Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing

Abstract

:1. Introduction

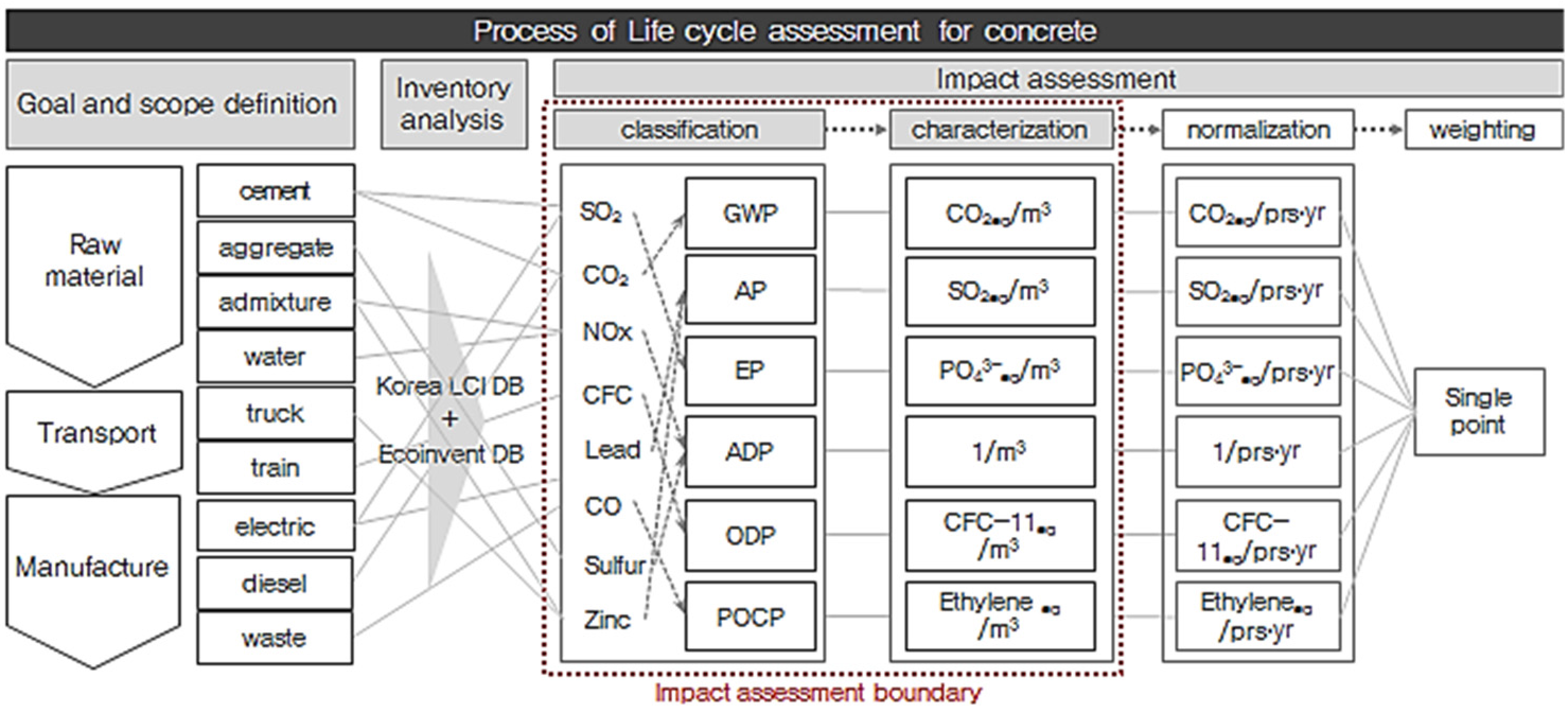

2. Method of Environmental Impact Assessment for Concrete

2.1. Goal and Scope Definition

2.2. Inventory Analysis

