Large-Scale Integration of All-Glass Valves on a Microfluidic Device

Abstract

:1. Introduction

2. Experimental Section

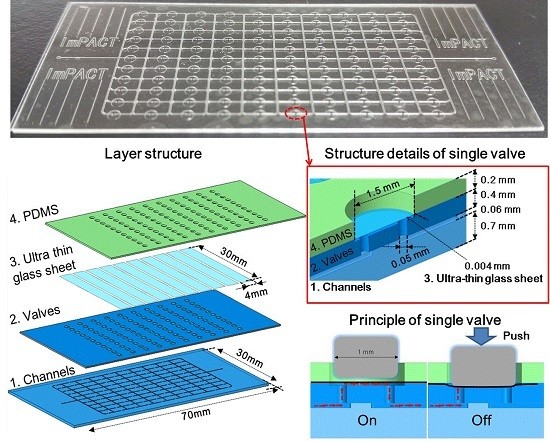

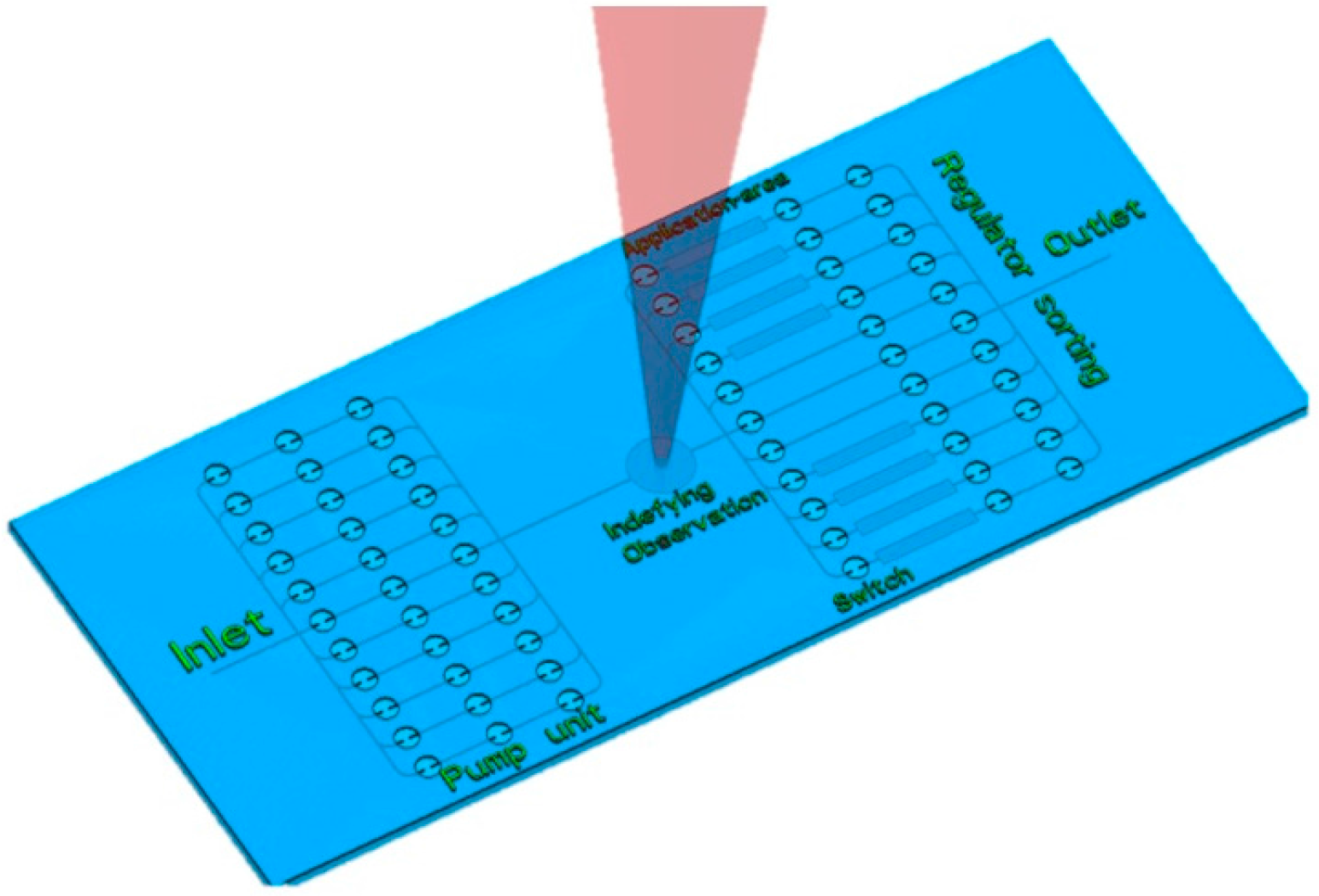

2.1. Design of a Prototype

2.2. Material Preparation

