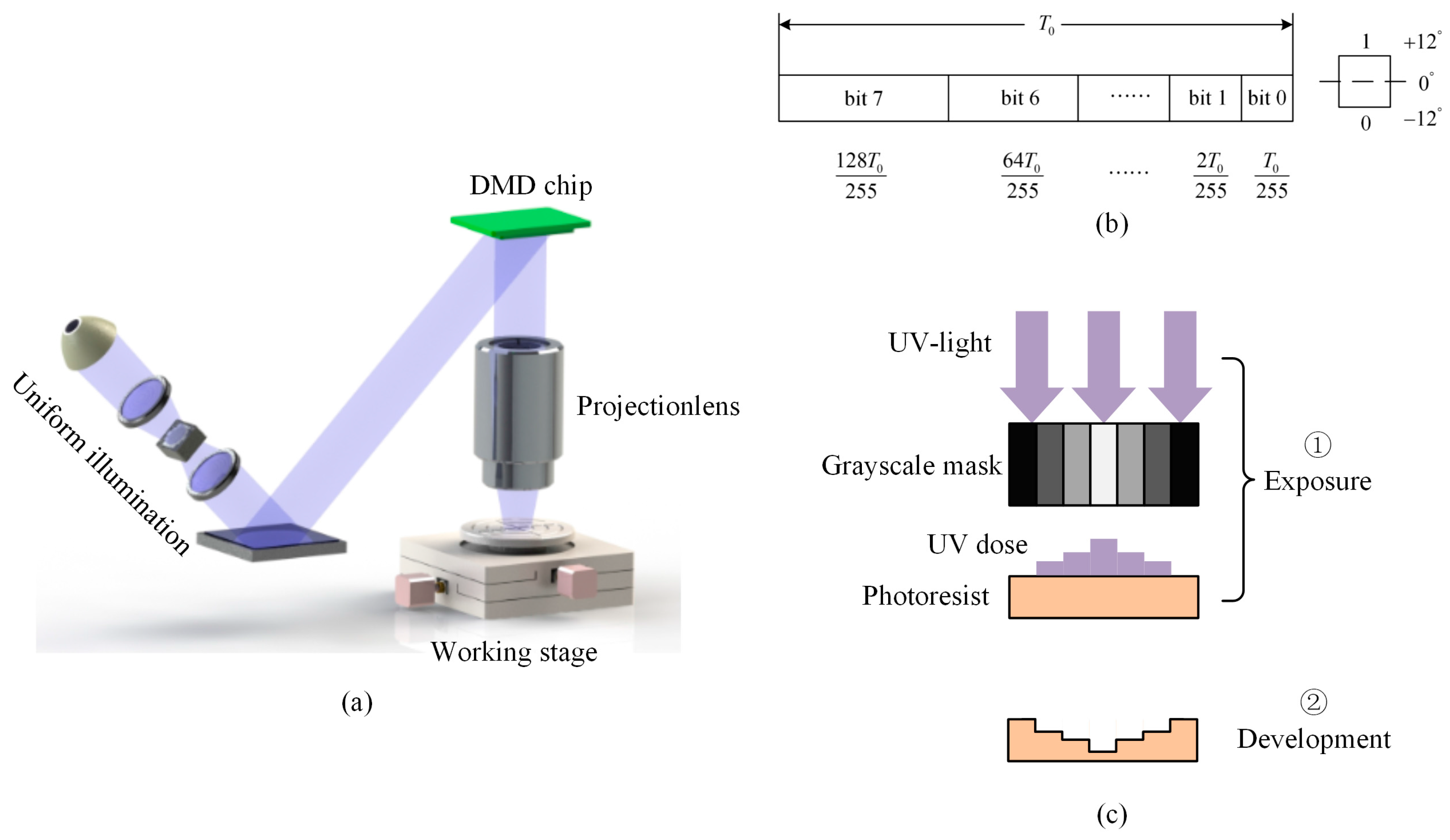

2.1. Maskless Photolithography System

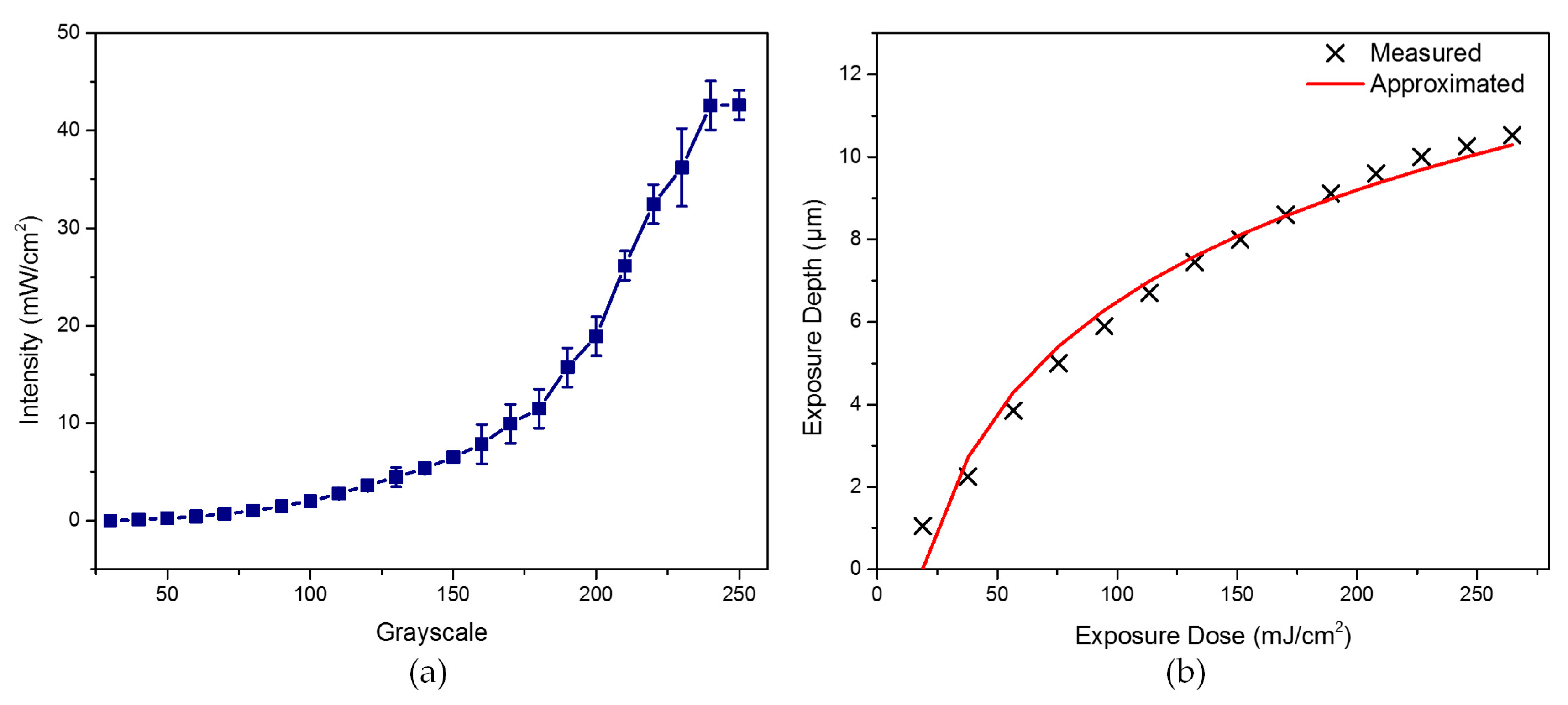