2.3. Environmental Impact Assessment

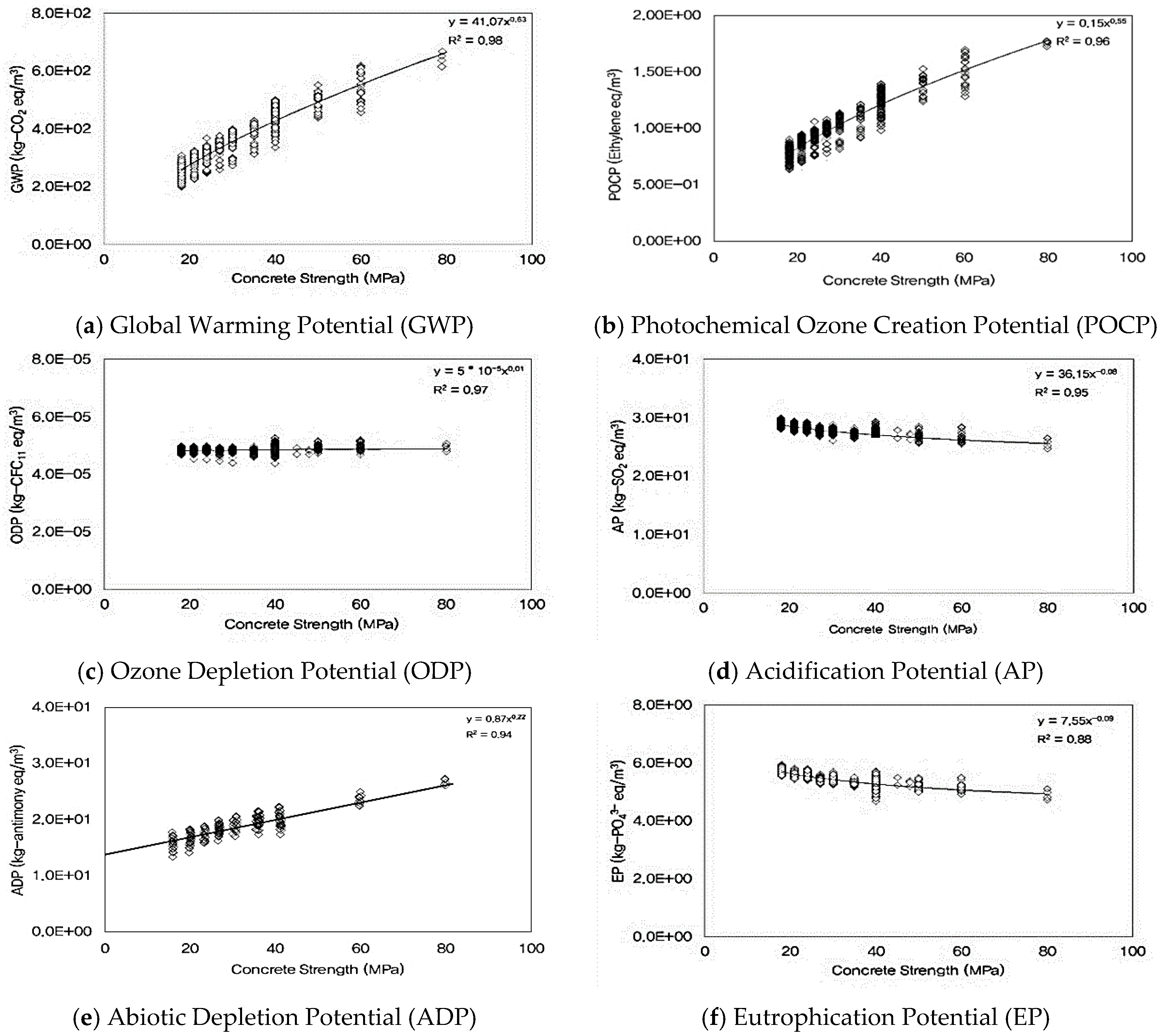

(1) Global Warming Potential (GWP)

(2) Ozone Depletion Potential (ODP)

(3) Acidification Potential (AP)

(4) Abiotic Depletion Potential (ADP)

