Module-Type Triboelectric Nanogenerators Capable of Harvesting Power from a Variety of Mechanical Energy Sources

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication Process of the Triboelectric Nanogenerator (TENG) Device and Silicone Rubber Balls

2.2. TENG Device Assessment

3. Results and Discussion

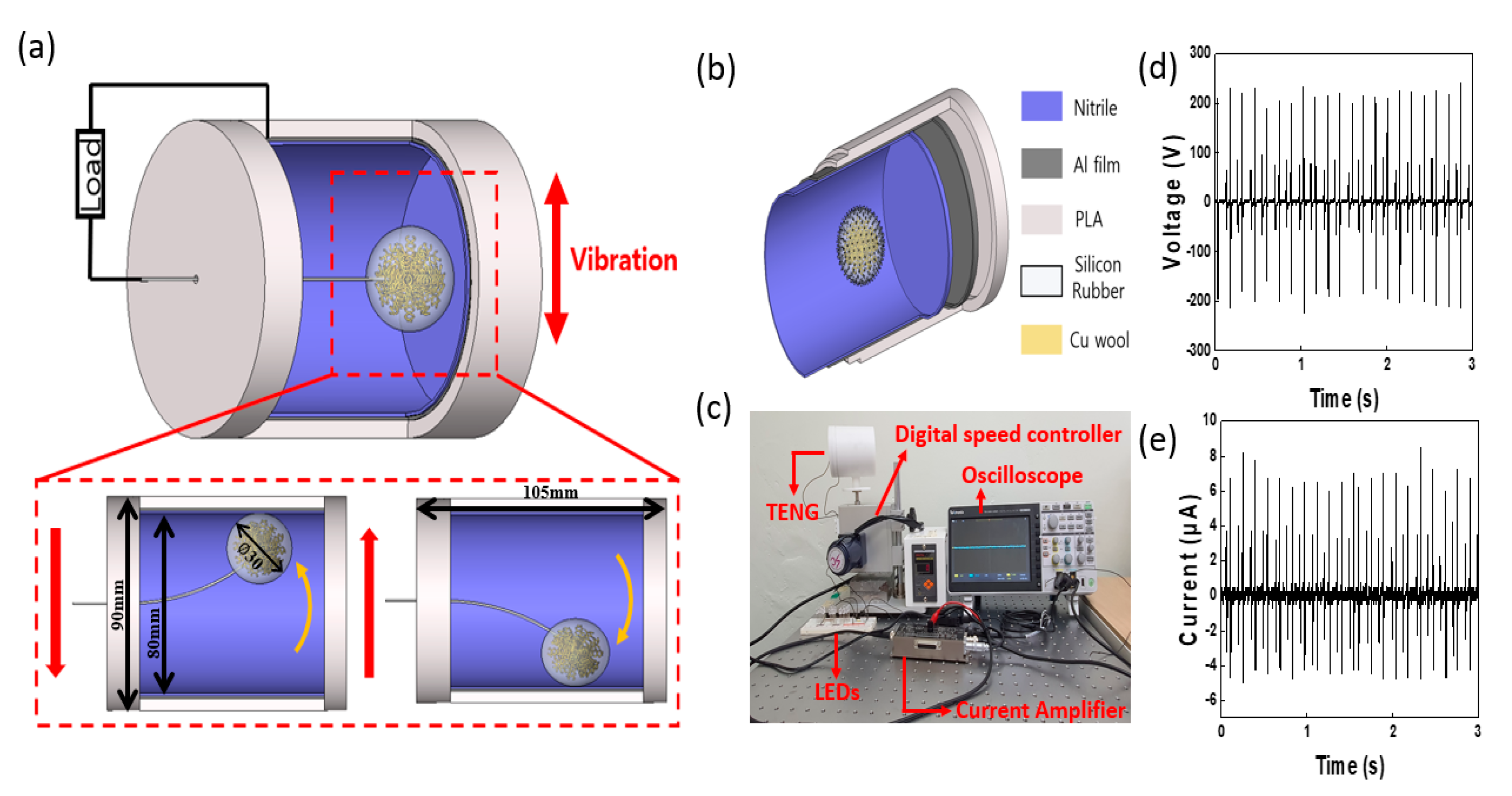

3.1. Preparation and Principle of the Potential Energy–TriboElectric NanoGenerator (P-TENG)

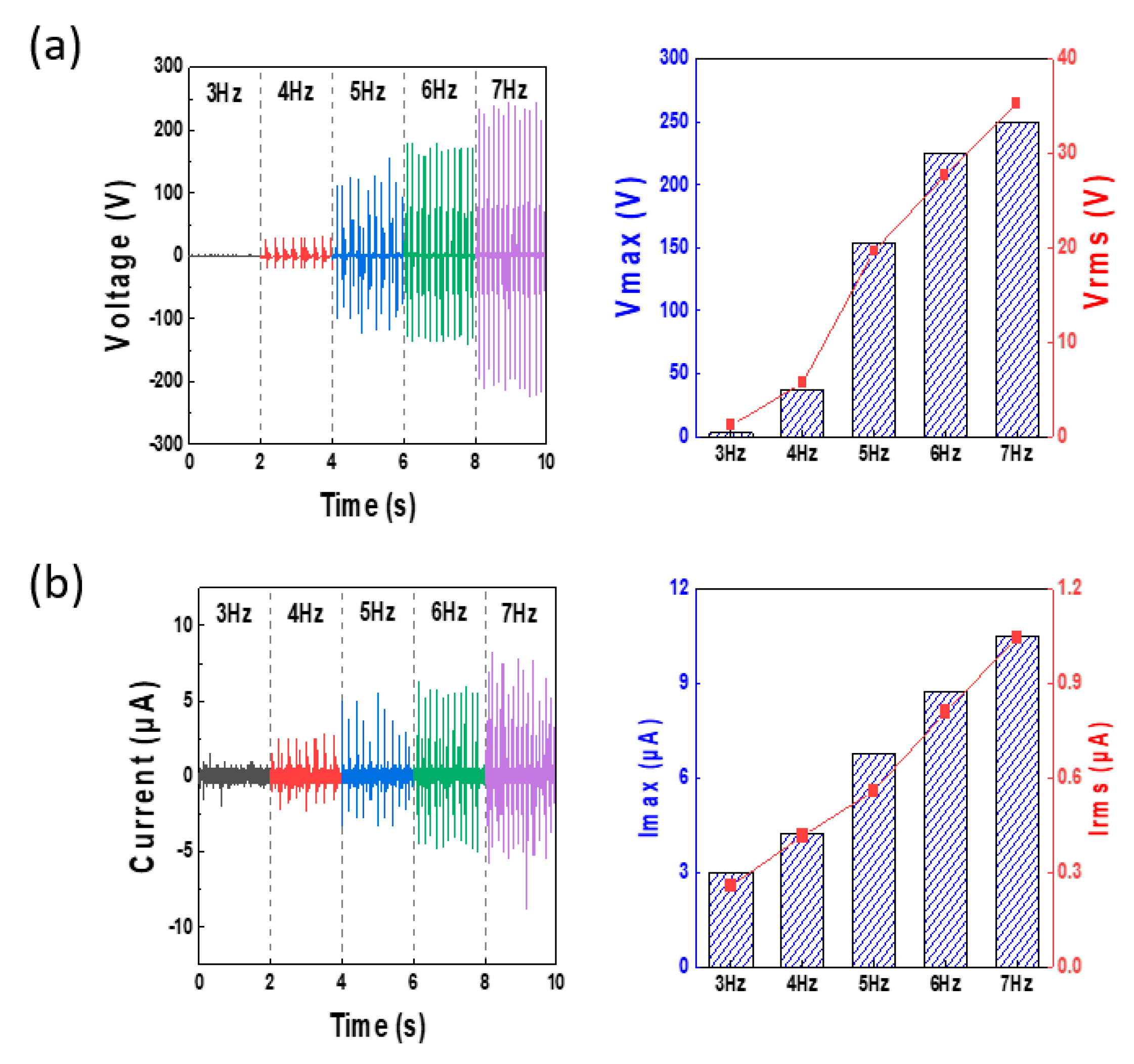

3.2. Electrical Performance of the P-TENG

