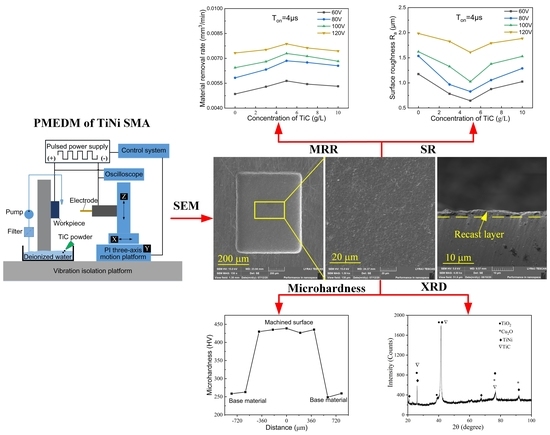

Processing Characteristics of Micro Electrical Discharge Machining for Surface Modification of TiNi Shape Memory Alloys Using a TiC Powder Dielectric

Abstract

:1. Introduction

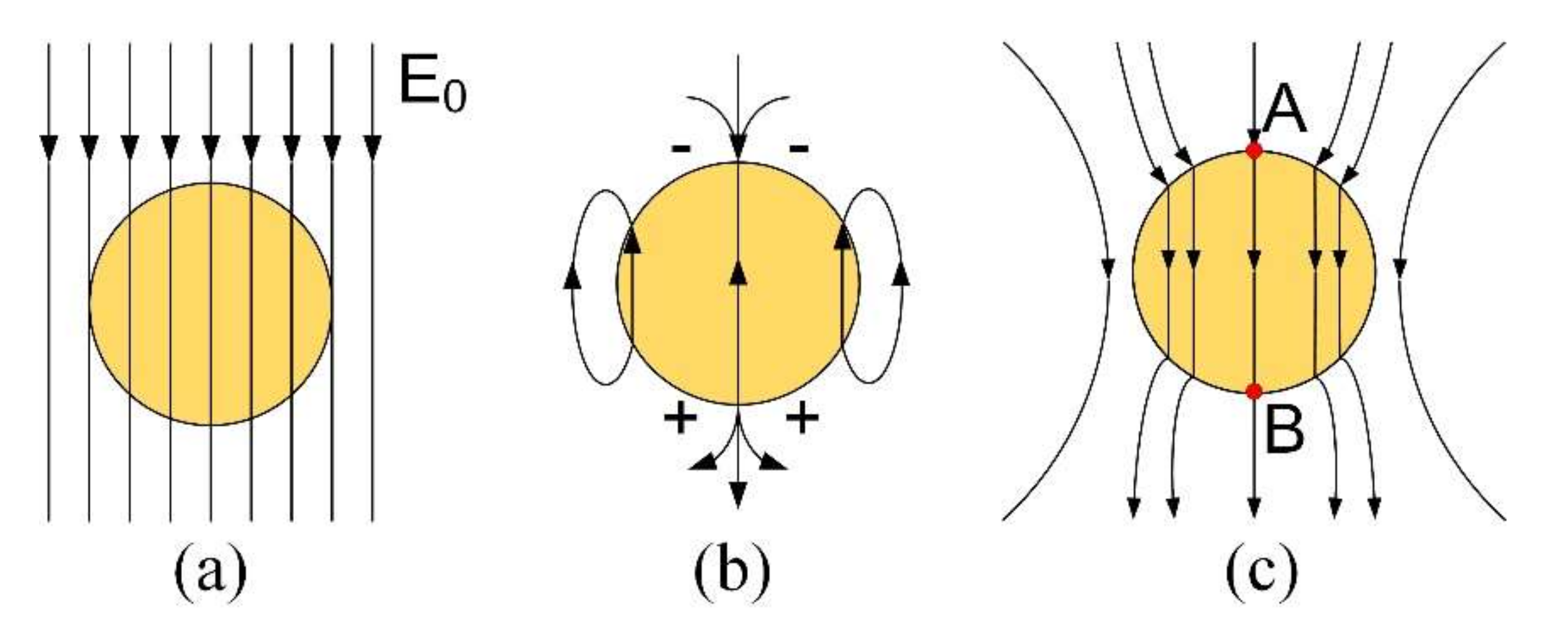

2. Principle and Mechanisms

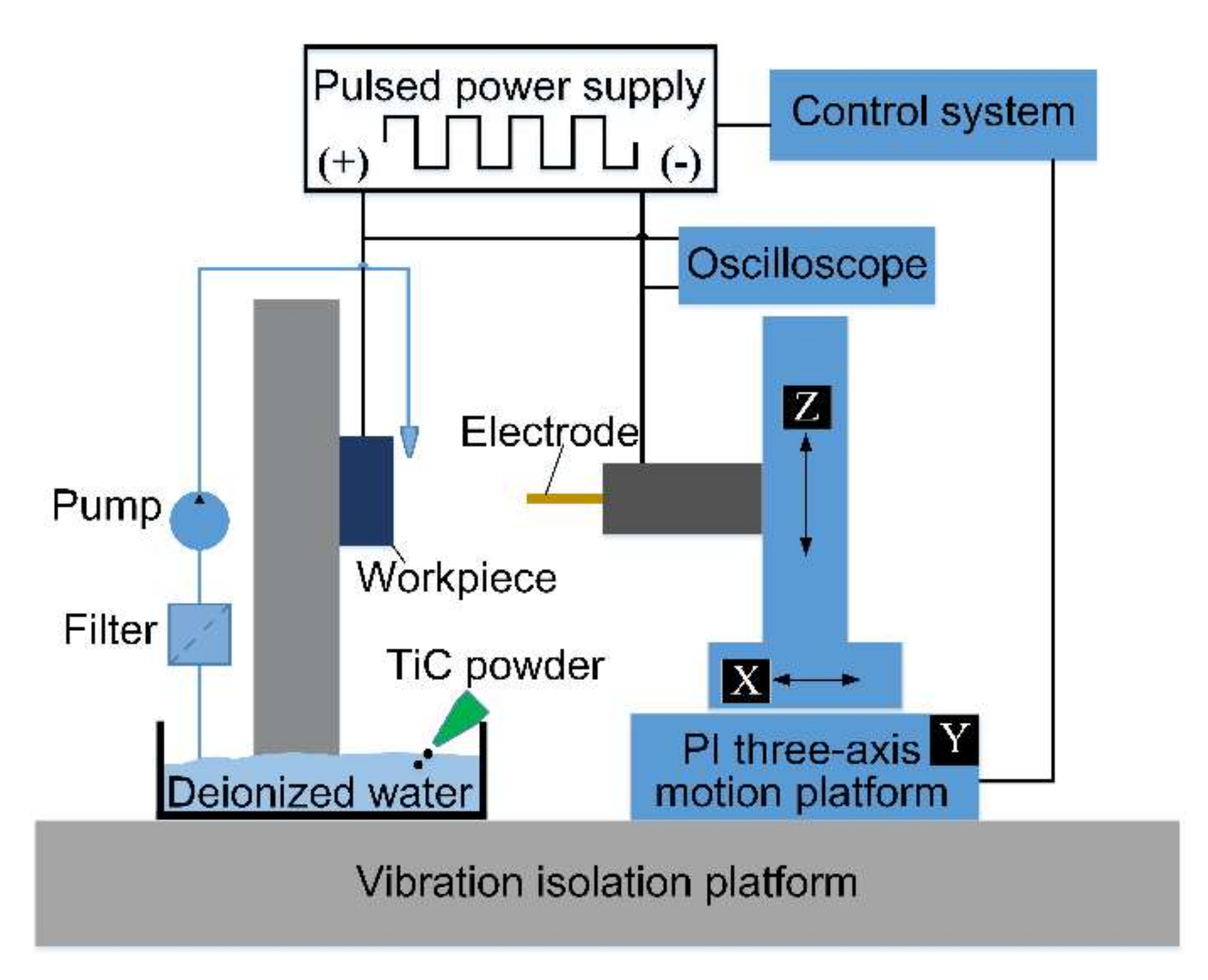

3. Experimental Methods

3.1. Experimental Procedure

3.2. Experimental Materials and Measurements

4. Results and Discussion

