Hybrid Integration of Magnetoresistive Sensors with MEMS as a Strategy to Detect Ultra-Low Magnetic Fields

Abstract

:1. Introduction

2. Background

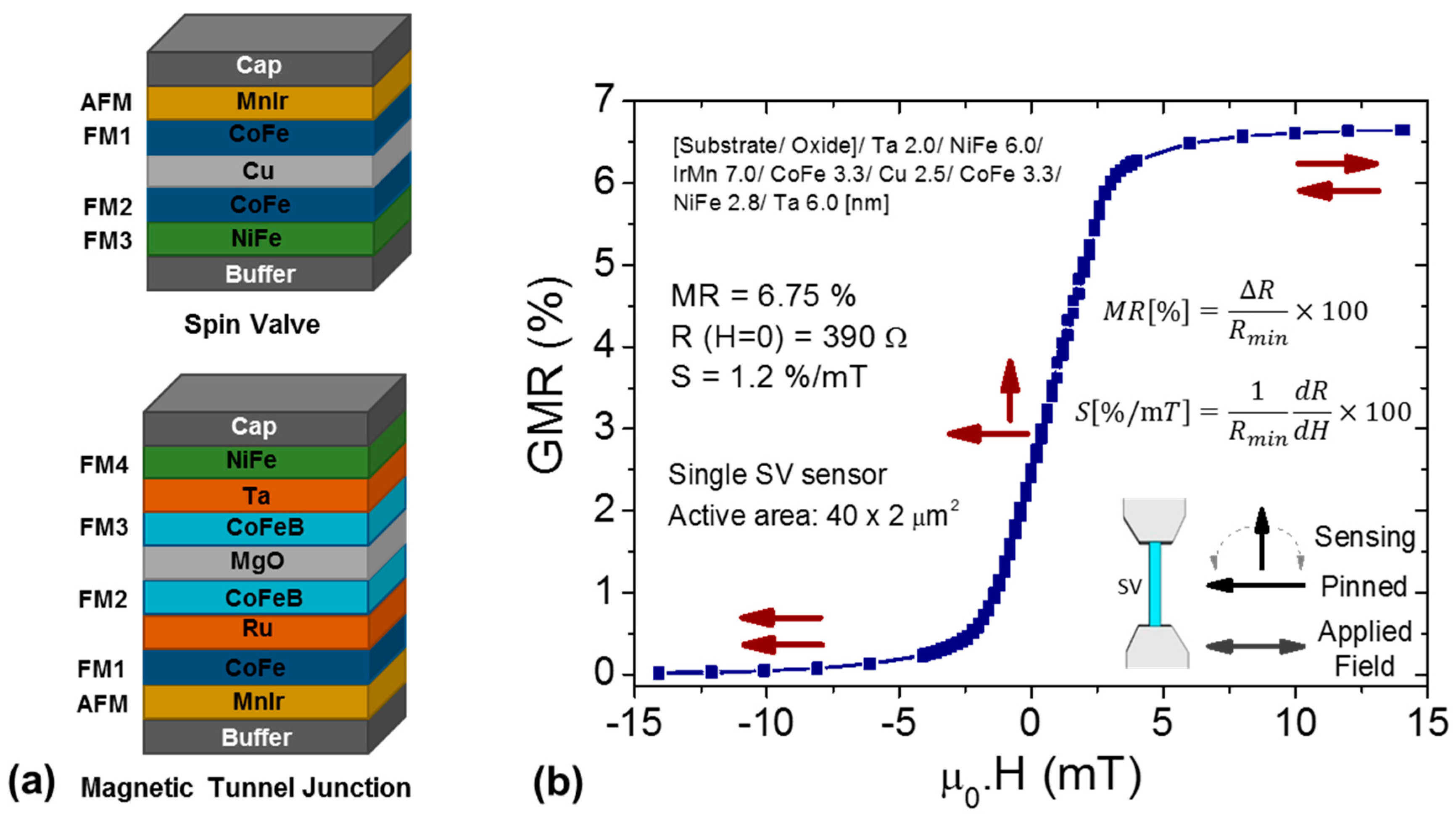

2.1. Magnetoresistive Sensors

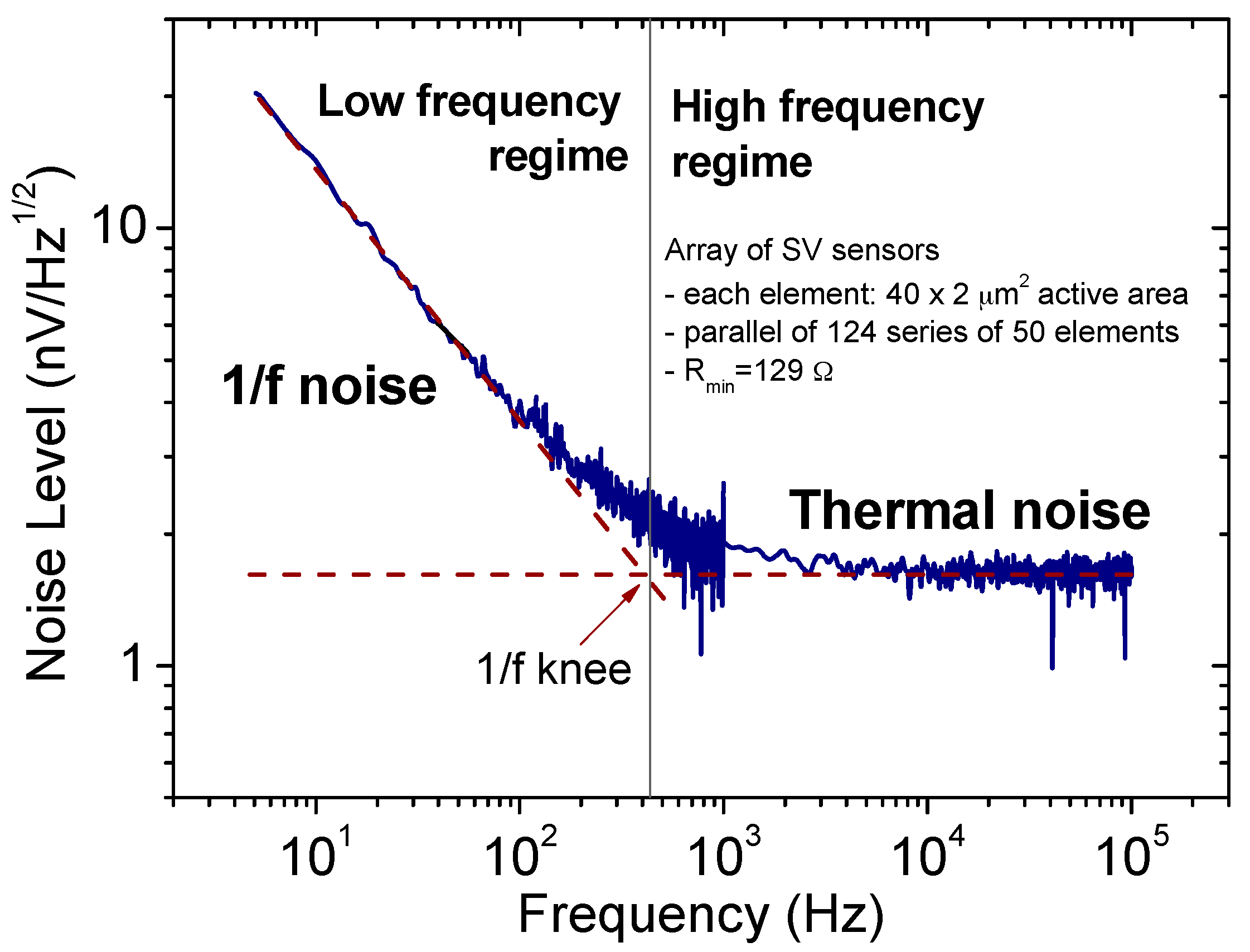

2.1.1. Noise Sources in MR Sensors

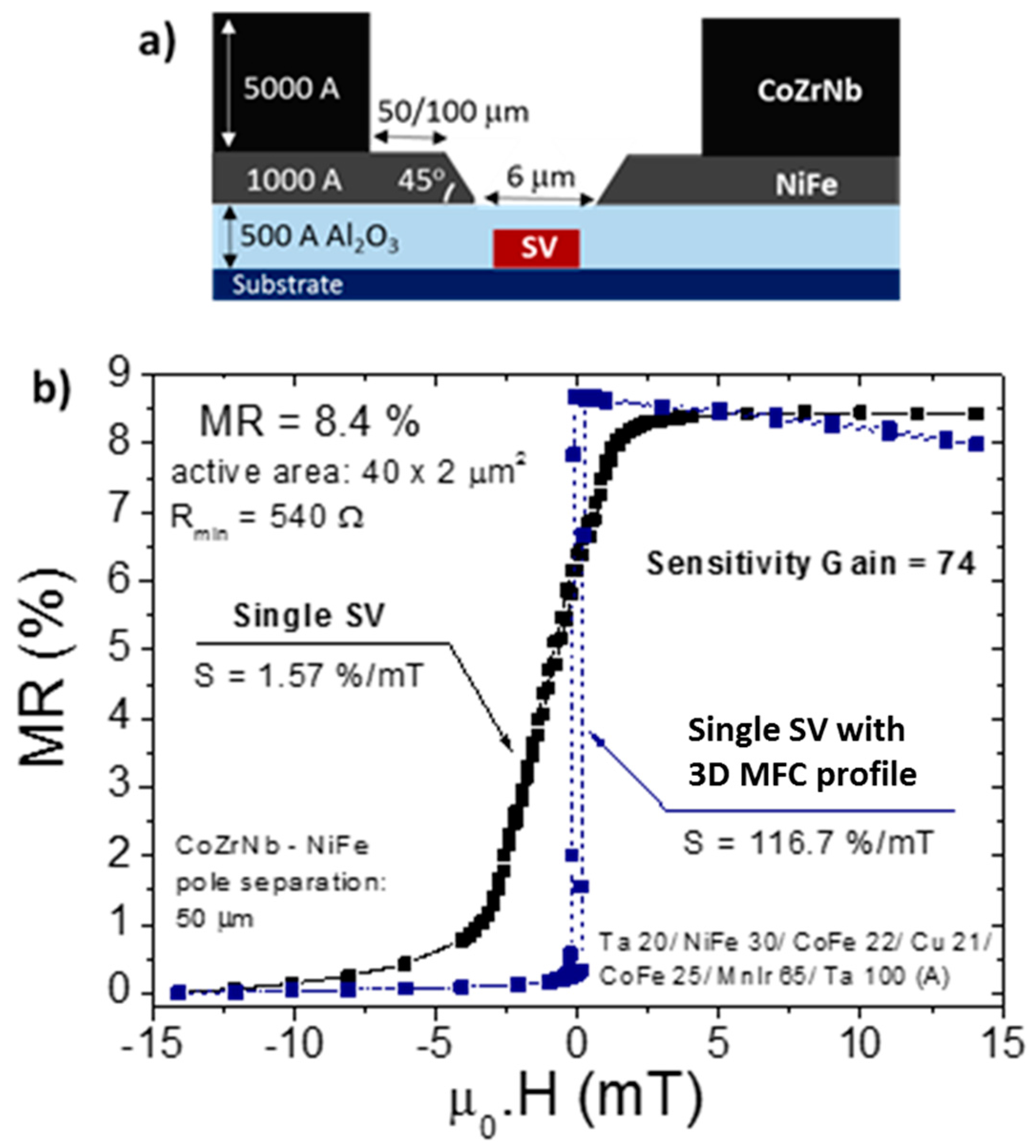

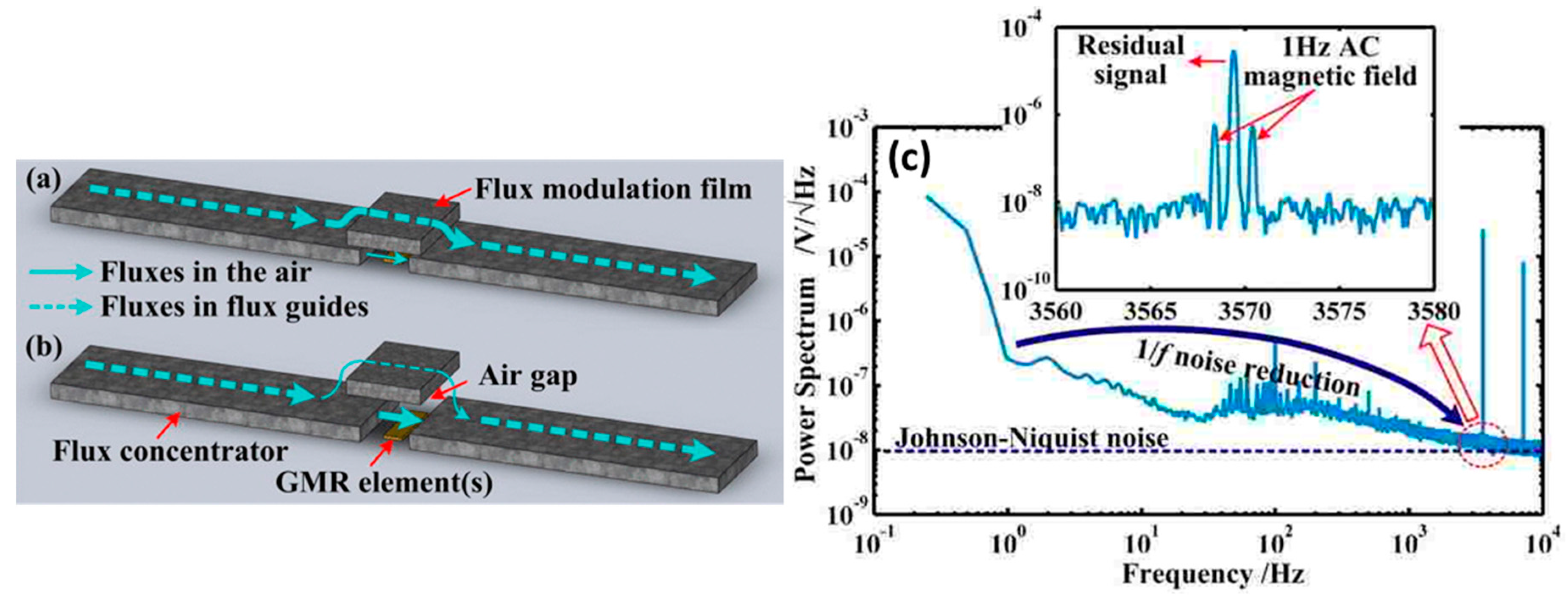

2.1.2. Detection Level Enhancement of MR Sensors

2.2. MEMS Resonators

2.3. Magnetic Flux Concentrators

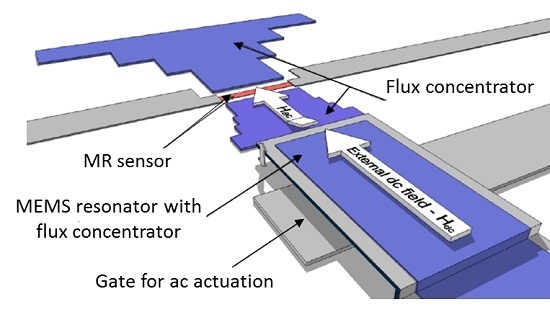

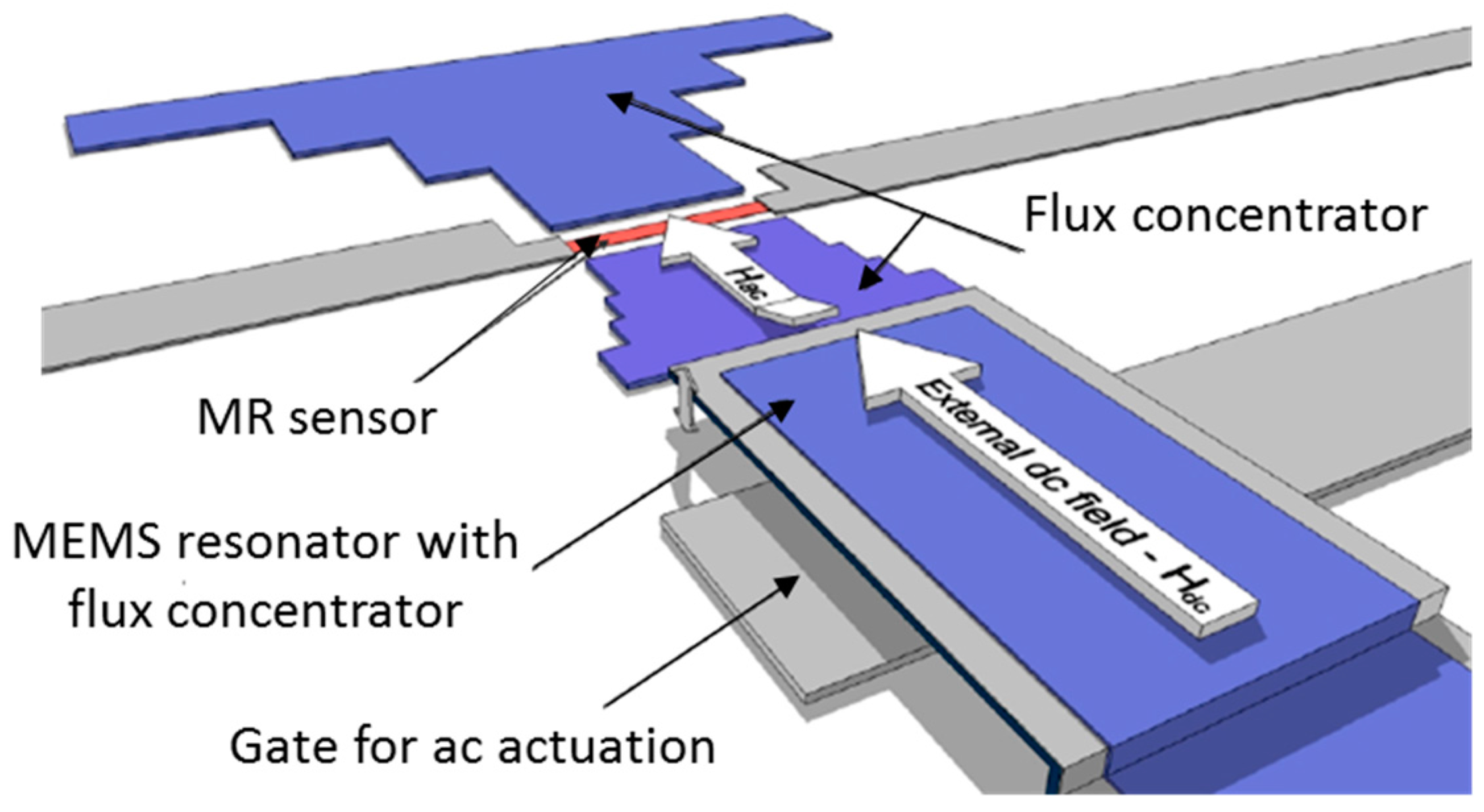

