Figure 2.

Grid dependency test for reference three-split micromixer (w1 = 0.2 mm, w21 = 0.05 mm, and w22 = 0.05 mm).

4.1. Comparison between Two-Split and Three-Split Micromixers

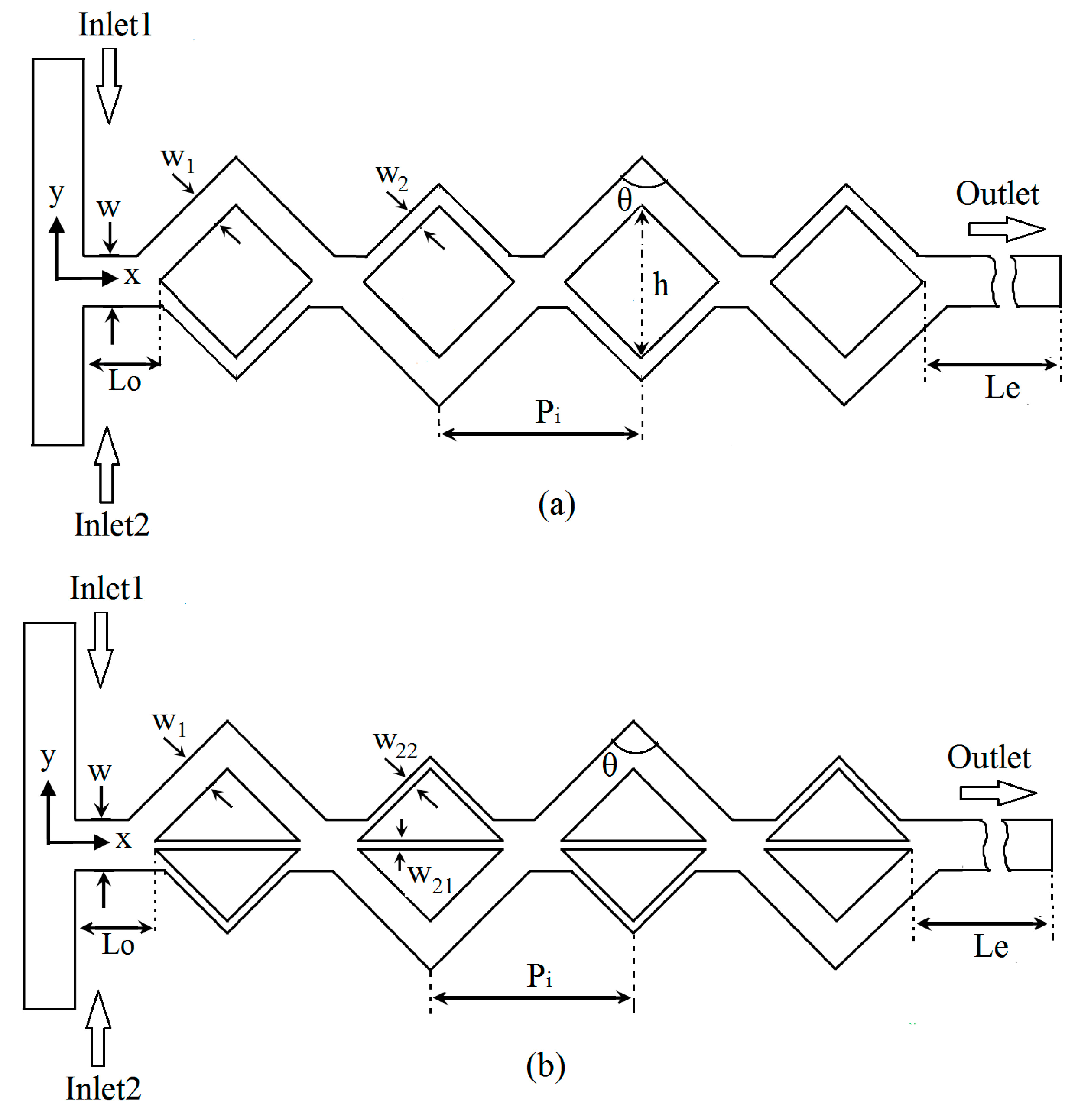

First, the performance of the reference unbalanced three-split rhombic micromixer (

Figure 1b) was evaluated compared with those of the two-split micromixer (

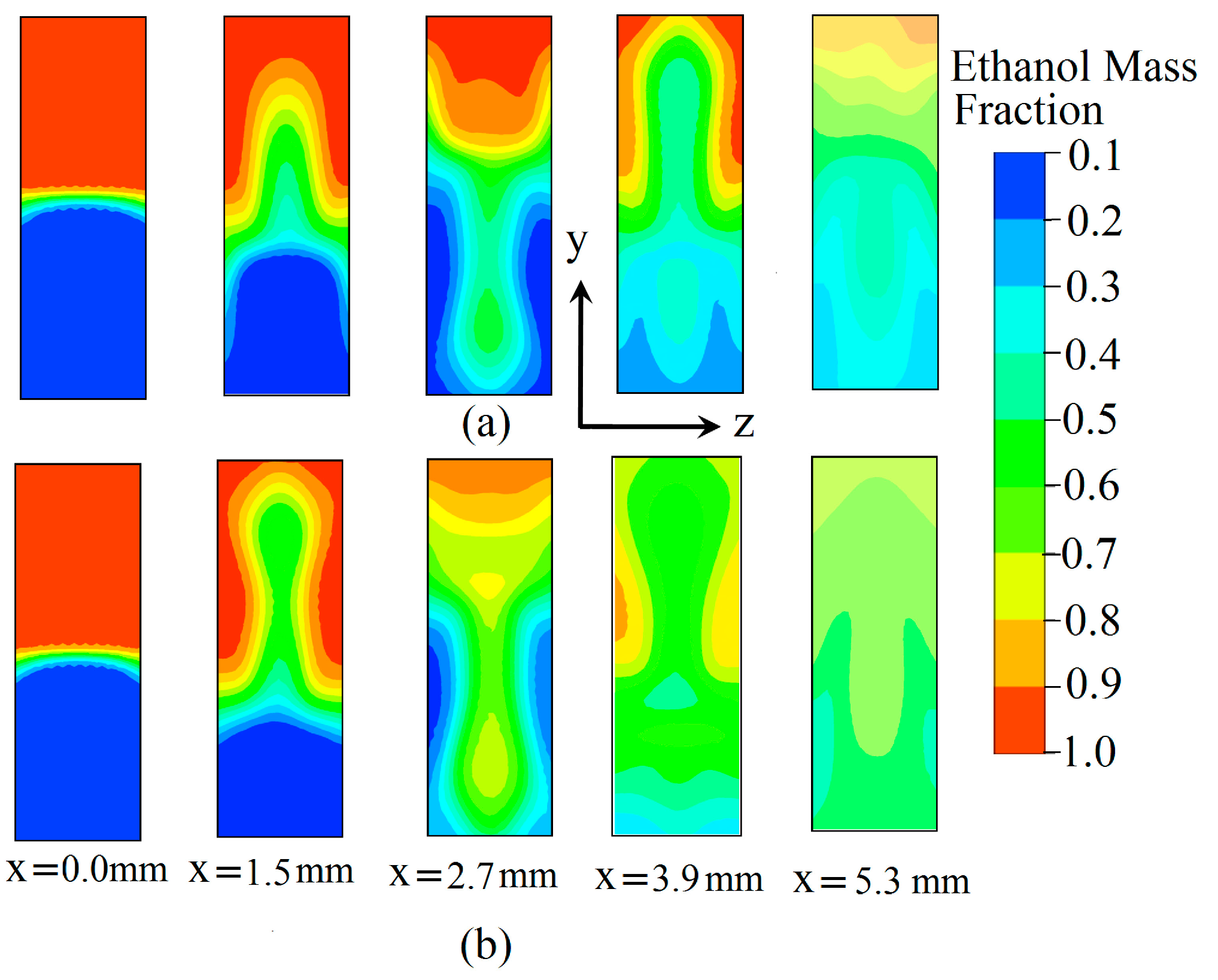

Figure 1a). Mass fraction distributions of ethanol on

y-

z planes at a Reynolds number of 60 are shown in

Figure 3. To analyze the mixing behavior, each ethanol mass fraction distribution was plotted at the exit of each rhombic unit. At

