1. Introduction

The integrated gasification combined cycle is a new technology that enables chemical recycling of solid waste for high efficient power production [

1]. The technology arises to improve the current thermal and electrical efficiencies of waste to energy single cycle chemical plants, and will be commercially available within the next 10 years [

2]. The worldwide capacity of gasification is growing exponentially, and 80% of expansion is in Asia, where the majority of development is in China [

3]. Integration in waste to energy plants can only occur by sharing a steam cycle or by integrating more than one chemical reactor in series or parallel [

4]. The integrated gasification combined cycle (IGCC) shows higher thermal efficiencies, in both medium scale and large scale gas turbines [

4]. Integrated combined cycles show 7% higher electrical efficiency in medium scale plants with higher initial investment justified by more equipment and more complex heat exchange networks [

5]. In addition, the IGCC has higher feedstock flexibility such as biomass, municipal solid waste (MSW), refinery residues or coke showing better environmental performance and higher energy conversion in comparable with single cycle gasification systems [

6]. Due to high operating pressures and temperatures, improving the process efficiency has emerged as one of the high priorities in waste to energy plants [

7]. Integrated waste to energy systems have become a very interesting topic for both industry and research institutes due to interest in energy production from waste and improved chemical and thermal efficiencies with more cost effective designs achieved in such systems [

8]. Below are recommended design considerations that improve process optimization and energy usage [

6]:

High and low temperature heat recovery networks

Optimization of operating parameters in reactors

Air extraction from gas turbine and integration with air separation unit (ASU)

Polygeneration of steam and other main streams

Optimize gas turbine power due to higher gas flow rates

Due to the increasing amount of global solid waste production, more efficient chemical recycling strategies and technologies are needed [

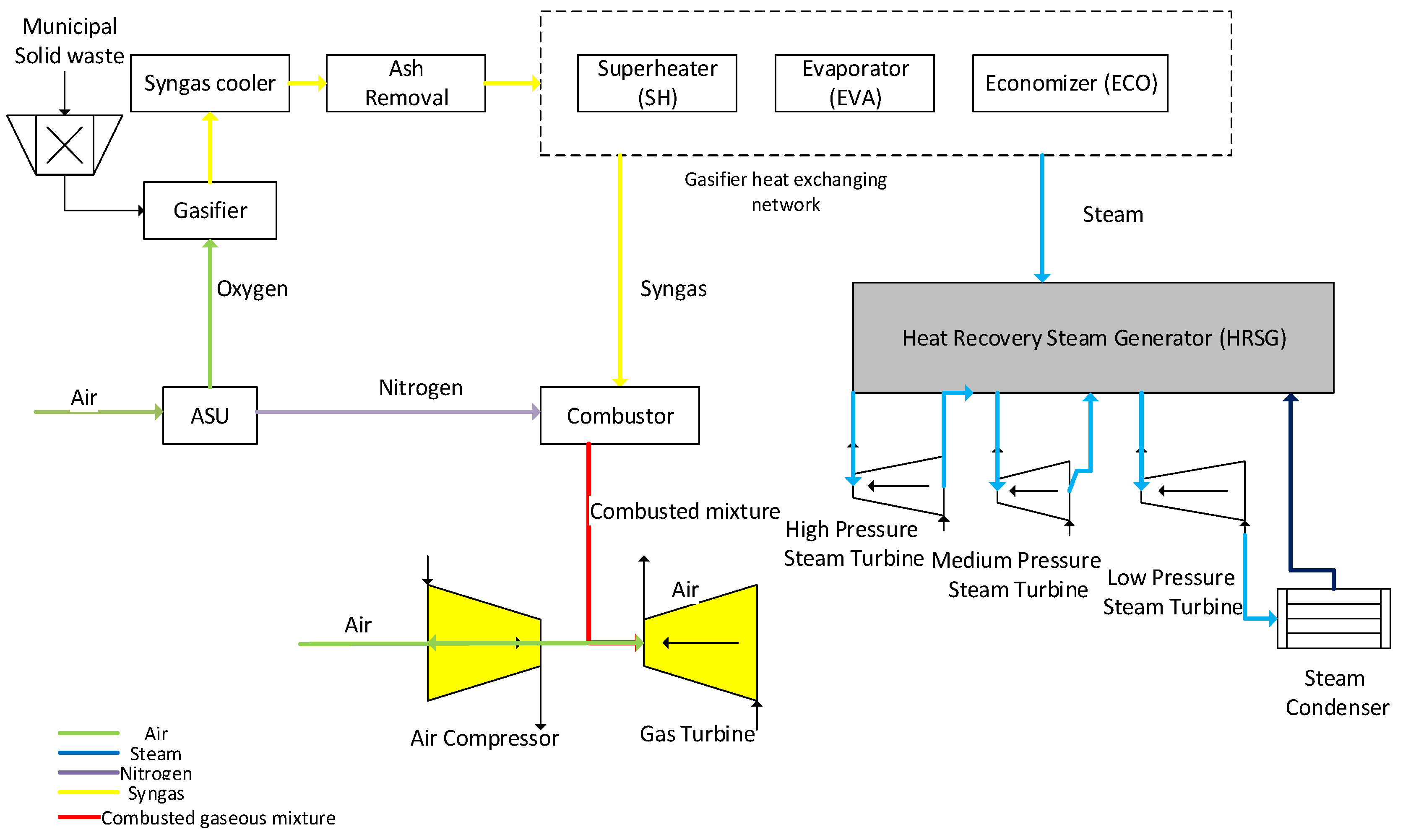

9]. In our work, a proposed integrated gasification combined cycle is designed for municipal solid waste (MSW) treatment. Steam integration is accomplished by sharing steam cycle: saturated steam is generated in MSW reactors using heat exchanging network (HEN) and converted to high pressure steam (HPS) through heat recovery steam generator (HRSG) zone. A schematic diagram of an integrated gasification combined cycle (IGCC) conceptual design is shown in

Figure 1.

As seen in

Figure 1, an integrated gasification cycle consists of solid waste pretreatment stage which consists of pretreatment, mechanical separation or RDF production of solid waste. The carbonaceous feedstock material should include only combustibles, which are converted to gaseous products using gasification process in an oxygen starved environment [

10]. Syngas mainly consists of carbon monoxide (CO) and hydrogen (H

2), which are produced through series of endothermic and exothermic reactions as shown in

Table 1 after passing through heat exchanging networks that generate steam. A heat exchanging network includes superheater (SH), Evaporator (EVA), and an Economizer (ECO) [

11]. The superheater is usually located close to gasifier effluents where high temperature zones generate high pressure steam (HPS) followed by evaporator and economizer [

12]. To utilize syngas, cooling and cleaning are required, including particulate removal, and tar, sulfur and ammonia formation before combustion. A gas cyclone, filters and acid removal equipment are used after the gasification process to ensure no toxic gases are combusted. The operating conditions affect the gaseous effluents, thermal and electrical efficiencies achieved in single cycle gasification plants. For example, methane (CH

4) and carbon dioxide (CO

2) formation favors lower operating temperatures and higher operating pressures [

13], while carbon monoxide (CO) and H

2 formation favors higher operating temperatures and lower operating pressures. Thus, gasifier temperatures are controlled for optimal concentration for desired products.

The electrical efficiency in waste to energy (WTE) single cycle varies in steam and gas turbines. Gas turbine efficiencies for gasification plants are in the range 13–24% and steam turbines achieve 9–20% [

14]. The main process stages in an integrated gasification combined cycle (IGCC) is shown below:

Waste pretreatment unit

Gasification unit (GU)

Acid gas removal unit

Sulfur recovery unit (SRU)

Air separation unit (SRU)

Combined cycle of gas turbine and steam turbine (CC)

Heat recovery steam generator (HRSG)

2. Integrated Gasification Plant Concept

The concept combines gasifier effluents in both thermal integration and thermochemical conversion of MSW over two reactors in series as seen in

Figure 1. This also allows the possibility to maximize process efficiency and thermally crack heavy waxes into a second reaction system. Below are the main advantages of integrated combined gasification cycle (IGCC) compared to single waste to energy (WTE) [

15]:

Higher chemical conversion of MSW per unit mass to useful hydrocarbon products since reactants are thermochemical treated in two reaction systems rather than a single reactor

Increase the maximum temperature of steam cycle due to more heat zones allowing high pressure steam production

Increase steam turbine efficiency due to higher steam capacity and larger turbine size

Less capital cost per unit mass since a number of equipment are shared in hybrid waste to energy systems such as steam turbine serving high pressure steam from two reactors

Production and optimization of syngas flow and composition from two gasifier reactors rather than a single gasifier reactor

Reduction in tar production since heavy components from pyrolysis reactor are thermally cracked to syngas, thus no tar is produced in the process system

Reduction of the total exhaust mass flow rate due to high process conversion to desired products

Lower environmental impact since all flue gases flew through same stack [

4]. In addition, integrated combined cycles reduce toxic emissions due to higher operating pressures which improves process efficiency leading to lower SO

2, NO

2, particulate matter and particularly 73.2% reduction in CO

2 emissions [

16]

Higher heat exchanger optimization and integration in two reaction systems

The average efficiency of electrical power production in a WTE plant is approximately 18% with a conversion efficiency in the gasifier of only 63%. For integrated gasification combined cycle plants, the electrical power efficiency reaches up to 43% [

17]. As seen above, the solid waste is granulated and fed to the gasification reactor where most of the MSW is converted to hydrocarbon oils at 400–700 °C. The heavy components and waxes are fed to the gasifier where they are thermally cracked at elevated temperatures to produce syngas. Below are the operating conditions of gasification reactor (

Table 1).