(5) Photochemical Oxidant Creation Potential (POCP)

(6) Eutrophication Potential (EP)

3. Environmental Impact Analysis of Concrete

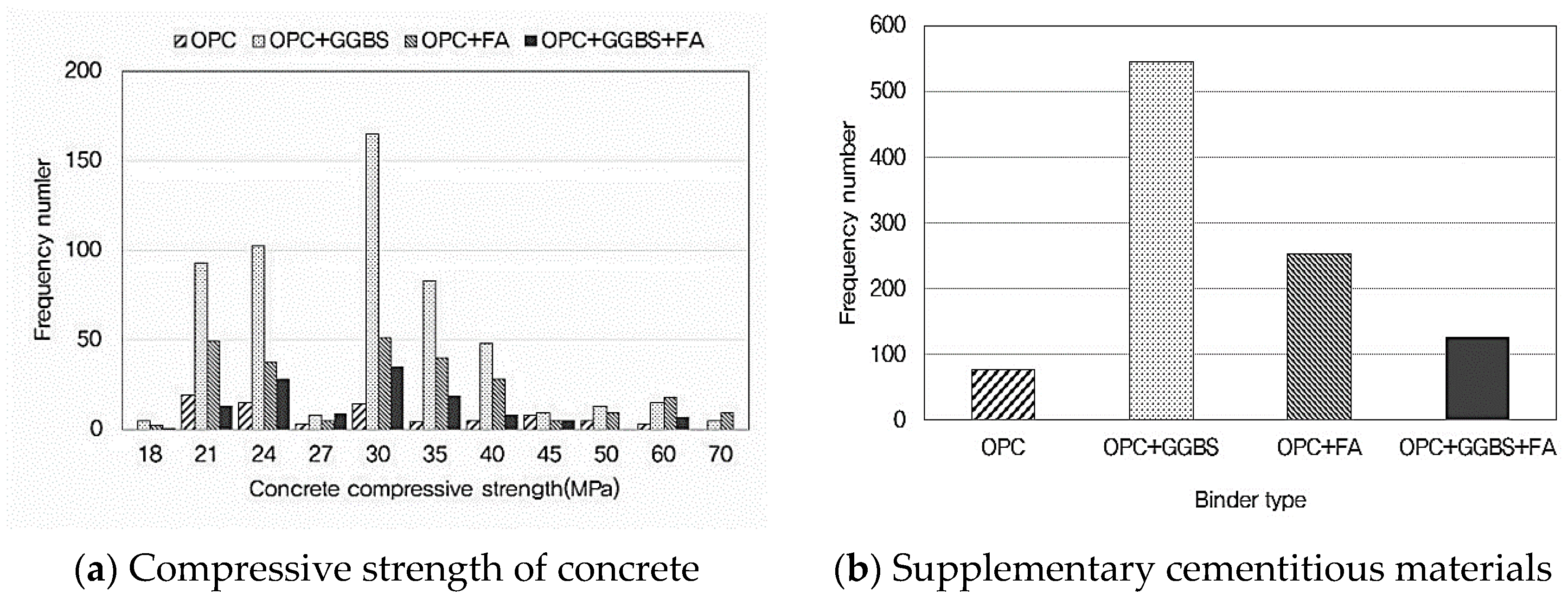

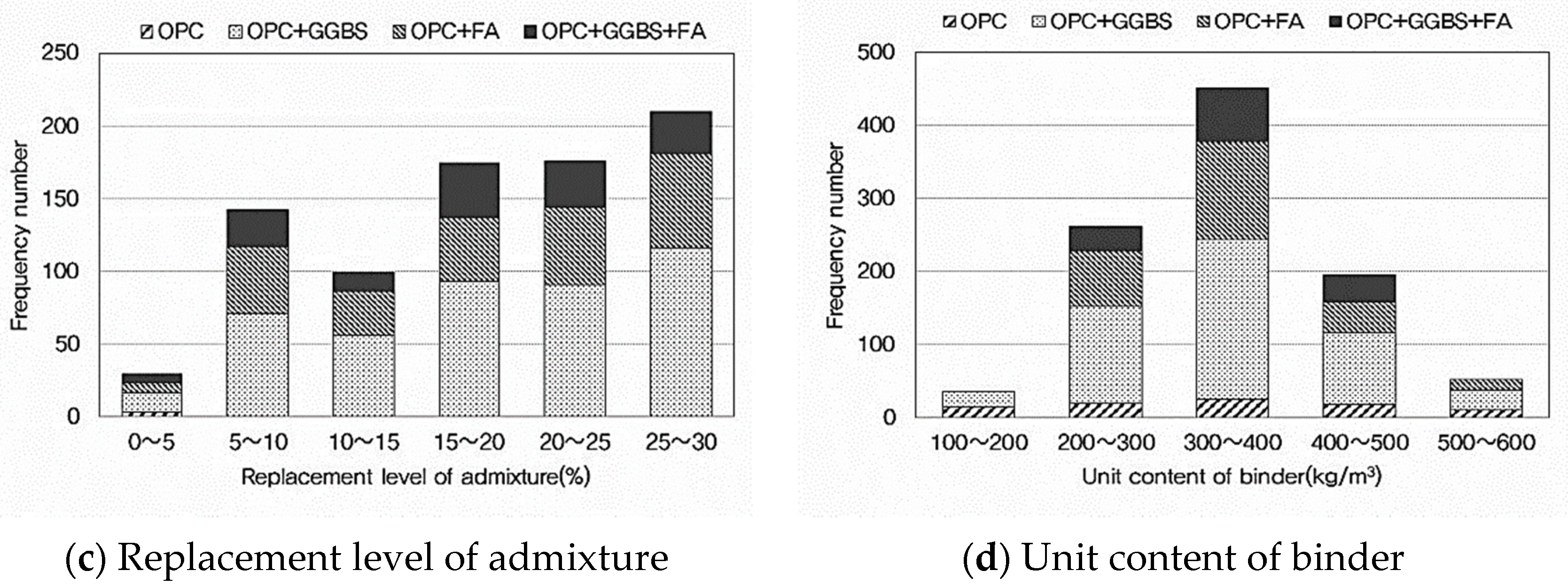

3.1. Mix Design Database

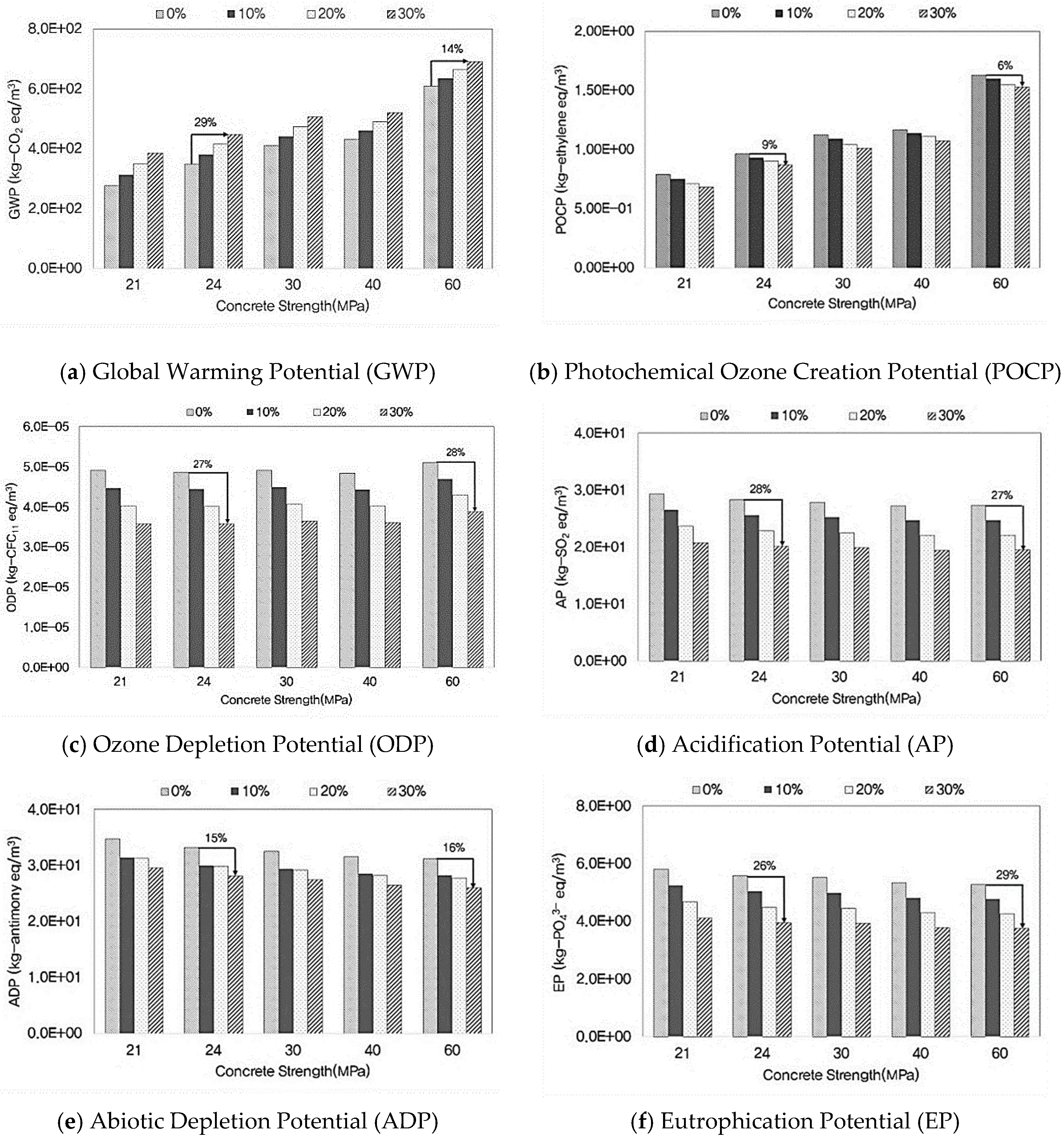

3.2. Environmental Impact According to Concrete Strength

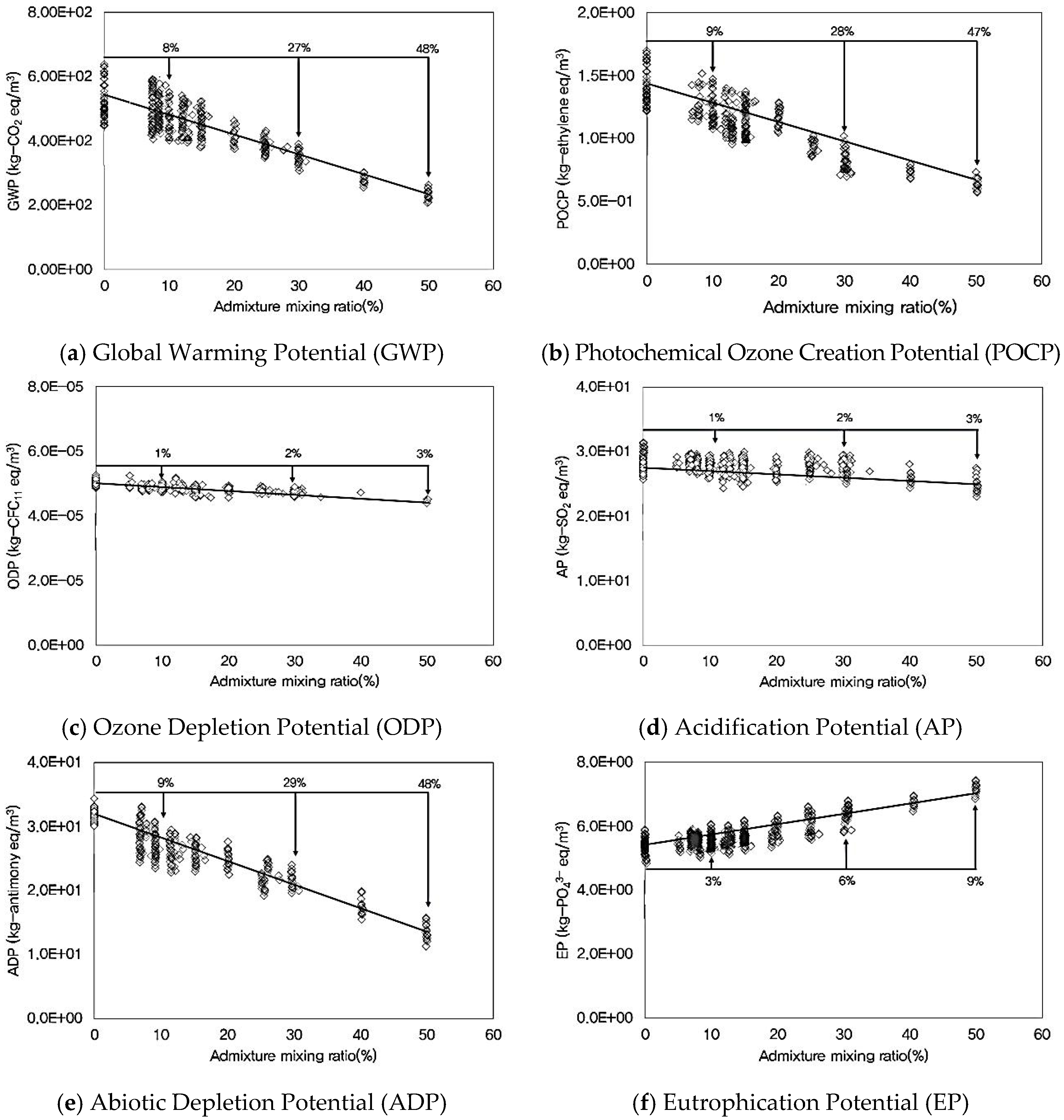

3.3. Environmental Impact According to Admixture

3.4. Environmental Impact According to Recycled Aggregate

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dayoung, O.; Takafumi, N.; Ryoma, K.; Wonjun, P. CO2 emission reduction by reuse of building material waste in the Japanese cement industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar]