x = 0,

Figure 3a,b show that the paths of the two fluids are nearly parallel to each other, and there is no secondary flow. As the flow proceeds through the channel, secondary flows are induced, and hence the mixing is enhanced. Whenever the position of a major sub-channel is reversed, an alternation of distribution occurs. At Re = 60, the values of the mixing index at the end of the fourth cell are 0.61 and 0.86 for the two-split and three-split micromixers, respectively. To find the flow structures in unbalanced two-split and three-split rhombic micromixers, velocity vectors were plotted on the

x-

y plane at Re = 40, as shown in

Figure 4. The flow in the main channel was divided into two or three sub-streams according to their geometries, and they collided with each other in the combination zone. The same pattern was repeated in the microchannels. The magnified images show the flow phenomena in the combination zone after the third rhombic cell. The velocity vectors are parallel to the channel wall without any transverse flow in the major sub-channel, and the flow patterns are almost the same for both micromixers. No transverse flow occurred in the two-split rhombic micromixer, while two small recirculation flows were generated in the three-split unbalanced rhombic micromixer near the inlet of the minor sub-channel. Additionally, these small recirculation flows contributed to the enhancement of mixing.

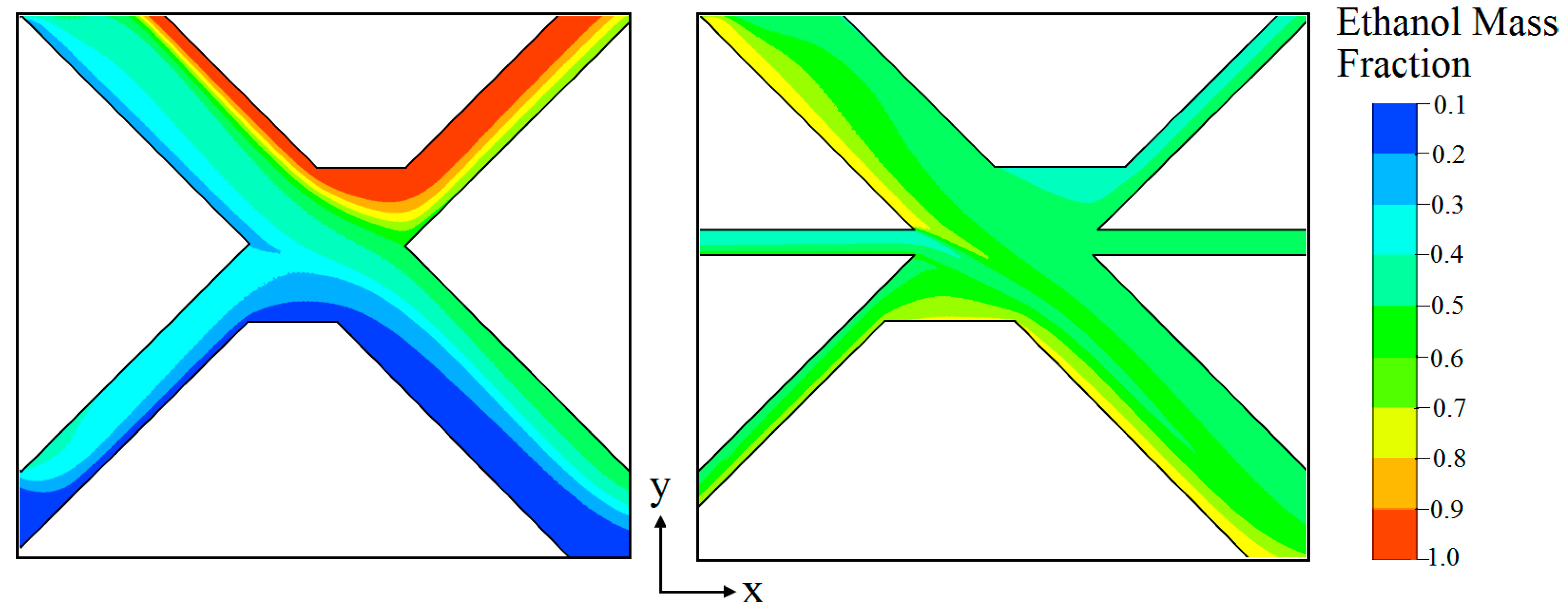

Figure 5 shows the mass fraction distributions of ethanol on the

x-

y plane at a Reynolds number of 40 in the same enlarged area indicated in

Figure 4. The figure shows that the three-split micromixer exhibited far better mixing than the two-split micromixer in this combination zone after the third rhombic cell, especially in the two small recirculation zones indicated in

Figure 4.

Figure 3.

Concentration distributions of ethanol on y-z planes at various cross-sections (Re = 60): (a) two-split unbalanced rhombic micromixer, and (b) three-split unbalanced rhombic micromixer.

Figure 3.

Concentration distributions of ethanol on y-z planes at various cross-sections (Re = 60): (a) two-split unbalanced rhombic micromixer, and (b) three-split unbalanced rhombic micromixer.

Figure 4.

Velocity vector plots on x-y plane at Re = 40 in unbalanced two-split and three-split rhombic micromixers.

Figure 4.

Velocity vector plots on x-y plane at Re = 40 in unbalanced two-split and three-split rhombic micromixers.

Figure 5.

Concentration distributions of ethanol on the

x-

y plane at Re = 40 in the region indicated in

Figure 4 in unbalanced two-split and three-split rhombic micromixers.

Figure 5.

Concentration distributions of ethanol on the

x-

y plane at Re = 40 in the region indicated in

Figure 4 in unbalanced two-split and three-split rhombic micromixers.