2.3. Fabrication of Microchip

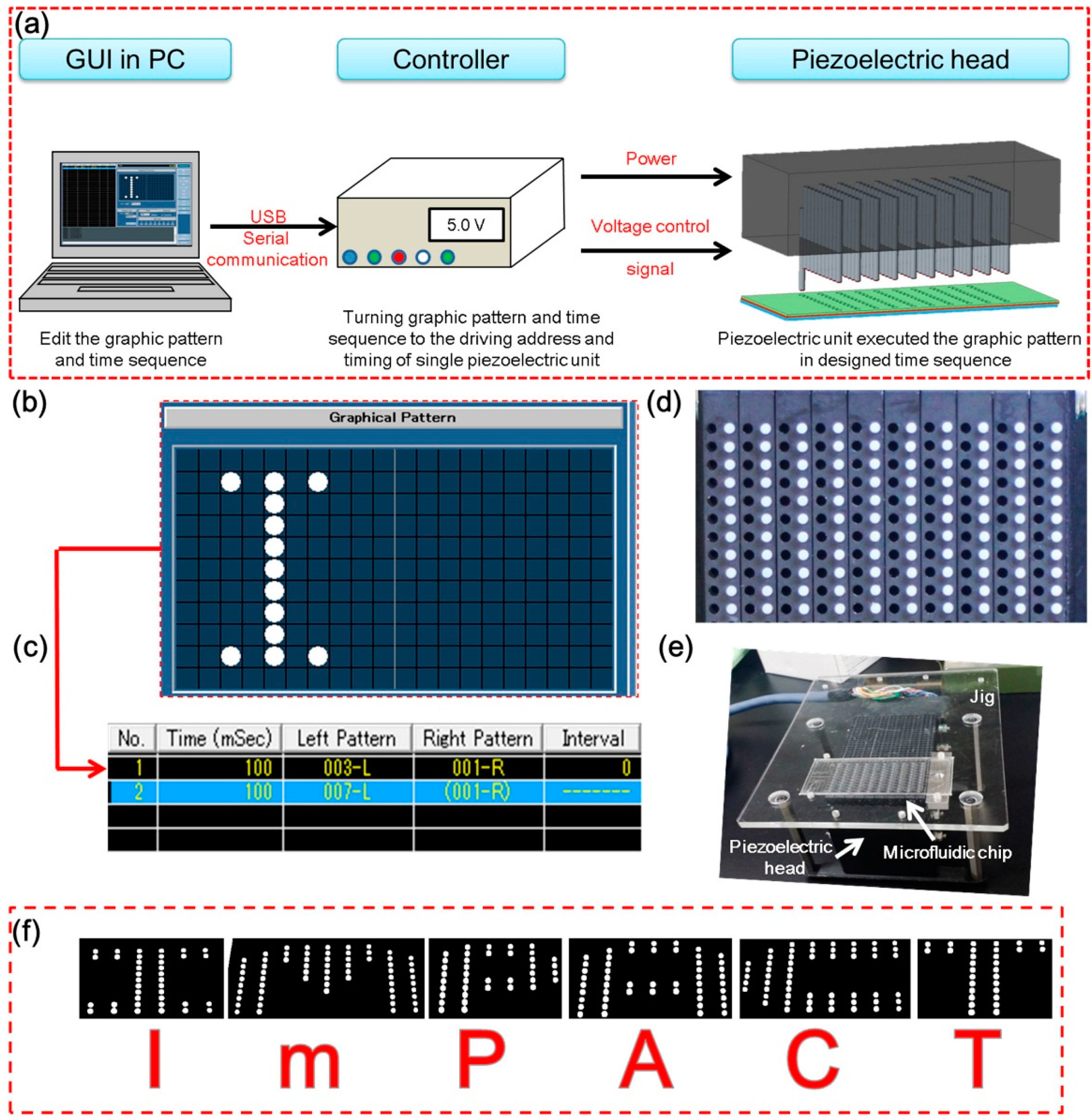

2.4. Design of Actuator and Software

2.5. Types of Experiments

2.6. Experimental Set-Up

3. Results and Discussion

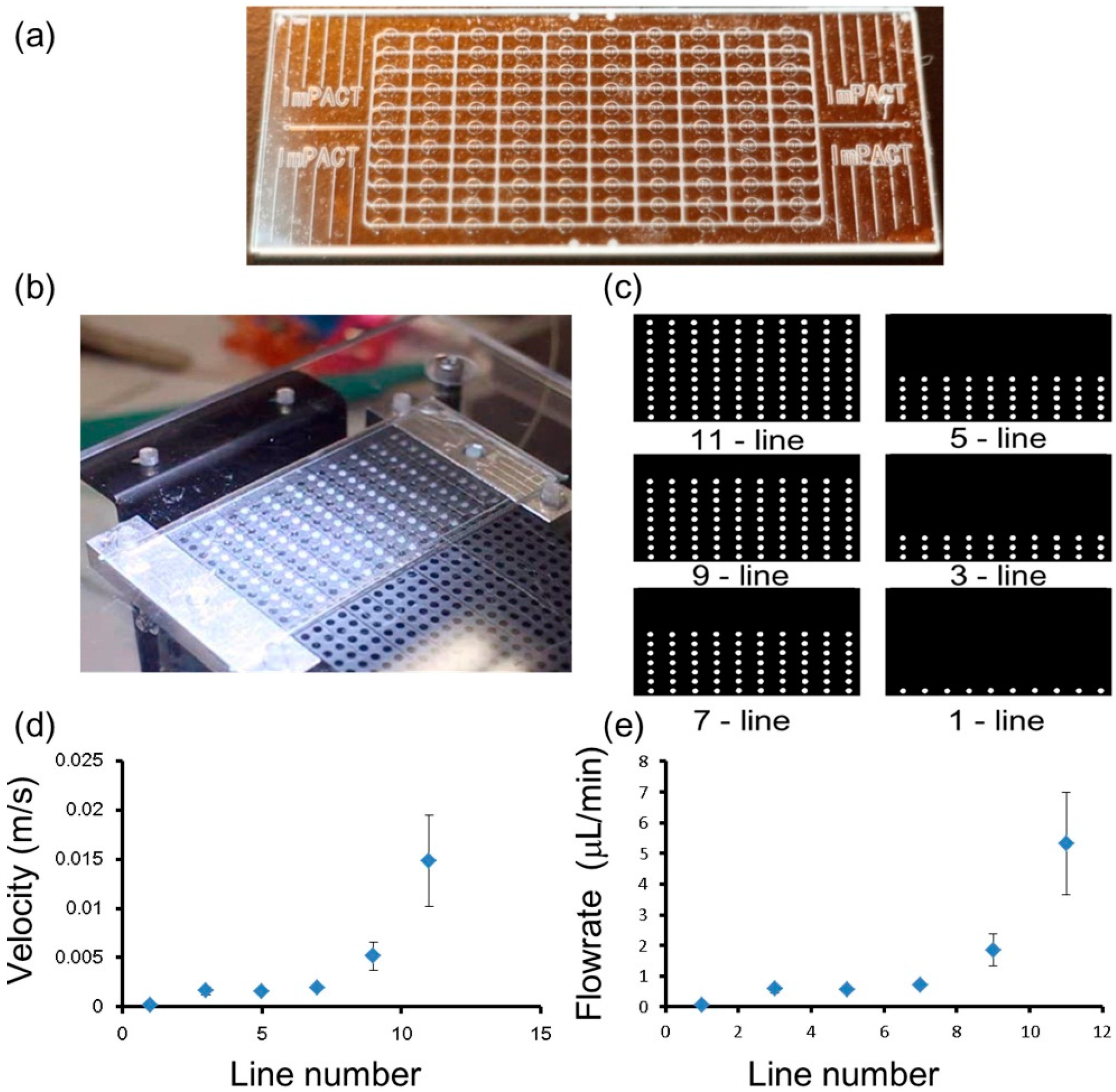

3.1. Prototype Microchip

3.2. Confirmation of Single Valve Action