2.4. Hybrid Technology Integrating MR Sensors, MEMS and MFCs

3. Towards picoTesla Field Detection

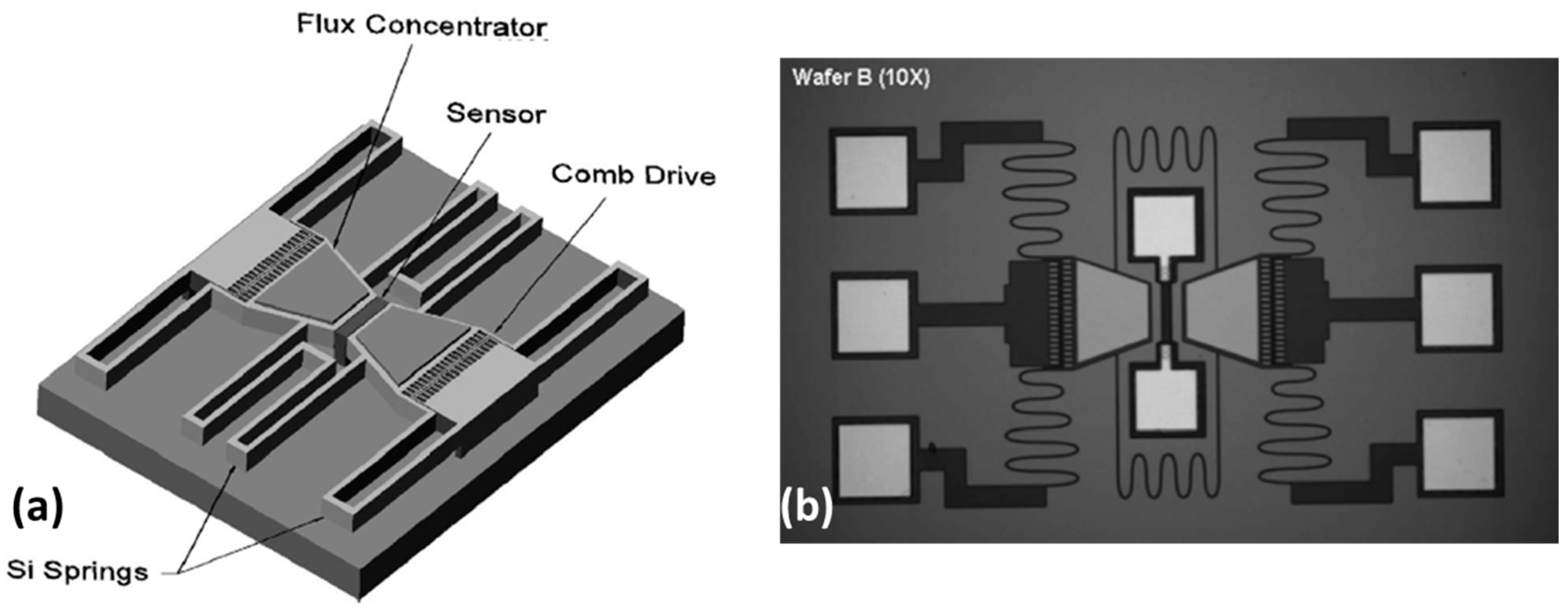

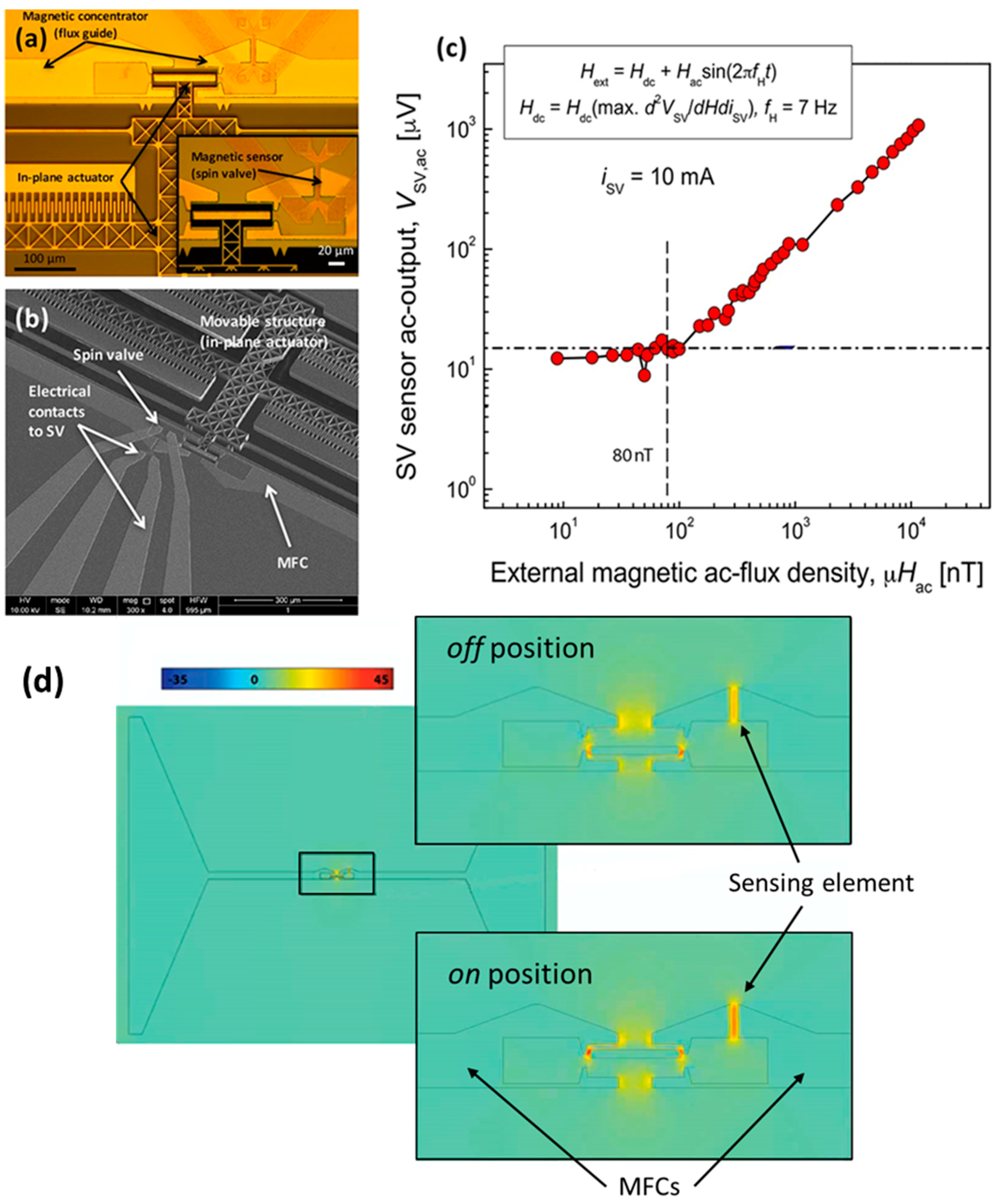

3.1. Approach I: MR Sensors, Coupled Capacitive MEMS with MFCs

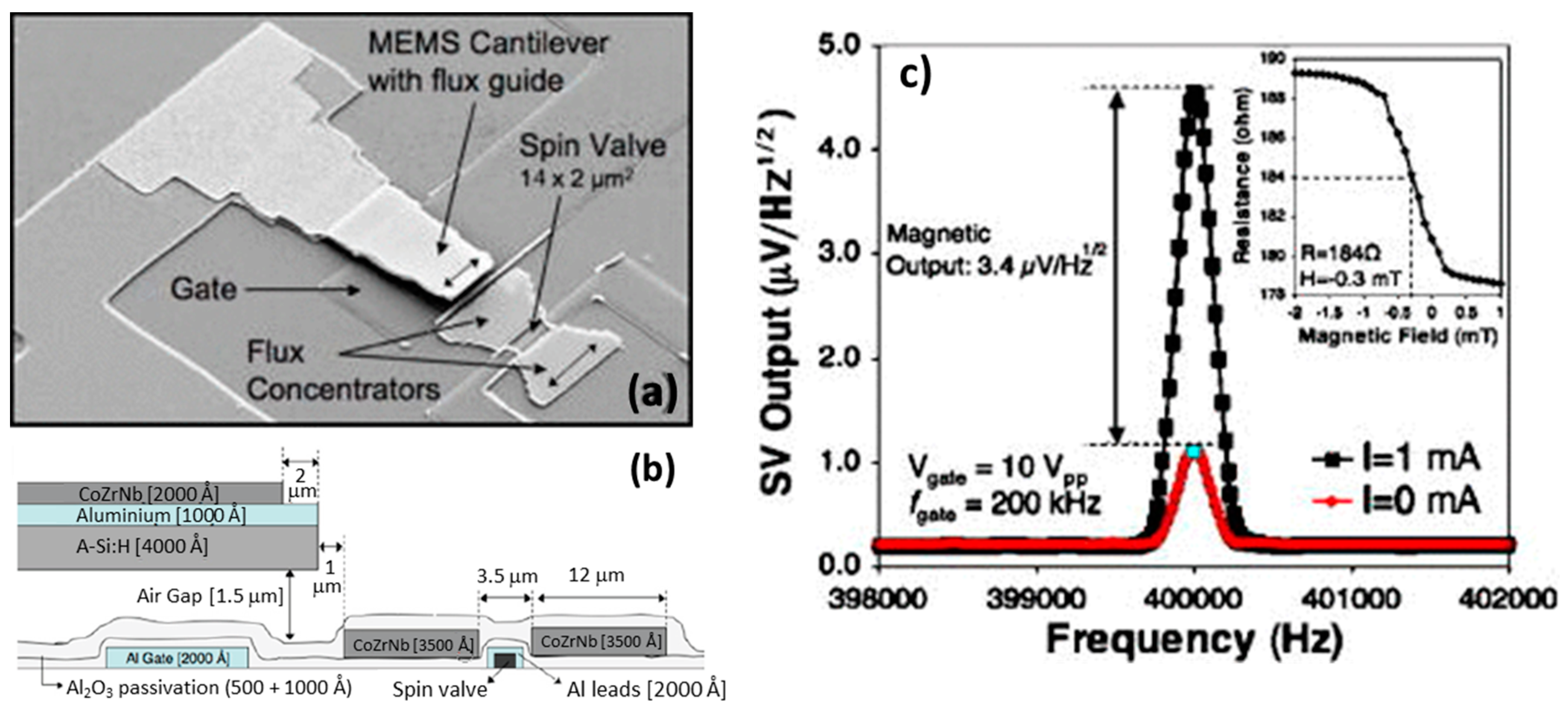

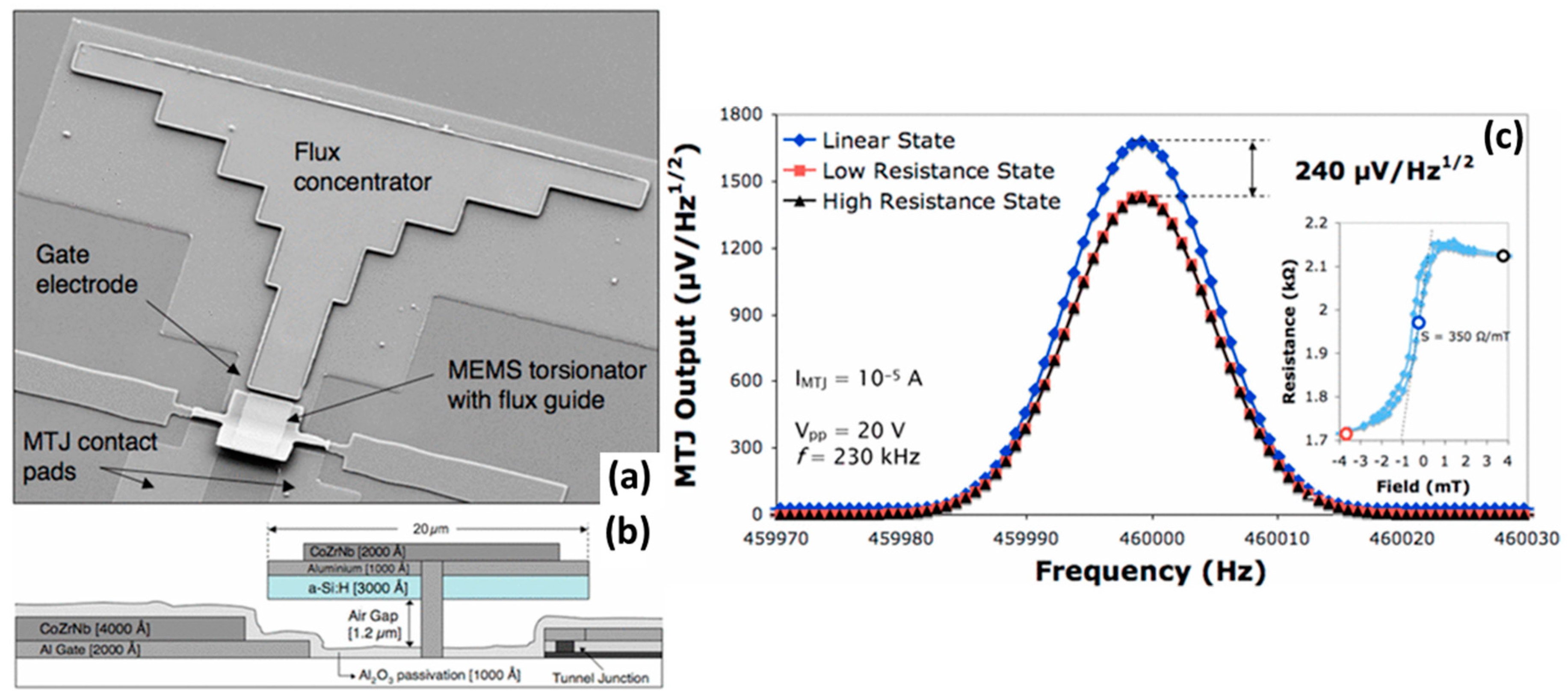

3.2. Approach II: MR Sensors, Capacitive MEMS (Single Cantilever and Torsional Paddle) with MFCs

3.3. Approach III: MR Sensors, Piezoelectric MEMS with MFCs

3.4. Approach IV: MR Sensors, Bulk-Micromachined MEMS with MFCs