2.2. Nonlinear Effects

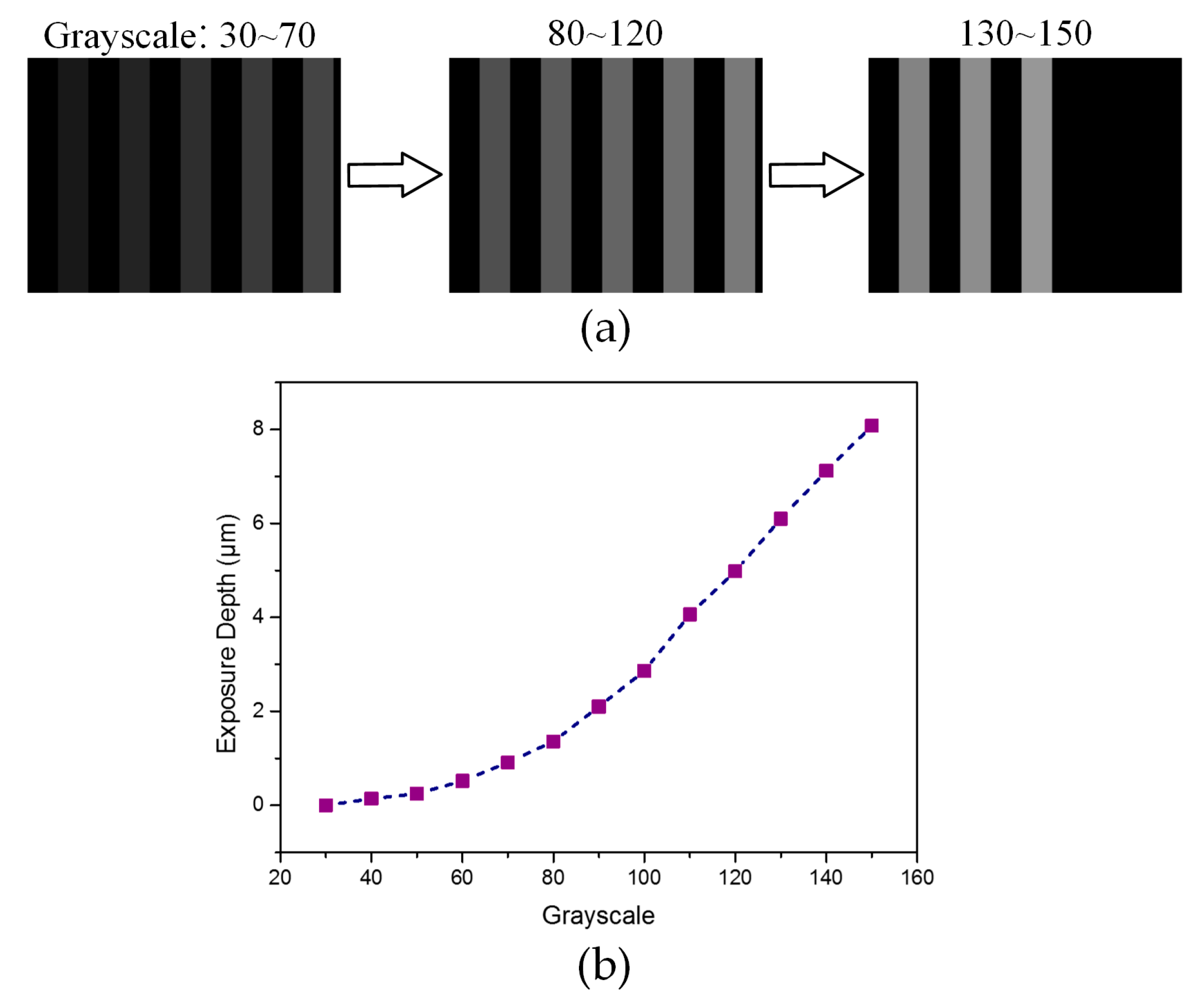

2.3. Grayscale Mask Design