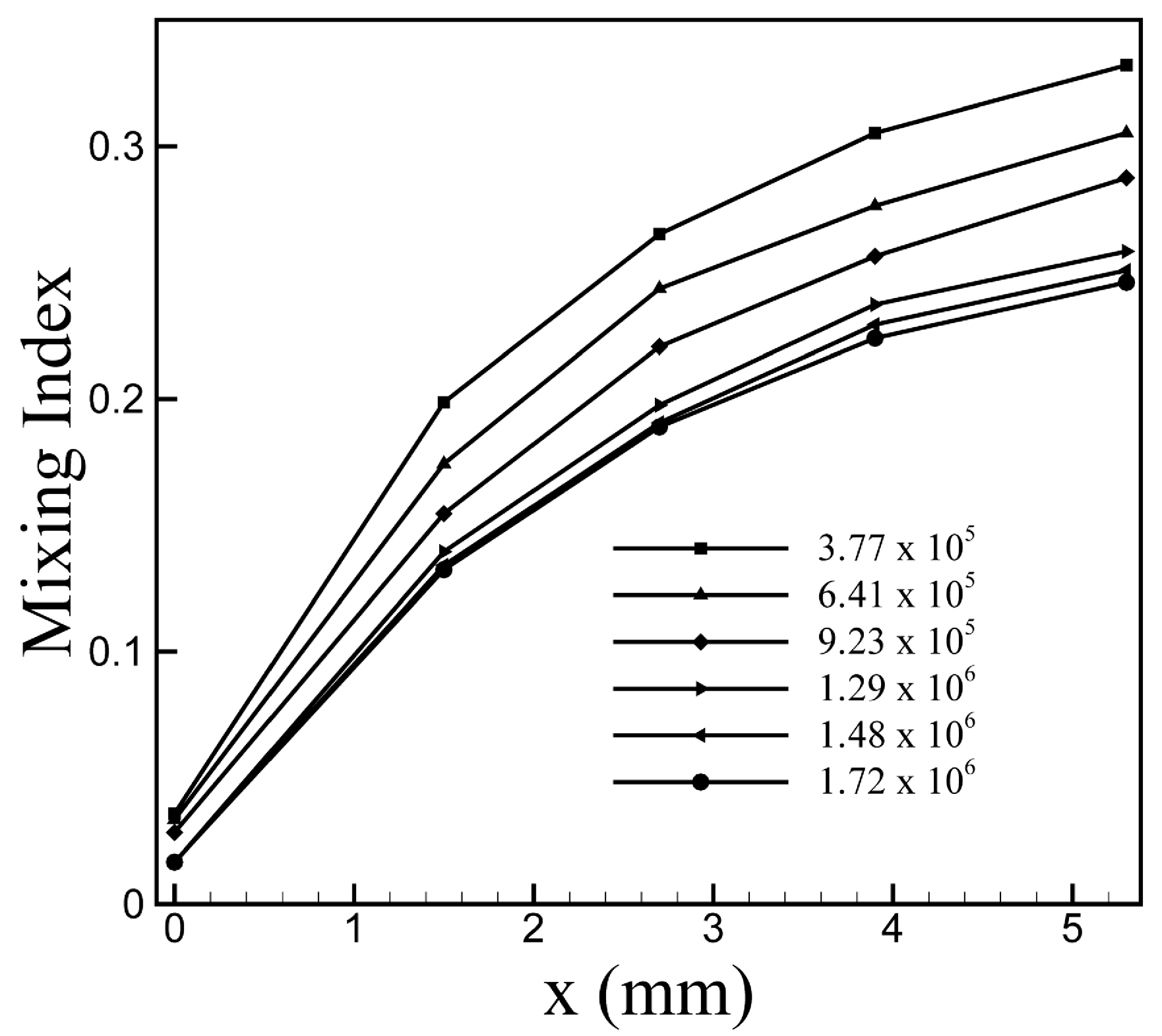

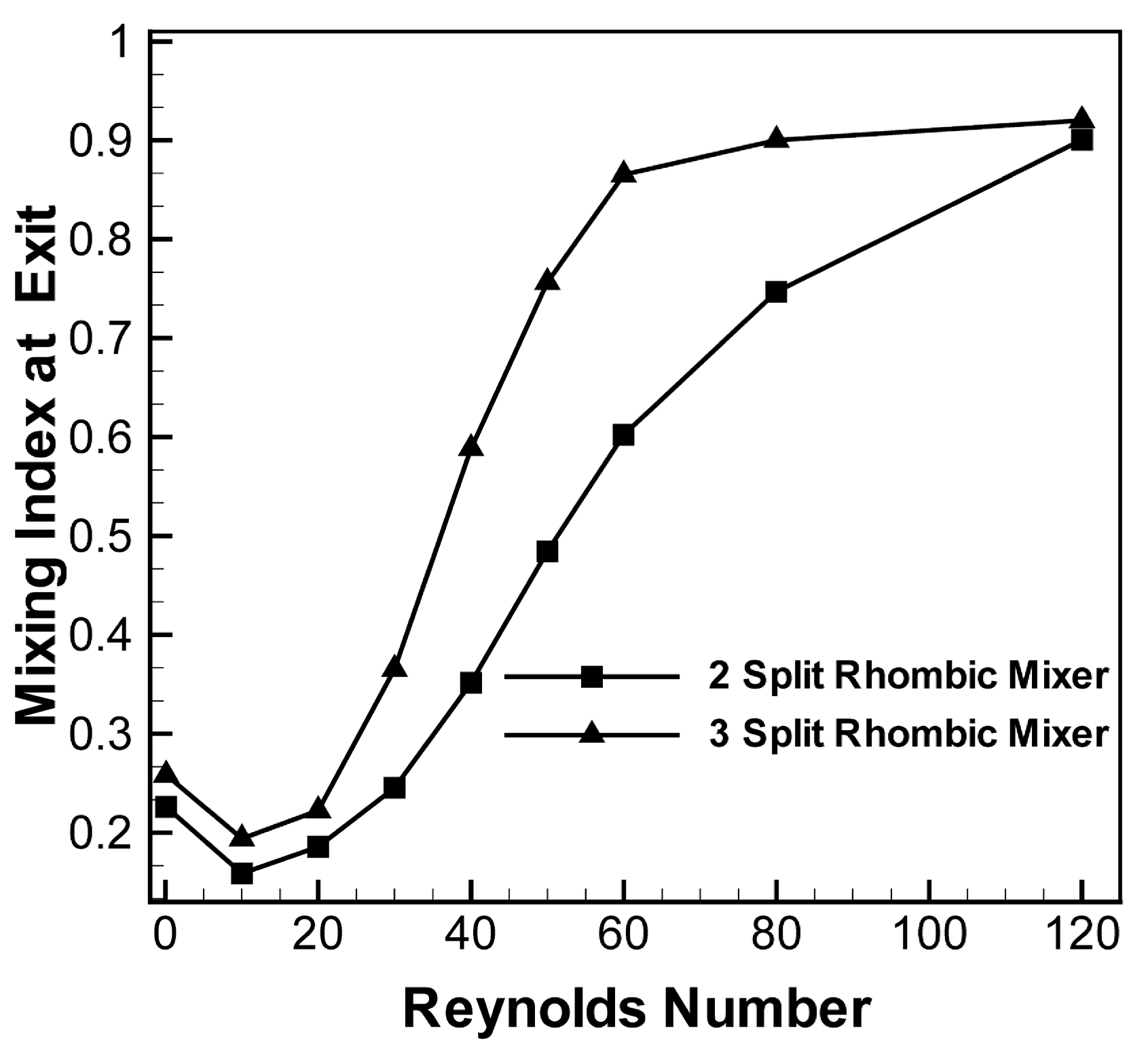

Figure 6 shows variations of the mixing index at the exit of the fourth rhombic unit (

x = 5.3 mm) of the micromixer for Reynolds numbers from 0.1–120 for the unbalanced two-split and three-split rhombic micromixers with the same axial length. At low Reynolds numbers (less than 1), the mixing is mainly governed by molecular diffusion, and mechanical stirring is ineffective [

33]. Thus, at a low Reynolds number, the mixing is dominated by the residence time and depends on the total path length of the flow. As the Reynolds number increased, the level of the mixing index decreased rapidly due to the decrease in the residence time, and reached its minimum at Re = 10. For this Reynolds number range, the residence time is insufficient and the transverse flow is still inactive; thus, the mixing index remained at the lower level. Thus, modification of the geometry of the micromixer is not so effective for mixing at these low Reynolds numbers. However, beyond this Reynolds number, even though the residence time decreased further, the transverse flows rapidly become active, and mixing started to increase as the Reynolds number increased. The micromixer with unbalanced three-split rhombic sub-channels showed better mixing performance throughout the intermediate Reynolds number range (less than 120). From Re = 20, the difference in the mixing index between the two micromixers starts to increase, and the maximum difference in the mixing index is found at Re = 50. Thereafter, the difference decreases and nearly disappears at Re = 120. Unlike the two-split micromixer, the three-split micromixer shows almost full development of the mixing index at Re = 60. At Reynolds numbers of 30, 40, 50, and 60, the mixing indices at the end of the unbalanced three-split rhombic micromixer are 1.49, 1.67, 1.56, and 1.44 times the corresponding mixing index of the unbalanced two-split rhombic micromixer, respectively.