- Federica, C.; Idiano, D.; Massimo, G. Sustainable management of waste-to-energy facilities. Renew. Sustain. Energy Rev. 2014, 33, 719–728. [Google Scholar]

- Global BRE. Methodology for Environmental Profiles of Construction Products-Product Category Rules for Type 3 Environmental Product Declaration of Construction Product; BRE Press: Watford, UK, 2011. [Google Scholar]

- International EPD system. Product category rules-Concrete. 2013. Available online: http://www.environdec.com/PCR/ (accessed on 13 April 2016).

- ISO/DIS 13315-2. In Environmental Management for Concrete and Concrete Structures)-Part 2: System Boundary and Inventory Data; ISO: Geneva, Switzerland, 2013.

- Ministry of government legislation. Law of Low-Carbon on Green growth. 2013. Available online: http://www.moleg.go.kr/english/korLawEng?pstSeq=54792 (accessed on 13 April 2016). [Google Scholar]

- Sakai, K.; Kawai, K. Recommendation of Environmental Performance Verification for Concrete Structures, JSCE Guidelines for Concrete No. 7. Available online: http://www.jsce.or.jp/committee/concrete/e/newsletter/newsletter06/newsletter06.asp (accessed on 13 April 2016).

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Organización Internacional de Normalización. ISO 14025: Environmental Labels and Declarations-Principles and Procedures; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Organización Internacional de Normalización. ISO 14044: Life Cycle Assessment-Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Youngche, H.; Sangwon, S.; Sangwon, H.; Keonmo, L. Determination of normalization values for korean eco-indicator. Korean Soc. Life Cycle Assess. 2000, 2, 69–78. [Google Scholar]

- Korea Concrete Institute. Concrete and Environment; Kimoondang Publishing Company: Seoul, Korea, 2011; pp. 16–30. [Google Scholar]

- MOLIT. National Database for Environmental Information of Building Products; Ministry of Land, Transport and Maritime Affairs of the Korean Government: Sejong-si, Korea, 2008.

