Stop-flow Lithography to Continuously Fabricate Microlens Structures Utilizing an Adjustable Three-Dimensional Mask

Abstract

:1. Introduction

2. Experimental Section

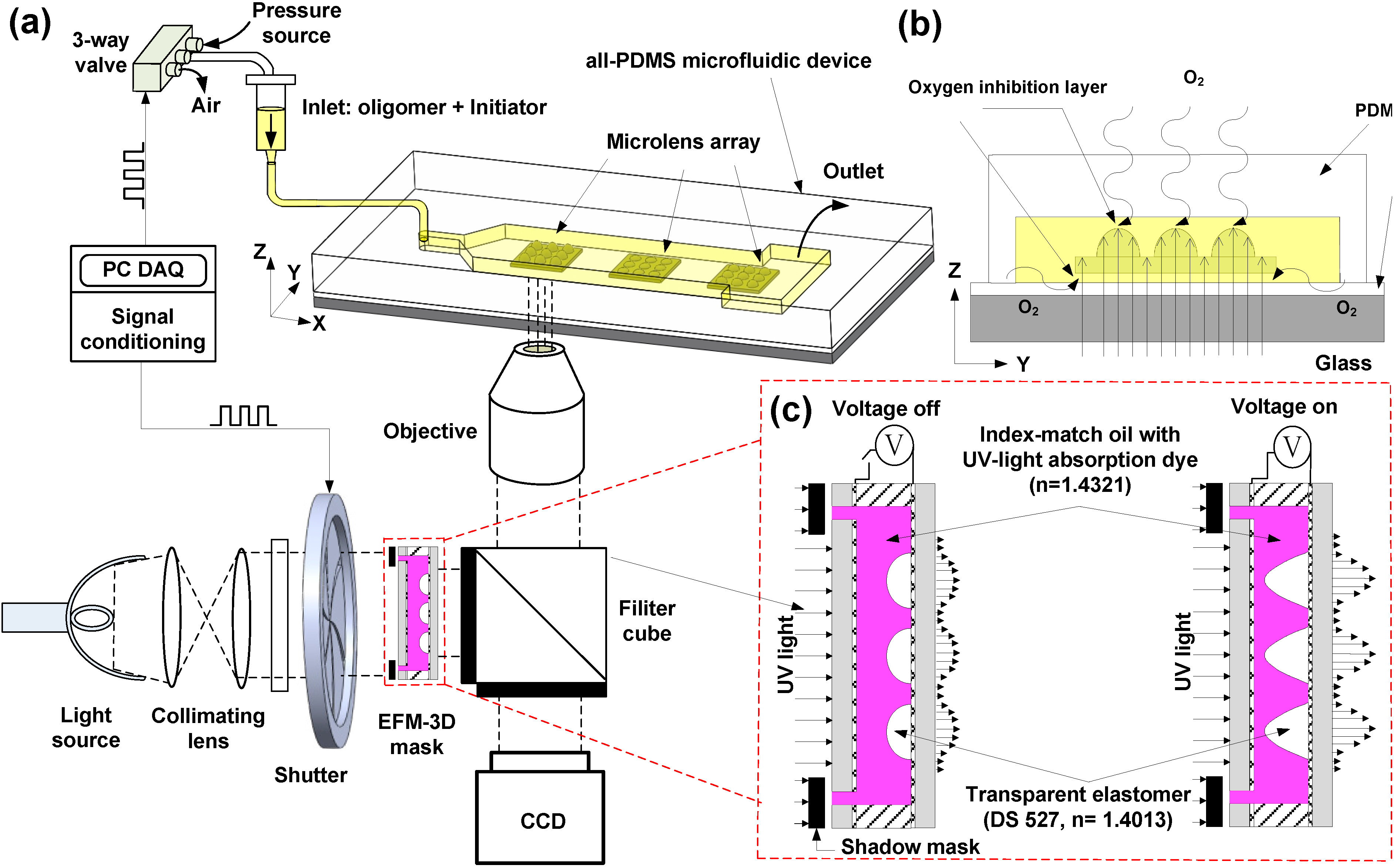

2.1. Principle of Operation

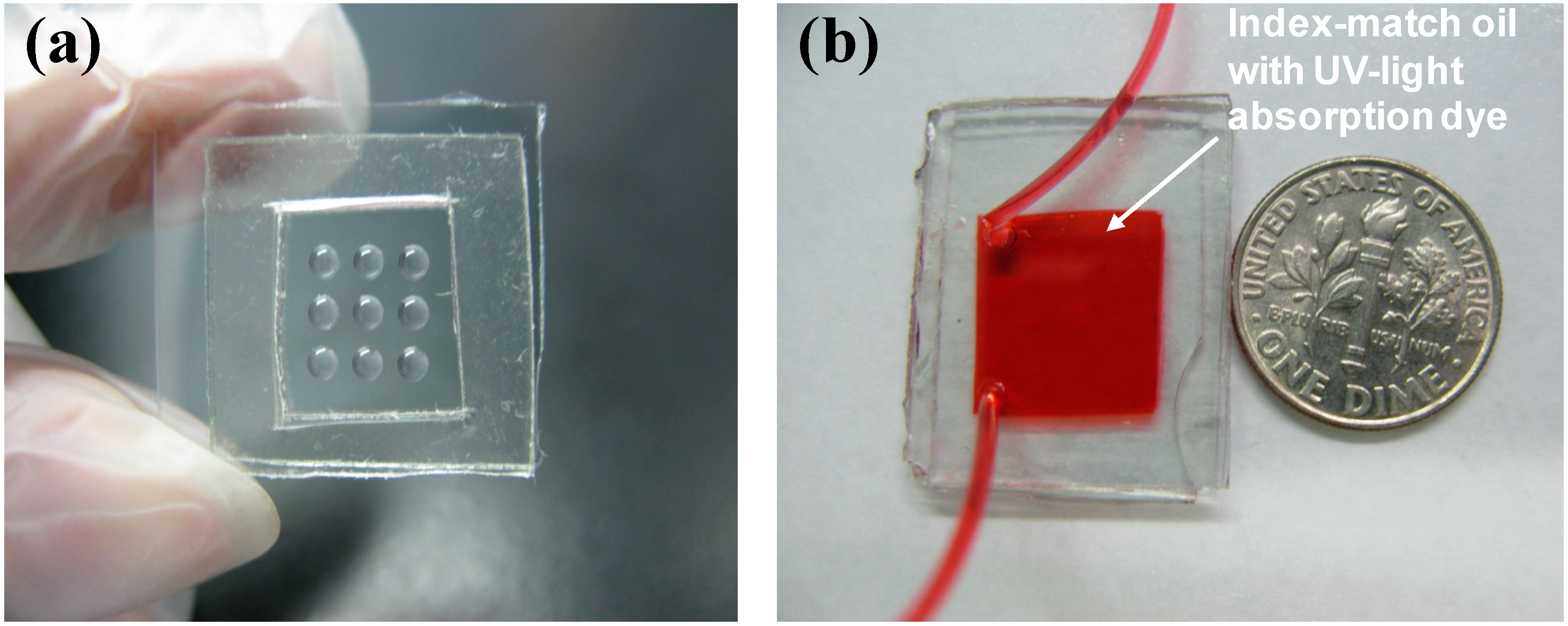

