1. Introduction

Atmospheric emissions arising from human activities are a common problem in medium and large conurbations and urban transport is often a major source of emissions [

1,

2]. Apart from carbon dioxide emissions, the increase in the number of vehicles leads to a rise in emissions of nitrogen oxides as well as air pollution with fine dust resulting from abrasive wear of brake pads [

3], tires [

4,

5] and road surfaces [

6]. In addition, the consumption of non-renewable fuels translates directly into environmental pollution [

7], comprising emissions of: carbon monoxide (CO), nitrogen oxides (NO

x), sulphur dioxide (SO

2), hydrocarbons (CH

x, including polycyclic aromatic hydrocarbons (PAH)), dioxins and benzene, as well as particulate matter (PM, mainly carbon, cadmium, zinc, nickel, platinum and chromium) [

8,

9].

The particularly discrete ecological footprint in urban environment is made by urban freight transport [

10,

11]. Urban logistics involve various entities whose interests are often conflicting, which makes it more difficult to implement ecological solutions in this regard [

12]. Crainic et al. [

13] assert that this is mainly due to the fact that the urban sector of freight transport is private. Private shippers often pay less heed to generating negative effects that mainly include noise, environmental pollution, compromised traffic safety and deterioration of urban infrastructure [

14]. A good example might be the problem with sustaining consolidation centres that often discontinue their activity as soon as the supporting project aimed at their establishing and start-up has expired [

15]. To a significant extent, this is caused by disparity of interests within public–private partnerships.

In view of the above, the problem of urban logistics operations in the context of its impact on the environment has become the key challenge for all stakeholder groups involved in freight transport in urban areas [

16,

17,

18]. Numerous initiatives have emerged in direct response to these problems, including international projects, such as BestUFS (BEST Urban Freight Solutions,), TRAILBLAZER (Transport and Innovation Logistics by Local Authorities with a Zest for Efficiency and Realisation), SUGAR (Sustainable Urban Goods logistics Achieved by Regional and local policies), C-LIEGE (Clean Last mile transport and logistics management for smart and Efficient local Governments in Europe), STRAIGHTSOL (Strategies and measures for smarter urban freight solutions), COFRET (Carbon Footprint of Freight Transport) and GRASS (Green And Sustainable freight transport Systems in cities). While local authorities and inhabitants are the ones most affected by the negative effects of urban freight transport, it is the private companies that are to a large extent able to increase the stability of solutions that reduce them. Dablanc describes it as a badly organized urban logistics system—when delivering goods, shippers adapt to the imposed restrictions, but, from the cities’ point of view, the deliveries could be much more optimized in terms of their destinations, which would help reduce the number of vehicles entering the cities [

19]. Nevertheless, over the recent years there has been a growing interest in using alternative fuel vehicles in urban logistics, including those equipped with electric drive systems [

20].

Since the 1970s, there has been a noticeable increase in interest in alternative fuels for cars [

21,

22]. Actions aimed at implementing new technologies were forced by the oil crises [

23]: first in 1973, then shortly afterwards in 1979–1982 and in 1990. The result of those actions led to the development of alternative car fuels. Currently, the alternative propulsion systems for motor vehicles include mainly [

24,

25,

26]: gas-powered drives-LPG (Liquefied Petroleum Gas) and CNG (Compressed Natural Gas) [

27], biofuels, hydrogen-based technologies [

28] and electric drives [

29]. Gas-powered drives (LPG I CNG), compared to traditional fuels, produce 18% less greenhouse gas and generate ca. 3 dB less noise [

26]. Their major drawbacks include greater fuel consumption and limited possibilities of filling up the tank [

27]. Currently, it is the most popular alternative for vehicle powering; moreover, studies on gas fuels are at the most advanced level. Biofuels—in this case IC engines—are modified in such a way that instead of petrol or diesel they use ethanol, being the result of biomass fermentation [

1]. Currently, the US is the leader in biofuels use [

30], as half of the maize grown there is intended for bioethanol production. There are two major ways of obtaining energy in hydrogen drives, where the fuel is hydrogen [

31]: hydrogen combustion taking place in a typical piston engine combustion chamber and using fuel cells that produce energy as a result of oxidizing the fuel constantly supplied from outside. Hybrid drives involve a traditional engine combined with an electric one [

32]. Currently, the basic types of solutions used are, serial drives (IC engine operates all the time, driving the generator which in turn supplies power to the electric motor that propels the vehicle wheels, while any excess power is stored in the battery) and parallel drives (where both the IC engine and the electric one propel the wheels of the vehicle). Electric drives can use only battery powered electric engines [

25]. They produce less pollution as well as operate more quietly [

33]. Considering the restrictions that are more and more frequently imposed on freight vehicle traffic, as well as taxes and fees charged by local self-governments, application of electric vehicles may contribute to a reduction in delivery costs in cities, which may account for up to 40% of total transport costs [

34].

One of the first research projects regarding the use of electric vehicles in urban freight transport was the ELCIDIS (Electric Vehicle City Distribution) project [

35]. However, the costs of purchasing electric vehicles are still perceived to be a substantial barrier to their widespread use. Additionally, a substantial difficulty lies in selecting vehicles with operation parameters that fulfil the needs of the logistic processes they are to serve. Therefore, the key challenge is the optimization of the transport fleet while taking into account a multi-criteria evaluation of benefits. City logistics involves implementing schemes in cities for reducing the impacts and costs of freight [

36]. There are a number of city logistic solutions that involve modifying freight vehicles including alternative fuels such as electric vehicles that can be implemented [

37]. More and more effective measures have started to be implemented in cities in recent years [

38,

39].

Although it has been more than 100 years since an electric vehicle first exceeded a speed of 100 km/h [

40], the fundamental difficulty still to be overcome is the problem of storing large amounts of energy in batteries with relatively small weight, as well as the problem of how to charge them rapidly [

41]. The “Jamais Contente” electric vehicle developed by the designer Camille Jenatzy was equipped with 40 kM DC motor and a powerful acid battery bank that ensured the travel range of several kilometres. The problems encountered by Jenatzy have not yet been fully solved. Research on new electric motor designs is still underway, aiming at obtaining high operating parameters as well as advanced systems of drive control, supported by telematic solutions [

42]. The EU transport policy stipulates—according to the intentions presented in the White Book—to reduce the number of IC engine vehicles to 50% by 2030, and phasing them out by 2060 [

43]. Although EVs (Electric Vehicles) do not yet have a significant share in the European vehicle market, there is a noticeable, fast and continuous increase in the number of electric vehicles sold [

34].

The application of electric vehicles in urban logistics is related to fundamental advantages of using this type of drives. However, it is important to underline some impediments and barriers that must be overcome in order to enable a significant increase in the interest in utilization of them in urban freight transport systems, especially considering the business stakeholders’ perspective. One of them is the proper choice of the vehicles. The technical parameters of electric vehicles in city logistics are strongly related to the specificity of the tasks, which are realized by the stakeholder, including type of deliveries, number of deliveries, distance, etc. [

44,

45]. Nowadays, no general method to help properly choose electric vehicles considers the needs of urban freight transport business’ stakeholders. Due to the many technical parameters related to the city logistics tasks, these decisions are based on a multi-criteria approach [

46].