- National Life Cycle Index Database Information Network. Available online: http://www.edp.or.kr (accessed on 11 August 2015).

- The Ecoinvent Database. Available online: http://www.ecoinvent.org/database (accessed on 11 August 2015).

- Eco-Labeling. Available online: http://www.edp.or.kr/edp/edp_intro.asp (accessed on 11 August 2015).

- IPCC guidelines for national greenhouse gas inventories. 2006. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 13 April 2016).

- Guinee, J.B. Development of a Methodology for the Environmental Life Cycle Assessment of Products: With a Case Study on Margarines. Ph.D. Thesis, Leiden University, Leiden, The Netherlands, 1995. [Google Scholar]

- Heijungs, R.; Guinée, J.B.; Huppes, G.; Lamkreijer, R.M.; Udo de Haes, H.A.; Wegener Sleeswijk, A.; Ansems, A.M.M.; Eggels, P.G.; van Duin, R.; de Goede, H.P. Environmental Life Cycle Assessment of Products. Guide (Part1) and Background (Part 2); CML Leiden University: Leiden, The Netherlands, 1992. [Google Scholar]

- World Metrological Organization (WMO). Scientific Assessment of Ozone Depletion: Global Ozone Research and Monitoring Project; WHO: Geneva, Switzerland, 1991; p. 25. [Google Scholar]

- Derwent, R.G.; Jenkin, M.E.; Saunders, S.M.; Piling, M.J. Photochemical ozone creation potentials for organic compounds in Northwest Europe calculated with a master chemical mechanism. Atmos. Environ. 1998, 32, 2429–2441. [Google Scholar] [CrossRef]

- Jenkin, M.; Hayman, G. Photochemical Ozone Creation Potentials for oxygenated volatile organic compounds: Sensitivity to variation is in kinetic and mechanistic parameters. Atmos. Environ. 1999, 33, 1275–1293. [Google Scholar] [CrossRef]

- Ministry of Government Legislation. Details of Laws and enforcement ordinance and regulations on recycling promotion of construction wastes. 2010. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0ahUKEwiB1u7mwJDMAhULjiwKHRZTDXgQFggdMAA&url=http%3a%2f%2fwww.meti.go.jp%2fenglish%2finformation%2fdownloadfiles%2fcRecycle3R20403e.pdf&usg=AFQjCNE3tzbP17a8V2s7OVD1biXT4gN6KQ&sig2=8AccAo4Gl6buk49UI46BKw (accessed on 11 August 2015). [Google Scholar]

- Taehyoung, K.; Sungho, T.; Seongjun, R. Assessment of the CO2 emission and cost reduction performance of a low-carbon-emission concrete mix design using an optimal mix design system. Renew. Sustain. Energy Rev. 2013, 25, 729–741. [Google Scholar]

- Sungho, T.; Sungwoo, S.; Ganghee, L. The Environmental Load Reduction Effect of the Reinforced Concrete Structure Using High-Strength Concrete. Korea Inst. Ecol. Archit. Environ. 2008, 8, 61–66. [Google Scholar]

- Junghoon, P.; Sungho, T.; Taehyoung, K. Life Cycle CO2 Assessment of Concrete by compressive strength on Construction site in Korea. Renew. Sustain. Energy Rev. 2012, 16, 2940–2946. [Google Scholar]

- Gazquez, M.J.; Bolivar, J.P.; Vaca, F.; Garcia-Tenorio, R.; Caparros, A. Evaluation of the use of TiO2 industry red gypsum waste in cement production. Cem. Concr. Compos. 2013, 37, 76–81. [Google Scholar] [CrossRef]