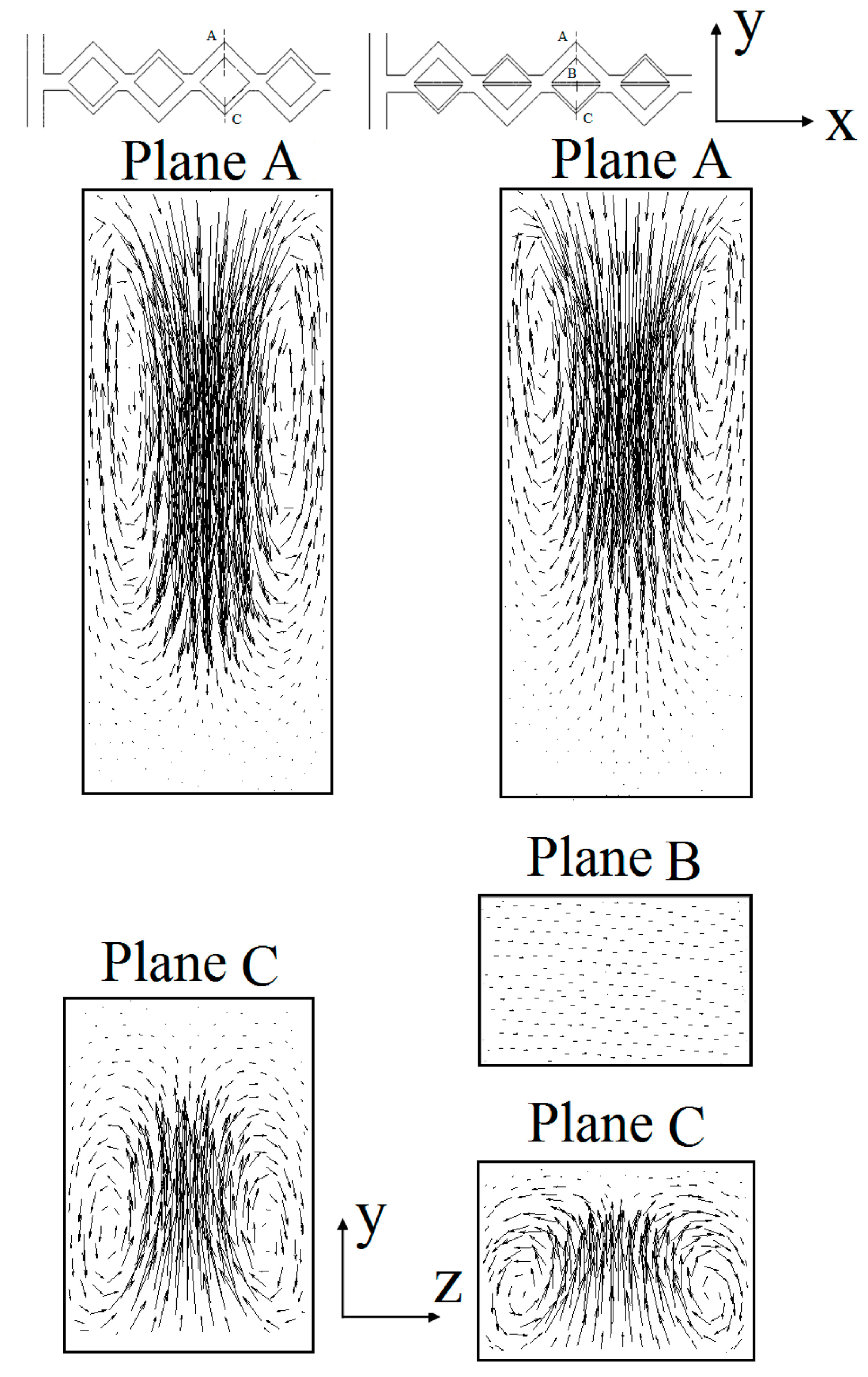

Velocity vector plots for two different rhombic micromixers at Re = 40 are shown in

Figure 7. Velocity vectors were plotted on the cross sections located at tip of the third rhombic unit (planes A, B, and C). In both micromixers, two strong counter-rotating vortices were present in the major sub-channel (plan A). Compared to the micromixer with two-split sub-channels in the three-split micromixer, the center of the vortices shifted to the top of the cross-section. As a result, the velocity vectors became weak near the bottom of the plane. Velocity vectors on planes B and C represent the flow structures in the minor sub-channels. Two counter-rotating vortices were also observed in plane C in both micromixers. In the case of the three-split micromixer, two comparatively small circular-shaped vortices occupied most of the cross-sectional area of the channel, whereas in the two-split micromixer elliptical counter-rotating vortices shifted to the bottom. In the three-split micromixer, weak transverse flow occurred at plane B.

Figure 6.

Variations in the mixing index at the exit of the micromixer versus Reynolds number.

Figure 6.

Variations in the mixing index at the exit of the micromixer versus Reynolds number.

Figure 7.

Velocity vector plots on y-z planes at Re = 40 in unbalanced two-split and three-split rhombic micromixers.

Figure 7.

Velocity vector plots on y-z planes at Re = 40 in unbalanced two-split and three-split rhombic micromixers.