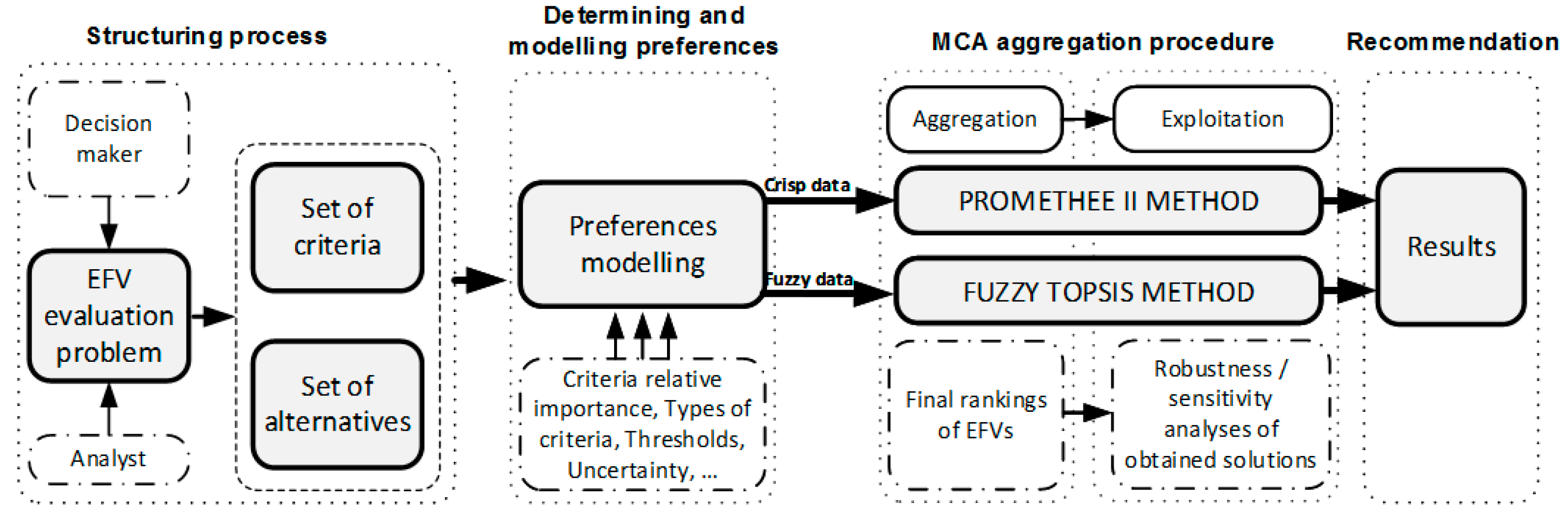

The general aim of the paper is to provide a multi-criteria analysis approach as a support for this kind of decision processes. The authors’ methodological contribution is an attempt to create a unique multistep approach based on MCA methods. This approach accommodates the analysis of certain data, as well as it provides recommendations in cases of both lacking or uncertain data in an integrated multistep decision model. Thus, it produces recommendations based on certain data, consistent with the decision maker’s (DM’s) preferences, as well as, concurrently, it allows including recommendations for the cases where the data are partially missing or uncertain. In practical terms, we apply the proposed framework in a future-proof problem of the choice of EFVs, for the purpose of deliveries in cities. In addition, generalized guidelines to facilitate effective selection of such solutions in urban logistics are provided. The article also presents the current state of knowledge regarding the extent to which electric vehicles are used in urban logistics and it describes the key parameters for determining the usability of electric vehicles in urban deliveries. Finally, based on the formulated assumptions, a multi-criteria model is presented to enable the selection, out of the defined vehicles catalogue, solutions that are optimal in terms of potential effectiveness.

The article does not discuss the use of passenger vehicles for the goods and passengers delivery at once, focusing exclusively on vehicles dedicated just to the cargo delivery. It is worth noting, however, that passenger vehicles are often used to carry loads and people at the same time. Considering this fact, it may be an interesting extension of our research but it would require expanding the database of electric vehicles with additional models and it requires the introduction of new decision criteria, such as a different payload than for freight vehicles, the number of people, etc.

2. Overview of the Current State of Knowledge Regarding Application of Electric Drives in Urban Logistics—Selected Examples

According to a report prepared by IHS Automotive, currently, the share of electric and hybrid vehicles registered in most countries worldwide does not exceed 1%. However, their number is growing rapidly, which is being confirmed by statistical data every year. Navigant Research predicts that by 2023 the share of electric vehicles in the global market will have risen to 2.4%.

According to the analyses prepared by Frost & Sullivan, the fastest growing sale markets for electric vehicles are Europe and China, and the number of such vehicles to be used worldwide is expected to approach 10 million within the next five years [

47]. As for non-European countries, apart from China, the greatest interest in electric vehicles is observed in, inter alia, the USA and Japan. These countries have become leaders in electric automotive industry development. In Europe, a significant increase in electric vehicles sales was not seen until a few years ago. In 2009, as few as 700 electric vehicles were sold, while in 2017 more than 100,000 EVs were registered; this does not include all types of hybrids with the possibility of external charging. In terms of the number of electric vehicles purchased in Europe, the leaders are: Norway, France, Germany and Great Britain.

One of the vital arguments for e-transport is not only ecology, but also economic considerations. The electric power needed to charge traction batteries costs six times less than fuel combusted by IC engine vehicles, assuming similar distances covered by both types of vehicles. Besides, the insurance and servicing costs are also lower. An electric drive is not only more ecological, but also simpler and less susceptible to technical failures compared to IC engines. Despite the higher price of electric vehicles, the maintenance costs of large company fleets based on electric drives may be substantially lower compared to conventionally powered vehicles. However, the prerequisite for introducing e-mobility is a well-developed and well-managed EV charging infrastructure [

47].

2.1. Applications of Electric Vehicles in Urban Logistics

Traffic generated by freight transport accounts for 20–30% of kilometres covered by vehicles in urban areas and for 16–50% of air pollution derived by all kinds of transport [

19,

48]. It would seem that the optimal solution should be a switchover to electric propulsion and replacing the conventional fleet with electric vehicles. Alas, shippers and drivers have bad experience related to initial implementation of electric vehicles. They primarily point out the lesser performance of electric vehicles (in comparison to the conventional ones) in terms of travel range, speed, acceleration and unreliability [

49]. Many research studies in that respect date back at least 20 years, e.g., under projects financed by the EU, such as EVD-POST (Electric Vehicle Deliveries in Postal Services) [

50]. The main conclusions highlighted the high costs of goods delivery, limited choice of vehicle models, lack of support with regard to vehicle sales and long lead time for spare parts, low capacity of batteries, limited travel range, relatively low speed and limited carrying capacity. In short, the authors of those studies indicated that the early versions of EFVs were far from perfect and they were not a serious alternative to conventional vehicles for the purposes of logistic operations in cities.

One of the first successes in terms of EV implementation is described in [

51]. It pertained to using EFVs within a cooperative framework for the purposes of urban freight transport, wherein its main idea was to establish an EFVs depot in the centre of Osaka and enable their use by multiple distribution companies. The project involved 28 electric freight vehicles, and 79 companies volunteered to participate in the undertaking. As a result of the system implementation, the number of kilometres covered was reduced, which led to a decrease in congestion. Another implementation involved a three-year project described in [

52] that was mainly aimed at long-term measurements of fuel and energy consumption, travel range when using an electric motor, drivability, lithium-ion battery capacity and durability. A van prototype was proposed, equipped with a parallel architecture of hybrid drive based on five-cylinder 2.7 L diesel engine. The electric drive system was based on a permanent magnet 90 kW motor and 15 kWh lithium-ion (Li-Ion) battery. Another attempt at developing a modular structure of electric light trucks or vans (ELTVs) was the OPTIBODY project [

53]. This time, the new architecture was to contribute to improve the passive vehicle safety, in order to reduce the number of fatal accidents and injuries.

The authors of [

54] provide a comparison of electric and fuel-powered urban freight vehicles in terms of life cycle, energy consumption, greenhouse gases (GHG) emissions and total cost of ownership (TCO). The authors engaged in studies using the New York City driving cycle that included frequent stopping and a low average speed, electric vehicles emitted 42–61% less greenhouse gas and consumed 32–54% less energy than freight vehicles equipped with diesel engines, depending on performance of individual vehicles.

Table 1 presents selected EU projects implemented in 1998–2016, the main goals of those projects and involvement of twin cities. The analysis was based on [

34] as well as final reports and web pages of the projects presented in

Table 1.

Research studies focused on comparing three-wheel electric freight vehicles of small carrying capacity in relation to freight vehicles equipped with diesel engine were performed by Tipagornwong and Figliozzi [

55]. The studies were undertaken in urban areas, and the vehicles in question were the so-called trikes, low-emission vehicles using a combination of human effort and an electric motor for propulsion.

Other studies, described in [

48], pertained to Amsterdam, a city that for many years has been striving to improve the air quality, road traffic safety and capacity, as well as to reduce noise levels by means of applying intelligent delivery methods and ecological transport. The research found that the current generation of electric vehicles is capable of operating urban freight transport quite efficiently, at the same reducing the distance covered by the vehicles by 19% (when applying consolidation), concurrently improving the air quality and reducing CO

2 emissions by 90%.

Taefi et al. [

56] features an extensive analysis regarding the existing EFV initiatives in Denmark, Germany, Holland, Sweden and Great Britain. It concluded that there is a need for such research, as urban freight transport is thought to be one of the most promising areas of electric vehicles application.

2.2. Impediments to Application of Alternative Drive Vehicles in Urban Logistics Systems

Application of alternative drive vehicles—in particular electric vehicles—in urban logistics is related to fundamental advantages of using this type of drives. These involve the possibility to produce energy from any source, lack of gaseous or solid pollutant emissions into the atmosphere, lack of noise emissions, higher energy efficiency compared to traditional drives, cheaper production of drives, their maintenance and servicing, providing energy independence, low operation costs depending on the vehicle velocity and the price of 1 kWh. The existing electric power distribution network is the best developed part of the infrastructure. However, it is also important to stress the limitations and impediments which must be overcome in order to enable a significant increase in the interest in alternative drive vehicles. These may be broken down into three basic groups [

57]: (a) economic difficulties including costs of purchasing such vehicles, costs of producing electric power for the vehicles, and costs of utilizing used-up batteries; (b) safety-related problems regarding the aspect of hardly audible operation of electric motor compared to conventional engines, which may consequently lead to collisions or accidents; but also potential risk of battery self-ignition; and (c) operational barriers, mainly connected with the fact that the full potential of alternative drives efficiency has not been fully achieved yet, long battery charging time, and limited cargo space in the case of electric vehicles.

