With the rapid development of the electronics industry and precision machinery, product miniaturization has become a trend in the fields of communications, electronics, micro-electromechanical systems, so manufacture of high quality micro device is a requiring problem nowadays [

1].

Based on the traditional punching techniques, micro-stamping technology attracts widespread concern home and abroad [

2] because of its reliability, convenience, efficiency and good quality. Yi

et al. [

3] used the micro-punching technology to punch a 15 µm micro-hole on the brass foils with a two-way image acquisition system and punching tools were fabricated by micro electrical discharge machining (micro-EDM). Ghassemali

et al. [

4] researched the feasibility of producing micro-pins with diameters of 0.3 mm, 0.5 mm and 0.8 mm successfully and effects of punch/pin diameter ratio on the pin aspect ratio using a progressive forming set-up. The maximum forming loads were also investigated. Masuzawa and Tönshoff

et al. [

5] used wire EDM electrode grinding technology to fabricate micro punch and micro molds, and solved the eccentric difficulties between them. Joo

et al. [

6] developed a high-precision guiding and detecting micro-punching system, and used tungsten carbide micro punch to punch high-quality micro-holes on brass foils. Xu

et al. [

2] fabricated micro punch of several hundred microns in diameter by means of micro-EDM grinding technology and punched out 100, 150 and 300 μm on SUS304 stainless steel sheets. However, there exist difficulties in manufacturing punching tools economically as well as complex alignment problems between micro punch and die in these researches, thus, Rhim

et al. [

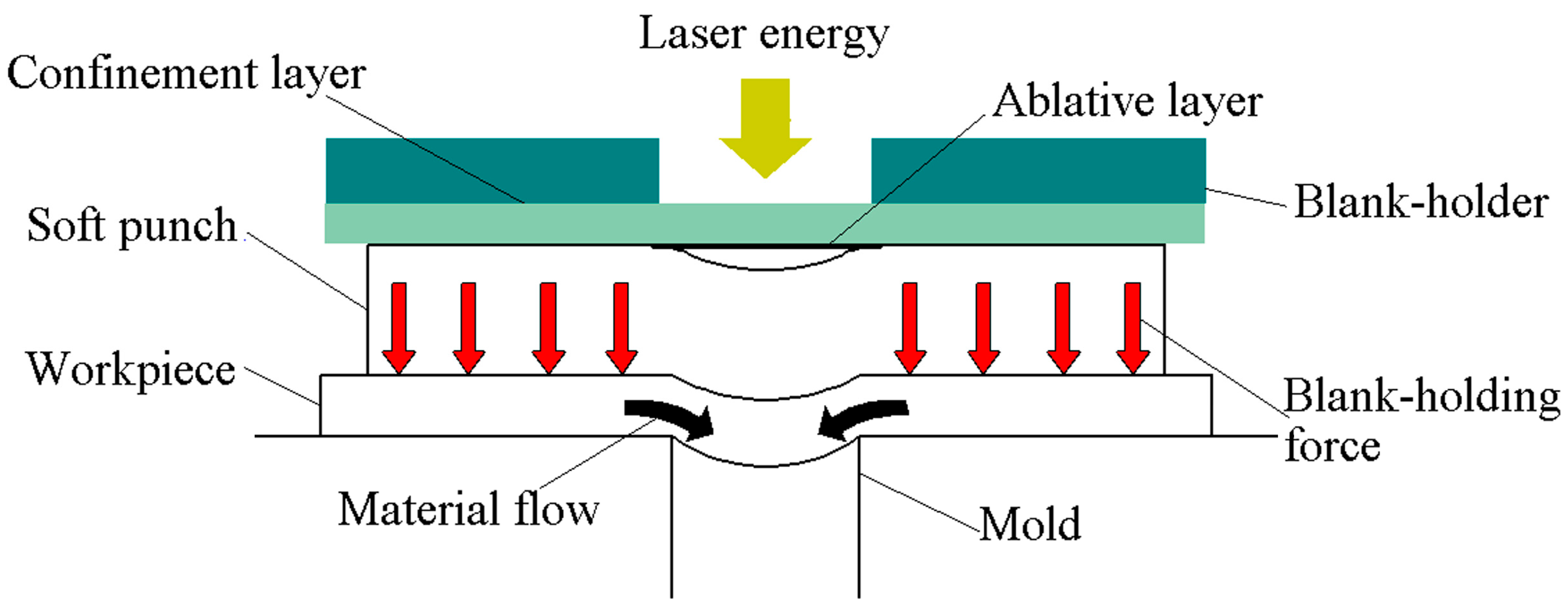

7] used silicone rubber instead of the rigid punch as a pressure transmission medium, and punched array of micro-holes on copper and titanium foil successfully with the single crystal silicon die. Liu