3.3. Confirmation of a Large Number of Valve Actions: Experiment Demonstrating the Peristaltic Pump Mode

3.3.1. Dependence of Activated Number of Valves and on-Chip Flow Rate

3.3.2. Dependency of Valve Operation Time Interval and on-Chip Flow Rate

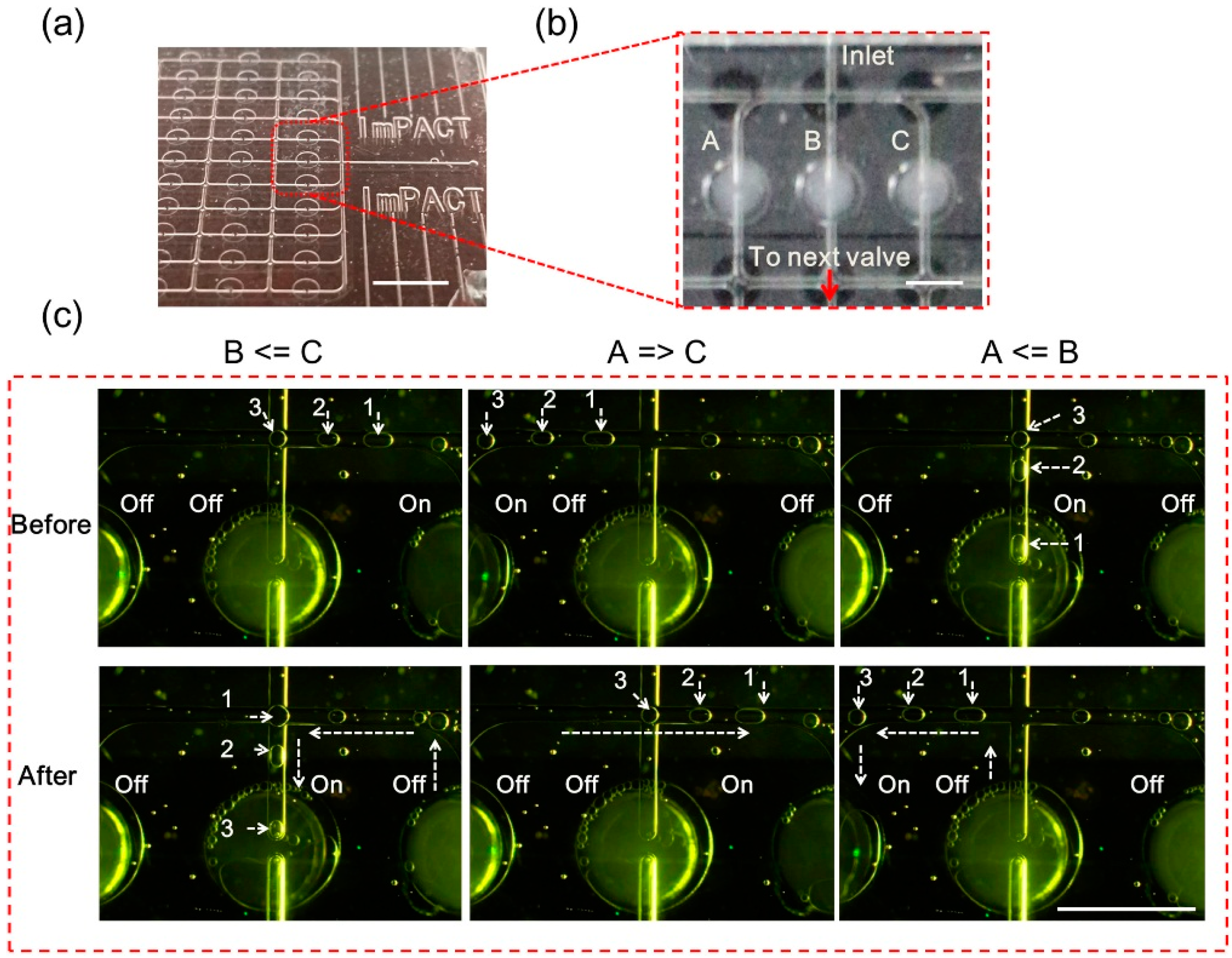

3.4. Demonstration of Channel Selection

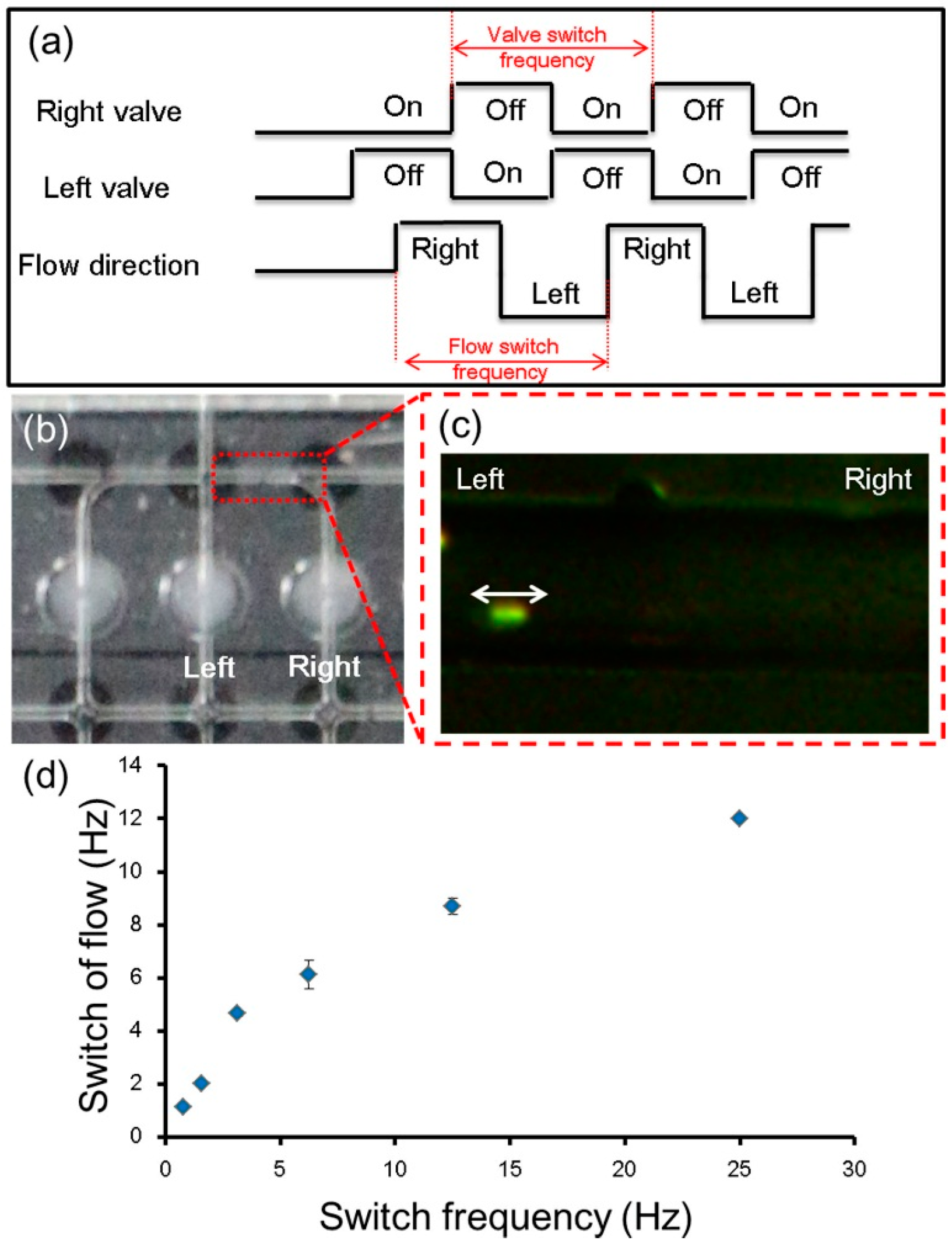

3.5. Dependency on Frequency of Flow Switching

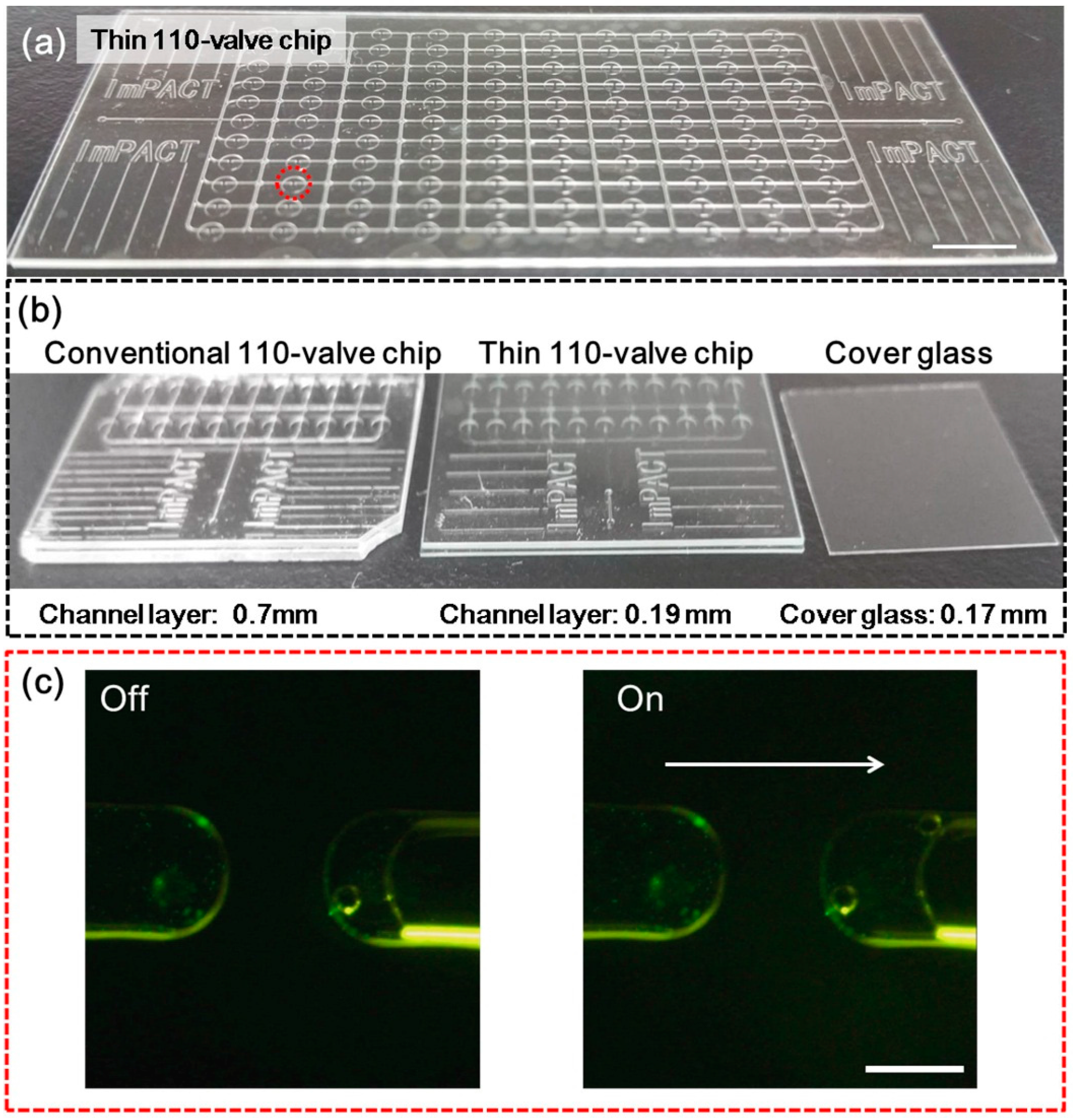

3.6. Thin Microfluidic Device with Integrated Large-Scale All-Glass Valves

3.7. Sample Limitation for the Microfluidic Device with Integrated Large-Scale All-Glass Valves

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oh, K.W.; Ahn, C.H. A review of microvalves. J. Micromech. Microeng. 2006, 16, R13–R39. [Google Scholar] [CrossRef]