3.5. Fabrication Details on MEMS Integration with MR Sensors

4. Final Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lenz, J.; Edelstein, A. Magnetic Sensors and Their Applications. IEEE Sens. J. 2006, 6, 631–649. [Google Scholar] [CrossRef]

- Jogschies, L.; Klaas, D.; Kruppe, R.; Rittinger, J.; Taptimthong, P.; Wienecke, A.; Rissing, L.; Wurz, M. Recent Developments of Magnetoresistive Sensors for Industrial Applications. Sensors 2015, 15, 28665–28689. [Google Scholar] [CrossRef] [PubMed]

- He, D.F.; Tachiki, M.; Itozaki, H. Highly sensitive anisotropic magnetoresistance magnetometer for eddy-current nondestructive evaluation. Rev. Sci. Instrum. 2009, 80, 036102. [Google Scholar] [CrossRef] [PubMed]

- Freitas, P.P.; Cardoso, F.A.; Martins, V.C.; Martins, S.; Loureiro, J.; Amaral, J.; Chaves, R.C.; Cardoso, S.; Germano, J.; Piedade, M.S.; et al. Spintronic platforms for biomedical applications. Lab Chip 2012, 12, 546–557. [Google Scholar] [CrossRef] [PubMed]

- Pannetier-Lecoeur, M.; Fermon, C.; Le Goff, G.; Simola, J.; Kerr, E. Femtotesla magnetic field measurement with magnetoresistive sensors. Science 2004, 304, 1648–1650. [Google Scholar] [CrossRef] [PubMed]

- Smith, N.; Jeffers, F.; Freeman, J. A High-Sensitivity Magnetoresistive Magnetometer. J. Appl. Phys. 1991, 69, 5082–5084. [Google Scholar] [CrossRef]

- Damsgaard, C.D.; Freitas, S.C.; Freitas, P.P.; Hansen, F.M. Exchange-biased planar Hall effect sensor optimized for biosensor applications. J. Appl. Phys. 2008, 103, 07A302. [Google Scholar] [CrossRef] [Green Version]

- Tsymbal, E.; Pettifor, D.G. Perspectives of giant magnetoresistance. Solid State Phys. 2001, 56, 113–237. [Google Scholar]