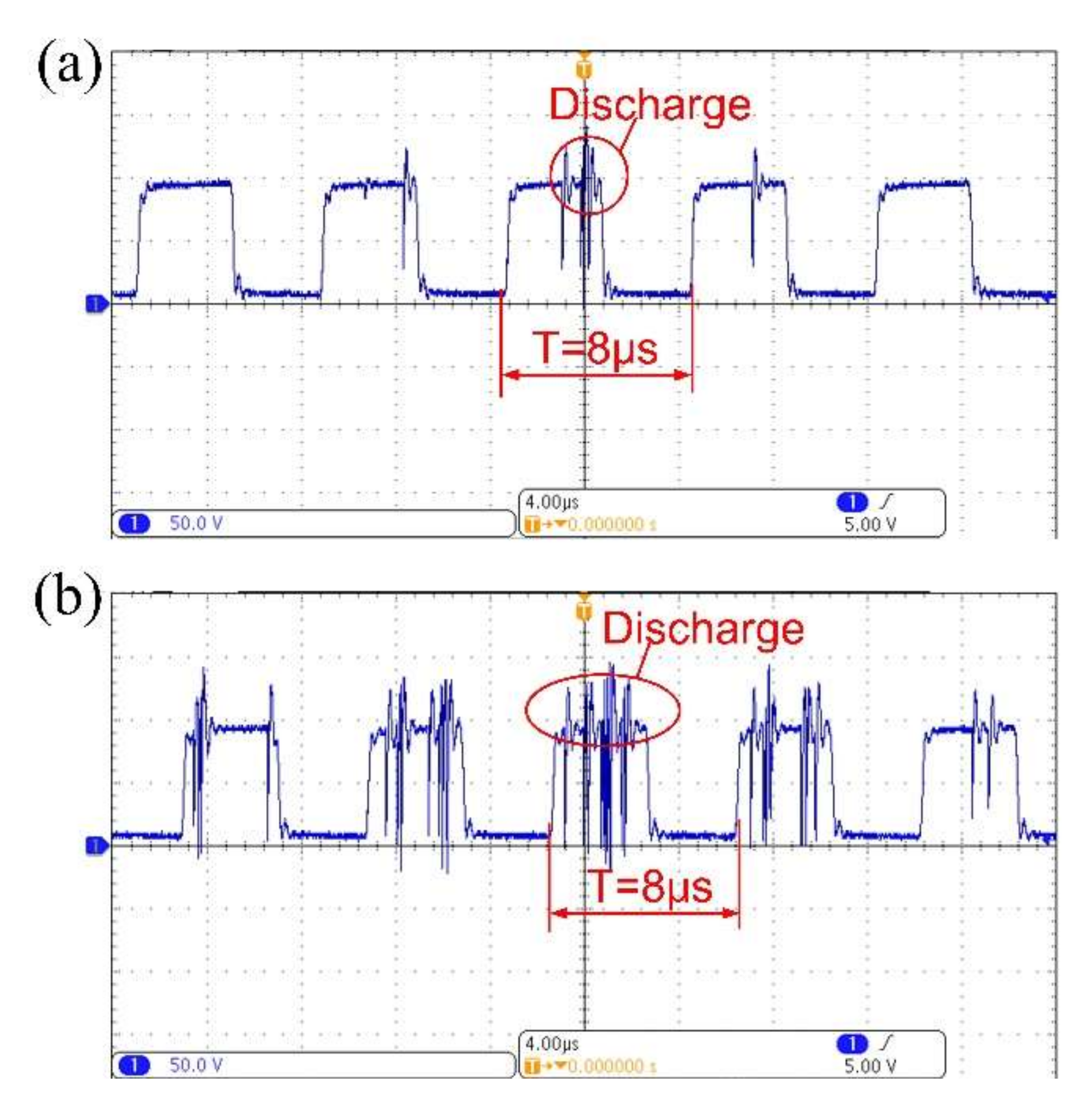

4.1. Discharge Waveforms Comparison of EDM and PMEDM

4.2. Influence of Machining Process Parameters on the Material Removal Rate

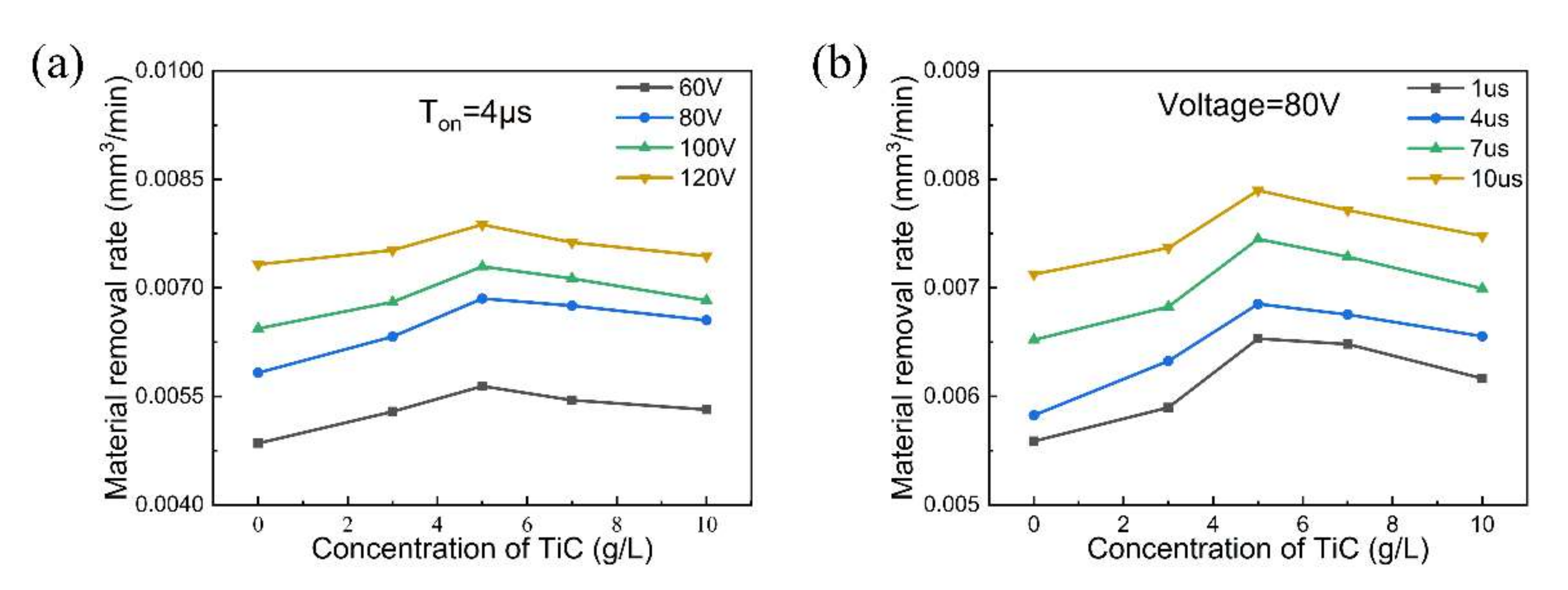

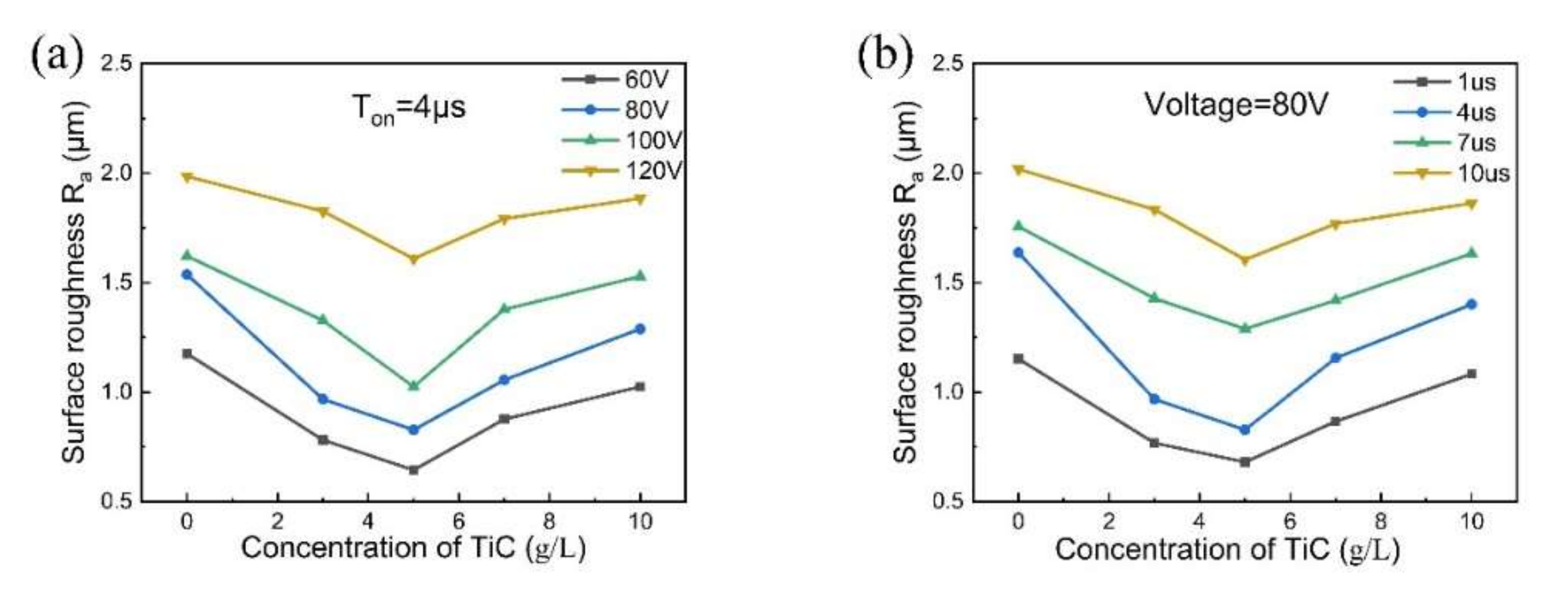