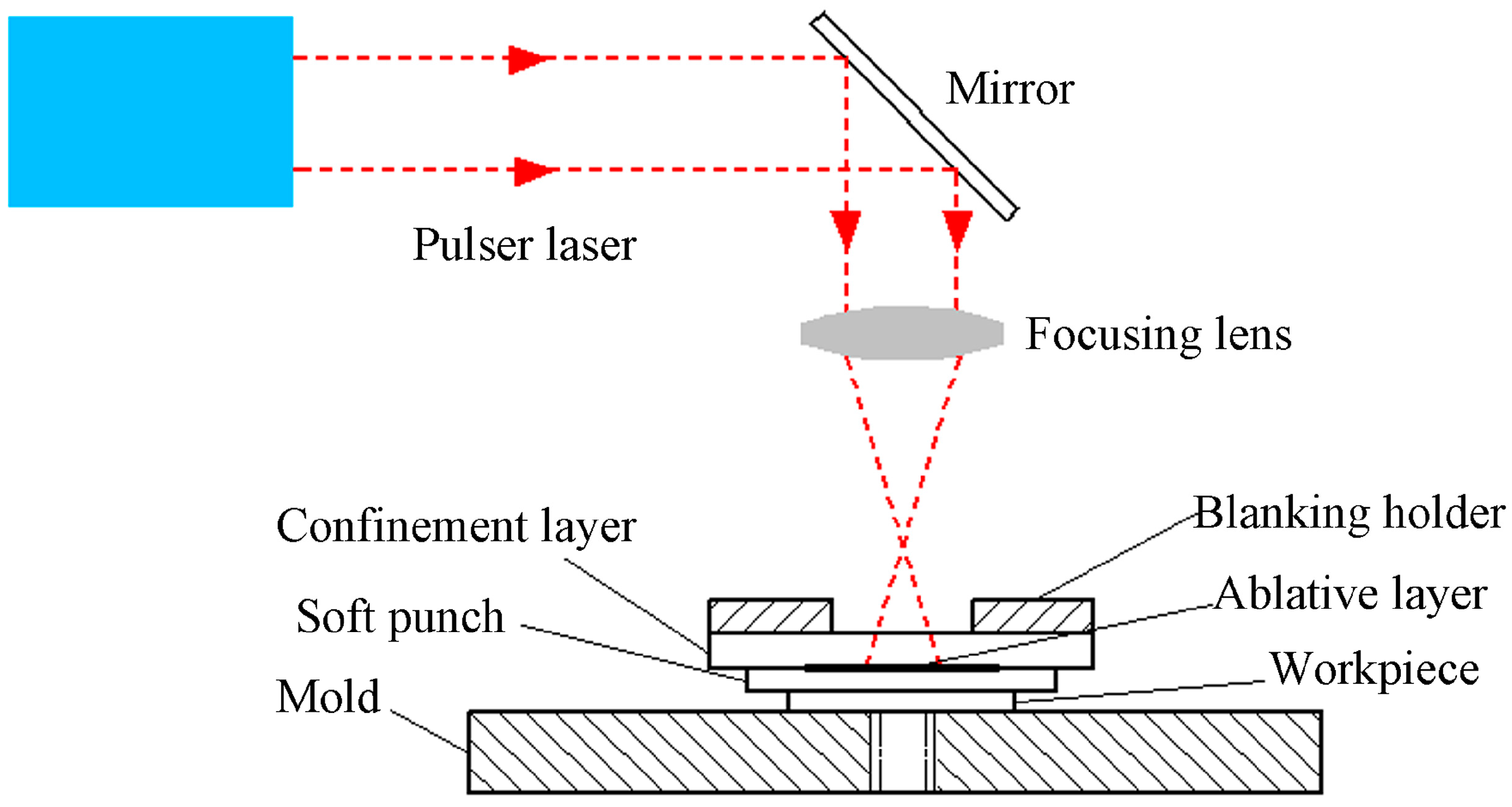

et al. [

8] combined laser shock technique with punching process, and developed a new type of micro-forming technology, so that the 250 µm micro-hole was punched successfully on the copper foil of thickness between 10 and 30 µm. This technique used the intense laser beam as the micro punch rather than a traditional punch in order to solve the difficulty of complex punch-to-die alignment and punch fabrication in the process of micro punching to a great extent. Afterwards, Liu

et al. [

9] improved this technology, in which polyurethane soft film acted as a medium of transmitting impact pressure [

7,

10]. Cooperated with a machined mold, arrays of square holes were machined successfully on the Al foil of 20 µm in the thickness.