- Heim, D.E.; Fontana, R.E.; Tsang, C.; Speriosu, V.S.; Gurney, B.A.; Williams, M.L. Design and operation of spin valve sensors. IEEE Trans. Magn. 1994, 30, 316–321. [Google Scholar] [CrossRef]

- Chaves, R.; Freitas, P.P.; Ocker, B.; Maass, W. Low frequency picoTesla field detection using hybrid MgO based tunnel sensors. Appl. Phys. Lett. 2007, 91, 102504. [Google Scholar] [CrossRef]

- Paz, E.; Serrano-Guisan, S.; Ferreira, R.; Freitas, P.P. Room temperature direct detection of low frequency magnetic fields in the 100 pT/Hz0.5 range using large arrays of magnetic tunnel junctions. J. Appl. Phys. 2014, 115, 17E501. [Google Scholar] [CrossRef]

- Cardoso, S.; Leitao, D.C.; Gameiro, L.; Cardoso, F.; Ferreira, R.; Paz, E.; Freitas, P.P. Magnetic tunnel junction sensors with pTesla sensitivity. Microsyst. Technol. 2014, 20, 793–802. [Google Scholar] [CrossRef]

- Dieny, B. Giant magnetoresistance in spin-valve multilayers. J. Magn. Magn. Mater. 1994, 136, 335–359. [Google Scholar] [CrossRef]

- Cardoso, S.; Gehanno, V.; Ferreira, R.; Freitas, P.P. Ion Beam Deposition and oxidation of Spin Dependent Tunnel Junctions. IEEE Trans. Magn. 1999, 35, 2952–2954. [Google Scholar] [CrossRef]

- Yuasa, S.; Djayaprawira, D.D. Giant tunnel magnetoresistance in magnetic tunnel junctions with a crystalline MgO(001) barrier. J. Phys. D Appl. Phys. 2007, 40, R337. [Google Scholar] [CrossRef]

- Freitas, P.P.; Ferreira, R.; Cardoso, S.; Cardoso, F. Magnetoresistive sensors. J. Phys. Condens. Matter 2007, 19, 165221. [Google Scholar] [CrossRef]

- Silva, A.V.; Leitao, D.C.; Valadeiro, J.; Amaral, J.; Freitas, P.P.; Cardoso, S. Linearization strategies for high sensitivity magnetoresistive sensors. Eur. Phys. J. Appl. Phys. 2015, 72, 10601. [Google Scholar] [CrossRef]

- Ferreira, R.; Paz, E.; Freitas, P.P.; Wang, J.; Xue, S. Large area and low aspect ratio linear magnetic tunnel junctions with a soft-pinned sensing layer. IEEE Trans. Magn. 2012, 48, 3719–3722. [Google Scholar] [CrossRef]

- Freitas, P.P.; Cardoso, S.; Ferreira, R.; Martins, V.R.; Guedes, A.; Cardoso, F.; Loureiro, J.; Macedo, R.; Chaves, R.; Amaral, J.P. Optimization and integration of magnetoresistive sensors. J. SPIN 2011, 1, 71. [Google Scholar] [CrossRef]

- Lei, Z.Q.; Li, G.J.; Egelhoff, W.F., Jr.; Lai, P.T.; Pong, P.W. Review of Noise Sources in Magnetic Tunnel Junction Sensors. IEEE Trans. Magn. 2011, 47, 602–612. [Google Scholar] [CrossRef] [Green Version]

- Ozbay, A.; Gokce, A.; Flanagan, T.; Stearrett, R.A.; Nowak, E.R.; Nordman, C. Low frequency magnetoresistive noise in spin-valve structures. Appl. Phys. Lett. 2009, 94, 202506. [Google Scholar] [CrossRef]

- Jiang, L.; Nowak, E.R.; Scott, P.E.; Johnson, J.; Slaughter, J.M.; Sun, J.J.; Dave, R.W. Low-frequency magnetic and resistance noise in magnetic tunnel junctions. Phys. Rev. B 2004, 69, 054407. [Google Scholar] [CrossRef]

- Johnson, J.B. Thermal agitation of electricity in conductors. Phys. Rev. Lett. 1928, 32, 97. [Google Scholar] [CrossRef]

- George, P.K.; Wu, Y.; White, R.M.; Murdock, E.; Tondra, M. Shot noise in low resistance magnetic tunnel junctions. Appl. Phys. Lett. 2002, 80, 682–684. [Google Scholar] [CrossRef]

- Zhu, J.G. Thermal magnetic noise and spectra in spinvalve heads. J. Appl. Phys. 2002, 91, 7273–7275. [Google Scholar] [CrossRef]

- Egelhoff, W.F., Jr.; Pong, P.W.T.; Unguris, J.; McMichael, R.D.; Nowak, E.R.; Edelstein, A.S.; Burnette, J.E.; Fisher, G.A. Critical challenges for picoTesla magnetic-tunnel-junction sensors. Sens. Actuators A 2009, 155, 217–225. [Google Scholar] [CrossRef]

- Kogan, S. Electronic Noise and Fluctuations in Solids; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Han, G.C.; Zong, B.Y.; Luo, P.; Wang, C.C. Magnetic field dependence of low frequency noise in tunnel magnetoresistance heads. J. Appl. Phys. 2010, 107. [Google Scholar] [CrossRef]

- Ren, C.; Liu, X.; Schrang, B.D.; Xiao, G. Low-frequency magnetic noise in magnetic tunnel junctions. Phys. Rev. B 2004, 69. [Google Scholar] [CrossRef]

- Hooge, F.N.; Hoppenbrouwers, A. 1/f noise in continuous gold films. Physica 1969, 45, 386–392. [Google Scholar] [CrossRef]

- Chaves, R.C.; Cardoso, S.; Ferreira, R.; Freitas, P.P. Low aspect ratio micron size tunnel magnetoresistance sensors with permanent magnet biasing integrated in the top lead. J. Appl. Phys. 2011, 109, 07E506. [Google Scholar] [CrossRef]

- Valadeiro, J.; Amaral, J.; Leitao, D.C.; Ferreira, R.; Cardoso, S.F.; Freitas, P.P. Strategies for pTesla field detection using magnetoresistive sensors with a soft pinned sensing layer. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Guo, D.W.; Cardoso, F.A.; Ferreira, R.; Paz, E.; Cardoso, S.; Freitas, P.P. MgO-based magnetic tunnel junction sensors array for non-destructive testing applications. J. Appl. Phys. 2014, 115, 17E513. [Google Scholar] [CrossRef]

- Leitao, D.C.; Paz, E.; Silva, A.V.; Moskaltsova, A.; Knudde, S.; Deepak, F.; Ferreira, R.; Cardoso, S.; Freitas, P.P. Nanoscale Magnetic Tunnel Junction sensing devices with soft pinned sensing layer and low aspect ratio. IEEE Trans. Magn. 2014, 50. [Google Scholar] [CrossRef]

- Liou, S.H.; Yin, X.; Russek, S.E.; Heindl, R.; Silva, F.; Moreland, J.; Pappas, D.; Yuan, D.P.; Shen, J. Picotesla magnetic sensors for low-frequency applications. IEEE Trans. Magn. 2011, 47. [Google Scholar] [CrossRef]