4.3. Influence of Machining Process Parameters on the Surface Roughness

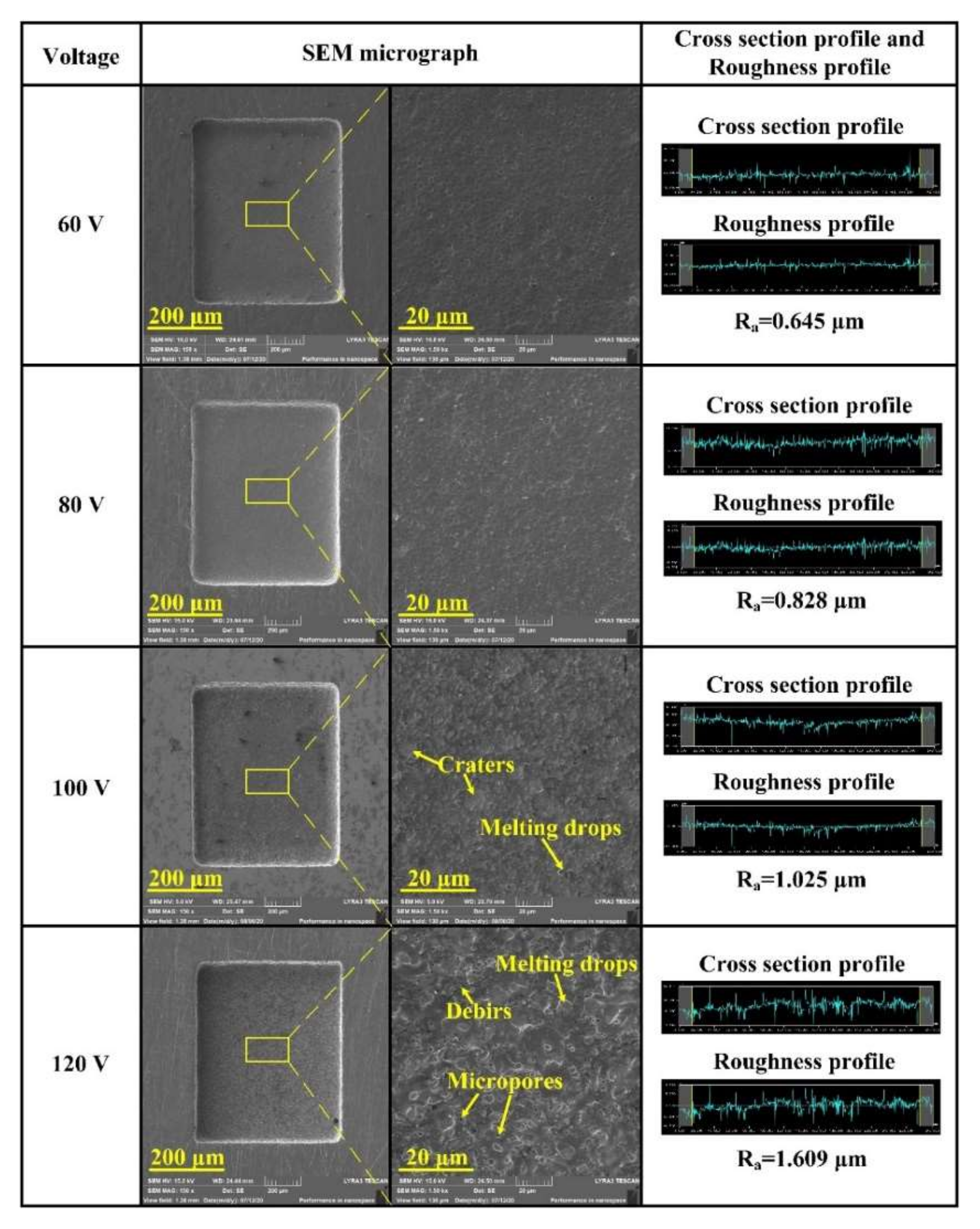

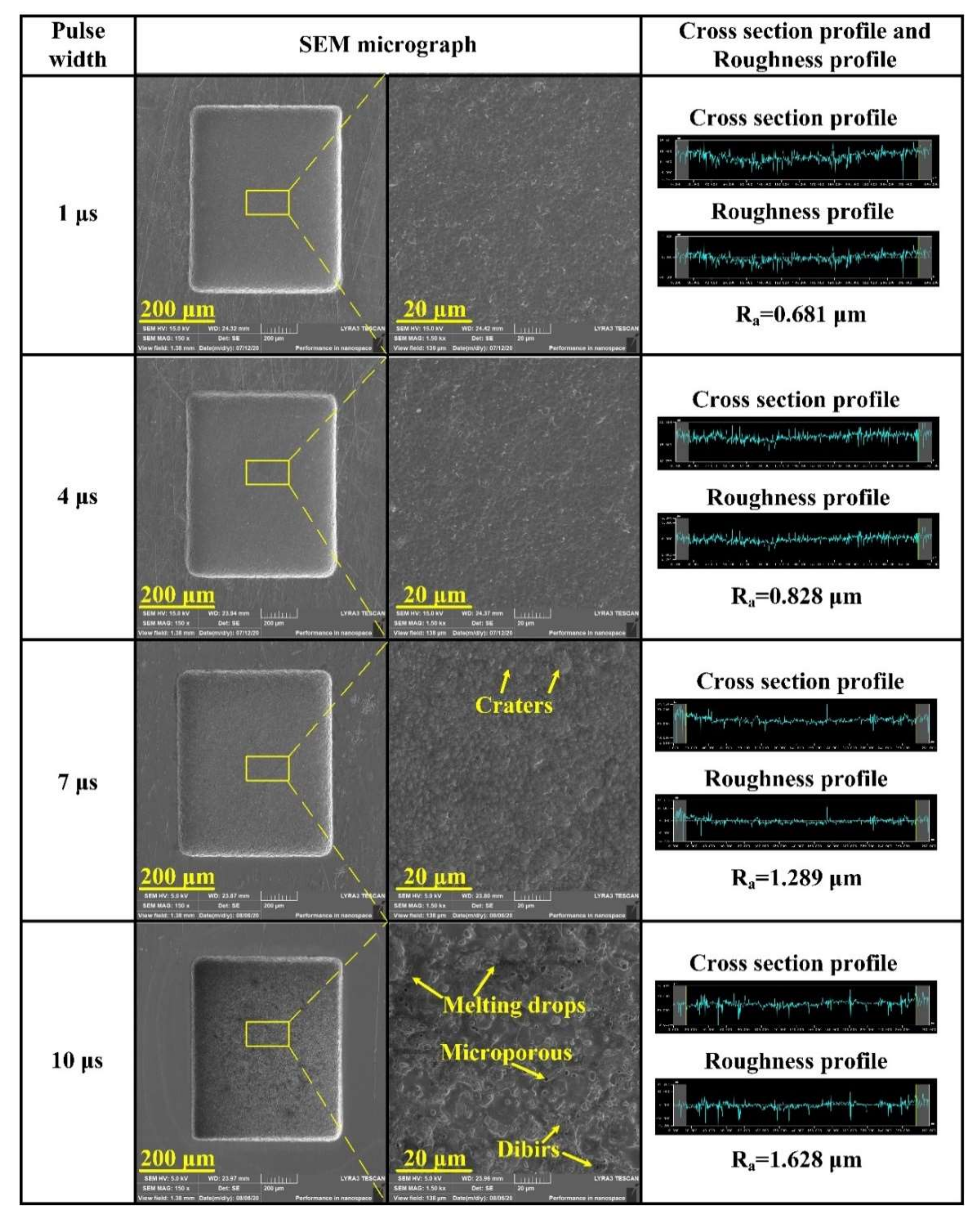

4.4. Surface Morphology of the EDM-Treated TiNi SMA

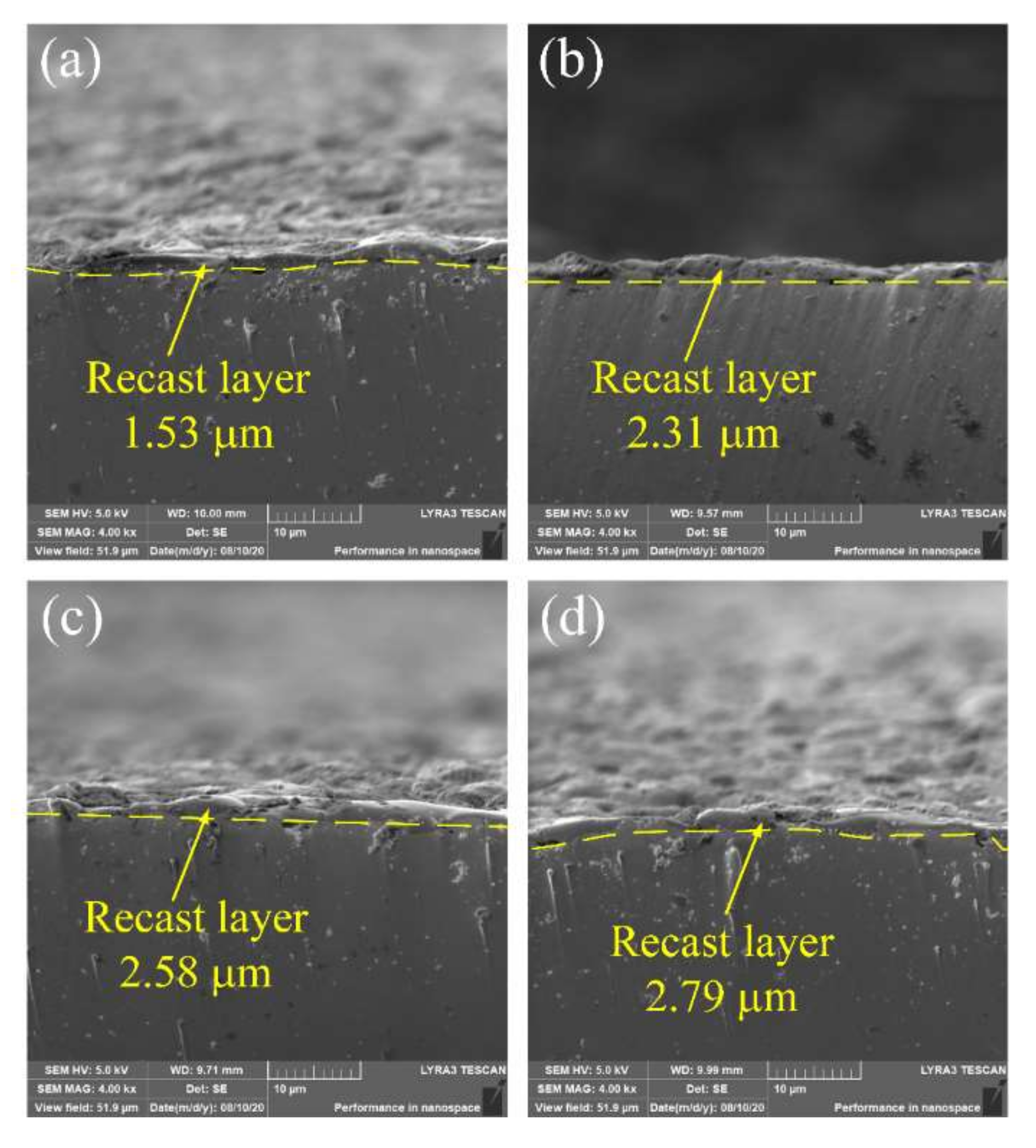