2.2. Fabrication of Adjustable EFM-3D Mask and PDMS Microchannel

2.3. Materials

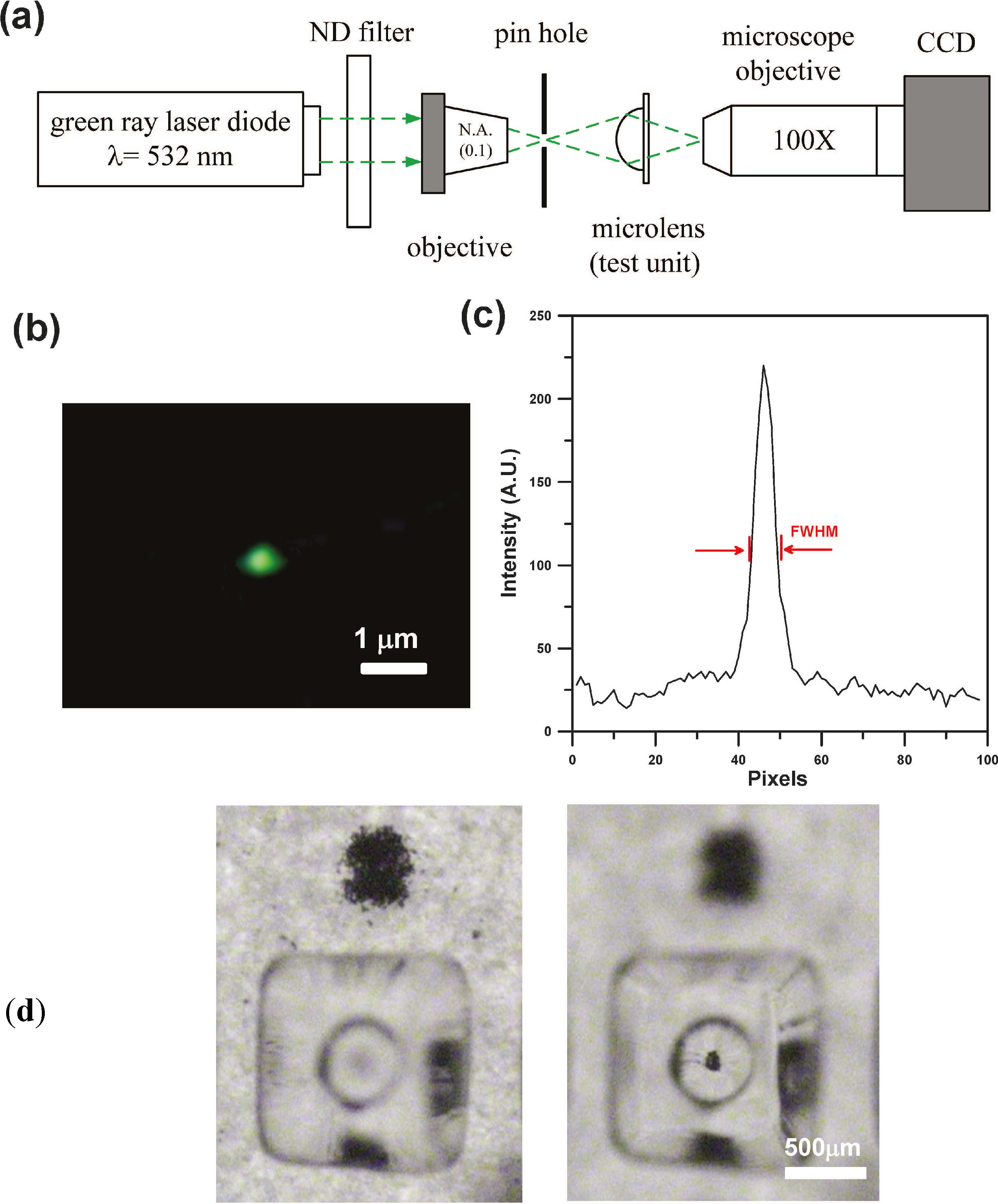

2.4. Experimental Setup of the Stop-Flow Lithography

3. Results and Discussion

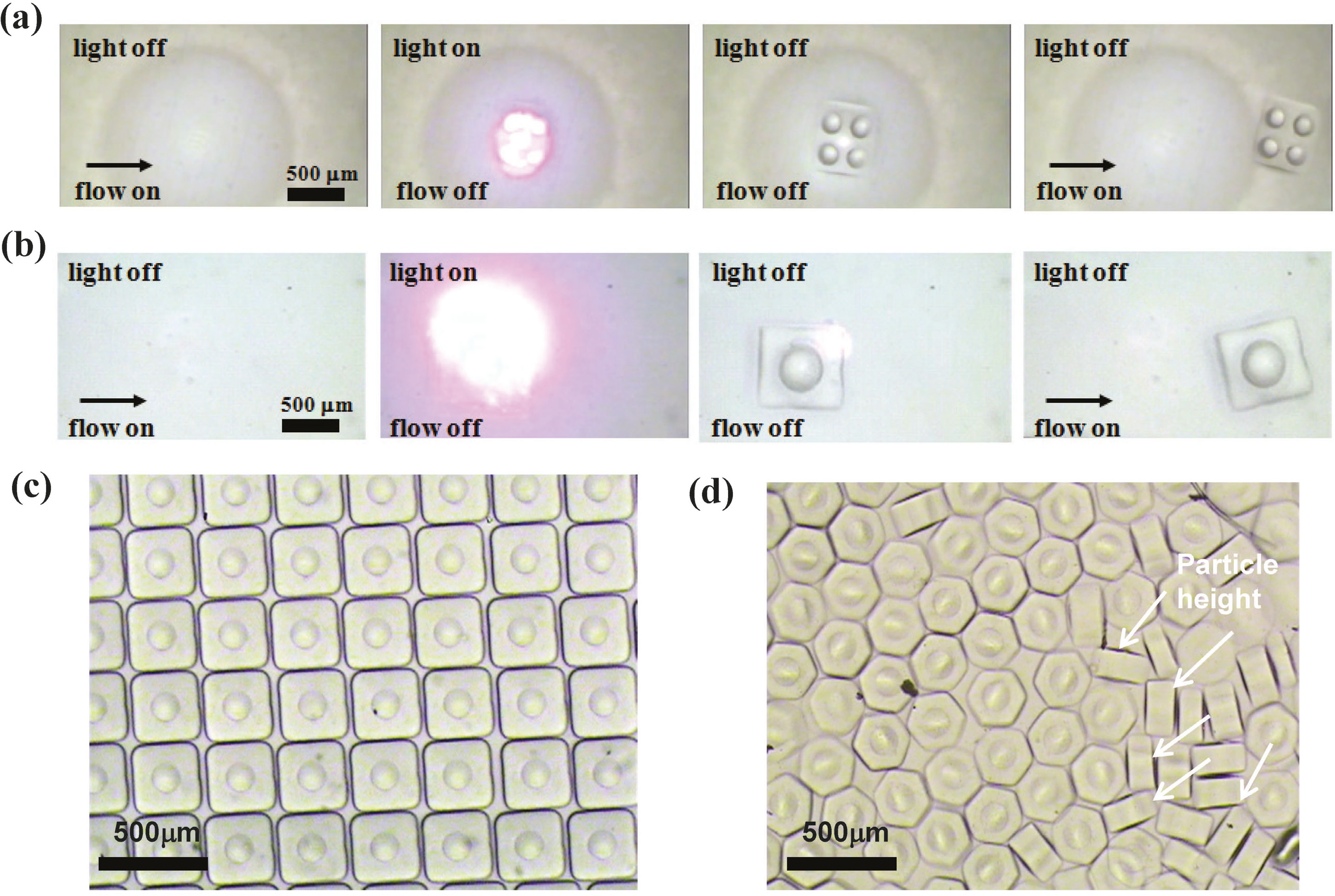