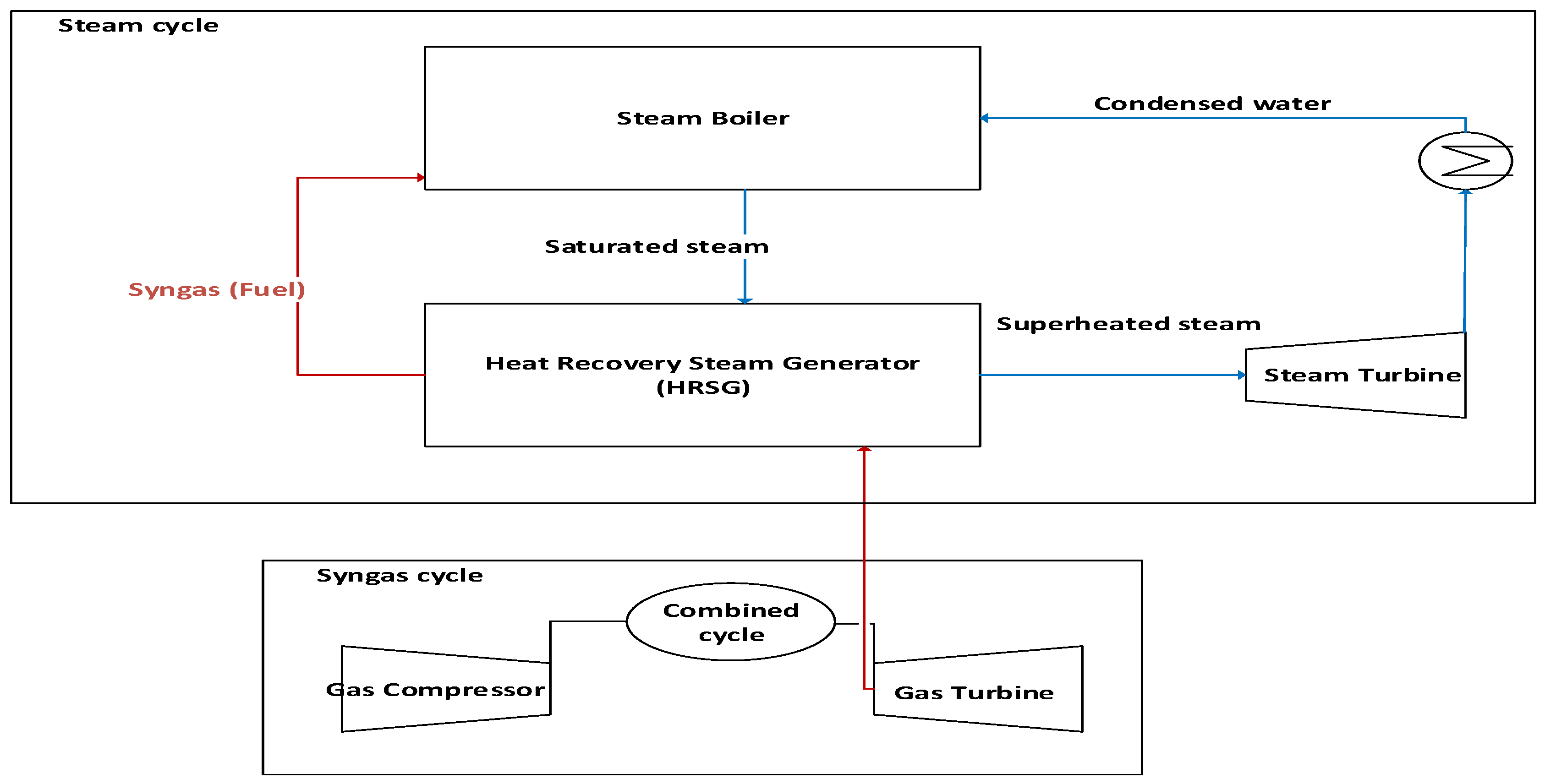

The possibility of using more than one reactor or one chemical reaction at a time is an advantage of integrated waste to energy systems. The reactor effluents are integrated in a combined syngas and steam cycle as shown in Figure 3. The heat recovery steam generator (HRSG) generates steam in the range 520–560 °C, which is utilized in the steam turbine to generate electricity. The steam turbine exhaust is exchanged with a heat exchanger before exiting to steam boiler. The electrical efficiency of combined syngas and steam cycle exceeds individual single fuel plants and may reach up to 25% efficiency [

19]. The heat recovery steam generator (HRSG) consists of several heat exchanging equipment including the following three heat exchanging zones as stated below. The combined syngas and steam cycle is shown in

Figure 2.

Superheater (SH): The superheater raises the temperature of saturated steam to high pressure steam and is located at the high temperature zone in the gasifier stream due to higher available temperature zones.

Evaporator (EVA): The evaporator converts the saturated water to saturated steam.

Economizer (ECO): The economizer consists of water pipes made of steel or cast iron materials that stands high pressure and temperature and used to heat feed water to saturated water temperatures before entering evaporator.

Combined Syngas and Steam Cycle

The integrated gasification system relies on syngas and steam combined cycles to boost the process efficiency including integrating more than one gas turbine (GT) and several steam turbines depending on the steam flow rate. Higher flow rates in the integrated combined cycle allows higher flow rate to steam turbines thus maximizes thermal efficiency [

20]. The steam boiler generates saturated steam above 100 °C, which reaches to superheated steam at 230 °C after passing through HRSG before entering the steam turbine, as shown in

Figure 2.

3. Integrated Gasification Combined Cycle Process Description

In gasification, several factors have an impact on reaction rate and products composition. The gasification reacting gases either oxygen, air or steam affect the final products. Air as a reacting agent promotes nitrous products, about 47.5 vol % on dry basis [

21]. The gasification reactions occurring simultaneously in a gasifier are shown in

Table 2.

The MSW is supplied to the gasifier which is partially oxidized under high pressure up to 80 bar based on stoichiometric ratio. High temperatures may reach 1500 °C which ensures that the ash is liquefied and allowed to escape at the lower end of the gasifier chamber [

23]. The produced syngas is cooled and cleaned before combusted in the syngas turbine which helps to meet air emission standards. The combusted gases pass through the HRSG for steam generation and heat exchanged with saturated steam before combustion. The high thermal conversion efficiencies result in a significant decrease in CO

2 and SO

2 emissions [

6].

The three major types of gasifiers are moving bed/fixed bed gasifiers, fluidized bed gasifiers and entrained flow gasifiers. In moving bed gasifiers, large particles of MSW moves slowly down the bed while reacting with oxygen forming gaseous products. Moving bed gasifiers form more than 42% of world’s installed gasifiers [

24]. The moving bed gasifiers are divided into the following three zones [

25]:

Dry zone: Located at top of the reactor

Carbonization zone: A high temperature zone located in the middle of the gasifier for heating and devolatilization of MSW feedstock

Gasification zone: This zone is located at the bottom of the reactor where the highest temperature initiates MSW and ash gasification with oxygen

Fluidized bed gasifiers are divided into bubbling bed and circulating bed gasifiers. Below are the stated advantages of fluidized bed gasifiers [

25]:

Avoidance of hot spots and good temperature distribution

Optimum heat exchanging with low operating times (i.e., seconds to minutes)

Easy startup and possibility to operate at partial loads

Steady gas flow due to fluidization and low tar content

High reaction conversion efficiency

The entrained-flow gasifiers are one of the most common gasification technologies. The advantages of this type of gasifiers are [

26]:

Reliable and proven design

No internal moving parts

Ability to supply syngas at higher pressures

Ability to gasify MSW feedstocks regardless of composition

Uniform temperature

Short residence time

4. Integrated Combined Gasification Cycle Aspen HYSYS Simulation

The assumptions made in the simulation are as follows:

All MSW used as feedstock are conventional solids with no sludge or undissolved solids.

MSW is defined using ultimate analysis and heat of formation.

Thermodynamic properties for phase separation are calculated using Peng–Robinson equation of state.

Isentropic efficiencies of all turbines are set to 86% [

27].