What is important in terms of electric vehicles efficiency is the climate of the geographic area where such vehicles are used. It predominantly affects the vehicle’s travel range: in winter months, more energy is needed for heating the interior, whereas, in summer months, air-conditioning increases the power demand. An important factor to limit the efficiency of urban freight transport using EFVs is city topography. As indicated in [

58], energy consumption was high when driving on motorways and uphill. On the other hand, EFVs did well in urban traffic. Undoubtedly, the greatest barrier is the still high price of purchasing electric vehicles. They are usually more expensive than their traditionally powered counterparts. On the other hand, we can expect that businesses will be able to use different forms of support in purchasing vehicles of this type. This may mean tax relief as well as subsidies from local governments. A good example in this respect is Norway experiencing a substantial increase, the highest in Europe, in the number of electric vehicles. In this context, it is worth noting the conclusion drawn from the studies published in [

59] that EFVs will not become competitive until savings derived from the operating costs reduction are sufficient to cover the substantially higher initial costs of purchase.

The most costly component of EFVs is usually batteries, the cost of which accounts for circa half of EFV retail price. Manufacturers focus on the technical capacity of batteries and increasing the operation range while decreasing their weight and charging time. Electric vehicle batteries must feature high Ah capacity; besides, they must be characterized by high power-to-weight and energy-to-weight ratios, as well as high energy density. Research and development in this regard is still underway [

60]. Currently, economic efficiency of EFVs is characterized by high purchasing costs of batteries, and lower costs of maintenance and fuel purchase. Over a short and medium term, EV costs are considerable, however, their advantages make them more competitive in a long run. The latest research has shown that TCO may be lower for electric vehicles compared to the conventional ones [

54,

61]. It should be noted that EV purchases are currently most often financed with public funds. Private operators will be inclined to replace their fleets if: they notice benefits for their companies, an appropriate number of alternative fuel stations is provided, there are marketing benefits for the company, the given company is in any way connected with environmental protection, appropriate vehicles are available [

62]. Often, operators are forced to apply solutions of this kind by way of administrative decisions which prohibit in historic city centres or other specified areas vehicles other than those with alternative drives. The limited availability of information in model specifications and its operation is perceived as another factor to inhibit purchasing EFVs and using them in urban logistics. Source London reports that, “at the moment of purchase, there was not much information on basic elements i.e., screws and nuts or if the vehicle required water or oil”. Additionally, the impediments that inhibit the use of electric and hybrid vehicles include [

62]: higher operating costs of applying electric vehicles, small capacity of batteries, lack of battery charging infrastructure, low reliability and a large number of defects during complicated operation of the vehicles.

Over the recent years, considerable progress has been made with regard to improving the performance of electric vehicles, and many problems identified in earlier attempts at EFVs implementation in urban logistics have been resolved. Unfortunately, many problems entered a new dimension, and solutions have not yet been developed, even though the new EFVs feature longer travel ranges, more carrying capacity, better batteries and it takes less time to charge them completely or partially. It should also be noted that it is not plausible to perform all freight operations by means of EFVs. This relates to particular situations calling for vehicles with a large carrying capacity or long time of effective operation, e.g., when the vehicle must be in continuous operation for more than 12 h.

2.3. Key Factors Determining the Usability of Electric Drives in City Logistics

Although today’s EFVs demonstrate better performance parameters: longer travel range and more capacious batteries and more carrying capacity, their actual usability in urban logistics still remains limited. The authors of the report [

34] specified the challenges and factors that influence successful implementation of EFVs in everyday logistic operations in a city [

57]: (a) Technical performance: travel range of EFVs usually does not exceed 100–150 km, even though the values specified by manufacturers tend to be higher. Potential stakeholders declare a greater interest in EFVs if they see improvement of operational parameters such as travel range, operation time with a battery, increasing the number of charging points and charging stations. (b) Operational performance: EFVs show both positive and negative features in comparison to IC engine vehicles. The positive features include the limited impact on the natural environment and decrease in noise level, which translates into their usability in city centres and time windows. At the same time, the charging, carrying capacity, maintenance and the need to adjust the logistic concepts to EFV application are perceived by operators to be the major operational challenges. (c) Economics: Purchase price and TCO still exceed corresponding values related to conventional vehicles. This results mainly from high costs of batteries and EFV small production limits. In the long run, these costs are expected to diminish, which will be connected with improving the operational parameters and efficiency, cutting the purchase prices, e.g., as a result of mass production. Resale value is highly unknown, which stops investors from making purchase on the primary market. (d) Environmental performance: EFVs cause less CO

2 emissions compared to their conventional counterparts, however, their demand for energy as well as energy prices in a long run and energy capacities of individual countries require analyses and research studies. (e) Social and attitudinal impact: EFVs are less noisy and more environmentally friendly than conventional ones, therefore most of the public show a positive view on this direction of development. (f) Impact of local policy and governance structure: Governments of many European countries take up new directives aimed at increasing the use of EFVs while decreasing the use of conventional vehicles.

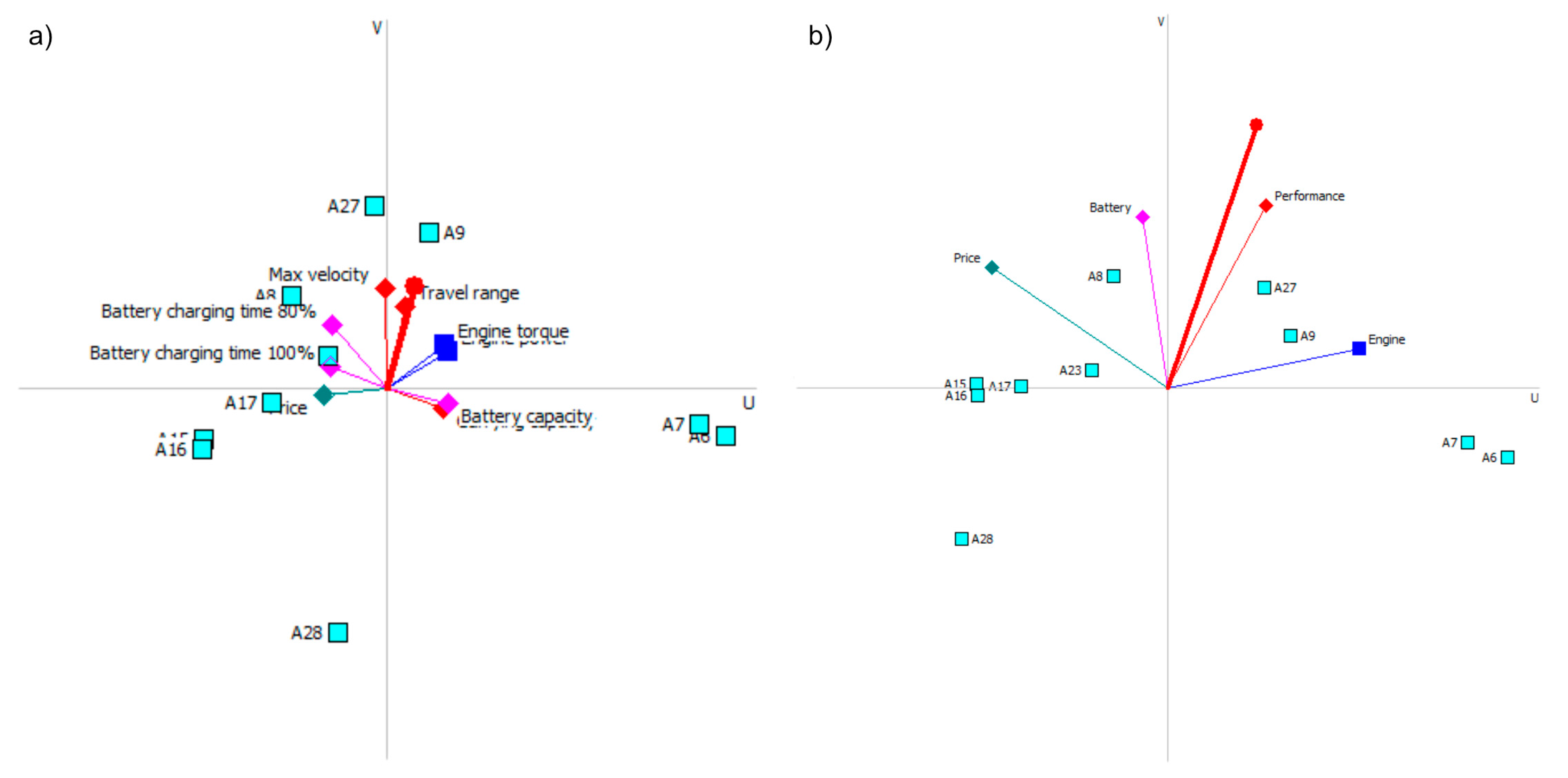

Technical performance of EFVs (within the scope discussed further on in this article, i.e., carrying capacity, maximum velocity, travel range, engine power, engine torque, battery charging time, battery capacity) is improving with every new design and model. In addition, the economic factor, i.e., price, is changing. This considerably contributes to the growing interest from potential investors who also pay attention to additional aspects that are already implemented in conventional vehicles, e.g., telematics solutions and applications related to safety of drivers, passengers and cargo.