- Melin, J.; Quake, S.R. Microfluidic Large-Scale Integration: The Evolution of Design Rules for Biological Automation. Annu. Rev. Biophys. Biomol. Struct. 2007, 36, 213–231. [Google Scholar] [CrossRef] [PubMed]

- Thorsen, T.; Maerkl, S.J.; Quake, S.R. Microfluidic large-scale integration. Science 2002, 298, 580–584. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y. A peristaltic pump integrated on a 100% glass microchip using computer controlled piezoelectric actuators. Micromachines 2014, 5, 289–299. [Google Scholar] [CrossRef]

- Vandelli, N.; Wroblewski, D.; Velonis, M.; Bifano, T. Development of a MEMS microvalve array for fluid flow control. J. Microelectromech. Syst. 1998, 7, 395–402. [Google Scholar] [CrossRef]

- Moriguchi, H.; Kawai, T.; Tanaka, Y. Simple bilayer on-chip valves using reversible sealability of PDMS. RSC Adv. 2015, 5, 5237–5243. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.S.; Swaddiwudhipong, S.; Miao, H.; Ding, Z.; Yang, Z. pH-Sensitive Hydrogel for Micro-Fluidic Valve. J. Funct. Biomater. 2012, 3, 464–479. [Google Scholar] [CrossRef] [PubMed]

- Mosadegh, B.; Mazzeo, A.D.; Shepherd, R.F.; Morin, S.A.; Gupta, U.; Sani, I.Z.; Lai, D.; Takayama, S.; Whitesides, G.M.; Zhalehdoust Sani, I. Control of Soft Machines using Actuators Operated by a Braille Display. Lab Chip 2013, 14, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Rho, H.S.; Yang, Y.; Hanke, A.T.; Ottens, M.; Terstappen, L. Gardeniers, HanProgrammable V-type Valve for Cell and Particle Manipulation in Microfluidic Devices. Lab Chip 2015, 16, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.G.; Shin, D.D.; Carman, G.P. High Performance Microvalve Array. In Microelectromechanical Systems; ASME: New York, NY, USA, 2005; Volume 2005, pp. 611–615. [Google Scholar]

- Tanaka, Y.; Fujikawa, T.; Kazoe, Y.; Kitamori, T. An active valve incorporated into a microchip using a high strain electroactive polymer. Sens. Actuators B Chem. 2013, 184, 163–169. [Google Scholar] [CrossRef]

- Hua, Z.; Xia, Y.; Srivannavit, O.; Rouillard, J.-M.; Zhou, X.; Gao, X.; Gulari, E. A versatile microreactor platform featuring a chemical-resistant microvalve array for addressable multiplex syntheses and assays. J. Micromech. Microeng. 2006, 16, 1433–1443. [Google Scholar] [CrossRef]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Quake, S.R.; Scherer, A. From micro- to nanofabrication with soft materials. Science 2000, 290, 1536–1540. [Google Scholar] [CrossRef] [PubMed]

- Augustine, S.; Gu, P.; Zheng, X.; Nishida, T.; Fan, Z.H. Development of all-plastic microvalve array for multiplexed immunoassay. In Proceedings of the ASME 2014, Montreal, QC, Cannda, 16–18 November 2014; pp. 14–20.

- Sugiura, Y.; Hirama, H.; Torii, T. Fabrication of Microfluidic Valves Using a Hydrogel Molding Method. Sci Rep. 2015, 5, 13375–13381. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y. Electric actuating valves incorporated into an all glass-based microchip exploiting the flexibility of ultra thin glass. RSC Adv. 2013, 3, 10213–10220. [Google Scholar] [CrossRef]

- Grover, W.H.; von Muhlen, M.G.; Manalis, S.R. Teflon films for chemically-inert microfluidic valves and pumps. Lab Chip 2008, 8, 913–918. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent Compatibility of Poly(dimethylsiloxane)-Based Microfluidic Devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef] [PubMed]

- Eddings, M.A.; Johnson, M.A.; Gale, B.K. Determining the optimal PDMS–PDMS bonding technique for microfluidic devices. J. Micromech. Microeng. 2008, 18, 067001. [Google Scholar] [CrossRef]

- Howlader, M.M.R.; Suehara, S.; Suga, T. Room temperature wafer level glass/glass bonding. Sens. Actuators A Phys. 2006, 127, 31–36. [Google Scholar] [CrossRef]

- Wang, Z. Polydimethylsiloxane Mechanical Properties Measured by Macroscopic Compression and Nanoindentation Techniques. Master’s Thesis, University of South Florida, Tampa, FL, USA, March 2011. [Google Scholar]

- Nippon Electric Glass. Glass-Ribbon. Available online: http://www.neg.co.jp/en/product/ep/glass-ribbon (accessed on 1 December 2015).