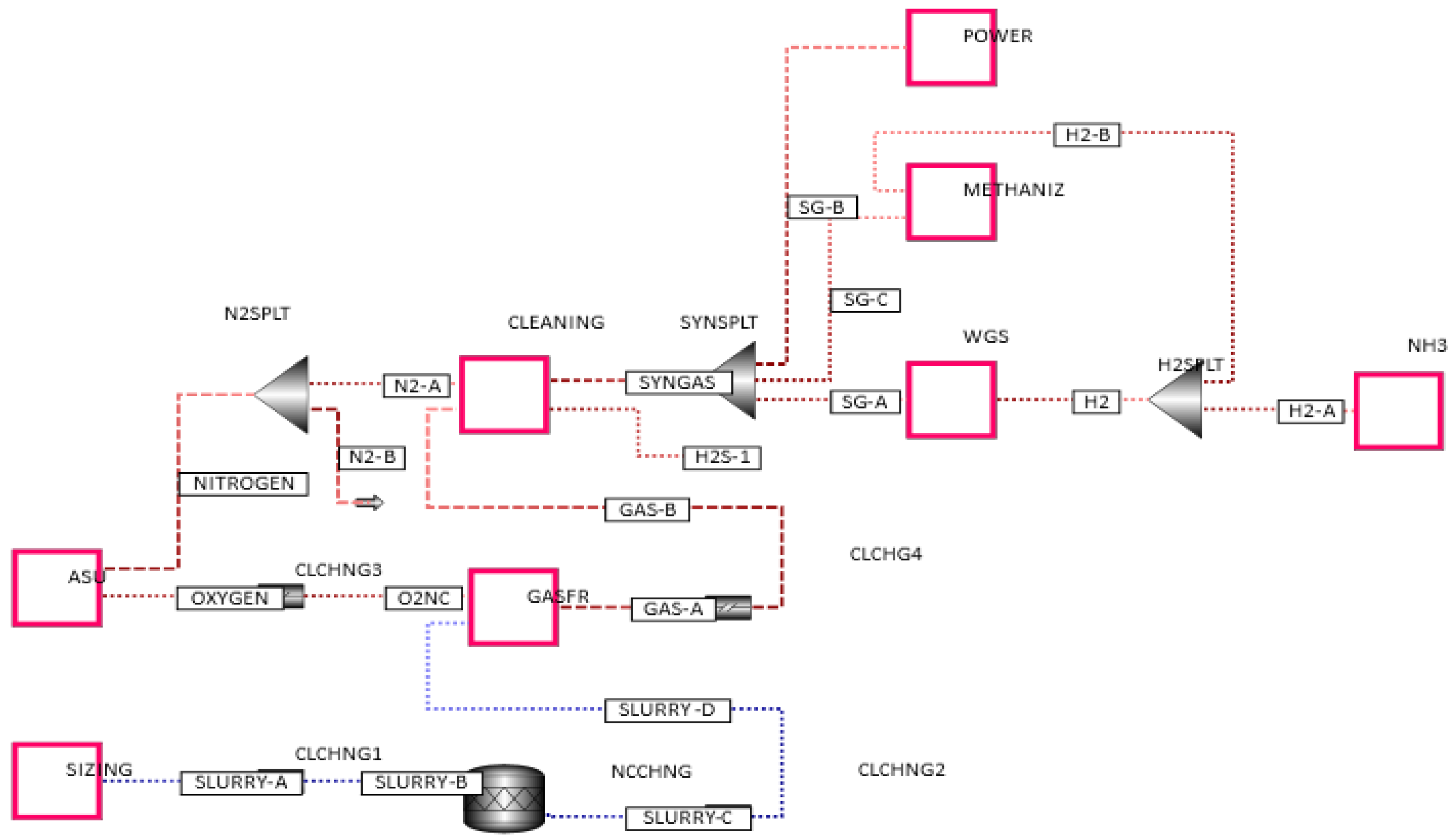

Below is the flow sheet used in integrated gasification combined cycle (IGCC) using Aspen HYSYS version 8.8 process simulation tool. The Advantages of using Aspen HYSYS includes optimization of plant operations, reducing energy consumption through heat integration, GHGs emissions estimations, and powerful approach in steady state modeling [

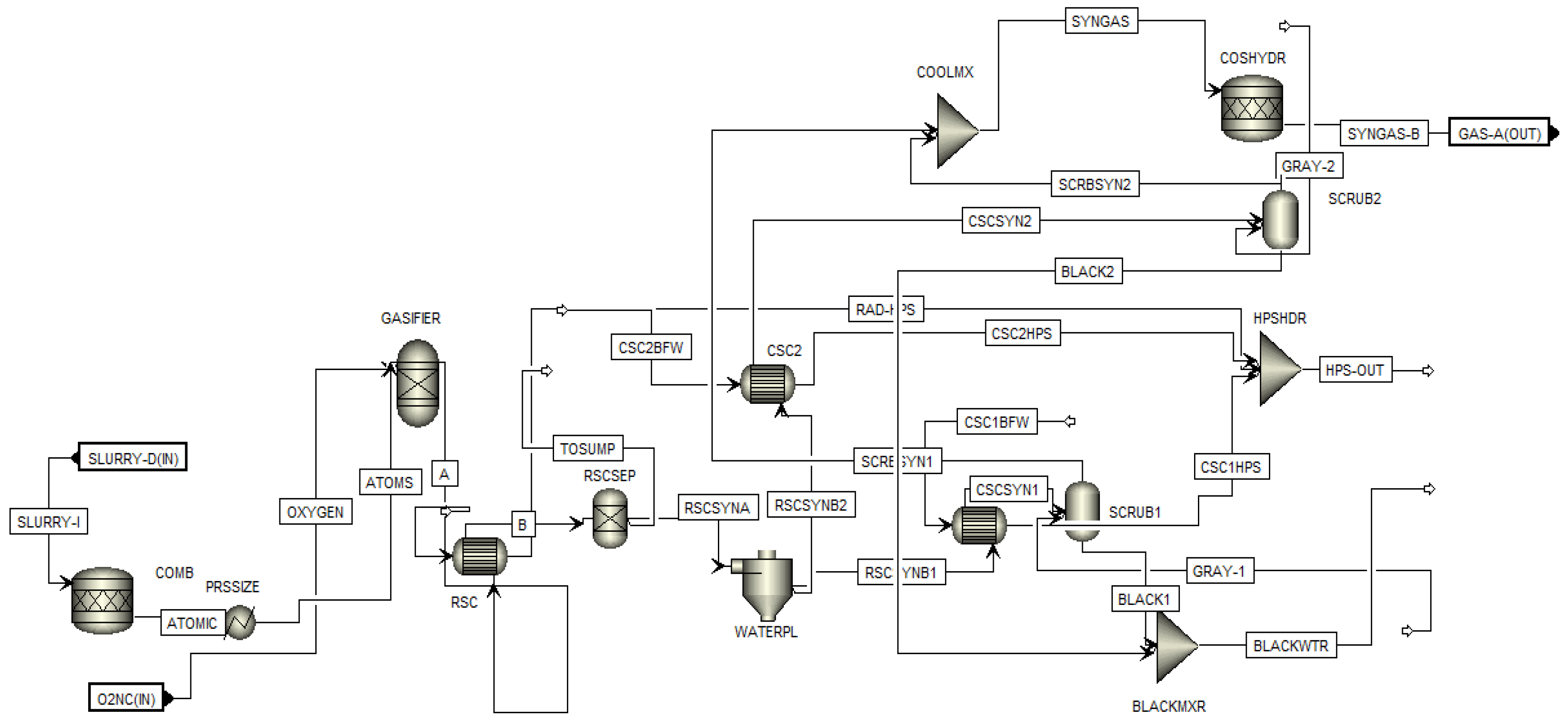

28]. Thus, these simulation tools provide optimum conceptual design and operations. The plant feed flow rate is 67,766.35 kg/h or 543.13 KTA (kilo tonnes per annum) based on 8000 h of annual plant operation. The chemical plant main process stages are listed below and seen in

Figure 3:

MSW feedstock sizing

Air separation unit (ASU)

Gasification unit (GASFR)

Syngas cleaning

Water gas shift (WGS)

Methanation

Ammonia synthesis

Electric power generation

The feedstock consists of the following municipal solid waste (MSW) mass composition shown in

Table 3. The feedstock stream slurry A passes through CLCHNG1 which changes the simulation feed from stream class MIXCINC (conventional and nonconventional solids) to slurry B, a conventional stream [

29]. In addition, slurry C stream (i.e., MIXNCPSD: non-conventional solids with particle distribution of D10: 0.01 mm; D20: 0.02 mm; D50: 0.0759; D75: 0.108 mm; D90: 0.143; and D100: 0.2 mm, which are intercepts of 10%, 20%, 50%, 75% and 90% of the cumulative mass) is converted to slurry D (i.e., MIXNC: non-conventional solids with no particle distribution) before being sent to gasifier unit. The air separation unit (ASU) separates the air into two main streams which are oxygen stream (O2NC) fed to gasifier and nitrogen stream (NITROGEN) which is utilized in syngas cleaning. The air separation unit divides 477.7 tonne per hour (TPH) air flow by ratio of 1:3.0968 for O

2:N

2. The product exiting the gasification unit consists of the mass composition shown in

Table 4, and is mainly CO, CO

2 and H

2O.