3.1. Photopolymerized Microlens Structures via EFM-3D Masks

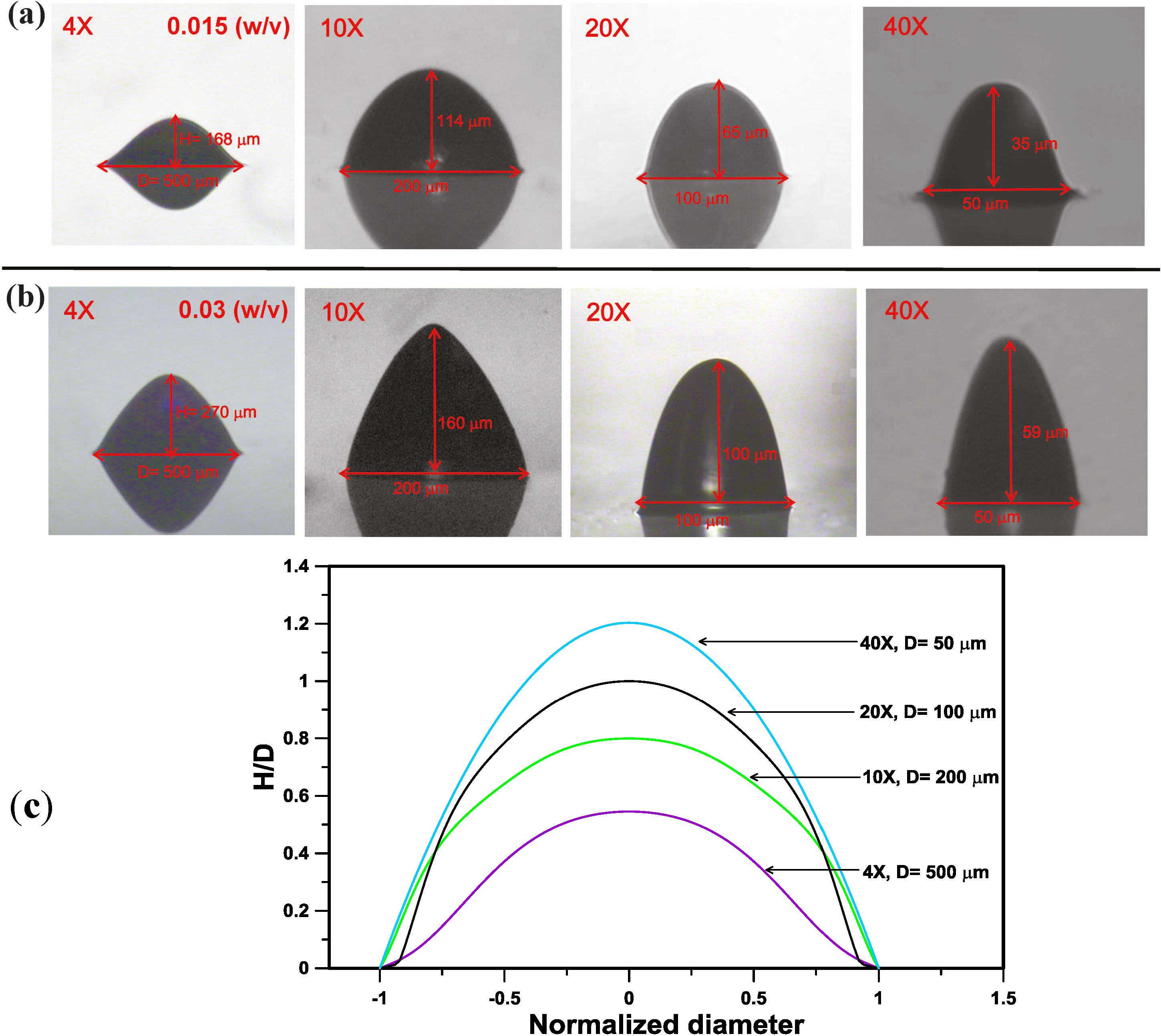

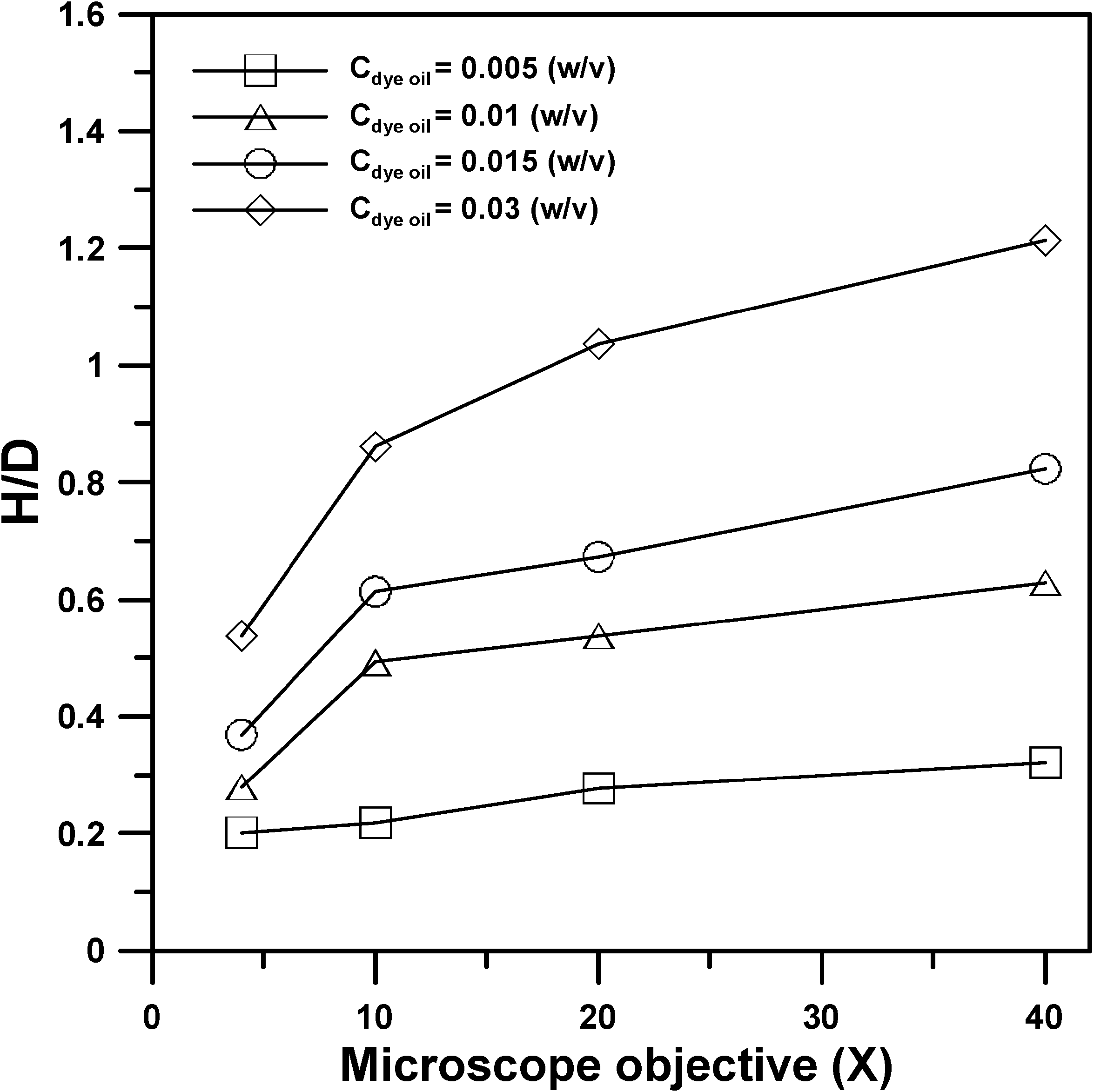

3.2. Morphology Control of the Photopolymerized Microlens Structures

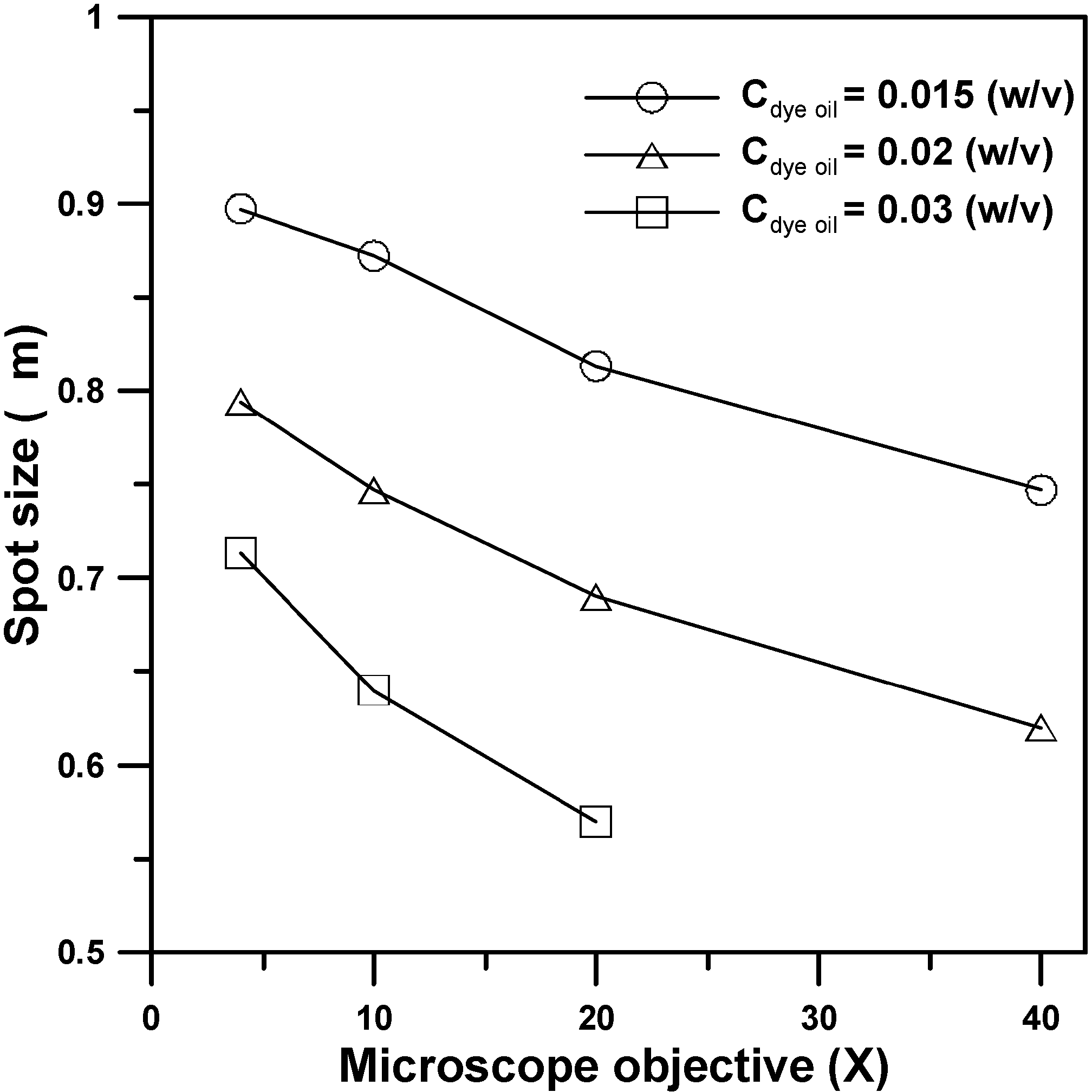

3.3. Spot Size Measurements of the Produced Microlens Structures