- Guerrero, R.; Pannetier-Lecoeur, M.; Fermon, C.; Cardoso, S.; Ferreira, R.; Freitas, P.P. Low frequency noise in arrays of magnetic tunnel junctions connected in series and parallel. J. Appl. Phys. 2009, 105, 113922. [Google Scholar] [CrossRef]

- Leitao, D.C.; Gameiro, L.; Silva, A.V.; Cardoso, S.; Freitas, P.P. Field detection in spin valve sensors using CoFeB/Ru synthetic-antiferromagnetic multilayers as magnetic flux concentrators. IEEE Trans. Magn. 2012, 48. [Google Scholar] [CrossRef]

- Almeida, J.M.; Freitas, P.P. Field detection in MgO magnetic tunnel junctions with superparamagnetic free layer and magnetic flux concentrators. J. Appl. Phys. 2009, 105. [Google Scholar] [CrossRef]

- Marinho, Z.; Cardoso, S.; Chaves, R.; Ferreira, R.; Melo, L.V.; Freitas, P.P. Three dimensional magnetic flux concentrators with improved efficiency for magnetoresistive sensors. J. Appl. Phys. 2011, 109, 07E521. [Google Scholar] [CrossRef]

- Edelstein, A.; Fisher, G.A. Minimizing 1/f noise in magnetic sensors using a microelectromechanical system flux concentrator. J. Appl. Phys. 2002, 91, 7795–7797. [Google Scholar] [CrossRef]

- Edelstein, A.; Fisher, G.A.; Pedersen, M.; Nowak, E.R.; Cheng, S.F.; Nordman, C.A. Progress toward a thousandfold reduction in 1/f noise in magnetic sensors using an AC microelectromechanical system flux concentrator. J. Appl. Phys. 2006, 99, 08B317. [Google Scholar] [CrossRef]

- Khoshnoud, F.; de Silva, C.W. Recent advances in MEMS sensor technology–mechanical applications. IEEE Instrum. Meas. Mag. 2012, 15, 14–24. [Google Scholar] [CrossRef]

- Ikeda, K.; Kuwayama, H.; Kobayashi, T.; Watanabe, T.; Nishikawa, T.; Yoshida, T.; Harada, K. Three-dimensional micromachining of silicon pressure sensor integrating resonant strain gauge on diaphragm. Sens. Actuators A Phys. 1990, 23, 1007–1010. [Google Scholar] [CrossRef]

- Greenwood, J.; Wray, T. High accuracy pressure measurement with a silicon resonant sensor. Sens. Actuators A Phys. 1993, 37–38, 82–85. [Google Scholar] [CrossRef]

- Seshia, A.A.; Roessig, T.A.; Howe, R.T.; Gooch, R.W.; Schimert, T.R.; Montague, S. A vacuum packaged surface micromachined resonant accelerometer. J. Microelectromech. Syst. 2002, 11, 784–793. [Google Scholar] [CrossRef]

- Wen, M.; Luo, Z.; Wang, W.; Liu, S. A characterization of the performance of MEMS vibratory gyroscope in different fields. In Proceedings of the 15th International Conference on IEEE Electronic Packaging Technology (ICEPT), Chengdu, China, 12–15 August 2014; pp. 1547–1551.

- Cleland, A.N.; Roukes, M.L. Fabrication of high frequency nanometer scale mechanical resonators from bulk Si crystals. Appl. Phys. Lett. 1996, 69, 2653–2655. [Google Scholar] [CrossRef]

- Li, M.; Rouf, V.T.; Jaramillo, G.; Horsley, D.A. MEMS Lorentz force magnetic sensor based on a balanced torsional resonator. Solid-State Sensors. In Proceedings of the 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 66–69.

- Nguyen, C.T.C.; Katehi, L.P.B.; Rebeiz, G.M. Micromachined devices for wireless communications. Proc. IEEE 1998, 86, 1756–1768. [Google Scholar] [CrossRef]

- Joshi, M.; Kale, N.; Lal, R.; Rao, V.R.; Mukherji, S. A novel dry method for surface modification of SU-8 for immobilization of biomolecules in Bio-MEMS. Biosens. Bioelectron. 2007, 22, 2429–2435. [Google Scholar] [CrossRef] [PubMed]

- Bao, G.; Suresh, S. Cell and molecular mechanics of biological materials. Nat. Mater. 2003, 2, 715–725. [Google Scholar] [CrossRef] [PubMed]

- Gau, J.J.; Lan, E.H.; Dunn, B.; Ho, C.M.; Woo, J.C.S. A MEMS based amperometric detector for E. coli bacteria using self-assembled monolayers. Biosens. Bioelectron. 2001, 16, 745–755. [Google Scholar] [CrossRef]

- Gaspar, J.; Li, H.; Freitas, P.P.; Chu, V.; Conde, J.P. Integrated magnetic sensing of electrostatically actuated thin-film microbridges. J. Microelectromech. Syst. 2003, 12, 550–556. [Google Scholar] [CrossRef]

- Edelstein, A.S.; Burnette, J.E.; Fischer, G.A.; Olver, K.; Egelhoff, W., Jr.; Nowak, E.; Cheng, S.F. Validation of the microelectromechanical system flux concentrator concept for minimizing the effect of 1/f noise. J. Appl. Phys. 2009, 105, 07E720. [Google Scholar] [CrossRef]

- Guedes, A.; Patil, S.B.; Cardoso, S.; Chu, V.; Conde, J.P.; Freitas, P.P. Hybrid magnetoresistive/microelectromechanical devices for static field modulation and sensor 1/f noise cancellation. J. Appl. Phys. 2008, 103, 07E924. [Google Scholar] [CrossRef]

- Guedes, A.; Jaramillo, G.; Buffa, C.; Vigevani, G.; Cardoso, S.; Leitao, D.C.; Freitas, P.P.; Horsley, D.A. Towards picoTesla Magnetic Field Detection Using a GMR-MEMS Hybrid Device. IEEE Trans. Magn. 2012, 48, 4115–4118. [Google Scholar] [CrossRef]

- Guedes, A.; Patil, S.; Wisniowski, P.; Chu, V.; Conde, J.P.; Freitas, P.P. Hybrid Magnetic Tunnel Junction-MEMS High Frequency Field Modulator for 1/f Noise Suppression. IEEE Trans. Magn. 2008, 44, 2554–2557. [Google Scholar] [CrossRef]

- Hu, J.; Pan, M.; Tian, W.; Chen, D.; Luo, F. Integrating magnetoresistive sensors with microelectromechanical systems for noise reduction. Appl. Phys. Lett. 2012, 101, 234101. [Google Scholar] [CrossRef]

- Hu, J.; Pan, M.; Tian, W.; Chen, D.; Zhao, J. Magnetostatic detection using magnetoresistive sensors with vertical flux modulation. Rev. Sci. Instrum. 2012, 83, 055009. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Pan, M.; Tian, W.; Chen, D.; Zhao, J.; Luo, F. 1/f noise suppression of giant magnetoresistive sensors with vertical motion flux modulation. Appl. Phys. Lett. 2012, 100, 244102. [Google Scholar] [CrossRef]