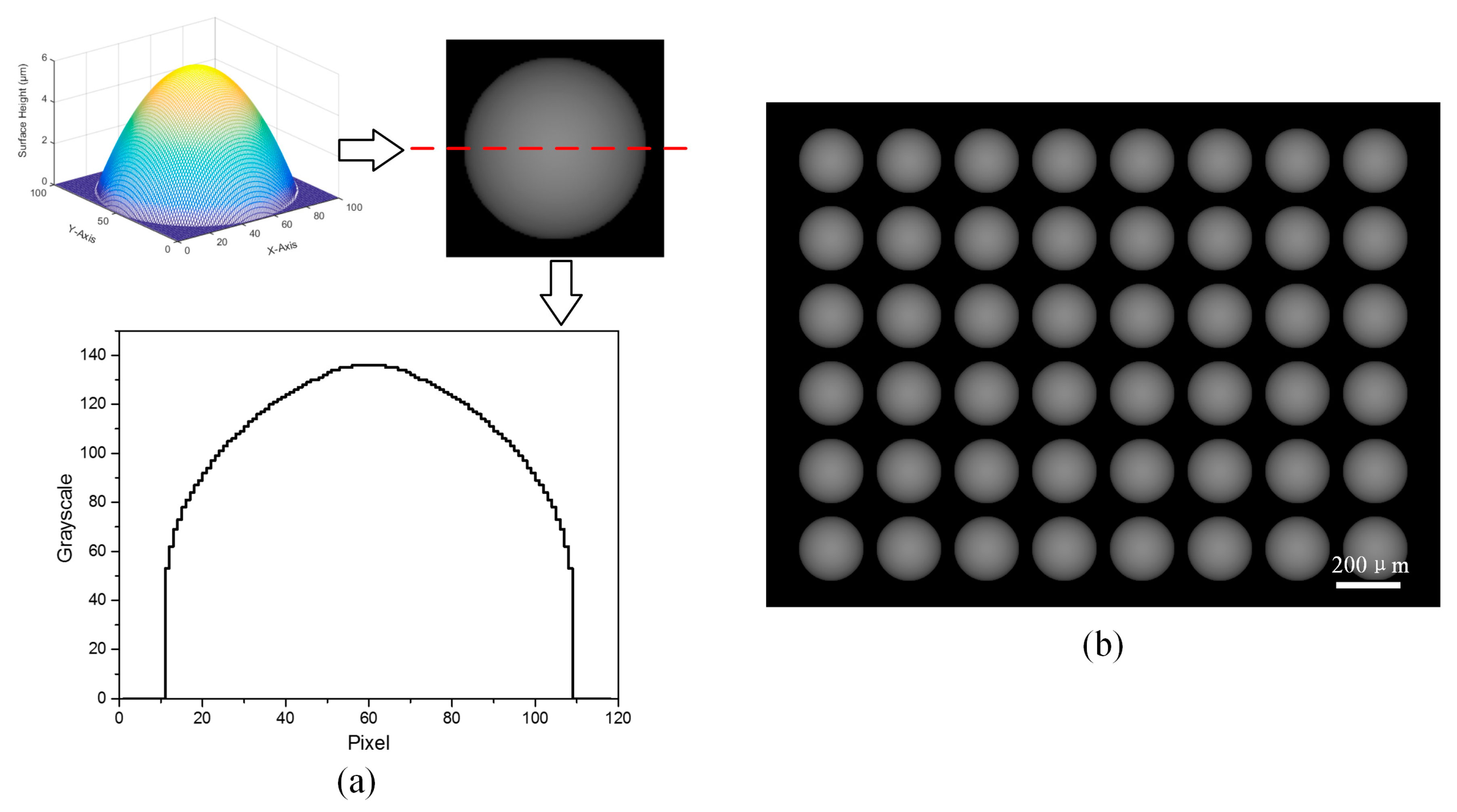

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lima Monteiro, D.W.D. CMOS-Based Integrated Wavefront Sensor; Delft University Press: Delft, The Netherlands, 2002. [Google Scholar]