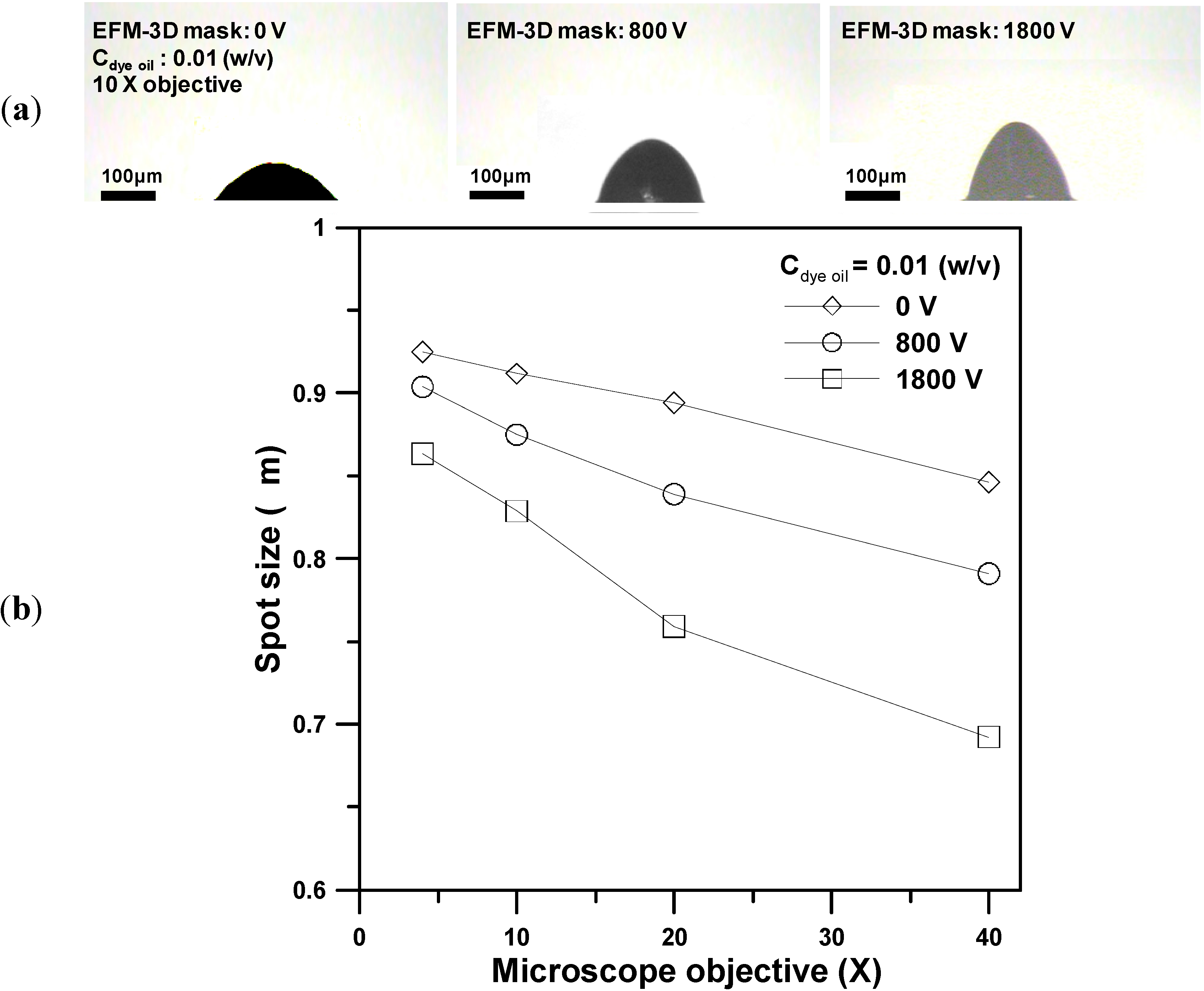

3.4. Adjust the EFM-3D Mask through Electrostatic Force to Produce Microlens Structures

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dendukuri, D.; Gu, S.S.; Pregibon, D.C.; Hatton, T.A.; Doyle, P.S. Stop-flow lithography in a microfluidic device. Lab Chip 2007, 7, 818–828. [Google Scholar] [CrossRef] [PubMed]

- Shepherd, R.F.; Panda, P.; Bao, Z.; Sandhage, K.H.; Hatton, T.A.; Lewis, J.A.; Doyle, P.S. Stop-flow lithography of colloidal, glass, and silicon microcomponents. Adv. Mater. 2008, 20, 1–6. [Google Scholar] [CrossRef]

- Suh, S.K.; Bong, K.W.; Hatton, T.A.; Doyle, P.S. Using stop-flow lithography to produce opaque microparticles: Synthesis and modeling. Langmuir 2011, 27, 13813–13819. [Google Scholar] [CrossRef] [PubMed]

- Suh, S.K.; Yuet, K.; Hwang, D.K.; Bong, K.W.; Doyle, P.S.; Hatton, T.A. Synthesis of nonspherical superparamagnetic Particles: In situ coprecipitation of magnetic nanoparticles in microgels prepared by stop-flow lithography. J. Am. Chem. Soc. 2012, 134, 7337–7343. [Google Scholar] [CrossRef] [PubMed]