The assumptions for the model introduced below are one of the results of the cooperation with city logistics stakeholders under the work of the Freight Quality Partnership in Szczecin. The partnership has been established as a major activity of international projects C-LIEGE. The activities have been continued under the next international project GRASS. The FQP in Szczecin was focused on identification of major problems and establishing of the proper actions to improve the functioning of urban freight transport in city. The utilization of electric vehicles was one of the most important potential measures. The meetings with UFT stakeholders helped to establish among others the general expectations regarding implementation of electric vehicles in Szczecin city logistics system.

4. Conclusions

This paper has presented a unique MCA-based approach to the evaluation of electric freight vehicles for use in urban areas. The key factor determining the increase in the number of alternative drive vehicles is adapting the infrastructure to meet their specific needs. This relates in particular to electric vehicles for which it is necessary to develop battery charging systems. Due to the discussed impediments, for alternative drive vehicles to be used in urban deliveries, it is first necessary to take specific actions and implement adjustment processes. However, on the other hand, benefits embodied by a reduction of negative impacts on urban environment make alternative drive vehicles increasingly attractive, all the more that their operational parameters make it already possible to use them effectively.

Undoubtedly, implementation of electric vehicles is the most problematic. For urban freight transport to use electric vehicles and function properly, it is necessary to provide integrated networks of charging terminals in cities, so that all places with limited access to power supply sources are eliminated. The report by Frost and Sullivan, entitled “The strategic analysis of EV charging stations infrastructure in Europe”, says that there has recently been a significant progress in that regard, and, in accordance with the forecasts, the number of public chargers provided on the initiative of the governments will exceed two million by 2017, while seven West European countries will spend ca. EUR 700 million over the next seven years [

47]. The aforementioned report additionally emphasizes the possibilities of developing inductive systems of vehicle battery charging, which may play a key role for freight transport, providing possibilities of rapid charging during short stops connected with deliveries. Therefore, it seems that, as a result of the requirements of the European Union regarding sustainable transport development and the worldwide trends connected with popularization of alternative sources of energy, in the near future the dynamics of urban logistics development based on using alternatively powered vehicles, in particular using electric motors, will be growing and playing an increasingly more important role.

The results introduced in the paper are the first part of the work, realized in Poland. The second stage will focus on utilization of the model in the real business environment. However, nowadays the major obstacle for that is the very low level of development of electric vehicles in Poland, especially taking to the account the UFT systems. Nevertheless, a distinct and steady growth can be observed in the number of electric vehicles and plug-in hybrids being sold in Poland. Most car manufacturers offer electric or hybrid vehicles. The current state of e-mobility in Poland resembles the one observed in Europe 5–6 years ago. Therefore, it is expected that, in the years to come, if sufficiently favourable conditions exist, the electric vehicles sales market in Poland will improve significantly. Moreover, Szczecin Municipality is strongly focused on development of electro-mobility at the city area. Due to that, the model will be introduced under present and future projects and activities realized or supported by the Municipality.