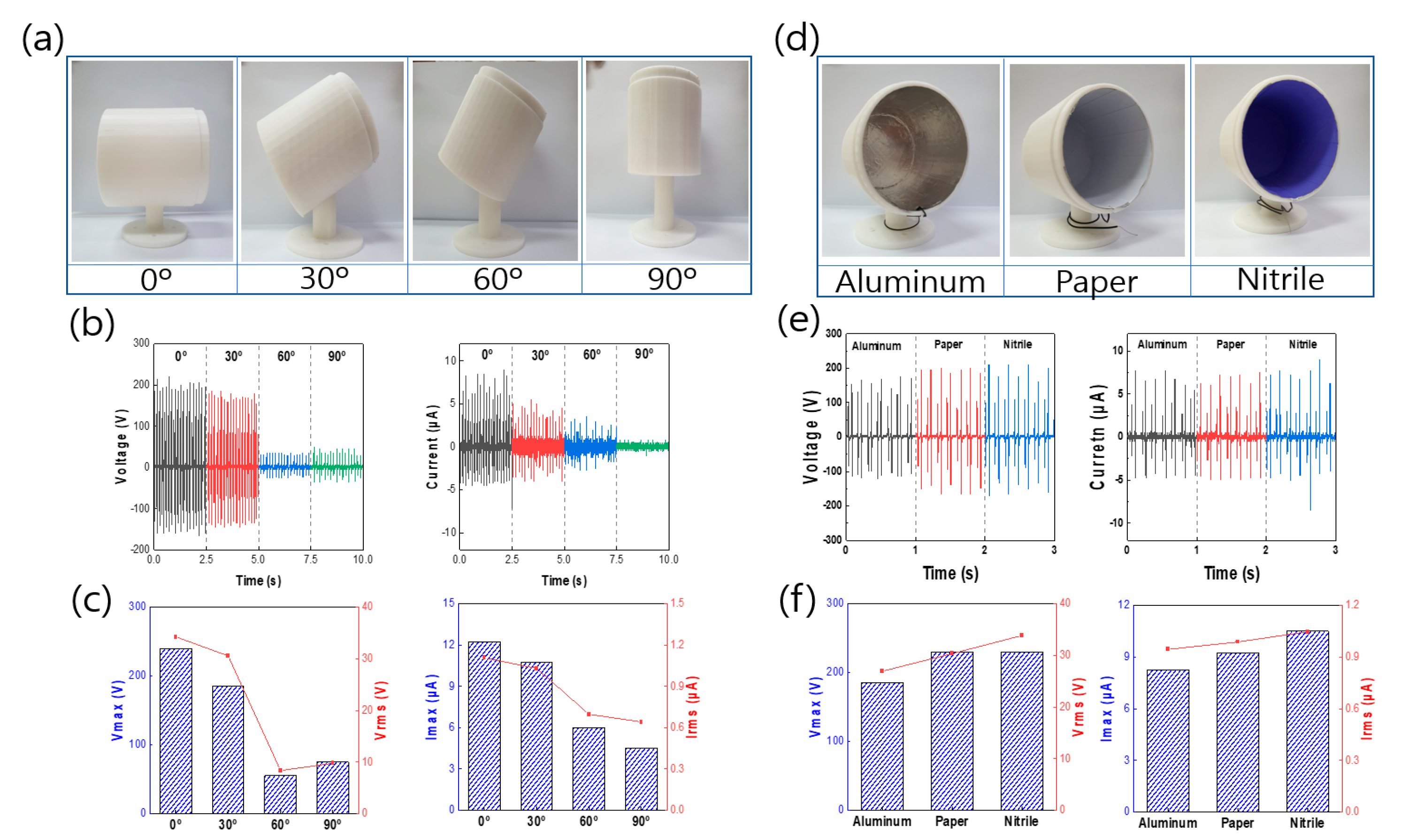

3.3. Properties of Location and Material

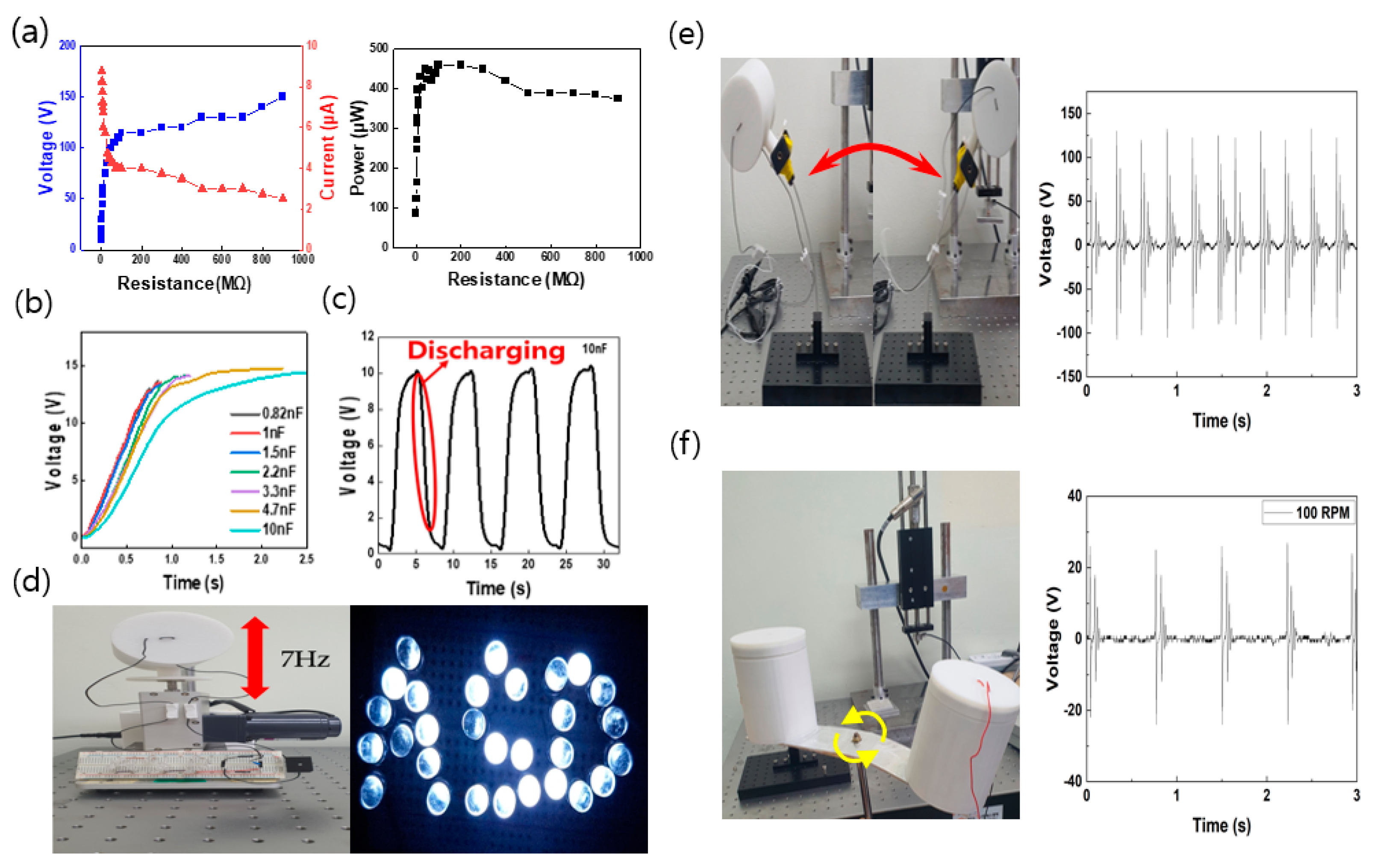

3.4. Application

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vu, R.J.M.; SchaijkaI, R.; Doms, I.; Hoof, C.V.; Mertens, R. Micropower energy harvesting. Solid-State Electron. 2009, 53, 684–693. [Google Scholar]

- Je, I.; Sem, J.R.; Wang, J. On-Body Bioelectronics: Wearable Biofuel Cells for Bioenergy Harvesting and Self-Powered Biosensing. Adv. Funct. Mater. 2019, 30, 1906243. [Google Scholar]