The syngas enters the syngas cleaning unit which consists of series of heat exchangers that reduces temperature from (stream B(IN) 152.22 °C to stream (Gas-AA) 140 °C after passing through SG-HTX and is cooled to (stream Gas-B2) 12.22 °C after passing through cooler. The stream passes through H

2S separator followed by CO

2 separator explained further in

Section 4.4. The pure syngas at a flow rate of 216,491.28 kg/h passes through a syngas split (SYNSPLT) which divides the syngas to the following units:

Methanation (stream SG-C), 16268.27 kg/h; mass fraction: 0.0751

Power generation (stream SG-B), 196,470.81 kg/h; mass fraction: 0.908

Ammonia synthesis (stream SG-A), 37,542.21 kg/h; mass fraction: 0.01733

For stream SG-A, the syngas passes through an equilibrium gas shift reactor that converts carbon monoxide and water to carbon dioxide and hydrogen in a stoichiometric in Table 6 [

30]. For ammonia synthesis, the treated gas, stream H2-A (IN), passes through a pressure swing adsorption (PSA) unit which separates hydrogen and carbon dioxide. The hydrogen stream (stream H

2) is mixed with nitrogen stream and converted to ammonia gas at 471.9 °C and 159 bar using Benedict–Webb–Rubin–Starling (BWRS) equation of state property method. For methane synthesis, hydrogen is mixed with carbon monoxide in ratio of 0.9958:1. The methanation reactor converts carbon monoxide and hydrogen to methane and water at 271.11 °C in a Sabatier reaction [

31]. For power production, more than 90% of the syngas passes through heat exchangers and combusted with excess oxygen to yield high gases at 1362.44 °C that is compressed before entering a turbine.

4.1. MSW Sizing

The MSW feedstock is fed at 125,840.58 kg/h and mixed with water stream in ratio of 2.392:1 respectively and converted to slurry before being grinded to 0.2 mm using a multiple roll crushers (BMILL1 and BMILL 2) followed by a wet screening which screens to 0.3 mm using coarse split entrainment specification as seen in

Figure 4.

Crushers BMILL1 and BMILL2 each has a mass flow rate of 33,880.16 kg/h and uses 306 HP of power using screening equipment which have power efficiency of 0.324.

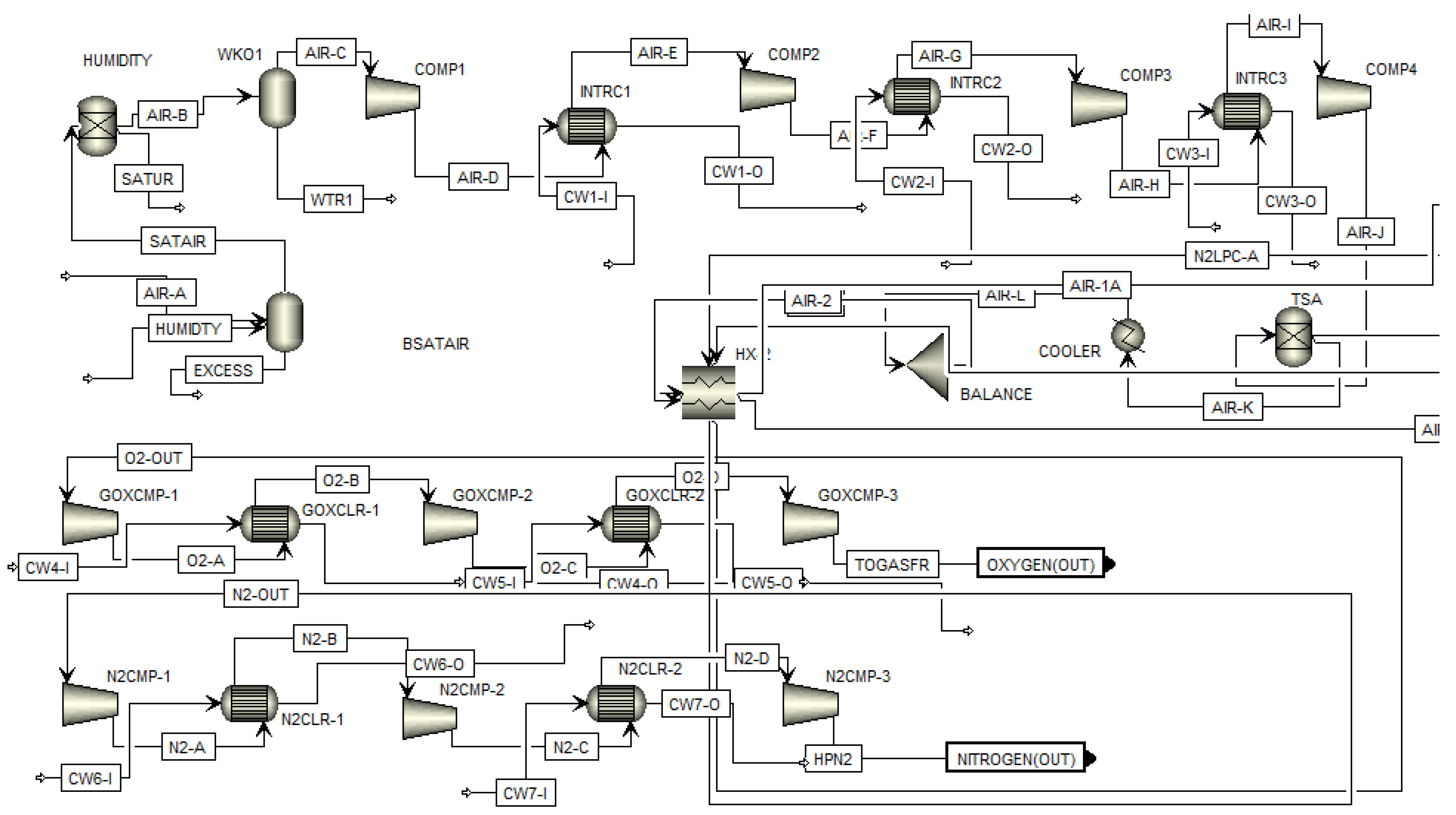

4.2. Air Separation Unit (ASU)

The inlet air (stream AIR-A), is fed at a flow rate of 16,495.22 kg/h and mixed with water vapor to produce saturated air stream (SATAIR). The temperature of saturation drums (BSATAIR) is adjusted based on relative humidity and saturated air (stream AIR-B) is fed to coolant drum that reduces its temperature to 10 °C followed by four compression stages that increases air pressure from 1.01 bar to 1.97 bar, 3.65 bar, 5.13 bar and 6.22 bar, respectively, over four compressors (COMP1 to COMP4). The compressed air enters the temperature swing adsorption unit (TSA) which operates at 60.2 °C. The temperature swing adsorber (TSA) separates O

2 and N

2 gases where both gases are compressed separately over three compressors (For O

2: GOXCMP1, GOXCMP2, and GOXCMP3, For N

2:N2CMP1, N2CMP2 and N2CMP3), as shown in

Figure 5. For O

2, the gas is compressed from 1.1 bar to 6.5 bar, 23.08 bar and 41.03 bar, respectively, before being sent to gasifier unit, as seen in

Figure 5. For N

2 gas, it is compressed from 1.1 bar to 5.52 bar, 20.7 bar and 27.58 bar, respectively, and sent to gasifier at the latter pressure (stream: NITROGENOUT). The work duties of compressors are shown in

Table 5.

4.3. Gasification Unit

The municipal solid waste slurry enters the gasification unit at a flow rate of 67,766.35 kg/h and mixed with air flow at 116,601.36 kg/h in a ratio of 1.721:1 (air: MSW) at 49.6 bar in the gasification chamber. The gasifier operates at 32.75 bar and 1437.92 °C in a continuous reaction emitting vapor phase at a composition of 49% CO, 22.4% CO

2, 20% H

2O and traces of argon and nitrogen gas. The gasification effluent pass through heat exchangers that reduce its temperature from 1437.92 °C to 818.728 °C before passing through two scrubbers (SCRUB1 and SCRUB2) that reduces water content, H

2S, methane, CO, CO

2, and COS before being sent to syngas cleaning unit (stream: GAS-A(OUT)) as seen in

Figure 6.