- Sun, Y.; Forrest, S.R. Enhanced light out-coupling of organic light-emitting devices using embedded low-index grids. Nat. Photon. 2008, 2, 483–487. [Google Scholar] [CrossRef]

- Seabra, A.C.; Araes, F.G.; Romero, M.A.; Neto, L.G.; Nabet, B. Increasing the optical coupling efficiency of planar photodetectors: Electron beam writing of an integrated microlens array on top of an MSM device. In Proceedings of the SPIE 4089, Optics in Computing 2000, Quebec City, QC, Canada, 24 May 2000; pp. 890–894. [Google Scholar]

- Chen, Y.; Elshobaki, M.; Ye, Z.; Park, J.M.; Noack, M.A.; Ho, K.M.; Chaudhary, S. Microlens array induced light absorption enhancement in polymer solar cells. Phys. Chem. Chem. Phys. PCCP 2013, 15, 4297–4302. [Google Scholar] [CrossRef] [PubMed]

- Cho, M.; Daneshpanah, M.; Moon, I.; Javidi, B. Three-dimensional optical sensing and visualization using integral imaging. Proc. IEEE 2006, 99, 556–575. [Google Scholar]

- Balslev, S.; Rasmussen, T.; Shi, P.; Kristensen, A. Single mode solid state distributed feedback dye laser fabricated by gray scale electron beam lithography on a dye doped SU-8 resist. J. Micromech. Microeng. 2005, 15, 2456. [Google Scholar] [CrossRef]

- Graells, S.; Aćimović, S.; Volpe, G.; Quidant, R. Direct growth of optical antennas using e-beam-induced gold deposition. Plasmonics 2010, 5, 135–139. [Google Scholar] [CrossRef]

- Henry, M.D.; Shearn, M.J.; Chhim, B.; Scherer, A. Ga(+) beam lithography for nanoscale silicon reactive ion etching. Nanotechnology 2010, 21, 245303. [Google Scholar] [CrossRef] [PubMed]

- Kohoutek, T.; Hughes, M.A.; Orava, J.; Mastumoto, M.; Misumi, T.; Kawashima, H.; Suzuki, T.; Ohishi, Y. Direct laser writing of relief diffraction gratings into a bulk chalcogenide glass. J. Opt. Soc. Am. B 2012, 29, 2779–2786. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Purlys, V.; Gaidukevičiu, A.; Balevičius, Z.; Piskarskas, A.; Fotakis, C.; Pissadakis, S.; Gray, D.; Gadonas, R. 3D microoptical elements formed in a photostructurable germanium silicate by direct laser writing. Opt. Lasers Eng. 2012, 50, 1785–1788. [Google Scholar] [CrossRef]

- Yang, Q.; Tong, S.; Chen, F.; Deng, Z.; Bian, H.; Du, G.; Yong, J.; Hou, X. Lens-on-lens microstructures. Opt. Lett. 2015, 40, 5359–5362. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.Y.; Yang, S.Y.; Huang, L.S.; Chang, J.H. Fabrication of plastic microlens array using gas-assisted micro-hot-embossing with a silicon mold. Infrared Phys. Technol. 2006, 48, 163–173. [Google Scholar] [CrossRef]

- Yang, H.; Chao, C.K.; Wei, M.K.; Lin, C.P. High fill-factor microlens array mold insert fabrication using a thermal reflow process. J. Micromech. Microeng. 2004, 14, 1197. [Google Scholar] [CrossRef]

- He, M.; Yuan, X.C.; Ngo, N.Q.; Bu, J.; Kudryashov, V. Simple reflow technique for fabrication of a microlens array in solgel glass. Opt. Lett. 2003, 28, 731–733. [Google Scholar] [CrossRef] [PubMed]