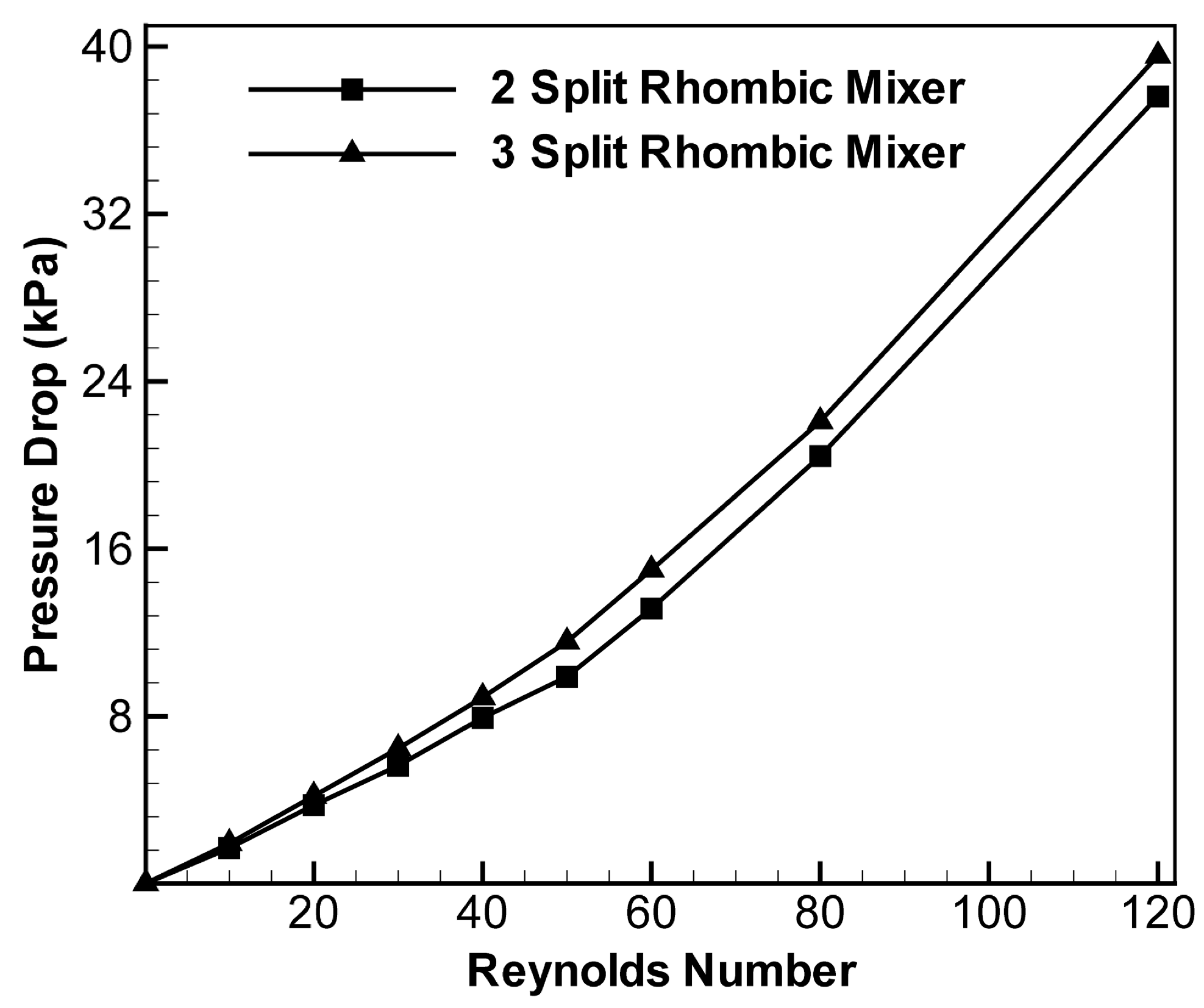

Figure 8 shows the pressure drop characteristics as a function of Reynolds number in a range of Reynolds number from 0.1–120 for both micromixers. In all cases, the pressure drop was calculated at the exit of the fourth rhombic unit (

x = 5.3 mm). The pressure drop increases with the Reynolds number for both cases. At lower Reynolds numbers (less than 10), where wall friction is small and the transverse flow is inactive, the effect of micromixer geometry on pressure drop is almost negligible. Beyond this Reynolds number, the three-split micromixer shows a higher pressure drop due to the higher wall friction and stronger transverse motion, but the relative increase in the pressure drop is less than only 16.8% throughout the Re range.

Figure 8.

Variations of the pressure drop with Reynolds number in unbalanced two-split and three-split rhombic micromixers.

Figure 8.

Variations of the pressure drop with Reynolds number in unbalanced two-split and three-split rhombic micromixers.