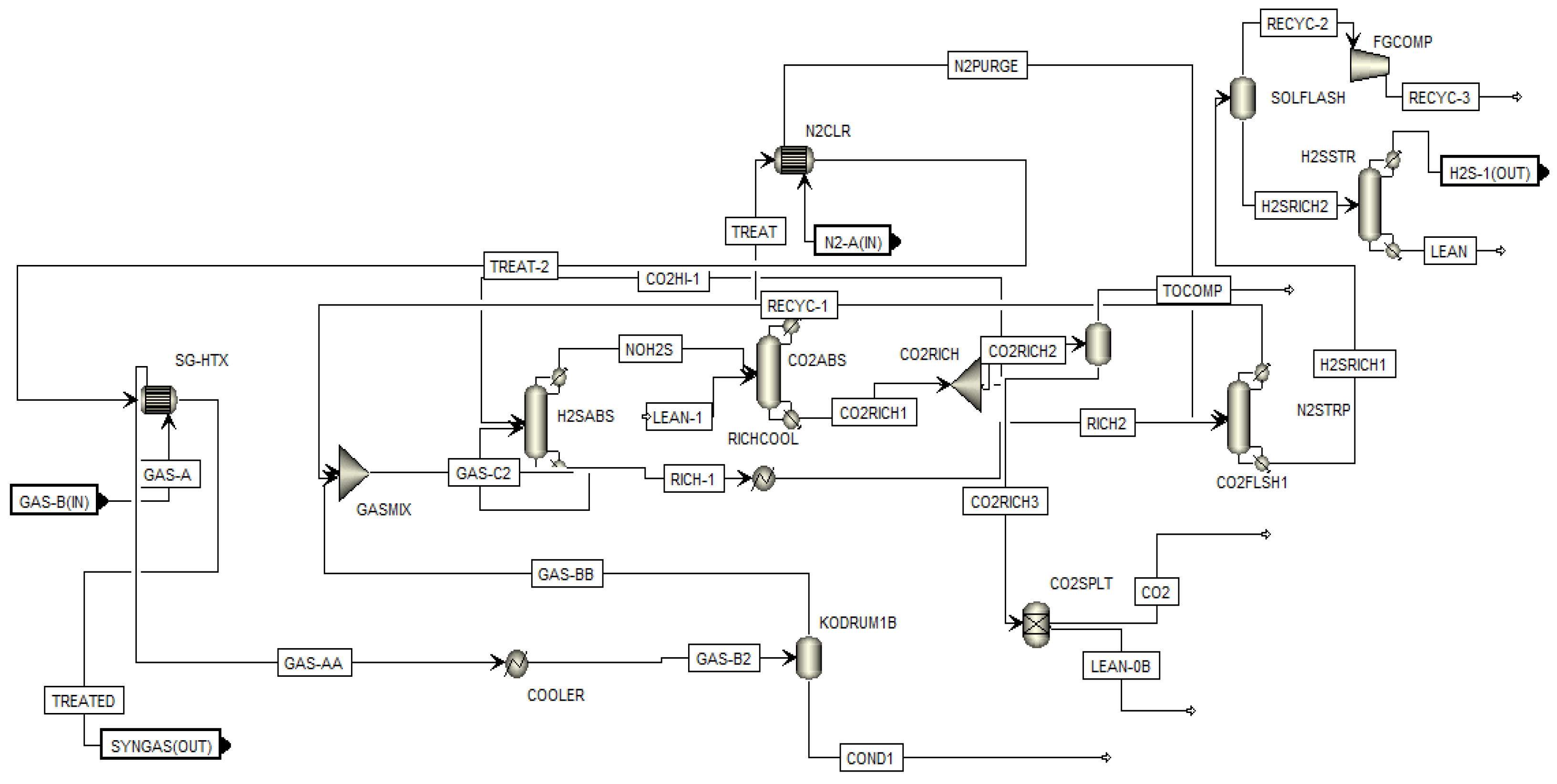

4.4. Syngas Cleaning Unit

The inlet syngas flow rate is 272,183.998 kg/h which enters SG-HTX where it is mixed with treated syngas and nitrogen and cooled from 140 °C to 12.22 °C. The cooled gas enters KODRUM for O

2, Argon, CO, N

2, COS and H

2S removal and cleaning. The outlet gas is mixed with CO

2 free syngas and enters 20 stage H

2S absorber (H2SABS) that operates at 27.58 bar where H

2S is removed and pure outlet stream (NOH2S) is sent to carbon dioxide absorber (CO2ABS), as seen in

Figure 7. The CO

2ABS is a 10-stage equilibrium reaction that operates at 27.58 bar and removes CO

2. The effluent gas is then mixed with nitrogen stream (N2-A (IN) and is sent to N2STRP vessel. The N2STRP vessel consists of a 15-stage vessel that separates nitrogen allowing the effluent to be recirculated again in gas mixture (GASMIX) before H

2S absorber. The final gas stream SYNGAS (OUT) is heat exchanged and sent to at 93.33 °C at a flow rate of 13, 440 m

3/h to methanizer, power generator and ammonia synthesis unit.

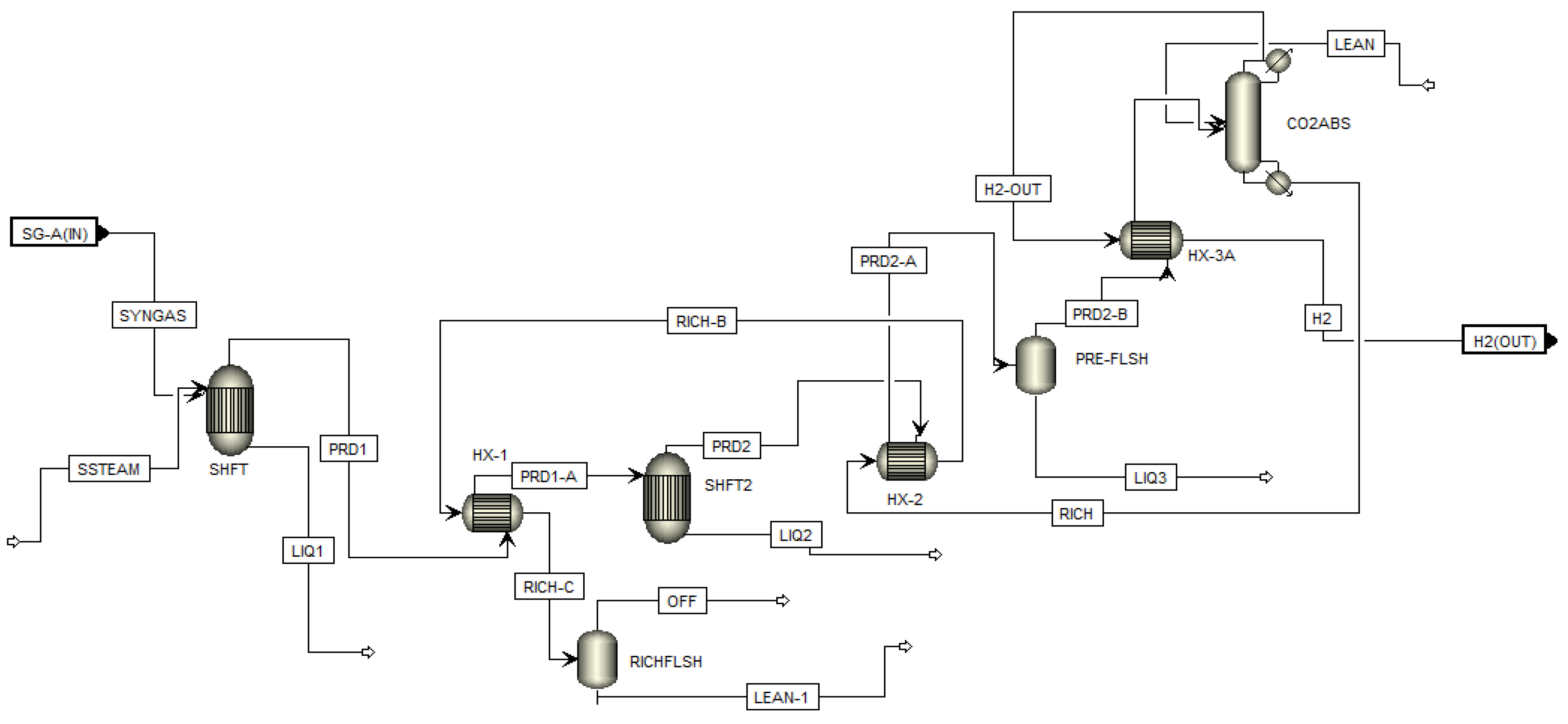

4.5. Water Gas Shift Unit (WGS)

The inlet syngas flow rate is 37,542.21 kg/h which enters the first shift reactor (SHFT, 2.73:1, syngas: H2O) with 13,778.05 kg/h steam at 343.33 °C and 24.13 bar to achieve the stoichiometric reaction. The product gas is 51,320.35 kg/h consisting of 41% hydrogen, 20% carbon dioxide, 19% nitrogen and traces of methane and carbon monoxide. The effluent stream (PRD1) is cooled from 415.75 °C to 132.22 °C in HX-1 before entering second shift reactor (SHFT2).

In the second shift reactor, water and carbon monoxide are converted to carbon dioxide and hydrogen at 210.44 °C and 24.13 bar. The effluent gases consists of 48%, 27% CO

2 and traces of nitrogen and water and cooled in HX-2 from 210.44 °C to 0 °C. The effluent gas PRD2-A enters flash separator (PRE-FLSH) where 94% of water is removed through a bottom outlet stream (LIQ3). The effluent of flash separator is cooled from 0 °C to −23.33 °C before entering the carbon dioxide separator (CO2ABS). The carbon dioxide separator is a 15-stage equilibrium reactor at −22.55 °C and 24.13 bar that absorbs 88% of CO

2 as seen in

Figure 8.