4.5. Influence of Micro-EDM Parameters on the Recast Layer

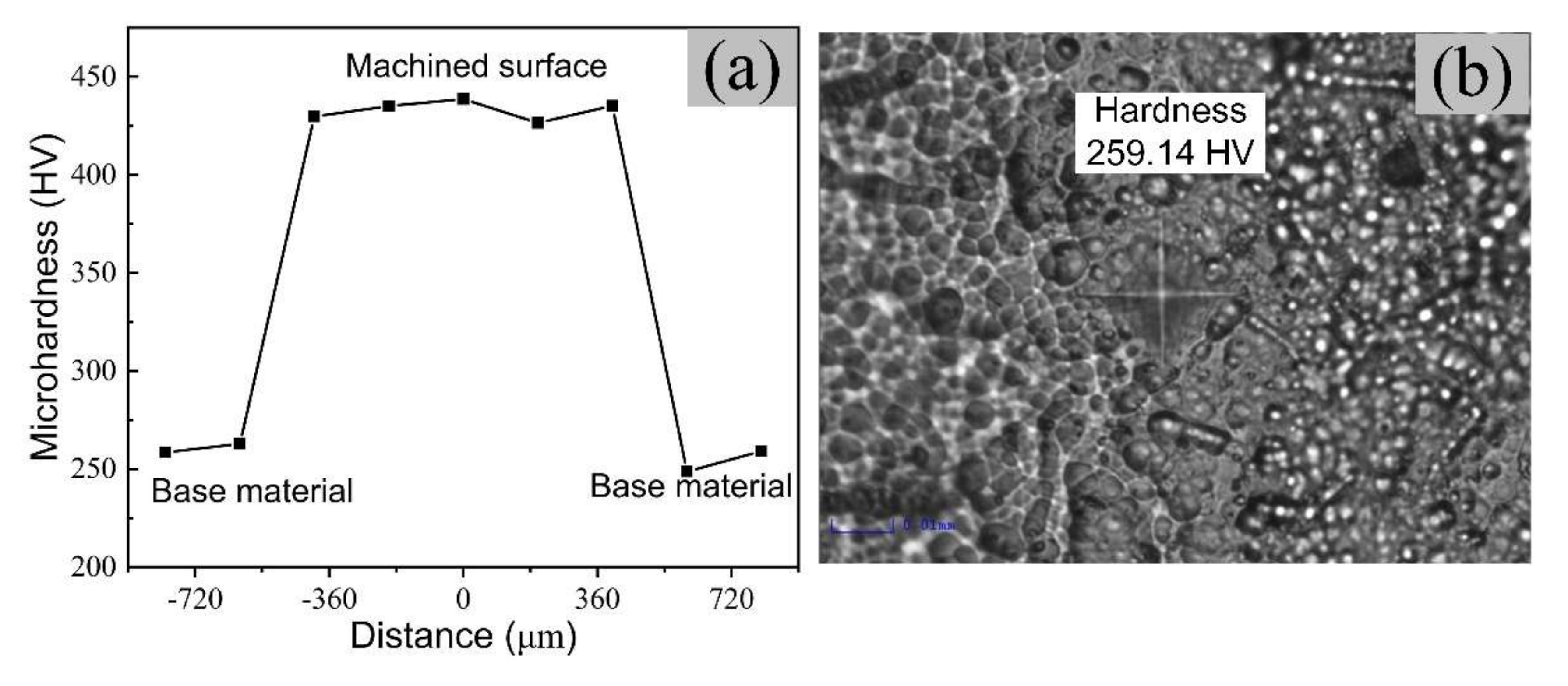

4.6. Effect of Compound Composition on Microhardness

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Hsieh, S.F.; Hsue, A.W.J.; Chen, S.L.; Lin, M.H.; Ou, K.L.; Mao, P.L. Edm surface characteristics and shape recovery ability of Ti35.5Ni48.5Zr16 and Ni60Al24.5Fe15.5 ternary shape memory alloys. J. Alloy. Compd. 2013, 571, 63–68. [Google Scholar] [CrossRef]