4.2. Effects of Design Parameters on Mixing and Pressure Drop

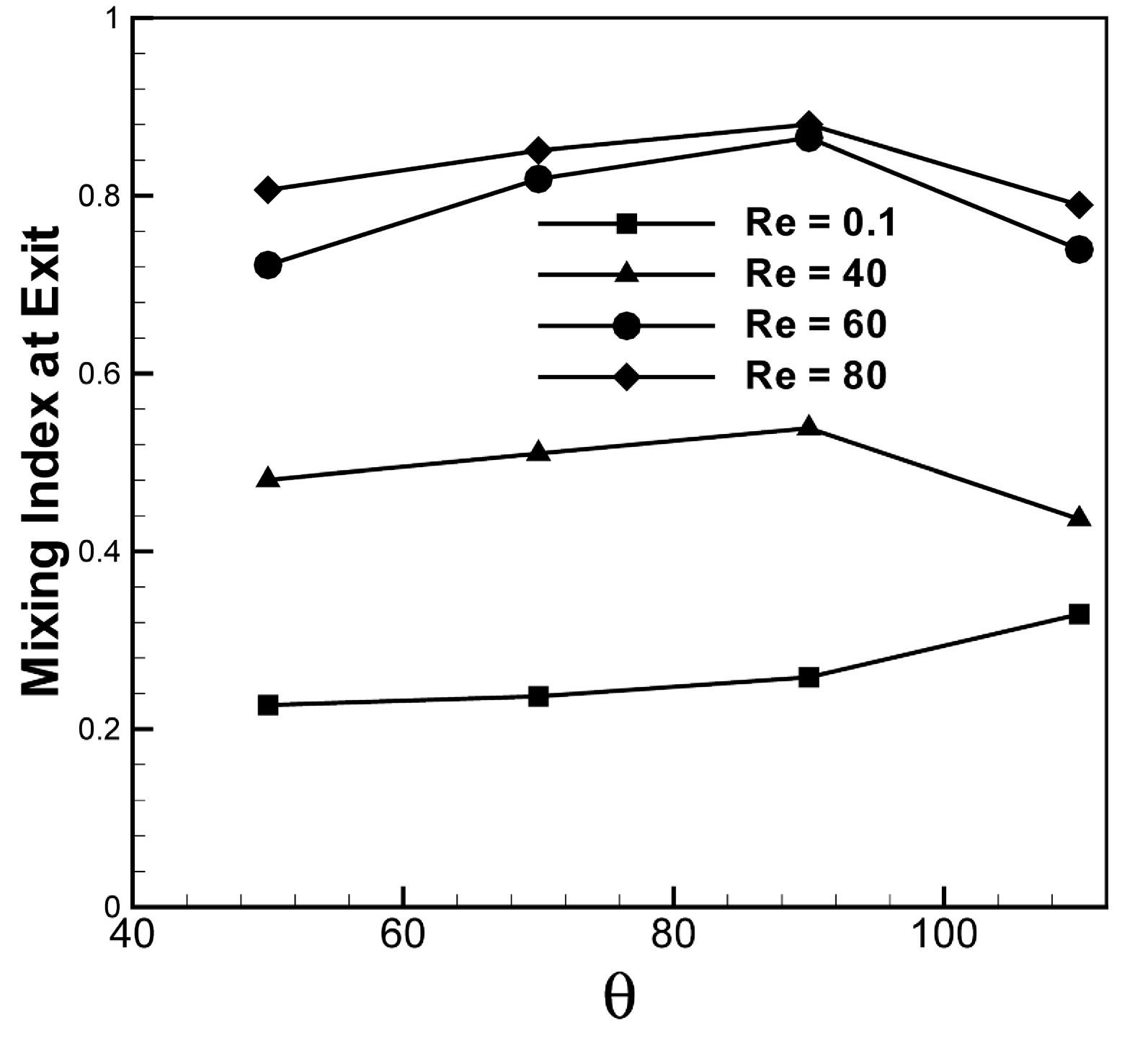

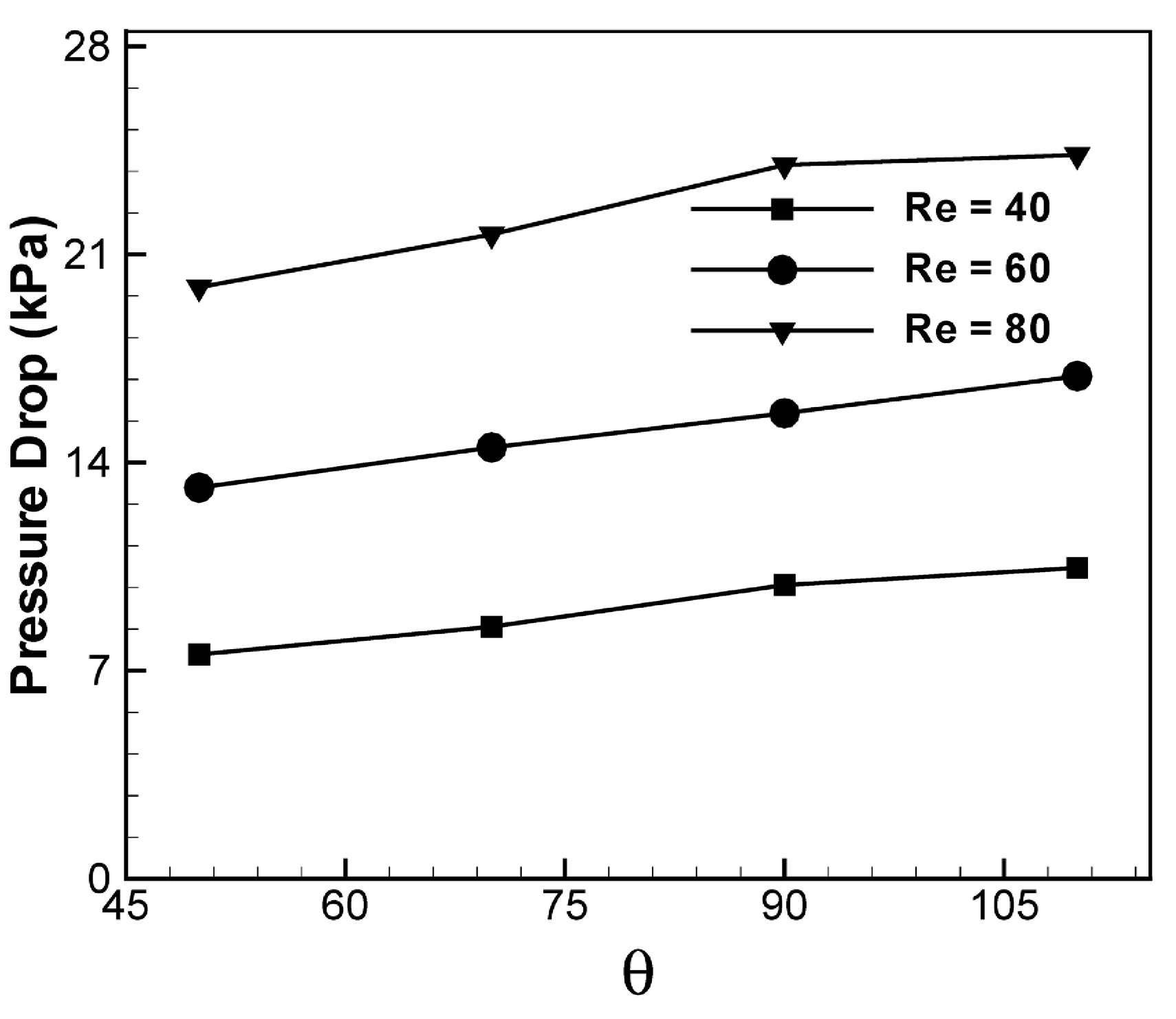

To analyze the effect of the rhombic angle (θ in

Figure 1) on mixing, the variations of the mixing index at the exit of the three-split micromixer

versus θ for Reynolds numbers ranging from 0.1–80 were plotted, as shown in

Figure 9. The total number of rhombic units was kept constant. θ was varied from 50°–110°, and the pitch (Pi) was changed with the fixed height,

h, according to the change in θ.

Figure 9 shows that the mixing index has a maximum value at 90° except for the lowest Reynolds number, Re = 0.1. At Re = 0.1, the mixing index increased as the angle increased throughout the test range of the angle. With the increase in the angle, the flow path increased, thereby resulting in an increase in residence time. This enhanced mixing at low Reynolds numbers, where mixing is mainly governed by molecular diffusion.

Figure 9 also demonstrates that a Reynolds number of 60 shows the largest variation in the mixing index with θ among the tested Reynolds numbers.

To determine why the mixing index shows its maximum at θ = 90°, the flow structures were plotted for different rhombic angles at Re = 50 (

Figure 10). Velocity vectors were plotted on two

y-

z planes (AB and CD) just before and after the apex of the first rhombus, respectively. The flow patterns at plane AB are almost identical for all cases, and no transverse flow was observed throughout the cross-sectional area. At plane CD, the micromixer with θ = 50° creates a single elliptical vortex near the outer wall. A pair of counter-rotating vortices occur at θ = 70° and 110°. The centers of the vortices shifted to the outer wall at θ = 70°. Two pairs of counter-rotating vortices that occupy the entire cross-sectional area appear at θ = 90°. The strongest transverse motion produces the highest mixing index at θ = 90°, as shown in

Figure 9.

Figure 11 shows the effect of the rhombic angle on pressure drop in the three-split micromixer at Reynolds numbers of 40, 60, and 80. Pressure drops were calculated at the exit of the fourth rhombic unit for all cases. The pressure drop slowly increases at nearly a constant rate as the angle increases from 50°–110° for all tested Reynolds numbers. In the case of the three-split micromixer shown in

Figure 1a, as the angle increases, the total flow path increases due to the increase in the pitch with fixed height, which contributes to the increase in pressure drop.

Figure 9.

Effect of rhombic angle on mixing in the three-split micromixer for various Reynolds numbers.

Figure 9.

Effect of rhombic angle on mixing in the three-split micromixer for various Reynolds numbers.

Figure 10.

Velocity vector plots on y-z planes at Re = 50 in the three-split micromixer for various rhombic angles.

Figure 10.

Velocity vector plots on y-z planes at Re = 50 in the three-split micromixer for various rhombic angles.

Figure 11.

Effect of rhombic angle on the pressure drop in the three-split micromixer for various Reynolds numbers.

Figure 11.

Effect of rhombic angle on the pressure drop in the three-split micromixer for various Reynolds numbers.