- Kuncová-Kallio, J.; Kallio, P.J. PDMS and its suitability for analytical microfluidic devices. Conf. Proc. IEEE Eng. Med. Biol. Soc. 2006, 1, 2486–2489. [Google Scholar] [PubMed]

- Hisamoto, H.; Shimizu, Y.; Uchiyama, K.; Tokeshi, M.; Kikutani, Y.; Hibara, A.; Kitamori, T. Chemicofunctional membrane for integrated chemical processes on a microchip. Anal. Chem. 2003, 75, 350–354. [Google Scholar] [CrossRef] [PubMed]

- Hiki, S.; Mawatari, K.; Aota, A.; Saito, M.; Kitamori, T. Sensitive gas analysis system on a microchip and application for on-site monitoring of NH3 in a clean room. Anal. Chem. 2011, 83, 5017–5022. [Google Scholar] [CrossRef] [PubMed]

- Jang, K.; Sato, K.; Tanaka, Y.; Xu, Y.; Sato, M.; Nakajima, T.; Mawatari, K.; Konno, T.; Ishihara, K.; Kitamori, T. An efficient surface modification using 2-methacryloyloxyethyl phosphorylcholine to control cell attachment via photochemical reaction in a microchannel. Lab Chip 2010, 10, 1937–1945. [Google Scholar] [CrossRef] [PubMed]

- Sugioka, K.; Cheng, Y. Femtosecond laser processing for optofluidic fabrication. Lab Chip 2012, 12, 3576–3589. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.-Y.; Pardo-Martin, C.; Allalou, A.; Wahlby, C.; Yanik, M.F. Fully automated cellular-resolution vertebrate screening platform with parallel animal processing. Lab Chip 2012, 12, 711–716. [Google Scholar] [CrossRef] [PubMed]

- Iliescu, C.; Taylor, H.; Avram, M.; Miao, J.; Franssila, S. A practical guide for the fabrication of microfluidic devices using glass and silicon. Biomicrofluidics 2012, 6, 16505. [Google Scholar] [CrossRef] [PubMed]

- Ichiki, T.; Sugiyama, Y.; Ujiie, T.; Horiike, Y. Deep dry etching of borosilicate glass using fluorine-based high-density plasmas for microelectromechanical system fabrication. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2003, 21, 2188–2192. [Google Scholar] [CrossRef]

- Ahamed, M.J.; Senkal, D.; Trusov, A.A.; Shkel, A.M. Deep NLD plasma etching of fused silica and borosilicate glass. In Proceedings of the 2013 IEEE SENSORS, Baltimore, MD, USA, 3–6 November 2013; pp. 1767–1770.

- Pawlowski, A.G.; Sayah, A.; Gijs, M.A.M. Precision poly-(dimethyl siloxane) masking technology for high-resolution powder blasting. J. Microelectromech. Syst. 2005, 14, 619–624. [Google Scholar] [CrossRef]

- Belloy, E.; Pawlowski, A.-G.; Sayah, A.; Gijs, M.A.M. Microfabrication of high-aspect ratio and complex monolithic structures in glass. J. Microelectromech. Syst. 2002, 11, 521–527. [Google Scholar] [CrossRef]

- Brusberg, L.; Queisser, M.; Gentsch, C.; Schröder, H.; Lang, K.-D. Advances in CO2-Laser Drilling of Glass Substrates. Phys. Procedia 2012, 39, 548–555. [Google Scholar] [CrossRef]

- Kim, D.-J.; Ahn, Y.; Lee, S.-H.; Kim, Y.-K. Voltage pulse frequency and duty ratio effects in an electrochemical discharge microdrilling process of Pyrex glass. Int. J. Mach. Tools Manuf. 2006, 46, 1064–1067. [Google Scholar] [CrossRef]

- Zheng, Z.; Wu, K.; Hsu, Y.; Huang, F.; Yan, B. Feasibility of 3D surface machining on pyrex glass by electrochemical discharge machining (ECDM). In Proceedings of the Asian Electrical Machining Symposium 2007, Nagoya, Japan, 28–30 November 2007; pp. 98–103.

- Krishnaraj, V.; Vijayarangan, S.; Suresh, G. An investigation on high speed drilling of glass fibre reinforced plastic (GFRP). Indian J. Eng. Mater. Sci. 2005, 12, 189–195. [Google Scholar]

- Takahashi, S.; Tatsukoshi, K.; Ono, M.; Mikayama, M.; Imajo, N. Development of TGV Interposer for 3D IC. Int. Symp. Microelectron. 2013, 2013, 631–634. [Google Scholar] [CrossRef]

- Hosokawa, K.; Maeda, R. A pneumatically-actuated three-way microvalve fabricated with polydimethylsiloxane using the membrane transfer technique. J. Micromech. Microeng. 2000, 10, 415–420. [Google Scholar] [CrossRef]

- Baldi, A.; Gu, Y.; Loftness, P.E.; Siegel, R.A.; Ziaie, B. A hydrogel-actuated environmentally sensitive microvalve for active flow control. J. Microelectromech. Syst. 2003, 12, 613–621. [Google Scholar] [CrossRef] [Green Version]