- Baah, D.; Donnell, T.; Tigner, J.; Floyd-Smith, T. Stop flow lithography synthesis of non-spherical metal oxide particles. Particuology 2014, 14, 91–97. [Google Scholar] [CrossRef]

- Hwang, D.K.; Oakey, J.; Toner, M.; Arthur, J.A.; Anseth, K.S.; Lee, S.; Zeiger, A.; Van Vliet, K.J.; Doyle, P.S. Stop-flow lithography for the production of shape-evolving degradable microgel particles. J. Am. Chem. Soc. 2009, 131, 4499–4504. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.; Ali, S.; Lo, E.; Chung, B.G.; Hatton, T.A.; Khademhosseini, A.; Doyle, P.S. Stop-flow lithography to generate cell-laden microgel particles. Lab Chip 2008, 8, 1056–1061. [Google Scholar] [CrossRef] [PubMed]

- Appleyard, D.C.; Chapin, S.C.; Srinivas, R.L.; Doyle, P.S. Bar-coded hydrogel microparticles for protein detection: Synthesis, assay and scanning. Nat. Protoc. 2011, 6, 1761–1774. [Google Scholar] [CrossRef] [PubMed]

- Pregibon, D.C.; Toner, M.; Doyle, P.S. Multifunctional encoded particles for high-throughput biomolecule analysis. Science 2007, 315, 1393–1396. [Google Scholar] [CrossRef] [PubMed]

- Chung, S.E.; Park, W.; Park, H.; Yu, K.; Park, N.; Kwon, S. Optofluidic maskless lithography system for real-time synthesis of photopolymerized microstructures in microfluidic channels. Appl. Phys. Lett. 2007, 91, 041106. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, S.C. Direct write of microlens array using digital projection photopolymerization. Appl. Phys. Lett. 2008, 92, 041109. [Google Scholar] [CrossRef]

- Lee, S.A.; Chung, S.E.; Park, W.; Lee, S.H.; Kwon, S. Three-dimensional fabrication of heterogeneous microstructures using soft membrane deformation and optofluidic maskless lithography. Lab Chip 2009, 9, 1670–1675. [Google Scholar] [CrossRef] [PubMed]

- Hayashia, T.; Shibata, T.; Kawashima, T.; Makino, E.; Mineta, T.; Masuzawa, T. Photolithography system with liquid crystal display as active gray-tone mask for 3D structuring of photoresist. Sens. Actuators A Phys. 2008, 144, 381–388. [Google Scholar] [CrossRef]

- Huang, S.H.; Yu, Z.Y.; Lin, C.K.; Hung, K.Y. Dynamically adjustable three-dimensional gray masks operated by electrostatic force modulation for the fabrication of microlens arrays in microchannels. J Micro-Nanolith MEMS MOEMS 2010, 9, 043002. [Google Scholar]

- Dendukuri, D.; Panda, P.; Haghgooie, R.; Kim, J.M.; Hatton, T.A.; Doyle, P.S. Modeling of oxygen-inhibited free radical photopolymerization in a PDMS microfluidic device. Macromolecules 2008, 41, 8547–8556. [Google Scholar] [CrossRef]

- Hung, K.Y.; Fan, C.C.; Tseng, F.G.; Chen, Y.K. Design and fabrication of a copolymer aspheric bi-convex lens utilizing thermal energy and electrostatic force in a dynamic fluidic. Opt. Express 2010, 18, 6014–6023. [Google Scholar] [CrossRef] [PubMed]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Huang, S.-H.; Lin, C.-K. Stop-flow Lithography to Continuously Fabricate Microlens Structures Utilizing an Adjustable Three-Dimensional Mask. Micromachines 2014, 5, 667-680. https://doi.org/10.3390/mi5030667

Huang S-H, Lin C-K. Stop-flow Lithography to Continuously Fabricate Microlens Structures Utilizing an Adjustable Three-Dimensional Mask. Micromachines. 2014; 5(3):667-680. https://doi.org/10.3390/mi5030667

Chicago/Turabian StyleHuang, Shih-Hao, and Chia-Kai Lin. 2014. "Stop-flow Lithography to Continuously Fabricate Microlens Structures Utilizing an Adjustable Three-Dimensional Mask" Micromachines 5, no. 3: 667-680. https://doi.org/10.3390/mi5030667

APA StyleHuang, S.-H., & Lin, C.-K. (2014). Stop-flow Lithography to Continuously Fabricate Microlens Structures Utilizing an Adjustable Three-Dimensional Mask. Micromachines, 5(3), 667-680. https://doi.org/10.3390/mi5030667