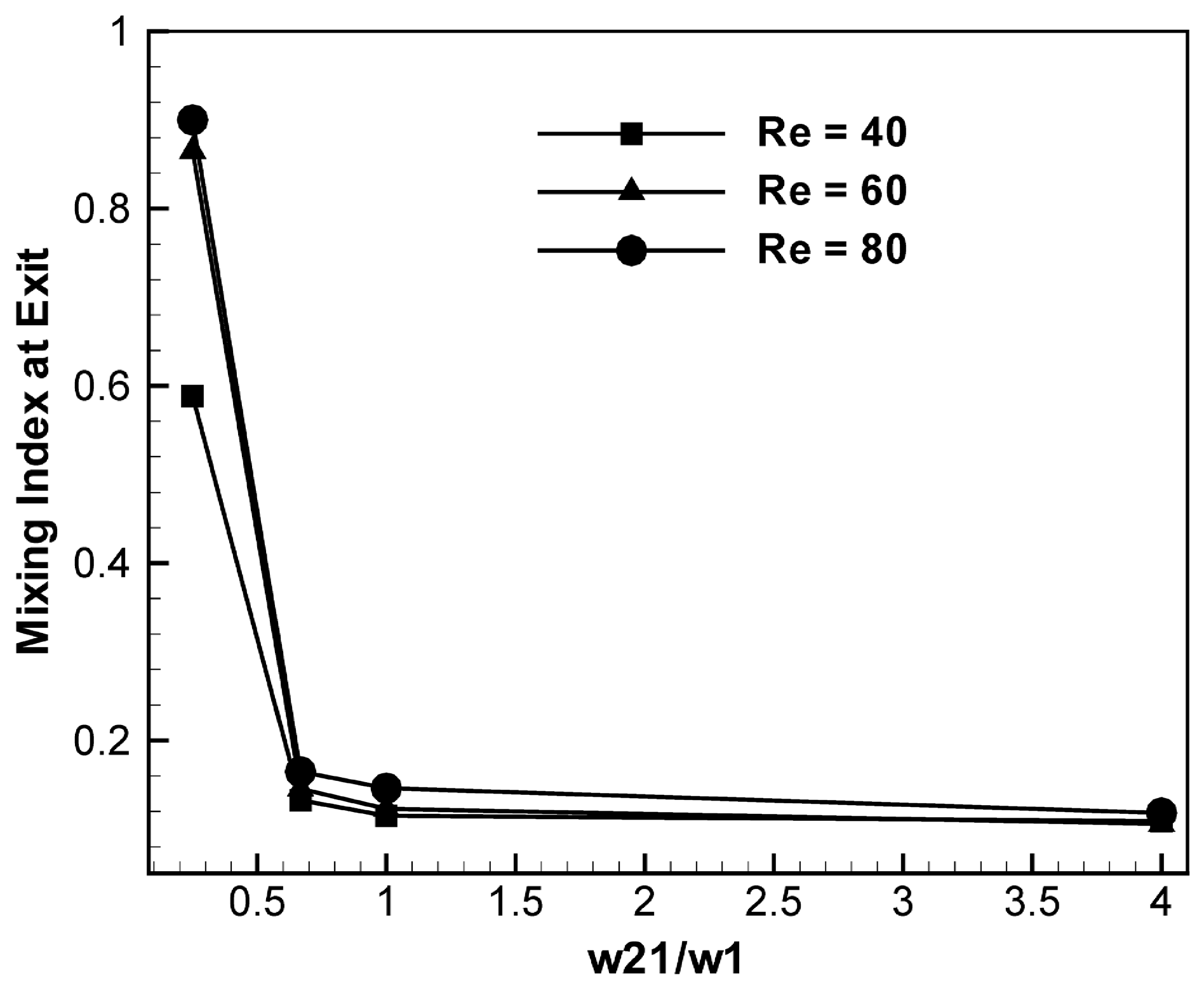

Figure 12 shows the effect of channel width on mixing at the exit of the fourth rhombic unit with Reynolds numbers of 40, 60, and 80. To understand the effect of sub-channel width on mixing performance and pressure drop, the value of the dimensionless parameter

w21/

w1 was varied from 0.25 to 4.0, as shown in

Figure 13. The other geometric parameters (pitch, Pi, channel height,

h, θ, and

w = 0.3 mm) were kept constant. At the minimum value of

w21/

w1 (

w21/

w1 = 0.25), the mixing index reaches the maximum regardless of the Reynolds number, as shown in

Figure 12. With an increase in

w21/

w1 from 0.25 to 1.0 mm, the mixing index decreases significantly. A further increase in

w21/

w1 causes only a slight decrease in the mixing index. A Reynolds number of 40 results in a much smaller mixing index than the other Reynolds numbers at

w21/

w1 = 0.25, but at the other values of

w21, the mixing indices do not show much of a difference.

Figure 12.

Effect of width of minor sub-channel 1 (w21) on mixing in the three-split micromixer for various Reynolds numbers.

Figure 12.

Effect of width of minor sub-channel 1 (w21) on mixing in the three-split micromixer for various Reynolds numbers.

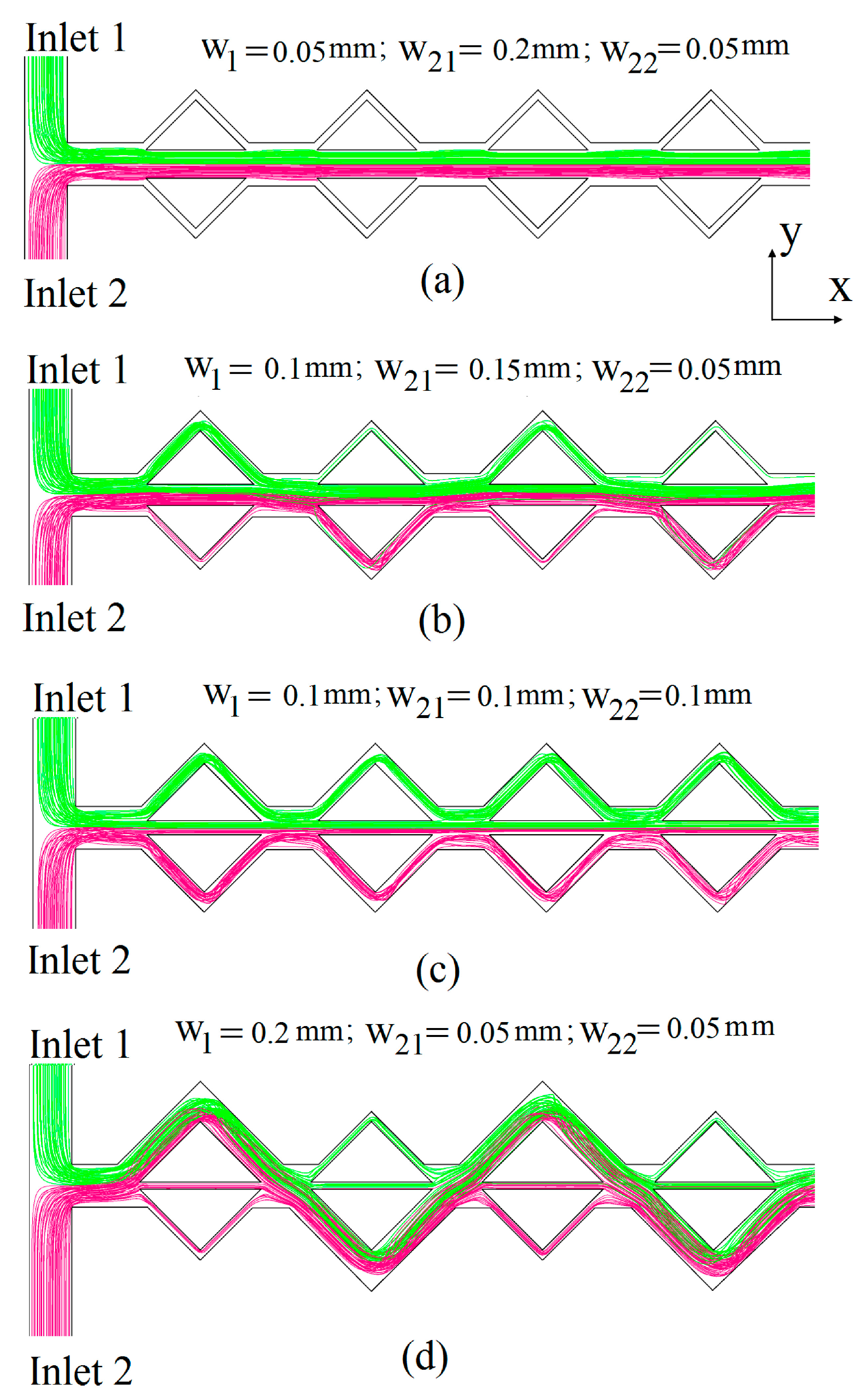

The mechanism of mixing between the fluids in the sub-channels, and the effect of sub-channel widths on mixing, can be seen in

Figure 13, which shows projected streamlines of two different fluids entering from Inlet 1 and Inlet 2, respectively, at Re = 40.