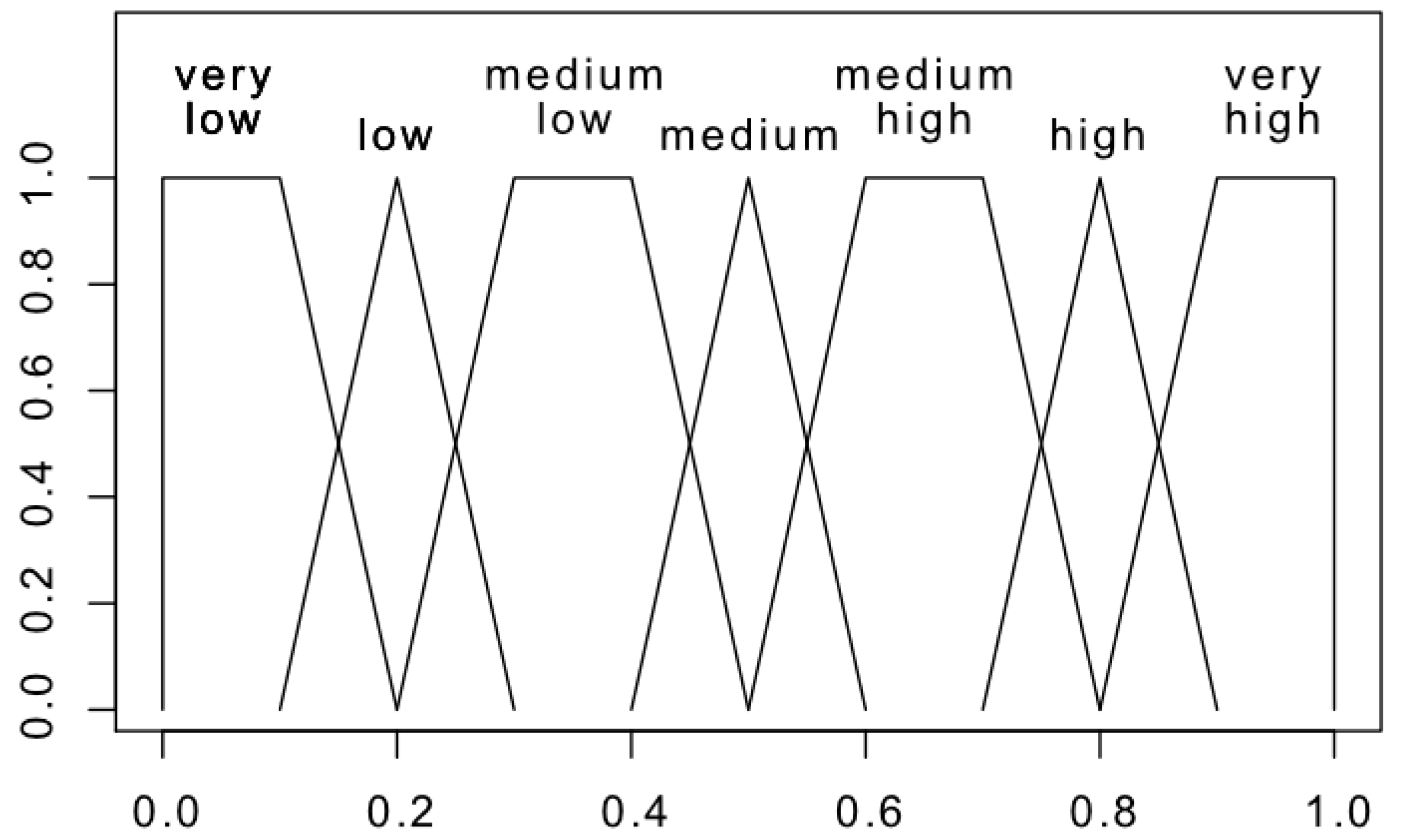

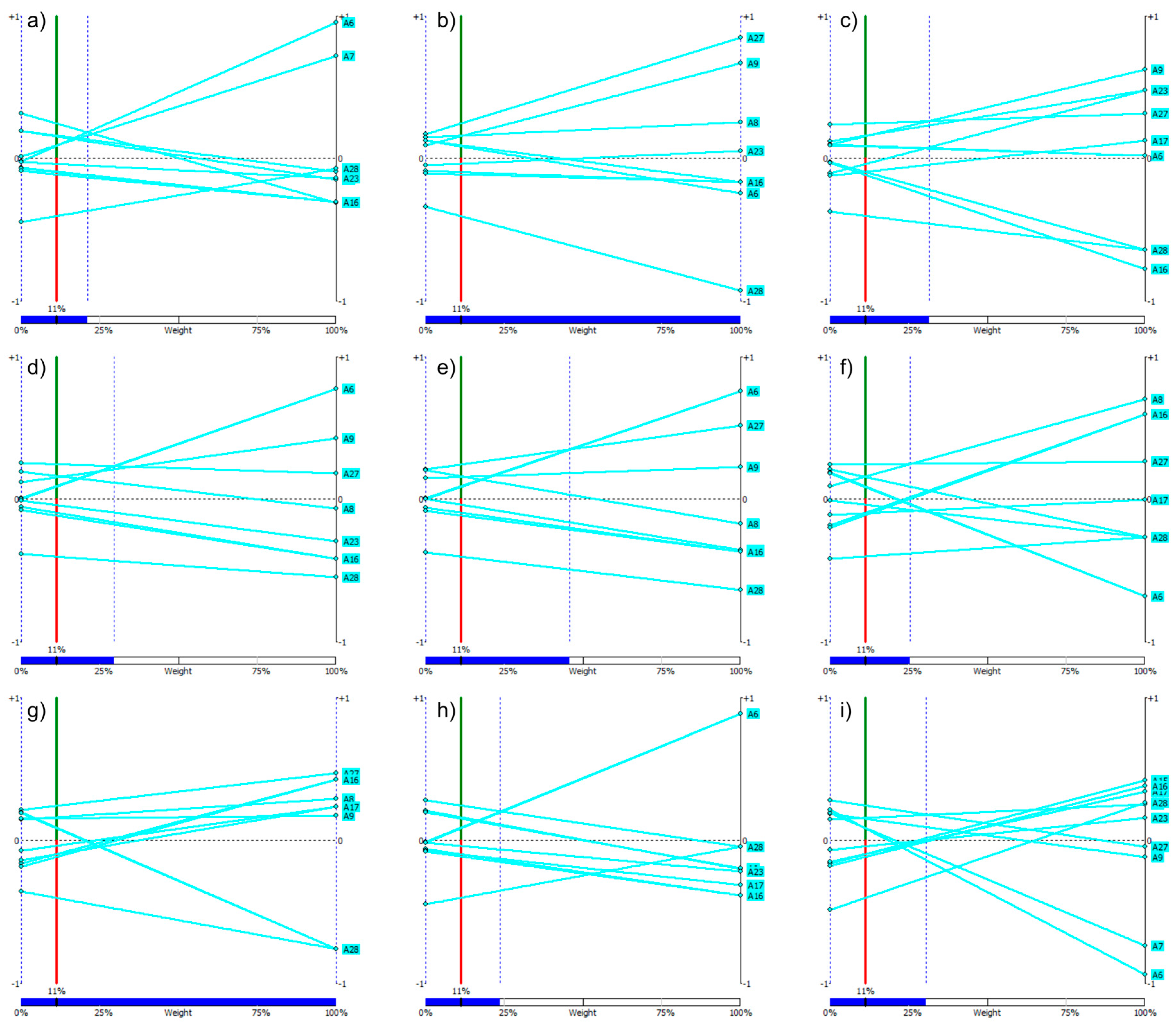

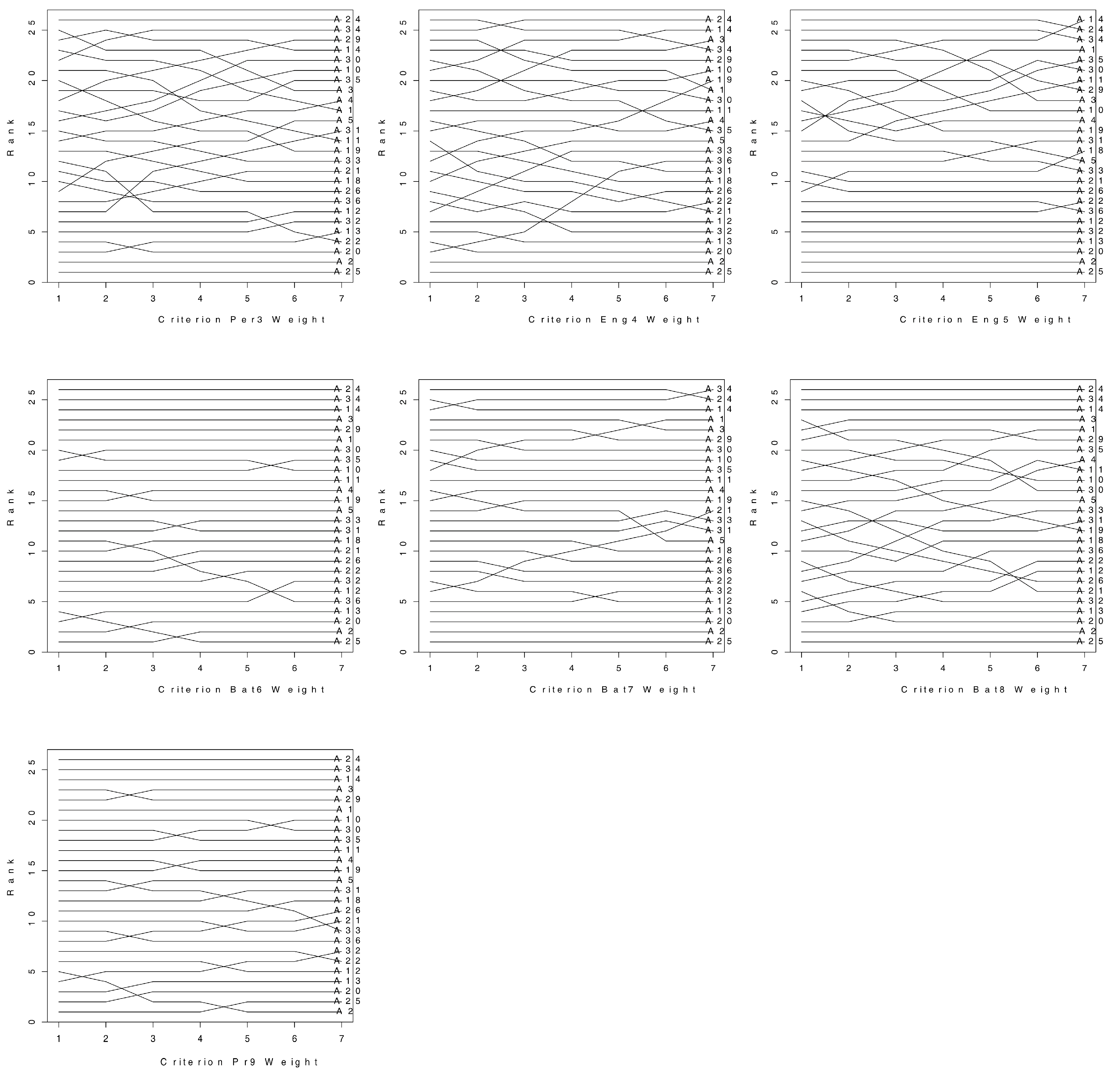

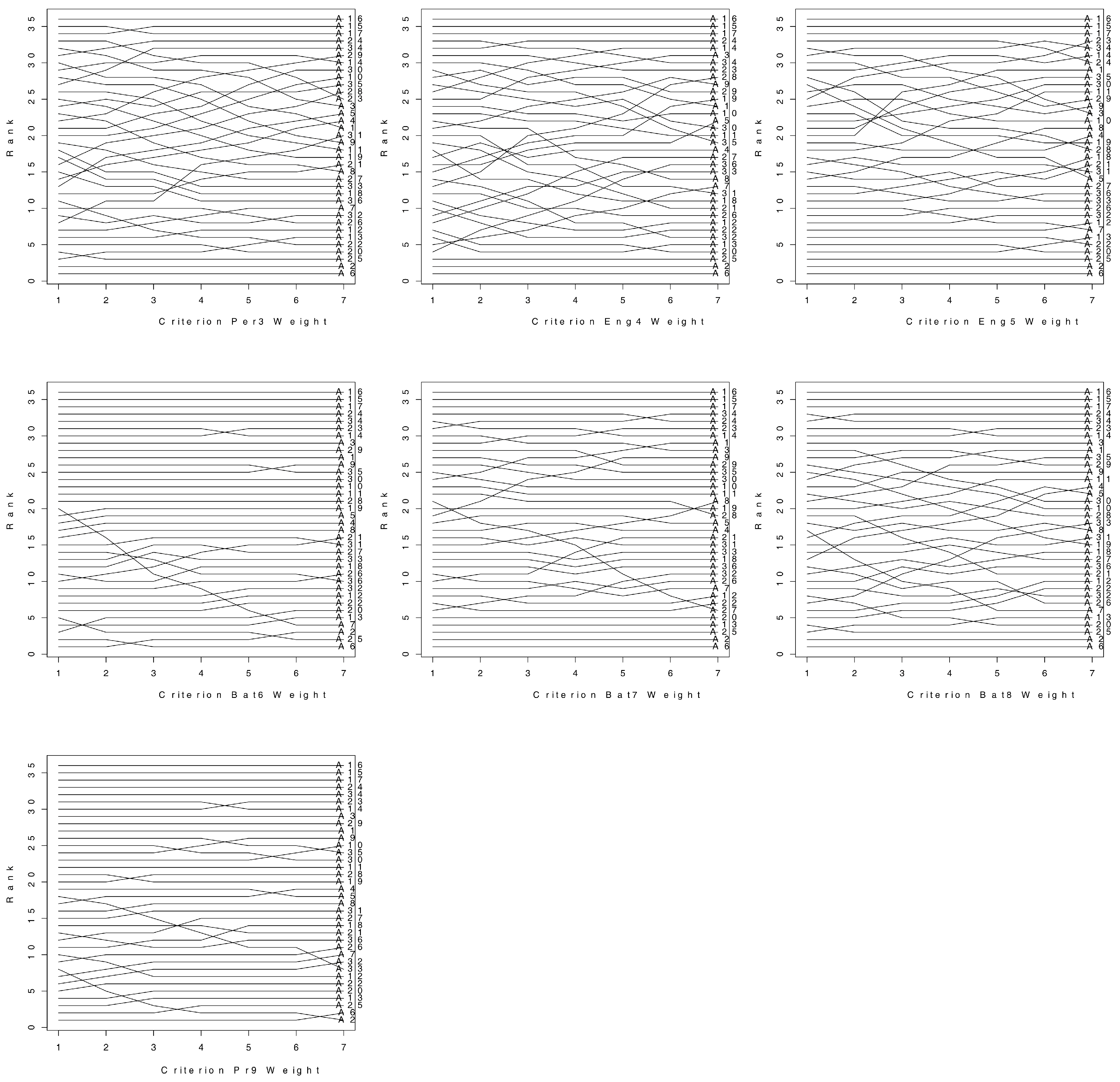

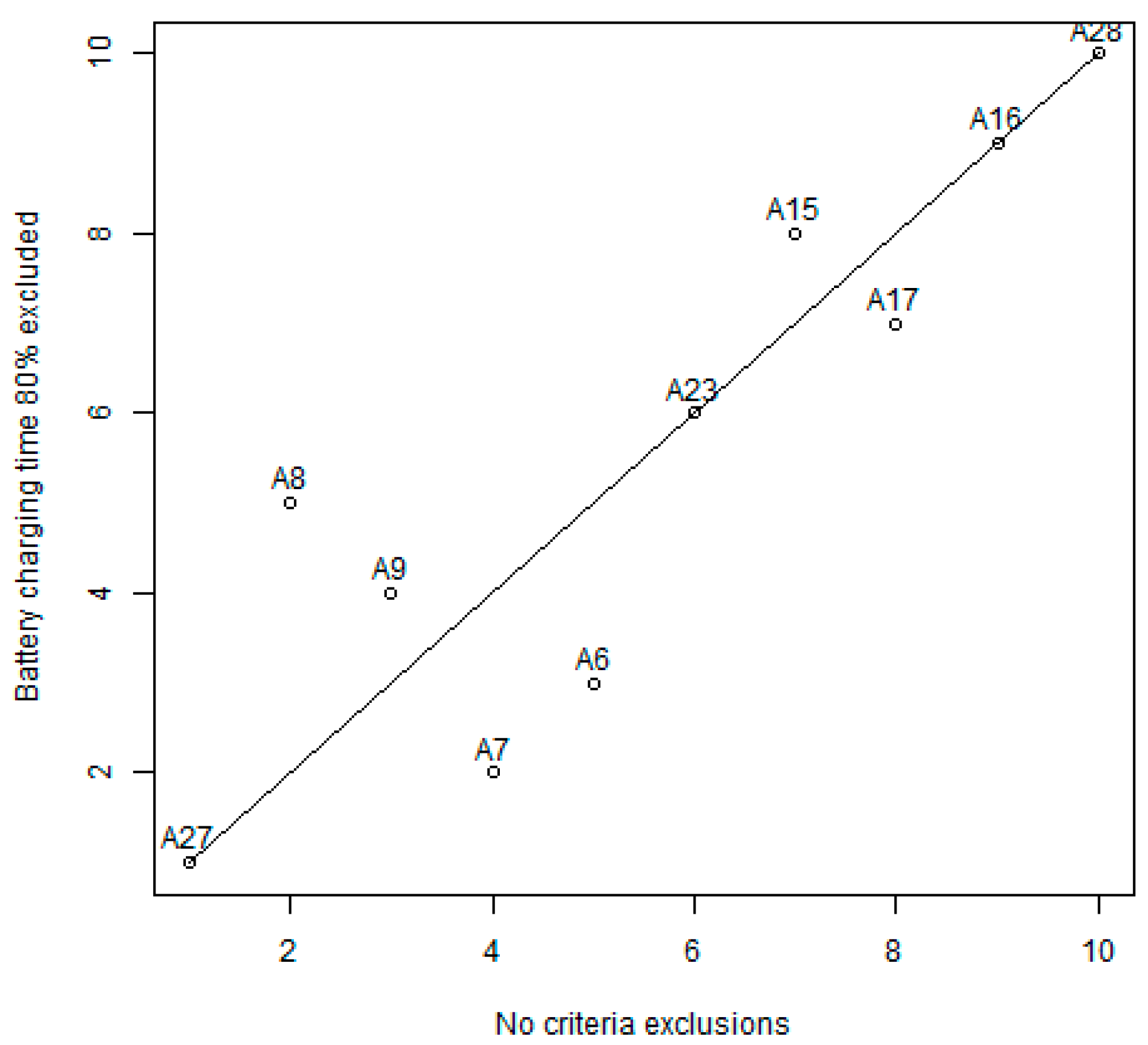

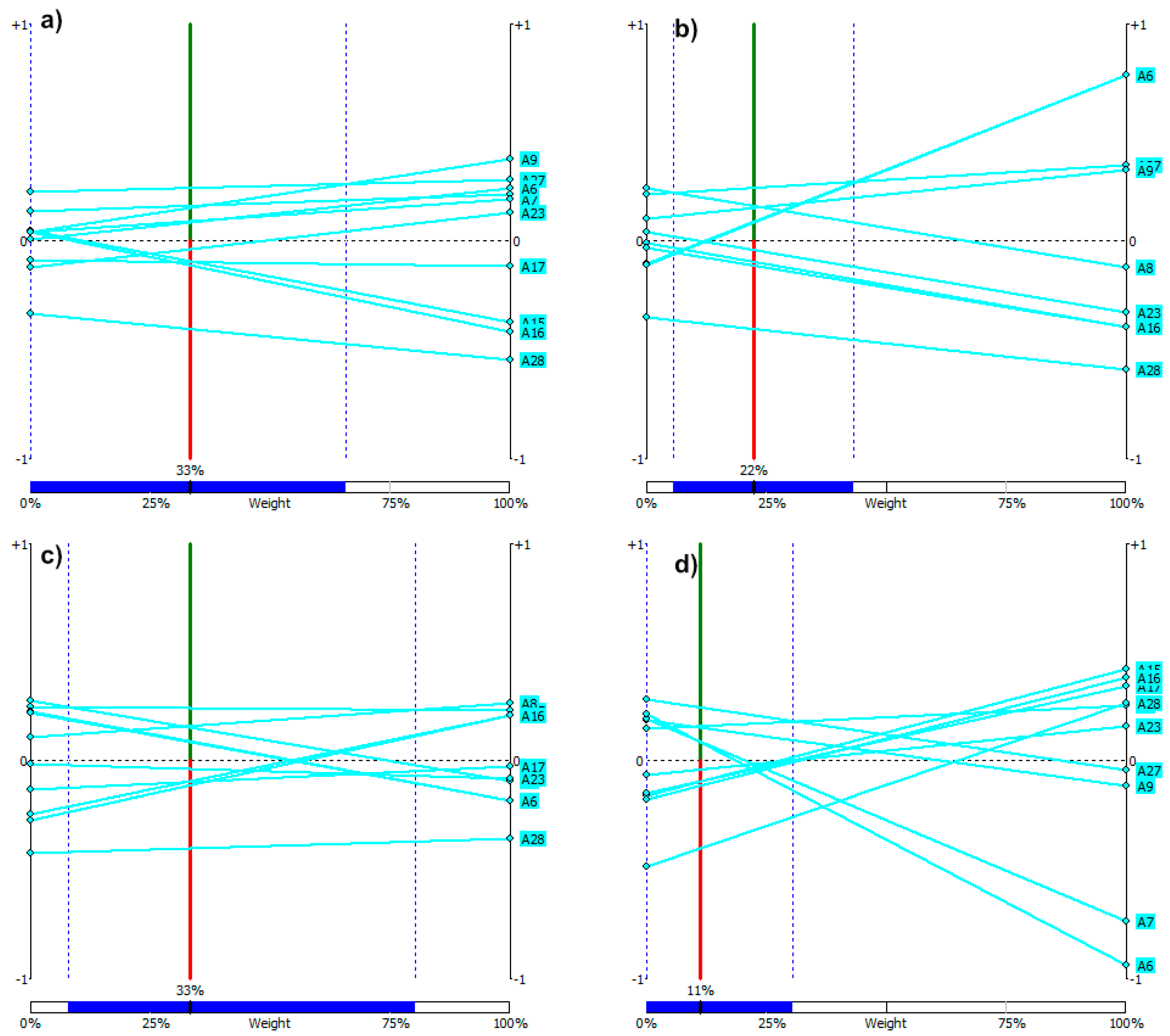

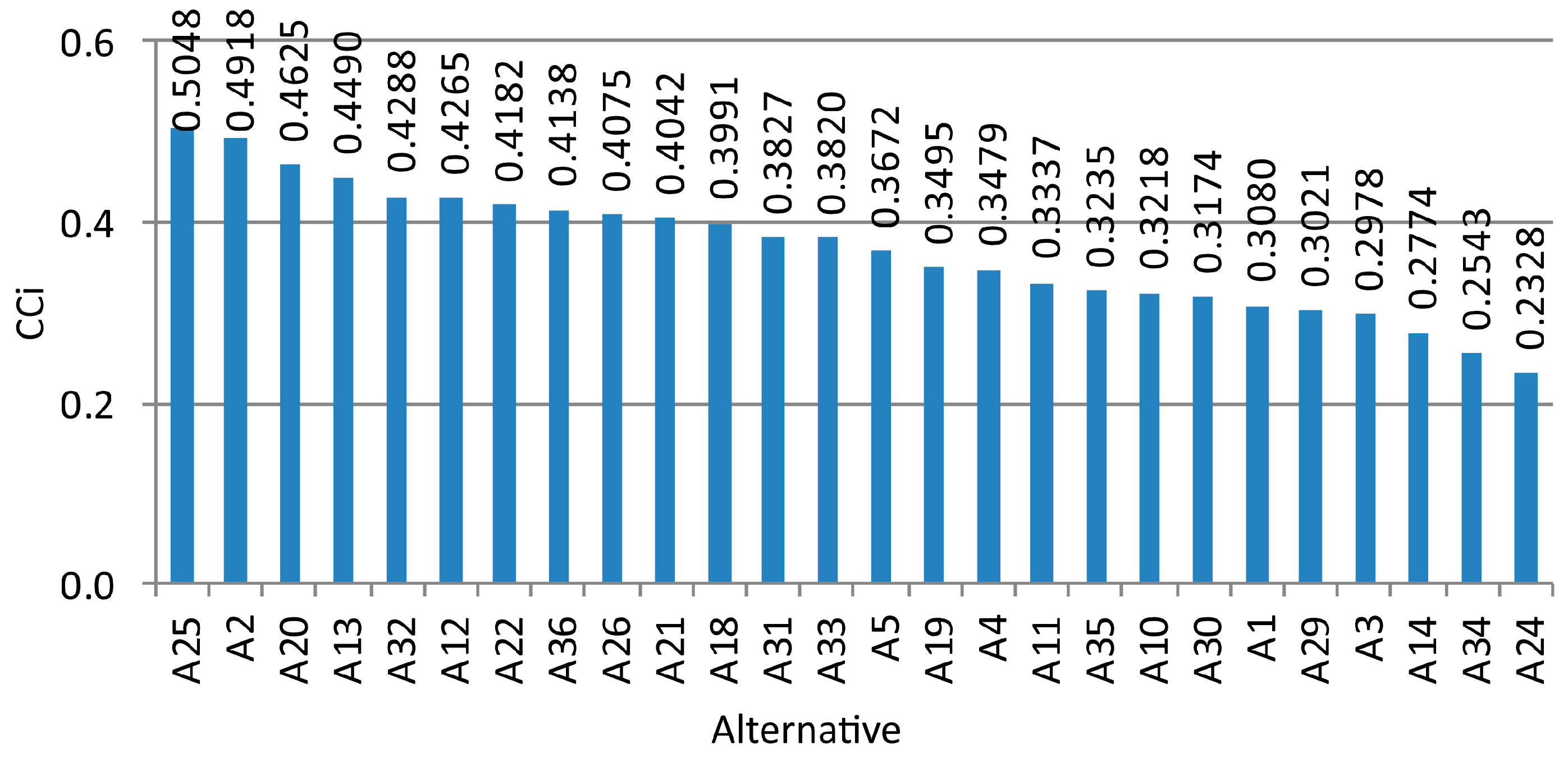

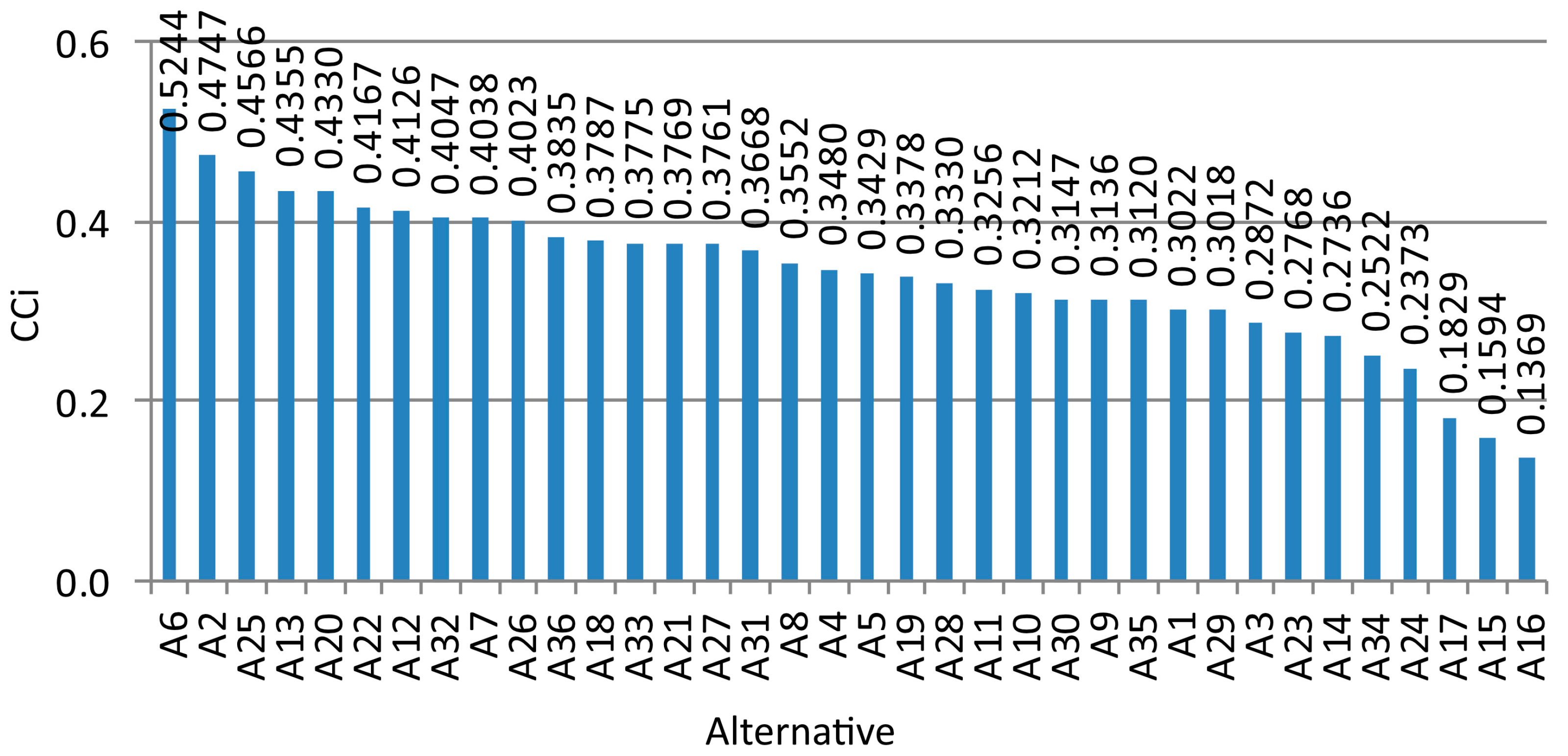

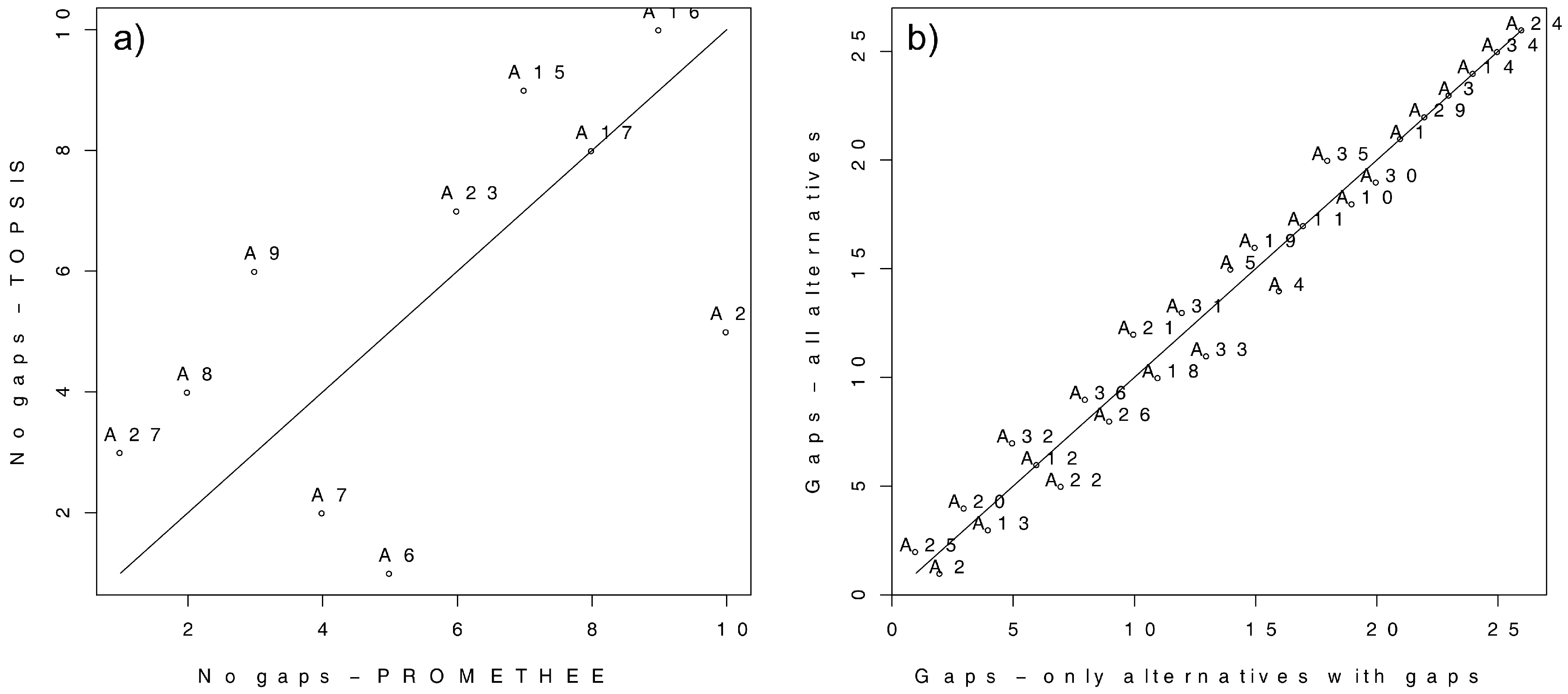

The authors’ contribution in this paper was to present a framework to solve MCA problems based on a set of alternatives with both certain and uncertain data, by creating an integrated multistep model reflecting decision maker’s preferences. In practical terms, an evaluation of 36 carefully selected Electric Freight Vehicles (EFVs) was performed based on nine indicators. From the set of alternatives, a complete set of measurements data was