- Chi, S.; Wa, T.; Hi, Y.; Ma, K.; Ikoma, T. Consistent ocean wave energy harvesting using electroactive polymer (dielectric elastomer) artificial muscle generators. Appl. Energy 2013, 104, 497–502. [Google Scholar]

- Wu, X.; Lee, D.-W. An electromagnetic energy harvesting device based on high efficiency windmill structure for wireless forest fire monitoring application. Sens. Actuators A Phys. 2014, 219, 73–79. [Google Scholar] [CrossRef]

- No, A.; Kis, R.A.; Po, B.; Sa, U.; Li, W.; Cruz, R.; Priya, S. High Power Density Body Heat Energy Harvesting. ACS Appl. Mater. Interfaces 2019, 11, 40107–40113. [Google Scholar]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Kim, W.; Bhatia, D.; Jeong, S.; Choi, D. Mechanical energy conversion systems for triboelectric nanogenerators: Kinematic and vibrational designs. Nano Energy 2019, 56, 307–321. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Du, T.; Zuo, X.; Dong, F.; Li, S.; Mtui, A.E.; Zou, Y.; Zhang, P.; Zhao, J.; Zhang, Y.; Sun, P.; et al. A self-powered and highly accurate vibration sensor based on bouncing-ball triboelectric nanogenerator for intelligent ship machinery monitoring. Micromachines 2021, 12, 218. [Google Scholar] [CrossRef]

- Pu, X.; Guo, H.; Tang, Q.; Chen, J.; Feng, L.; Liu, G.; Wang, X.; Xi, Y.; Hu, C.; Wang, Z.L. Rotation sensing and gesture control of a robot joint via triboelectric quantization sensor. Nano Energy 2018, 54, 453–460. [Google Scholar] [CrossRef]

- Li, R.; Wei, X.; Xu, J.; Chen, J.; Li, B.; Wu, Z.; Wang, Z. Smart wearable sensors based on triboelectric nanogenerator for personal healthcare monitoring. Micromachines 2021, 12, 352. [Google Scholar] [CrossRef] [PubMed]

- Hwang, H.J.; Lee, Y.; Lee, C.; Nam, Y.; Park, J.; Choi, D.; Kim, D. Mesoporous highly-deformable composite polymer for a gapless triboelectric nanogenerator via a one-step metal oxidation process. Micromachines 2018, 9, 656. [Google Scholar] [CrossRef] [Green Version]

- Gao, Q.; Cheng, T.; Wang, Z.L. Triboelectric mechanical sensors—progress and prospects. Extreme Mech. Lett. 2021, 42, 101100. [Google Scholar] [CrossRef]

- Zhang, S.L.; Xu, M.; Zhang, C.; Wang, Y.-C.; Zou, H.; He, X.; Wang, Z.; Wang, Z.L. Rationally designed sea snake structure based triboelectric nanogenerators for effectively and efficiently harvesting ocean wave energy with minimized water screening effect. Nano Energy 2018, 48, 421–429. [Google Scholar] [CrossRef]

- Xiao, T.X.; Liang, X.; Jiang, T.; Xu, L.; Shao, J.J.; Nie, J.H.; Bai, Y.; Zhong, W.; Wang, Z.L. Spherical triboelectric nanogenerators based on spring-assisted multilayered structure for efficient water wave energy harvesting. Adv. Funct. Mater. 2018, 28, 1802634. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, B.; Guo, H.; Wu, Z.; Zou, H.; Yang, J.; Wang, Z.L. Super-robust and frequency-multiplied triboelectric nanogenerator for efficient harvesting water and wind energy. Nano Energy 2019, 64, 103908. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.-W.; Kim, K.; Yoo, D.; Kim, D.S.; Hwang, W.; Song, I.; Sim, J. A spherical hybrid triboelectric nanogenerator for enhanced water wave energy harvesting. Micromachines 2018, 9, 598. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Niu, S.; Yin, Y.; Yi, F.; You, Z.; Wang, Z.L. Triboelectric nanogenerator based on fully enclosed rolling spherical structure for harvesting low-frequency water wave energy. Adv. Energy Mater. 2015, 5, 1501467. [Google Scholar] [CrossRef]