Figure 13a shows that the fluids entering from Inlet 1 and Inlet 2 mix at the T-joint, and most of the streamlines go to minor sub-channel 1 throughout the micromixer. Therefore, the unbalanced three-split rhombic micromixer with

w21/

w1 = 4.0 acts as a simple T-mixer, and mixing mainly occurs due to diffusion at the interface of the fluids.

Figure 13b shows that for

w21/

w1 = 1.5, the streamlines from Inlet 1 enter the major sub-channel and minor sub-channels while most of the streamlines from Inlet 2 pass through minor sub-channel 1. Almost 95% of the total streamlines pass through minor sub-channel 1 with

w21 = 0.15 mm.

Figure 13c shows that for equal sub-channel widths (

w21/

w1 = 1.0), almost a half of the total number of streamlines pass through minor sub-channel 1. The remaining streamlines pass through the other sub-channels equally. Flow streamlines entering from each inlet stay in the sub-channel on their own side, and do not cross or alter each other.

Figure 13d for the case with

w21/

w1 = 0.25 shows the best mixing performance (

Figure 12), and indicates that the streamlines from Inlet 2 are divided into mainly two sub-streams. Most of the streamlines enter the major sub-channel and the remaining streamlines enter minor sub-channel 1, while the streamlines from Inlet 1 mostly go to the major sub-channel. After the first rhombic cell, the streamlines from the major sub-channel are divided into three sub-streams: the larger part goes to the next major sub-channel, and the remaining part enters the minor sub-channels equally. The streamlines from minor sub-channel 1 mostly go to the major sub-channel due to the inertia of the fluid. After the second rhombic unit, the streamlines mix at the combination zone and are divided into sub-streams in a similar fashion. This complicated SAR process enhances the mixing in the unbalanced three-split micromixer.

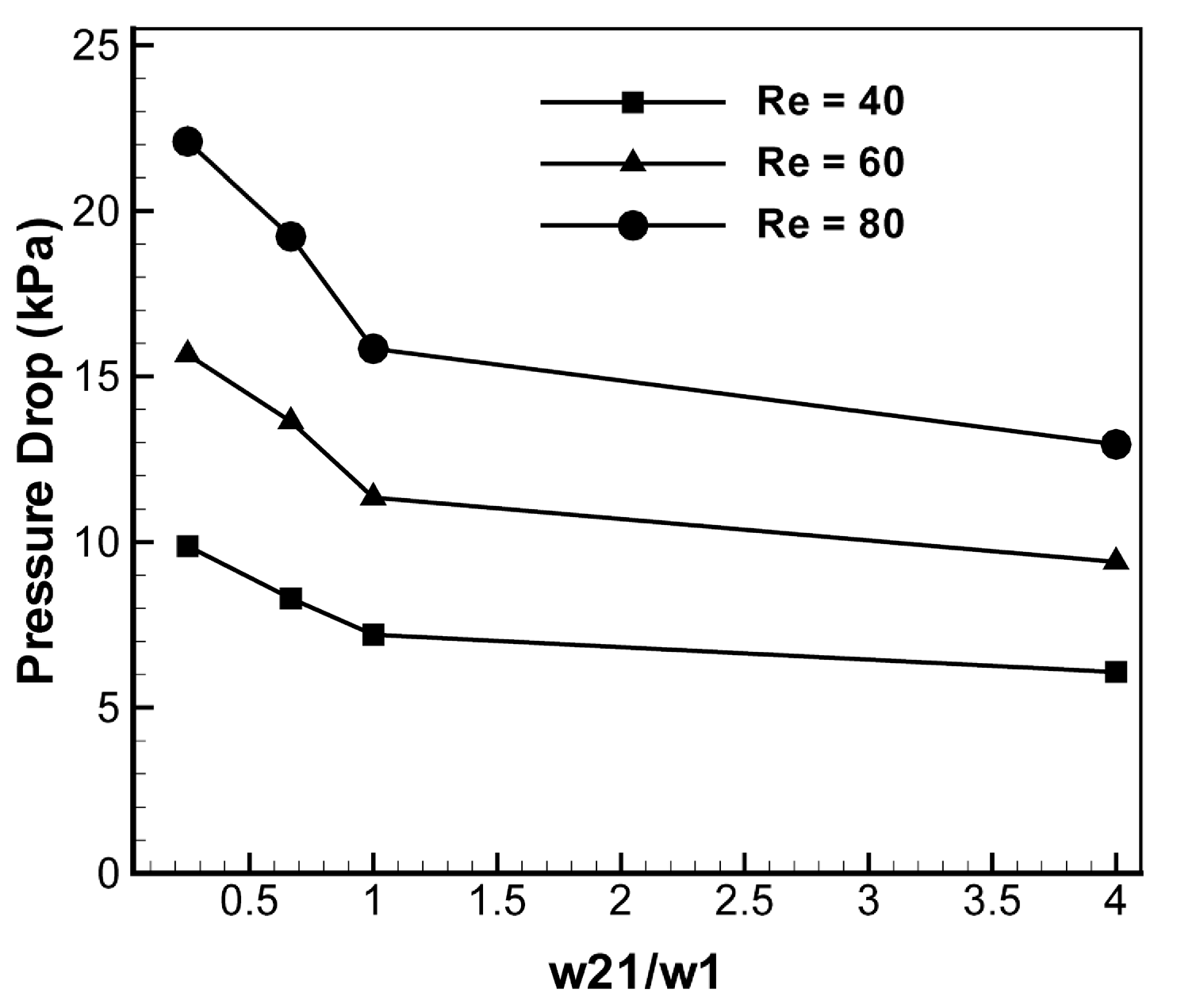

The effects of w

21 on the pressure drop for Reynolds numbers of 40, 60, and 80 are shown in

Figure 14. An equal axial distance of

x = 5.3 mm was used to calculate the pressure drops. As

w21/

w1 increases, the pressure drop decreases at a nearly constant rate. This indicates that the wider central sub-channel causes the lower pressure drop, because it does not require a change in the flow direction of the incoming flow.

Figure 13.

Projected streamlines starting from Inlet 1 and Inlet 2 at middle height of the channel and Re = 40 for the three-split micromixer for various minor sub-channel widths.

Figure 13.

Projected streamlines starting from Inlet 1 and Inlet 2 at middle height of the channel and Re = 40 for the three-split micromixer for various minor sub-channel widths.

Figure 14.

Effect of sub-channel width on the pressure drop for various Reynolds numbers.

Figure 14.

Effect of sub-channel width on the pressure drop for various Reynolds numbers.