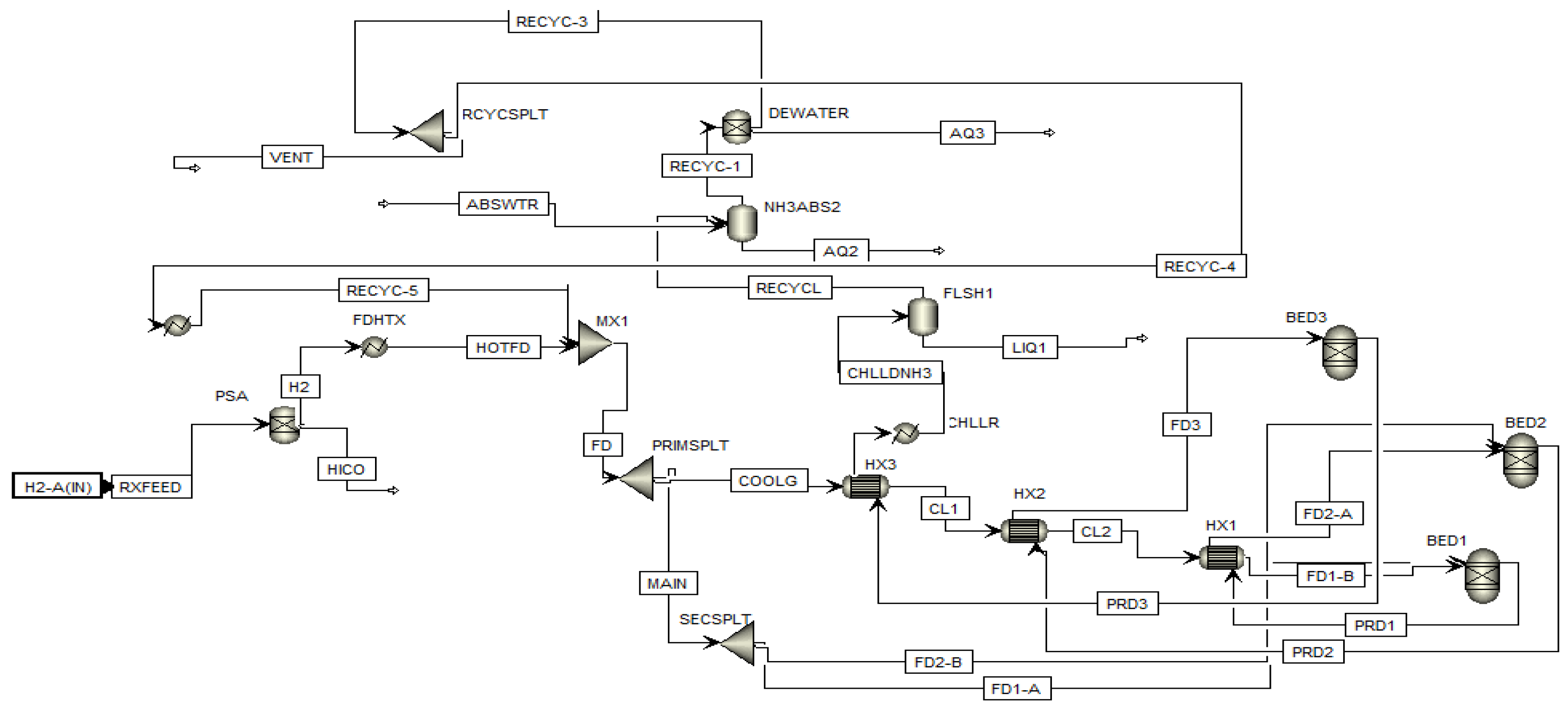

4.6. Ammonia Synthesis Unit

As seen in

Figure 9, 8723.26 kg/h (H2-A (IN)) hydrogen and nitrogen mixture stream is fed to the pressure swing adsorber (PSA) in ratio (H

2:N

2, 0.75:0.2502) where pure hydrogen is produced at a flow rate of 6047.07 kg/h and heated from −4.04 °C to 219 °C in FDHTX. The hydrogen is then heated over three heat exchangers (HX3, HX2, and HX1) from 218.99 °C to 239.21 °C, 366.68 °C and 390.76 °C, respectively, and enters ammonia synthesis reactor. The ammonia synthesis reactor (Bed1 and Bed2) operates at 426.99 °C and 159 bar in a phase equilibrium reaction followed by ammonia absorption vessel (NH3ABS2).

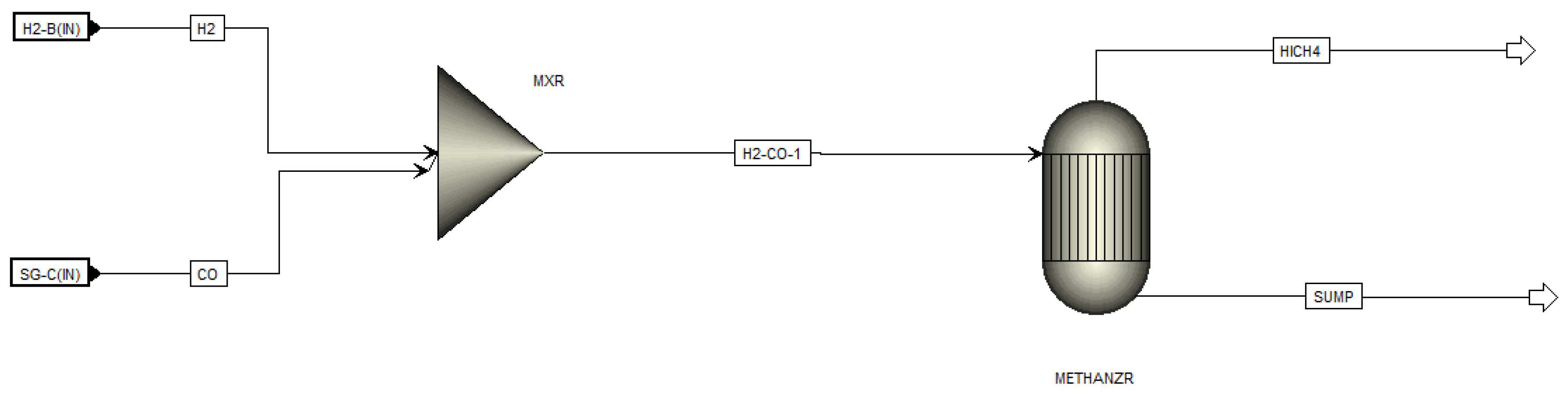

4.7. Methanation Unit

In this unit, carbon monoxide reacts with hydrogen in a reverse reaction to yield methane and water, as shown in

Figure 10. The flow rate of hydrogen is 16,200.38 kg/h which reacts with 61,627 kg/h N

2 (H2:N2, 1:3.804) at 271.11 °C in an equilibrium reaction producing 32,468.66 kg/h CH

4 at product yield of 24% with nitrogen steam (HICH

4) [

32,

33].