- Patil1, S.; Guedes, A.; Freitas, P.P.; Cardoso, S.; Chu, V.; Conde, J.P. On-chip magnetoresistive detection of resonance in microcantilevers. Appl. Phys. Lett. 2009, 95, 023502. [Google Scholar] [CrossRef]

- Jander, A.; Nordman, C.A.; Pohm, A.V.; Anderson, J.M. Chopping techniques for low-frequency nanotesla spin-dependent tunneling field sensors. Appl. Phys. Lett. 2003, 93, 8382–8384. [Google Scholar] [CrossRef]

- Kobayashi, N.; Ohnuma, S.; Murakami, S.; Masumoto, T.; Mitani, S.; Fujimori, H. Enhancement of low-field-magnetoresistive response of tunnel-type magnetoresistance in metal–nonmetal granular thin films. J. Magn. Magn. Mater. 1998, 188, 30–34. [Google Scholar] [CrossRef]

- Freitas, P.P.; Costa, J.L.; Almeida, N.; Melo, L.V.; Silva, F.; Bernardo, J.; Santos, C. Giant magnetoresistive sensors for rotational speed control. J. Appl. Phys. 1999, 85, 5459–5461. [Google Scholar] [CrossRef]

- Leitao, D.C.; Coelho, P.; Borme, J.; Knudde, S.; Cardoso, S.; Freitas, P.P. Ultra-Compact 100 × 100 μm2 Footprint Hybrid Device with Spin-Valve Nanosensors. Sensors 2015, 15, 30311–30318. [Google Scholar] [CrossRef] [PubMed]

- Haykin, S.; Moher, M. Introduction to Analog & Digital Communications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Lathi, B.P. Modern Digital and Analog Communication Systems, 3rd ed.; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Ozdemir, S.; Akhtar, S.; Gunal, O.E.; Khater, M.E.; Saritas, R.; Abdel-Rahman, E.M.; Yavuz, M. Measuring the Quality Factor in MEMS Devices. Micromachines 2015, 6, 1935–1945. [Google Scholar] [CrossRef]

- Le Foulgoc, B.; Bourouina, T.; Le Traon, O.; Bosseboeuf, A.; Marty, F.; Breluzeau, C.; Grandchamp, J.P.; Masson, S. Highly decoupled single-crystal silicon resonators: An approach for the intrinsic quality factor. J. Micromech. Microeng. 2006, 16, S45–S53. [Google Scholar] [CrossRef]

- Cheng, S.F.; Lubitz, P.; Zheng, Y.; Edelstein, A.S. Effects of spacer layer on growth, stress and magnetic properties of sputtered permalloy film. J. Magn. Magn. Mater. 2004, 282, 109–114. [Google Scholar] [CrossRef]

- Klaasse, G.; Puers, R.; Tilmans, H.A.C. Piezoelectric versus electrostatic actuation for a capacitive RF-MEMS switch. In Proceedings of the 3rd Workshop on Semiconductor Sensor and Actuator, Leuven, Belgium, 29 November 2002; pp. 631–634.

- Alves, F.S.; Dias, R.A.; Cabral, J.; Gaspar, J.; Rocha, L.A. High-resolution MEMS inclinometer based on pull-in voltage. IEEE J. Microlectromech. Syst. 2105, 24, 931–939. [Google Scholar] [CrossRef]

- Gaspar, J.; Chu, V.; Conde, J.P. Amorphous silicon electrostatic microresonators with high quality factors. Appl. Phys. Lett. 2004, 84, 622–624. [Google Scholar] [CrossRef]

- Pedrini, G.; Gaspar, J.; Tu, W.; Osten, W.; Paul, O. Calibration of optical systems for the measurement of microcomponents. Opt. Lasers Eng. 2009, 47, 203–210. [Google Scholar] [CrossRef]

- Bartsch, U.; Gaspar, J.; Paul, O. Low-frequency two-dimensional resonators for vibrational micro energy harvesting. J. Micromech. Microeng. 2010, 20, 035016. [Google Scholar] [CrossRef]

- Passi, V.; Sodervall, U.; Nilsson, B.; Petersson, G.; Hagberg, M.; Krzeminski, C.; Dubois, E.; Du Bois, B.; Raskin, J.-P. Anisotropic vapor HF etching of silicon dioxide for Si microstructure release. Microelectron. Eng. 2012, 95, 83–89. [Google Scholar] [CrossRef]

- Hooda, M.K.; Wadhwa, M.; Verma, S.; Nayak, M.M.; George, P.J.; Paul, A.K. A systematic study of DRIE process for high aspect ratio microstructuring. Vacuum 2010, 84, 1142–1148. [Google Scholar] [CrossRef]

| Sensor Type | Individual Sensor Area (μm2) | Device Footprint (μm2) | Noise Level at 30 Hz (nV/Hz1/2) | Noise Level at 10 kHz (nV/Hz1/2) | Detectivity at 30 Hz (nT/Hz1/2) | Detectivity at 10 kHz (nT/Hz1/2) |

|---|---|---|---|---|---|---|

| Single SV sensor | 40 × 2 | 40 × 2 | 84.7 | 4.1 | 21.2 | 1.32 |

| Single SV sensor with MFCs | 40 × 2 | 400 × 293 | 84.7 | 4.1 | 1.9 | 0.12 |

| Array of 992 SV elements | 40 × 2 | 886 × 895 | 2.4 | 1.3 | 2.2 | 0.61 |

| Used Strategy | MR Sensor | Modulation Frequency (kHz) | Modulation Efficiency (%) | Minimum Detectable Field (nT/Hz1/2) |

|---|---|---|---|---|

| INESC-MN #1: capacitive single cantilever [55] | SV | 400 | 0.11 | 540 (DC) |

| INESC-MN #2: capacitive micro-paddle [57] | MTJ | 460 | 11 | 40 (DC) |

| Picosense/INESC-MN: piezoelectric paired cantilevers [56] | SV | 35.4 | 1.6 | 301 (DC) |

| 602 (AC) | ||||

| Hu J. et al.: single piezoelectric cantilever [58,59,60] | SV | 3.57 | 19 | 0.530 (DC) |

| INL/INESC-MN: bulk micromachined electrostatic actuator | SV | 7.5 | 1.03 | 80 (AC) |

| 15 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valadeiro, J.; Cardoso, S.; Macedo, R.; Guedes, A.; Gaspar, J.; Freitas, P.P. Hybrid Integration of Magnetoresistive Sensors with MEMS as a Strategy to Detect Ultra-Low Magnetic Fields. Micromachines 2016, 7, 88. https://doi.org/10.3390/mi7050088

Valadeiro J, Cardoso S, Macedo R, Guedes A, Gaspar J, Freitas PP. Hybrid Integration of Magnetoresistive Sensors with MEMS as a Strategy to Detect Ultra-Low Magnetic Fields. Micromachines. 2016; 7(5):88. https://doi.org/10.3390/mi7050088

Chicago/Turabian StyleValadeiro, João, Susana Cardoso, Rita Macedo, Andre Guedes, João Gaspar, and Paulo P. Freitas. 2016. "Hybrid Integration of Magnetoresistive Sensors with MEMS as a Strategy to Detect Ultra-Low Magnetic Fields" Micromachines 7, no. 5: 88. https://doi.org/10.3390/mi7050088