- Peng, P.W.; Ou, K.L.; Lin, H.C.; Pan, Y.N.; Wang, C.H. Effect of electrical-discharging on formation of nanoporous biocompatible layer on titanium. J. Alloy. Compd. 2010, 492, 625–630. [Google Scholar] [CrossRef]

- McKay, G.C.; Macnair, R.; MacDonald, C.; Grant, M.H. Interactions of orthopaedic metals with an immortalized rat osteoblast cell line. Biomaterials 1996, 17, 1339–1344. [Google Scholar] [CrossRef]

- Hsieh, S.F.; Lin, M.H.; Chen, S.L.; Ou, S.F.; Huang, T.S.; Zhou, X.Q. Surface modification and machining of TiNi/TiNb-based alloys by electrical discharge machining. Int. J. Adv. Manuf. Technol. 2016, 86, 1475–1485. [Google Scholar] [CrossRef]

- Cheng, H.C.; Lee, S.Y.; Chen, C.C.; Shyng, Y.C.; Ou, K.L. Titanium nanostructural surface processing for improved biocompatibility. Appl. Phys. Lett. 2006, 89, 3. [Google Scholar] [CrossRef]

- Shih, Y.H.; Lin, C.T.; Liu, C.M.; Chen, C.C.; Chen, C.S.; Ou, K.L. Effect of nano-titanium hydride on formation of multi-nanoporous TiO2 film on ti. Appl. Surf. Sci. 2007, 253, 3678–3682. [Google Scholar] [CrossRef]

- Ou, S.F.; Chou, H.H.; Lin, C.S.; Shih, C.J.; Wang, K.K.; Pan, Y.N. Effects of anodic oxidation and hydrothermal treatment on surface characteristics and biocompatibility of Ti-30Nb-1Fe-1Hf alloy. Appl. Surface Sci. 2012, 258, 6190–6198. [Google Scholar] [CrossRef]

- Gurrappa, I.; Manova, D.; Gerlach, J.W.; Mandl, S.; Rauschenbach, B. Influence of nitrogen implantation on the high temperature oxidation of titanium-base alloys. Surf. Coat. Technol. 2006, 201, 3536–3546. [Google Scholar] [CrossRef]

- Maleki-Ghaleh, H.; Khalili, V.; Khalil-Allafi, J.; Javidi, M. Hydroxyapatite coating on NiTi shape memory alloy by electrophoretic deposition process. Surf. Coat. Technol. 2012, 208, 57–63. [Google Scholar] [CrossRef]

- Chu, C.L.; Wang, R.M.; Hu, T.; Yin, L.H.; Pu, Y.P.; Lin, P.H.; Wu, S.L.; Chung, C.Y.; Yeung, K.W.K.; Chu, P.K. Surface structure and biomedical properties of chemically polished and electropolished NiTi shape memory alloys. Mater. Sci. Eng. C Biomimetic Supramol. Syst. 2008, 28, 1430–1434. [Google Scholar] [CrossRef]

- Qin, R.; Ding, D.Y.; Ning, C.Q.; Liu, H.G.; Zhu, B.S.; Li, M.; Mao, D.L. Ni-doped TiO2 nanotube arrays on shape memory alloy. Appl. Surface Sci. 2011, 257, 6308–6313. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.P.; Talamona, D.; Perveen, A. Electro-discharge machining of ceramics: A review. Micromachines 2019, 10, 10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wyszynski, D.; Bizon, W.; Miernik, K. Electrodischarge drilling of microholes in c-BN. Micromachines 2020, 10, 179. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.Y.; Huang, T.W.; Sheu, D.Y. Desktop Micro-EDM system for high-aspect ratio micro-hole drilling in tungsten cemented carbide by cut-side Micro-tool. Micromachines 2020, 11, 14. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Zhang, Q.H.; Zhang, M.; Yang, F.Z. Study on the discharge characteristics of single-pulse discharge in Micro-EDM. Micromachines 2020, 11, 55. [Google Scholar] [CrossRef] [Green Version]

- Almacinha, J.A.; Lopes, A.M.; Rosa, P.; Marafona, J.D. How hydrogen dielectric strength forces the work voltage in the electric discharge machining. Micromachines 2018, 9, 240. [Google Scholar] [CrossRef] [Green Version]

- Roy, T.; Balasubramaniam, R. Influence of ion-rich plasma discharge channel on unusually high discharging points in reverse micro electrical discharge machining. Int. J. Adv. Manuf. Technol. 2020, 106, 4467–4475. [Google Scholar] [CrossRef]

- Roy, T.; Balasubramaniam, R. Effect of various factors influencing the generation of hemispherical micro features using non-conformal RMEDM. J. Micromanuf. 2019, 2, 110–122. [Google Scholar] [CrossRef]

- Chen, S.L.; Yan, B.H.; Huang, F.Y. Influence of kerosene and distilled water as dielectrics on the electric discharge machining characteristics of Ti-6Al-4V. J. Mater. Process. Technol. 1999, 87, 107–111. [Google Scholar] [CrossRef]

- Buckley, R.V. Electrostatic Field Theory; Palgrave: London, UK, 1981. [Google Scholar]

- Wang, X.Z.; Yi, S.; Guo, H.; Li, C.J.; Ding, S.L. Erosion characteristics of electrical discharge machining using graphene powder in deionized water as dielectric. Int. J. Adv. Manuf. Technol. 2020, 108, 357–368. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yan, B.H.; Chang, Y.S. Machining characteristics of titanium alloy (Ti-6Al-4V) using a combination process of EDM with USM. J. Mater. Process. Technol. 2000, 104, 171–177. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. Modelling and experimental investigation on the effect of nanopowder-mixed dielectric in micro-electrodischarge machining of tungsten carbide. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1725–1739. [Google Scholar] [CrossRef]