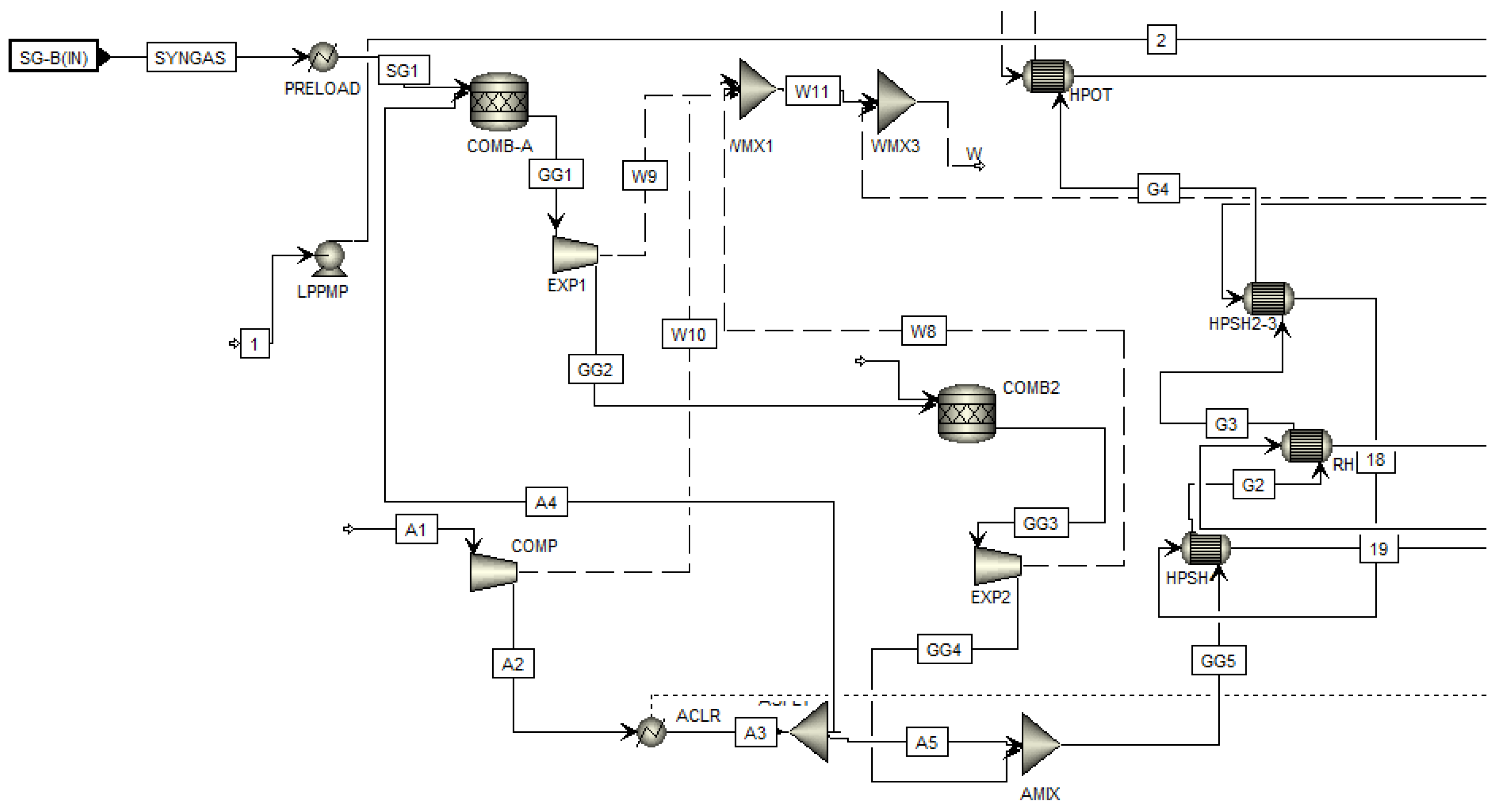

4.8. Power Generation Unit

The input flow rate of syngas to power generation unit is 196,470.81 kg/h which accounts for 90.8% of syngas and is combusted with 1,344,103.05 kg/h in ratio of (Syngas: Air, 1: 6.84) generating 1,540,576.59 kg/h of combustible gases. The gases generate 121,104 HP in turbine 1 (EXP1), and 470,269 HP in turbine 2 (EXP2). In the first combustion chamber (COMB1), carbon monoxide is combusted to carbon dioxide, while, in the second combustion chamber (COMB2), hydrogen is combusted to water as seen in

Figure 11.

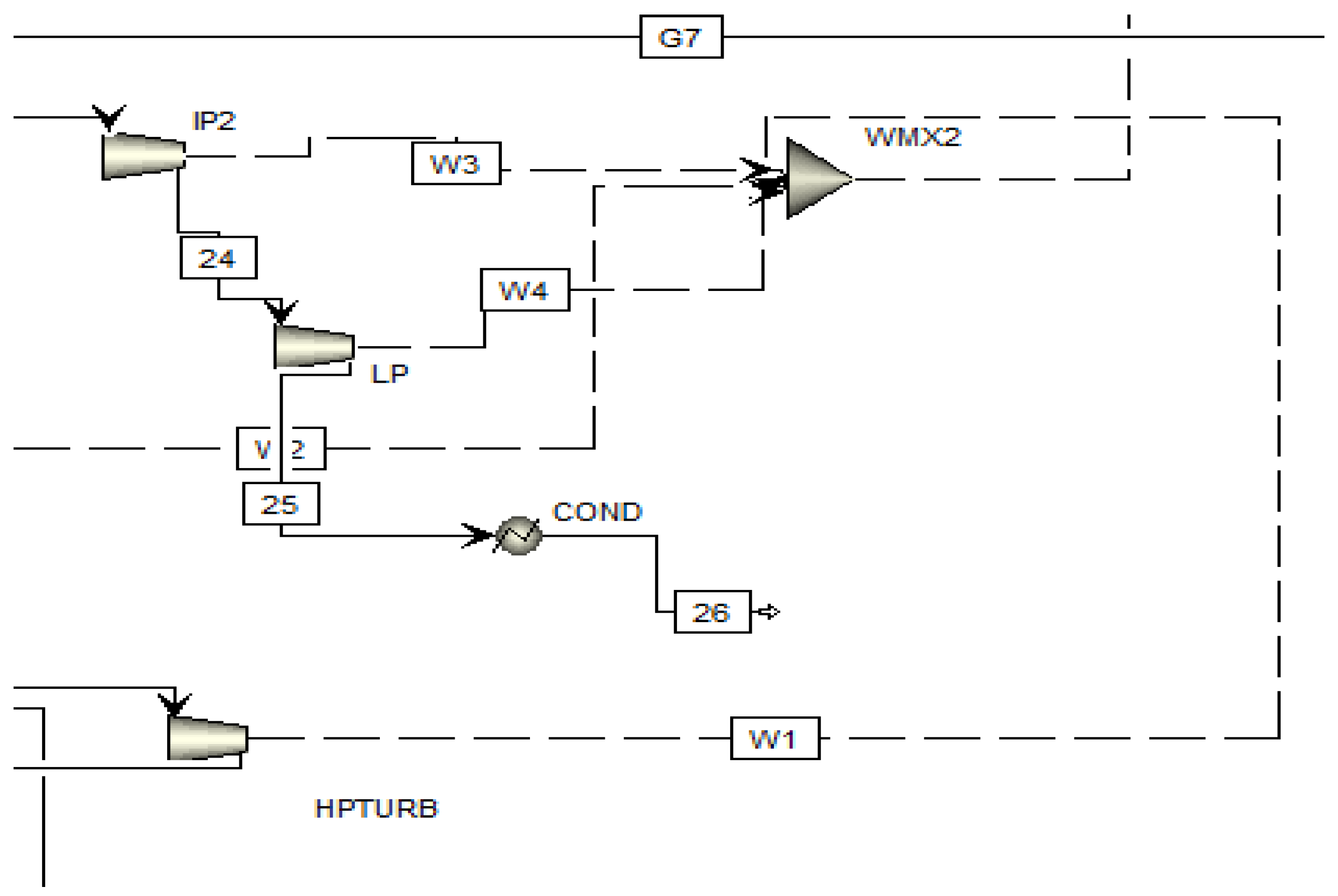

In the second stage of electricity generation (

Figure 12), there are four turbines that generate electricity: IP1, IP2, LPTURB and HPTURB. IP1 generates 38,157 HP, IP2 generates 15,123 HP, LPTURB generates 52,887 HP and HPTURB generates 28,801 HP. Overall, this unit generates 1284.89 MW using combusted fuels from syngas. The isentropic efficiencies of all the turbines are 86%.

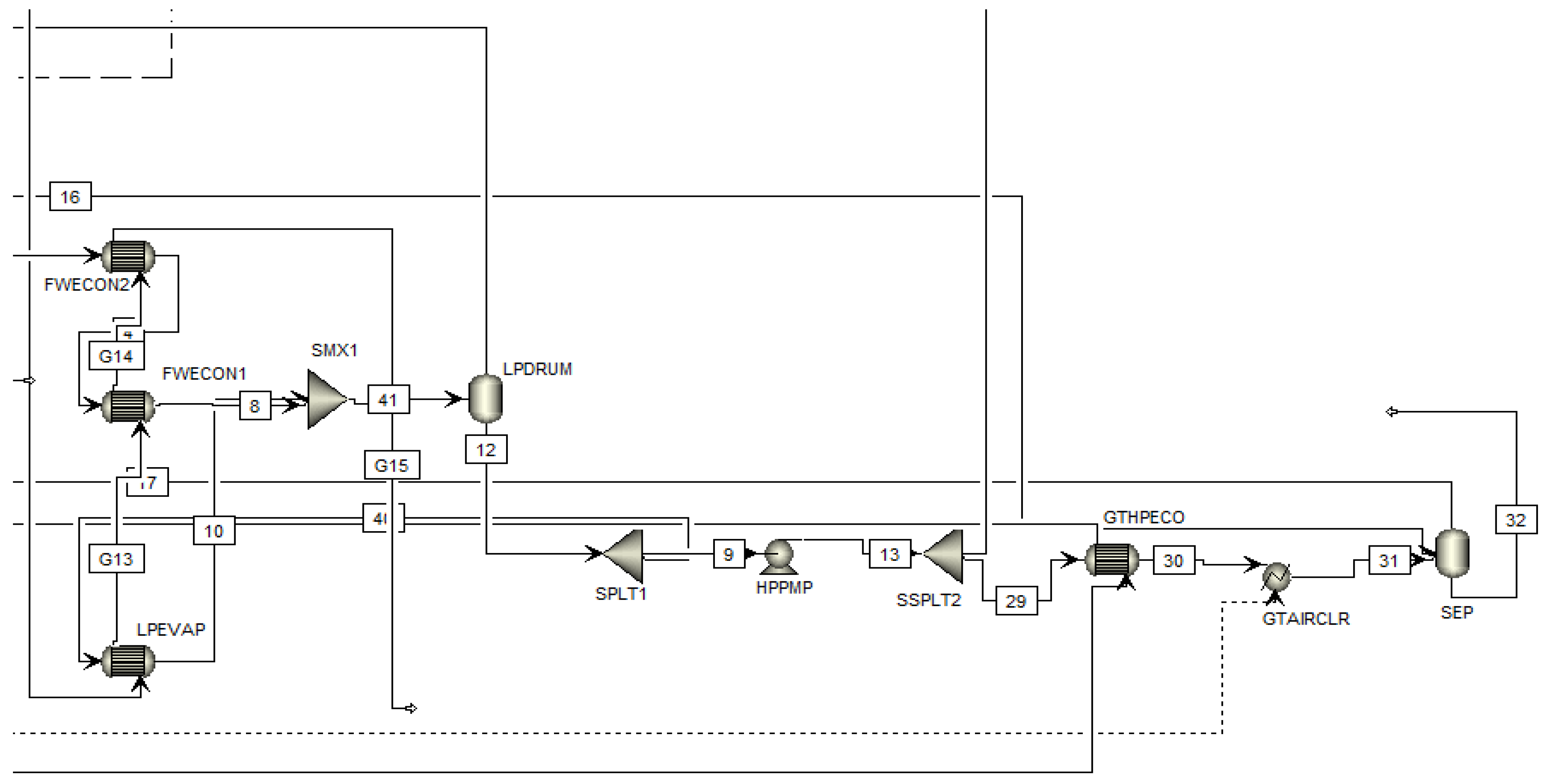

As seen in

Figure 13, FWECON1 and FWECON2 heat exchanges water with air, where water is exchanged from 177 °C to 38.42 °C in FWECON1 and sent to LPDRUM which separates vapor from liquid content. The liquid content (Stream 12) is sent for further separation (

Figure 13), while vapor content leaves the drum as effluent.