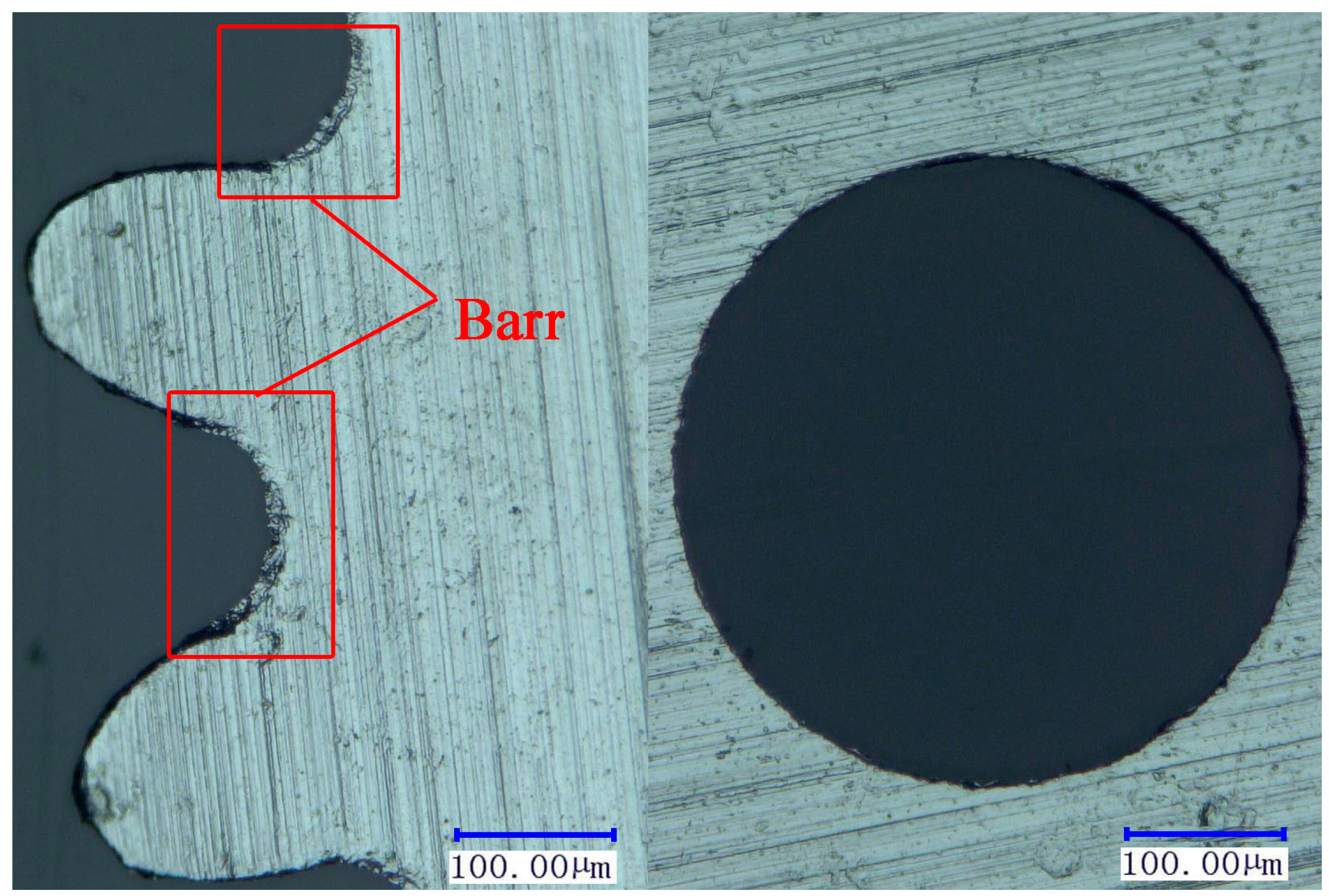

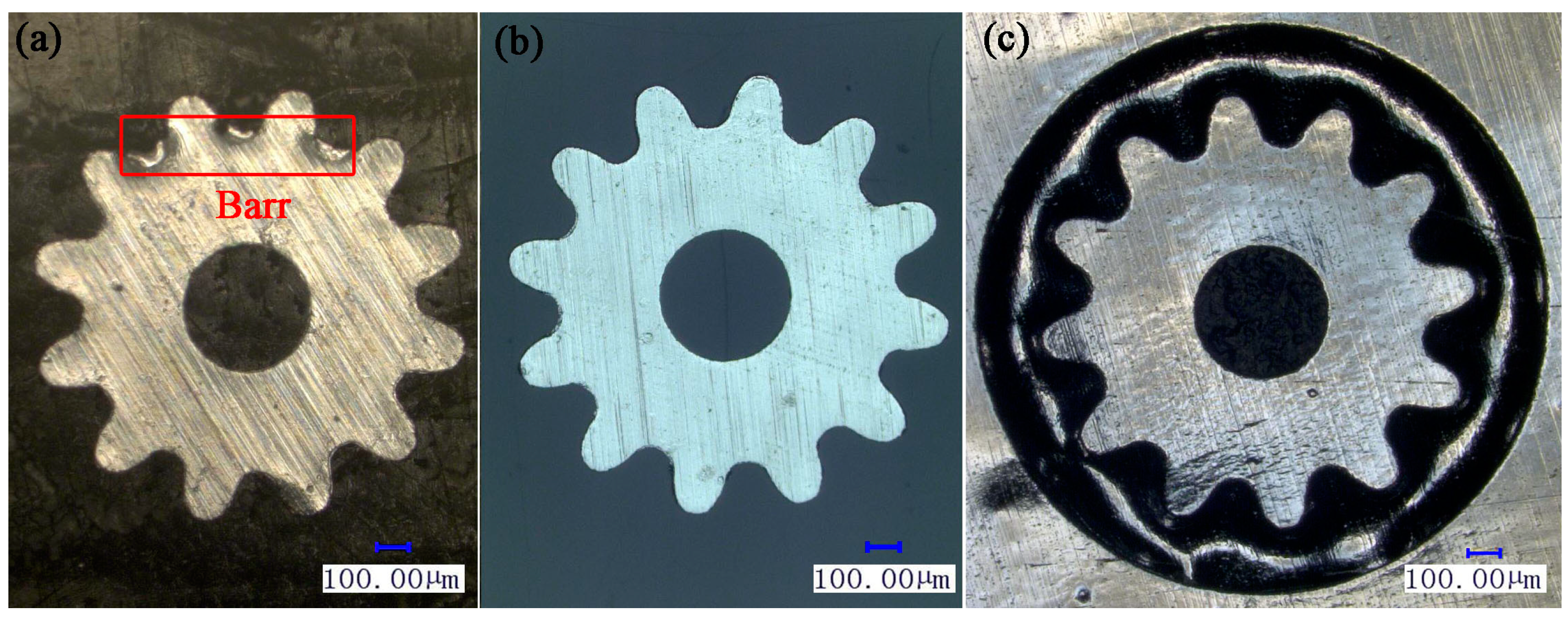

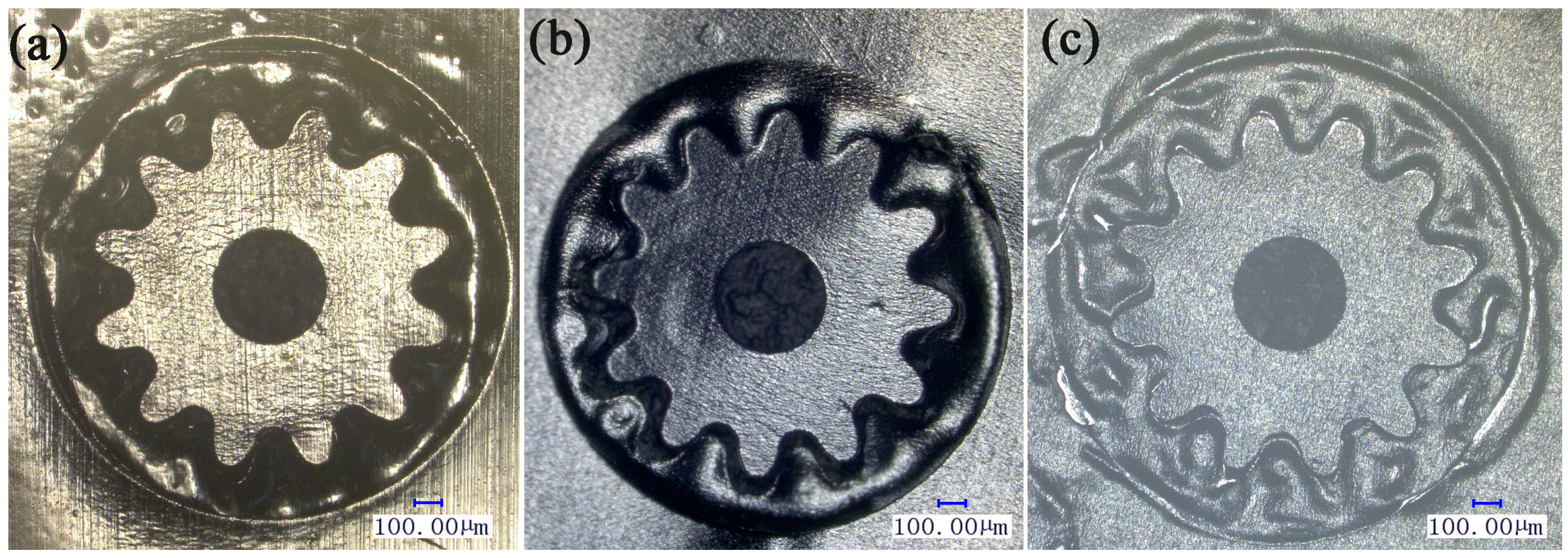

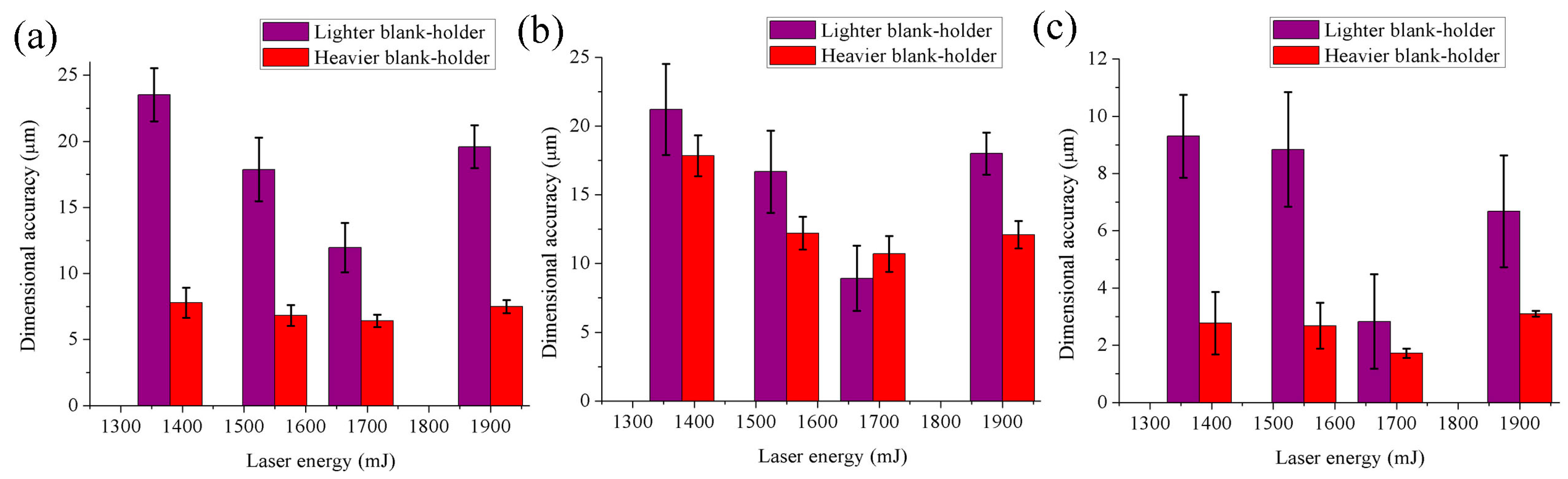

Whether the traditional micro-punching technique or the laser shock punching process, little attention has been paid to micro-gear fabrication. This paper aims to fabricate micro-gears with laser shock punching technique and conducts an in-depth research of the process parameters and its effects on the quality of micro gears.