- Liew, P.J.; Yan, J.W.; Kuriyagawa, T. Carbon nanofiber assisted micro electro discharge machining of reaction-bonded silicon carbide. J. Mater. Process. Technol. 2013, 213, 1076–1087. [Google Scholar] [CrossRef]

- Xu, B.; Guo, K.; Wu, X.Y.; Lei, J.G.; Liang, X.O.; Guo, D.J.; Ma, J.; Cheng, R. Applying a foil queue micro-electrode in micro-edm to fabricate a 3D micro-structure. J. Micromech. Microeng. 2018, 28, 11. [Google Scholar] [CrossRef]

- Wu, Z.Z.; Wu, X.Y.; Xu, B.; Guo, D.J.; Tang, Y.; Diao, D.F. Reverse-polarity pmedm using self-welding bundled 3d-laminated microelectrodes. J. Mater. Process. Technol. 2019, 273, 8. [Google Scholar] [CrossRef]

- Bui, V.D.; Mwangi, J.W.; Schubert, A. Powder mixed electrical discharge machining for antibacterial coating on titanium implant surfaces. J. Manuf. Process. 2019, 44, 261–270. [Google Scholar] [CrossRef]

- Reddy, V.V.; Kumar, A.; Valli, P.M.; Reddy, C.S. Influence of surfactant and graphite powder concentration on electrical discharge machining of ph17-4 stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 641–655. [Google Scholar] [CrossRef]

- Tiwary, A.P.; Pradhan, B.B.; Bhattacharyya, B. Influence of various metal powder mixed dielectric on micro-edm characteristics of ti-6al-4v. Mater. Manuf. Process. 2019, 34, 1103–1119. [Google Scholar] [CrossRef]

- Amorim, F.L.; Dalcin, V.A.; Soares, P.; Mendes, L.A. Surface modification of tool steel by electrical discharge machining with molybdenum powder mixed in dielectric fluid. Int. J. Adv. Manuf. Technol. 2017, 91, 341–350. [Google Scholar] [CrossRef]

- Li, C.J.; Xu, X.; Li, Y.; Tong, H.; Ding, S.L.; Kong, Q.C.; Zhao, L.; Ding, J. Effects of dielectric fluids on surface integrity for the recast layer in high speed EDM drilling of nickel alloy. J. Alloy. Compd. 2019, 783, 95–102. [Google Scholar] [CrossRef]

- Tan, P.C.; Yeo, S.H. Modeling of recast layer in Micro-electrical discharge machining. J. Manuf. Sci. Eng. Trans. ASME 2010, 132, 9. [Google Scholar] [CrossRef]

- Jahan, M.P.; Mahbub, R.; Kirwin, R.; Alavi, F. Micro-EDM induced surface modification of titanium alloy for biocompatibility. Int. J. Mach. Mach. Mater. 2018, 20, 274. [Google Scholar]

- Chen, S.L.; Hsieh, S.F.; Lin, H.C.; Lin, M.H.; Huang, J.S. Electrical discharge machining of TiNiCr and TiNiZr ternary shape memory alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2007, 445, 486–492. [Google Scholar] [CrossRef]

| Work Conditions | Description |

|---|---|

| Workpiece material | TiNi SMA |

| Electrode material | Brass (C2680) |

| Polarity | Positive |

| Dielectric fluid | Deionized water |

| Additive | TiC (2 μm) |

| Concentrations (g/L) | 0, 3, 5, 7, 10 |

| Duty (%) | 50 |

| Pulse durations (ms) | 1, 4, 7, 10 |

| Machining voltages (V) | 60, 80, 100, 120 |

| Cavity depth (mm) | 100 |

| Element | Ni | Ti | Nb | C | O | Other |

|---|---|---|---|---|---|---|

| Wt.% | 50.9 | 48.9 | 0.025 | 0.036 | 0.043 | <0.025 |

| Workpiece Material | TiNi SMA |

|---|---|

| Density (kg/m3) | 6450 |

| Melting point (°C) | 1310 |

| Electrical resistivity (μΩ·m) | 820 |

| Modulus of elasticity (MPa) | 42.3 × 103 |

| Coefficient of thermal expansion (/°C) | 11 × 10−6 |

| Ultimate tensile strength (MPa) | 880 |

| Total elongation (%) | 16 |

| Property | Value |

|---|---|

| Density (kg/m3) | 4930 |

| Melting point (°C) | 3140 |

| Thermal conductivity (W/m·K) | 21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Guo, D.; Xu, J.; Lin, J.; Lei, J.; Xu, B.; Wu, X.; Wang, X. Processing Characteristics of Micro Electrical Discharge Machining for Surface Modification of TiNi Shape Memory Alloys Using a TiC Powder Dielectric. Micromachines 2020, 11, 1018. https://doi.org/10.3390/mi11111018

Zhu Z, Guo D, Xu J, Lin J, Lei J, Xu B, Wu X, Wang X. Processing Characteristics of Micro Electrical Discharge Machining for Surface Modification of TiNi Shape Memory Alloys Using a TiC Powder Dielectric. Micromachines. 2020; 11(11):1018. https://doi.org/10.3390/mi11111018

Chicago/Turabian StyleZhu, Ziliang, Dengji Guo, Jiao Xu, Jianjun Lin, Jianguo Lei, Bin Xu, Xiaoyu Wu, and Xujin Wang. 2020. "Processing Characteristics of Micro Electrical Discharge Machining for Surface Modification of TiNi Shape Memory Alloys Using a TiC Powder Dielectric" Micromachines 11, no. 11: 1018. https://doi.org/10.3390/mi11111018