- Chen, A.; Pan, T. Manually operatable on-chip bistable pneumatic microstructures for microfluidic manipulations. Lab Chip 2014, 14, 3401–3408. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Zhu, X.; Futai, N.; Cho, B.S.; Takayama, S. Computerized microfluidic cell culture using elastomeric channels and Braille displays. Proc. Natl. Acad. Sci. USA 2004, 101, 15861–15866. [Google Scholar] [CrossRef] [PubMed]

- Chang, P.J.; Chang, F.W.; Yuen, M.C.; Otillar, R.; Horsley, D.A. Force measurements of a magnetic micro actuator proposed for a microvalve array. J. Micromech. Microeng. 2014, 24, 034005. [Google Scholar] [CrossRef]

- Wei, H.; Chueh, B.; Wu, H.; Hall, E.W.; Li, C.; Schirhagl, R.; Lin, J.-M.; Zare, R.N. Particle sorting using a porous membrane in a microfluidic device. Lab Chip 2011, 11, 238–245. [Google Scholar] [CrossRef] [PubMed]

- Koschwanez, J.H.; Carlson, R.H.; Meldrum, D.R. Thin PDMS films using long spin times or tert-butyl alcohol as a solvent. PLoS ONE 2009, 4, 2–6. [Google Scholar] [CrossRef] [PubMed]

- Iliescu, C.; Tan, K.L.; Tay, F.E.H.; Miao, J. Deep wet and dry etching of Pyrex glass: A review. In Proceedings of the ICMAT 2005, Singapore, Singapore, 3–8 July 2005; Volume 44, pp. 75–78.

- Christian, S. Manufacturing and Use of Microperforated Substrates. U.S. Patent 8,759,707, 1 February 2007. [Google Scholar]

- Jui, S.K.; Kamaraj, A.B.; Sundaram, M.M. High aspect ratio micromachining of glass by electrochemical discharge machining (ECDM). J. Manuf. Process. 2013, 15, 460–466. [Google Scholar] [CrossRef]

- Jang, K.-J.; Suh, K.-Y. A multi-layer microfluidic device for efficient culture and analysis of renal tubular cells. Lab Chip 2010, 10, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Ichikawa, A.; Tanikawa, T. Fluorescent monitoring using microfluidics chip and development of syringe pump for automation of enucleation to automate cloning. In Proceedings of the IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 2231–2236.

- Cheong, F.C.; Wong, C.C.; Gao, Y.; Nai, M.H.; Cui, Y.; Park, S.; Kenney, L.J.; Lim, C.T. Rapid, High-Throughput Tracking of Bacterial Motility in 3D via Phase-Contrast Holographic Video Microscopy. Biophys. J. 2015, 108, 1248–1256. [Google Scholar] [CrossRef] [PubMed]

- Liszka, B.M.; Rho, H.S.; Yang, Y.; Lenferink, A.T.M.; Terstappen, L.W.M.M.; Otto, C. A microfluidic chip for high resolution Raman imaging of biological cells. RSC Adv. 2015, 5, 49350–49355. [Google Scholar] [CrossRef]

- Epshteyn, A.A.; Maher, S.; Taylor, A.J.; Holton, A.B.; Borenstein, J.T.; Cuiffi, J.D. Membrane-integrated microfluidic device for high-resolution live cell imaging. Biomicrofluidics 2011, 5, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Bruus, H. Theoretical Microfluidics; OUP: Oxford, UK, 2007. [Google Scholar]

| Methods | Minimum Fabricated Hole Size (μm) | Aspect Ratio | Drilling Rate (μm/min) | Cutting Tool Needed | Risk of Defects or Cracks Being Generated | Pre-process Quired | Ref. |

|---|---|---|---|---|---|---|---|

| Focused electrical discharging method | >20 | Approx. 10 | 24,000,000 | No | No | No | [39] |

| Wet etching | 1 | Approx. 0.7 | 15 | No | Yes | Yes | [30] |

| Dry etching | 0.5 | <10 | Approx. 1.2 | No | Yes | Yes | [31] |

| Deep NLD etching a | >1 | >8 | 0.75 | No | Yes | Yes | [32] |

| Powder blasting | >20 | <3 | 0.4 | Yes | Yes | Yes | [33,34] |

| Mechanical drilling | >100 | >40 | 1520 | Yes | Yes | Yes | [38] |

| Laser drilling | >100 | >5 | 120,000 | No | Yes | No | [35] |

| Electrochemical discharge method | >50 | >7 | 100–4000 | Yes | No | No | [36,37] |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalikun, Y.; Tanaka, Y. Large-Scale Integration of All-Glass Valves on a Microfluidic Device. Micromachines 2016, 7, 83. https://doi.org/10.3390/mi7050083

Yalikun Y, Tanaka Y. Large-Scale Integration of All-Glass Valves on a Microfluidic Device. Micromachines. 2016; 7(5):83. https://doi.org/10.3390/mi7050083

Chicago/Turabian StyleYalikun, Yaxiaer, and Yo Tanaka. 2016. "Large-Scale Integration of All-Glass Valves on a Microfluidic Device" Micromachines 7, no. 5: 83. https://doi.org/10.3390/mi7050083