- Levy, U.; Desiatov, B.; Goykhman, I.; Nachmias, T.; Ohayon, A.; Meltzer, S.E. Design, fabrication, and characterization of circular dammann gratings based on grayscale lithography. Opt. Lett. 2010, 35, 880–882. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Guo, C.; Wang, Y.; Miao, J.; Tian, Y.; Liu, Q. Micro-optical elements fabricated by metal-transparent-metallic-oxides grayscale photomasks. Appl. Opt. 2012, 51, 6606–6611. [Google Scholar] [CrossRef] [PubMed]

- Mori, R.; Hanai, K.; Matsumoto, Y. Three dimensional micro fabrication of photoresist and resin materials by using gray-scale lithography and molding. IEEJ Trans. Sens. Micromach. 2006, 124, 359–363. [Google Scholar] [CrossRef]

- Kessels, M.V.; Nassour, C.; Grosso, P.; Heggarty, K. Direct write of optical diffractive elements and planar waveguides with a digital micromirror device based UV photoplotter. Opt. Commun. 2010, 283, 3089–3094. [Google Scholar] [CrossRef]

- Iwasaki, W.; Takeshita, T.; Peng, Y.; Ogino, H.; Shibata, H.; Kudo, Y.; Maeda, R.; Sawada, R. Maskless lithographic fine patterning on deeply etched or slanted surfaces, and grayscale lithography, using newly developed digital mirror device lithography equipment. Jpn. J. Appl. Phys. 2012, 51, 06FB05. [Google Scholar] [CrossRef]

- Song, S.H.; Kim, K.; Choi, S.E.; Han, S.; Lee, H.S.; Kwon, S.; Park, W. Fine-tuned grayscale optofluidic maskless lithography for three-dimensional freeform shape microstructure fabrication. Opt. Lett. 2014, 39, 5162–5165. [Google Scholar] [CrossRef] [PubMed]

- Kumaresan, Y.; Rammohan, A.; Dwivedi, P.K.; Sharma, A. Large area ir microlens arrays of chalcogenide glass photoresists by grayscale maskless lithography. ACS Appl. Mater. Interfaces 2013, 5, 7094–7100. [Google Scholar] [CrossRef] [PubMed]

- Aristizabal, S.L.; Cirino, G.A.; Montagnoli, A.N.; Sobrinho, A.A.; Rubert, J.B.; Mansano, R.D. Microlens array fabricated by a low-cost grayscale lithography maskless system. Opt. Eng. 2013, 52, 125101. [Google Scholar] [CrossRef]

- Totsu, K.; Fujishiro, K.; Tanaka, S.; Esashi, M. Fabrication of three-dimensional microstructure using maskless gray-scale lithography. Sens. Actuators A Phys. 2006, 130, 387–392. [Google Scholar] [CrossRef]

- Zhong, K.; Gao, Y.; Li, F.; Luo, N.; Zhang, W. Fabrication of continuous relief micro-optic elements using real-time maskless lithography technique based on dmd. Opt. Laser Technol. 2014, 56, 367–371. [Google Scholar] [CrossRef]

- Wang, P.; Dominguez-Caballero, J.A.; Friedman, D.J.; Menon, R. A new class of multi-bandgap high-efficiency photovoltaics enabled by broadband diffractive optics. Progress Photovolt. Res. Appl. 2015, 23, 1073–1079. [Google Scholar] [CrossRef]

- Wang, P.; Mohammad, N.; Menon, R. Chromatic-aberration-corrected diffractive lenses for ultra-broadband focusing. Sci. Rep. 2016, 6, 21545. [Google Scholar] [CrossRef] [PubMed]

- Rammohan, A.; Dwivedi, P.K.; Martinez-Duarte, R.; Katepalli, H.; Madou, M.J.; Sharma, A. One-step maskless grayscale lithography for the fabrication of 3-dimensional structures in SU-8. Sens. Actuators B Chem. 2010, 153, 125–134. [Google Scholar] [CrossRef]