The Steam/Water heat exchange integration is chosen in which the turbine exhausts are exchanged with water. This solution guarantees an increasing of the WTE plant efficiency and avoids corrosion problems.

4.9. Chemical Reactions

Table 6 lists the chemical reactions used in simulation.

4.10. Energy Analysis

4.10.1. Heating and Cooling Duty Analysis

Figure 14 shows the overall energy plant results, comparing actual energy duties with target duties. The heating duties form 55.3% while cooling duties form 44.65% of a 543.13 KTA MSW IGCC gasification plant.

4.10.2. Energy Analysis

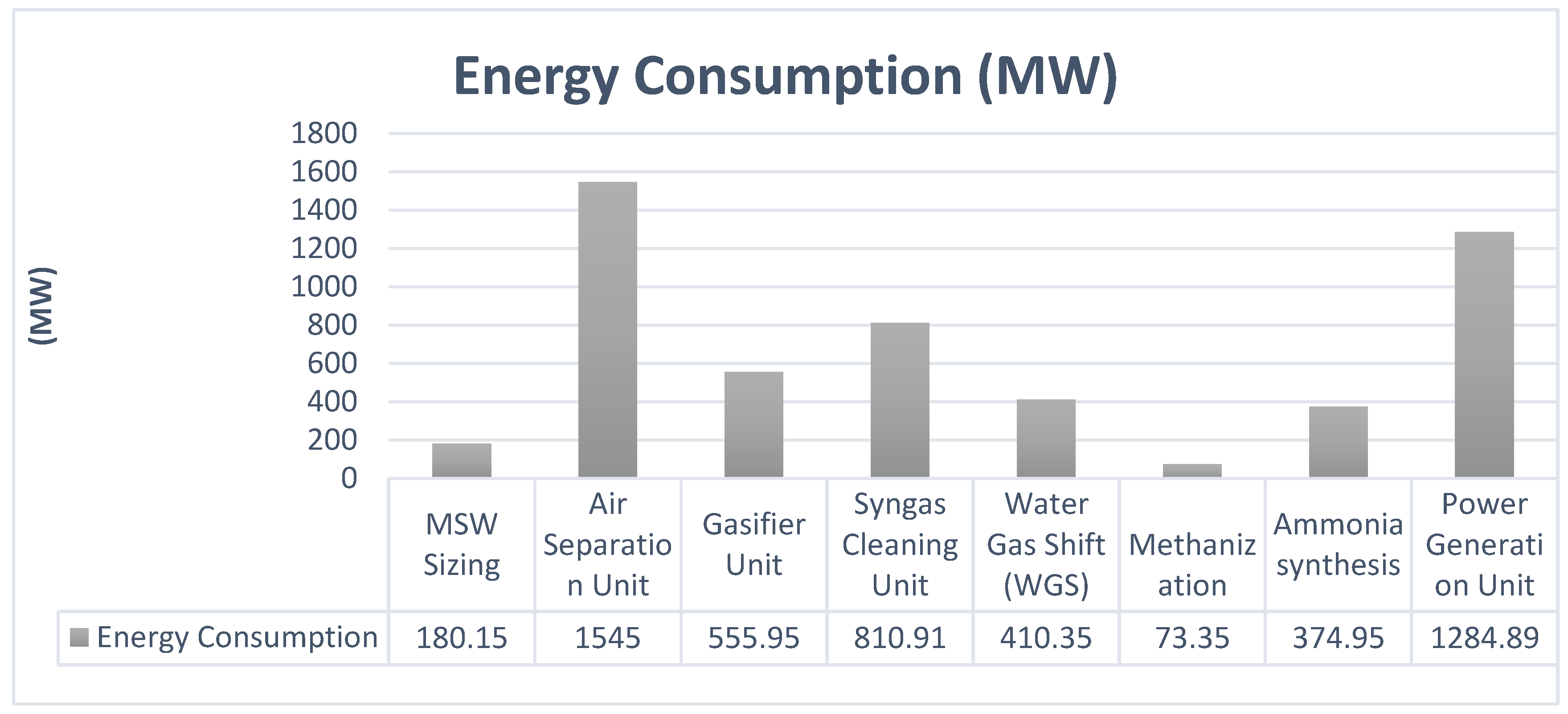

Figure 15 shows the energy consumption for every stage in the MSW IGCC plant.

5. Discussion

The 543.13 KTA IGCC plant consists of seven process units in which the air separation unit (ASU) consumes 30% of energy consumption used in the process system. This can be justified by use of 10 compressors in ASU as well as the very high flow rates. In addition, the syngas cleaning unit consumes 15.5% of energy used due to large number of separators, coolers and compressors. In terms of heat integration network, 693.3 MW is saved, accounting for 82.9% of total energy. The final products are the following:

1284.89 MW of energy produced

Liquid ammonia: 8,731.07 kg/h at 8 °C

Methane: 32,468 kg/h at 271 °C

In the MSW sizing unit, MSW is wet mixed with water in ratio of 2.392:1 followed by two crushing units to 0.2 mm and one screening unit. The screened MSW is then sent to the gasifier unit. Advantages of wet crushing design are the ability to crush highly cohesive materials, shorter processing times in comparison to dry crushers and less equipment maintenance. The air separation unit (ASU) receives 16,495.22 kg/h of air, which is mixed with water vapor, forming the saturated air stream that is fed to four compressors raising its pressure to 6.22 bar before entering the temperature swing adsorption (TSA) unit that operates at 60.2 °C and separates nitrogen and oxygen into two streams. The oxygen is then compressed over four compressors to 41.03 bar and fed to gasifier in a stoichiometric ratio. Nitrogen stream is compressed over three compressors to 27.58 bar and is sent to syngas cleaning unit. This ASU design has the advantage of fast operations using continuous TSA as well as multistage compressors for oxygen and nitrogen thus increasing operation reliability. It is noted that nitrogen compressors have higher working duties justified by higher pressure differentials. The gasifier unit gasifies MSW at air ratio of (1.721:1, air:MSW) at 32.75 bar and 1437.92 °C in a continuous process releasing syngas with a composition of 49% CO, 22.4% CO

2, and 20% H

2O following the gas scrubbing stage. The scrubbed syngas is sent for syngas cleaning unit followed by power generation, methanation and ammonia units. The advantage of the gasification unit is continuous gasifier operations with multistage syngas scrubbing, which increases reliability and delivers continuous syngas to the whole plant. The syngas cleaning unit consists of H

2S absorbers, CO

2 absorbers and N

2S absorbers, respectively. This design starts with H

2S absorber since this improves process stability and reduces severity in other separation drums [

34]. The water gas shift (WGS) unit is a preliminary stage of ammonia synthesis, which includes a shift reactor followed by heat exchangers and a CO

2 absorber. This design eliminates toxication of reactors in methanation and ammonia synthesis units and ensures continuous flow of hydrogen to both units [

35]. The ammonia synthesis unit consists of pressure swing adsorber (PSA) followed by ammonia equilibrium reactors that operate in a stoichiometric continuous flow. The methanizer unit consists of a methanation equilibrium reactor that mixes hydrogen and carbon monoxide. The power generation unit consists of two combustors in series that utilize syngas to generate electricity followed by series of gas and steam turbines. This design has an advantage of multistage pressure turbines, which increases both thermal and electrical efficiencies [

36]. Overall, the plant shows reliability and steady stage modeling in all units

6. Conclusions

In conclusion, the proposed conceptual design achieves 82.9% energy integration efficiency, which is much higher than non-integrated single cycle gasification plants. The conceptual design converts 542.13 KTA of MSW to 1284.89 MW electricity, 8731.07 kg/h liquid ammonia and 32,468 kg/h methane. The electricity is produced using four syngas turbines and three steam turbines as well as liquid ammonia at a flow rate of 8731.07 kg/h and methane at a flow rate of 32,468 kg/h. The air separation unit (ASU) consumes the highest energy, approximately 30%, followed by syngas cleaning unit (15.5%), while the gasification unit consumes only 10.7%. The conceptual simulation model reflects real plant simulations and enhances system energy efficiency considering heat integration and continuous operations. It can be concluded that integrated gasification systems have higher thermal efficiencies with lower environmental emissions.