available only for 10 alternatives. For the remaining set of alternatives, the methods of fuzzy set theory were used to provide uncertain values for the data gaps. A comparative analytical study of the results from rankings based on certain data, uncertain data and mixed data was performed. A verification of correlation between the solutions obtained with the usage of certain and uncertain data was performed.

The presented above methodological contribution included the following highlights:

We propose a unique approach that aggregates certain and uncertain data in an integrated multistep model.

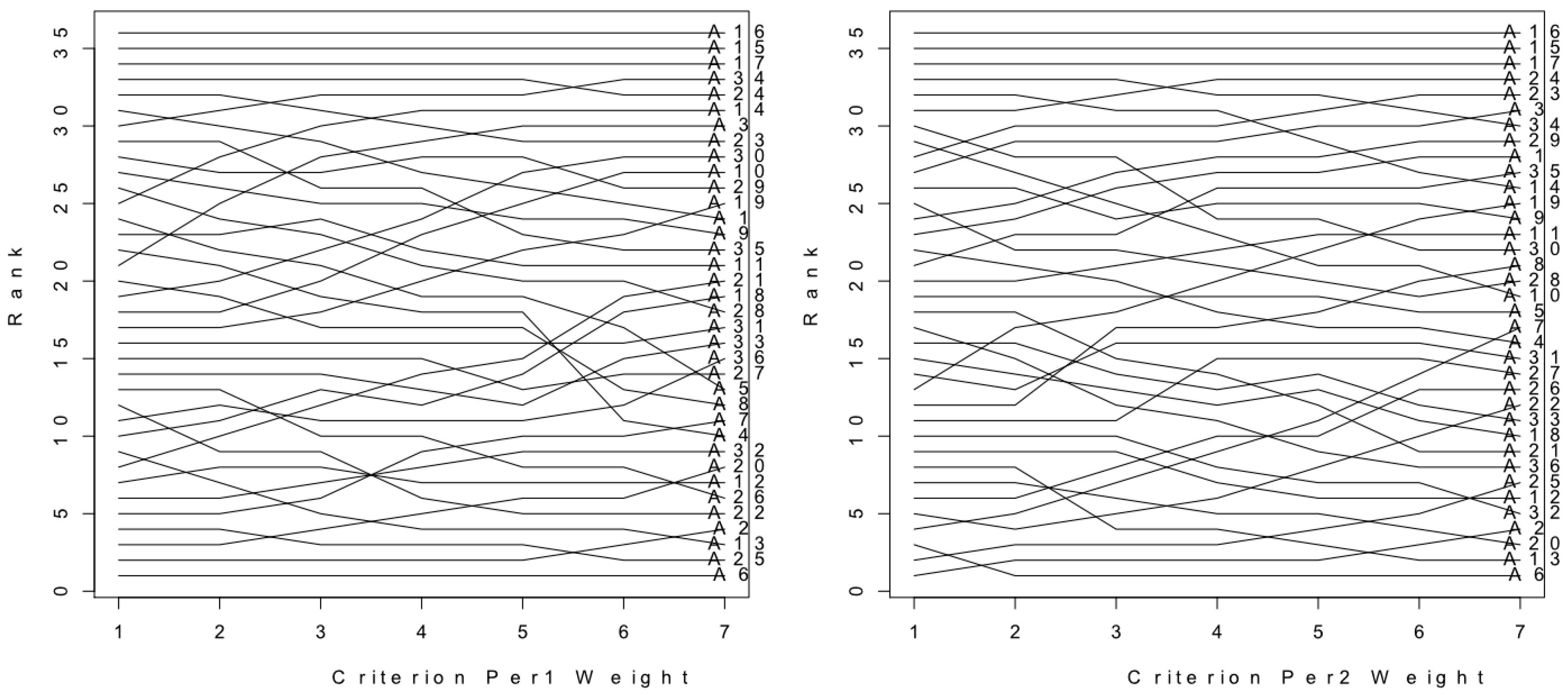

Following the multi-criteria approach, we incorporate the robustness and sensitivity analyses to the evaluation model in order to achieve an improvement of the practical application of the presented approach.

We perform a verification of successful usage of MCA-based methods in the problem of EFVs evaluation.

During the research, some possible areas of improvements of proposed approach and future work directions were identified. The presented model used catalogue information for the battery charging time. However, in “real life” situations, the actual battery charging time can vary as the operating conditions (temperature, charging or discharging current, state of charge, etc.) change, therefore it is important to address this problem in future research. One of the possible approaches of solving this problem would be to use the battery models of each car’s battery as a parameter of the MCA model. Moreover, the study was oriented on freight vehicles, while the model could be extended to accommodate research on passenger electric vehicles. Additionally, the utilization of the TOPSIS method provides the researchers with a model of a positive ideal solution. This could be used to form a set of guidelines for creating urban EFVs. Finally, the MCA methods used to create the proposed framework are vulnerable to the rank reversal phenomenon. It would be beneficial to construct a similar model based on methods that are free of this phenomenon, such as the COMET method [

91]. This is important because the rank reversal problem remains an essential challenge in MCA [

92], and even more important in the considered problem, where it should be assumed that, along with the lapse of time, the order of the alternatives would vary because of the changes in the evaluated alternatives’ set (commercially available EFVs).