- Smith, B.W.; Suzuki, K. Microlithography: Science and Technology; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2007. [Google Scholar]

- Hur, J.G. Maskless fabrication of three-dimensional microstructures with high isotropic resolution: Practical and theoretical considerations. Appl. Opt. 2011, 50, 2383–2390. [Google Scholar] [CrossRef] [PubMed]

| Grayscale | Intensity (mW/cm2) | Standard Deviation (mW/cm2) | Grayscale | Intensity (mW/cm2) | Standard Deviation (mW/cm2) |

|---|---|---|---|---|---|

| 30 | 0 | 0 | 150 | 6.51 | 0 |

| 40 | 0.13 | 0 | 160 | 7.85 | 0.02 |

| 50 | 0.26 | 0 | 170 | 9.95 | 0.02 |

| 60 | 0.43 | 0 | 180 | 11.5 | 0.02 |

| 70 | 0.7 | 0 | 190 | 15.73 | 0.02 |

| 80 | 1.03 | 0 | 200 | 18.91 | 0.02 |

| 90 | 1.5 | 0 | 210 | 26.15 | 0.015 |

| 100 | 2 | 0 | 220 | 32.46 | 0.02 |

| 110 | 2.78 | 0.005 | 230 | 36.22 | 0.04 |

| 120 | 3.63 | 0.005 | 240 | 42.6 | 0.025 |

| 130 | 4.47 | 0.01 | 250 | 42.63 | 0.015 |

| 140 | 5.37 | 0.005 | - | - | - |

| Exposure Dose (mJ/cm2) | Exposure Depth (μm) | Standard Deviation (μm) | Exposure Dose (mJ/cm2) | Exposure Depth (μm) | Standard Deviation (μm) |

|---|---|---|---|---|---|

| 18.9 | 1.05 | 0.025 | 151.2 | 8 | 0.25 |

| 37.8 | 2.25 | 0.2 | 170.1 | 8.6 | 0.23 |

| 56.7 | 3.85 | 0.1 | 189 | 9.12 | 0.19 |

| 75.6 | 5 | 0.15 | 207.9 | 9.6 | 0.18 |

| 94.5 | 5.9 | 0.15 | 226.8 | 10 | 0.15 |

| 113.4 | 6.7 | 0.2 | 245.7 | 10.26 | 0.18 |

| 132.3 | 7.45 | 0.25 | 264.6 | 10.53 | 0.19 |

| Grayscale | Exposure Depth (μm) | Grayscale | Exposure Depth (μm) |

|---|---|---|---|

| 30 | 0 | 100 | 2.86 |

| 40 | 0.14 | 110 | 4.06 |

| 50 | 0.25 | 120 | 4.98 |

| 60 | 0.52 | 130 | 6.1 |

| 70 | 0.91 | 140 | 7.12 |

| 80 | 1.36 | 150 | 8.08 |

| 90 | 2.1 | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Q.; Yang, Y.; Gao, H.; Zhou, Y.; He, Y.; Hu, S. Fabrication of Micro-Optics Elements with Arbitrary Surface Profiles Based on One-Step Maskless Grayscale Lithography. Micromachines 2017, 8, 314. https://doi.org/10.3390/mi8100314

Deng Q, Yang Y, Gao H, Zhou Y, He Y, Hu S. Fabrication of Micro-Optics Elements with Arbitrary Surface Profiles Based on One-Step Maskless Grayscale Lithography. Micromachines. 2017; 8(10):314. https://doi.org/10.3390/mi8100314

Chicago/Turabian StyleDeng, Qinyuan, Yong Yang, Hongtao Gao, Yi Zhou, Yu He, and Song Hu. 2017. "Fabrication of Micro-Optics Elements with Arbitrary Surface Profiles Based on One-Step Maskless Grayscale Lithography" Micromachines 8, no. 10: 314. https://doi.org/10.3390/mi8100314