- Owaid, H.M.; Hamid, R.B.; Taha, M.R. A review of sustainable supplementary cementitious materials as an alternative to all-Portland cement mortar and concrete. Aust. J. Basic Appl. 2012, 6, 2887–3303. [Google Scholar]

- Taehyoung, K.; Sungho, T.; Seongjun, R. Life Cycle Assessment for Carbon Emission Impact Analysis of Concrete Mixing Ground Granulated Blast-furnace Slag (GGBS). Archit. Inst. Korea 2013, 29, 75–82. [Google Scholar]

- Yang, K.H.; Seo, E.A.; Jung, Y.B.; Tae, S.H. Effect of Ground Granulated Blast-Furnace Slag on Life-Cycle Environmental Impact of Concrete. Korea Concr. Inst. 2014, 26, 13–21. [Google Scholar] [CrossRef]

- Korea Ground Granulated Furnace Slag Association. Technical Report. 2015. Available online: http://www.asa-inc.org.au/news-and-events/connections (accessed on 11 August 2015).

- Jongsuk, J.; Jaesung, L.; Yangjin, A.; Kyunghee, L.; Kisun, B.; Myunghun, J. An Analysis of Emission of Carbon Dioxide from Recycling of Waste Concrete. Archit. Inst. Korea 2008, 24, 109–116. [Google Scholar]

| Division | Reference | Nation | |

|---|---|---|---|

| Raw material | Cement | National LCI | Korea |

| Coarse aggregate | National LCI | Korea | |

| Fine aggregate | National LCI | Korea | |

| Blast furnace slag | Ecoinvent | Swiss | |

| Fly ash | Ecoinvent | Swiss | |

| Water | National LCI | Korea | |

| Chemical admixture | Ecoinvent | Swiss | |

| Energy | Electric | National LCI | Korea |

| Diesel | National LCI | Korea | |

| Transportation | Truck | National LCI | Korea |

| Composition Material | Unit | Environmental Impact Categories | |||

|---|---|---|---|---|---|

| GWP (kg-CO2eq/unit) | AP (kg-SO2eq/unit) | EP (kg-PO43−eq/unit) | POCP (kg-Ethyleneeq/unit) | ||

| Cement | kg | 9.48 × 10−1 | 1.28 × 10−3 | 1.34 × 10−4 | 2.43 × 10−3 |

| Fine aggregate | kg | 1.49 × 10−3 | 1.10 × 10−2 | 1.92 × 10−3 | 1.07 × 10−4 |

| Fly ash | kg | 1.50 × 10−2 | 1.16 × 10−4 | 6.94 × 10−5 | 6.57 × 10−5 |

| Water | kg | 1.14 × 10−1 | 1.94 × 10−4 | 6.57 × 10−5 | 4.86 × 10−7 |

| Inventory List | Environmental Impact Categories | Composition Material | ||||||

|---|---|---|---|---|---|---|---|---|

| GWP | ADP | AP | EP | ODP | POCP | Cement | Aggregate | |

| Ammonia (NH3) | ■ | ■ | 6.95 × 10−7 | |||||

| Carbon dioxide (CO2) | ■ | 9.31 × 10−1 | 3.40 × 10−1 | |||||

| CFC-11 | ■ | 2.05 × 10−9 | 4.02 × 10−13 | |||||

| Methane (CH4) | ■ | ■ | 1.71 × 10−2 | 5.57 × 10−4 | ||||

| Sulfur dioxide (SO2) | ■ | ■ | 1.27 × 10−2 | 4.42 × 10−4 | ||||

| Phosphate (PO43−) | ■ | 4.22 × 10−8 | ||||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.; Tae, S.; Chae, C.U. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. https://doi.org/10.3390/su8040389

Kim T, Tae S, Chae CU. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability. 2016; 8(4):389. https://doi.org/10.3390/su8040389

Chicago/Turabian StyleKim, Taehyoung, Sungho Tae, and Chang U Chae. 2016. "Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing" Sustainability 8, no. 4: 389. https://doi.org/10.3390/su8040389