- Park, J.; Han, M.; Kim, G.; Jung, Y.; Cho, H. Tree-wrapped triboelectric generator for harvesting wind energy. J. Nanosci. Nanotechnol. 2020, 20, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Bae, J.; Lee, J.; Kim, S.; Ha, J.; Lee, B.S.; Park, Y.; Choong, C.; Kim, J.B.; Wang, Z.L.; Kim, H.Y.; et al. Flutter-driven triboelectrification for harvesting wind energy. Nat. Commun. 2014, 5, 4929. [Google Scholar] [CrossRef] [Green Version]

- Win Zaw, N.Y.; Roh, H.; Kim, I.; Goh, T.S.; Kim, D. Omnidirectional triboelectric nanogenerator operated by weak wind towards a self-powered anemoscope. Micromachines 2020, 11, 414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xia, Y.; Tian, Y.; Zhang, L.; Ma, Z.; Dai, H.; Meng, B.; Peng, Z. An optimized flutter-driven triboelectric nanogenerator with a low cut-in wind speed. Micromachines 2021, 12, 366. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.-H.; Park, J.; Kim, W.K.; Yang, Y.; Lee, E.; Han, C.J.; Park, S.Y.; Lee, J.; Kim, Y.S. An effective energy harvesting method from a natural water motion active transducer. Energy Environ. Sci. 2014, 7, 3279–3283. [Google Scholar] [CrossRef]

- Chatterjee, S.; Saha, S.; Barman, S.R.; Khan, I.; Pao, Y.-P.; Lee, S.; Choi, D.; Lin, Z. Enhanced sensing performance of triboelectric nanosensors by solid–liquid contact electrification. Nano Energy 2020, 77, 105093. [Google Scholar] [CrossRef]

- Kim, T.; Chung, J.; Kim, D.Y.; Moon, J.H.; Lee, S.; Cho, M.; Lee, S.H.; Lee, S. Design and optimization of rotating triboelectric nanogenerator by water electrification and inertia. Nano Energy 2016, 27, 340–351. [Google Scholar] [CrossRef]

- Chung, S.-H.; Chung, J.; Kim, B.; Kim, S.; Lee, S. Screw pump-type water triboelectric nanogenerator for active water flow control. Adv. Eng. Mater. 2021, 23, 2000758. [Google Scholar] [CrossRef]

- Kim, T.; Kim, D.Y.; Yun, J.; Kim, B.; Lee, S.H.; Kim, D.; Lee, S. Direct-current triboelectric nanogenerator via water electrification and phase control. Nano Energy 2018, 52, 95–104. [Google Scholar] [CrossRef]

- Kim, J.; Cho, H.; Han, M.; Jung, Y.; Kwak, S.S.; Yoon, H.J.; Park, B.; Kim, H.; Kim, H.; Park, J.; et al. Ultrahigh power output from triboelectric nanogenerator based on serrated electrode via spark discharge. Adv. Energy Mater. 2020, 10, 2002312. [Google Scholar] [CrossRef]

- Park, J.; Cho, H.; Lee, Y.-S. Enhancing the triboelectric nanogenerator output by micro plasma generation in a micro-cracked surface structure. Appl. Sci. 2021, 11, 4262. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.; Ji, S.; Yoon, J.; Park, J. Module-Type Triboelectric Nanogenerators Capable of Harvesting Power from a Variety of Mechanical Energy Sources. Micromachines 2021, 12, 1043. https://doi.org/10.3390/mi12091043

Shin J, Ji S, Yoon J, Park J. Module-Type Triboelectric Nanogenerators Capable of Harvesting Power from a Variety of Mechanical Energy Sources. Micromachines. 2021; 12(9):1043. https://doi.org/10.3390/mi12091043

Chicago/Turabian StyleShin, Jaehee, Sungho Ji, Jiyoung Yoon, and Jinhyoung Park. 2021. "Module-Type Triboelectric Nanogenerators Capable of Harvesting Power from a Variety of Mechanical Energy Sources" Micromachines 12, no. 9: 1043. https://doi.org/10.3390/mi12091043